#Flanges

Explore tagged Tumblr posts

Text

553 notes

·

View notes

Text

What do we do in April 2025?

My dear friend, Xinyue will attend 2025 OGU (Oil & Gas Uzbekistan) from 13th May to 15th May 2025! Location: Uzekspocentre Exhibition Centre (Tashkent, 700084107, Amir Temu street Uzbekistan) Come and join us this time! For all your oil and gas pipeline or seamless steel pipe request, feel free contact us at anytime; BR Josie

#Xinyue Steel#XinYue#Steel Pipe#Steel Project#Steel Construction#Global Steel Buyers#Metal Working#Manufacturing#Carbon Steel#Marine Steel#Steel Engineering#Steel Tube#Pipeline#Tubo de Acero#API 5L#tuberia#seamless steel pipe#seamless tube#Flanges#steel flanges

2 notes

·

View notes

Text

SMLS Stainless steel pipe From Xinyue Steel Deliver To North America Specification: ASTM A312-2 SUS304

Want to know more about SMLS Stainless steel pipe? Contact us now! WhatsApp: +8618974849825 [email protected] www.xysteelpipe.com

Xinyue's Vision: Build The World, Serve The Globe! Xinyue's Mission: To promote steel industry, to represent Made-in-China !

SteelSolutions #XinyueSteel #SteelIndustry #SteelPipe #SteelProject #GlobalSteelBuyers #MetalWorking #SteelConstruction #XinYue #Manufacturing #SMLSStainless #steelpipe #StainlessSteel #StainlessPipe #NorthAmerica #ASTMA312 #SUS304 #SMLSpipe

#Xinyue Steel#XinYue#Steel Pipe#Steel Project#Steel Construction#Global Steel Buyers#Metal Working#Manufacturing#Carbon Steel#Marine Steel#Steel Engineering#Steel Tube#Pipeline#Tubo de Acero#API 5L#tuberia#seamless steel pipe#seamless tube#Flanges#steel flanges#stainless steel#stainless pipe#stainless steel pipe#North America#ASTM A312#SUS 304#SMLS Stainless steel pipe

3 notes

·

View notes

Text

February 1949 cold weather railroading. Frozen flangeways: MILW boxcar being chopped out of ice by the unlucky Milwaukee Road crew in Coeur d'Alene, Idaho. So cold the nearby tug boats are completely locked in ice as well. Also in town the shortline Spokane International attempts snow removal with Jordan spreaders.

#frio#jordan spreader#snowplow#brr#railroading#flanges#ice#frozen solid#snow plowing#steam locomotive#coeur d'alene#idaho#winter#february#1949#milw#milwaukee road#❄️

3 notes

·

View notes

Text

Forged Stainless Steel 304 Flanges: Key Features and Applications

1. Material Composition:

Produced using forging processes from Stainless Steel 304.

Contains 18% chromium and 8% nickel.

2. Corrosion Resistance:

Superior corrosion resistance in both chemical and marine environments.

3. Temperature Resistance:

Exceptional performance under high temperatures and pressure conditions.

4. Types of Flanges Available:

Weld Neck Flanges

Slip-On Flanges

Blind Flanges

Socket Weld Flanges

Threaded Flanges

5. Applications:

Widely used in oil and gas, power plants, and food processing.

Ideal for piping connections where high strength and temperature tolerance are necessary.

6. Durability:

Forged flanges ensure long-lasting durability, high strength, and enhanced mechanical properties.

3 notes

·

View notes

Text

Buy MS Flange at Minimum Price

Introduction

Are you searching for high-quality MS flanges at the minimum price? Look no further! MS (Mild Steel) flanges are essential components in various industrial applications, providing reliable connections in piping systems. Whether you're in construction, manufacturing, or any other sector, Udhhyog offers the best deals on MS flanges without compromising on quality.

Why Choose MS Flanges?

Cost-Effective: MS flanges are among the most affordable flange options available, making them ideal for budget-conscious projects.

Durability: Made from mild steel, these flanges are strong and robust, suitable for a wide range of applications.

Versatility: MS flanges are adaptable for use in various industries, including plumbing, construction, and manufacturing.

Easy to Install: With straightforward installation processes, MS flanges help streamline your project timelines.

Wide Range of Sizes: Available in multiple sizes and specifications, Udhhyog ensures that you find the right fit for your needs.

Why Buy from Udhhyog?

Lowest Prices: Udhhyog is committed to providing MS flanges at the minimum price, making us a top choice for suppliers in the industry.

Quality Assurance: Our MS flanges are sourced from reputable manufacturers, ensuring they meet high-quality standards for performance and durability.

Expert Guidance: Our knowledgeable team is ready to assist you in selecting the right flanges for your specific requirements.

Timely Delivery: We understand the importance of deadlines, and our efficient logistics ensure your orders arrive on time.

Customer Satisfaction: We prioritize customer satisfaction, and our track record speaks for itself. We aim to build long-term relationships with our clients.

#MSFlange#MildSteel#FlangeSupplier#LowestPrice#Udhhyog#IndustrialSupplies#CostEffective#FlangeManufacturer#QualityFlanges#PipingSolutions#ConstructionMaterials#DurableProducts#Flanges#AffordableFlanges#SteelProducts

5 notes

·

View notes

Text

DN150 XXS wall thickness grade seamless alloy elbow semi-finished product blank

45 years of professional carbon steel, stainless steel, alloy steel pipe fittings and flange manufacturers

#flange #pipeelbow #pipetee #pipeReducer #pipebend

#pipe fittings#asme#stainless steel pipe fittings#flanges#pipe elbow#pipe tee#flange#elbow#elbow band#elbow brace#pipe reducer#pipebend

3 notes

·

View notes

Text

Flanges In UAE

Looking for best quality Flanges for your construction or industrial projects? Get a wide range of durable and reliable flanges supplier companies on TradersFind. 🔩🔧 Visit our website now to explore our Flanges category in UAE! : https://www.tradersfind.com/category/flanges

For inquiries, contact us on WhatsApp: +971 569773623

#flanges#industrialsupplies#constructionmaterials#highqualityflanges#reliableconnections#steelflanges#metalflanges#flangeconnections#industrialhardware#uaeconstruction#dubaisupplies#flangesuppliers#tradersfind#uaeindustry#uae#uaebusiness#b2b#businessgrowth#growyourbusiness

2 notes

·

View notes

Text

Rock ON!

2 notes

·

View notes

Text

This petal-like shape is the coated sand process. Compared with traditional manual sand casting, this process has the advantages of beautiful appearance, high yield, and fast production efficiency. With automatic precision casting, the daily production capacity can reach 50- 80 tons range. Castings include malleable steel pipe fittings, gray iron pipe fittings, malleable steel handwheels, electric fittings, turbine starters, automobile brake wheels and other products, which are the preferred process of Monday's customers. You are welcome to visit the factory and place an order for win-win cooperation!

#fittings

#pipe

#valve

#flanges

#feidingtrade

#hebeifeiding

#forgedflanges

#mifittings

#cifittings

Tommy

Hebei Feiding Trade Co.,Ltd

WhatsApp 0086-13231170855

Email: [email protected]

Web: www.hbfeiding.com

2 notes

·

View notes

Text

Forged Fittings and Stainless Steel Flanges Built for Industrial Reliability

Riddhi Siddhi Metal Impex is the Best Manufacturer of Forged Fitting. The quality of fittings plays a significant role in ensuring long-term performance, safety, and operational reliability. Forged fittings, known for their high strength and leak-proof sealing capabilities, are used widely across industries like oil & gas, petrochemicals, power generation, and marine applications. These components are vital for connecting, redirecting, or terminating piping layouts in systems where high pressure, temperature, or corrosion are concerns.

As a reputed forged fitting manufacturer in India, we deliver industrial-grade solutions that align with rigorous quality standards and application demands. Our forged fittings are manufactured using superior raw materials and undergo stringent quality checks, ensuring they maintain strength and consistency even under extreme operating conditions.

Industrial Importance of Forged Fittings

Forged fittings are produced by shaping metal using compressive forces, resulting in a highly durable and dense structure with refined grain flow. Unlike cast or machined fittings, forged options offer higher fatigue strength, improved impact resistance, and longer life expectancy.

These fittings come in various categories such as:

Socket Weld Fittings – Ideal for small pipe diameters and high-pressure systems, offering a strong and reliable connection.

Threaded Fittings – Suitable for non-weld environments, offering ease of installation in combustible or hazardous zones.

Elbows, Tees, Couplings, Unions – Designed to accommodate complex flow paths and structural transitions in pipeline systems.

Being a trusted forged fitting supplier in India, our offerings are compatible with global standards like ASME, ASTM, and MSS-SP. Each fitting is engineered to deliver optimal performance while minimizing the risk of leakage, mechanical failure, or pressure drop.

Material and Design Considerations

Selection of the appropriate material and fitting design is crucial to ensure system longevity. Our forged fittings are available in a wide range of materials including stainless steel, carbon steel, and alloy steel—each chosen based on operating pressure, temperature, and fluid characteristics.

We provide fittings in both standard and customized dimensions to meet specific client requirements. The surface finish, wall thickness, end connections, and threading are executed with precision to ensure perfect integration into existing systems. As a dependable forged fitting supplier, we also assist clients in selecting the right configurations for their unique operating environments.

We Also Lead in Stainless Steel Flanges

In addition to forged fittings, we are also a prominent stainless steel flanges manufacturer, offering an extensive range of products suitable for high-performance applications. Flanges act as the joining components that connect pipes, valves, pumps, and other equipment, allowing for easy access and maintenance of piping systems.

Our stainless steel flanges are designed for robustness, corrosion resistance, and high-temperature endurance. These are widely used in sectors such as chemical processing, food-grade systems, desalination plants, and offshore platforms. As a recognized stainless steel flanges supplier, we offer several flange types including:

Weld Neck Flanges – Preferred for high-pressure environments due to their tapered hub and smooth transition.

Slip-On Flanges – Economical and ideal for low-pressure pipelines requiring quick installation.

Blind Flanges – Used to seal off pipeline ends or unused openings.

Socket Weld and Threaded Flanges – Suitable for smaller pipe sizes or hazardous zones where welding is restricted.

Each product is manufactured to meet standards such as ANSI, DIN, and EN, ensuring compatibility across global projects.

Application-Driven Performance

Whether you are working on refinery pipelines, power station layouts, or chemical distribution networks, both forged fittings and stainless steel flanges must meet the project’s mechanical and environmental demands. Pressure rating, fluid compatibility, ease of maintenance, and long-term reliability are key factors in component selection.

Our combined expertise as a forged fitting manufacturer and stainless steel flanges supplier allows us to serve turnkey requirements with coordinated product solutions. This integrated support not only reduces procurement complexity but also enhances system integrity and safety.

0 notes

Text

How Custom Flanges Can Solve 80% of Your On-Site Compatibility Issues

Ever stood on-site with your team, staring at a pipe that just won’t fit? The specs looked right. The angle seemed okay. But the connection? Off. By a sliver.

Now multiply that by 20 pipe joints across a tight project deadline — and suddenly, that “silver” is a serious setback.

Welcome to the world of on-site compatibility issues, where mismatched pipe ends, uneven surfaces, and non-standard dimensions wreak havoc on industrial timelines. But what if we told you that 80% of these headaches could be avoided with one smart decision?

Custom flanges.

Why Standard Flanges Often Don’t Cut It

In theory, standard flanges are great. They’re readily available, budget-friendly, and follow universal specifications.

In reality?

a. That old pipe was installed years ago with custom specs. b. Your imported machinery uses a different pressure class. c. The orientation needs an angular offset. d. The required material grade isn’t available off-the-shelf.

Now you’re either spending hours modifying parts on-site (not ideal) or calling in urgent replacements (even worse).

Real-World Scenarios Where Custom Flanges Saved the Day

Scenario 1: Offshore Platform Retrofit An oil company was retrofitting pipelines on an offshore rig. Standard flanges weren’t aligning due to corroded pipe ends and mismatched bolt patterns. Solution? Custom flanges machined to match both the old and new equipment specs — saving two weeks of delay and thousands in downtime.

Scenario 2: Food Processing Plant Upgrade A food plant switching to stainless steel pipelines found that their imported equipment used DIN-standard connections while the rest of the plant used ANSI. Solution? Dual-standard custom flanges made the conversion seamless without replacing expensive machinery.

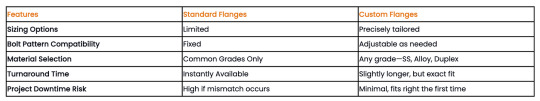

Custom v/s Standard Flanges: A Quick Comparison

How Custom Flanges Solve Compatibility Issues

1. Tailored Dimensions From OD and ID to bolt circle diameter, every spec is customized. No need to force-fit or modify pipe ends.

2. Mixed Standards? No Problem. Need to bridge JIS to ANSI or DIN to BS10? A custom flange can be your translator — engineering-wise.

3. Material Matching for Unique Environments Acidic fluids? High pressure? Extreme temperatures? Choose a custom flange in exotic materials like Inconel, Hastelloy, or Super Duplex.

4. Angular Adjustments and Tapered Ends When alignment is tricky, custom flanges with slight tapers or offset holes solve the issue with surgical precision.

But What About Cost and Time?

We get it — custom sounds expensive. But consider the full picture:

a. Cost of rework b. Labour hours wasted on poor fits c. Downtime penalties d. Delays in commissioning

A one-time custom part can eliminate cascading costs across your entire project.

Still Not Sure? Start Small

If you’re uncertain, begin with just the critical junctions. Let OnlineFittings.com help you spec out custom flanges only where needed. With CNC machining, fast delivery, and material certification — we make custom feel like standard.

Final Thought: Fit First, Fix Later or Never Fix at All?

Currently where industrial efficiency is currency, every misalignment is money lost. Custom flanges don’t just solve problems — they prevent them altogether.

So the next time your project demands precision, think beyond off-the-shelf. Think custom.

Think Online Fittings — where we don’t just deliver steel, we deliver peace of mind.

Tailored. Tested. Trusted.

0 notes

Text

Nothing but one beautiful picture share of our former project loading photo!!!

Project Info as below:

Over 3600 tons of #Ssaw #Pile #Pipe from #Tianjin #XinyueSteel Deliver to Philippines for #PortConstruction

Specification: #ASTMA252 GR 2 & 3

Want to know more about Ssaw Pile Pipe? Contact us now! WhatsApp: +8618974849825 [email protected] www.xysteelpipe.com

Xinyue's Vision: Build The World, Serve The Globe! Xinyue's Mission: To promote steel industry, to represent Made-in-China !

#Xinyue Steel#XinYue#Steel Pipe#Steel Project#Steel Construction#Global Steel Buyers#Metal Working#Manufacturing#Carbon Steel#Marine Steel#Steel Engineering#Steel Tube#Pipeline#Tubo de Acero#API 5L#tuberia#seamless steel pipe#seamless tube#Flanges#steel flanges#Energy Project

1 note

·

View note

Text

Manilaxmi Industrial Announcing New Blog Site

Our blog provides Insights, industry updates, and in-depth information on industrial products, including pipes, fittings, and flanges, tailored to help businesses stay informed and succeed.

#Blog#Blogging#ManilaxmiIndustrial#IndustrialProducts#IndustrialSupplies#IndustrialEquipment#PipesAndFittings#PipeFittings#Flanges#SteelProducts#MetalProducts#AlloySteel#ForgedFittings#StainlessSteel#NickelAlloys#Hastelloy#Monel#Inconel#DuplexSteel#PipeManufacturers#SteelSuppliers#IndustrialManufacturers#Manufacturing#Engineering#Fabrication#SteelIndustry#FAQ#FrequentlyAskedQuestions#ProductFAQs#TechnicalSupport

3 notes

·

View notes

Text

SS 304 Flange at Lowest Price in Gujarat

Introduction

In the realm of industrial applications, flanges are vital components that provide a robust connection between pipes, valves, and other equipment. Among the various types available, SS 304 flanges are renowned for their excellent corrosion resistance and versatility. If you're searching for high-quality SS 304 flanges at the lowest price in Gujarat, Udhhyog is your trusted supplier.

What is an SS 304 Flange?

An SS 304 flange is crafted from stainless steel grade 304, known for its composition of chromium and nickel, which enhances its resistance to oxidation and corrosion. This type of flange is widely used in numerous industries, including food processing, pharmaceuticals, and chemical processing, due to its hygienic properties and ability to withstand varying temperatures.

Key Features of SS 304 Flanges

Corrosion Resistance: SS 304 flanges are highly resistant to rust and corrosion, making them suitable for both indoor and outdoor applications.

Temperature Tolerance: These flanges can endure high temperatures, which makes them ideal for applications that involve heat or steam.

Durability: Known for their strength and durability, SS 304 flanges offer long-lasting performance, reducing the need for frequent replacements.

Hygienic Properties: The smooth surface finish of SS 304 flanges prevents the buildup of bacteria and contaminants, making them perfect for sanitary applications.

Versatile Applications: From plumbing and construction to chemical processing and food manufacturing, SS 304 flanges are adaptable to a wide range of uses.

Why Choose Udhhyog for SS 304 Flanges?

At Udhhyog, we are dedicated to providing our clients with top-notch products at competitive prices. Here’s why we stand out as your ideal supplier for SS 304 flanges in Gujarat:

Quality Assurance: We source our SS 304 flanges from reputable manufacturers who adhere to international quality standards. Each product undergoes stringent quality checks to ensure reliability and performance.

Lowest Price Guarantee: Our pricing strategy ensures you receive SS 304 flanges at the lowest prices in Gujarat, allowing you to maximize your project budget.

Wide Range of Options: We offer a comprehensive selection of SS 304 flanges in various sizes and types, ensuring you find the right fit for your application.

Expert Support: Our knowledgeable team is always available to assist you in selecting the ideal products for your needs. We can provide insights into the specifications and benefits of different flanges.

Prompt Delivery: We prioritize timely delivery of your orders, ensuring that your projects stay on track.

#SS304Flange#StainlessSteel#FlangeSupplier#Gujarat#IndustrialSupplies#LowestPriceFlanges#Udhhyog#FlangeManufacturer#QualityFlanges#PipingSolutions#DurableProducts#CorrosionResistance#HygienicFlanges#Flanges#SteelProducts

5 notes

·

View notes