#Corrosionresistance

Text

How to solve air conditioner power problems in heavy vehicles during long distance driving?🚛

Leoch AGM parking air-conditioner batteries help you to relieve your worries! 💡

✅Designed for truck AC application with superior deep cycle performance.

✅Superior cranking performance under severe cold conditions

✅4x higher cycle life than flooded batteries

✅Superior vibration and corrosion resistance

#HeavyVehicles#Truck#AGMBattery#Air-conditioner#CarBatteries#TruckACPowerProblems#LongDistanceDriving#AirConditionerBattery#LeochAGMBattery#DeepCyclePerformance#CrankingPerformance#CycleLife#VibrationResistance#CorrosionResistance#HeavyVehicleAC

3 notes

·

View notes

Text

Lega di acciaio senza ruggine e autorigenerante

Perché l’acciaio Corten sembra arrugginito? Cos’è, caratteristiche e vantaggi della lega. L'acciaio Cor-Ten è un particolare tipo di lega sempre più apprezzatto nel settore edile per la sua capacità di autorigenerarsi e autoproteggersi. Come funziona?

Nel mondo delle costruzioni, l'acciaio rappresenta uno dei materiali più versatili, grazie alla sua resistenza, duttilità e capacità di adattamento alle architetture richieste in fase di progettazione. Tuttavia, l'esposizione all'ambiente esterno lo rende suscettibile alla corrosione e, senza una adeguata protezione e manutenzione nel tempo, il prodotto si indebolisce progressivamente fino a perdere la resistenza di cui necessita per assolvere al suo compito. Il Corten (o Cor-Ten) permette di eliminare questi problemi.

Dove sta la particolarità? Questa lega presenta un colore e una consistenza similare alla ruggine, cioè proprio il prodotto di scarto formato dalle reazioni di corrosione. Sembrerebbe quindi di avere a che fare con un materiale arrugginito, ma stranamente funzionale, che merita un approfondimento teorico e una descrizione delle possibili applicazioni pratiche.

Le caratteristiche dell'acciaio Corten

Brevettato negli anni '30, il Corten non è altro che una lega dell'acciaio il cui nome deriva dalle due caratteristiche principali della lega:

COR sta per corrosion resistance ed indica la capacità di questa lega di avere elevata resistenza alla corrosione propria, ovvero senza la necessità di rivestimenti aggiuntivi;

TEN sta per tensile strength ed indica le elevate resistenze meccaniche della lega, il che rendono il prodotto utile per applicazioni strutturali.

Come cambia quindi la ricetta della lega di questo particolare acciaio? Oltre al ferro e al carbonio, la lega si compone di rame, cromo e fosforo. Questi componenti, a contatto con l'atmosfera, reagiscono e formano degli ossidi che, spontaneamente, creano una patina superficiale all'elemento che protegge dalla corrosione. Il processo è spontaneo, ma ha bisogno di tempo per verificarsi (circa 6 mesi).

Per questa ragione, solitamente si accelera con apposite sostanze chimiche che riducono il tempo di ossidazione fino anche a 2 ore. Il colore della patina quindi cambia nel tempo perché è strettamente legata al tempo di esposizione all'atmosfera e agli agenti atmosferici, come la pioggia. Inoltre, essendo la patina esterna legata alla presenza degli elementi della lega, può autorigenerarsi se nel tempo dovesse essere rimossa per qualche motivo.

Quindi, sebbene dello stesso colore, il rivestimento spontaneo che si forma attorno all'elemento in Corten non è identificabile come ruggine nel senso chimico del termine, nonostante continui ad essere comunque un ossido. Quest'ultima, infatti, dovrebbe formarsi utilizzando il Ferro e non questi elementi aggiuntivi presenti nella lega.

Le principali tipologie di leghe Corten

Non esiste un'unica tipologia di lega Corten. I prodotti siderurgici si distinguono in tre tipi:

CORTEN-A: è quello che maggiormente protegge dalla corrosione ed è la lega che risulta meno resistente tra tutte le altre. Per tale ragione, viene solitamente utilizzata per applicazioni di tipo architettoniche;

CORTEN-B: ha un grado di protezione dalla corrosione leggermente inferiore rispetto al tipo A. Permette di mantenere elevate caratteristiche meccaniche anche con elevati spessori e viene quindi usato principalmente in applicazioni strutturali.

CORTEN-C: di più recente produzione rispetto agli altri due, presenta resistenza meccanica notevolmente superiore ma meno protezione dalla corrosione. Viene quindi usato in condizioni in cui le necessità di resistenza diventano vincolanti.

I vantaggi dell'acciaio Corten

Quali sono i vantaggi nell'utilizzare una lega Corten rispetto ad una classica lega di acciaio? La capacità del materiale di auto-proteggersi dai fenomeni di corrosione comporta grandi benefici di lungo termine, soprattutto di tipo economico. Infatti, gli elementi realizzati in Corten non avranno bisogno di una protezione nei confronti della corrosione (normalmente, gli elementi di acciaio sono zincati o cromati).

In aggiunta, questa patina – autorigenerandosi – garantisce da sola quel minimo di manutenzione ordinaria, necessaria invece in strutture formate da ordinarie leghe di acciaio. Nei casi canonici, infatti, si potrebbe assistere al degrado dello stesso rivestimento di protezione o, in altri casi, ad una sua rimozione indotta da cause esterne di varia natura. Necessita quindi di un operaio che, all'occorrenza, vada a ripristinare quanto rimosso o degradato.

In molti casi, addirittura, l'utilizzo del Corten può comportare una riduzione del materiale necessario per la realizzazione dell'opera. Infatti, per sopperire alle riduzioni di spessore che nel tempo si avranno negli elementi per via della formazione di ruggine, i progettisti considerando spessori maggiorati, già consapevoli del fatto che una parte di materiale andrà sacrificata nel tempo.

Riferimenti: Arcelor Mittal - Indaten - COR-TEN Datasheet Arcelor Mittal - AISC - Weathering steel in architectural applications

Read the full article

0 notes

Text

Marine Oil - High-Performance Lubrication for Marine Engines

Discover premium Marine Oil designed for optimal performance and protection of marine engines. Our high-quality oil ensures smooth operation, reduces wear, and extends engine life even in harsh marine environments. Ideal for boats and ships, our Marine Oil offers superior lubrication, corrosion resistance, and reliability. Enhance your marine engine's performance with our trusted solutions today! Call us at: +65 9838 5264

#MarineOil#MarineEngines#EngineLubrication#BoatMaintenance#ShipMaintenance#HighPerformanceOil#CorrosionResistance#SmoothOperation#EngineProtection#MarineFuel

0 notes

Text

Stainless Steel 316L Coils Manufacturers In India

0 notes

Text

Discover the power and efficiency of Potassium Hydroxide Pumps, engineered to handle the most demanding chemical processes. Our pumps offer reliable performance, corrosion resistance, and precise control for your industrial applications.

0 notes

Text

Discover the power of titanium pipes: lightweight, strong, and built to last in the toughest conditions.

For more information Visit: www.platinexpiping.com

#TitaniumPipes#EngineeringExcellence#AerospaceMaterials#MedicalInnovation#ChemicalProcessing#MarineEngineering#IndustrialStrength#LightweightMaterials#CorrosionResistance#AdvancedManufacturing#HighPerformanceMaterials

#TitaniumPipes#EngineeringExcellence#AerospaceMaterials#MedicalInnovation#ChemicalProcessing#MarineEngineering#IndustrialStrength#LightweightMaterials#CorrosionResistance#AdvancedManufacturing#HighPerformanceMaterials

0 notes

Text

All Grades of Stainless Steel- In India

Ganpati Industries offers a wide range of steel sheets and coils, including 304, 316, 430, 201, and 410 grades. Known for their excellent corrosion resistance, durability, and cost-effectiveness, these products cater to automotive, kitchenware, and construction industries, ensuring top-quality and reliable service.

Visit- https://ganpatiindustries.in/shop/

#steel sheet#stainless steel#steel industry#steelsupplier#steel coil#qualitysteel#corrosionresistance

0 notes

Text

Common Applications of Bimetallic Washers

The article provides a comprehensive overview of bimetallic washers. It starts by defining what a bimetallic washer is and how it's manufactured.

A bimetallic washer is a type of washer that is made from two different metals bonded together. The most common type of bimetallic washer is made from a layer of stainless steel bonded to a layer of brass. Bimetallic washers are made using a process called cladding. Cladding is a process where two different metals are bonded together using heat and pressure. The two metals are melted together and then cooled to form a single piece of metal.

Bimetallic washers are often used in applications where both strength and corrosion resistance are required. The stainless steel layer provides strength and durability, while the brass layer provides corrosion resistance.

The key benefits of using bimetallic washers, such as increased strength, corrosion resistance, and reduced weight, are highlighted.

The core of the article focuses on the various applications of bimetallic washers across different industries, including automotive, aerospace, construction, marine, and industrial machinery. It also offers guidance on selecting the right bimetallic washer for specific needs and provides tips on their proper use.

The article also provides tips of using bimetallic washers

When using bimetallic washers, there are a few tips that you should follow:

Make sure that the washer is the correct size for the bolt or screw that you are using.

Make sure that the washer is installed correctly.

Make sure that the washer is tightened properly.

Essentially, the article aims to inform readers about the advantages and uses of bimetallic washers, making it a valuable resource for those seeking knowledge about these components.

0 notes

Text

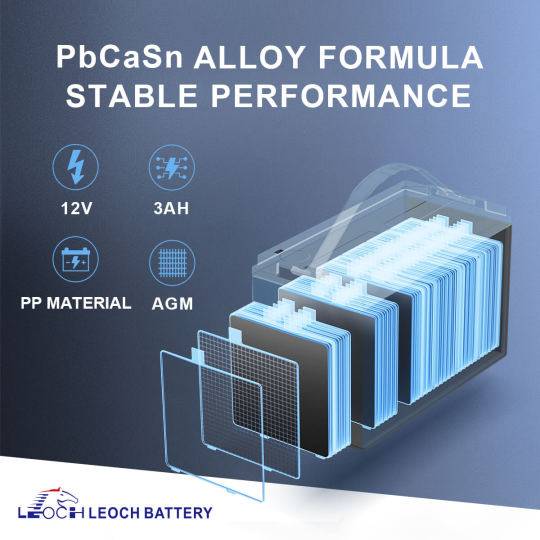

LP Series batteries adapted PbCaSn alloy plate grids,

which are less gassing and less self-discharging. 🧪

After using this formula, the battery performance is greatly improved and the corrosion resistance becomes better.

For the user, it reduces the risk of premature battery failure.

LP Series batteries adapted PbCaSn alloy plate grids

#BatteryPerformance#ImprovedBattery#BatteryTechnology#EnergyStorage#BatteryExpert#BatteryInnovation#SustainableEnergy#RenewablePower#CleanEnergy#GreenTechnology#EnergyEfficiency#PowerStorage#BatterySolutions#BatteryIndustry#BatteryLife#BatteryPower#PbCaSn#LeadAcidBattery#CorrosionResistance#PlateGrids

2 notes

·

View notes

Text

Why Choose FRP Over Traditional Materials for Industrial Storage Solutions?

Discover why industries are choosing FRP over traditional materials for storage tanks—corrosion resistance, durability, low maintenance, and cost-efficiency. Learn more with ASK Enterprises.

Contact us for best quotation on M: +91 9106892627

for more info visit: https://bit.ly/3Wa4OVz

#FRP#IndustrialStorage#CorrosionResistance#Durable#CostEffective#ChemicalResistance#Sustainable#ASKEnterprises

0 notes

Text

Hastelloy Wire Mesh

Introduction:

In the chemical industry, the choice of materials is crucial to ensure safety, efficiency, and longevity. Hastelloy wire mesh has emerged as a superior material, offering remarkable benefits in terms of corrosion resistance and durability. Let’s explore how Hastelloy wire mesh is enhancing chemical processes.

Understanding Hastelloy Wire Mesh: Hastelloy wire mesh is crafted from nickel-based alloys designed to withstand the harshest chemical environments. These alloys are known for their exceptional resistance to corrosion, making them ideal for use in chemical processing.

Why Hastelloy Wire Mesh is Ideal for Chemical Processes:

Superior Corrosion Resistance: Hastelloy wire mesh can resist the corrosive effects of acids, alkalis, and other aggressive chemicals, ensuring long-lasting performance.

Thermal Stability: Capable of maintaining its properties at high temperatures, Hastelloy wire mesh is suitable for processes involving extreme heat.

Mechanical Strength: Despite its fine mesh structure, Hastelloy wire mesh offers high mechanical strength and durability.

Applications in the Chemical Industry:

Filtration Systems: Hastelloy wire mesh is used in filtration systems to separate and filter out impurities in chemical processes.

Reactor Components: Its resistance to corrosion makes Hastelloy wire mesh ideal for use in reactors and other critical components.

Heat Exchangers: The thermal stability of Hastelloy wire mesh enhances the efficiency of heat exchangers in chemical plants.

Conclusion: For the chemical industry, Hastelloy wire mesh provides unmatched benefits, ensuring the safety and efficiency of chemical processes. Its superior properties make it a preferred choice for various applications, delivering reliable performance even in the most challenging environments.

0 notes

Text

Advantages and Versatility of Stainless Steel Fabrication in Abu Dhabi

Discover the unmatched benefits and diverse applications of stainless steel fabrication services in Abu Dhabi with Sea Global UAE. From architectural marvels to industrial infrastructure, our precision engineering ensures durability, corrosion resistance, and aesthetic appeal. Elevate your projects with our expertise, setting new standards in quality and reliability. Contact us (+971 563745538) today for inquiries and assistance. Book now.

#SeaGlobalUAE#StainlessSteel#FabricationServices#AbuDhabi#PrecisionEngineering#Durability#CorrosionResistance#ArchitecturalDesign#IndustrialInfrastructure#QualityAssurance

0 notes

Text

Inconel RA330 Sheets & Plates Manufacturers In India

Incoloy 330 Sheets offer amazing security from carburization and oxidation. Oxidation obstacle and Carburization to around 2100 Deg F are improved by the substance of silicon of these Incoloy 330 Plates.

0 notes

Text

AISI 316 hard coil is a high-performance stainless steel product known for its superior corrosion resistance, particularly against chlorides and other industrial solvents. This alloy contains molybdenum, enhancing its durability in harsh environments, making it ideal for marine, chemical, and pharmaceutical applications. Its excellent mechanical properties, including high tensile strength and hardness, ensure long-lasting performance in demanding conditions. The coil's versatility allows it to be easily formed and welded, catering to diverse manufacturing needs. Additionally, AISI 316 hard coil maintains its structural integrity at both high and low temperatures, offering reliable performance across various industries.

LEARN ABOUT MORE VISIT US SITE :

0 notes

Text

Safeguard your assets from rust and corrosion with Molygraph's Neverust 530, a robust solvent-based inhibitor. Its specialized formula creates a protective barrier that easily infiltrates grooves and notches, ensuring unparalleled defense against corrosion, especially in humid environments. Don't let corrosive elements compromise your equipment—choose Neverust 530 as your ultimate corrosion protector. Explore its advanced protection today!

1 note

·

View note

Text

Supplier of Stainless Steel Pipes and Tubes in Tamil Nadu

Meghmani Metal Industries is a Manufacturer and Supplier of Stainless Steel Pipes and Tubes in Tamil Nadu, India.

Established in 2011, Meghmani Metal Industries is dedicated to providing exceptional products to the metal industry.

We offer a wide array of stainless steel products, including plates, coils, bars, pipes, tubes, flanges, valves, fittings, fasteners, channels, and flats, meticulously catering to various industrial requirements.

Stainless Steel Pipes and Tubes refer to stainless steel pipes and tubes. Stainless steel is a type of steel alloy containing chromium, which provides excellent resistance to corrosion and oxidation, making it ideal for various industries.

Stainless steel pipes and tubes come in grades like 304 for general use, 316 for marine environments, and 321 for high temperatures.

Stainless steel pipes and tubes facilitate the seamless transfer of materials, enabling efficient production across diverse industries. Their smooth surfaces and uniform dimensions ensure minimal friction and consistent flow, optimizing productivity and reducing downtime.

Their sleek and modern appearance adds a touch of sophistication to architectural designs, interior decor, and industrial machinery, enhancing the visual appeal of any environment.

Stainless steel pipes and tubes find applications in construction, oil and gas, chemical, food and beverage, automotive, medical, water treatment, aerospace, heat exchangers, renewable energy, marine, pharmaceutical, and power industries.

Meghmani Metal Industries is a Manufacturer and Supplier of Stainless Steel Pipes and Tubes in Tamil Nadu and locations like Arcot, Chengalpattu, Chennai, Chidambaram, Coimbatore, Cuddalore, Dharmapuri, Dindigul, Erode, Kanchipuram, Kanniyakumari, Kodaikanal, Kumbakonam, Madurai, Mamallapuram, Nagappattinam, Nagercoil, Palayamkottai, Salem, Thanjavur, Tiruchchirappalli, Tirunelveli, Tiruppur, Thoothukudi, Udhagamandalam, Vellore.

If you have any questions or need further information, feel free to reach out to us.

Read the full article

#aerospace#architecturaldesigns#Arcot#Automotive#bars#channels#chemicalindustry#Chengalpattu#Chennai#Chidambaram#chromium#coils#Coimbatore#consistentflow#construction#Corrosionresistance#Cuddalore#Dharmapuri#Dindigul#efficientproduction#Erode#fasteners#fittings#Flanges#Flats#foodandbeverage#heatexchangers#hightemperatures#IndustrialApplications#Industrialmachinery

0 notes