#DIN 1.4539 Seamless Tube

Text

Shree Ashapura Steel Centre an ISO Certified company. We are India's largest Manufacturers, Suppliers and Exporters of Pipe & Tubes and Fasteners, etc. in a various material such as Stainless Steel, Duplex & Super Duplex, Nickel Alloy, Monel, Inconel.

#Stainless Steel 310 Seamless Pipe Manufacturer#DIN 1.4841 Seamless Tube#ASME SA312 SS 310 Polished Pipe#UNS S31000 Seamless Pipe Supplier#ASTM A312 TP310 Pipe#Stainless Steel 310 ERW pipe Stockiest#ss 310 tube#310 stainless steel square tubing#DIN 1.4539 Seamless Tube#ASME SA673 SS 904L Polished Pipe Manufacturer#UNS N08904 Seamless Pipe Supplier#ASTM A312 tp 904L Welded Pipe#DIN 1.4539 Rectangular Pipe#Stainless Steel 904L Seamless Tube Stockiest

0 notes

Video

undefined

tumblr

UNS N08904 SS Pipe

India-Based Leading 904L Stainless Steel Seamless Pipe Suppliers. Ready stock of UNS N08904 SS Welded Pipes, SS DIN 1.4539 Square Tubes Material, SS SUS 904L Seamless Pipe in Mumbai, India.

https://www.siliconsteelalloys.com/stainless-steel-904l-seamless-welded-pipe-supplier-stockist.html

0 notes

Link

ASME 36.19 ASTM A312 TP904L SMLS Pipe 1/2 Inch SCH10S

FOB PriceUSD 8,00- 30,000/Piece

PortNingbo or Shanghai Port

MOQ1 Piece/Ton

Supply Ability1000 Tons Per Month

Payment TermsL/C,T/T,Western Union,MoneyGram

PackagingSeaworthy plywood cases or pallets

Delivery7- 20 days

Quick Details

Thickness: SCH10S

Section Shape: Round

Outer Diameter: 1/2" (DN15)

Place of Origin: Zhejiang, China (Mainland)

Application: Construction, oil, gas, etc

Technique: ERW

Surface Treatment: Pickled, 2B, No.4, BA, Hairline, Mirror

Material: 904L Stainless Steel, etc

Standard: ASTM, ASME, etc

Type: 904L SMLS Pipe

Lenth: 3M

Brand Name: Yaang

Packaging & Delivery

Packaging Detail:Standard export packing or as per requestDelivery Detail:7 - 20 days

Specifications

ASME 36.19 ASTM A312 TP904L SMLS Pipe

1. Seamless

2. Thickness: SCH10S

3. OD: 1/2" (DN15)

4. Lenth: 3M

China SMLS Pipe Manufacturer www.yaang.com offers ASME 36.19 ASTM A312 TP904L SMLS Pipe, 1/2 Inch, SCH10S.

ALLOY 904L is a multipurpose highly corrosion resistant stainless steel. The chromium, nickel, molybdenum and copper content of the alloy renders it suitable for many applications dealing with medium to corrosive environments. It is particularly useful in sulphuric acid applications where the range of concentrations and temperatures in which it can be used, is wider than that for grades such as 317L and duplex grade ALLOY 2205. This is in part due to the copper content of the alloy. In industrial grade phosphoric acid environments, the performance of ALLOY 904L / 1.4539 is again superior to that of 317L stainless steel and, at higher temperatures, duplex grade ALLOY 2205 as well. Performance in phosphoric acid is strongly influenced by the level of impurities present. The Alloy also has useful resistance to organic acids such as formic and oxalic acids. With respect to localised corrosion, the high nickel content of ALLOY 904L / 1.4539 makes it more resistant to stress corrosion cracking than other common austenitic stainless steels whilst the levels of chromium, molybdenum and nitrogen impart excellent resistance to pitting and crevice corrosion.

Composition ranges for 904L grade of stainless steels

Grade

C

Mn

Si

P

S

Cr

Mo

Ni

Cu

904L

min.

max.

-

0.02

-

2

-

1

-

0.045

-

0.035

19

23

4

5

23

28

1

2

Tolerance

a) Outer Diameter: +/- 0.1mm

b) Wall Thickness: +/- 0.02mm

c) Length: +/- 6mm

Surface

180G, 320G, 400G Satin / Hairline 400G, 500G, 600G or

800G Mirror finish and so on.

Standard

AISI, ASTM, DIN, EN, GB and JIS

ASTM A213,ASTM A312,ASTM A269,ASTM A778,ASTM A790

DIN 17456,DIN 17458

JIS G3459,JIS G3463 etc

Material

300series: 301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti,317L,321,347

200series: 201,202,202cu,204

400series: 409,409L,410,420,430,431,439,440,441,444

Others: 2205,2507,2906,330,660,630,631,17-4ph,17-7ph, S318039 904L,etc

Duplex stainless steel: S22053,S25073,S22253,S31803,S32205,S32304

Special Stainless Steel: 904L,347/347H,317/317L,316Ti,254Mo

Application range

TP904L SMLS Pipe is widely used in below fields:

1).Petroleum,Chemical enterprise, superheater of boiler, heat exchanger

2).High temperature resistant transmission fluid pipe in power station

3).Ship with pressure pipe

4).The exhaust purification devices

5).Construction and ornament

Main market

We have frequenter customers from

Europe: Germany,Netherland,Russia, Finland,Czech,Ukraine,Italy,Spain,Poland

Middle East: Iran,UAE,SA,Iraq,Qatar,Isreal,Jordan,Bahrain,Kuwait

South America: Brazil,Chile,Peru,Venezuela,Uruguay,Argentina

Africa: Egypt,South Africa,Nigeria

Central&North America: Mexico,US,Canada,Costa Rica

South East Asia and Pacific: Japan,South Korea,Singapore,Thailand,Indonesia,Australia

Delivery conditions

Annealed, pickled & polished.

Note

We can produce other standard as the customers’ requirement.

Typical physical properties of grade 904L stainless steels

Grade

Density(kg/m3)

Elastic Modulus(GPa)

Mean Co-eff of Thermal Expansion (µm/m/°C)

Thermal Conductivity(W/m.K)

Specific Heat 0-100°C(J/kg.K)

Elec Resistivity(nΩ.m)

0-100°C

0-315°C

0-538°C

At 20°C

At 500°C

904L

7900

190

15

-

-

11.5

-

500

952

Application of ASME 36.19 ASTM A312 TP904L SMLS Pipe 1/2 Inch SCH10S:

Food processing equipment, particularly in beer brewing, milk processing & wine making.

Kitchen benches, sinks, troughs, equipment and appliances

Architectural panelling, railings & trim

Chemical containers, including for transport

Heat Exchangers

Woven or welded screens for mining, quarrying & water filtration

Threaded fasteners

Springs

Others

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce pipes with special specifications according to customers’ requirements;

TP904L SMLS pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases (fluids), slurries, powders and masses of small solids. It can also be used for structural applications; hollow pipe is far stiffer per unit weight than solid members.

TP904L SMLS pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

TP904L SMLS pipe's Marking & Packaging

While marking we choose a specific item number as well different color shade to differentiate steel grades. We mark TP904L SMLS pipe as needed with the most suitable & visible marking technique.

Packaging is an integral part of the product. It guarantees that the TP904L SMLS pipe is delivered to the customer in the required quality. For smaller orders the size of the TP904L SMLS pipe bundle depends on the no. of Tubes ordered, for larger orders the tubes are packed into individual bundles and in such a way that the maximum weight of 4000kg per bundle is not excedded. Bundle tied down with steel tape. Bundle tied down by steel strap underlaid by tapaten.

We can also provide TP904L SMLS pipe wooden box packing, cardboard boxes, plastic wrapping, using hardened paper with PE meshing (used as protection against mechanical damages of tubes), into tapaten and polyethylene sheet etc.

Where can we find the high quality TP904L SMLS pipe.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry, please feel free to contact by email [email protected]

youtube

Related products:More>>

High Pressure 302 Stainless Steel Pipe

ASTM A790 UNS32750 GR2507 Welded Pipe SCH80S DN400

SUS Standard Seamless Stainless Steel Pipe For Shipbuilding Austenitic Cr17n6Ni5N

ASTM Large Diameter Seamless Steel Stainless Pipe For Water , Schedule 80 TP317 TP317L

0 notes

Link

DIN 1.4539 904L stainless steel ASME SB673 AISI 904L pipe, is stainless because of presence of the element Chromium in that, it’s alternate name in metallurgy is inox steel. SIDDHAGIRI is a Stockist and suppliers of 904L stainless steel pipe ASTM B677 UNS N08904 904L Stainless Steel Pipe Specifications are as mentioned here ASTM A789/A790 and Equivalent grades for standard 904L, BS 904S13, euronorm no 904S13, name 904S13, Swedish SS 256.Applications of Type 904L stainless are common in typical applications including Processing plant for sulphuric, phosphoric and acetic acids, Pulp and paper processing, Components in gas scrubbing plants, Seawater cooling equipment, Oil refinery components and Wires in electrostatic precipitators.

0 notes

Text

STAINLESS STEEL 904L SEAMLESS PIPE

Stainless steel is the backbone of many industries, providing durability, corrosion resistance, and reliability. Among the array of stainless steel grades, one stands out for its exceptional performance in corrosive environments and extreme conditions: Stainless Steel 904L. In this blog, we explore the characteristics, variants, and applications of Stainless Steel 904L Seamless Pipe, shedding light on its unparalleled qualities and why it's a preferred choice in critical applications.

Understanding Stainless Steel 904L Seamless Pipe:

Stainless Steel 904L, also known as UNS N08904, is a high-alloy austenitic stainless steel with low carbon content. It exhibits superior corrosion resistance in various environments, including acids, chloride solutions, and seawater. This makes it ideal for applications in industries such as chemical processing, petrochemical, pharmaceuticals, and more.

Features of Stainless Steel 904L Seamless Pipe:

Corrosion Resistance: One of the most notable features of Stainless Steel 904L is its exceptional resistance to corrosion, especially in acidic and chloride-rich environments.

High Alloy Content: With high levels of chromium, nickel, and molybdenum, 904L Seamless Pipe offers enhanced corrosion resistance and durability.

Low Carbon Content: The low carbon content in 904L improves weldability and resistance to sensitization, reducing the risk of intergranular corrosion.

Excellent Formability: Stainless Steel 904L can be easily formed, welded, and fabricated, allowing for the creation of complex structures and components.

Exploring Variants and Specifications:

When it comes to Stainless Steel 904L Seamless Pipe, various variants and specifications cater to diverse application requirements. Some commonly used variants include:

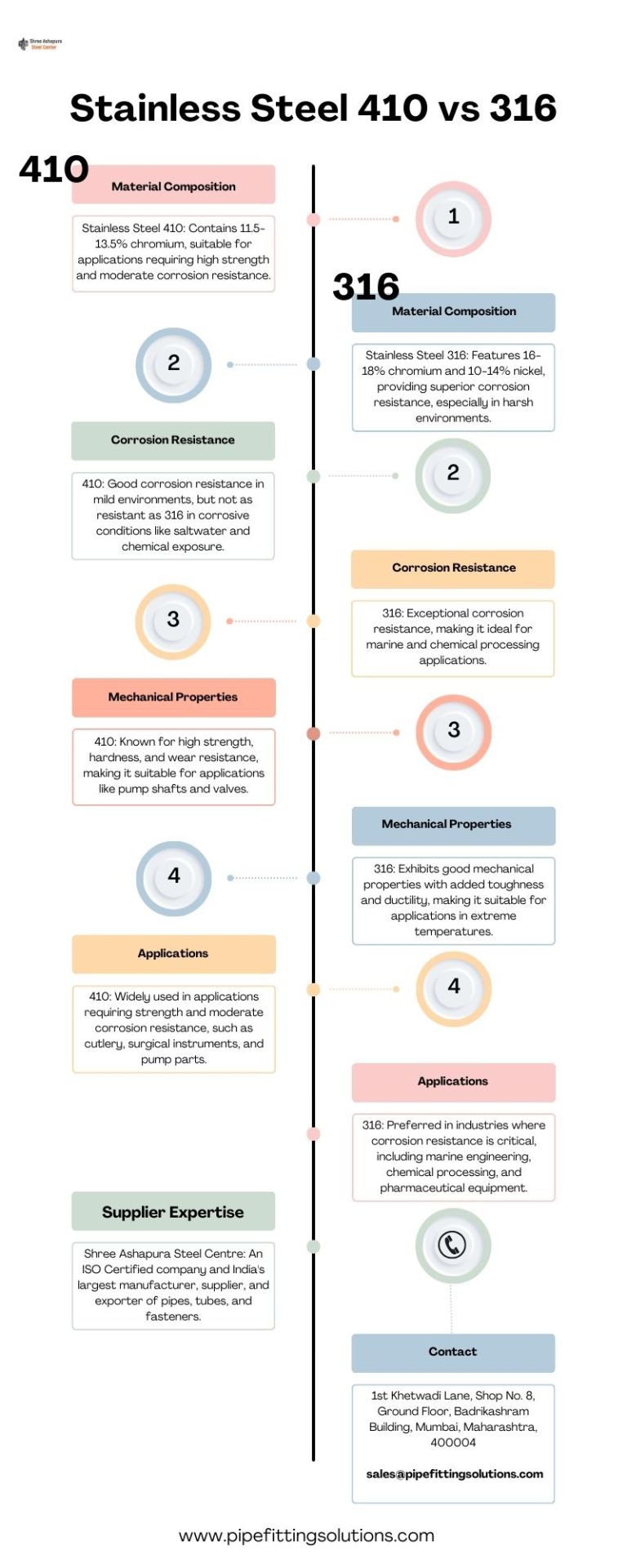

DIN 1.4539 Seamless Tube: Compliant with DIN standards, this seamless tube ensures quality and reliability, meeting European market demands and specifications.

ASME SA673 SS 904L Polished Pipe: Polished pipes offer enhanced surface finish and aesthetics, making them suitable for architectural and decorative applications.

UNS N08904 Seamless Mirror Finish Pipe: Mirror finish pipes provide a sleek and reflective surface, ideal for applications where aesthetics play a crucial role.

ASTM A673 SS 904L Boiler Pipe: Specifically designed for boiler applications, these pipes offer high-temperature resistance and corrosion resistance, ensuring reliable performance in demanding environments.

Applications of Stainless Steel 904L Seamless Pipe:

Stainless Steel 904L Seamless Pipe finds extensive applications across various industries, including:

Chemical Processing: Used in equipment such as reactors, storage tanks, and piping systems handling corrosive chemicals and acids.

Petrochemical Industry: Widely employed in offshore platforms, heat exchangers, and piping systems for its resistance to seawater and chloride solutions.

Pharmaceuticals: Utilized in pharmaceutical manufacturing equipment, where hygiene, corrosion resistance, and durability are paramount.

Oil and Gas: Commonly used in oil refineries, desalination plants, and gas processing facilities due to its resistance to corrosion in aggressive environments.

Conclusion:

In conclusion, Stainless Steel 904L Seamless Pipe stands out as a premium choice for applications requiring superior corrosion resistance, durability, and reliability. Its high alloy content, coupled with low carbon content, ensures excellent performance in corrosive environments and extreme conditions. Whether it's chemical processing, petrochemicals, pharmaceuticals, or oil and gas, Stainless Steel 904L Seamless Pipe delivers unmatched performance, making it an indispensable component in critical applications.

#StainlessSteel #904LStainlessSteel #SeamlessPipe #CorrosionResistance #HighAlloyContent #IndustrialApplications

#StainlessSteel#904LStainlessSteel#SeamlessPipe#CorrosionResistance#HighAlloyContent#IndustrialApplications

0 notes