#Cableassembly

Explore tagged Tumblr posts

Text

Revolutionizing Wire Harness Production with Automated Crimping Technology

The modern manufacturing landscape increasingly hinges on automation to boost both efficiency and accuracy. A standout innovation driving this transformation is the advent of automatic wire cutting and crimping machines. These sophisticated systems offer a host of compelling advantages, fundamentally reshaping the way wire harnesses are produced.

At the core of these machines' appeal is their ability to combine blazing-fast operation with a remarkably streamlined wire changeover process. Unlike older, more labor-intensive methods, these automated solutions harness cutting-edge Computer Numerical Control (CNC) technology. This allows for precise, computer-managed adjustments to both the leading and trailing wire ends, eliminating the need for tedious manual tweaks to cutting and stripping lengths. What's more, the integration of electrically controlled blades drastically simplifies the engineering challenges typically associated with adapting to different wire specifications. This built-in flexibility enables swift transitions between various wire types and dimensions, a critical factor in maximizing production agility and minimizing costly downtime.

Precision and Efficiency Through Digital Control

The operational backbone of automatic wire cutting and crimping machines lies in a fully digital and mathematically driven control system. Every crucial parameter—from cutting and stripping lengths to blade values, semi-stripping settings, and terminal crimping specifications—can be precisely configured via an intuitive interface. This comprehensive digital mastery, particularly the electrically adjustable blades, not only supercharges production efficiency but also positions these machines at the forefront of automation compared to other models. For instance, single-head automatic wire crimping machines are adept at handling multiple tasks: wire cutting, single-end stripping, double-end stripping, and single-end crimping, all executed with remarkable speed, stability, and intelligence. Their touchscreen interface further refines the setup experience, making all adjustments fully digitized and straightforward.

Workforce Optimization and Cost Savings

The advanced automation inherent in these machines empowers manufacturers to optimize their workforce deployment. By taking over repetitive and intricate tasks, these systems free up human capital, allowing employees to focus on more strategic, value-added activities. This shift often translates into significant reductions in overall operational costs. Another key benefit is the modular design of these machines. Their reliance on standardized components not only simplifies initial setup but also dramatically cuts down on ongoing maintenance expenses, thanks to readily available and easily replaceable parts. Equipped with cutting-edge electrical controls and proprietary software, these machines boast a highly user-friendly Human-Machine Interface (HMI). This accessibility means that even operators with minimal specialized training can efficiently manage complex wire processing, including wire and terminal changes, effectively "democratizing" the operation of such sophisticated equipment.

Conclusion

In essence, automatic wire cutting and crimping machines represent a monumental leap forward in manufacturing technology. Their synergy of high-speed performance, CNC-driven precision, electrically controlled blades, and intuitive digital interfaces offers compelling advantages over traditional approaches. These machines stand out across various categories of terminal equipment and have secured widespread adoption in today's market, garnering widespread acclaim from users for their innovative design and robust performance.

For in-depth technical resources on automatic terminal crimping machines, explore our specialized page.

2 notes

·

View notes

Text

TNC MALE CONNECTOR WITH RG58 CABLE + SMA MALE CONNECTOR

#eteily#tech#technology#RFSMAcable#RFAdapters#RFConnectors#CoaxialCableConnector#TNCMaleConnector#cableassembly#TNCMalePlug#RPTNCMaleConnector#rfantenna#cable#connector#evcharger#iotloraantenna#gainantenna#4Gantenna#5Gantenna#indoorantenna#outdoorantenna#manufacturing#manufacturer#telecom#telecommunications#pune#bangalore#chennai#worldwide#india

2 notes

·

View notes

Text

Latest Trends in Wire Harness & Electrical Assembly Industry – 2025 Update

The wire harness and electrical assembly industry is witnessing rapid advancements in 2025, driven by growing demand from electric vehicles (EVs), industrial automation, and energy infrastructure. At Popular Systems, we're excited to be at the forefront of these changes, delivering high-quality and customized solutions across India and beyond.

🔌 Smarter, More Compact Wiring Solutions

As devices and vehicles become more compact and power-dense, so do their wiring systems. Manufacturers are shifting toward custom wiring harness solutions that are lightweight, flexible, and capable of handling higher current loads without overheating. Our team at Popular Systems delivers tailor-made wiring harnesses using cutting-edge materials and techniques.

👉 Learn more: Cable loom manufacturers | Automotive wiring harness connectors

🧠 Integrated Diagnostics with Smart Harnessing

Modern wire harness assembly isn’t just about connecting components—it's about intelligence. From embedded sensors to real-time diagnostics, our electrical sub-assembly solutions are designed to enhance performance and reduce downtime across industries.

👉 Relevant terms: Cable harness assembly suppliers | Custom cable manufacturers

🛠️ Expansion in Control Panels & Box Builds

Demand for reliable, scalable control systems continues to grow. Our electrical control panels and box build assembly services are built for diverse environments—from factory floors to outdoor installations.

👉 Explore more:

Electrical control panel manufacturers

Outdoor electrical box

Electrical junction box manufacturers

🌍 Sustainability & Local Sourcing

At Popular Systems, we prioritize eco-compliant materials and regional sourcing to minimize our carbon footprint. Whether it's cable accessories or complete cable assembly services, we’re committed to quality and sustainability.

👉 View products:

Cable assembly manufacturers

Automotive wire connectors

Wiring harness

🏢 About Popular Systems

We are one of India’s trusted cable harness assembly suppliers, delivering end-to-end solutions in wire harnessing, junction boxes, electrical panels, and sub-assemblies. Our expert engineering and fast-turnaround production make us a reliable partner for OEMs across automotive, agriculture, industrial automation, and renewable energy sectors.

🌐 Visit us: https://www.popularsystems.net 📬 Contact for inquiries, custom solutions, or bulk orders.

#WireHarness#ControlPanels#CableAssembly#ElectricalManufacturing#IndiaElectronics#IndustrialAutomation#EVComponents#OEMsolutions

0 notes

Video

youtube

Rf connectors

An RF (Radio Frequency) connector plays a crucial role in facilitating the transmission of radio frequency signals between devices. These connectors ensure a secure, low-loss connection in high-frequency applications. Here’s why they are essential:

Signal Integrity: RF connectors are designed to maintain signal quality by minimizing reflections, interference, and loss. This is especially important in high-frequency systems like 5G networks or broadcast systems.

Versatility: They connect various components, such as cables, antennas, transmitters, and receivers, ensuring seamless integration in complex setups.

Durability: High-quality RF connectors are built to withstand environmental factors like temperature, vibration, and moisture, making them reliable for demanding applications.

Precision Engineering: They’re designed with specific impedance (e.g., 50 ohm, 75 ohm) to ensure compatibility and efficient power transfer between devices.

In summary, RF connectors are the backbone of systems that rely on high-frequency signal transmission, ensuring efficiency and reliability in fields like telecommunications, medical devices, and aerospace systems.

0 notes

Video

youtube

Henryuan Group Cable Assembly www.ruiyuanpower.com,www.henryuan.com

#cableassembly#usbcable#batterycable#audiocable#videocable#newenergycable#vgacable#lemocable#solarcable

0 notes

Text

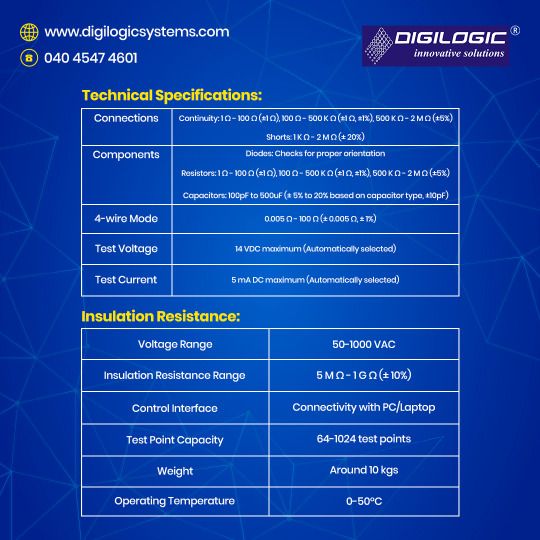

Cable Harness Tester from Digilogic Systems

Digilogic's Cable Harness Tester is a PC-based device designed to test cable continuity and resistance. It detects open circuits, short circuits, crossed wires, and pin-to-pin connectivity, recording all test results for further analysis on a PC.

The Tester is fast, accurate, and user-friendly, utilizing the latest technologies to provide a flexible and adaptable product suite. It is used in the defense and aerospace industries for testing harnesses in aircraft, missiles, tanks, armored vehicles, and satellites.

Digilogic Systems Cable Harness Tester offers unparalleled precision and efficiency, meeting the demands of defense and aerospace. With cutting-edge technology and innovative design, we deliver reliable, future-ready solutions for critical applications.

If you would like more information (or) to request a quote, please feel free to contact us.

Phone: Hyderabad: (+91) 40 4547 4601 Bengaluru: (+91) 80 4975 6034 Website: https://www.digilogicsystems.com/ Email: [email protected]

#CableHarnessTester#harnesstester#cableassembly#wiresandcables#digilogicsystems#TestEquipment#TestandMeasurement#defense#aerospace#makeinindia#Hyderabad

0 notes

Text

#cableaccessories#cable#cablemanagement#cableassembly#cablesolutions#cableaccessoriesmarketresearch#cableaccessoriesmarketreport#cableaccessoriesmarketsize#cableaccessoriesmarketgrowth#cableaccessoriesmarketanalysis

0 notes

Text

General Electric WB27X35382 Range Diode-Cable Assembly | HnKparts

The General Electric WB27X35382 Range Diode-Cable Assembly is an OEM replacement part designed for use in various GE ovens and ranges. This assembly connects key electronic components, ensuring efficient power transmission and functionality. It features durable materials that withstand high temperatures and extended usage. The assembly is essential for maintaining the proper operation of your appliance, particularly for microwave features in combination ovens. Easy to install, it helps restore optimal performance when a faulty diode or cable is detected. Compatible with select GE models, it guarantees a reliable fit. Genuine OEM quality ensures long-lasting performance. Replace damaged parts promptly to avoid appliance issues.

#HnKParts#homeappliances#HnKBuzz#KitchenApplianceParts#appliacepartsonline#WB27X35382#RangeDiode-CableAssembly#GeneralElectric#GeneralElectricparts

0 notes

Text

Eteily Technologies India Pvt. Ltd.

MMCX (M) R/A To UFL Connector With 1.13mm RF Coaxial Black Cable (L-10 CM)

SKU: ET-MMMRA-5BL10C-U

For More Info -

Website - https://eteily.com/13-rf-cable-assembly

#eteily#technologies#eteilyindia#mmcx#rf#coaxial#cableassemblies#ufl#connector#noida#delhi#india

#RF Cable Assembly#RF Cable Assembly in india#Cable Assembly#RF Cable Assembly Manufacturers#coaxial cable assembly#coax cable assembly#coaxial cable assembly manufacturers in india#rf coaxial cable assembly#sma rf cable assembly

0 notes

Text

Eteily Technologies India Pvt. Ltd.

SMA (M) St. Connector With Rg178 Cable (L-50 CM) + UFL Connector SKU: ET-SMS-3L50C-U

For More Info - Contact Us - 9343643799 📞 👉Website - https://eteily.com/

#eteily#technologies#eteilyindia#telecom#telecomunication#tnc#rf#connector#cableassemblies#goa#usa#manufacturing#supplier#india#sma#uflconnector#rg178

#cable assembly#rf cable assembly#spiral cable assembly#integrated cable assembly#sma cable assembly#cable assembly automation#wire assembly#automated cable assembly#american standard cable assembly#cable assembly business for sale#cable assembly brazil#battery cable assembly#bnc cable assembly

0 notes

Text

Optimizing Performance: A Troubleshooting Guide for Automatic Wire Twisting and Tying Machines

Automatic wire twisting and tying machines are essential for various packaging and manufacturing processes. However, like all complex machinery, they can experience issues that impact their efficiency and the quality of their output, particularly regarding inconsistent tie lengths. This guide explores common reasons for machine malfunctions and provides practical steps to rectify an unstable twist tie length.

Identifying the Root Causes of Machine Malfunctions

Understanding why a machine might fail is the first step toward effective troubleshooting. Several factors can contribute to operational problems:

Mechanical Degradation: Over time, critical mechanical components such as bearings, gears, and drive belts are subject to wear and tear. This gradual deterioration can lead to imprecise movements, compromised power transmission, and ultimately, a decline in overall machine accuracy.

Electrical System Flaws: The electrical system is the machine's nervous system. Problems like loose power connections, damaged wiring, or a failing motor can prevent the machine from starting, cause erratic operation, or lead to complete shutdown.

Sensor Inaccuracies: Sensors are vital for precise control, detecting parameters such as wire position and speed. If these sensors become dirty, misaligned, or faulty, they can send incorrect data to the control system, resulting in significant deviations from intended operations.

Software Anomalies: Modern machines rely heavily on their control software. Programming bugs, compatibility issues between software versions, or corrupted files can prevent the machine from executing its programmed routines correctly, leading to unpredictable behavior and performance issues.

Resolving Inconsistent Twist Tie Length

When you notice the twist tie length varying, these systematic adjustments can help restore consistency:

Thorough Mechanical Inspection: Begin by meticulously examining all mechanical parts directly involved in the coiling and tying process. Pay close attention to the coiling wheels, cutting blades, and any clamping mechanisms. Check for any signs of damage, unusual wear, or improper installation. Promptly replace any components that are worn beyond tolerance or appear damaged.

Optimizing Wire Tension: The tension applied to the wire as it feeds through the machine is critical. Too much tension can stretch the wire, leading to shorter ties, while insufficient tension can cause slack, resulting in longer ties. Consult your machine's operation manual for the manufacturer's recommended tension settings, or seek advice from a qualified technician to achieve the optimal balance.

Recalibrating Sensors: Ensure that all sensors responsible for monitoring wire feed and positioning are functioning accurately. Clean any accumulated dust or debris from sensor surfaces, verify their alignment, and if necessary, recalibrate them according to the manufacturer's guidelines. Should a sensor consistently report significant errors, replacement may be necessary.

Software System Update and Review: If software is suspected to be the culprit, check for available software updates or patches from the manufacturer. These updates often contain bug fixes and performance enhancements. For persistent software-related issues, contact the machine manufacturer's technical support to ensure full hardware-software compatibility and troubleshoot any deeper programming errors.

Fine-tuning Twist Tie Time Parameters: The duration for which the twisting mechanism operates directly influences the final tie length. Access the machine's control interface and experiment with adjusting the "twist tie time" or "cycle time" parameters. Increasing or decreasing this value in small increments can help stabilize the length by ensuring the twisting process is consistently applied for the correct duration.

Maintaining Peak Performance

Effective troubleshooting and regular maintenance are paramount for ensuring the continuous, stable performance of automatic wire twisting and tying machines. Users should establish a routine of periodic inspections and address any minor issues proactively to prevent them from escalating into major malfunctions. By prioritizing machine care, businesses can significantly improve production efficiency and maintain consistent product quality.

0 notes

Text

SMA FEMALE TO UFL FEMALE WİTH1.13MM CABLE ASSEMBLY

#eteily#tech#technology#CABLEASSEMBLY#SMAfemale#PCBMountConnector#RFCoaxialConnector#UFLInterfaceCable#SMAFemale#UFL#RFantenna#evcharger#cable#connector#iotloraantenna#3Gantenna#4Gantenna#5Gantenna#indoorantenna#outdoorantenna#gainantenna#GPSantenna#manufacturing#telecom#telecommunication#mumbai#delhi#pune#kolkata#worldwide

1 note

·

View note

Text

At Yongrui Wire Rope, we understand that the right cable can make all the difference. That's why we offer a comprehensive range of wire ropes and cable assemblies, meticulously crafted to meet your rigorous standards. Let us be the backbone of your operations with our superior quality and reliable performance. #YongruiQuality #CableAssemblies #EngineeringSuccess

0 notes

Photo

We are a manufacturer of cable trays,cable trays and accessories Cable trays Perforated Manufacturer |ladder cable tray| Cable trays Ladder-type|Cable tray Hot-dip galvanized | Cable tray GI |Cable tray Powder-coated | Ladder Type Cable Tray | Cable tray | cable trays all type in Pakistan... cable tray manufacturer in Pakistan... Ladder type cable tray manufacturer in Pakistan... Cable tray manufacturer in Lahore... Ladder type cable tray manufacturer in Lahore... Cable tray manufacturer in Karachi... Ladder type cable tray manufacturer in Karachi... Cable tray manufacturer in Islamabad... Ladder type cable tray manufacturer in Islamabad... Cable tray manufacturer in Faisalabad... Ladder type cable tray manufacturer in Faisalabad.... Cable trays complete with accessories... Contact us for your cable trays inquiries 03009444907 #cablemanagement #cableassembly #cabletray #cableprotection #cabletrays #cabletray #cabletrays #cablecovers #cableladders #cablemanagementsystems #karachi #lahore #pakistan #sales https://www.instagram.com/p/CWKjmlVjfwv/?utm_medium=tumblr

#cablemanagement#cableassembly#cabletray#cableprotection#cabletrays#cablecovers#cableladders#cablemanagementsystems#karachi#lahore#pakistan#sales

3 notes

·

View notes

Photo

Stahl Metall - Mining Solutions. IP67 “Custom” Control System/Junction Box Assembly. #Stahl_Metall @Stahl_Metall #Aerospace #Defence #Marine #Rail #Mining Stahl Metall products are known for their reliability, precision and resistance to demanding and harsh environments, and commonly used in fields requiring faultless quality, such as Aerospace and Defence, Marine, and Subsea applications with proven track record in complex Defence platforms. Stahl Metall specialises in the design and manufacture of custom “Robust” cable and harness assemblies, complete communication, power / electrical enclosures & box assemblies, custom IP68 enclosures and distributing of high-performance interconnect components. Full 'Plug and Play' Systems. AS 9100D (Aerospace Quality System Standard) certified, IPC-WHMA-A-620A Certified, Build-to-Print and/or Custom Design and Manufacturing.

#Stahl_Metall @Stahl_Metall #Stahl_Metall #Aerospace #Defence #Marine #Space #Rail #Mining #stahl #AS9100 #CommunicationSystems #C4I #C4ISR #PowerDistributionSystems #military #defense #C4i #C4ISR #WeaponControlSystems #MissileGuidanceSystems #MilspecEngineering #CableAssembly #drone #enclosure #ip68 #CustomCableAseembly https://www.stahlmetall.com/ https://www.instagram.com/p/CRIZGtVLIIa/?utm_medium=tumblr

#stahl_metall#aerospace#defence#marine#rail#mining#space#stahl#as9100#communicationsystems#c4i#c4isr#powerdistributionsystems#military#defense#weaponcontrolsystems#missileguidancesystems#milspecengineering#cableassembly#drone#enclosure#ip68#customcableaseembly

1 note

·

View note