#ColdChainPackaging

Explore tagged Tumblr posts

Text

Cold Chain Packaging Market Poised for Transformation with Emerging Technologies and Eco-Friendly Materials

The cold chain packaging market is experiencing robust growth as industries demand more efficient and reliable temperature-sensitive logistics solutions. Cold chain packaging refers to systems and materials used to maintain a consistent low-temperature range for perishable products during storage and transportation. It plays a pivotal role in preserving the integrity of products such as pharmaceuticals, food and beverages, chemicals, and biological samples.

Rising Demand in Key Industries

The primary driver behind the growth of the cold chain packaging market is the increasing global demand for temperature-controlled pharmaceuticals and biologics. With the rise in chronic diseases and the expansion of biopharmaceuticals, there is a pressing need for secure and reliable cold chain systems to maintain product efficacy and safety. The COVID-19 pandemic further amplified this need, showcasing the importance of efficient cold chain logistics in vaccine distribution.

In the food and beverage industry, globalization of trade and shifting consumer preferences toward fresh and organic products have necessitated high-performance cold chain packaging. Perishable foods like dairy, meat, seafood, and frozen goods require stable temperature environments to prevent spoilage, maintain quality, and comply with stringent food safety regulations.

Innovation in Packaging Materials and Technology

Technological advancements are playing a crucial role in the evolution of cold chain packaging. The development of phase change materials (PCMs), vacuum insulated panels (VIPs), and smart packaging with temperature indicators and GPS tracking have revolutionized the way sensitive goods are stored and transported. These technologies help companies monitor temperature in real-time and mitigate risks during transit, ensuring product safety and reducing losses.

Sustainable and reusable cold chain packaging solutions are also gaining traction. With increasing environmental concerns and regulations on plastic use, companies are adopting eco-friendly packaging materials made from recycled content or biodegradable polymers. Reusable insulated containers, along with active and passive refrigeration systems, are becoming standard in many cold chain operations to minimize waste and optimize cost-efficiency.

Market Segmentation and Regional Insights

The cold chain packaging market can be segmented by product type, material, application, and geography. Popular product types include insulated containers and boxes, refrigerants (such as gel packs and dry ice), labels, and temperature monitoring devices. Materials used range from polystyrene foam and polyurethane to corrugated fiberboard and advanced insulation films.

Geographically, North America holds a significant share of the market due to its established pharmaceutical and processed food industries, along with a strong regulatory framework. Europe follows closely, driven by stringent quality and safety standards. However, the Asia-Pacific region is projected to grow at the highest CAGR, owing to rising healthcare investments, increasing food exports, and expanding cold storage infrastructure in countries like China and India.

Challenges and Opportunities

Despite the promising outlook, the cold chain packaging market faces several challenges. High initial investment and maintenance costs for temperature-controlled packaging systems can deter small and medium-sized enterprises. Inconsistent infrastructure in developing economies, along with varying regulations across regions, also hinders market expansion.

However, these challenges present opportunities for innovation and collaboration. Companies are investing in R&D to develop low-cost, high-efficiency packaging alternatives. Partnerships between packaging manufacturers, logistics providers, and technology firms are creating integrated cold chain ecosystems. Furthermore, digitalization and automation are enhancing traceability and compliance, thereby improving overall supply chain efficiency.

Future Outlook

The future of the cold chain packaging market looks promising, with projections indicating consistent growth through 2030. Increasing globalization, urbanization, and online grocery and pharmaceutical deliveries are expected to further drive demand. As companies strive to meet regulatory compliance, reduce waste, and improve sustainability, innovation in materials and smart packaging technologies will remain at the forefront.

Emerging trends such as blockchain for enhanced traceability, AI for demand forecasting, and the use of IoT sensors for real-time monitoring will likely shape the next generation of cold chain packaging. Governments and private sector players must work collaboratively to strengthen infrastructure and standardize practices globally.

In summary, the cold chain packaging market is evolving rapidly in response to changing industry needs, consumer expectations, and environmental concerns. By embracing technological advancements and sustainable practices, the industry is set to meet the growing demand for safe and efficient cold chain logistics worldwide.

#ColdChain#ColdChainPackaging#ColdChainLogistics#TemperatureControlled#PharmaLogistics#FoodLogistics

0 notes

Text

#ColdChainPackaging#Biologics#TemperatureControl#PharmaceuticalPackaging#TemperatureSensitive#ColdChainLogistics

0 notes

Text

0 notes

Text

Cold Chain Packaging Market Innovations Shaping the Future of Temperature Controlled Logistics

The cold chain packaging market is a critical segment of the global supply chain ecosystem, playing an essential role in maintaining the quality and safety of temperature-sensitive products. This market encompasses the packaging materials and technologies used to preserve goods at controlled temperatures throughout storage and transportation. With the rising demand for pharmaceuticals, perishable food products, and biologics, the cold chain packaging market has witnessed significant growth, driven by technological innovations and stricter regulatory frameworks.

Overview of Cold Chain Packaging

Cold chain packaging involves specialized containers, insulated boxes, refrigerants, and temperature monitoring devices that help maintain specific temperature ranges required for sensitive products. These products include vaccines, blood samples, fresh fruits and vegetables, dairy products, seafood, and certain chemicals that degrade if exposed to temperature fluctuations.

The importance of cold chain packaging became particularly evident during the COVID-19 pandemic when vaccines requiring ultra-low temperatures were distributed globally. This event highlighted the need for reliable packaging solutions capable of maintaining temperatures as low as -70°C, emphasizing the market’s growth potential and innovation opportunities.

Market Drivers

Several factors are propelling the growth of the cold chain packaging market:

Rising Demand for Pharmaceuticals and Biologics: The pharmaceutical industry, especially biologics and vaccines, requires stringent temperature control to ensure product efficacy and safety. With the increase in chronic diseases and the development of personalized medicine, the need for cold chain packaging has surged.

Growth in Perishable Food Industry: Increasing consumer preference for fresh and organic food has led to a rise in cold storage and transportation requirements. The expansion of e-commerce and online grocery delivery services also fuels demand for reliable cold chain solutions.

Stringent Regulatory Standards: Governments and international bodies have implemented strict regulations around the handling and transportation of temperature-sensitive products. Compliance with these regulations necessitates the use of advanced packaging technologies, further driving market growth.

Technological Advancements: Innovations such as phase change materials (PCMs), vacuum insulated panels (VIPs), smart packaging with IoT-enabled temperature sensors, and eco-friendly insulation materials are revolutionizing cold chain packaging, making it more efficient and sustainable.

Market Challenges

Despite strong growth prospects, the market faces certain challenges:

High Costs: Advanced cold chain packaging solutions can be expensive, limiting adoption, especially in developing regions.

Logistical Complexities: Maintaining an unbroken cold chain across long distances, especially in countries with poor infrastructure, is challenging.

Environmental Concerns: Many cold chain packaging materials are non-biodegradable, raising sustainability issues.

Key Market Segments

The cold chain packaging market is segmented based on material type, application, end-user, and region:

Material Type: Includes insulated containers, gel packs, dry ice, phase change materials, and refrigerants.

Application: Pharmaceuticals, food and beverages, chemicals, and others.

End-User: Hospitals and clinics, food distributors, research laboratories, and logistics companies.

Region: North America, Europe, Asia Pacific, Latin America, and Middle East & Africa.

Among these, the pharmaceutical segment is one of the fastest-growing due to the increasing need for vaccines and biologics. Asia Pacific is expected to witness rapid growth driven by expanding healthcare infrastructure and rising demand for fresh food products.

Future Trends and Opportunities

The future of the cold chain packaging market looks promising with several emerging trends:

Sustainable Packaging Solutions: Growing environmental awareness is pushing manufacturers to develop biodegradable and recyclable cold chain packaging materials.

Digital Integration: The integration of IoT and blockchain technology in cold chain packaging enhances real-time temperature monitoring and traceability, improving transparency and reducing product loss.

Customized Solutions: Demand for tailor-made packaging solutions that cater to specific temperature ranges and product types is increasing.

Expansion in Emerging Markets: Increasing healthcare spending and food consumption in regions like Asia, Latin America, and Africa present vast opportunities for market players.

Conclusion

The cold chain packaging market is at a pivotal stage of growth, driven by increasing demand for temperature-sensitive pharmaceuticals and perishable food products. Technological innovations and rising regulatory standards are shaping the market’s trajectory, pushing for more efficient, sustainable, and smarter packaging solutions. While challenges such as cost and logistics remain, the opportunities offered by digital integration and expanding markets make cold chain packaging an exciting and dynamic industry to watch in the coming years.

#ColdChainPackaging#ColdChainMarket#TemperatureControlledLogistics#PharmaceuticalPackaging#PerishableGoods#SupplyChainInnovation

0 notes

Text

Cold Chain Packaging Market Trends Highlight Need for Eco-Friendly Materials and Smart Logistics Systems

The cold chain packaging market is rapidly evolving, driven by the increasing global demand for temperature-sensitive goods such as pharmaceuticals, biologics, and perishable foods. As globalization expands trade routes and healthcare needs become more complex, the requirement for reliable, efficient, and sustainable cold chain solutions has never been more urgent.

Cold chain packaging refers to the use of materials and systems that ensure the safe transport and storage of products within specific temperature ranges. These solutions are essential in maintaining the integrity and efficacy of sensitive goods during transit. The market encompasses a wide range of products, including insulated containers, phase change materials (PCMs), refrigerants, gel packs, and temperature-controlled boxes, among others.

One of the primary drivers of the cold chain packaging market is the pharmaceutical and biotechnology industry. The rise of personalized medicine, vaccines, and biologics has led to increased demand for packaging solutions that can preserve product stability. For instance, mRNA vaccines such as those developed for COVID-19 require extremely low storage temperatures, sparking innovation and investment in advanced cold chain technologies.

Similarly, the food and beverage sector is a major contributor to market growth. The global consumption of perishable goods like dairy, seafood, and ready-to-eat meals continues to rise. Consumers now expect fresher, healthier food options delivered rapidly, which necessitates robust packaging systems that ensure temperature control throughout the supply chain.

The growth of e-commerce has also transformed the landscape. Online grocery and meal kit delivery services have surged in popularity, especially post-pandemic, placing pressure on cold chain logistics providers to deliver high-quality solutions that maintain product integrity from warehouse to doorstep. This shift has encouraged the development of user-friendly and recyclable cold packaging options that balance performance with environmental responsibility.

Sustainability is a growing trend in the cold chain packaging market. Companies are under increasing scrutiny to reduce the environmental impact of their packaging materials. As a result, there is a significant push toward eco-friendly packaging designs made from recyclable, biodegradable, or reusable materials. The market is also seeing innovations in insulation materials that offer high thermal performance with a lower environmental footprint.

Technological advancements are reshaping how temperature-sensitive products are tracked and managed. Smart packaging equipped with IoT-enabled sensors can monitor and report real-time temperature data, alerting handlers to potential breaches in the cold chain. These solutions not only improve compliance with regulatory standards but also enhance transparency and trust throughout the supply chain.

Geographically, North America and Europe dominate the cold chain packaging market due to their strong pharmaceutical and food industries, advanced logistics infrastructure, and stringent regulatory environments. However, Asia-Pacific is witnessing the fastest growth, fueled by rising healthcare investments, urbanization, and increasing disposable incomes. Countries like China and India are experiencing growing demand for biologics and high-quality food products, thus accelerating the adoption of cold chain packaging solutions.

Despite its promising outlook, the market faces several challenges. High capital investment, complex logistics coordination, and compliance with diverse international regulations can hinder market entry and expansion, especially for smaller players. However, partnerships, mergers, and acquisitions are helping companies scale up and innovate faster to meet growing demand.

Looking forward, the cold chain packaging market is expected to continue its upward trajectory. Innovations in material science, automation, and data analytics are likely to redefine industry standards. With an increasing emphasis on sustainability and quality assurance, companies that can provide efficient, eco-friendly, and compliant packaging solutions will be well-positioned to thrive.

In conclusion, the cold chain packaging market plays a crucial role in supporting global industries that depend on temperature-sensitive products. As technology advances and consumer expectations evolve, this market will remain a key component in maintaining the quality, safety, and integrity of critical goods across various sectors.

0 notes

Text

#ColdChainPackaging#TemperatureSensitiveLogistics#PackagingSolutions#ThermalInsulation#RefrigeratedTransport#ColdChainManagement#LogisticsSolutions#SupplyChainManagement

0 notes

Text

0 notes

Text

#FrozenFoodShipping#ColdChainPackaging#FoodShippingGuide#FoodPackaging#PackagingSolutions#FrozenFoodDelivery#ShippingBestPractices

0 notes

Text

#coldchainpackagingforfoodtransportation#temperaturecontrolledpackaging#coldchainpackagingproducts#coldchainpackagingcompany#coldchainpackaging#coldchainpackagingforpharmaceuticletransportation

0 notes

Photo

Qualified, Single-Use Control Room Temperature Packaging

Maintain control room temperatures for up to 48 hours and priced for either single or multi-use applications. The qualified single-use packaging system balances cost with reliability to provide the best temperature-controlled packaging system on the market today

Visit Website: https://www.tempaid.net/qualified-packaging/qualified-single-use-control-room-temperature-packaging/

#singleusecontrolroomtemperaturepackaging#controlroomtemperaturepackagingsolutions#coldchainshipping#temperaturecontrolledpackagingsystem#coldchainpackaging#coldchainpackagingproducts#coldchainpackagingsolutions#coldchainpackagingcompany#coldchainpackagingtransportation#coldchainpackagingforpharmaceuticletransportation#coldchainpackagingforfoodtransportation#coldchainpackagingshipments#temperaturecontrolledtransportation#supplychainmanagement#temperaturecontrolledpackaging

0 notes

Photo

EarthWise Qualified Control Room Temperature Packaging

EarthWise pre-qualified control-room temperature packaging solutions are designed to support sustainable packaging initiatives by providing a complete solution that is biodegradable and/or recyclable.

Visit Website: https://www.tempaid.net/qualified-packaging/earthwise-qualified-control-room-temperature-packaging/

#biodegradablepackagingsolutions#sustainablepackaging#controlroomtemperaturepackagingsolutions#controlroomtemperaturepackaging#coldchainshipping#temperaturecontrolledpackagingsystem#coldchainpackaging#coldchainpackagingproducts#coldchainpackagingsolutions#coldchainpackagingcompany#coldchainpackagingtransportation#coldchainpackagingforpharmaceuticletransportation#coldchainpackagingforfoodtransportation#coldchainpackagingshipments#temperaturecontrolledtransportation#supplychainmanagement#temperaturecontrolledpackaging

0 notes

Photo

Qualified Control Room Temperature Packaging

Maintain control room temperatures for up to 48 hours and priced for either single or multi-use applications. The qualified single-use packaging system balances cost with reliability to provide the best temperature-controlled packaging system on the market today

Visit Website: https://www.tempaid.net/qualified-packaging/qualified-control-room-temperature-packaging/

#controlroomtemperaturepackaging#coldchainshipping#temperaturecontrolledpackagingsystem#coldchainpackaging#coldchainpackagingproducts#coldchainpackagingsolutions#coldchainpackagingcompany#coldchainpackagingtransportation#coldchainpackagingforpharmaceuticletransportation#coldchainpackagingforfoodtransportation#coldchainpackagingshipments#temperaturecontrolledtransportation#supplychainmanagement#temperaturecontrolledpackaging

0 notes

Photo

PCM-based Qualified Cold Chain Packaging For Refrigerated Shipments

Our PCM-based qualified refrigerated packaging solutions are designed to maintain refrigerated temperatures up to 72 hours. Balances cost & reliability providing the best temperature-controlled packaging system on the market.

Visit Website: https://www.tempaid.net/qualified-packaging/pcm-based-qualified-refrigerated-packaging-solutions/

#refrigeratedpackagingsolutions#pcmbasedqualifiedcoldchainpackaging#refrigeratedshipments#coldchainshipping#temperaturecontrolledpackagingsystem#coldchainpackaging#coldchainpackagingproducts#coldchainpackagingsolutions#coldchainpackagingcompany#coldchainpackagingtransportation#coldchainpackagingforpharmaceuticletransportation#coldchainpackagingforfoodtransportation#coldchainpackagingshipments#temperaturecontrolledtransportation#supplychainmanagement#temperaturecontrolledpackaging

0 notes

Photo

ISTA Certified Thermal Testing Laboratory Services From TempAid

Ensure your product meets regulatory standards and reaches its destination safety with - ISTA Certified Thermal Testing Laboratory Services from TempAid

Visit Website: https://www.tempaid.net/solutions/packaging-services/ista-certified-thermal-testing-laboratory-services/

#istacertificate#thermaltestinglaboratory#laboratoryservices#coldchainshipping#temperaturecontrolledpackagingsystem#coldchainpackaging#coldchainpackagingproducts#coldchainpackagingsolutions#coldchainpackagingcompany#coldchainpackagingtransportation#coldchainpackagingforpharmaceuticletransportation#coldchainpackagingforfoodtransportation#coldchainpackagingshipments#temperaturecontrolledtransportation#supplychainmanagement#temperaturecontrolledpackaging

0 notes

Photo

Durable EPS Coolers | Durable Insulated Shipping Coolers With ARCEL

Our durable EPS coolers are infused with lightweight, rugged and cost-effective solutions for reusable, temperature-controlled packaging. 25 sizes available.

Visit Website: https://www.tempaid.net/packaging-components/durable-eps-coolers/

#durableepscoolers#durableinsulatedshippingcoolers#coldchainshipping#temperaturecontrolledpackagingsystem#coldchainpackaging#coldchainpackagingproducts#coldchainpackagingsolutions#coldchainpackagingcompany#coldchainpackagingtransportation#coldchainpackagingforpharmaceuticletransportation#coldchainpackagingforfoodtransportation#coldchainpackagingshipments#temperaturecontrolledtransportation#supplychainmanagement#temperaturecontrolledpackaging

0 notes

Photo

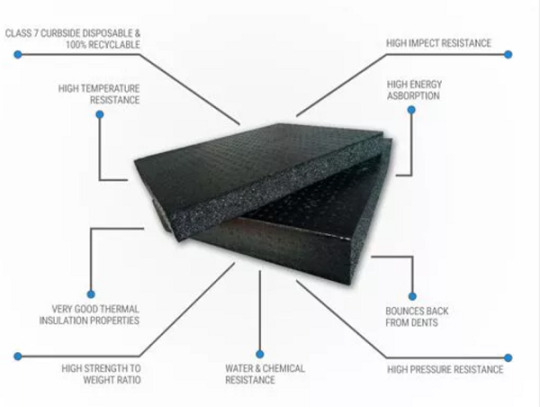

Insulated Rugged EPP Coolers | Insulated EPP Shipping Coolers

TempAid rugged EPP coolers are made from a rigid foam making them lightweight and ideal for temperature-controlled packaging where return & reuse is needed.

Visit Website: https://www.tempaid.net/packaging-components/rugged-epp-coolers/

#ruggedeppcoolers#insulatedeppshippingcoolers#coldchainshipping#temperaturecontrolledpackagingsystem#coldchainpackaging#coldchainpackagingproducts#coldchainpackagingsolutions#coldchainpackagingcompany#coldchainpackagingtransportation#coldchainpackagingforpharmaceuticletransportation#coldchainpackagingforfoodtransportation#coldchainpackagingshipments#temperaturecontrolledtransportation#supplychainmanagement#temperaturecontrolledpackaging

0 notes