#ASME SA312 SS 310 Polished Pipe

Text

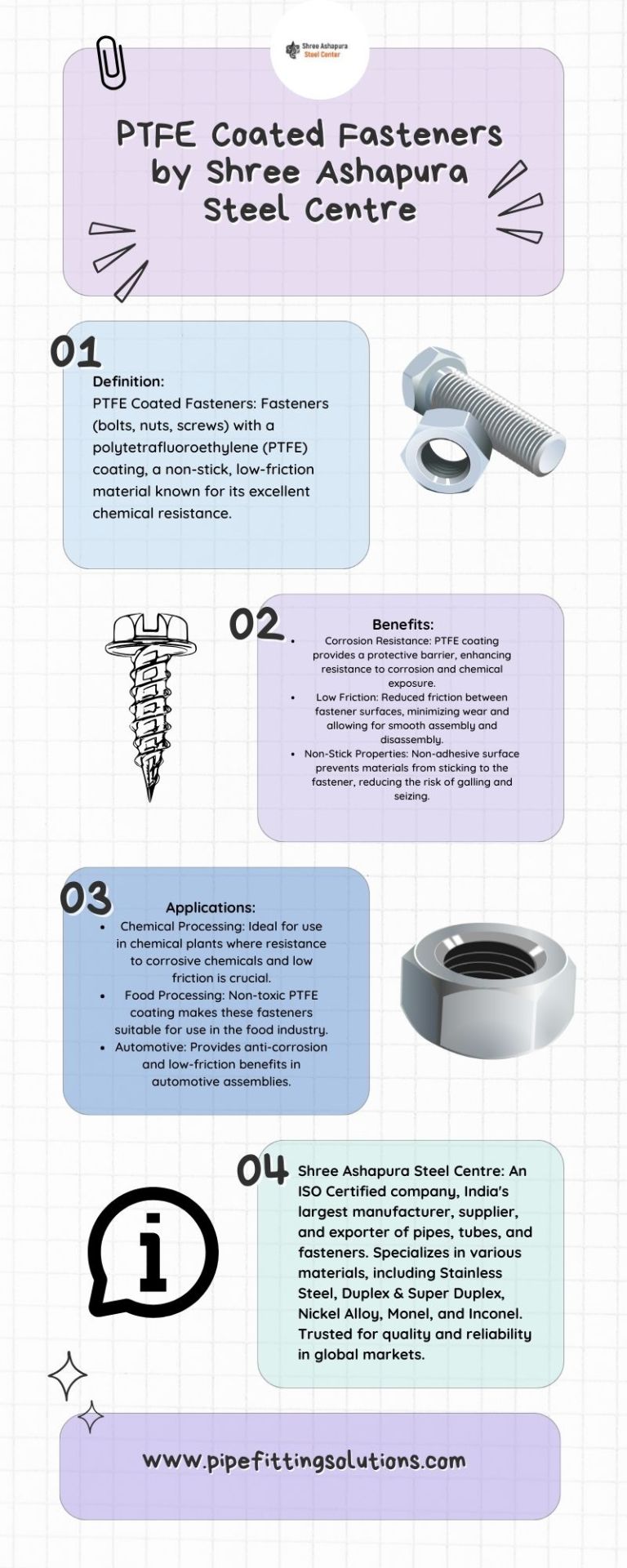

Shree Ashapura Steel Centre an ISO Certified company. We are India's largest Manufacturers, Suppliers and Exporters of Pipe & Tubes and Fasteners, etc. in a various material such as Stainless Steel, Duplex & Super Duplex, Nickel Alloy, Monel, Inconel.

#Stainless Steel 310 Seamless Pipe Manufacturer#DIN 1.4841 Seamless Tube#ASME SA312 SS 310 Polished Pipe#UNS S31000 Seamless Pipe Supplier#ASTM A312 TP310 Pipe#Stainless Steel 310 ERW pipe Stockiest#ss 310 tube#310 stainless steel square tubing#DIN 1.4539 Seamless Tube#ASME SA673 SS 904L Polished Pipe Manufacturer#UNS N08904 Seamless Pipe Supplier#ASTM A312 tp 904L Welded Pipe#DIN 1.4539 Rectangular Pipe#Stainless Steel 904L Seamless Tube Stockiest

0 notes

Text

Nascent Pipe & Tubes is the noticeable stockiest and exporter of the wide levels of the SS 309/310/310S Pipes & Tubes . Regardless, we are additionally radiant at party and giving the normal thought of the Pipes & Tubes to all the all around getting to clients. This is the way that the Pipes & Tubes are additionally imported with the leaned toward fulfillments of the clients. A piece of the nuances where the Pipes & Tubes are open are surface fulfillment, end finish, points of view, shapes, sizes, or length.

Specification Of Stainless Steel 309/310/310S Seamless Welded Pipes & Tubes

Stainless Steel Pipe Specification : ASTM A312, A358 / ASME SA312, SA358

SS Tube Specification : ASTM A213, A269, A249, A511, A554 / ASME SA213, SA269, SA249, SA511, SA554

Pipe Size : 1/8” NB to 24” NB, 1/4” OD to 24” OD sizes.

Tube Size :1/2" OD to 8" OD.

Thickness Range : 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type :Seamless / ERW / Welded / Fabricated Pipes

Form : Round, Square, Rectangular, Oval, Hydraulic Etc

Length :Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

End Protection : Plastic Caps

Outside Finish :2B, No.4, No.1, No.8 Mirror Finish for Stainless Steel Pipes, Finish as per customer Requirements

Delivery Condition : Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Inspection, Test Reports :Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing :Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials :Sizes and Specifications other than above can be manufactured on request

For more Information

Visit website:https://www.nehametalalloys.com/stainless-steel-309-310-310s-seamless-welded-pipes-tubes-manufacturer-exporter.html

Email: [email protected]

Contact: 8779038854

0 notes

Text

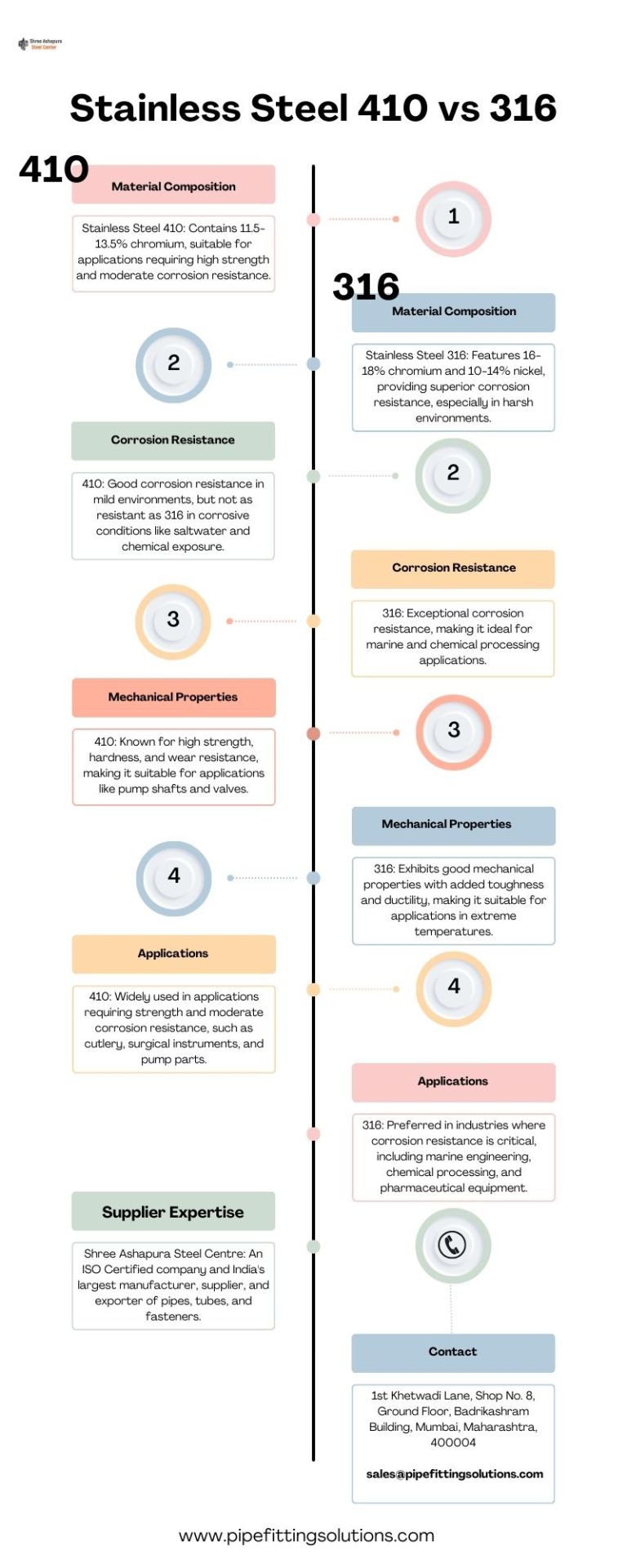

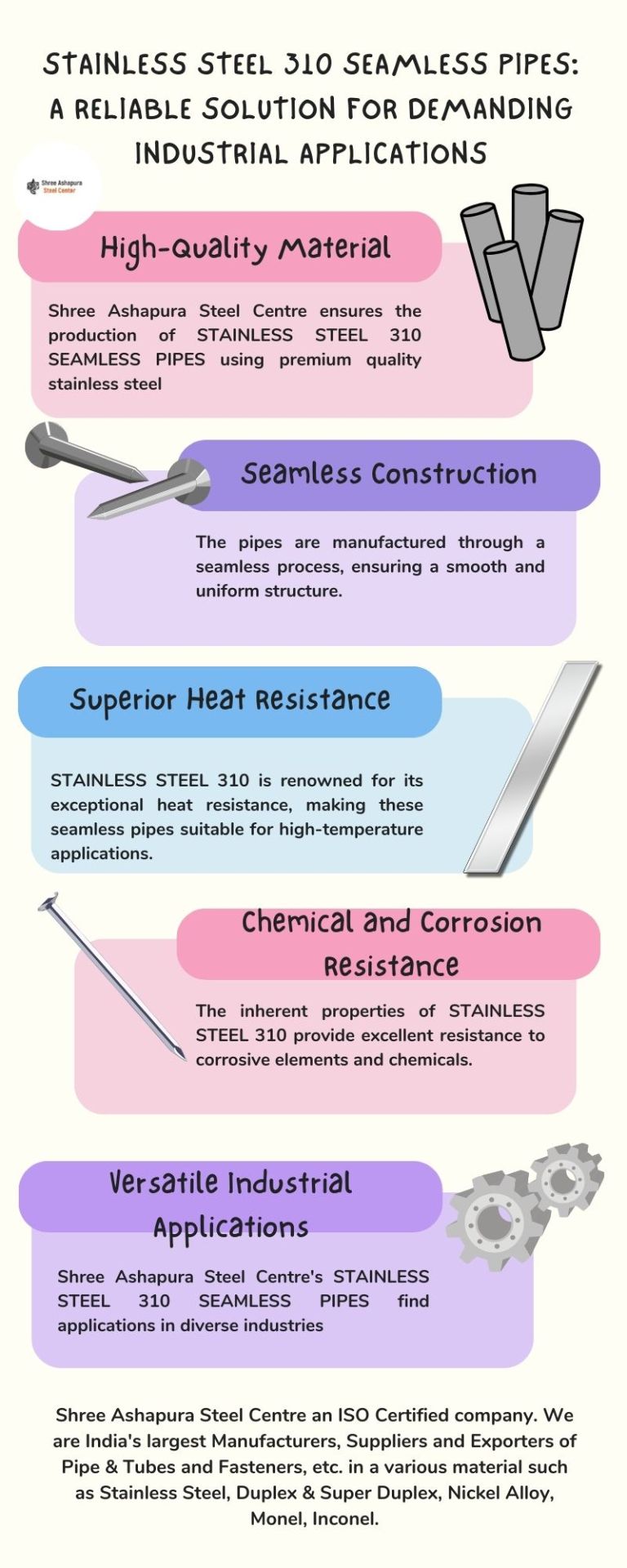

STAINLESS STEEL 310 SEAMLESS PIPES: A RELIABLE SOLUTION FOR DEMANDING INDUSTRIAL APPLICATIONS

#Stainless Steel 310 Seamless Pipe#DIN 1.4841 Seamless Tube#ASME SA312 SS 310 Polished Pipe#UNS S31000 Seamless Mirror Finish Pipe#ASTM A312 SS 310 Boiler Pipe.

0 notes

Text

310 STAINLESS STEEL PIPE

Stainless steel is renowned for its durability, versatility, and resistance to corrosion, making it a top choice in various industries. Among the myriad of stainless steel grades available, one stands out for its exceptional performance and reliability: 310 Stainless Steel. In this blog, we delve into the characteristics and applications of 310 Stainless Steel Pipe, shedding light on its unmatched qualities and why it's a preferred option in critical applications.

Understanding 310 Stainless Steel Pipe:

310 Stainless Steel, also known as UNS S31000, is a high-chromium and nickel-containing austenitic stainless steel. It offers excellent high-temperature properties and resistance to oxidation, sulfidation, and carburization. These properties make it suitable for applications in environments with elevated temperatures, such as heat treatment equipment, chemical processing, and thermal processing industries.

Features of 310 Stainless Steel Pipe:

High Temperature Resistance: 310 Stainless Steel exhibits remarkable resistance to high temperatures, making it ideal for applications involving heat treatment processes and thermal cycles.

Corrosion Resistance: It provides excellent resistance to oxidation, sulfidation, and carburization, ensuring longevity and reliability in corrosive environments.

Strength and Durability: With its superior mechanical properties, 310 Stainless Steel Pipe offers high strength and durability, contributing to its longevity and performance in demanding applications.

Versatility: Due to its exceptional properties, 310 Stainless Steel Pipe finds applications across various industries, including aerospace, chemical processing, and power generation.

Exploring Variants and Specifications:

When it comes to 310 Stainless Steel Pipe, several variants and specifications cater to diverse application requirements. Some commonly used variants include:

Stainless Steel 310 Seamless Pipe: Seamless pipes offer uniformity in structure and enhanced corrosion resistance, making them suitable for high-pressure and critical applications.

DIN 1.4841 Seamless Tube: Compliant with DIN standards, this seamless tube ensures quality and reliability in European markets and industries.

ASME SA312 SS 310 Polished Pipe: Polished pipes not only provide aesthetic appeal but also enhance corrosion resistance, making them suitable for architectural and decorative applications.

UNS S31000 Seamless Mirror Finish Pipe: Mirror finish pipes offer a sleek and reflective surface, making them ideal for applications where aesthetics are crucial, such as in furniture and interior design.

ASTM A312 SS 310 Boiler Pipe: Designed specifically for boiler applications, these pipes offer high-temperature resistance and durability, ensuring reliable performance in demanding environments.

Applications of 310 Stainless Steel Pipe:

The versatility and superior properties of 310 Stainless Steel Pipe make it indispensable in various industries, including:

Chemical Processing: Used in reactors, furnaces, and other equipment subjected to corrosive chemicals and high temperatures.

Power Generation: Commonly employed in boiler systems, heat exchangers, and turbines due to its high-temperature resistance and corrosion resistance.

Aerospace: Utilized in aircraft components and structures requiring resistance to high temperatures and harsh environments.

Thermal Processing: Widely used in furnaces, heat treatment equipment, and annealing processes due to its excellent high-temperature properties.

Conclusion:

In conclusion, 310 Stainless Steel Pipe stands out as a superior choice for applications requiring high-temperature resistance, corrosion resistance, and durability. Its versatility, coupled with various specifications and variants, makes it suitable for a wide range of industries and applications. Whether it's chemical processing, power generation, aerospace, or thermal processing, 310 Stainless Steel Pipe delivers unparalleled performance and reliability, ensuring longevity and efficiency in critical applications.

#StainlessSteel #310StainlessSteel #StainlessSteelPipe #HighTemperatureResistance #CorrosionResistance #IndustrialApplications

#StainlessSteel#310StainlessSteel#StainlessSteelPipe#HighTemperatureResistance#CorrosionResistance#IndustrialApplications

1 note

·

View note