#High Speed Capsule Filling Machine

Explore tagged Tumblr posts

Text

Double Loader Semi Automatic Capsule Filling Machine

Double Loader Semi Automatic Capsule Filling Machine is furnished with exceptional features and an inventive design. In terms of productivity and operational efficiency, the machine is fully compatible with cGMP regulations and provides precise capsule filling and production.

This equipment, which has a large production capacity, is also known as a high speed capsule filling machine. It has an hourly production capacity of about 45,000 capsules. It is easy to operate and has been designed with precision to fill pellets and powders. Robust design and increased productivity characterize this amazing capsule pellet filling machine. It features a unique hopper that is made for simple assembly and cleanup. You should be aware that replacing parts is not a hassle if necessary. Automatic closure and ejection features provide for the highest level of operational safety.

0 notes

Text

Lodha Pharma's Capsule Filling Machine is an innovative product intended to fulfill the wide range of pharmaceutical company requirements. This machine, designed for accuracy and efficiency, fills capsules precisely and consistently with a variety of powders, granules, or pellets. It is a dependable option for high-volume production applications because to its sophisticated technology and sturdy design. Check this page at https://www.lodhapharma.com/high-speed-capsule-filling-machine.php for further details.

0 notes

Text

Ok so I've had this idea for an au(?) where the toons are twisted in the ways of other twisteds, if that makes sense. So if (random example) Rodger was twisted like Finn, Rodger would have the same mechanics + stats as Finn, and he'd lose his legs and mimic any other changes Finn went through when twisted. Just because Rodger is hypothetically twisted in the way Finn is, doesn't mean that Finn has to twist in the same way as Rodger. I've drawn a couple of twisteds so far as a sort of "proof of concept"

(click the art for better quality)

Glisten -> Shelly

Twisted Shelly has that sort of "you CAN'T forget about me now" kinda look on her face, and I felt it worked with Glisten because he likes attention. My idea on how being twisted affects a toon mentally is that it takes one of the toon's worst/most prominent personality traits, and exemplifies it in some sort of horrible awful terrifying way. So, while regular Twisted Glisten's need for attention is exemplified into a deep fear of being alone, This AU Twisted Glisten's need for attention is exaggerated into a vengeful sort of craving for attention, of any kind, which he usually seeks out in the form of fear. Being feared registers in his fucked up little twisted brain as the same as being adored. He has the same mechanics as Shelly - high speed, low attention span, applies confusion 1 to all toons on the floor - which I feel fits him. If the toons do machines slower, then they have to deal with him for longer, thus giving him more time in the "spotlight."

Sprout -> Rodger

While making this, the main thing I was thinking about was how, when playing as Sprout, the only thing on my mind is tapes, and how Sprout mains go absolutely BALLISTIC on anyone who picks up even a single tape (rightfully so imo). That feeling of thinking that you have to hold everyone together, because you have the ability to make hearts out of thin air; that stress, is mainly what inspired this. Basically, sprout is BEYOND fed up with other toons taking his tapes, and disguises himself for the sole purpose of seeking out "greedy" toons who are out to steal "his" tapes. He's filled with nothing but RAGE at ALL times. He has the same mechanics as Rodger - hiding as (an object), using a long-range attack, short detection radius, hiding if left unbothered for long enough - except he hides as fake tapes instead of research capsules. His attack animation isn't an eye laser, but his morphed, ichor-ified, tentacle-tail-scarf thingy. Not sure I'm too proud of the fake tape design, but they don't really have to be perfect, just recognizable from a distance.

Let me know if you have any other cool ideas for this AU of who to swap! I already have a few in mind 😈

#dandys world#dandy's world#glisten dw#dw glisten#twisted glisten#dandys world glisten#glisten dandys world#twisted glisten dw#dw twisted glisten#dandys world au#sprout dw#dw sprout#dandys world sprout#sprout dandys world#twisted sprout#dw twisted sprout#twisted sprout dw#dandys world art#dandys world fanart#my art#ibispaintx#twisted shelly dw#twisted rodger dw#swapped twisteds au

108 notes

·

View notes

Text

Why Tablube® (Magnesium Stearate) is a Go-To Excipient for Pharmaceutical Manufacturers

In the world of pharmaceutical manufacturing, excipients often play an underrated yet pivotal role in the quality and consistency of finished drug products. Among these, Magnesium Stearate stands out as one of the most widely used lubricants in tablet formulation. When reliability, consistency, and regulatory compliance matter, Tablube®, a premium-grade Magnesium Stearate from Nitika Pharmaceutical Specialities, has become a trusted choice for manufacturers around the globe.

In this blog, we explore why Tablube® Magnesium Stearate is essential for pharmaceutical professionals—from formulation scientists to procurement teams—and how it delivers superior value across various tablet manufacturing processes.

What is Tablube®?

Tablube® is a pharmaceutical-grade Magnesium Stearate, a fatty acid salt derived from stearic acid and magnesium. It is widely used as a tablet lubricant, helping ensure smooth tablet ejection during compression and preventing formulation materials from sticking to punches and dies.

What differentiates Tablube® from other grades of Magnesium Stearate on the market is its:

Controlled particle size

Consistent batch quality

High purity and compliance with pharmacopeial standards (IP, BP, USP, Ph.Eur.)

Excellent flow and lubricating properties

Tablube® is manufactured under cGMP conditions with robust quality control, ensuring it meets the stringent demands of both regulated and semi-regulated pharmaceutical markets.

Why Magnesium Stearate is Crucial in Tablet Manufacturing

Magnesium Stearate plays a vital role as a lubricant in tablet and capsule formulations. It offers several functional benefits that directly impact the efficiency of production and the quality of the final product:

Improved Compressibility: By reducing friction between the tablet blend and machinery, Magnesium Stearate enables better compaction during tablet formation.

Reduced Die Wall Friction: It prevents sticking and picking issues, ensuring smoother ejection of tablets from the press.

Enhanced Flowability: Magnesium Stearate contributes to the flowability of the powder blend, making it easier to fill dies accurately.

Tablet Uniformity: Uniform distribution of Magnesium Stearate in the formulation supports consistent tablet weight and active pharmaceutical ingredient (API) content.

Cost-Efficiency: By minimizing machine wear and reducing downtime, it contributes to more cost-effective production cycles.

When you choose Tablube®, you’re not just buying an excipient—you’re investing in process reliability and superior product quality.

Applications of Tablube® in Pharmaceutical Formulations

Tablube® is suitable for a wide range of solid oral dosage forms, including:

Tablets (uncoated, film-coated, sugar-coated)

Capsules

Powder blends

Direct compression formulations

Direct Compression

In direct compression, Tablube®'s optimized lubrication properties are especially important. It allows uniform tablet hardness and prevents capping or lamination during tablet formation.

High-Speed Tableting

With the rise of high-speed rotary tablet presses, having a consistent and high-performing lubricant like Tablube® ensures that frictional heat and tool wear are minimized.

Moisture-Sensitive APIs

Tablube® is available in various grades with low moisture content, making it suitable for formulations with APIs sensitive to hydrolysis or oxidation.

By choosing Tablube®, procurement teams and formulation scientists can reduce variability and streamline regulatory submissions, thanks to detailed DMFs (Drug Master Files) and full traceability documentation available on request.

Regulatory Compliance & Quality Assurance

Nitika Pharmaceutical Specialities is a WHO-GMP, ISO-certified, and US FDA-audited manufacturer. Tablube® meets all international pharmacopeial requirements (IP/BP/USP/Ph.Eur.), and is supported by:

Comprehensive CoAs

DMFs

Regulatory documentation

Consistent global supply chain support

For pharmaceutical manufacturers targeting export markets or needing regulatory filings, these quality assurances make Tablube® a low-risk, high-performance solution.

Supporting Sustainable & Scalable Manufacturing

As environmental regulations tighten, Nitika’s eco-conscious production process ensures that Tablube® is made with minimal environmental impact, without compromising on product quality.

Moreover, the availability of multiple packaging formats—from small R&D trial packs to bulk industrial drums—makes it easier for manufacturers to scale from pilot to commercial batches.

Who Should Use Tablube®?

Formulation Scientists Ideal for developing robust, scalable formulations with consistent tablet properties.

Procurement Heads Reliable quality, global compliance, and dependable supply chain support make Tablube® a strategic procurement choice.

Pharmaceutical Manufacturers From generics to nutraceuticals, Tablube® is designed to support high-speed, high-efficiency production environments.

Why Partner with Nitika?

Nitika Pharmaceutical Specialities has built a reputation as one of India’s leading manufacturers of pharmaceutical excipients, specializing in lubricants like Magnesium Stearate, as well as Microcrystalline Cellulose (MCC) and Sodium Stearyl Fumarate (SSF).

With over two decades of experience and a strong global footprint, Nitika provides:

Technical support from formulation experts

Custom excipient solutions for complex formulations

Reliable logistics for global delivery

For more information on Nitika’s full range of pharmaceutical excipients, visit https://nitikapharma.com.

Final Thoughts

Whether you're a formulation scientist optimizing your next tablet formulation or a procurement professional evaluating suppliers, Tablube® Magnesium Stearate delivers the quality, consistency, and regulatory backing you need. From improved flow and lubrication to minimized production costs, Tablube® is a smart choice for any serious pharmaceutical manufacturer.

💡 Ready to Elevate Your Tablet Manufacturing?

Partner with Nitika today and experience the benefits of a world-class excipient in your formulations. 📩 Contact us at https://nitikapharma.com 📧 [email protected] 📱 +91 7122554812 to request a product sample .

#Magnesium Stearate#Tablet manufacturing excipients#Pharmaceutical-grade lubricants#Direct compression excipients#Tablube®#Nitika#Nitika Pharma#Nitika Pharmaceutical#Nitika Pharmaceutical Specialities Pvt Ltd#Excipients#India

0 notes

Text

Nichrome T-110 with Tablet Filler | High-Precision Pharma Packaging Machine for Tablets & Capsules Nichrome’s T-110 with Tablet Filler is built for pharma-grade precision from dual hopper feeding to accurate counting, pouch sealing, and smart automation. For soft gels or hard tablets, combo fills or high-speed runs, every stage is backed by technology that ensures nothing gets through our defenses. Visit our website to learn more details about this model.https://www.nichrome.com/machines/hffs-machines/hffs-totpack-t110.php

#integrated packaging solutions#pharma packaging#table filler#pharmaceutical packaging#capsule packaging#tablet packaging

0 notes

Text

Pouch Filling Machine: The Definitive Guide for Modern Packaging Solutions

What is a Pouch Filling Machine? A pouch filling machine is an automated packaging system designed to fill pre-formed pouches with liquid, powder, granules, or paste-based products. These machines are engineered to perform multiple tasks such as pouch feeding, product dosing, filling, sealing, coding, and sometimes even cutting or perforating—all in a single streamlined process.

Pouch filling machines are critical to ensuring speed, hygiene, product integrity, and cost efficiency in modern production lines.

Types of Pouch Filling Machines

Vertical Form Fill Seal (VFFS) Machines These machines form pouches from a roll of film, fill them vertically, and then seal them. Ideal for products like snacks, rice, sugar, and detergents.

Horizontal Form Fill Seal (HFFS) Machines Pouches are formed horizontally, making them perfect for solid and fragile items like biscuits, chocolates, and wrapped confectionery.

Pre-Made Pouch Filling Machines These handle pre-formed pouches (like doypacks or zipper bags), filling and sealing them. They are widely used for liquids, sauces, oils, and ready-to-eat foods.

Rotary Pouch Filling Machines Known for their compact design and high speed, rotary machines handle all pouch filling stages in a circular layout, offering consistent performance and versatility.

Applications Across Industries Food & Beverage Fruit juices, milk, water, ketchup, sauces, oil, spices, flour, snacks, grains

Use of food-grade contact parts, anti-drip nozzles, and nitrogen flushing for extended shelf life

Pharmaceutical & Nutraceutical Oral liquids, powders, capsules, herbal supplements

Requires adherence to GMP and FDA standards

Cosmetic & Personal Care Lotions, shampoos, gels, creams, serums

Need high viscosity handling and anti-leak sealing

Chemical & Agrochemical Liquid pesticides, fertilizers, and industrial chemicals

Involves corrosive resistance materials like SS316L or PTFE coatings

Key Features of Modern Pouch Filling Machines

Servo-Driven Dosing System Allows precise product fill levels with minimal variation, enhancing consistency.

Touchscreen HMI with PLC Control Offers easy recipe changes, fault diagnostics, and real-time performance data.

Automatic Pouch Detection The machine detects pouch presence and alignment before initiating filling.

Nitrogen Flushing Used to remove oxygen from the pouch, increasing product shelf life.

Zipper Opening and Closing Mechanism Essential for resealable pouches such as those used for dry fruits, coffee, and snacks.

High-Speed Operation Modern machines can fill up to 120 pouches per minute, depending on pouch size and product type.

Advantages of Using a Pouch Filling Machine Hygienic Packaging: Contactless filling and sealing in a clean environment

Reduced Labor Cost: Fully automated lines require minimal manpower

Higher Output: Consistent speeds and reduced downtime boost production

Versatile Packaging: Can handle stand-up, flat, zipper, gusseted, or spouted pouches

Enhanced Brand Appeal: Clean, wrinkle-free sealing with clear date coding

Minimal Wastage: Drip-proof nozzles and accurate dosing reduce overfilling or spillage

Top Considerations Before Buying

Product Type Is it a powder, granule, paste, or liquid? Each needs different dosing systems (auger filler, piston filler, volumetric cup filler, etc.).

Pouch Format and Size Ensure the machine supports your pouch type: flat, stand-up, zipper, three-side seal, or four-side seal.

Production Volume Calculate your expected pouches per hour and match it with the machine's speed.

Space Availability Rotary machines are compact, while VFFS may need vertical clearance.

Compliance and Certifications Machines for food and pharma should follow GMP, ISO 22000, or FSSAI standards.

Estimated Pricing in India (2025) Machine Type Price Range (INR) Capacity (Pouches/Min) Manual Pouch Filler ₹70,000 – ₹1.5 lakh 10–20 Semi-Automatic Machine ₹1.5 – ₹4 lakh 20–40 Automatic VFFS Machine ₹5 – ₹18 lakh 30–100 Rotary Pre-Made Pouch Filler ₹20 lakh – ₹1 crore+ 60–120

Prices depend on machine materials, number of filling heads, pouch size, and customization.

Top Indian Manufacturers of Pouch Filling Machines Nichrome India Ltd.

Durga Packaging Machine

Uflex Limited

Sampack India Pvt. Ltd.

Mamata Machinery Pvt. Ltd.

These companies offer end-to-end solutions including pouch making, filling, sealing, and after-sales support with installation and operator training.

Common Accessories and Integrations Coding Machines (Inkjet/thermal) for MRP & date

Weighing Systems

Checkweighers and Metal Detectors

Nitrogen Flushing Units

Pouch Pick-and-Place Robots

Pouch Counting and Batching Units

Routine Maintenance Tips Lubricate moving parts every 15 days

Calibrate dosing systems monthly

Replace sealing jaws annually or as needed

Inspect sensors and PLC connections for moisture or dust

Clean nozzles and product pathways daily

Future of Pouch Filling Technology AI-Powered Fill Accuracy Adjustment

Self-Cleaning Filling Valves

Real-Time Batch Tracking

Smart HMI Panels with Cloud Storage

Recyclable Pouch Compatibility

Conclusion A pouch filling machine is an indispensable part of modern packaging automation. Whether you’re in the food, pharma, cosmetic, or chemical industry, the right machine can significantly improve productivity, reduce human error, and increase your product’s market appeal. With rising consumer demand for flexible and eco-friendly packaging, investing in the right pouch filling solution ensures long-term operational success and brand growth.

0 notes

Text

Materials & Machines: The Unchanging Pillars of the Pharmaceutical Industry

In an industry built on precision, trust, and life-saving innovation, two unsung heroes remain at the core of every pharmaceutical breakthrough: materials and machines. While technology and techniques evolve, these foundational elements continue to power the global pharmaceutical engine—making them truly the heart and soul of the industry.

A Legacy Built on Science and Innovation

The modern pharmaceutical journey took a pivotal turn in 1953 with the discovery of the DNA double helix by James Watson and Francis Crick. This scientific revolution paved the way for cures to diseases like smallpox and polio, marking the Golden Era of Science and Pharmaceutical Progress from 1930 to 1970.

But none of it would have been possible without the perfect interplay of quality materials and reliable machines.

Materials: The Building Blocks of Every Dose

Every medicine begins with two types of materials:

Active Pharmaceutical Ingredients (APIs): These are the core substances that deliver therapeutic effects.

Excipients: Though inactive, they make up 70��90% of the dosage form, ensuring the API is stable, safe, effective, and bioavailable.

From binders and disintegrants to lubricants and controlled-release polymers, each excipient plays a vital role in making sure the drug performs effectively and meets patient expectations.

Machines: Precision in Every Step

Behind every tablet or capsule lies a sophisticated series of processes—each powered by specialised equipment designed for speed, accuracy, and consistency. A typical tablet manufacturing process includes:

Sifting: Vibratory or rotary sifters ensure uniform particle size, which is essential for blend and content uniformity.

Granulation: Rapid Mixer Granulators (RMG) combine powders and binders to form a wet mass.

Milling & Drying: Wet mills and fluid bed dryers prepare granules with ideal moisture levels and particle sizes.

Blending: V-cone, double-cone, or octagonal blenders ensure a homogenous mix.

Compression: Tablets are formed with desired size, weight, and hardness using precision tablet compression machines.

From there, processes such as coating, capsule filling, and packing are completed using advanced systems that guarantee quality and compliance.

The Next Frontier: Automation & AI

The pharmaceutical industry is on the brink of an automation revolution. With the rise of Artificial Intelligence, manufacturers are embracing:

Automated quality control

Predictive maintenance

AI-driven process optimisation

But while AI will enhance accuracy and reduce human error, materials and machines will remain irreplaceable constants. AI may guide and monitor, but it will still depend on high-quality ingredients and dependable equipment to deliver results.

Health Trends Driving the Future

Today’s fast-changing lifestyles, poor dietary habits, and environmental stressors are accelerating the prevalence of chronic and infectious diseases—from hypertension and ulcers to viral outbreaks and cancer. As a result:

New medicines will continue to emerge.

Regulatory standards will evolve to meet emerging risks.

Demand for robust pharmaceutical infrastructure will surge.

And through all of this, materials and machines will stay central to the evolution of pharmaceutical manufacturing.

Anish Pharma: Engineering Excellence for Over 30 Years

At Anish Pharma, we understand the irreplaceable role machines play in shaping medicine. With over three decades of expertise, we manufacture cutting-edge pharmaceutical processing equipment trusted by 500+ manufacturers across six continents.

Our commitment is to empower your processes with precision, reliability, and regulatory compliance—every step of the way.

Join the future of pharmaceutical manufacturing with Anish Pharma.

#Pelletization Line#pharma equipment manufacturers in maharashtra#fluidized bed dryer#fluid bed granulation machine manufacturers maharashtra#wurster fluid bed coating machine manufacturers in india

0 notes

Text

Rotary Pouch Filler and Sealer | Packaging Made Easy

Rotary Pouch Filler and Sealer is an modern-day packaging gadget extensively carried out in numerous industries to fill and seal pouches with precision, pace, and consistency. This automatic tool performs an important feature in cutting-edge production lines, specially in meals, pharmaceuticals, cosmetics, and chemical industries in which packaging great and regular common overall performance are paramount.

What Is a Rotary Pouch Filler and Sealer?

A rotary pouch filler and sealer is a sort of packaging tool designed to fill pre-made pouches or form-fill-seal (FFS) pouches in a rotary movement. Unlike linear machines, which paint in a right away line, rotary machines carry out the useful resource of moving pouches via a round or listed rotating desk. This format allows for higher pace, superior accuracy, and non-prevent packaging strategies.

The tool fills the pouches with a product—drinks, powders, granules, or solids—then seals them securely, organized for distribution or sale.

How Does It Work?

The Rotary Pouch Filler and Sealer typically includes the following stages:

Pouch Loading- Pre-made pouches are placed or robotically fed onto the rotary table, in which the tool grips and moves them via the filling and sealing stations.

Pouch Opening- The tool opens every pouch, preparing it for filling. This also can moreover consist of mechanical palms, air blowers, or vacuum suction.

Product Filling- The device fills the pouch with a particular amount of the product. Depending on the product kind, brilliant filling mechanisms may be used—auger fillers for powders, volumetric cups for granules, or liquid pumps for beverages.

Pouch Sealing- After filling, the pouches skip to the sealing station, in which warmth sealing or ultrasonic sealing techniques close to the pouch securely, making sure product freshness and stopping leaks.

Discharge- The sealed pouches are ejected from the system, prepared for packing or cargo.

Benefits of Rotary Pouch Filler and Sealer Machines

High-Speed Operation: The rotary layout lets in non-stop movement, notably boosting throughput in comparison to linear machines.

Precise Filling: Advanced fillers blanketed with the system ensure correct product dosing, lowering waste.

Versatility: Suitable for a big type of pouch types, which incorporates stand-up pouches, gusseted pouches, flat pouches, and zipper pouches.

User-Friendly Controls: Equipped with touchscreen interfaces and programmable not unusual revel in controllers (PLC) for smooth operation and quick modifications.

Compact Footprint: Rotary machines keep floor area at the same time as maximizing packaging capability.

Hygienic Design: Stainless metal production and clean surfaces make cleaning clean, assembly stringent hygiene necessities, especially in meals and pharmaceutical sectors.

Applications

Rotary Pouch Filler and Sealer Machines are appreciably used inside the course of industries, which include:

Food and Beverage: Packaging snacks, espresso, sugar, spices, sauces, and beverages.

Pharmaceuticals: Sealing powders, capsules, or liquid drug remedies.

Cosmetics: Filling lotions, gels, and powders into hygienic pouches.

Chemicals: Packaging detergents, fertilizers, and one-of-a-kind granular or liquid chemical substances.

Choosing the Right Machine

When choosing a Rotary Pouch Filler and Sealer, elements to keep in mind embody product kind, pouch length and fabric, required pace, and automation diploma. Customizable alternatives at the side of multi-head weighers, nitrogen flushing for freshness, or protected labeling structures can further optimize packaging average overall performance.

Conclusion

A Rotary Pouch Filler and Sealer in China is a crucial funding for agencies aiming to boom packaging velocity without compromising amazing. Its flexibility, precision, and hygienic format make it appropriate for several products and industries. By automating the filling and sealing manner, manufacturers can beautify productivity, reduce tough painting charges, and preserve excessive necessities in product packaging.

0 notes

Text

Double Loader Semi Automatic Capsule Filling Machine

youtube

Double Loader Semi Automatic Capsule Filling Machine features an innovative design and equipped with outstanding features. The machine offers precision capsule filling and manufacturing and is completely cGMP compliant in terms of operational efficiency and productivity.

This machine is also known as high speed capsule filling machine and it has a vast production capacity. It can produce approximately 45,000 capsules/ hour. It is user-friendly and precision engineered to fill powders and pellets. Sturdy construction and higher outputs are the hallmarks of this fabulous capsule pellet filling machine. It has a special hopper that is designed for easy dismantling and cleaning. In case you need to change parts, you must know that it is not a hassle either. Utmost operational safety can be achieved due to automatic closing and ejection capabilities.

#Semi Automatic Capsule Filling Machine#high speed capsule filling machine#capsule pellet filling machine#Youtube

0 notes

Text

Softgel Manufacturing Equipment Market Growth Analysis, Market Dynamics, Key Players and Innovations, Outlook and Forecast 2025-2032

As of 2024, the global Softgel Manufacturing Equipment market was valued at approximately US$ 85.90 million. With a forecasted Compound Annual Growth Rate (CAGR) of 6.6% during 2025-2031, the market is expected to reach US$ 129.30 million by 2031. This growth reflects increasing global demand for softgel products in health supplements, pharmaceuticals, and cosmetic applications. Rising health consciousness, demand for dietary supplements, and pharmaceutical advancements have significantly contributed to market expansion. Furthermore, the growth in contract manufacturing and technological innovations in encapsulation processes are pivotal in boosting market size and demand.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/878/Softgel-Manufacturing-Equipment-Market

Softgel manufacturing equipment encompasses the range of machinery and tools used in the production of soft gelatin capsules, commonly known as softgels. These capsules are a preferred dosage form for pharmaceuticals and nutraceuticals due to their smooth texture, ease of swallowing, and ability to encapsulate both liquid and semi-solid substances. Key equipment includes soft capsule encapsulation machines, drying systems, and various auxiliary devices involved in forming, filling, sealing, and drying softgel capsules. The equipment ensures uniformity, hygiene, precision dosing, and high production efficiency, making it indispensable in health supplement and pharmaceutical manufacturing sectors. The growing need for softgel capsules in the dietary supplement, pharmaceutical, and nutraceutical sectors is propelling the market for softgel manufacturing equipment worldwide. Softgel capsules are a preferred dosage form for a variety of active ingredients because of their benefits, which include increased product stability, ease of swallowing, and improved bioavailability. To meet the increasing demands of the market, manufacturers are investing in sophisticated, automated, and high-speed softgel production technologies as health-conscious consumers look for convenient and efficient delivery methods. The use of advanced softgel manufacturing equipment is being accelerated globally by advancements in encapsulation techniques, an emphasis on quality control, and the growth of personalized medicine. The market is positioned for major technological advancements and worldwide expansion due to the growing applications of vitamins, herbal supplements, and prescription medications.

Market Dynamics (Drivers, Restraints, Opportunities, and Challenges)

Drivers

Growing Demand for Nutraceutical and Dietary Supplements

The rise in the use of dietary supplements and nutraceuticals worldwide, especially softgel capsules, is one of the main factors propelling the market for softgel manufacturing equipment. Supplements that promote immunity, cognitive function, joint health, and general well-being are becoming more and more popular among consumers; these trends have accelerated since the pandemic. The ease of ingestion, improved bioavailability, and capacity to encapsulate fat-soluble or oil-based nutrients such as vitamin D, omega-3, and herbal extracts make softgel capsules the preferred form of supplementation. Nutraceutical companies are increasing production in response to this change in consumer preferences, which is increasing demand for automated, high-speed softgel manufacturing equipment that can provide scalability, precision, and hygiene. This demand is especially high in North America, Europe, and Asia-Pacific due to aging populations and rising health consciousness..

Restraints

High Initial Investment and Maintenance Costs

The substantial capital outlay needed to buy, install, and maintain sophisticated machinery is one of the main factors limiting the market for softgel manufacturing equipment. For small and mid-sized manufacturers, the high upfront costs of high-end encapsulation machines, drying systems, and auxiliary equipment can be a deterrent. To guarantee consistent output and quality, these machines also need to be operated by trained personnel and receive routine maintenance, which raises operating costs even more. Overall market penetration may be slowed by this financial burden, which may prevent adoption in emerging markets or among startups.

Opportunities

Rising Demand for Personalized Medicine and Niche Formulations

The growing popularity of niche formulations and the trend toward personalized medicine present an emerging opportunity. Flexible and modular softgel manufacturing systems that facilitate small-batch production are becoming more and more necessary as pharmaceutical and nutraceutical companies work to provide more individualized therapies. Complex APIs, combination ingredients, and customized dosages are all perfectly encapsulated by these systems. The creation of softgel capsules for particular consumer segments, such as children, the elderly, and vegans, also gives equipment manufacturers the chance to develop flexible, clean-label, and multipurpose products..

Challenges

Regulatory Compliance and Product Quality Standards

Complying with strict regulatory standards in various regions, particularly in the pharmaceutical industry, is a significant challenge for the sector. Strict regulations pertaining to ingredient traceability, manufacturing process validation, and capsule consistency are enforced by regulatory agencies such as the FDA (U.S.), EMA (Europe), and CFDA (China). Manufacturers of equipment must create devices that adhere to strict quality control procedures, clean-in-place (CIP) systems, and good manufacturing practices (GMP). Maintaining cost-effectiveness and production efficiency while remaining compliant is a never-ending balancing act that can impact scalability and postpone product rollouts.

Regional Analysis

North America leads the global softgel manufacturing equipment market, accounting for thw highest market share of the total market share. This dominance is attributed to advanced healthcare infrastructure, a mature pharmaceutical industry, and widespread adoption of dietary supplements. Europe follows, with key contributions from Germany, France, and the U.K., driven by regulatory mandates and robust R&D investment. The continent holds a significant share in the global market. Asia Pacific exhibits the highest growth rate due to rising pharmaceutical outsourcing, expanding healthcare sectors in China and India, and supportive government initiatives. South America and Middle East & Africa are emerging regions, with growing investments in healthcare manufacturing and infrastructure modernization acting as key growth levers.

Competitor Analysis

The softgel manufacturing equipment market is moderately consolidated with the top three global vendors accounting for highest market share. Leading companies include:

Changsung Softgel System: Known for innovative encapsulation technologies and a strong international presence.

SKY SOFTGEL & PACK: Offers turnkey solutions for softgel production with high customization options.

Technophar: A pioneer in softgel encapsulation technology, emphasizing quality control and precision.

Other notable players such as Pharmagel, GIC Engineering, Sankyo, Kamata, and Long March Tianmin have established regional footprints and contribute significantly to the competitive landscape through technological collaborations and strategic expansions.

In December 2024, Novo Holdings A/S acquired Catalent for $16.5 billion. As part of the transaction, Novo Nordisk acquired three manufacturing facilities from Novo Holdings for $11 billion to scale up production to meet the demand for products like Wegovy and Ozempic.

Global Softgel Manufacturing Equipment: Market Segmentation Analysis

This report provides a deep insight into the global Softgel Manufacturing Equipment, covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and assessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Softgel Manufacturing Equipment. This report introduces in detail the market share, market performance, product situation, operation situation, etc., of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Softgel Manufacturing Equipment in any manner.

Market Segmentation (by Equipment Type)

Encapsulation Machines

Drying Systems

Softgel Inspection Machines

Softgel Polishing Machines

Support Equipment

Market Segmentation (by Mode of Operation)

Automatic Machines

Semi-Automatic Machines

Manual Machines

Market Segmentation (by Application)

Pharmaceuticals

Nutraceuticals

Cosmetics

Veterinary Products

Others

Key Company

Changsung

SKY

Technophar

Pharmagel

GIC Engineering

Sankyo

Kamata

Bochang

Tooltronics

Long March Tianmin

Geographic Segmentation

North America

US

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Russia

Nordic Countries

Benelux

Rest of Europe

Asia

China

Japan

South Korea

Southeast Asia

India

Rest of Asia

South America

Brazil

Argentina

Rest of South America

Middle East & Africa

Turkey

Israel

Saudi Arabia

UAE

Rest of Middle East & Africa

FAQ Section

▶ What is the current market size of Softgel Manufacturing Equipment?

The global Softgel Manufacturing Equipment market was valued at US$ 85.90 million in 2024 and is projected to reach US$ 129.30 million by 2031.

▶ Which are the key companies operating in the Softgel Manufacturing Equipment market?

Key players include Changsung Softgel System, SKY SOFTGEL & PACK, Technophar, Pharmagel, GIC Engineering, Sankyo, Kamata, Bochang, Tooltronics, and Long March Tianmin.

▶ What are the key growth drivers in the Softgel Manufacturing Equipment market?

Major growth drivers include increasing demand for health supplements, pharmaceutical product innovations, rising health awareness, and technological advancements in softgel production.

▶ Which regions dominate the Softgel Manufacturing Equipment market?

North America leads the market, followed by Europe and Asia Pacific, which together account for a significant majority of the market share.

▶ What are the emerging trends in the Softgel Manufacturing Equipment market?

Emerging trends include automation of manufacturing processes, adoption of Industry 4.0 technologies, growth in contract manufacturing, and increasing focus on personalized medicine and nutraceuticals.

Get free sample of this report at : https://www.intelmarketresearch.com/manufacturing-and-construction/878/Softgel-Manufacturing-Equipment-Market

0 notes

Text

Automatic Capsule Filling Machine Manufacturer | IRM Enterprise Pvt. Ltd

Looking for a reliable Automatic Capsule Filling Machine Manufacturer? IRM Enterprise Pvt. Ltd. is a trusted name in the pharmaceutical machinery industry, offering high-performance automatic capsule filling machines designed for precision, speed, and efficiency. Our machines are ideal for pharmaceutical, nutraceutical, and herbal product manufacturers, providing consistent filling of powder, granules, or pellets into capsules of various sizes. With robust construction, user-friendly operation, and low maintenance requirements, IRM’s capsule fillers meet global quality standards and help streamline production processes. Choose IRM Enterprise Pvt. Ltd. for dependable, innovative, and cost-effective capsule filling solutions. Perfect for businesses aiming to scale up with automation and accuracy.

Visit: https://www.karnavatiengineering.com/cf-125.aspx?pid=118

#Automatic Capsule Filling Machine Manufacturer#Capsule Filling Machine Manufacturer#Automatic Capsule Filler#Capsule Filling Machine#Capsule Filler Machine#Pharmaceutical Capsule Filling Machine#Capsule Filling Equipment#High-Speed Capsule Filling Machine#Capsule Filling Machine India#Automatic Capsule Filling Machine Supplier

0 notes

Text

The Power of High-Speed Rotary Packaging Machines

In today's fast-paced manufacturing world, speed and efficiency are no longer just competitive advantages—they're essential for survival. As industries evolve to meet the rising demands of global consumers, packaging plays a critical role in the production process. One innovation that has significantly transformed the packaging landscape is the high-speed rotary packaging machine. These mechanical marvels are driving productivity, ensuring consistency, and reducing labor costs across multiple industries. Let’s explore how these powerful machines are revolutionizing packaging as we know it.

What Are High-Speed Rotary Packaging Machines?

High-speed rotary packaging machines are advanced systems designed to automate the process of forming, filling, and sealing packages at exceptional speeds. Unlike traditional linear machines, rotary machines operate in a circular or rotary fashion, enabling continuous motion packaging. pouch packaging machines This not only boosts output rates but also ensures a more compact footprint and higher efficiency.

Typically used in industries such as food and beverage, pharmaceuticals, cosmetics, and consumer goods, these machines are capable of handling various package types including pouches, sachets, bags, and even bottles, depending on the machine design.

Key Features That Set Rotary Machines Apart

High-Speed Output As the name suggests, speed is the hallmark of rotary packaging machines. Capable of completing hundreds of cycles per minute, these machines dramatically increase throughput, helping manufacturers meet large-scale production goals with ease.

Precision and Consistency Automation ensures that every package is filled, sealed, and labeled with unmatched precision. This reduces product waste and improves overall quality control, which is especially crucial in regulated industries like pharmaceuticals and food.

Versatility Many rotary systems come equipped with interchangeable parts or modular designs, allowing for quick changeovers between different products or packaging formats. This flexibility is a major benefit in dynamic markets where product lines frequently evolve.

Compact Footprint By organizing the packaging process in a circular layout, rotary machines occupy less floor space compared to linear systems. This makes them ideal for manufacturers with space constraints.

Reduced Downtime These machines are designed for continuous motion, which translates to less downtime. vacuum packaging machine Some models also include features like automatic film alignment, error detection, and tool-less changeovers to further enhance uptime.

Industries Benefiting from High-Speed Rotary Packaging

1. Food and Beverage

Whether it’s single-serve snacks, coffee pods, or liquid beverages, rotary packaging machines ensure that food items are packaged quickly and safely. These machines support vacuum sealing, nitrogen flushing, and tamper-evident sealing—key features that preserve freshness and extend shelf life.

2. Pharmaceuticals

In the pharmaceutical sector, speed must never compromise accuracy. Rotary machines used here are engineered for precise dosing and strict hygiene standards. They are often used to package tablets, capsules, and powders into blister packs or sachets.

3. Cosmetics and Personal Care

From face creams to shampoos and lotions, the cosmetics industry benefits from rotary machines for filling and sealing both flexible and rigid packaging. Their precision helps ensure every unit looks professional and meets branding requirements.

4. Chemical and Industrial Goods

Even in heavy-duty sectors like chemicals or automotive products, rotary machines are utilized for packaging adhesives, lubricants, and cleaning agents. Specialized designs can handle corrosive or viscous substances with ease.

The Economic Impact: Why Speed Matters

High-speed rotary packaging machines are not just a technological upgrade—they're a strategic investment. Here’s why:

Lower Labor Costs: Automation reduces the need for manual labor, helping manufacturers save on wages, training, and human error correction.

Faster Time-to-Market: Quicker packaging allows for faster product launches and better responsiveness to market trends.

Improved ROI: Though the initial cost of a high-speed rotary machine can be significant, the return on investment is high thanks to reduced waste, lower overhead, and faster production.

Environmental Considerations

Sustainability is becoming a driving force in packaging decisions. High-speed rotary machines contribute to green initiatives in several ways:

Efficient Use of Materials: These machines optimize material usage, reducing film waste and over-packaging.

Energy Efficiency: Newer models are designed to consume less power while delivering higher output.

Compatibility with Eco-Friendly Films: Many machines can work with biodegradable or recyclable materials, helping companies align with sustainability goals.

Trends and Innovations

As technology continues to evolve, rotary packaging machines are becoming smarter and more efficient. Here are some emerging trends:

Integration with IoT: Modern machines are equipped with sensors and connectivity features that allow real-time monitoring, predictive maintenance, and data-driven optimization.

Artificial Intelligence (AI): AI algorithms can help fine-tune operations by predicting jams, adjusting speeds, or identifying inconsistencies.

Robotic Integration: Robotics are being paired with rotary systems for tasks like automated loading/unloading and quality inspection.

Choosing the Right Machine: What to Consider

When selecting a high-speed rotary packaging machine, manufacturers should consider several factors:

Production Needs: Define the desired output speed and volume.

Product Type: Different machines handle liquids, powders, or solids differently.

Package Style: Whether you need stand-up pouches, flat sachets, or spouted bags, make sure the machine supports your preferred format.

Space Availability: Assess your factory layout to ensure a suitable fit.

Budget and ROI: Factor in the total cost of ownership, not just the upfront price.

Conclusion

The power of high-speed rotary packaging machines lies in their ability to combine speed, accuracy, and flexibility in one compact unit. As industries face mounting pressure to deliver more, faster, and with greater sustainability, these machines are stepping up to the challenge. Investing in rotary packaging technology isn't just about keeping up—it's about staying ahead.

Whether you're a small manufacturer looking to scale or a large enterprise seeking to optimize efficiency, embracing this cutting-edge machinery could be the key to unlocking your full production potential.

0 notes

Text

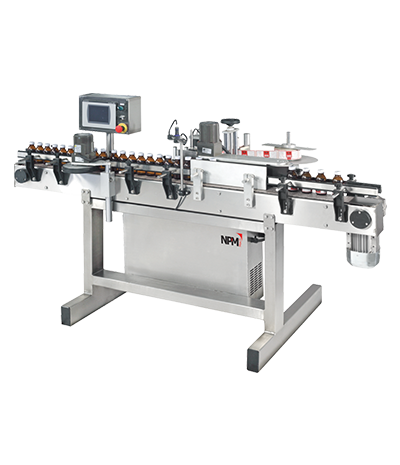

Revolutionizing Pharma Production: The Role of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Introduction

In the dynamic world of pharmaceuticals, precision, hygiene, speed, and compliance are non-negotiable. As the demand for high-quality medicines continues to rise globally, the pharmaceutical industry must meet rigorous standards in both production and packaging. This is where Pharma Packaging Machines come into play—ensuring products are safely, efficiently, and accurately packed before reaching the end-user.

At NPM Machinery Pvt. Ltd., we understand the critical importance of packaging in the pharma value chain. As a leading manufacturer of pharma packaging machines, our mission is to empower pharmaceutical companies with robust, automated, and intelligent machinery that supports regulatory compliance while improving productivity and product integrity.

In this blog, we will delve into the importance of pharma packaging machines, the types available, their benefits, and why NPM Machinery Pvt. Ltd. is your ideal partner in pharmaceutical automation.

Why Pharma Packaging Machines Matter

Pharmaceutical packaging is far more than just enclosing a product in a container. It is a protective barrier, a compliance requirement, a branding tool, and an enabler of global logistics. A well-packaged pharmaceutical product ensures:

Product integrity during transport and storage

Accurate dosage and ease of administration

Protection against contamination and tampering

Compliance with FDA and other global regulatory norms

Efficient serialization and tracking

Manual packaging simply cannot keep up with the high-volume, high-precision demands of modern pharmaceutical production. That’s where automated packaging solutions step in—offering speed, consistency, and compliance.

Core Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

At NPM Machinery Pvt. Ltd., we design and manufacture a full spectrum of advanced pharma packaging machines tailored to the needs of small-scale manufacturers as well as large pharmaceutical giants. Here are the most common types and their applications:

📦 1. Blister Packaging Machines

Ideal for packing tablets and capsules in pre-formed plastic blisters sealed with aluminum foil

Ensures tamper-proof packaging and extended shelf life

Used widely in retail and hospital pharmacy sectors

💊 2. Strip Packaging Machines

Designed to wrap tablets and capsules between aluminum or plastic strip foils

Compact, precise, and perfect for heat-sensitive medicines

Offers high output and minimal material wastage

🧪 3. Bottle Filling and Capping Machines

Automates filling of syrups, suspensions, and other liquids into bottles with accurate volume control

Integrates seamlessly with capping units for secure sealing

Customizable for different bottle sizes and materials

🏷️ 4. Labeling Machines

Applies labels accurately on bottles, ampoules, vials, or boxes

Supports serialization and barcoding for traceability

Compatible with multiple label shapes and sizes

🧼 5. Washing & Sterilizing Machines

Cleans vials, ampoules, and bottles before filling to ensure zero contamination

Uses air and water jets with complete automation

Essential for injectable and parenteral products

🧴 6. Cartoning Machines

Automates the packing of blister packs, bottles, or tubes into cartons

Integrates leaflet insertion and batch coding

Enhances product presentation and traceability

🎯 7. Inspection Machines

Detects broken tablets, missing capsules, misprinted labels, and other defects

Ensures every packaged product meets quality control standards

Reduces human error and improves customer trust

Benefits of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Choosing the right packaging solution is not just about machinery—it’s about performance, reliability, and long-term value. NPM Machinery's pharma packaging machines offer:

✅ 1. High-Speed Automation

Boost production rates with minimal human intervention

Ideal for mass manufacturing and 24/7 operations

✅ 2. Unmatched Accuracy

Delivers exact filling, sealing, and labeling

Reduces product loss and ensures dosage consistency

✅ 3. Compliance & Validation

Built with GMP, FDA, and CE compliance in mind

Supports 21 CFR Part 11 for electronic data integrity

✅ 4. Flexibility & Customization

Machines tailored to your product specifications

Modular designs allow for future scalability

✅ 5. Advanced Technology Integration

Equipped with PLC-based controls, SCADA systems, and IoT capabilities

Enables remote monitoring, real-time alerts, and preventive maintenance

✅ 6. Superior Build Quality

Made with stainless steel and corrosion-resistant materials

Long machine life, low maintenance, and robust performance

✅ 7. Global Support & Service

On-site training, remote diagnostics, and spare parts availability

Dedicated support teams for installation, validation, and upgrades

Industries We Serve

While our core strength lies in pharmaceutical packaging, our machines are versatile enough for other regulated industries such as:

Nutraceuticals

Ayurveda and Herbal

Cosmetics

Food & Beverage

Veterinary Medicine

Why Choose NPM Machinery Pvt. Ltd.?

With decades of experience, NPM Machinery Pvt. Ltd. has built a reputation for engineering excellence and customer-centric innovation. Here's what sets us apart:

✔️ 150+ skilled professionals including engineers, technologists, and validation experts

✔️ ISO-certified manufacturing with a focus on precision and safety

✔️ Custom turnkey packaging lines from design to commissioning

✔️ Strong domestic and global footprint with clients across Asia, Africa, Europe, and South America

✔️ Client-first approach—we adapt our solutions to your needs, not the other way around

Our goal is not just to sell machines—but to build long-term partnerships that add value to your production process, protect your brand, and ensure regulatory peace of mind.

Conclusion

The future of pharmaceutical manufacturing lies in smart, integrated, and efficient packaging systems. With increasing global demand, strict compliance requirements, and growing competition, investing in high-performance pharma packaging machines is no longer optional—it's essential.

At NPM Machinery Pvt. Ltd., we don’t just provide machines—we deliver confidence, quality, and peace of mind. Whether you're launching a new production line or upgrading your existing setup, we are here to guide you every step of the way with reliable, cutting-edge, and compliant solutions.

✅ Call to Action

Ready to upgrade your pharma packaging line? Partner with NPM Machinery Pvt. Ltd. and experience unmatched quality, service, and innovation. 📩 Contact us today for a free consultation or demo customized to your packaging needs! 🌐 Visit us at www.npmmachinery.com | 📞 +91-XXXXXXXXXX

0 notes

Text

In today’s fast-evolving healthcare landscape, pharmaceutical manufacturing is pressured to be more efficient, precise, and safe. Behind every successful medicine is a line of sophisticated equipment that ensures consistency, compliance, and quality. At the forefront of this critical industry is Universe Mach Work, a trusted name in pharmaceutical machinery design and manufacturing. With a proven track record of excellence, Universe Mach Work delivers not just machines, but integrated solutions that empower pharmaceutical companies to meet global standards. Whether it's tablet compression, capsule filling, granulation, coating, or packaging—Universe Mach Work offers cutting-edge equipment tailored to your operational needs.

What Makes Universe Mach Work Stand Out?

1. Engineering Excellence

At Universe Mach Work, every piece of pharmaceutical machinery is built with precision engineering. The company understands that even the smallest defect can have a large impact on pharmaceutical production, where tolerance for error is virtually zero. Their machines are designed with robust construction, advanced automation, and compliance with GMP (Good Manufacturing Practice) standards.

2. Tailored Solutions

No two pharmaceutical operations are exactly alike. Whether you're a small-scale lab or a large multinational production facility, Universe Mach Work offers customizable machinery. Clients can choose from semi-automatic to fully automatic models, compact designs for space-limited facilities, and modular systems that can scale with production demand.

3. Innovative Technology

Pharmaceutical machinery is no longer just about mechanical performance—it’s about smart technology. Universe Mach Work integrates modern features like touchscreen PLC controls, data logging, remote diagnostics, and energy-efficient systems. These innovations help reduce downtime, optimize workflow, and ensure better traceability for quality assurance.

4. Compliance & Quality Assurance

Compliance is the backbone of pharmaceutical manufacturing. Universe Mach Work ensures that all its machinery meets stringent regulatory requirements, including FDA, WHO-GMP, and CE standards. Every machine goes through rigorous testing, documentation, and validation before it reaches the client.

Key Product Categories in Pharmaceutical Machinery

Universe Mach Work offers a wide portfolio of pharmaceutical machines that cover every stage of production. Here are some of the core categories which is most used these days:

• Tablet Press Machines

These are designed for high-speed compression of powder into uniform tablets. The machines are equipped with cutting-edge tooling systems that confidently handle a wide range of tablet sizes and shapes with unmatched precision.

• Capsule Filling Machines

Precision and speed are critical for capsule filling. Universe Mach Work provides automatic and semi-automatic capsule fillers with accuracy in dosage and excellent powder flow handling.

• Granulation Machines

For solid dosage forms, granulation is a key step. The company offers high-shear mixers, fluid bed dryers, and oscillating granulators that produce consistent granules ready for tableting.

• Coating Machines

Tablet coating requires uniformity and controlled environment settings. Universe Mach Work’s coating systems ensure smooth, glossy finishes without compromising the integrity of the active ingredient.

• Packaging Machines

From blister packing to strip packaging and bottle filling, Universe Mach Work’s packaging solutions offer high-speed performance with reliable sealing, labeling, and serialization features.

Serving a Global Market

With a global clientele spread across Asia, Africa, Europe, and the Americas, Universe Mach Work is more than just a manufacturer—it’s a partner in pharmaceutical progress. The company provides end-to-end support, from installation and training to preventive maintenance and upgrades. Their export-ready models are adapted to suit country-specific power ratings, voltage standards, and regulatory requirements, making them ideal for international deployment.

Commitment to After-Sales Support

Purchasing pharmaceutical machinery is a long-term investment. Universe Mach Work ensures that clients get maximum ROI with robust after-sales service. This includes:

Installation and commissioning

Operator training

Troubleshooting and remote support

Spare parts availability

Annual maintenance contracts (AMCs)

Their team of skilled engineers is always on hand to ensure that your machinery keeps running at peak performance.

Future-Ready Manufacturing

Universe Mach Work isn’t resting on its laurels. With increasing demand for personalized medicine, rapid vaccine production, and strict serialization mandates, the future of pharmaceutical manufacturing is digital, agile, and sustainable. The company invests in Industry 4.0 capabilities, IoT integration, and energy-efficient systems to help clients stay competitive. If you're looking for pharmaceutical machinery that combines engineering excellence, regulatory compliance, and state-of-the-art technology, look no further than Universe Mach Work. Their commitment to quality and customer satisfaction makes them a trusted partner in your pharmaceutical journey.

#pharmaceutical manufacturing#gmp compliance#contract manufacturing#quality control systems#pharmaceutical equipment#pharmaceutical supply chain#pharma equipment

0 notes

Text

Nigeria, Indonesia, and Turkey: The New Frontiers for Oscillating Granulators Market Players

Nigeria, Indonesia, and Turkey are rapidly emerging as high-growth markets within the global Oscillating Granulators industry. With the market currently valued at $439.5 million, these three countries are forecasted to experience compound annual growth rates (CAGR) ranging from 6.1% to 8.7% between 2025 and 2030. This surge is primarily driven by rising demand in pharmaceutical manufacturing and food processing—two industries where granulators are essential for precision granulation and particle size control.

Check detailed insights here - https://datastringconsulting.com/industry-analysis/oscillating-granulators-market-research-report

Expanding Role in Food and Pharmaceutical Sectors

Oscillating granulators are widely utilized in the food processing sector to ensure uniform particle sizes during the size reduction and sieving phases. These machines help maintain the physical integrity of food products during granulation, offering efficiency without compromising quality. Prominent industry names such as GEA Group and Sotuken have successfully integrated oscillating granulators into their food production lines to meet stringent quality standards.

In the pharmaceutical industry, oscillating granulators play a critical role in the formulation process. They ensure consistent granule size for tablet compression and capsule filling, a necessity for dose accuracy and stability. The rising focus on automation and compliance with Good Manufacturing Practices (GMP) continues to propel adoption.

Technological Advancements Driving Efficiency

The global oscillating granulators market is undergoing a digital transformation. The integration of programmable logic controllers (PLCs) has significantly enhanced machine performance. These controllers allow operators to regulate oscillation speed, frequency, and timing with high precision, reducing manual intervention and streamlining production. Moreover, the growing adoption of AI and machine learning in pharmaceutical and chemical granulation processes is optimizing outcomes and enabling predictive maintenance, which enhances machine longevity and minimizes downtime.

Global and Regional Growth Trends

From a global perspective, the Oscillating Granulators market is projected to grow from $439.5 million in 2024 to $1,056.5 million by 2035, reflecting a robust CAGR of 8.3%. North America remains a dominant force in the market, driven by its high-tech pharmaceutical and chemical sectors. The region's demand is shaped by increasing automation, focus on energy-efficient equipment, and the need for compact, high-speed granulators that align with waste reduction goals.

However, competition in North America is intense, with well-established players setting high performance and compliance benchmarks. New entrants face challenges in breaking into the market due to these elevated standards and entrenched supplier relationships.

Industry Landscape and Innovation

Key manufacturers—including GEA Group, SaintyCo, The Elizabeth Companies, Alexanderwerk, Cadmach Machinery, Frewitt Fabrique de machines SA, Chamunda Pharma Machinery, SOTAX Group, and Kevin Process Technologies Pvt. Ltd.—are actively innovating to capture market share. Strategic collaborations, investment in R&D, and an increasing focus on smart granulation systems are key approaches adopted to stay competitive.

Market Segmentation and Use Cases

Oscillating granulators are segmented by product types (horizontal and vertical), applications (pharmaceutical, chemical & fertilizer, food & beverage), and technology types (mechanical and digital). End-users range from research laboratories and pharmaceutical manufacturers to food processing units, reflecting the versatile utility of these machines across industries.

About DataString Consulting

DataString Consulting provides deep market intelligence and strategic insights that help organizations craft successful business roadmaps. With over three decades of combined experience in market research and strategy advisory, DataString supports companies in expanding into new territories, growing their total addressable markets, and diversifying revenue streams. With continuous monitoring across more than 15 industries and 60 sub-sectors, DataString helps businesses cut through the noise and discover new opportunities for innovation, growth, and market penetration.

#OscillatingGranulators#PharmaceuticalMachinery#FoodProcessingEquipment#GranulationTechnology#EmergingMarkets#NigeriaBusiness#IndonesiaIndustry#TurkeyManufacturing#PharmaInnovation#SmartManufacturing#IndustrialAutomation#AIinManufacturing#MachineLearning#ProcessEfficiency#DataStringConsulting#GlobalMarkets#TechInFood#AutomationSolutions#MarketResearch#GrowthMarkets

0 notes

Text

The Invisible Hero in Your Medicine Cabinet: Magnesium Stearate 💊✨

Ever wondered what makes your supplements and medicines so perfectly shaped and consistent? Let me introduce you to the unsung hero of the pharmaceutical world: magnesium stearate powder.

What's This White Powder All About?

Magnesium stearate is that behind-the-scenes ingredient making sure your tablets don't stick to machines during manufacturing. It's like the stage crew of a Broadway show – you never see them, but without them, the whole production falls apart!

Fun fact: It's actually just magnesium combined with stearic acid (which naturally occurs in many foods).

Why Should You Even Care About This?

Because it's in practically EVERYTHING in your medicine cabinet:

Those multivitamins you take? Contains magnesium stearate.

That prescription medication? Yep, probably has it too.

Even some of your favorite powdered makeup products!

The Manufacturing Magic ✨

Here's what this powder actually does:

🔹 Prevents Sticking: Imagine trying to stamp out thousands of tablets per minute and having them constantly stick to the machine. Manufacturing nightmare! Magnesium stearate creates a thin barrier that prevents this.

🔹 Even Distribution: It ensures that all the ingredients mix evenly, so you're not getting a random amount of ingredients in each pill.

🔹 Smooth Operation: During high-speed production, things heat up and create friction. This magical powder reduces that friction, helping maintain the quality of the product.

![Image description: A capsule filled with yellow powder, representing pharmaceutical manufacturing]

The Science-y Bit

Technically speaking, magnesium stearate is a "flow agent" – it makes powders flow better. If you've ever had trouble pouring flour smoothly for baking, you understand the importance of powder flowability. Now imagine that problem but with medicines where exact amounts matter!

Industry Secret

Manufacturers LOVE this stuff because it makes production faster, more efficient, and more reliable. It's like the ultimate industrial lubricant for pharmaceutical production.

In Conclusion...

Next time you easily swallow a perfectly formed tablet or capsule, give a little mental thanks to magnesium stearate – the invisible ingredient making your medicine cabinet more reliable.

#PharmaceuticalScience #BehindTheScenes #SupplementFacts #ManufacturingSecrets #TheMoreYouKnow

1 note

·

View note