#Capsule Filler Machine

Explore tagged Tumblr posts

Text

Capsule Pill Maker

Our range of Capsule Making Machines and filling equipment is designed to provide precision and ease in the creation of high-quality vitamin capsules, supplements, and other nutritional products. Whether you're filling size 00 capsules or any other size, our machines are built for optimal performance and versatility.

Capsule Making Machine for 00 Capsules: This capsule making machine is perfect for filling size 00 capsules with powders, herbs, or other substances. Ideal for small-scale or DIY production, it ensures fast, clean, and accurate filling. Check it out here: Capsule Making Machine for 00 Capsules.

Capsule Pill Maker: This pill capsule maker is perfect for those who want to create their own capsules at home or in small batches. With its manual operation, it’s easy to use and offers flexibility in filling various capsule sizes. Learn more here: Capsule Pill Maker.

Pill Capsule Filler: The pill capsule filler provides a cost-effective way to fill multiple capsules quickly and efficiently. It’s perfect for making vitamin or nootropic pills. View the details here: Pill Capsule Filler.

Capsule Filling Equipment: This capsule filling equipment is ideal for both beginners and small-scale manufacturers. It offers a simple, manual method to fill capsules with precision. It's designed to accommodate various capsule sizes, including size 00, 0, and others. Explore it here: Capsule Filling Equipment.

Capsule Machine Filler: The capsule machine filler is designed for high efficiency, making it ideal for those who need to fill many capsules quickly. It’s easy to assemble, clean, and use, ensuring minimal downtime between batches. Learn more here: Capsule Machine Filler.

Capsule Filler Kit: For those looking for a complete capsule filler kit, this package includes everything needed to fill capsules with your desired materials. It’s a great choice for DIY enthusiasts or small businesses just starting out. Check it out here: Capsule Filler Kit.

Capsule Filler Machine: Our capsule filler machine is an excellent choice for efficient, high-quality production. With a capacity to fill up to 100 capsules at once, it’s perfect for both small and medium-scale production of vitamins and other dietary supplements. Learn more here: Capsule Filler Machine.

These manual capsule filling machines offer easy operation, high productivity, and reliable results. Whether you're making gelatin capsules, vegan pills, or pullulan capsules, our machines help ensure that every batch is filled precisely and efficiently. Perfect for supplement creators, herbalists, and DIY enthusiasts alike.

0 notes

Text

Manual Capsule Filler

Manual Capsule Filler (300 holes capsule filler) including capsule filler with loader uses to fill powder, pellets and granules into capsules. Machine is having 300 holes with orientation of 25 x 12 rows. All contact parts made from Stainless Steel 304 materials. Machine designed with utmost care to handle all capsule sizes ranging from 00 to 5 with different machine and format parts. Assembly has been done in such a way that it can be easily dismantle for cleaning operations. Though all the operations are manual, the machine calls for precision machined components and assembled with highly skilled personnel. Machine having wide usage in R&D laboratories, Research Institutions, Herbal & Nutraceutical preparations, Unani & Ayurvedic medicines, Pilot batch productions etc.

Capsule Filler Machine is widely uses in Research Laboratories, Academic Institution, Herbal/Ayurvedic preparation and medium to small scale manufacturing industries. Our range consist of 100 holes capsule filling machine, 300 holes capsule filler with option of automatic capsule loader to load trays of capsule filling machines.

0 notes

Text

Unlocking Efficiency with Capsule Filling & Weigher Machines

In today’s fast-paced pharmaceutical and nutraceutical industries, precision and efficiency are paramount. Capsule filling and weigher machines have emerged as essential tools in achieving these goals. These advanced machines streamline the encapsulation process, ensuring consistent and accurate dosage with minimal human intervention.

Capsule-filling machines automate the task of inserting powders or granules into capsules, dramatically increasing production speed while maintaining high standards of quality. These machines are designed to handle various capsule sizes and formulations, making them versatile for different products.

On the other hand, weigher machines complement the filling process by providing precise measurements of the capsule contents. They ensure that each capsule meets the specified weight requirements, which is crucial for regulatory compliance and product efficacy. Modern weigher machines offer high-speed performance and integration with other systems, such as automated filling lines, enhancing overall productivity.

Investing in advanced capsule filling and weigher machines not only boosts operational efficiency but also improves product consistency. As industries strive for higher standards and greater output, these machines are proving indispensable in achieving excellence in production. Embracing this technology can lead to significant advancements in both quality and efficiency.

0 notes

Text

Lodha Pharma's Capsule Filling Machine is an innovative product intended to fulfill the wide range of pharmaceutical company requirements. This machine, designed for accuracy and efficiency, fills capsules precisely and consistently with a variety of powders, granules, or pellets. It is a dependable option for high-volume production applications because to its sophisticated technology and sturdy design. Check this page at https://www.lodhapharma.com/high-speed-capsule-filling-machine.php for further details.

0 notes

Text

Lodha Machines is the largest manufacturer and exporter of pharmaceutical machinery in Gujarat, India. Offers the best solutions for medicine filling and packaging machines in the pharmaceutical industry. We take pride in providing the highest quality pharma machines, ensuring efficiency, reliability, and compliance with industry standards. We are committed to providing the best quality pharmaceutical machinery, which is designed with precision and meets strong quality control demands. We are also manufacturers of various types of pharmaceutical machinery like Washing & Air jet Cleaning Machines, Autoclaves and Sterilizers, Ampoule Filler Sealer, Liquid Filling Machine, Powder Filling Machine. If you require visit our site: https://www.lodhamachines.com/ or Contact us: +919687731331

#pharmaceutical machinery#capsule filling machine price#pharmaceutical machinery manufacturer#capsule filling machine manufacturer#tablet making machine manufacturer#pharma machine Manufacturer#Washing & Air jet Cleaning Machines#Autoclaves and Sterilizers#Ampoule Filler Sealer#Liquid Filling Machine#Powder Filling Machine

0 notes

Text

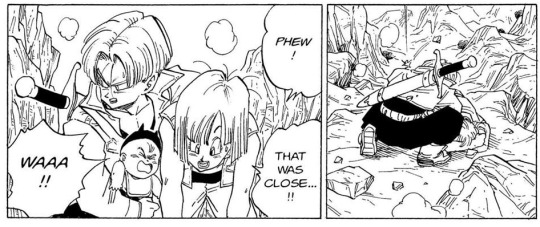

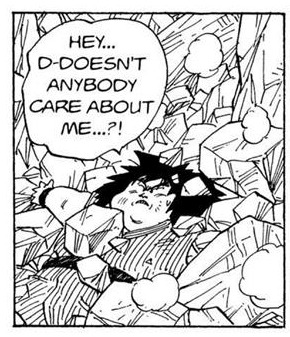

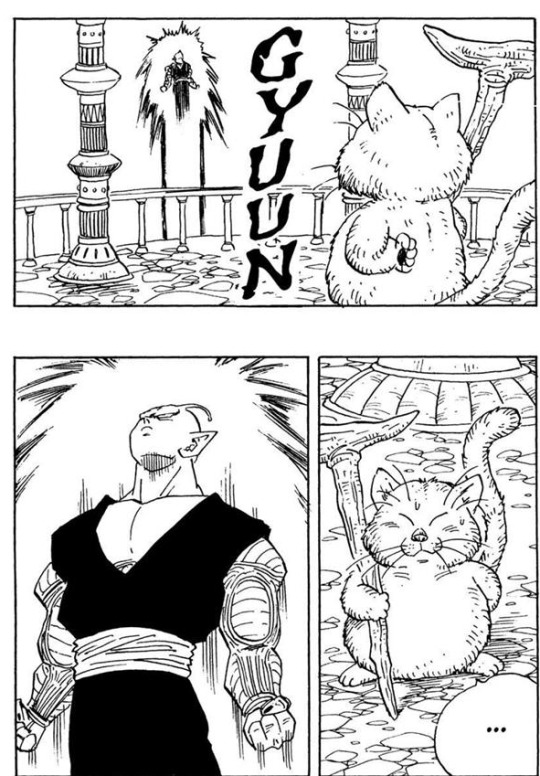

Fun Fact (stealing the format from @tobiasdrake): Yajirobe going to Capsule Corp in the Cell Saga is anime filler!

In the anime and manga, Bulma takes Yajirobe and Trunks via hover-car to the battlefield to see the Androids, then gets shot down by Dr. Gero and saved by Trunks.

Well, Yajirobe didn't get saved by Trunks, he survived just by tanking the explosion. Yajirobe still trained with Kami, he's still really strong.

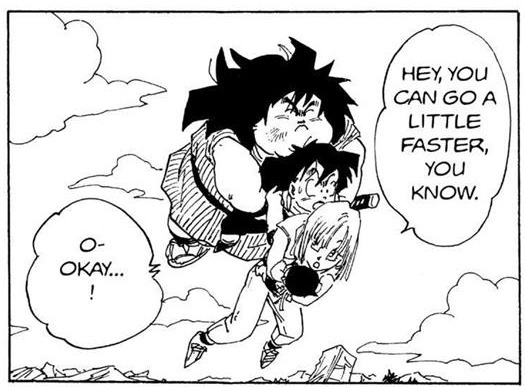

Anyway, after Bulma exposits that she knows where Dr. Gero's lab is to re-orient the plot, Gohan has to take her, Trunks, and Yajirobe home.

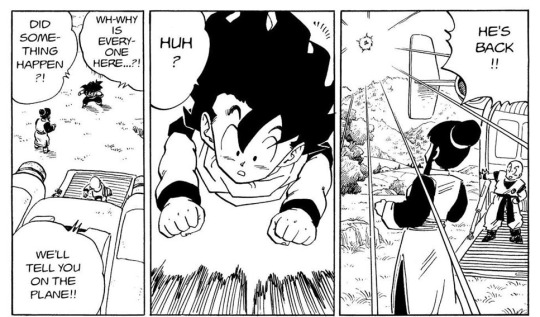

Which he does. Kind of. See, the manga never showed him taking them home. In the manga, the next time we see Gohan is when he arrives at his own house alone while everyone else is evacuating Goku.

The anime decided to flesh this out by randomly deciding that Gohan must have dropped off ALL THREE at Capsule Corp, including Yajirobe. Anime Gohan sure is inconsiderate.

Guess Toei really liked "Yajirobe deals with Bulma and baby Trunks" jokes. TFS got a lot of great mileage out of it.

And it's true that in the manga, we don't see Yajirobe on the lookout when Piccolo flies past to meet with Kami, we just see Korin alone.

Except that scene takes place in chapter 161 of Z, while Gohan returning home takes place in chapter 162, one chapter later. So it's possible at this point that Gohan returned Yajirobe off-panel after Piccolo arrived.

Later, the manga does have a few scenes of Bulma at Capsule Corp, one when she's calling Trunks about the duplicate time machine.

And a follow-up.

And then another scene where she and Briefs are analyzing the blueprints.

And a follow-up.

Notice how Yajirobe is absent from all these scenes? Yeah, the anime added him into them. The next time Yajirobe appears in the manga is when Goku is asking Korin (the God of Martial Arts) to rate his Power Level compared to Cell.

Though given Gohan's line about meeting Korin and Goku commenting on Yajirobe making it back, it seems like Manga Gohan didn't drop Yajirobe off directly at Korin tower.

That exchange would justify why the anime felt like they had room to put Yajirobe at Capsule Corp for comedic filler shenanigans, except I'm pretty sure the anime put Yajirobe at Capsule Corp before this scene in the manga happened.

As far as the manga goes, it looks to me like Gohan dropped him off nearby and Yajirobe hiked the rest of the way. This scene is only two days after Gohan was told to take him home, so he couldn't have been that far.

23 notes

·

View notes

Text

Yu Sleep Review - Is Yu Sleep Supplement Legit?

Yu Sleep Review — Introduction

Read a complete review of the Yu Sleep Supplement. Discover how this natural formula helps improve sleep quality, reduce stress, and boost daytime energy.

Tired of tossing and turning every night? The Yu Sleep Supplement might just be the gentle push your body needs to slip into peaceful slumber. Crafted with natural ingredients, it promises better rest without the morning drag. Let’s dive into this detailed review and find out how Yu Sleep is helping real users sleep like babies.

Rest Easy, the Natural Way

Let’s face it—good sleep has become somewhat of a luxury these days. With buzzing phones, busy minds, and long to-do lists, many folks are left counting sheep way past midnight. That’s where the Yu Sleep Supplement comes into play. This all-natural sleep aid has been making waves among those seeking a restful night without the groggy after-effects of common sleep pills.

But is it all it's cracked up to be? Well, this deep dive will walk you through its ingredients, user experiences, benefits, and more—so you’ll know if Yu Sleep is the bedtime buddy you’ve been waiting for.

# What Makes the Yu Sleep Supplement Stand Out?

There are plenty of sleep supplements crowding the shelves, but Yu Sleep has managed to carve out its own cozy corner. Here's why:

All-natural ingredients – No artificial fillers, just clean and calming herbs.

Gentle effects – Helps the body relax without knocking it out cold.

No addiction risk – It supports sleep without creating dependency.

Non-drowsy mornings – Users say they wake up refreshed, not dazed.

# Key Ingredients in the Yu Sleep Supplement

You’re probably wondering, “What’s in this stuff?” Well, here’s a peek at the powerhouse ingredients packed inside every capsule:

Melatonin – Helps regulate the body’s internal sleep clock.

L-Theanine – An amino acid known for calming the mind.

Chamomile Extract – A traditional herb for easing anxiety and promoting sleep.

Valerian Root – Known to reduce the time it takes to fall asleep.

Magnesium – Helps relax muscles and nerves for smoother sleep.

Put together, these ingredients work like a well-oiled machine—quietly supporting your body as it drifts off naturally.

# First Impressions: Users Speak on Yu Sleep Supplement

Users who've tried the Yu Sleep Supplement often share one thing in common: a sigh of relief. Here's a week-by-week glimpse into what many have reported during their first 60 days:

Full Yu Sleep Review here! at https://scamorno.com/Yu-Sleep-Review-Supplement/?id=tumblr

Week 1: Sleep came quicker, though some woke up a bit groggy initially.

Week 2: Less time tossing and turning, more time snoozing.

Week 3: Consistent sleep patterns began to form.

Week 4: Deeper sleep and fewer interruptions through the night.

Week 5–6: Daytime energy got a noticeable boost; users felt more alert and focused.

# Yu Sleep Supplement Benefits: What’s the Buzz About?

Here's the lowdown on what makes users sing Yu Sleep’s praises:

✔ Quicker sleep onset – No more staring at the ceiling.

✔ Deeper, more restful sleep – Like being wrapped in a cozy blanket of calm.

✔ Improved morning mood – Waking up is easier when you've had quality rest.

✔ Reduced stress levels – A good night’s sleep sets the tone for a better day.

✔ Better focus and energy – Say goodbye to that 3 PM slump.

# Honest Voices: What Real People Are Saying

Let’s hear it straight from the folks who've tried Yu Sleep:

Sandra B., 41, Oregon ⭐⭐⭐⭐⭐ “After years of restless nights, I finally feel like myself again. Yu Sleep helped me find peace at night and energy during the day.”

Mike P., 35, Arizona ⭐⭐⭐⭐⭐ “I used to dread bedtime because sleep never came easy. This supplement changed everything. Now, I’m asleep before I even realize it!”

Tina R., 52, Texas ⭐⭐⭐⭐⭐ “No more midnight wake-ups or groggy mornings. Yu Sleep fits perfectly into my nighttime routine.”

Leo H., 28, Georgia ⭐⭐⭐⭐⭐ “Tried melatonin on its own and it never did the trick. Yu Sleep’s formula works like magic for me. Highly recommended!”

# Side Effects? Let’s Not Lose Sleep Over That

Naturally, safety is top of mind when it comes to supplements. The good news? Most users report no serious side effects from using the Yu Sleep Supplement. Since it’s made with natural, non-habit-forming ingredients, the risk is low.

However, those with pre-existing health issues or who are on medications should check in with their doctor before adding any new supplement to their routine. Better safe than sorry, right?

# Tips for Getting the Most Out of Yu Sleep Supplement

To really squeeze the most benefit out of Yu Sleep, try pairing it with a solid bedtime routine. Here are a few pro tips:

🕯️ Keep a regular sleep schedule

📱 Limit screen time before bed

🌿 Try deep breathing or meditation

🛏️ Create a calm, cool sleep environment

🚫 Avoid caffeine late in the day

Used together, these habits and Yu Sleep can make a pretty dreamy combo.

# Frequently Asked Questions (FAQs)

1. How long does it take for Yu Sleep Supplement to start working? Most users notice improvements within the first week, though full results may take up to 2–4 weeks of consistent use.

2. Can I take Yu Sleep every night? Yes, it's designed for nightly use. However, it’s always a good idea to take short breaks now and then or follow your doctor’s advice.

3. Will I feel groggy in the morning? Many users report waking up clear-headed and energized. A few mention slight grogginess during the first few days, but this often fades.

4. Is it safe to use with other medications? It’s best to consult with your healthcare provider to make sure Yu Sleep won’t interact with any other medications you're taking.

5. Is Yu Sleep Supplement addictive? Nope! It’s made with non-habit-forming ingredients that support sleep naturally, without creating dependency...

Full Yu Sleep Review here! at https://scamorno.com/Yu-Sleep-Review-Supplement/?id=tumblr

2 notes

·

View notes

Text

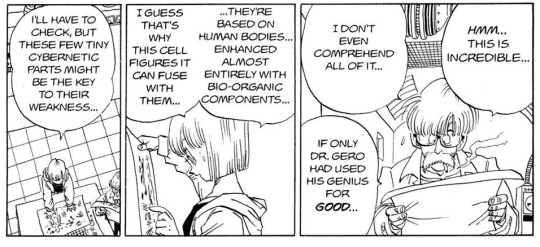

The intellectual instincts and intelligence of Saiyans

Unlike what it often appears to be, which makes it seem like Saiyans are not very intelligent (especially Goku in Super, which takes away a lot of his character through humor, portraying him as less intelligent than he really is, when in fact , on some occasions, Goku makes connections between information much faster and more pragmatically than others caracters, proof of this is at the beginning of the android saga, he was faster than Bulma self in realizing that Trunks was her son. (When Trunks said that his mother knew him very well and was the person who made the time machine, Goku quickly realized that she was Bulma, before Trunks finishes the sentence). Despite this being a genius!, she didn't realize that he was her son from the future, even though he had all the tips that a very intelligent and perceptive person like her could have, he looked like her (or his father in the anime), wore a jacket with the Capsule Corporation emblem and traveled in a time machine and the basic design was very similar to the last ships built by her company and shown in the series (and she herself never tires of boasting about it - of his genius) and there was a Saiyan living in his house (and she even noticed his resemblance to Vegeta, but not to herself), and this human-looking boy transformed into a Super Saiyan, and Trunks didn't hide that he was a time traveler, it's funny that she didn't come to that conclusion alone, a little bit of creativity would do that for her (fanfiction fans are experts at this LOL).

The Saiyans shown are the main ones in the series (it's not like there were enough Saiyans to show their real average level of intelligence, and at the current time in the series, most of them are hybrids, but to have been a species that managed to destroy your home planet (not unlike what we in real life are doing with our own planet and it won't be long before we literally put the physical integrity of the planet itself at risk of being destroyed by weapons, we have no powers but we are so aggressive, violent and destructive as, to build increasingly powerful weapons of mass destruction, and very little control/prudence or whatever else, over their use) and to have been able to have aero-spaceships to travel to another planet and colonize it, including probably exterminating the local native species, after all Vegeta clearly says that the planet was CONQUERED, which means that they invaded the planet and (they must have exterminated it, after all they were mercenary soldiers in the service of Freeza and did the even with other planets to sell) the population that lived there, in his conversation with Cable (I won't look for links, images or more references about this as this was talked about in fillers throughout the series, films, in GT and canonized in the anime and manga Super, you can see Vegeta talking about the planets Vegeta and Sadala with Cable, where Sadala was destroyed in a Civil War (does anyone see any resemblance to us or not? forgive me those who believe that we are a peaceful and harmonious species, but these Saiyans are looking too human, maybe in the future we will do something very similar, how sad), the series really shows that Saiyans have the same average level of intelligence as a human, but with his intellectual capacity and his instincts being almost entirely oriented towards battle (in the circumstances of the world of Dragon Ball, of course, because in our world Ki does not exist).

But in many circumstances, this was shown in the series, when Vegeta learns to control Ki and manipulate his strength/power/Ki level (and hide it from scouters) and feel it simply by observing Earthlings, doing so without need prior instructions or classes, but no other species in the series has the same feat, not even Frieza and his father do it. Despite being a clan of powerful mutants who have an interplanetary/galactic or intergalactic empire (I don't know what level it is at, I don't remember if the series ever delved into this or not), they are not beyond, neither in intelligence, skill or battle-oriented instinct, they are equal to the rest of Dragonball's NPCs in this regard. What makes them powerful and dominant is only their mutation.

I don't want to expand here, but throughout the Frieza and Android saga, Vegeta talks about his discoveries about the use of Ki and Super Saiyan transformation and how it works, showing his perception of its advantages and disadvantages in battle and the changes in the body that it causes and their strengths and weaknesses, such as energy expenditure, stamina, etc, and Goku is equally aware of this and also shows that Trunks and Gohan, as hybrids, do not share the same intuition for battle as their parents, and make a lot of mistakes in this regard area. And unlike Goku, who despite his poor formal academic and civic education, he had and has, extensive and continuous education in martial arts, having had different masters throughout his life and Vegeta no longer had any formal training or training elite after the destruction of Planet Vegeta (and it's something that bothers me about Super, as it does nothing more than recycle concepts already used and presented previously in the series, especially during the phase when Goku is young, and portrays Goku's character as ignorant or oblivious to that) So far you can say - but this is all basic in shonen - is it basic in shonen?, yes! - but no other human or alien character shows it in the series, with the exception of masters and experts in martial arts, gods and members of special races with innate supernatural abilities like the Namekians, like Hoshi and Tao Pai Pai (masters in their respective schools of martial arts), Kami-Sama, Popo, Karin, Piccolo, the Kai and so on. Even though Yamcha, Krillin and Tien are exceptional martial artists, powerful and talented to human levels, they do not demonstrate much intuition for battle and understanding of "key" components during the series (and Krillin created Kienzan! technique that the entire cast copied!) , in the Buu saga we have a little of this too, both from Goku, Vegeta and other characters.

And this is much better shown in the Buu saga by none other than Vegetto, the Potara fusion of Goku and Vegeta, who combines Goku's talent, experience and knowledge with Vegeta's analytical and strategic mind, where Vegetto, based on an assumption of how Buu's powers worked (which are very unusual by the series' standards, Dragonball is not like Naruto for the characters to be so familiar with techniques like that), he managed to devise a plan to enter his body and not be absorbed to save Gohan , Trunks, Goten and Piccolo. Showing the ability that a pure Saiyan has to abstract, theorize, create hypotheses and work with variables and uncertainties, and make decisions based on that. And how he psychologically manipulates Majin Buu, so that he doesn't discover his real intentions (this Buu had Piccolo absorbed), showing that a Saiyan is even capable of estimating how intelligent and what could possibly be going on in the minds of other individuals. Psychological manipulation is a characteristic of Goku, he always pretended to be more naive, foolish, convinced or out of control than he really is, he used this against Cell to fire a Kamehameha at close range so he didn't have time to escape and against Vegeta in this same saga, to make him go to the time chamber before him, so that he could have an idea of the results of the training that Vegeta and Trunks would do, so that he could think of a better way to do it (and he did and discovered a way to get rid of the instability of the transformation into SS.

And in the Broly movie (have I mentioned that I love this movie?), it shows Paragas, demonstrating his hypothesis about how Broly's powers work, even though he doesn't know how to sense Ki and apparently has no advanced knowledge about fighting or Saiyan techniques or even about his Oozaru forms and his power level was only 4,500, even though Paragus was a Colonel, he wasn't a low-class Saiyan, but he wasn't elite either.

(I think it's been said that the only elite Saiyans were only members of the royal family.)

He seemed to only know the basics that a Saiyan knows about fighting and the Oozaru form, as he mentions to Beats (the skinny Saiyan who was not from the warrior class, and seemed to be a technician) that when transforming into Oozaru, even adult Saiyans he has no control over himself and he himself seemed to avoid looking at the Moon to avoid transforming, he does not mention anything about any training or way of learning to control himself in this form and he was unable to teach it to Broly, with Vegeta being the only one who, I remember in the original series, maintaining consciousness in this form and knowing a technique to produce blutz rays without depending on a Moon to transform.

I don't think Vegeta is special, but with that, I just think that as a member of the royal family, he had special training to control himself and transform into Oozaru at will, as it wouldn't make sense for him to have learned to produce blutz rays if he didn't know if control in this way. It was shown that Bardock could also control himself in this form, but it may have been the result of his innate ability or talent, as he was a low-class Saiyan. For now that's it.

I thought of this initially to write, but perhaps to make a better post, I will have to divide it into more than one part, so that I can show in more detail what I mean, if I have time (and patience, and I don't lose my interest, I will do this in the future).

2 notes

·

View notes

Text

Automatic Capsule Filling Machine Manufacturer | IRM Enterprise Pvt. Ltd

Looking for a reliable Automatic Capsule Filling Machine Manufacturer? IRM Enterprise Pvt. Ltd. is a trusted name in the pharmaceutical machinery industry, offering high-performance automatic capsule filling machines designed for precision, speed, and efficiency. Our machines are ideal for pharmaceutical, nutraceutical, and herbal product manufacturers, providing consistent filling of powder, granules, or pellets into capsules of various sizes. With robust construction, user-friendly operation, and low maintenance requirements, IRM’s capsule fillers meet global quality standards and help streamline production processes. Choose IRM Enterprise Pvt. Ltd. for dependable, innovative, and cost-effective capsule filling solutions. Perfect for businesses aiming to scale up with automation and accuracy.

Visit: https://www.karnavatiengineering.com/cf-125.aspx?pid=118

#Automatic Capsule Filling Machine Manufacturer#Capsule Filling Machine Manufacturer#Automatic Capsule Filler#Capsule Filling Machine#Capsule Filler Machine#Pharmaceutical Capsule Filling Machine#Capsule Filling Equipment#High-Speed Capsule Filling Machine#Capsule Filling Machine India#Automatic Capsule Filling Machine Supplier

0 notes

Text

Nichrome T-110 with Tablet Filler | High-Precision Pharma Packaging Machine for Tablets & Capsules Nichrome’s T-110 with Tablet Filler is built for pharma-grade precision from dual hopper feeding to accurate counting, pouch sealing, and smart automation. For soft gels or hard tablets, combo fills or high-speed runs, every stage is backed by technology that ensures nothing gets through our defenses. Visit our website to learn more details about this model.https://www.nichrome.com/machines/hffs-machines/hffs-totpack-t110.php

#integrated packaging solutions#pharma packaging#table filler#pharmaceutical packaging#capsule packaging#tablet packaging

0 notes

Text

Automatic Capsule Filler Machine

youtube

Automatic Capsule Filler Machine is suitable for filling powder/pellets in hard gelatin capsules. It adopts indexing motion and multi-position tamping method to complete capsule orientation, separation, filling, closing and ejection etc. With help of different size parts, machine is suitable for size #00, #0, #1, #2, #3 & #4 capsules. The production speed can be controlled by means of a VFD (Variable Frequency Drive). Machine is designed in accordance with cGMP standards. All product contact parts are made of Stainless Steel 316 & machine covered by Stainless Steel 304. Advantage of the machine is advanced design, study structure, precise dosing, and safe and reliable, high filling rate etc.Machine having wide usage in R&D laboratories, Research Institutions, Herbal & Nutraceutical preparations, Unani &Ayurvedic medicines, Pilot batch productions etc.

We can provide line equipments naming Capsule Sorter Elevator, Capsule Conveying System, Capsule Polishing Machine, Dust Extractor, Damage Capsule Sorter and Empty Capsule Ejector to make complete Automatic Capsule Filling Line.

0 notes

Text

Global Capsule Fillers Market Growth Analysis 2025

Capsule fillers play a pivotal role in the pharmaceutical industry, enabling the efficient and precise encapsulation of various drug formulations. These specialized machines are designed to streamline the capsule-filling process, ensuring consistent dosage and quality control. As the demand for pharmaceuticals continues to rise globally, the capsule fillers market is poised for significant growth, driven by technological advancements and the need for enhanced production capabilities.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/246/capsule-fillers

Market Overview:

Market Size and Projections:

In 2023, the global capsule fillers market was valued at US$ 223.8 million, reflecting the essential nature of these machines in pharmaceutical manufacturing.

The market is anticipated to reach US$ 321.1 million by 2030, witnessing a compound annual growth rate (CAGR) of 6.0% during the forecast period of 2024-2030.

Key Players and Market Concentration:

The global capsule fillers market is dominated by several major manufacturers, including Mettler Toledo, Syntegon, Sejong, Schaefer Technologies, IMA, ACG Worldwide, Lonza (Capsugel), Anchor Mark, and MG2.

In 2023, the world's top three vendors accounted for approximately 21% of the market's revenue, indicating a moderate level of market concentration.

This report aims to provide a comprehensive presentation of the global market for Capsule Fillers, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Capsule Fillers.

The Capsule Fillers market size, estimations, and forecasts are provided in terms of output/shipments (Units) and revenue ($ millions), considering 2023 as the base year, with history and forecast data for the period from 2019 to 2030. This report segments the global Capsule Fillers market comprehensively. Regional market sizes, concerning products by Type, by Application, and by players, are also provided.

For a more in-depth understanding of the market, the report provides profiles of the competitive landscape, key competitors, and their respective market ranks. The report also discusses technological trends and new product developments.

The report will help the Capsule Fillers manufacturers, new entrants, and industry chain related companies in this market with information on the revenues, production, and average price for the overall market and the sub-segments across the different segments, by company, by Type, by Application, and by regions.

Market Segmentation

By Company

Mettler Toledo

Syntegon

Sejong

Schaefer Technologies

IMA

ACG Worldwide

Lonza (Capsugel)

Anchor Mark

MG2

Qualicaps

Chin Yi Machinery

Feton

Fette Compacting

IRM Enterprises

Harro Hofliger

Hanlin Hangyu Industrial

Zhejiang Fuchang Machinery

Adinath International

by Type

Fully Automatic

Semi-automatic

Manual

by Application

Pharmaceutical Company

Nutraceutical Company

Biological Company

Other

Production by Region

North America

Europe

China

India

Consumption by Region

North America

U.S.

Canada

Asia-Pacific

China

Japan

South Korea

Southeast Asia

India

Europe

Germany

France

U.K.

Italy

Netherlands

Rest of Europe

South America

Mexico

Brazil

Rest of South America

Market Drivers:

Increasing Demand for Pharmaceuticals:

The growing global population, rising healthcare expenditure, and the prevalence of chronic diseases have fueled the demand for pharmaceuticals, driving the need for efficient and high-throughput capsule filling solutions.

Automation and Digitalization in Pharmaceutical Manufacturing:

The pharmaceutical industry's focus on automation, digitalization, and Industry 4.0 initiatives has driven the adoption of advanced capsule fillers with integrated control systems, data logging, and remote monitoring capabilities.

Regulatory Compliance and Quality Standards:

Stringent regulatory requirements and quality standards set by governing bodies, such as the Food and Drug Administration (FDA) and the European Medicines Agency (EMA), have prompted pharmaceutical companies to invest in precise and reliable capsule filling equipment.

Growing Demand for Specialized Dosage Forms:

The rise in demand for specialized dosage forms, such as delayed-release, enteric-coated, and sustained-release capsules, has necessitated the use of advanced capsule fillers capable of handling unique formulations and encapsulation processes.

Competitive Landscape:

The capsule fillers market is highly competitive, with established players and emerging companies vying for market share. Key strategies adopted by market participants include:

Technological Innovation: Companies are investing in research and development activities to introduce advanced capsule fillers with enhanced productivity, precision, and automation capabilities, catering to the evolving needs of the pharmaceutical industry.

Strategic Partnerships and Collaborations: Market players are forming partnerships and collaborations with pharmaceutical companies, research institutes, and regulatory bodies to gain insights into industry trends, regulatory requirements, and product development opportunities.

Expansion into Emerging Markets: With the increasing demand for pharmaceuticals in emerging markets, capsule filler manufacturers are expanding their global presence and exploring new market opportunities.

Mergers and Acquisitions: Strategic mergers and acquisitions are being pursued to consolidate market share, acquire complementary technologies, and expand product portfolios.

Focus on Customization and Flexibility: Companies are offering customized and flexible capsule filling solutions to cater to the specific needs of pharmaceutical manufacturers, accommodating various capsule sizes, formulations, and production volumes.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/246/capsule-fillers

0 notes

Text

Pouch Filling Machine: The Definitive Guide for Modern Packaging Solutions

What is a Pouch Filling Machine? A pouch filling machine is an automated packaging system designed to fill pre-formed pouches with liquid, powder, granules, or paste-based products. These machines are engineered to perform multiple tasks such as pouch feeding, product dosing, filling, sealing, coding, and sometimes even cutting or perforating—all in a single streamlined process.

Pouch filling machines are critical to ensuring speed, hygiene, product integrity, and cost efficiency in modern production lines.

Types of Pouch Filling Machines

Vertical Form Fill Seal (VFFS) Machines These machines form pouches from a roll of film, fill them vertically, and then seal them. Ideal for products like snacks, rice, sugar, and detergents.

Horizontal Form Fill Seal (HFFS) Machines Pouches are formed horizontally, making them perfect for solid and fragile items like biscuits, chocolates, and wrapped confectionery.

Pre-Made Pouch Filling Machines These handle pre-formed pouches (like doypacks or zipper bags), filling and sealing them. They are widely used for liquids, sauces, oils, and ready-to-eat foods.

Rotary Pouch Filling Machines Known for their compact design and high speed, rotary machines handle all pouch filling stages in a circular layout, offering consistent performance and versatility.

Applications Across Industries Food & Beverage Fruit juices, milk, water, ketchup, sauces, oil, spices, flour, snacks, grains

Use of food-grade contact parts, anti-drip nozzles, and nitrogen flushing for extended shelf life

Pharmaceutical & Nutraceutical Oral liquids, powders, capsules, herbal supplements

Requires adherence to GMP and FDA standards

Cosmetic & Personal Care Lotions, shampoos, gels, creams, serums

Need high viscosity handling and anti-leak sealing

Chemical & Agrochemical Liquid pesticides, fertilizers, and industrial chemicals

Involves corrosive resistance materials like SS316L or PTFE coatings

Key Features of Modern Pouch Filling Machines

Servo-Driven Dosing System Allows precise product fill levels with minimal variation, enhancing consistency.

Touchscreen HMI with PLC Control Offers easy recipe changes, fault diagnostics, and real-time performance data.

Automatic Pouch Detection The machine detects pouch presence and alignment before initiating filling.

Nitrogen Flushing Used to remove oxygen from the pouch, increasing product shelf life.

Zipper Opening and Closing Mechanism Essential for resealable pouches such as those used for dry fruits, coffee, and snacks.

High-Speed Operation Modern machines can fill up to 120 pouches per minute, depending on pouch size and product type.

Advantages of Using a Pouch Filling Machine Hygienic Packaging: Contactless filling and sealing in a clean environment

Reduced Labor Cost: Fully automated lines require minimal manpower

Higher Output: Consistent speeds and reduced downtime boost production

Versatile Packaging: Can handle stand-up, flat, zipper, gusseted, or spouted pouches

Enhanced Brand Appeal: Clean, wrinkle-free sealing with clear date coding

Minimal Wastage: Drip-proof nozzles and accurate dosing reduce overfilling or spillage

Top Considerations Before Buying

Product Type Is it a powder, granule, paste, or liquid? Each needs different dosing systems (auger filler, piston filler, volumetric cup filler, etc.).

Pouch Format and Size Ensure the machine supports your pouch type: flat, stand-up, zipper, three-side seal, or four-side seal.

Production Volume Calculate your expected pouches per hour and match it with the machine's speed.

Space Availability Rotary machines are compact, while VFFS may need vertical clearance.

Compliance and Certifications Machines for food and pharma should follow GMP, ISO 22000, or FSSAI standards.

Estimated Pricing in India (2025) Machine Type Price Range (INR) Capacity (Pouches/Min) Manual Pouch Filler ₹70,000 – ₹1.5 lakh 10–20 Semi-Automatic Machine ₹1.5 – ₹4 lakh 20–40 Automatic VFFS Machine ₹5 – ₹18 lakh 30–100 Rotary Pre-Made Pouch Filler ₹20 lakh – ₹1 crore+ 60–120

Prices depend on machine materials, number of filling heads, pouch size, and customization.

Top Indian Manufacturers of Pouch Filling Machines Nichrome India Ltd.

Durga Packaging Machine

Uflex Limited

Sampack India Pvt. Ltd.

Mamata Machinery Pvt. Ltd.

These companies offer end-to-end solutions including pouch making, filling, sealing, and after-sales support with installation and operator training.

Common Accessories and Integrations Coding Machines (Inkjet/thermal) for MRP & date

Weighing Systems

Checkweighers and Metal Detectors

Nitrogen Flushing Units

Pouch Pick-and-Place Robots

Pouch Counting and Batching Units

Routine Maintenance Tips Lubricate moving parts every 15 days

Calibrate dosing systems monthly

Replace sealing jaws annually or as needed

Inspect sensors and PLC connections for moisture or dust

Clean nozzles and product pathways daily

Future of Pouch Filling Technology AI-Powered Fill Accuracy Adjustment

Self-Cleaning Filling Valves

Real-Time Batch Tracking

Smart HMI Panels with Cloud Storage

Recyclable Pouch Compatibility

Conclusion A pouch filling machine is an indispensable part of modern packaging automation. Whether you’re in the food, pharma, cosmetic, or chemical industry, the right machine can significantly improve productivity, reduce human error, and increase your product’s market appeal. With rising consumer demand for flexible and eco-friendly packaging, investing in the right pouch filling solution ensures long-term operational success and brand growth.

0 notes

Text

Rotary Pouch Filler and Sealer | Packaging Made Easy

Rotary Pouch Filler and Sealer is an modern-day packaging gadget extensively carried out in numerous industries to fill and seal pouches with precision, pace, and consistency. This automatic tool performs an important feature in cutting-edge production lines, specially in meals, pharmaceuticals, cosmetics, and chemical industries in which packaging great and regular common overall performance are paramount.

What Is a Rotary Pouch Filler and Sealer?

A rotary pouch filler and sealer is a sort of packaging tool designed to fill pre-made pouches or form-fill-seal (FFS) pouches in a rotary movement. Unlike linear machines, which paint in a right away line, rotary machines carry out the useful resource of moving pouches via a round or listed rotating desk. This format allows for higher pace, superior accuracy, and non-prevent packaging strategies.

The tool fills the pouches with a product—drinks, powders, granules, or solids—then seals them securely, organized for distribution or sale.

How Does It Work?

The Rotary Pouch Filler and Sealer typically includes the following stages:

Pouch Loading- Pre-made pouches are placed or robotically fed onto the rotary table, in which the tool grips and moves them via the filling and sealing stations.

Pouch Opening- The tool opens every pouch, preparing it for filling. This also can moreover consist of mechanical palms, air blowers, or vacuum suction.

Product Filling- The device fills the pouch with a particular amount of the product. Depending on the product kind, brilliant filling mechanisms may be used—auger fillers for powders, volumetric cups for granules, or liquid pumps for beverages.

Pouch Sealing- After filling, the pouches skip to the sealing station, in which warmth sealing or ultrasonic sealing techniques close to the pouch securely, making sure product freshness and stopping leaks.

Discharge- The sealed pouches are ejected from the system, prepared for packing or cargo.

Benefits of Rotary Pouch Filler and Sealer Machines

High-Speed Operation: The rotary layout lets in non-stop movement, notably boosting throughput in comparison to linear machines.

Precise Filling: Advanced fillers blanketed with the system ensure correct product dosing, lowering waste.

Versatility: Suitable for a big type of pouch types, which incorporates stand-up pouches, gusseted pouches, flat pouches, and zipper pouches.

User-Friendly Controls: Equipped with touchscreen interfaces and programmable not unusual revel in controllers (PLC) for smooth operation and quick modifications.

Compact Footprint: Rotary machines keep floor area at the same time as maximizing packaging capability.

Hygienic Design: Stainless metal production and clean surfaces make cleaning clean, assembly stringent hygiene necessities, especially in meals and pharmaceutical sectors.

Applications

Rotary Pouch Filler and Sealer Machines are appreciably used inside the course of industries, which include:

Food and Beverage: Packaging snacks, espresso, sugar, spices, sauces, and beverages.

Pharmaceuticals: Sealing powders, capsules, or liquid drug remedies.

Cosmetics: Filling lotions, gels, and powders into hygienic pouches.

Chemicals: Packaging detergents, fertilizers, and one-of-a-kind granular or liquid chemical substances.

Choosing the Right Machine

When choosing a Rotary Pouch Filler and Sealer, elements to keep in mind embody product kind, pouch length and fabric, required pace, and automation diploma. Customizable alternatives at the side of multi-head weighers, nitrogen flushing for freshness, or protected labeling structures can further optimize packaging average overall performance.

Conclusion

A Rotary Pouch Filler and Sealer in China is a crucial funding for agencies aiming to boom packaging velocity without compromising amazing. Its flexibility, precision, and hygienic format make it appropriate for several products and industries. By automating the filling and sealing manner, manufacturers can beautify productivity, reduce tough painting charges, and preserve excessive necessities in product packaging.

0 notes

Text

The Best Way to Fill Pill Capsules in 2025: A Complete Guide

In 2025, the DIY supplement trend continues to grow, and more people are filling their own capsules at home for better control over ingredients, dosages, and costs. Whether you're an herbalist, a health enthusiast, or a small-scale supplement maker, knowing the best way to fill pill capsules efficiently and accurately is crucial. This guide covers the best tools, methods, and tips for filling capsules in 2025.

Why Fill Your Own Capsules?

Filling your own capsules offers numerous benefits:

Customization: Choose exactly what ingredients and dosages go into your capsules.

Cost Efficiency: Bulk powders are often much cheaper than pre-made capsules.

Clean Ingredients: Avoid fillers, binders, and additives commonly found in commercial supplements.

What You Need

To fill capsules effectively in 2025, you’ll need the following:

Empty Capsules: Available in gelatin or vegan (HPMC) form. Common sizes are 00, 0, and 1.

Capsule Filler Machine: Manual or semi-automatic models are widely available and affordable.

Powder Tamper: Helps compress powder for more accurate filling.

Weighing Scale: Precision scales ensure consistent dosages.

Scoop or Spatula: For transferring powder into the capsule filler.

Step-by-Step: How to Fill Capsules

1. Choose Your Capsule Size

Size 00 holds approximately 400-600 mg of powder, while size 0 holds 300-500 mg. Match your dosage requirements with the appropriate size.

2. Prepare Your Powder

Ensure your powder is finely ground and dry. Clumpy or moist powder will not fill evenly and https://yiticapsule.com/blogs/news/capsule-maker-000-100-hole-capsule-filling-machine can degrade capsule quality. You can sift or grind it further if needed.

3. Set Up Your Capsule Machine

Place the capsule filler on a clean, dry surface. Insert the bottom halves of the capsules into the machine. Most machines hold 50 to 100 capsules at once.

4. Fill With Powder

Spread your supplement powder evenly over the capsules using a spatula or scoop. Use the tamper tool to compress the powder, then repeat the filling until each capsule is full.

5. Attach the Tops

Place the capsule tops into the alignment tray. Close the machine to join the capsule halves securely.

6. Inspect and Store

Remove completed capsules, inspect for defects, and store them in an airtight container away from heat and moisture.

New in 2025: Smart Capsule Fillers

This year, smart capsule fillers have become more popular. These devices integrate with mobile apps to help track dosages, batch sizes, and ingredient logs. While pricier, they are perfect for small supplement businesses or health professionals creating personalized regimens.

Tips for Best Results

Wear gloves and a mask when working with potent herbs or powders.

Label your capsules clearly to avoid confusion.

Work in small batches to maintain freshness and accuracy.

Filling your own capsules in 2025 is easier than ever thanks to advanced tools and accessible resources. Whether you’re making supplements for yourself or others, following a clear, step-by-step process will ensure high-quality, safe, and effective capsules every time.

0 notes

Text

In today’s fast-evolving healthcare landscape, pharmaceutical manufacturing is pressured to be more efficient, precise, and safe. Behind every successful medicine is a line of sophisticated equipment that ensures consistency, compliance, and quality. At the forefront of this critical industry is Universe Mach Work, a trusted name in pharmaceutical machinery design and manufacturing. With a proven track record of excellence, Universe Mach Work delivers not just machines, but integrated solutions that empower pharmaceutical companies to meet global standards. Whether it's tablet compression, capsule filling, granulation, coating, or packaging—Universe Mach Work offers cutting-edge equipment tailored to your operational needs.

What Makes Universe Mach Work Stand Out?

1. Engineering Excellence

At Universe Mach Work, every piece of pharmaceutical machinery is built with precision engineering. The company understands that even the smallest defect can have a large impact on pharmaceutical production, where tolerance for error is virtually zero. Their machines are designed with robust construction, advanced automation, and compliance with GMP (Good Manufacturing Practice) standards.

2. Tailored Solutions

No two pharmaceutical operations are exactly alike. Whether you're a small-scale lab or a large multinational production facility, Universe Mach Work offers customizable machinery. Clients can choose from semi-automatic to fully automatic models, compact designs for space-limited facilities, and modular systems that can scale with production demand.

3. Innovative Technology

Pharmaceutical machinery is no longer just about mechanical performance—it’s about smart technology. Universe Mach Work integrates modern features like touchscreen PLC controls, data logging, remote diagnostics, and energy-efficient systems. These innovations help reduce downtime, optimize workflow, and ensure better traceability for quality assurance.

4. Compliance & Quality Assurance

Compliance is the backbone of pharmaceutical manufacturing. Universe Mach Work ensures that all its machinery meets stringent regulatory requirements, including FDA, WHO-GMP, and CE standards. Every machine goes through rigorous testing, documentation, and validation before it reaches the client.

Key Product Categories in Pharmaceutical Machinery

Universe Mach Work offers a wide portfolio of pharmaceutical machines that cover every stage of production. Here are some of the core categories which is most used these days:

• Tablet Press Machines

These are designed for high-speed compression of powder into uniform tablets. The machines are equipped with cutting-edge tooling systems that confidently handle a wide range of tablet sizes and shapes with unmatched precision.

• Capsule Filling Machines

Precision and speed are critical for capsule filling. Universe Mach Work provides automatic and semi-automatic capsule fillers with accuracy in dosage and excellent powder flow handling.

• Granulation Machines

For solid dosage forms, granulation is a key step. The company offers high-shear mixers, fluid bed dryers, and oscillating granulators that produce consistent granules ready for tableting.

• Coating Machines

Tablet coating requires uniformity and controlled environment settings. Universe Mach Work’s coating systems ensure smooth, glossy finishes without compromising the integrity of the active ingredient.

• Packaging Machines

From blister packing to strip packaging and bottle filling, Universe Mach Work’s packaging solutions offer high-speed performance with reliable sealing, labeling, and serialization features.

Serving a Global Market

With a global clientele spread across Asia, Africa, Europe, and the Americas, Universe Mach Work is more than just a manufacturer—it’s a partner in pharmaceutical progress. The company provides end-to-end support, from installation and training to preventive maintenance and upgrades. Their export-ready models are adapted to suit country-specific power ratings, voltage standards, and regulatory requirements, making them ideal for international deployment.

Commitment to After-Sales Support

Purchasing pharmaceutical machinery is a long-term investment. Universe Mach Work ensures that clients get maximum ROI with robust after-sales service. This includes:

Installation and commissioning

Operator training

Troubleshooting and remote support

Spare parts availability

Annual maintenance contracts (AMCs)

Their team of skilled engineers is always on hand to ensure that your machinery keeps running at peak performance.

Future-Ready Manufacturing

Universe Mach Work isn’t resting on its laurels. With increasing demand for personalized medicine, rapid vaccine production, and strict serialization mandates, the future of pharmaceutical manufacturing is digital, agile, and sustainable. The company invests in Industry 4.0 capabilities, IoT integration, and energy-efficient systems to help clients stay competitive. If you're looking for pharmaceutical machinery that combines engineering excellence, regulatory compliance, and state-of-the-art technology, look no further than Universe Mach Work. Their commitment to quality and customer satisfaction makes them a trusted partner in your pharmaceutical journey.

#pharmaceutical manufacturing#gmp compliance#contract manufacturing#quality control systems#pharmaceutical equipment#pharmaceutical supply chain#pharma equipment

0 notes