#ContinuousImprovement

Explore tagged Tumblr posts

Text

ICYMI: Operational Leadership Models: Strategies, Frameworks, and Trends for Success https://kamyarshah.com/operational-leadership-models-strategies-frameworks-and-trends-for-success/

14 notes

·

View notes

Text

Experience is a hard teacher because she gives the test first, the lesson afterward. ―Vernon Sanders Law

3 notes

·

View notes

Text

#️⃣Team Coaching Strategies for Leadership Development: Elevate Performance and Achieve Coaching Success.

In the ever-changing landscape of modern organizations, leaders face the constant challenge of maximizing their team’s potential while maintaining motivation and collaboration. This article explores innovative team coaching strategies that foster leadership development, elevate performance, and ensure coaching success. By integrating practical tools and proven case studies, leaders can learn how…

View On WordPress

#success#Coffee#ContinuousImprovement#inspired#MindsetMatters#Motivational#MotivationalJourney#PersonalGrowth#SalesLeadership#SelfImprovement

2 notes

·

View notes

Text

Kanban in action! Visualize your workflow, identify bottlenecks, and improve continuously. 🔍💡

Visit http://vabro.com and try for free!!!!

#Vabro#Agile#Kanban#Lean#ProjectManagement#Kaizen#LeanManufacturing#ContinuousImprovement#TaiichiOhno#ProcessImprovement#QualityControl

2 notes

·

View notes

Text

Strategic Coaching for Professional Excellence - Being In Action

The goal of Being In Action is to help professionals to realize their full potential. This program offers practical strategies and one-on-one coaching to improve abilities, increase self-assurance, and promote professional development. Participants will receive helpful feedback, performance analysis, and goal-setting techniques to help them reach their professional goals and flourish in their current positions. Come along with us to realize your full potential, embrace lifelong learning, and take decisive action in the direction of professional success.

#ProfessionalExcellence#StrategicCoaching#CareerGrowth#UnlockYourPotential#ActionableStrategies#PersonalDevelopment#CareerSuccess#SkillEnhancement#ContinuousImprovement#LeadershipDevelopment

2 notes

·

View notes

Text

What fo you think about success

2 notes

·

View notes

Text

Five Essential Things HOA Leadership Should Know for a Successful Community: How "Mastering the Art of Management" Can Assist You in This Endeavor

Introduction

As an HOA leader, you strive to create a successful and harmonious community. To achieve this, it's crucial to possess effective management skills that can guide you through the challenges of community leadership. In this post, we will explore five essential things HOA leadership should know for a successful community, and how my book, "Mastering the Art of Management: A Step-by-Step Guide to Building Leadership Skills and Achieving Success as a Manager," can assist you in this endeavor.

Effective Communication

Clear and efficient communication is vital in community leadership. "Mastering the Art of Management" provides valuable insights on various communication strategies and techniques that can help you foster open dialogue with residents, board members, and other stakeholders. You'll learn how to convey information effectively, address conflicts, and build consensus, creating a strong foundation for transparent and productive communication within your HOA.

Strategic Decision Making

Successful HOA leadership requires making informed and strategic decisions. Through my book, you'll gain a deeper understanding of decision-making frameworks and tools that can assist you in evaluating options, considering long-term consequences, and selecting the best course of action for your community. The book offers practical advice on prioritizing community needs, handling complex situations, and aligning decisions with the overall vision of your HOA.

Building and Leading Teams

A cohesive and motivated team can make a significant difference in the success of an HOA. "Mastering the Art of Management" provides valuable guidance on team building, including recruitment, training, and fostering a positive work environment. You'll discover effective leadership techniques to inspire and empower team members, delegate responsibilities, and promote collaboration, ultimately creating a strong and committed team within your HOA.

Conflict Resolution

HOA leadership often involves navigating conflicts and managing challenging situations. My book equips you with conflict resolution strategies and techniques that can help you handle disputes with professionalism and fairness. You'll learn how to approach conflicts with empathy, mediate disagreements, and find win-win solutions that preserve community harmony. By mastering these skills, you'll be able to address conflicts promptly and maintain a positive atmosphere within your community.

Continuous Improvement and Growth

Leadership is a journey of continuous learning and growth. "Mastering the Art of Management" emphasizes the importance of personal and professional development as an HOA leader. The book offers guidance on setting goals, self-reflection, and seeking feedback to continually improve your leadership skills. By adopting a growth mindset and implementing the strategies outlined in the book, you'll become a more effective and influential HOA leader, contributing to the long-term success of your community.

Conclusion

As an HOA leader, your goal is to create a successful community that residents are proud to call home. By mastering the essential skills outlined in "Mastering the Art of Management: A Step-by-Step Guide to Building Leadership Skills and Achieving Success as a Manager," you'll be equipped with the tools and knowledge needed to navigate the challenges of community leadership. From effective communication to strategic decision-making, team building, conflict resolution, and continuous improvement, this book will serve as your comprehensive guide to HOA leadership success. Embrace the knowledge within its pages, and watch as your community thrives under your capable leadership.

#leadershipskills#HOALeadership#CommunitySuccess#ManagementSkills#EffectiveCommunication#BuildingTeams#StrategicDecisionMaking#ConflictResolution#CommunityHarmony#ContinuousImprovement#LeadershipGuide#HOABestPractices#CommunityEngagement#TransparentLeadership#TeamworkMatters#EmpoweringLeaders#ResponsibleFinancialManagement#StrongCommunity#HOAManagement#InclusiveLeadership#CommunityBuilding#HOAEvents#SuccessfulNeighborhoods#PositiveCommunityCulture#HOASuccess#HOALife#GrowthMindset#LeadershipDevelopment#HOABoard#EffectiveHOA

2 notes

·

View notes

Text

Are you ready to create a winning product development plan?

Don't overlook the crucial steps to success! Engage stakeholders, understand market needs, and develop a roadmap. With a Minimum Viable Product (MVP), gain valuable user feedback for continuous improvement. Let us guide you on the path to product excellence!

Visit our website : https://www.createproto.com/engineering/product-development/

#productdevelopment#innovationjourney#engineeringexcellence#marketneeds#stakeholderengagement#MVPdevelopment#continuousimprovement#createproto

2 notes

·

View notes

Text

The Real Journey of Coach Education: Growth Beyond the System

For years, I chased CPD points like they were the only measure of my growth as a coach. I attended workshops, logged hours, and ticked boxes, all to meet the requirements (correctly) set by our National Governing Body. And while maintaining our licensing is necessary, I slowly realized something deeper: true development isn’t just about collecting points; it’s about pursuing knowledge that fuels…

#BeyondTheChecklist#BreakingBarriers#ChampionMindset#CoachDevelopment#CoachEducation#CoachingJourney#CoachLife#CoachMindset#ContinuousImprovement#CPDforCoaches#OwnYourGrowth#PathToMastery#SportsCoaching#SuccessInSports#UnconventionalLearning

0 notes

Text

Monday Motivation: Embrace the Kaizen Mindset! 🔥🚀

Mondays aren't just the start of the week—they're the perfect chance to level up! The Kaizen methodology is all about making small, continuous improvements that lead to BIG results.

💡 Tweak your workflow. 💡 Optimize your habits. 💡 Push for growth—bit by bit, day by day.

Success isn’t about perfection; it’s about progress. What’s one small change you’re making today to build a better tomorrow?

0 notes

Text

Top 10 Benefits of Implementing an ISO 9001 Quality Management System

In today’s competitive world, businesses need a reliable way to guarantee quality, satisfy customers, and improve processes. That’s where the ISO 9001 quality management system comes into play. Recognized globally, this standard helps businesses of all sizes set up an effective system that focuses on consistent improvement and customer satisfaction.

Let’s dive into the top 10 benefits of implementing an ISO 9001 quality management system and why it’s a smart move for your organization.

1. Improved Product and Service Quality

One of the most significant benefits of an ISO 9001 quality management system is the enhancement of your products and services. Following ISO standards ensures that what you deliver consistently meets customer expectations. Better quality not only leads to satisfied customers but also builds long-term brand loyalty.

2. Boosted Customer Satisfaction

At its core, the ISO 9001 framework focuses heavily on customer needs. By aligning your processes with customer expectations, you naturally boost customer satisfaction. Happy customers are more likely to recommend your business and become repeat buyers — a crucial advantage in any market.

3. Enhanced Process Efficiency

An ISO 9001 quality management system helps organizations map out their processes, define responsibilities, and eliminate inefficiencies. This structured approach reduces waste, improves productivity, and saves money — allowing businesses to do more with fewer resources.

4. Stronger Marketability

Having ISO 9001 certification shows potential clients and partners that your business is committed to quality. In many industries, it’s a deciding factor for winning contracts, especially with larger corporations or government agencies. Certification makes your company more marketable and competitive.

5. Increased Employee Engagement

Implementing an ISO 9001 quality management system encourages employee involvement at all levels. When workers understand their roles clearly and see how they contribute to company goals, morale improves. Engaged employees are more motivated, productive, and loyal to the company.

6. Better Decision-Making

ISO 9001 promotes evidence-based decision-making. Rather than relying on guesswork, businesses use accurate data to improve processes and solve problems. This logical approach leads to better strategies, fewer mistakes, and smarter investments of time and money.

7. Improved Risk Management

Every business faces risks, but an ISO 9001 quality management system helps identify potential problems early. It emphasizes a risk-based approach, encouraging companies to plan for challenges instead of just reacting to them. This proactive mindset can save businesses from costly failures.

8. Greater International Recognition

Since ISO 9001 is an internationally recognized standard, businesses that achieve ISO 9001 certification often find it easier to enter global markets. Whether you’re exporting products or collaborating with international partners, certification gives your business a trusted reputation worldwide.

9. Continuous Improvement Culture

One of the best aspects of an ISO 9001 quality management system is its focus on continuous improvement. Businesses are encouraged to regularly assess their performance, set new goals, and strive for better results. This mindset leads to innovation and long-term success.

10. Cost Savings Over Time

Although there is an upfront investment involved in implementing ISO standards, the long-term savings are undeniable. Improved efficiency, fewer errors, less rework, and better resource management all contribute to significant cost reductions. Over time, businesses that invest in an ISO 9001 quality management system see impressive returns.

Final Thoughts

Implementing an ISO 9001 quality management system is more than just getting a certificate — it’s about building a strong foundation for quality, growth, and customer trust. From better decision-making to global recognition, the benefits are far-reaching.

If you’re serious about taking your business to the next level, working toward ISO 9001 certification is one of the smartest investments you can make. It’s not just about checking a box; it’s about creating a culture where quality and continuous improvement are part of your everyday operations.

#qualitymanagement#processimprovement#businessgrowth#iso9001#continuousimprovement#businessexcellence#isostandards#getcertified

0 notes

Text

Project management combines organizational skills, leadership, and a deep understanding of processes to achieve desired outcomes. Whether you’re managing small internal projects or overseeing large-scale collaborations with third-party developers, effective project management is vital to ensuring that projects are completed on time, within budget, and to the satisfaction of all stakeholders.

As the project management industry continues to evolve, new strategies, tools, and methodologies emerge to improve efficiency, reduce risks, and enhance outcomes. In this blog, we’ll explore the best practices for project management, including how to manage third-party developers, optimize project performance, and leverage the tools and techniques that drive success.

#ProjectManagement#BestPractices#ProjectManagementOffice#ProjectManager#RiskManagement#StakeholderEngagement#AgileMethodology#QualityAssurance#ProjectPlanning#ProjectSuccess#ITProjectManagement#ThirdPartyDevelopers#CollaborationTools#ContinuousImprovement#ProjectLeadership

0 notes

Text

How can value stream mapping help in identifying waste and how TCard helps

Learn how Value Stream Mapping identifies waste and how TCards streamline workflows. Discover real-time monitoring, task tracking, and customised solutions to optimise processes and eliminate bottlenecks efficiently.

For more details read our blog :

#ValueStreamMapping#TCards#IdentifyWaste#WasteElimination#WorkflowManagement#TaskTracking#ProcessEfficiency#BottleneckAnalysis#ContinuousImprovement#LeanManagement

0 notes

Text

Mastering Efficiency: A Deep Dive into the Lean Production 5S System

Source: operations1.com

Share Post:

LinkedIn

Twitter

Facebook

Reddit

Pinterest

In the industrial world, operational efficiency is the main factor in work completion and success achievement. Companies look for constant source that enhances workplace productivity, smooth methods, and eliminate waste. For such improvements, a systematic approach is introduced, named as the lean production 5S system. Being a Japanese manufacturing practice term, this system has become a crucial part of lean methodology, helping businesses in effectively organizing and managing their workplace. In this article, the lean production 5S system is explained in detail, including its meaning, origin, benefits, and implementation.

Understanding the Lean Production 5S System

The lean production 5S system is a systematic approach to workplace organization and standardization. The name “5S” refers to five Japanese words that begin with the letter ‘S’: Seiri, Seiton, Seiso, Seiketsu, and Shitsuke. Each element plays a crucial role in creating an efficient, safe, and organized work environment.

Here’s a breakdown of the 5S components:

Source – en.wikipedia.org

1. Seiri (Sort)

This step involves removing unnecessary items from the workspace. Only tools and materials that are essential to daily tasks should remain. Sorting helps reduce clutter, making it easier to find what is needed quickly.

2. Seiton (Set in Order)

Once the clutter is eliminated, the remaining tools and materials must be organized in a way that promotes efficiency. Every item should have a designated place, and its location should make sense for the workflow.

3. Seiso (Shine)

Cleaning the workspace regularly is vital. A clean environment not only promotes safety but also allows for better maintenance of equipment and a more pleasant workplace.

4. Seiketsu (Standardize)

This step focuses on creating standards for organizing and cleaning. Procedures should be documented and followed consistently. Visual aids such as charts, labels, and schedules can help maintain the standard.

5. Shitsuke (Sustain)

The final step is about discipline and habit. Employees should be trained and motivated to maintain the established procedures. Regular audits and reviews can help ensure that the 5S principles are being followed.

The Origin and Evolution of 5S

The lean production 5S system originated in Japan as part of the Toyota Production System (TPS). Toyota implemented this method to improve efficiency and quality in its manufacturing processes. Over time, 5S evolved and was adopted globally across various industries beyond manufacturing, including healthcare, education, logistics, and office environments.

Today, it is recognized as a foundational element of lean production practices and continuous improvement methodologies like Kaizen and Six Sigma.

Also Read: Lean Management Principles: Enhancing Efficiency and Reducing Waste

Why the Lean Production 5S System Matters?

Source – 5snews.com

Implementing the lean production 5S system can bring significant advantages to an organization, including:

1. Increased Productivity

By organizing the workspace and eliminating unnecessary items, employees spend less time searching for tools and materials, allowing them to focus more on value-added activities.

2. Improved Safety

A clean and orderly workplace reduces the risk of accidents and injuries. Clear labeling, proper storage, and regular cleaning all contribute to a safer environment.

3. Enhanced Quality

With standardized processes and a tidy workspace, the chances of errors and defects decrease. Employees can spot issues more easily, leading to faster problem-solving.

4. Greater Employee Satisfaction

An organized and efficient workspace fosters a positive work culture. Employees feel more in control of their environment, which can boost morale and job satisfaction.

5. Better Utilization of Space

By removing clutter and arranging tools effectively, organizations can optimize space usage, potentially reducing the need for larger facilities or additional storage.

Implementing the Lean Production 5S System

Rolling out the 5S system involves more than just cleaning and organizing—it requires a cultural shift and commitment from all levels of the organization.

Step 1: Training and Awareness

Educate your team about the purpose and benefits of 5S. Use workshops, presentations, and hands-on training sessions to explain each of the five steps.

Step 2: Initial 5S Event (Kaizen Blitz)

Organize a company-wide or departmental 5S event where employees sort, set in order, and shine their work areas. This creates momentum and demonstrates leadership commitment.

Step 3: Create Visual Management Tools

Develop checklists, floor markings, and signage to help standardize the process. Visual cues reinforce discipline and make the workspace self-explanatory.

Step 4: Assign Responsibilities

Clearly define roles and responsibilities for maintaining 5S. Designate team leaders and schedule regular audits to track progress.

Step 5: Sustain with Audits and Recognition

Regularly review and evaluate each area to ensure compliance. Recognize teams that consistently follow 5S practices to encourage ongoing participation.

Common Challenges and How to Overcome Them?

Source – fatfinger.io

1. Resistance to Change

Employees may be skeptical of new systems. Overcome this by involving them in planning and showing them how 5S will make their work easier.

2. Lack of Follow-Through

Without ongoing support, 5S efforts can fade. Assign ownership, conduct regular reviews, and celebrate successes to sustain the initiative.

3. Insufficient Training

Invest in thorough training to ensure everyone understands the system and their role within it. Use real-life examples to illustrate the benefits.

Also Read: Maximizing Efficiency: The Benefits of Production Scheduling Software

Industries Benefiting from the Lean Production 5S System

The lean production 5S system has proven effective in various sectors, including:

Manufacturing – Streamlining assembly lines and improving product quality.

Healthcare – Organizing surgical tools and reducing medical errors.

Warehousing – Enhancing inventory management and order fulfillment.

Education – Creating clutter-free classrooms and administrative offices.

Hospitality – Maintaining cleanliness and efficiency in kitchens and guest areas.

Case Study: 5S in Action

Company: XYZ Automotive

XYZ Automotive, a mid-sized car parts manufacturer, implemented the lean production 5S system across its production floor. Initially faced with inefficiencies and high defect rates, the company conducted a 5S audit and launched a training campaign.

Results After 6 Months:

30% increase in productivity

25% reduction in workplace accidents

40% improvement in product quality

The transformation not only improved operations but also boosted employee morale and customer satisfaction.

Tips for Sustaining 5S Long-Term

Engage Leadership – Leaders should model the behavior they want to see.

Incorporate 5S into Daily Routines – Make it part of standard operating procedures.

Celebrate Milestones – Recognize achievements to keep teams motivated.

Continuous Improvement – Use feedback to refine and improve the system.

Document Everything – Create manuals, videos, and checklists for easy reference.

Conclusion

The lean production 5S system is a structured initiative to improve the workplace environment. By implementing its principles, organizations manage to recognize their potential, achieve continuous improvement, and reduce waste. It can be applied in every industry, whether it’s manufacturing, healthcare, or service industries. The 5S system is a practical approach to making the workplace better.

The lean production 5S system needs continuous implementation to excel in operational efficiency. Disciplined and focused efforts on continuous improvements can contribute to a successful business.

0 notes

Text

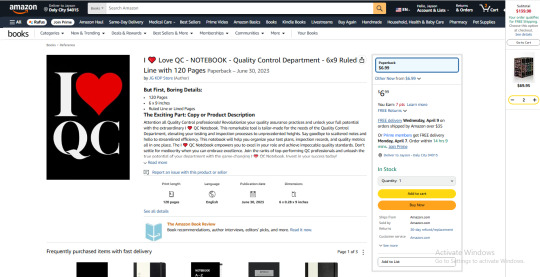

Quality Control Professionals! This is the perfect Notebook for YOU.

I ❤️ Love QC Quality Control NOTEBOOK on Amazon!

#QualityControl#QC#QualityAssurance#QAQC#QualityManagement#QMS#Inspection#Compliance#StandardOperatingProcedures#ContinuousImprovement

0 notes