#Desktop3DPrinter

Explore tagged Tumblr posts

Text

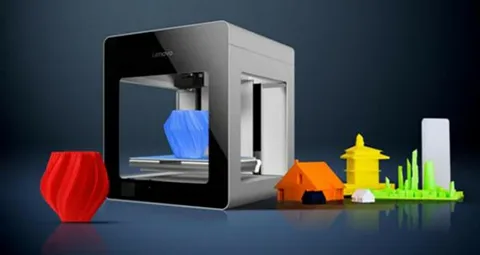

Desktop 3D Printer Market Growth Drivers Transforming Additive Manufacturing Industry Globally

The desktop 3D printer market has witnessed remarkable growth over recent years, revolutionizing how products are designed, prototyped, and even manufactured. As additive manufacturing technology continues to advance, the demand for desktop-sized 3D printers has surged among hobbyists, educators, small businesses, and professionals. Understanding the primary drivers behind this market growth is essential for stakeholders aiming to capitalize on the expanding opportunities. This article delves into the key factors propelling the desktop 3D printer market forward.

1. Technological Advancements and Innovation

One of the most significant drivers behind the desktop 3D printer market is ongoing technological innovation. Improvements in printer hardware, including better precision, faster print speeds, and enhanced reliability, have made desktop 3D printers more accessible and capable. The evolution from basic fused deposition modeling (FDM) to more sophisticated technologies such as stereolithography (SLA) and digital light processing (DLP) has broadened application possibilities, encouraging more users to adopt desktop 3D printing.

Moreover, advances in printing materials—from plastics to composites and even metal-infused filaments—have expanded the functional range of desktop 3D printers. These improvements enable users to create durable, high-quality prototypes and end-use parts, making desktop 3D printing a viable option across many industries.

2. Decreasing Costs and Increasing Affordability

Cost reduction is another powerful driver for the desktop 3D printer market. Early 3D printers were prohibitively expensive for individual users and small businesses. However, economies of scale, increased competition among manufacturers, and technological maturity have drastically lowered prices. Today, entry-level desktop 3D printers are available at affordable prices, opening the market to hobbyists, students, and startups.

Alongside hardware costs, the decreasing price of printing materials and software solutions further contributes to affordability. This overall reduction in total cost of ownership encourages wider adoption and frequent usage of desktop 3D printers.

3. Growing Demand for Rapid Prototyping and Customization

Industries increasingly demand rapid prototyping to accelerate product development cycles. Desktop 3D printers allow designers and engineers to quickly iterate designs without relying on costly third-party manufacturing. This on-demand prototyping significantly reduces lead times, lowers development costs, and enables faster time-to-market.

Additionally, the rise of mass customization in sectors like healthcare, fashion, and consumer goods boosts the need for flexible manufacturing solutions. Desktop 3D printers empower small-scale production of customized items tailored to individual specifications, meeting customer demands for uniqueness and personalization.

4. Expansion of Educational and DIY Markets

Educational institutions and maker communities play an influential role in expanding the desktop 3D printer market. Schools and universities integrate 3D printing into STEM curricula to provide students hands-on experience with emerging technologies. This exposure cultivates future professionals familiar with additive manufacturing, thereby sustaining market growth.

The DIY and maker movement thrives on accessible, affordable desktop 3D printers, enabling enthusiasts to create prototypes, replacement parts, and artistic projects. Online communities sharing designs and knowledge stimulate further interest and innovation, broadening the user base.

5. Enhanced Software and User-Friendly Interfaces

User experience improvements drive the market by making 3D printing less intimidating for new users. Advanced software with intuitive interfaces, pre-configured print profiles, and automated calibration simplify the printing process. Cloud-based platforms and mobile apps offer seamless remote management, design sharing, and collaboration.

Such user-friendly solutions lower the entry barriers and increase productivity, encouraging adoption by non-technical users and businesses alike.

6. Increasing Adoption in Healthcare and Other Key Industries

The healthcare industry’s adoption of desktop 3D printing significantly influences market growth. Customized implants, surgical guides, prosthetics, and anatomical models are increasingly produced using desktop printers for personalized patient care. This sector’s expanding use cases highlight the practical benefits of desktop 3D printing technology.

Similarly, industries like automotive, aerospace, consumer electronics, and architecture are leveraging desktop 3D printers for prototyping, tooling, and small-batch production, driving broader market demand.

7. Government Initiatives and Investments

Government policies and initiatives promoting innovation and advanced manufacturing also act as growth drivers. Funding for research, subsidies for equipment acquisition, and support for technological education encourage adoption of desktop 3D printing. Such measures foster an ecosystem conducive to market expansion.

Conclusion

The desktop 3D printer market is propelled by a combination of technological innovations, cost reductions, and growing demand for rapid prototyping and customization. Expanding applications in education, healthcare, and industry further amplify growth prospects. As software becomes more user-friendly and governments support advanced manufacturing initiatives, the desktop 3D printer market is set to continue its dynamic growth trajectory, reshaping traditional manufacturing paradigms and enabling creativity across sectors.

0 notes

Text

Desktop 3D Printer Market Growth: How Innovation and Affordability Are Shaping the Future

The desktop 3D printer market has witnessed remarkable growth in recent years, driven by technological innovations and an increased demand for affordable and accessible 3D printing solutions. From hobbyists and educational institutions to small businesses and industries, desktop 3D printers are now recognized for their potential to revolutionize how products are designed, prototyped, and even produced. As the market continues to evolve, two key factors—innovation and affordability—are significantly shaping its future.

1. Technological Innovation Driving Market Growth

Technological advancements in 3D printing have opened up new possibilities for desktop 3D printers, making them more powerful, efficient, and versatile. In the early days of 3D printing, the technology was primarily used by large corporations or research institutions due to the high cost and complex operation. Today, innovations in hardware and software are making desktop 3D printers more user-friendly and accessible to a wide range of industries.

Key Technological Advancements:

Improved Print Quality: The latest models of desktop 3D printers are capable of producing highly detailed and accurate prints. With better resolution, precision, and faster printing speeds, users can create more complex designs with greater ease.

Enhanced Materials: Desktop 3D printers now support a variety of materials beyond just plastic, such as metal, resin, and even biodegradable filaments. These innovations allow industries like healthcare, aerospace, and automotive to adopt 3D printing for functional prototypes, tools, and end-use parts.

Advanced Software: Along with hardware, 3D printing software has evolved to provide better design flexibility, error correction, and easier integration with digital manufacturing workflows. Software advancements have helped streamline the design-to-production process, reducing the complexity for users and enabling more efficient workflows.

Multi-material and Multi-color Printing: Some of the latest desktop 3D printers offer the ability to print using multiple materials or colors in a single print job, further expanding the potential for creating more intricate, customized products.

These innovations make desktop 3D printers not only more efficient but also more applicable across a broader range of industries. As technology continues to improve, the market will likely see even more powerful and specialized 3D printers entering the mainstream.

2. Affordability Driving Market Accessibility

Another critical factor fueling the growth of the desktop 3D printer market is the significant drop in prices over the past few years. Once limited to high-end industrial machines, 3D printers are now more affordable and accessible to small businesses, educational institutions, and even individual consumers. As the cost of hardware, materials, and software decreases, the adoption of desktop 3D printers has skyrocketed.

Factors Contributing to Affordability:

Mass Production and Increased Competition: As 3D printing technology became more widely adopted, manufacturers began producing more machines to meet demand. The rise in competition among printer manufacturers has led to lower prices, as companies seek to differentiate themselves by offering more affordable options.

Open-Source Platforms: Many companies have embraced open-source models, where users can modify and customize 3D printer designs. This model has significantly reduced the cost of hardware and software, making it easier for users to build their own printers or purchase low-cost models with high-quality performance.

Consumer Market Growth: With the increasing use of 3D printers in the consumer market, there is a larger supply of affordable desktop models designed for home use, hobbyists, and small businesses. This has opened up new avenues for entrepreneurs and makers to create prototypes, models, and even finished products without the need for expensive equipment.

Cost-effective Materials: The availability of low-cost filament and material options has made 3D printing more affordable for users. Today, materials like PLA, PETG, and ABS filaments are readily available at a fraction of the cost of earlier, specialized materials, further decreasing the overall cost of ownership.

As 3D printing becomes more affordable, businesses and individuals alike can take advantage of this technology to streamline product design, enhance prototyping, and even produce small batches of customized products on-demand.

3. Impact of Affordability and Innovation on Various Sectors

The convergence of affordability and technological innovation is paving the way for widespread adoption of desktop 3D printers across several sectors. Some of the most notable applications include:

Manufacturing and Prototyping: Small businesses are increasingly using desktop 3D printers for rapid prototyping and small-scale manufacturing. The ability to quickly iterate designs and produce low-cost prototypes accelerates the product development cycle, enabling faster time-to-market for new products.

Education: Educational institutions, from high schools to universities, are adopting desktop 3D printers to teach students about design, engineering, and manufacturing. This technology is empowering students to create tangible models of their ideas, fostering creativity, and developing critical skills in emerging technologies.

Healthcare and Medical Devices: Desktop 3D printers are finding growing applications in the healthcare sector, particularly in the creation of custom prosthetics, implants, and medical models. The affordability of 3D printers enables healthcare providers to create cost-effective, patient-specific solutions.

Arts and Design: The creative industries are also benefiting from desktop 3D printing, with designers using the technology to create intricate sculptures, jewelry, and art pieces. 3D printing allows for greater design freedom and the production of complex forms that would be difficult or impossible to achieve with traditional manufacturing methods.

Consumer Products and Customization: As more individuals gain access to desktop 3D printers, there is an increased demand for customized products. From personalized jewelry and home décor to custom phone cases and toys, 3D printing is enabling consumers to create unique, tailor-made products to meet their individual preferences.

4. Future Outlook of the Desktop 3D Printer Market

The desktop 3D printer market is expected to continue growing as innovations and affordability further lower the barriers to entry for businesses and consumers alike. As industries increasingly recognize the benefits of 3D printing—whether for rapid prototyping, customized production, or design freedom—the adoption rate is likely to rise.

The integration of AI and machine learning in 3D printing will also likely improve the precision, speed, and cost-effectiveness of printers. This, coupled with the development of new materials and the continuing trend toward personalization, will drive market expansion in the coming years.

Conclusion

The future of the desktop 3D printer market is undeniably bright, as ongoing innovation and decreasing costs are making the technology more accessible and powerful. Whether for manufacturing, healthcare, education, or personal use, 3D printing is transforming the way we design and produce goods. As the technology continues to evolve, we can expect to see even more applications across industries, shaping a future where desktop 3D printing becomes an integral part of everyday life and business operations.

0 notes

Link

3D print your own version of useful items with the STL file provided in the blog.

#3dprinter#3dprinting#3d technology#3Ddesign#3d modling#lifehack#desktop3dprinter#dogmuzzle#cablemanagement#Geeetech

1 note

·

View note

Photo

The first @3dbenchy printed on the @sculpto Pro 2 came out pretty good. Yes the layers are more visible than normally but the overall print quality is good. The Sculpto Pro 2 is a super easy to use 3D printer and great for starters. I like it. #3dprinting #3dprinter #3dprintlife #3dprint #3dp #sculpto #sculpto3d #sculptopro2 #makermovement #maker #makergram #desktop3dprinter #hobby #diy #tinkering #tinkercad #thingiverse #de3dprintman https://www.instagram.com/p/B_KNPLCDhGm/?igshid=oqei91f28h3m

#3dprinting#3dprinter#3dprintlife#3dprint#3dp#sculpto#sculpto3d#sculptopro2#makermovement#maker#makergram#desktop3dprinter#hobby#diy#tinkering#tinkercad#thingiverse#de3dprintman

0 notes

Photo

The new upgraded desktop 3D printer, made in India - Ether 2.0 Booking open, book your machine now. #3dparadise #3dprinterncr #3dprinterdelhi #3dprinterindia #3dprintingindia #3dprinter #3dprinting #desktop3dprinter #oneofitskind (at Delhi, India) https://www.instagram.com/p/B2CoyXYnDUY/?igshid=wlkvlwjjjiss

#3dparadise#3dprinterncr#3dprinterdelhi#3dprinterindia#3dprintingindia#3dprinter#3dprinting#desktop3dprinter#oneofitskind

0 notes

Video

Raise3D E2 Desktop 3D Printer - Includes Auto Leveling and IDEX. Learn more about the latest Raise 3D printer from the #3Dprinting experts at Profound3D.com

#raise3d#raise3de2#raise3dprinters#desktop3Dprinter#E2 3D printer#Raise E2 3D printer#3D printer#3D printing#additive manufacturing#auto bed leveling#dual extruder

0 notes

Photo

NEW BLOG POST: after over 100 hours of 3d printing, Dhemerae reviews @themicro3d desktop printed in depth! Read more, and see awesome pics, at thelasergirlsstudio.com! #3dprinting #desktop3dprinter #golaser

7 notes

·

View notes

Text

How To Trouble Shoot Warping

Warping is when one or more corners/edges at the bottom of the object are lifted and detached from the printing platform horizontally,leading to transverse cracks in the top.

Cause(s): Warping is a common problem and often occurs when the first layer of plastic contracts as it cools.

Solution(s): Level the printing platform. A tilted printer bed itself could result in warping. Most budget 3D printers require manual leveling, which is not an one-time thing as you may be wondering: You would have to adjust the printer bed manually between prints to make sure it is flush.

Use a heated printer bed. If your printer does not come with a heated bed(which is rare except for DIY kits ), like the Geeetech E180(this printer is specifically designed for educational purposes.It works with PLA,and an alternative to a heated bed,such as textured paper,is used to improve adhesion ), you can either get one yourself ,or apply glue to keep the first layer of the object stuck to the platform. After leveling the platform, make sure the nozzle height is correct. (P.S.: there are 2 types of heated beds on Geeetech 3D printers :MK2A/MK2B and aluminum substrates).

Slow down your print job. Warping could occur when it prints too fast, because the layers, especially the innitial layers are not given enough time to cool. It is recommended that users reduce the speed by 50% when printing the first layer to allow for better adhesion of the extruded material to the platform.

Create some extra parts that can be easily removed in the model design to prevent the base layer from rising from the edges.provided you are proficient in modeling software.

Placing a build surface onto the printer bed can also effectively reduce the chances of warping. Though removing the object off the plate could entail some extra work,if it is substantial.

Check the temperature parameters are set correctly. The extruded filament would not stay flat on the platform if the temperature of the printer bed is too low. The suggested range for PLA is 40 to 50 degrees celcius, ABS 60 to 70 degrees.

Should you have more questions regarding 3D printers or 3D printing in general, you can always visit our official forum or join our facebook user group where you will get your quesitons answered by 3D printing hobyyists /experts or geeetech staff.

Geeetech is one of the leading brands in 3D printers for home and office use.To find out more, go to https://www.geeetech.com/

.

1 note

·

View note

Text

A Self-healing 3D Printed Plastic Webs Could Save Cracked Phone Screen

There are few things more frustrating than getting a little tiny crack or even a big crack in your smartphone screen. That’s really annoying. My friend recently dropped his phone with a screen protector again. He’ve broken that screen about four times over the period of the last 2 or 3 months. Ah, If we could only get a self-healing phone screen!

Thanks to the efforts of the Professors Frédérick Gosselin and Daniel Therriault, Now we can do more than just imagine.

These two researchers have much success in producing an ultra-strong polymer fibre and the inspiration came from the structure of spider silk.They claimed it was made of the unique molecular structure of the proteinacious material,which can absorb up to 96 percent of impact energy before breaking. This helps to creat the unbreakable plastic coverings for various kinds of delicate technology devices.

Image credits: Ashkan Forouzani | Unsplash,Shibo Zou.

Other than this bionic design,the researchers adopted the technology of 3D printing. Heat the polycarbonate first to make it become viscous like honey.Then Professor Gosselin’s team made use of this property to print a series of fibres less than 2mm thick. They repeated the process quickly, “weaving” a new series of fibers in a vertical arrangement to achieve the entire network solidification.

It’s worth noting that as the 3D printer slowly extruded polycarbonate to form a fiber, the molten plastic finally formed a series of hardened loops that give the fiber extra strength as sacrificial links.

The molten plastic is slowly extruded by the 3D printer to form a fibre

Instability-assisted 3D printing of polycarbonate fiber with sacrificial bonds

When the impact happened, these fibers actively withstood the damage caused by the impact energy, sacrificing the ego in the similar way that spider silk proteins do to protect the integrity of the whole.

Looking forward , the technology is expected to help electronic devices achieve the desired effect of impact protection.We might also be able to make a new type of bullet-proof glass, or a protective coating for aircraft engines.

0 notes

Text

Aliexpress 11.11 Big Sale Has Up To 74% Off With Further Reductions For Two Days Only

Double Eleven (11.11) is the biggest sales event in the world of online shopping.Are you ready?Looking to maximise your savings this 11.11 Singles Day? Here’s a list of Geeetech products for 11.11 on Aliexpress with amazing campaigns full of special deals including 74% Off discount, $2.00 coupon with no other required conditions and so forth.You can also save $8 on every $150!This shocking promotion comes only once a year and you simply can’t miss out!

Our 11.11 Sale Is Here! Are You Ready For It?

Promotion for 3D printers,up to 35% off with $2.00 coupon,starting from $176. The max discount is as high as $100! Don't miss this sale!

Promotion for important 3D parts and other Geeetech products,up to 75% off with $2.00 coupon,starting from $1.01.

PLA filaments enjoy multiple discounts:

Buy 2 get 10% off;

Buy 3 get 15% off;

Buy 5 get 20% off.

Up to 25% off with $2.00 coupon,starting from $1.99.

Further Reductions:

$60 off over US $499;

$37 off over US $166;

$10 off over US $270;

$8 off over every US $150.

They can be combined with other discounts.

Activity time: US time 11/11/2020-12/11/2020

Shop address:

https://geeetech.aliexpress.com/store/110623/pages/promotion-20201111.html

https://geeetechglobal.aliexpress.com/store/1415075/pages/promotion-20201111.html

Add the shopping cart now!

0 notes

Text

The Smallest 3D-Printed Boat You’ve Ever Seen

You must be surprised When you see the iPhone 12 mini for the first time , which is literally tiny by contemporary standards.In the real world, , we may think of a small thing as nothing more than a bean or a grain of sand, or even a strand of hair.But you know what, scientists used a 3D printer to create a 3D Benchy boat, the length of which is 1/3 the thickness of a hair, 6 times larger than a bacterial cell.

Researchers used a scanning electron microscope to photograph the ship for purpose of showing its open cabin, a chimney, and even a small porthole. What’s most impressive is that the entire model is very tiny, which means it’s even smaller than a statuet created by artist Jonty Hurwitz in 2014 as a potential design for creating a little drug delivery vehicle.

The researchers conducted investigations into small particles called microswimmers that can move through fluids, and be followed by a microscope.They created many structures , including a spiky sphere, a spiral, a trimer,a 3D Benchy boat and so on. Research shows that particles created in a helix shape can go around and be efficient.

“When it moves forward, often it needs to rotate, and that helps, for example, to speed it up.”Daniela Kraft said, a physicist at the Dutch university,adding that the small particle that goes to a particular part of the body to deliver drugs has to propel itself and may have to deal with the complex environment in human’s body.

0 notes

Text

Will 3D Printers Change The Future of Garage Kits?

In the past few years, 3D printers have become easier to use and can do some really cool things.Like this guy.

3D Printing works of Thanos(Marvel Cinematic Universe) printed by Getech Technology Co.

Anyway, today I started thinking about what this means for the future of garage kits.As garage kits are sold at conventions and produced in limited quantities by individuals or groups, they are clearly hard to come by.

Generally, the official sales price of garage kits is determined according to their production process. The following processes are the factors that lead to its high price:

1. The first thing to do before making a garage kit is to ask the prototype designer to design the prototype.

2, The next step is to make the mold.

3, After completing the steps above,you should color and paint it.

4,It may be colored unevenly or too much on a certain part and need to be fixed.

5. Many garage kits are limited production. A garage kit is generally pre-displayed in the form of GK grey mold at WTF exhibition, and buyers will confirm the reservation according to this preview.

A Garage kit of Son Goku (Dragon Ball)

So as 3D printers become more mainstream,you may have the opportunity to use a program to create 3D images and make your own garage kits .This is likely to happen with 3D printers becoming cheap.

3D printer can print your favorite garage kits with high precision , without the expensive cost of hiring a prototype designer and making molds.Complex processes such as making eyes and nails can still be be simplified when using the 3D printer.After polishing and coloring, a delicate toy is finished.

The 3D printing garage kit has the advantages of low cost, high efficiency and guaranteed quality.For those who can’t afford expensive garage kits, getting a 3D printer is a great option,with which you can print your favorite animation role and participate in the whole process, which is also a very interesting experience.

0 notes

Text

5 Easy Ways to Prevent 3D Print Stringing

without a doubt,you can’t bear some minor flaws in the face of a 3d printing model, let alone “String”.You complained that this printer is such a trash Contrary to expectations.At that time,You may get mad but it will eventually ending up in a mess.

So firstly you need to calm down.Take a close look at what the problem is,make it clear that how it happened and how we can solve the problem.Let’s dive in.

What’s the Problem?

Stringing exists when small strings of plastic are left behind on a 3D printed model. This is usually due to plastic leaking out of the nozzle as the extruder moves to a new position.

Finished print affected by stringing

How to fix this?

In this article, we’re going to look at 5 Solutions that are common to all the major 3D printers.

1.Enable Retraction

Enabling retraction is the most ordinary way used to fight against 3D printer stringing. Enabling retraction means that means that when the extruder has to pass through a gap, the filament is retracted a little bit by the feeder.Once the extruder reaches the next position, the filament is pushed out and the print continues again from the nozzle.If the retraction setting is turned on and you’re still experiencing 3D printer stringing, you may then need to go into the details of the retraction settings:

Retraction distance

The most important retraction setting is the retraction distance. This determines how much plastic is pulled out of the nozzle. Generally speaking, the more plastic that is retracted from the nozzle, the less likely the nozzle is to seep out as it moves. Most direct-drive extruders only require a retraction distance of 0.5-2.0mm. If you run into stringing with your prints, try increasing the retraction distance by 1mm and test again to see if the performance improves.

Retraction speed

The next retraction setting that you should check is the retraction speed. This determines how fast the filament is retracted from the nozzle.If the retraction is too slow,the plastic will slowly leak out of the nozzle and may begin to leak before the extruder moves to its new position. If you retract too quickly, the filament may separate from the hot plastic inside the nozzle, or the rapid movement of the drive gear may even grind away pieces of your filament. There is usually an optimal point of retraction between 1200-6000 mm/min (20-100 mm/s) .

If standard retraction isn’t doing the trick, try reducing the minimum travel. This is usually the quickest solution to fix stringing issues. Drop the value by 0.5mm until the stringing has stopped completely.

2.Set the Right Temperature

The extruder temperature is the next most common cause for stringing.If the temperature is too high, the plastic inside the nozzle will become less sticky and more likely to leak out. Whereas, if the temperature is too low, the plastic will be kind of solid and difficulty in extruding from the nozzle. If you feel you have the right retraction settings, but you’re still having these problems, try decreasing your extruder temperature by 5-10 degrees. This will greatly improve the quality of your printing.

3.Movement Speed

Moreover,increasing the movement speed of your machine can also reduces the time it takes for the extruder to leak as it moves between parts. The X/Y Axis Movement Speed represents the side-to-side travel speed, and is frequently directly related to the amount of time your extruder spends moving over open air.As long as your machine can handle moving at higher speeds, increasing this settings may reduce stringing between parts.

4.Thoroughly Clean the Nozzle Before Printing

When you use a printer for a long time, the filament can leave a thin layer of residue in the nozzle. This thin layer can cause 3D printer stringing as filament strands will try to stick to the surface of your printed part.

To avoid this type of problem, ensure your nozzle is thoroughly cleaned before any printing to remove any dirt from the previous filaments.

5.Keep Your Filaments Moisture-Free

PLA, which absorbs more water than ABS, is the main culprit.The water turns to steam when the plastic is heated up, and it can mix with the plastic to increase the likelihood that it will seep out during non-printing movements.

Therefore, it is very important to store the filament properly, especially if you live in a humid environment.For more guidance, check out the previous blog here:https://www.geeetech.com/blog/2020/09/3d-printer-filament-storage-how-is-it-done-properly/

Source:

https://www.simplify3d.com/support/print-quality-troubleshooting/stringing-or-oozing/

https://all3dp.com/2/3d-print-stringing-easy-ways-to-prevent-it/

https://technologyoutlet.co.uk/blogs/news/the-most-common-3d-printing-problems-with-solutions

#3d printer#3d model#3D Printing#3D Printing Technology#3d printing filament#desktop3dprinter#getech

0 notes

Text

3D Printer Filament Storage – How Is It Done Properly?

If you have moisture and mold in your home, you’re more likely to have respiratory problems, allergies and weak immune system.When you know the cause of the moisture, you can take steps to limit the moisture in the air.

Likewise, humidity is a natural enemy of filaments.Some materials have no humidity problem.Others, such as PVA or nylon, are very hygroscopic and absorb water after a very short time.The wet filament sizzles and is easy to recognize during printing, and the results are terrible.Therefore, it is particularly important to store filaments spools carefully and correctly.

A comparison of dry vs wet filament. Source: Matterhackers

Why Water Damages Thermoplastics

All plastics are polymers or copolymers. you’ll see that the long molecular strands that make up them are woven together when you look at polymers or copolymers under a high-intensity microscope,That means there’s plenty of space between and around the strands.Thererfore, most polymers and copolymers are hygroscopic.Some filament materials, such as Nylon, are very sensitive to water .If they absorb only a little water, they can cause problems when printing.

How To Keep Your 3D Printer Filament Dry

Storing your filament in an airtight container with a desiccant is the easiest way to settle this issue.Filament dry boxes work well, but they can be bulky.

when it comes to airtight,most people think of plastic containers and bags.For the most part, these are good short-term solutions.

This is the cheapest way to store filament spools. Source: Paige Russell / Instructables

Nevertheless, over time, plastic containers and bags become slightly permeable.This means that the longer your printing materials stay in plastic bags, the more water they absorb, .especially when you live in a humid climate. .If you use a clear bag or box, UV light will also reduce the strength of the filament over time.

Using high-quality Mylar bags or bags made of similar materials is a better solution is to store your thermoplastic.Obviously, there is a layer of metal between two layers of plastic.

Mylar bags protect your printing material from water vapor.Source: rigid.ink

Desiccant packets keep the humidity in the containers to a minimum. Source: Amazon

This metal layer protects your printing material from any water vapor that permeates the plastic.So that your printing material produces a satisfactory result.

How You Know Your Printing Material Has Absorbed Water

Before printing, there are two simple ways to determine if your material is absorbing water.First, you can measure the diameter of the material itself.when a polymer absorbs water, it begins to grow in size.If the diameter of the filament increases by 10 percent or more, it most likely absorbs water.

Another way to determine whether a filament absorbs water is to extrude a small amount of filament before printing.We’ve all probably been there: sitting by a fire, listening to its crackle.This is because the water in the wood is changed into steam when heated.The same phenomenon occurs when you extrude thermoplastic that has absorbed water.The heat from the print end causes the water in the plastic to expand and escape.You can hear hissing or popping and also see bubbles.

How to Dry Out Filament

If your filament is wet, you must dry it out before using it to print.Why not use an oven?

Once the oven it up to temperature, place the spooled material inside.Source: Amazon

In the first place, check out the glass transition temperature for the filament that you are going to dry.You need to be sure that you keep your oven temperature below the transition temperature. In a general way , about 60-70C is just about right for most materials, except may be a bit hot for lower temp materials like PLA. Always keep in mind how hot your oven runs and only use electric ovens.

You should also be aware, even if the Glass Transition temp is very high, for a material like Nylon or Polycarbonate – the spool your filament is wound on is likely made from an ABS which will soften at lower temperatures than the filament.

How to dry PLA filament

You ought to be more careful when you dry PLA filament on account that 70C will be too hot. We recommend at the very lowest temp your oven will go around 40C. Even at this temp your PLA will soften, so drying PLA in the oven won’t always give you the results you’re after. It’s a small reminder as to the importance of keeping excellent PLA storage.

Once the oven it up to temperature, place the spooled material inside and leave it there for four to six hours. If you have a convection oven, this drying time may be shortened since the circulated air removes more moisture from the material more quickly.You can also ‘recharge’ the desiccant this way too, placing it in the oven over a low heat.

Once the time is up, remove the material from the oven, allow it to cool and place it into a water impermeable container or bag along with desiccants. Make sure that the container or bag is completely sealed.

Any material that you have oven-dried is slightly more brittle than normal.Remember,Handle the material with care.Only then can you achieve the superior results with your properly dry print material.

Source:

https://all3dp.com/2/filament-spool-8-ways-to-safely-store-your-filament/

https://rigid.ink/blogs/news/how-to-dry-your-filament?_pos=30&_sid=f8cdf3be6&_ss=r

0 notes

Photo

12 most innovative 3D printing materials.

When it comes to 3D printing, it’s hard to ignore the various types of materials it leverages: plastics, metals, ceramics and etc. There are, however, plenty of “raw” materials that will leave you wondering: “how is this even possible?” In light of this, 3Dnatives has chosen 12 of the most unusual 3D printing materials, which will blow you away.

TOP1- Edible filament

At the mention of chocolate, a smile naturally appears on people’s faces. So I should tell you that it is possible to 3D print chocolate using FDM technology:chocolate is extruded through the nozzle onto the bed layer by layer. The process is slow and takes a long time, for the printing temperature is relatively low (this is to preserve the flavor of the chocolate).

TOP2-Dust to dust, dust to …a statue?

Everyone wants to be remembered in one way or another after they perish. The Chinese artist ZhuFei fulfills such wish with a unique idea. He uses the ashes as material to 3D print a statue of the deceased. The whole process takes only three hours, after which the family can leave with the statue. The idea is outrageous, but it could help people retain memories of loved ones they lost.

TOP3-Beer is not only drinkable but also used to make long fiber!

An American fibre producer, best known for its biomaterials based on coffee and hemp, recently developed a long fiber made from beer. The long fibers have the natural color of beer, and the main materials are PLA and waste product from beer brewing. The 500g/roll of long fiber that 3D-Fuel sells costs $39.99 (about £32). Now you can make a beer mug out of your favorite beer. It’s amazing!

TOP4- Sand and Sahara

S&S (initials) is a 3D printer type invented by Kay,whose goal is to make 3D printers meet the needs of resource conservation. The printer is based on laser sintering technology, which leverages solar radiation to heat and melt materials made of sand and gravel collected in the desert.

TOP5- Art of granulated sugar

Sugar( in the form of a powder) was first used as material for 3D printing by a US firm. The company wanted to demonstrate its printer’s capabilities by using 3D-printed sugar to decorate the Chateau DE Versailles cake. A few months before, Victor Leugn, an MIT student, teamed up with a Chinese company to create a 3D sugar sculpture. Drawing inspiration from glass production, Victor discovered that the properties of sugar and glass are very similar.

TOP6- Recycle car tires

The United States scraps more than 259 million tires a year, making it a major global polluter. To solve this problem, a California-based company decided to reuse them by turning them into raw materials for 3D printing. Using selective laser sintering(SLS) and the powder from recycled tyres, they have made an object called Rubber Pouff, which they believe could be replicated in other companies.

TOP7- Dough progress

Italian manufacturer B(initials) has presented their first 3D pasta printer. This printer can print pasta in 2 minutes. The machine is aimed at restaurants, and the manufacturer says it’s perfect for restaurants and pasta lovers. The printing materials are water and flour. The 3D printes is based on FDM technology, and the batter is stacked layer by layer on the print bed to form the desired shape. The machine is still in the prototype stage, and is expected to be ready later this year,according to the manufacturer.

TOP8- Glass crystals

An Israeli company (in collaboration with MIT)demonstrated 3D glass printing a few months ago and the technology is ready for commercialization. Glass has excellent biological compatibility, and is easy to sterilize for medicine and aviation applications. To meet transparency requirements, the printer needs to be heated to 1640°C (2984°F). The process is based on FDM technology and the high temperature will have certain limitation to the whole production.

TOP9- Chewing gum

Chia-ling Lin and Maria Nelson set up the first UK company to 3D print chewing gum.The machine is called GumJet, a typical 3-axis FDM printer, but with different materials. So what are the ingredients? As you probably already know from the title, gum balls. During the printing process, various flavorings are added to the gumball to achieve different flavors. According to the designers, the 3D printed gum tastes the same as traditional gum, with a special texture that you will know in your first try.

TOP10-Who says corks can only be used to fill wine bottles?

Corks are usually used as stoppers for wine bottles (about 80% of corks are used as stoppers). A Dutch firm has found another use for it: cork fibre for 3D printing. The material, called CorkFill, can be used in any FDM 3D printer without special technical requirements such as temperature. This fibre is normally printed at 210°-230° C (410° -446° F).

TOP11- Re-creation of bamboo

After fibrils, a Netherland based company is targeting bamboo, a plant normally associated with pandas that flourish in China’s mountain forests. Bamboo is hollow and grows fast. The material, called BabooFill, is a blend of PLA/PHA and bamboo fibers, 100% organic, cohesive and isotropic, and has a nice smell, and the taste is similar to that of popcorn.

TOP12- Flax and fiber

A French design company, is innovating around flax. They designed flax based 3D-printed fibers that can be used in a variety of contexts, such as architecture, recreation and 3D printing. The fiber, which is based on PLA, is biodegradable and compatible with most FDM 3D printers. It is more durable and flexible than plastic, and each printed layer is thinner than that of plastic, reducing the overall weight of the print.

Disclaimer: this article is based on a Chinese post on xincailiao. The views expressed herein are those of the author alone.Geeetech makes no representations or warranties of any kind, expressed or implied, as to the accuracy, reliability or completeness of the content. The content of this article is for reference only and does not constitute any investment and application suggestions.Geeetech shall not be liable for any loss , damage,claim, injury of any kind resulting from any error(s),omission(s) in this artical post.

#3d printing#3d printing technology#3dprinter#3d printing material#3d printing filament#3d printing application#3d printing industtry#desktop3dprinter#additive manufacturing#Geeetech#innovation#creativity

0 notes

Photo

Lightning Deal, Amazon UK only

Geeetech filaments black&white: 5% off

Discount price: £18.55 (you save £6.46) Limited time offer: Aug 17, 2020 - Aug 23, 2020 Link:https://amzn.to/3d3it9H

0 notes