#Dielectric Filter

Text

0 notes

Text

Dielectric Filter Market Is Estimated To Witness High Growth Owing To Rising Demand for High-performance Filters

The global Dielectric Filter Market is estimated to be valued at US$ 2.73 Billion In 2023 and is expected to exhibit a CAGR of 7.5% over the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

Dielectric filters are electronic devices that allow the passage of certain frequencies while restricting the passage of others. These filters are widely used in various applications such as wireless communication, military, consumer electronics, and aerospace, among others. Dielectric filters offer several advantages, including high-quality performance, compact size, and low insertion loss. With the increasing demand for high-performance filters in wireless communication networks and electronic devices, the Dielectric Filter Market is expected to witness significant growth in the coming years.

Market Key Trends:

The key trend driving the Dielectric Filter Market Filter Market is the rising demand for high-performance filters in wireless communication networks. With the growing adoption of smartphones, tablets, and other wireless devices, the demand for faster data speeds and reliable connectivity is increasing. Dielectric filters play a crucial role in improving the performance of wireless communication networks by reducing interference and increasing signal quality. Moreover, the increasing deployment of 5G technology is expected to further drive the demand for dielectric filters with higher frequency capabilities. In addition, the growing adoption of advanced technologies such as Internet of Things (IoT) and smart devices is also fueling the demand for dielectric filters in various applications. Overall, the Dielectric Filter Market is poised to witness high growth in the coming years due to the increasing need for high-performance filters in wireless communication networks and electronic devices.

Key Takeaways:

The global dielectric filter market is expected to witness high growth, exhibiting a CAGR of 7.5% over the forecast period (2023-2030). This growth can be attributed to the increasing demand for wireless communication and the adoption of advanced technologies. The market size for 2023 is projected to reach US$ 2.73 billion.

In terms of regional analysis, North America is anticipated to be the fastest-growing and dominating region in the dielectric filter market. This can be attributed to the presence of key market players, technological advancements, and the high adoption rate of 5G technology in this region.

Key players operating in the dielectric filter market include Murata Manufacturing Co., Ltd., TDK Corporation, Qorvo, Inc., Broadcom Inc., Skyworks Solutions, Inc., and AVX Corporation, among others. These companies are focusing on product innovations, strategic partnerships, and mergers & acquisitions to strengthen their market position and meet the growing demand for dielectric filters.

Overall, the dielectric filter market is expected to witness significant growth in the coming years due to technological advancements, increasing demand for wireless communication, and the adoption of advanced technologies like 5G and IoT. The key players in this market are actively investing in research and development activities to introduce innovative products and gain a competitive edge in the market.

#Dielectric Filter Market#Dielectric Filter Market Demand#Dielectric Filter Market Trend#Information and Communication Technology

0 notes

Text

Shaping the Future: Innovations in the Dielectric Filter Market

The world of technology is in a constant state of evolution, and the dielectric filter market is no exception. As industries increasingly rely on efficient communication systems, the demand for dielectric filters continues to rise. These filters play a crucial role in enabling seamless wireless communication, making them a focal point for innovation in the tech world.

Innovations within the dielectric filter market are centered around improving performance, miniaturization, and adaptability to new communication standards. One of the most significant developments is the integration of dielectric filters into 5G networks. As 5G technology gains traction, the demand for filters that can handle higher frequencies and data rates has intensified. Innovators are working to design filters that maintain low insertion loss and high selectivity while accommodating the complexities of 5G infrastructure.

Moreover, the Internet of Things (IoT) is another driving force behind innovations in the dielectric filter market. As billions of devices become interconnected, the need for reliable and efficient communication becomes paramount. Dielectric filters with improved bandwidth and interference rejection capabilities are being developed to ensure that IoT devices can operate seamlessly in diverse environments.

The Dielectric Filter Market is expanding due to increased demand for better frequency control and signal filtering solutions in various sectors. Dielectric filters serve an important role in increasing the performance and efficiency of electronic circuits by selectively admitting or blocking specific frequencies. These filters are frequently utilized in applications such as wireless communication systems, satellite communications, radar systems, and high-frequency electrical equipment. The expanding adoption of wireless communication technologies, the expansion of 5G networks, and the increasing necessity for high-quality signal transmission are boosting demand for dielectric filters.

Furthermore, advancements in material science are contributing to the evolution of dielectric filters. Researchers are exploring novel materials that offer better thermal stability, reduced signal loss, and improved durability. These materials not only enhance the performance of filters but also enable their integration into a broader range of applications, from satellite communications to medical devices.

In the realm of manufacturing, innovations are focused on streamlining production processes and reducing costs. Additive manufacturing techniques, such as 3D printing, are being explored to create complex filter structures with high precision. This not only accelerates prototyping but also enables the production of customized filters tailored to specific applications.

The Treasury Management Market is likely to expand rapidly in the future years. The global treasury management system market was valued at $5.10 billion in 2023 and is predicted to grow to $12.60 billion by 2030. During the forecast period, the market is expected to expand at a CAGR of 13.8%. A variety of factors are driving the growth of the treasury management industry. These include the increasing complexity of treasury operations, the need for increased efficiency and control, and the growing demand for real-time information.

However, along with these innovations come challenges that need to be addressed. One key challenge is maintaining signal integrity as frequencies continue to rise. Higher frequencies can lead to increased losses and interference, necessitating innovative design approaches and advanced materials.

Another challenge lies in ensuring compatibility with existing communication systems. As new filter technologies emerge, it's essential to ensure that they can seamlessly integrate with established networks and devices without causing disruptions.

#Dielectric Filter Market#Dielectric Filter Market demand#Dielectric Filter Market values#Dielectric Filter Market analysiss#Coherent Market Insights

0 notes

Text

Capacitor Tester: A Crucial Tool for Electronics Troubleshooting

Capacitors are fundamental components in nearly all electronic devices, storing and releasing electrical energy as needed. Over time, capacitors can degrade, fail, or develop faults, leading to malfunctioning circuits or complete system breakdowns. To diagnose issues related to capacitors, electronic engineers and technicians use a specialized tool known as a capacitor tester.

A capacitor tester is an essential piece of equipment for anyone working with electronics. It measures a capacitor’s capacitance, and often other parameters such as Equivalent Series Resistance (ESR) or leakage current, to ensure the component is functioning properly. In this article, we'll explore what a capacitor tester is, how it works, different types of testers, and why it’s an invaluable tool for anyone involved in electronics repair and maintenance.

What is a Capacitor?

Before diving into capacitor testers, it’s important to understand the role of capacitors in an electrical circuit. A capacitor is a passive electrical component that stores energy in an electric field. It consists of two conductive plates separated by an insulating material (called the dielectric). When a voltage is applied across the plates, electric charge accumulates on them, and the energy is stored in the electric field created by the charge difference.

Capacitors have many uses in electronics, such as:

Smoothing the output of power supplies.

Filtering signals in audio and RF circuits.

Storing energy in flash photography or power backup systems.

Timing in oscillators and clocks.

Capacitors vary widely in capacitance values, typically measured in farads (F), but most practical capacitors used in everyday electronics operate in microfarads (µF), nanofarads (nF), or picofarads (pF).

The Need for Capacitor Testing

Over time, capacitors can degrade due to age, heat, voltage spikes, or physical damage. When a capacitor fails or becomes weak, it can lead to symptoms such as:

Power supply instability or failure.

Unwanted noise or distortion in audio circuits.

Loss of timing or frequency control in oscillators.

General malfunctioning of electronic devices.

In many cases, faulty capacitors don’t exhibit visible signs of failure, making it difficult to diagnose issues just by looking at the component. A capacitor tester is used to identify whether a capacitor is functioning properly or if it has degraded, helping technicians isolate and fix the problem.

What is a Capacitor Tester?

A capacitor tester is a specialized tool used to measure various characteristics of a capacitor to determine if it is operating within its specified parameters. The most common function of a capacitor tester is to measure the capacitance of a component, which is the amount of electrical charge it can store for a given voltage. Many capacitor testers can also measure other critical parameters such as:

Equivalent Series Resistance (ESR): A measure of the internal resistance of the capacitor, which can increase as the capacitor ages or becomes damaged.

Leakage Current: The current that flows through a capacitor when it should ideally act as an insulator. High leakage current indicates a degraded capacitor.

Voltage Rating: Some testers can apply a voltage to a capacitor to check whether it can hold the rated voltage without breaking down.

Types of Capacitor Testers

There are different types of capacitor testers available, ranging from basic handheld devices to advanced benchtop models. The type of tester required depends on the specific needs of the user and the level of detail needed for the diagnosis.

1. Handheld Digital Multimeters with Capacitance Mode

Many digital multimeters (DMMs) include a capacitance measurement mode, which allows users to measure the capacitance value of a capacitor directly. While DMMs with capacitance mode are convenient for basic testing, they typically cannot measure ESR or leakage current, which are critical in identifying aging or faulty capacitors.

Advantages:

Affordable and widely available.

Suitable for quick checks of capacitance values.

Limitations:

Limited to measuring capacitance only.

Not as accurate as dedicated capacitor testers for diagnosing faults such as high ESR or leakage current.

2. Dedicated Capacitance Meters

A dedicated capacitance meter is a tool designed specifically to measure the capacitance of a capacitor. These devices are more accurate than multimeters with capacitance functions, and they often provide better resolution for small capacitance values.

Advantages:

Higher accuracy and better resolution.

Useful for measuring a wide range of capacitance values.

Limitations:

Typically measures capacitance only, without ESR or leakage testing.

3. ESR Meters

ESR meters are specialized devices designed to measure the Equivalent Series Resistance of a capacitor. ESR is a critical parameter because even if the capacitance value remains within spec, a high ESR can severely affect the performance of the capacitor, especially in high-frequency circuits. High ESR can lead to overheating and inefficiency in power supplies or signal distortion in audio circuits.

Advantages:

Essential for testing capacitors in circuits where low ESR is critical.

Can diagnose aging capacitors without needing to remove them from the circuit in some cases.

Limitations:

Measures ESR only, so additional tools may be needed to measure capacitance.

4. LCR Meters

LCR meters are versatile devices that can measure inductance (L), capacitance (C), and resistance (R) in electronic components. These meters are typically used in more advanced electronics troubleshooting and design. High-end LCR meters can measure capacitance, ESR, and other key parameters, offering a comprehensive view of the capacitor’s performance.

Advantages:

Versatile tool for advanced users.

Provides accurate measurements of capacitance, ESR, and other parameters.

Limitations:

More expensive and often bulkier than handheld testers.

How to Use a Capacitor Tester

Using a capacitor tester is generally a straightforward process, though the exact steps can vary depending on the type of tester and the capacitor being tested. Below is a basic guide for testing a capacitor:

Discharge the Capacitor: Before testing, ensure that the capacitor is fully discharged to avoid any dangerous voltages. This can usually be done by shorting the capacitor leads with a resistor.

Set the Tester to Capacitance Mode: If using a digital multimeter or dedicated capacitance meter, set the device to the appropriate measurement range.

Connect the Capacitor: Attach the leads of the tester to the terminals of the capacitor. Ensure proper polarity if testing electrolytic capacitors.

Read the Measurement: The tester will display the capacitance value. Compare this value to the capacitor’s rated capacitance to determine if it is within an acceptable range.

Check ESR (Optional): If using an ESR meter, follow the same procedure to measure the Equivalent Series Resistance and compare it to the acceptable range for the capacitor.

The Importance of ESR Testing

While capacitance is the most obvious characteristic to test, ESR often reveals issues that capacitance testing alone may miss. A capacitor with high ESR may still show the correct capacitance value, but its performance in a circuit will be impaired due to internal resistance. Testing for ESR is particularly important in circuits like power supplies, where even a small increase in ESR can cause overheating and failure.

Conclusion

A capacitor tester is an invaluable tool for anyone involved in electronics, from hobbyists to professional technicians. Whether you are troubleshooting a malfunctioning circuit or performing preventive maintenance, capacitor testers provide critical insight into the health and performance of capacitors. With the ability to measure capacitance, ESR, and other key parameters, these devices help ensure that electronic systems continue to function reliably. By catching faulty capacitors early, you can avoid system failures and keep your devices running smoothly.

#capacitance#Inductance#ElectricalCircuits#Electronics#CircuitDesign#Capacitors#Inductors#ElectricalEngineering#CircuitTheory#EngineeringBasics#TechEducation#ElectronicsFundamentals#PowerManagement#SignalProcessing#ElectronicComponents

1 note

·

View note

Text

HVDC Capacitor Market Outlook, Size, Growth, Price, Latest Trends & Industry Forecast 2032

HVDC (High Voltage Direct Current) capacitors are integral components in high-voltage transmission systems, enabling efficient energy transfer over long distances with minimal loss. These capacitors store and regulate electrical energy, helping to stabilize and filter voltage fluctuations in HVDC systems. HVDC technology is becoming increasingly critical for modern energy grids, especially as renewable energy sources like wind and solar require stable long-distance transmission. HVDC capacitors ensure the reliability and efficiency of these systems, contributing to the optimization of energy infrastructure and supporting the global shift toward clean energy solutions.

The HVDC Capacitor Market size was $ 6.80 Billion in 2023 & expects a good growth by reaching USD 22.47 billion till end of year2032 at CAGR about 14.23 %during forecast period 2023-2032.

Future Scope

The demand for HVDC capacitors is set to grow as the energy sector continues to modernize and expand its reliance on renewable energy sources. With the increasing deployment of offshore wind farms and solar energy installations, HVDC systems will be essential for integrating these decentralized energy sources into the grid. Advances in capacitor technology, including higher energy density and greater durability, will further enhance the performance of HVDC systems. Additionally, the ongoing development of ultra-high voltage direct current (UHVDC) transmission systems will drive the need for capacitors capable of operating at even higher voltages and providing greater efficiency.

Trends

Key trends in HVDC capacitor technology include the rise of modular multilevel converters (MMCs), which enhance the scalability and efficiency of HVDC systems. Another trend is the use of environmentally friendly dielectric materials in capacitors, reducing their ecological impact while improving performance. The growing adoption of renewable energy sources is driving investment in HVDC infrastructure, and capacitors are being optimized for long-distance, high-efficiency energy transmission. Furthermore, advancements in digital monitoring systems allow for real-time condition monitoring of HVDC capacitors, improving maintenance practices and extending the lifespan of these critical components.

Applications

HVDC capacitors are primarily used in high-voltage direct current transmission systems, where they help maintain voltage stability and regulate power flow. These capacitors are essential for transmitting electricity over long distances with minimal loss, making them ideal for connecting remote renewable energy installations, such as offshore wind farms, to the power grid. HVDC capacitors are also used in industrial applications that require stable and efficient power supplies, such as in manufacturing plants and large-scale data centers. Additionally, they play a crucial role in the integration of renewable energy into existing grid systems, ensuring smooth and reliable power transmission.

Solutions and Services

Providers of HVDC capacitor solutions offer a range of products designed to meet the specific needs of high-voltage transmission systems. These solutions include capacitors with advanced dielectric materials that provide higher energy density and longer operational lifetimes. Service providers also offer installation, maintenance, and monitoring services to ensure that HVDC capacitors function optimally throughout their lifecycle. Condition monitoring systems are available, enabling real-time tracking of capacitor health and performance, allowing for predictive maintenance and reducing the risk of system failure.

Key Points

HVDC capacitors are essential for long-distance, high-efficiency power transmission.

Renewable energy integration and offshore wind farms drive demand for HVDC systems.

Trends include modular multilevel converters and environmentally friendly materials.

Applications include high-voltage transmission, renewable energy grids, and industrial power supply.

Solutions include advanced capacitors with real-time monitoring and maintenance services.

Read More Details: https://www.snsinsider.com/reports/hvdc-capacitor-market-4088

Contact Us:

Akash Anand — Head of Business Development & Strategy

Email: [email protected]

Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

0 notes

Text

Shreem Cylindrical Gas Filled Capacitors, Distributor, Supplier, Mumbai, India

Shree Trading Syndicate is The House Of Capacitors, Supplier, Dealer And Authorised Distributors Of Shreem Cylindrical Gas Filled Capacitors, Power Capacitors, LV Capacitors, Mumbai, India.

Capacitor, Capacitors, Power Capacitor, Power Capacitors, CV Capacitor, CV Capacitors, Epcos Capacitor, Epcos Capacitors, Epcos Round Capacitor, Epcos Square Capacitor, Epcos Oil Filled Capacitor, Epcos Gas Filled Capacitor, Epcos Phasecap Super Heavy Duty Capacitor, Epcos Capacitor Duty Contactors, Epcos Thyristor Duty Switching, Epcos Reactors, Detuned Pfc, Epcos Active Harmonic Filters, Epcos Apfc Panels, Buffer Card, Automatic Power Factor Relay, Epcos Power Factor Correction, Epcos APFC Relay BR4000, Epcos APFC Relay BR5000, Epcos APFC Relay BR6000, Epcos APFC Relay BR7000, Epcos APFC Relay BR5100, New BR4000 ER Relay, Epcos BR4000 ET Relay, Jaivc Power Capacitors, Jaivc Power Capacitors, MPP Oil Filled Capacitors, MPP Dry Capacitors, MPP Cylindrical Capacitors, MPP Square MFD Capacitors, APP LT Capacitors, HT App Shunt Capacitors, Jaivc AC Capacitors, Fan Capacitors, Motor Start Capacitors, Motor Run Capacitors, Tibcon AC Capacitors, AC Capacitors, Fan and Motor Run Capacitors, Submersible Pump Capacitors, Air Conditioning Capacitors, ESTAdry ACMKP Capacitors, ESTAprop ACMKP Capacitors, Low Voltage Power Factor Correction Capacitors, Shreem Power Capacitor, LV Capacitors, Cylindrical Jelly Filled Capacitors, Cylindrical Gas Filled Capacitors, Cylindrical Heavy Duty Capacitors, Box Type Capacitors, Heavy Duty Double Dielectric Capacitors, Agristar Capacitors, APP Type Capacitors, Ultra Heavy Duty Capacitors, Unistar Capacitor, High Voltage Capacitors, Low Voltage Capacitor, Keltron Capacitor, AC Motor Start Capacitor, Aluminium Electrolytic Motor Start Capacitors, MPP Capacitor, Priya Capacitors, Capacitors for Fan, Capacitors for Motors, Capacitors for Lighting Fixture, Electrolytic Capacitors, LT Power Factor Capacitors, Mumbai, Maharashtra, India.

#Capacitor#Capacitors#Power Capacitor#Power Capacitors#CV Capacitor#CV Capacitors#Epcos Capacitor#Epcos Capacitors#Epcos Round Capacitor#Epcos Square Capacitor#Epcos Oil Filled Capacitor#Epcos Gas Filled Capacitor#Epcos Phasecap Super Heavy Duty Capacitor#Epcos Capacitor Duty Contactors#Epcos Thyristor Duty Switching#Epcos Reactors#Detuned Pfc#Epcos Active Harmonic Filters#Epcos Apfc Panels#Buffer Card#Automatic Power Factor Relay#Epcos Power Factor Correction#Epcos APFC Relay BR4000#Epcos APFC Relay BR5000#Epcos APFC Relay BR6000#Epcos APFC Relay BR7000#Epcos APFC Relay BR5100#New BR4000 ER Relay#Epcos BR4000 ET Relay#Jaivc Power Capacitors

0 notes

Text

How to Test A Capacitor: Application and Capacitor Testing with LISUN LS6586 Capacitor Leakage Current Tester in Automated Equipment

Introduction

Capacitors are ubiquitous components in electronic circuits, critical for various functions such as energy storage, signal filtering, and voltage regulation. In automated equipment, the reliability of capacitors is paramount, as their failure can lead to significant system disruptions. To ensure their reliability, capacitors must undergo rigorous testing, including leakage current tests, which are essential for assessing the health and performance of these components.

The LISUN LS6586 Capacitor Leakage Current Tester is a state-of-the-art instrument designed specifically for testing the leakage current of capacitors. Leakage current is an important parameter that helps identify potential issues such as dielectric breakdown, contamination, or aging in capacitors. This paper explores the process of testing capacitors with the LISUN LS6586 and its application in automated equipment testing, providing detailed insights into its features, benefits, and practical use cases.

Understanding Capacitor Testing

Importance of Testing Capacitors

Capacitors play a vital role in electronic circuits by storing electrical energy and releasing it when needed. They are used in various applications, from power supplies and signal processing to filtering noise in electronic devices. However, capacitors can fail due to various reasons, including dielectric breakdown, physical damage, or aging. Such failures can lead to significant issues in electronic circuits, making it crucial to test capacitors before they are deployed in any system.

Common Testing Methods

Testing capacitors involves several methods, each designed to assess different aspects of a capacitor’s performance:

• Capacitance Measurement: This test measures the capacitor’s ability to store charge. It is the most basic test to ensure the capacitor is functioning as intended.

• Equivalent Series Resistance (ESR) Measurement: This test measures the internal resistance of the capacitor, which affects its performance at high frequencies.

• Insulation Resistance Test: This test checks the resistance between the capacitor’s plates, ensuring that the insulation material is not compromised.

• Leakage Current Test: This test measures the small current that leaks across the dielectric material when a voltage is applied. This is a critical test for assessing the long-term reliability of the capacitor.

Among these, the leakage current test is particularly important for identifying subtle issues that might not be apparent through other testing methods. The LISUN LS6586 is specifically designed for this purpose, providing accurate and reliable measurements of leakage current.

LISUN LS6586: Features and Benefits

Key Features

The LISUN LS6586 Capacitor Leakage Current Tester offers several advanced features that make it ideal for both laboratory and industrial applications:

• High Measurement Accuracy: The LS6586 provides precise measurements of leakage current, even at very low levels, making it suitable for testing a wide range of capacitors.

• Wide Voltage Range: The instrument supports a wide range of testing voltages, accommodating different types of capacitors used in various applications.

• Automated Testing Capabilities: The LS6586 can be integrated into automated testing setups, allowing for the efficient testing of large batches of capacitors.

• Data Logging and Analysis: The device can record test results, which can be analyzed to track the performance of capacitors over time, providing valuable insights for quality control.

• User-Friendly Interface: The LS6586 features an intuitive interface, making it easy to operate even for users with limited experience.

Benefits in Automated Equipment Testing

• Improved Efficiency: The ability to automate testing with the LS6586 significantly reduces the time required for capacitor testing, which is especially beneficial in high-volume manufacturing environments.

• Enhanced Reliability: By providing accurate and consistent measurements, the LS6586 helps ensure that only capacitors meeting the required specifications are used in automated equipment, thereby enhancing the overall reliability of the system.

• Cost Savings: Early detection of defective capacitors can prevent costly system failures and downtime, saving both time and money.

• Compliance with Industry Standards: The LS6586 allows for testing according to various industry standards, ensuring that capacitors used in critical applications meet the necessary safety and performance requirements.

LS6586_Capacitor Leakage Current Tester

How to Test a Capacitor Using LISUN LS6586

Testing a capacitor using the LISUN LS6586 involves the following steps:

Preparation:

• Ensure the capacitor is properly connected to the tester.

• Set the desired testing voltage on the LS6586 according to the capacitor’s rated voltage.

• Select the appropriate test mode on the device, typically the leakage current test mode.

Testing:

• Apply the test voltage to the capacitor.

• The LS6586 will measure the leakage current flowing through the capacitor.

• The test results, including the leakage current value, will be displayed on the device’s screen.

Analysis:

• Compare the measured leakage current with the acceptable limits for the specific capacitor type.

• If the leakage current exceeds the acceptable range, the capacitor may be defective and should be discarded.

Data Logging:

If necessary, record the test results using the LS6586’s data logging feature for further analysis or quality control documentation.

Interpretation of Results

• Low Leakage Current: A low leakage current indicates that the capacitor’s dielectric material is intact and the capacitor is likely to perform reliably in the circuit.

• High Leakage Current: A high leakage current suggests potential issues with the capacitor, such as dielectric degradation or contamination, which could lead to premature failure in the circuit.

Regular testing with the LISUN LS6586 helps in identifying and rejecting defective capacitors before they are integrated into automated equipment, thereby preventing potential failures.

Application Scenarios in Automated Equipment

1. Automotive Electronics

Capacitors are widely used in automotive electronics, including in power management systems, infotainment systems, and advanced driver-assistance systems (ADAS). These systems often operate under harsh conditions, such as extreme temperatures and voltage fluctuations. The LS6586 can be used to test the leakage current of capacitors used in these systems, ensuring their reliability and durability in challenging environments.

2. Industrial Automation

In industrial automation, capacitors are used in motor drives, power supplies, and control systems. These components are critical for the continuous and efficient operation of automated machinery. The LS6586 can be integrated into automated testing systems to regularly monitor the leakage current of capacitors, ensuring they remain within acceptable limits and preventing unexpected system failures.

3. Consumer Electronics Manufacturing

In the production of consumer electronics, such as smartphones, tablets, and home appliances, capacitors are essential components that must meet strict quality standards. The LS6586 can be used to perform batch testing of capacitors in manufacturing plants, ensuring that only high-quality components are used in final products, thereby enhancing product reliability and customer satisfaction.

4. Aerospace and Defense

Aerospace and defense systems rely on capacitors for various critical applications, including power distribution, signal processing, and communication systems. In these high-stakes environments, capacitor failure is not an option. The LS6586 allows for rigorous testing of capacitors to ensure they meet the stringent reliability and performance standards required in aerospace and defense applications.

5. Renewable Energy Systems

Capacitors are integral components in renewable energy systems, such as solar inverters and wind turbine controls. These systems operate under varying environmental conditions, making it essential to regularly test the capacitors to ensure long-term reliability. The LS6586 can be used to test capacitors for leakage current, helping to maintain the efficiency and reliability of renewable energy systems.

Conclusion

The LISUN LS6586 Capacitor Leakage Current Tester is an invaluable tool for ensuring the quality and reliability of capacitors used in automated equipment. Its high accuracy, wide voltage range, and automated testing capabilities make it an ideal choice for various industries, including automotive, industrial automation, consumer electronics, aerospace, and renewable energy.

By integrating the LS6586 into automated testing setups, manufacturers can significantly enhance their quality control processes, ensuring that only the best capacitors are used in their products. This not only improves the reliability of automated equipment but also helps in reducing costs associated with failures and downtime.

In conclusion, the LISUN LS6586 plays a crucial role in the capacitor testing process, providing the precision and reliability needed to maintain the performance and longevity of modern electronic systems. As the demand for high-quality capacitors continues to grow, the importance of accurate and reliable testing will only increase, making the LS6586 an indispensable tool for the future of automated equipment testing.

Read the full article

0 notes

Text

Harley FatBoy: Common Problems and Solutions

The Harley Davidson FatBoy is an iconic motorcycle known for its powerful performance and distinctive style. However, like any vehicle, it can experience issues that riders should be aware of.

In this article, we'll explore some common problems associated with the Harley Fat Boy and provide practical solutions to keep your ride smooth and enjoyable.

1. Electrical Issues

Symptoms

Difficulty starting the bike

Flickering lights

Inconsistent signals from the dashboard

Causes

Electrical problems in the Fat Boy can stem from corroded connections, faulty wiring, or a weak battery.

Solutions

Check the Battery: Ensure your battery is charged and in good condition. Replace it if it shows signs of wear or weakness.

Inspect Connections: Clean and tighten all electrical connections to prevent corrosion. Use dielectric grease to protect connectors.

Diagnose Wiring Issues: If problems persist, consider having a professional check for damaged wiring or faulty components.

2. Fuel System Problems

Symptoms

Rough idling

Poor acceleration

Decreased fuel efficiency

Causes

Fuel system issues can arise from clogged fuel injectors, a dirty air filter, or a failing fuel pump.

Solutions

Clean Fuel Injectors: Use a quality fuel injector cleaner periodically to keep your injectors free of deposits.

Replace Air Filter: Regularly check and replace your air filter to ensure optimal airflow.

Inspect Fuel Pump: If problems continue, have the fuel pump tested for proper function.

3. Transmission Issues

Symptoms

Difficulty shifting gears

Slipping out of gear

Unusual noises during gear changes

Causes

Transmission problems may result from low fluid levels, worn clutch components, or damaged gears.

Solutions

Check Fluid Levels: Regularly check and top off transmission fluid as needed. Low levels can cause shifting problems.

Inspect the Clutch: If the clutch feels spongy or engages poorly, it may need adjustment or replacement.

Seek Professional Help: For serious transmission issues, consult a mechanic to assess and repair the problem.

4. Brake Problems

Symptoms

Spongy or unresponsive brakes

Uneven brake wear

Squeaking or grinding noises

Causes

Brake problems can stem from worn brake pads, low fluid levels, or air in the brake lines.

Solutions

Replace Brake Pads: Check your brake pads regularly and replace them when they show significant wear.

Flush Brake Fluid: Change the brake fluid according to the manufacturer's recommendations to keep the system functioning properly.

Bleed the Brakes: If you suspect air in the lines, bleed the brakes to restore responsiveness.

5. Tire Wear and Maintenance

Symptoms

Uneven wear patterns

Vibration during rides

Loss of traction

Causes

Improper tire pressure, misalignment, or poor suspension can lead to tire wear and affect handling.

Solutions

Check Tire Pressure: Maintain the recommended tire pressure for optimal performance and safety.

Inspect for Alignment Issues: Have your motorcycle's alignment checked if you notice uneven tire wear or handling issues.

Rotate Tires: Regularly rotate your tires to promote even wear and extend their lifespan.

Conclusion

While the Harley Davidson Fat Boy is a reliable and enjoyable motorcycle, being aware of common problems can help you maintain its performance and extend its life. Regular maintenance and timely repairs are crucial to keeping your Fat Boy in top shape.

Always consult your owner’s manual for specific maintenance schedules, and don’t hesitate to seek professional assistance when needed. By addressing these common issues, you can continue to enjoy the thrill of riding your Harley Fat Boy for years to come.

0 notes

Text

Capacitors in PE Power

Capacitors in PE Power are one of the most important exam topics. But why? The reason is their notable usage and importance in regulating and improving the Power circuits. Capacitors in PE Power involve studying their types, behavior, and uses in AC and DC circuits.

This detailed study guide on Capacitors in PE Power will help you cover this topic in complete detail as per the NCEES® exam guidelines and roadmap. Let’s start with the fundamentals.

Capacitors and Their Importance in Power Circuits

A capacitor is a passive electronic component that stores electrical energy in an electric field. It consists of two conductors separated by an insulator, known as a dielectric.

The capacity of a capacitor to store charge is measured in farads (F). It is determined by the physical characteristics of the capacitor, including the area of the plates, the separation distance between the plates, and the dielectric material used.

Capacitors are used in circuits for various reasons. Let’s discuss a few important uses in a nutshell.

Harmonic Mitigation with Capacitors: Capacitors are used in power systems to mitigate harmonics by creating resonant circuits that filter out specific harmonic frequencies. This is achieved by tuning the capacitor and inductor combinations to resonate at unwanted harmonic frequencies, thereby reducing their presence in the power system.

Capacitors and Voltage Fluctuations: Capacitors help stabilize voltage fluctuations in power systems by providing reactive power compensation. When connected to a power network, capacitors can absorb or release reactive power, which helps maintain a more consistent voltage level, especially in systems with fluctuating loads or significant inductive components.

Capacitors and Line Loss Reduction: By providing reactive power locally, capacitors reduce the need to transport reactive power over long distances in power lines, thus reducing line losses. This improves the efficiency of power transmission and distribution networks, as it decreases I²R losses (where I is current and R is resistance) in the conductors

Types of Capacitors

Capacitors come in various types and classifications, each suited for specific applications and characteristics. Here’s a detailed overview of the different kinds and classifications of capacitors:

· Electrolytic Capacitors

Aluminum Electrolytic Capacitors: They are known for their high capacitance-to-volume ratio; these capacitors use an aluminum oxide film and an electrolytic solution. They are polarized, meaning they must be connected with the correct polarity. Commonly used in power supply filtering applications.

Tantalum Electrolytic Capacitors: They are smaller and more stable than aluminum types; they have a lower risk of leakage and are more reliable. Tantalum capacitors are also polarized and are used in space-constrained applications like mobile phones and laptops.

· Ceramic Capacitors

Multilayer Ceramic Capacitors (MLCCs): They are composed of alternating layers of metal and ceramic and offer a compact and non-polarized size. Used in a wide range of applications, from high-frequency to general electronic circuits.

Disc Ceramic Capacitors: They are often used for noise suppression and are non-polarized. They are suitable for relatively low capacitance requirements.

For more information visit here: https://www.studyforfe.com/blog/capacitors/

0 notes

Text

How Thin Film Coating Improves the Performance of Optical Devices

Thin Film Coating has revolutionized the field of optics, enhancing the performance and durability of a wide range of optical devices. From improving the efficiency of lenses and mirrors to enabling advanced functionalities in IR optics, thin film coatings are indispensable in modern optical technology.

At its core, Thin Film Coating involves depositing layers of material onto a substrate to alter its optical properties. These coatings can be tailored to reflect, transmit, or absorb light at specific wavelengths, making them crucial for applications that require precise control over light behavior. This capability is essential in industries ranging from telecommunications to medical imaging, where the performance of optical components can significantly impact the effectiveness and reliability of the overall system.

One of the primary benefits of thin film coatings is their ability to enhance the transmission and reflection properties of optical devices. For instance, anti-reflective coatings can reduce the amount of light lost due to reflection at the surface of a lens. By minimizing these reflections, more light passes through the lens, improving the brightness and clarity of the image. This is particularly important in applications like cameras and microscopes, where image quality is paramount.

Thin film coatings also play a vital role in IR optics. Infrared optics are used in a variety of applications, including thermal imaging, spectroscopy, and remote sensing. These devices often require coatings that can withstand harsh environmental conditions while maintaining high optical performance. Thin film coatings designed for IR optics can provide enhanced durability and resistance to abrasion, as well as improved thermal stability. This ensures that the optical components remain effective and reliable even in demanding settings.

Moreover, thin film coatings can be engineered to provide specific optical functionalities. For example, dielectric coatings, which are made from alternating layers of materials with different refractive indices, can be designed to reflect or transmit certain wavelengths while blocking others. This selective filtering capability is essential in applications like laser optics, where precise wavelength control is necessary to achieve the desired performance.

The advancements in thin film coating technology have been driven by companies like HHV Advanced Technologies, which specialize in developing innovative coating solutions for a wide range of optical applications. HHV Advanced Technologies utilizes deposition techniques to create coatings that meet the stringent requirements of modern optical devices. Their expertise in thin film coatings ensures that optical components deliver optimal performance, whether they are used in scientific research, industrial applications, or consumer electronics.

Additionally, thin film coatings contribute to the longevity and durability of optical devices. Coatings can protect the underlying substrate from environmental factors such as moisture, dust, and chemical exposure. This protective function is crucial for optical components used in outdoor or industrial environments, where they may be exposed to harsh conditions. By preventing damage and degradation, thin film coatings extend the operational life of optical devices, reducing the need for frequent replacements and maintenance.

In conclusion, thin film coatings are essential for enhancing the performance and durability of optical devices. They improve transmission and reflection properties, enable advanced functionalities, and provide protection against environmental damage. With the ongoing advancements in coating technologies by industry leaders like HHV Advanced Technologies, the capabilities of optical devices will continue to expand, driving innovation across various fields. The impact of thin film coatings on IR optics and other optical technologies underscores their significance in the modern world, where precise and reliable optical performance is more important than ever.

For more information, visit the website: https://hhvadvancedtech.com/

0 notes

Text

The Importance of Capacitors in Modern Industrial Automation

Industrial automation is transforming industries, making operations more efficient, reliable, and cost-effective. At the compassion of many of these automated systems are capacitors. These small yet powerful components are crucial for the performance and stability of industrial automation systems. This blog delves into the importance of capacitors in modern industrial automation, explaining their functions, benefits, and applications.

Understanding Capacitors

A capacitor is an electronic component that stores and releases electrical energy. It consists of two conductive plates separated by an insulating material called a dielectric. When voltage is applied, an electric field is created across the dielectric, storing energy. This energy can be quickly released when needed, making capacitors essential in managing power within electronic circuits. Capacitors come in various types, including ceramic, electrolytic, tantalum, and film capacitors, each with specific characteristics suited to different applications. In industrial automation, selecting the right capacitor type is crucial for ensuring optimal performance and longevity of the system.

Key Functions of Capacitors in Industrial Automation

Energy Storage and Release: Capacitors store energy and release it when needed, smoothing out power supply fluctuations. This capability is vital in industrial settings where power stability is crucial for continuous operations.

Power Conditioning: They help in conditioning the power supply by filtering out noise and stabilizing voltage levels. This ensures that sensitive electronic components receive a clean and stable power supply, reducing the risk of damage and improving reliability.

Signal Filtering: Capacitors are used in filter circuits to remove unwanted frequencies from signals. This is important in communication and control systems within industrial automation, where signal integrity is dominant.

Timing and Control: In timing circuits, capacitors work with resistors to create time delays. These delays are used in various control processes, such as regulating the operation of motors and other machinery.

Power Factor Correction: Capacitors improve power factor in industrial power systems, reducing energy losses and lowering electricity costs. This is particularly important in large-scale industrial operations where energy efficiency translates to significant cost savings.

Benefits of Using Capacitors in Industrial Automation

Enhanced Efficiency: By stabilizing power supply and improving power factor, capacitors make industrial systems more efficient. This leads to lower operational costs and better utilization of energy resources.

Improved Reliability: Capacitors reduce voltage fluctuations and power noise, protecting sensitive components from damage. This increases the reliability and lifespan of industrial automation systems.

Cost Savings: Efficient power usage and reduced energy losses translate to lower electricity bills. Additionally, capacitors help in avoiding costly downtime by ensuring smooth and uninterrupted operations.

Better Performance: With capacitors ensuring stable and clean power, industrial systems can operate at their optimal performance levels. This leads to increased productivity and higher quality outputs.

Applications of Capacitors in Industrial Automation

Motor Drives and Controls: Capacitors are integral to motor drives and controls, providing the necessary power conditioning and filtering. They help in smooth starting, running, and stopping of motors, essential for various industrial processes.

Power Supplies: In industrial power supplies, capacitors smooth out voltage fluctuations and filter out noise. This ensures that all connected equipment receives a stable power supply, crucial for reliable operations.

Robotics: Robotics heavily rely on capacitors for power management and control. Capacitors ensure that robotic systems have the necessary power stability to perform precise and complex tasks.

Programmable Logic Controllers (PLCs): PLCs, which are the intellect of industrial automation, use capacitors for timing, filtering, and power conditioning. This enhances their performance and reliability in controlling industrial processes.

Variable Frequency Drives (VFDs): VFDs use capacitors to manage the power supplied to electric motors, allowing precise control of motor speed and torque. This is crucial in applications requiring variable motor speeds.

Uninterruptible Power Supplies (UPS): Capacitors are key components in UPS systems, providing backup power and ensuring continuous operation during power outages. This is vital for critical industrial processes that cannot afford downtime.

Selecting the Right Capacitors for Industrial Automation

Choosing the appropriate capacitor involves understanding the specific requirements of the application. Key factors to consider include:

Capacitance Value: The required capacitance value depends on the amount of energy storage needed. Applications requiring large energy storage will need capacitors with higher capacitance values.

Voltage Rating: The voltage rating of a capacitor must match or exceed the maximum voltage it will be exposed to in the circuit. Using a capacitor with a lower voltage rating can lead to failure.

Tolerance: Tolerance indicates how much the capacitance value can vary from the specified value. For critical applications, capacitors with tight tolerances are preferred.

Temperature Stability: Industrial environments can experience extreme temperatures. Capacitors with good temperature stability ensure reliable performance under varying conditions.

Lifetime and Reliability: High-quality capacitors with long lifetimes and proven reliability are essential for minimizing maintenance and avoiding downtime in industrial automation systems.

Physical Size and Mounting: The physical size and mounting type of a capacitor should fit the design constraints of the system. Space-constrained applications may require compact capacitors.

Innovations and Trends in Capacitor Technology for Industrial Automation

The field of capacitor technology is continuously evolving, with innovations aimed at enhancing performance, efficiency, and reliability. Some of the latest trends include:

High-Density Capacitors: Advances in materials and manufacturing techniques are leading to capacitors with higher energy densities. These capacitors can store more energy in a smaller footprint, ideal for compact industrial applications.

Improved Dielectric Materials: New dielectric materials are being developed to enhance the performance and reliability of capacitors. These materials offer better temperature stability and longer lifetimes.

Smart Capacitors: Integrating sensors and communication capabilities into capacitors allows for real-time monitoring of their condition. This enables predictive maintenance and reduces the risk of unexpected failures.

Environmentally Friendly Capacitors: There is a growing emphasis on developing capacitors that are environmentally friendly, using materials and processes that reduce their ecological footprint.

Conclusion

Capacitors play a critical role in modern industrial automation, ensuring the efficiency, reliability, and performance of automated systems. From energy storage and power conditioning to signal filtering and timing, their functions are indispensable. By understanding the importance of capacitors and selecting the right types for specific applications, industries can achieve significant improvements in their automation processes. As technology advances, the role of capacitors in industrial automation will continue to grow, driving further innovations and efficiencies in the field.

#automation#industrial equipment#industrialautomation#industrial spare parts#industrial#industrial automation equipment#capacitors

0 notes

Text

Ozone Plates for Air Purifiers: Enhancing Indoor Air Quality

In the pursuit of healthier living environments, air purification has become a paramount concern. With increasing pollution levels and the rise of airborne contaminants, individuals seek effective solutions to ensure the air they breathe is clean and safe. Among the myriad of technologies available, ozone plates for air purifiers stand out as a powerful tool for enhancing indoor air quality. In this comprehensive guide, we delve into the intricacies of ozone plates, exploring their functionality, benefits, and considerations.

Understanding Ozone Plates:

Ozone plates, also known as ozone generator plates or ozone cells, are integral components of certain types of air purifiers. These plates are designed to produce ozone, a molecule composed of three oxygen atoms (O3), which possesses powerful oxidizing properties. Ozone works by reacting with and neutralizing various pollutants, such as bacteria, viruses, mold, odors, and volatile organic compounds (VOCs), thereby improving air quality.

Functionality and Operation:

The operation of ozone plates involves a process known as ozone generation. Within the air purifier, electrical energy is applied to a dielectric material, typically made of ceramic or glass, coated with a special catalyst. This catalyst facilitates the conversion of oxygen (O2) molecules in the surrounding air into ozone (O3) molecules through a process called corona discharge.

Once generated, ozone molecules are released into the air purification system, where they interact with pollutants. Through oxidation reactions, ozone breaks down the molecular structure of contaminants, rendering them harmless or less volatile. This process effectively eliminates odors, kills bacteria and viruses, and neutralizes other harmful substances, thereby improving indoor air quality.

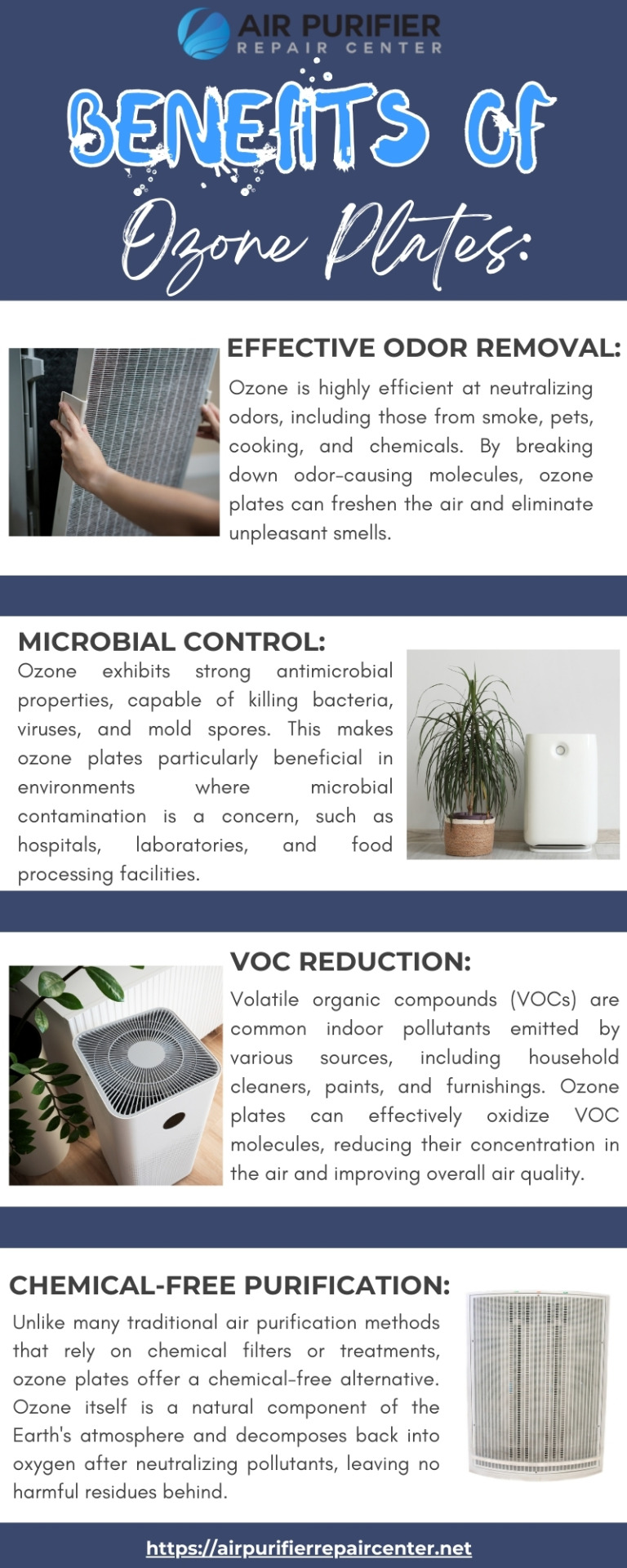

Benefits of Ozone Plates:

Effective Odor Removal: Ozone is highly efficient at neutralizing odors, including those from smoke, pets, cooking, and chemicals. By breaking down odor-causing molecules, ozone plates can freshen the air and eliminate unpleasant smells.

Microbial Control: Ozone exhibits strong antimicrobial properties, capable of killing bacteria, viruses, and mold spores. This makes ozone plates particularly beneficial in environments where microbial contamination is a concern, such as hospitals, laboratories, and food processing facilities.

VOC Reduction: Volatile organic compounds (VOCs) are common indoor pollutants emitted by various sources, including household cleaners, paints, and furnishings. Ozone plates can effectively oxidize VOC molecules, reducing their concentration in the air and improving overall air quality.

Chemical-Free Purification: Unlike many traditional air purification methods that rely on chemical filters or treatments, ozone plates offer a chemical-free alternative. Ozone itself is a natural component of the Earth's atmosphere and decomposes back into oxygen after neutralizing pollutants, leaving no harmful residues behind.

Comprehensive Air Purification: Ozone plates complement other filtration technologies, such as HEPA filters, by targeting different types of pollutants. Together, these technologies provide comprehensive air purification, ensuring the removal of a wide range of contaminants for healthier indoor environments.

Considerations and Safety Precautions:

While ozone plates offer significant benefits for air purification, it is essential to use them responsibly and consider certain safety precautions:

Ozone Levels: Excessive ozone levels can be harmful to human health, causing respiratory irritation and other adverse effects. It is crucial to select air purifiers with adjustable ozone output levels and to follow manufacturer recommendations for safe usage.

Occupancy: Ozone generators should not be used in occupied spaces, as prolonged exposure to high ozone concentrations can pose health risks. Instead, they are best suited for unoccupied areas or for use during times when occupants are away.

Proper Ventilation: Adequate ventilation is essential when using ozone plates to prevent ozone buildup and ensure the dispersal of ozone byproducts. Open windows or use air purifiers equipped with built-in fans to facilitate air circulation.

Maintenance: Regular maintenance of ozone plates is necessary to ensure optimal performance and longevity. This may include cleaning the plates, replacing worn components, and adhering to recommended maintenance schedules provided by the manufacturer.

Ozone plates for air purifiers offer an effective solution for enhancing indoor air quality by harnessing the oxidizing power of ozone. With their ability to neutralize odors, eliminate microbial contaminants, and reduce VOCs, ozone plates provide comprehensive air purification benefits. However, it is essential to use them responsibly, following safety guidelines and considering factors such as ozone levels, occupancy, ventilation, and maintenance. By incorporating ozone plates into air purification systems, individuals can create healthier and more comfortable living environments for themselves and their families.

0 notes

Text

Copper Elbow Joint Pipe & Fittings

Introduction

With a curved or bent shape, a copper elbow refers to a copper plumbing elbow, which is used to change the direction of a copper pipe and redirect the flow of water or other fluids at a specific angle, typically 90 degrees or 45 degrees.

Copper pipe elbows are essential components in plumbing systems, as they enable pipes to navigate corners, obstacles, or changes in direction without the need for sharp bends or kinks that could restrict the flow of fluids. If you want to learn more about 90 degree elbow copper, elbow copper pipe fittings, copper pipe elbow joints, and copper elbow prices, Please do not hesitate to contact Yaheng HVAC copper couplings manufacturer.

Can Copper Pipe Elbow Joints Be Used with Other Types of Pipes and Fittings?

Yes. Copper pipe elbow joints can be used with various types of pipes and fittings, including other copper components, brass, steel, PEX, PVC/CPVC, etc.

Copper to Copper: This is a standard practice in plumbing for both water supply and heating systems, creating a seamless and reliable connection.

Copper to Brass: Copper and brass are compatible materials, so copper pipe elbow joints can be used with brass pipes and fittings without any issues.

Copper to Steel: Transition fittings or dielectric unions should be used to prevent galvanic corrosion, which can occur when dissimilar metals come into contact with each other.

Copper to PEX: For flexibility and ease of installation, copper pipe elbow joints can be used with PEX pipes and compatible fittings by using transition fittings designed to connect the two materials.

Copper to PVC/CPVC: Transition fittings are available to connect copper pipes and fittings to PVC or CPVC pipes and fittings.

What Are Copper Pipe Elbow Joints Used For?

ACR Systems: Copper pipe elbow joints are widely used in air conditioning and refrigeration systems. Copper elbow joints help to create bends and turns in the copper tubing, allowing for the efficient routing of refrigerant lines and optimizing the overall system performance.

Plumbing Systems: Copper pipe elbow joints are essential components in plumbing systems. Copper elbow joints are used to connect copper pipes and create bends or turns in the piping layout. This enables the proper flow of hot and cold water lines, ensuring efficient water distribution throughout the plumbing system.

Hot and Cold Water Lines: Copper pipe elbow joints are specifically used in hot and cold water lines in plumbing systems. The copper pipe elbow joints provide the necessary bends and turns to navigate around obstacles or corners, allowing for the smooth flow of water and optimizing the functionality of the system.

Connecting Copper Pipes: Copper elbow joints are used to connect copper pipes. Copper elbow joints provide a secure and leak-free connection when properly installed, ensuring the integrity of the plumbing system.

Other HVAC Copper Pipe, Tubing, and fittings you may be interested in

copper pipe tee fittings

copper tube joints

copper branch pipe

copper pipe manifold

copper silencer

copper HVAC line

copper pipe filter

1 note

·

View note

Text

Submersible Pump Capacitors

Capacitor, Capacitors, Power Capacitor, Power Capacitors, CV Capacitor, CV Capacitors, Epcos Capacitor, Epcos Capacitors, Epcos Round Capacitor, Epcos Square Capacitor, Epcos Oil Filled Capacitor, Epcos Gas Filled Capacitor, Epcos Phasecap Super Heavy Duty Capacitor, Epcos Capacitor Duty Contactors, Epcos Thyristor Duty Switching, Epcos Reactors, Detuned Pfc, Epcos Active Harmonic Filters, Epcos Apfc Panels, Buffer Card, Automatic Power Factor Relay, Epcos Power Factor Correction, Epcos APFC Relay BR4000, Epcos APFC Relay BR5000, Epcos APFC Relay BR6000, Epcos APFC Relay BR7000, Epcos APFC Relay BR5100, New BR4000 ER Relay, Epcos BR4000 ET Relay, Jaivc Power Capacitors, Jaivc Power Capacitors, MPP Oil Filled Capacitors, MPP Dry Capacitors, MPP Cylindrical Capacitors, MPP Square MFD Capacitors, APP LT Capacitors, HT App Shunt Capacitors, Jaivc AC Capacitors, Fan Capacitors, Motor Start Capacitors, Motor Run Capacitors, Tibcon AC Capacitors, AC Capacitors, Fan and Motor Run Capacitors, Submersible Pump Capacitors, Air Conditioning Capacitors, ESTAdry ACMKP Capacitors, ESTAprop ACMKP Capacitors, Low Voltage Power Factor Correction Capacitors, Shreem Power Capacitor, LV Capacitors, Cylindrical Jelly Filled Capacitors, Cylindrical Gas Filled Capacitors, Cylindrical Heavy Duty Capacitors, Box Type Capacitors, Heavy Duty Double Dielectric Capacitors, Agristar Capacitors, APP Type Capacitors, Ultra Heavy Duty Capacitors, Unistar Capacitor, High Voltage Capacitors, Low Voltage Capacitor, Keltron Capacitor, AC Motor Start Capacitor, Aluminium Electrolytic Motor Start Capacitors, MPP Capacitor, Priya Capacitors, Capacitors for Fan, Capacitors for Motors, Capacitors for Lighting Fixture, Electrolytic Capacitors, LT Power Factor Capacitors, Mumbai, Maharashtra, India.

#Capacitor#Capacitors#Power Capacitor#Power Capacitors#CV Capacitor#CV Capacitors#Epcos Capacitor#Epcos Capacitors#Epcos Round Capacitor#Epcos Square Capacitor#Epcos Oil Filled Capacitor#Epcos Gas Filled Capacitor

0 notes

Text

Capacitors Decoded: Enhancing Automation in Industrial Processes

In the vast world of industrial automation, every component plays a crucial role in ensuring seamless operations. Among these components, capacitors stand out as under recognized contributors, silently enhancing efficiency and reliability in various industrial processes. In this blog post, we'll decode the significance of capacitors and how they contribute to the advancement of automation in industrial settings.

Understanding Capacitors

To put it simply, capacitors are electronic components that store and release electrical energy. They consist of two conductive plates separated by an insulating material called a dielectric. When voltage is applied across the plates, an electric field is created, leading to the accumulation of electric charge. This stored charge can then be discharged when needed.

Role in Industrial Automation

Now, you might wonder, how do these seemingly humble components contribute to automation in industries? Well, the answer lies in their flexible functionality:

Power Factor Correction: Capacitors help improve the power factor in industrial systems. A poor power factor can result in inefficient energy usage and increased utility costs. By adding capacitors strategically, the power factor can be optimized, leading to reduced energy wastage and lower bills.

Voltage Regulation: In industrial processes, fluctuations in voltage can cause havoc on sensitive equipment. Capacitors act as voltage regulators, stabilizing the voltage levels and ensuring consistent operation of machinery and electronic devices.

Filtering and Noise Reduction: Industrial environments are often extensive with electrical noise and interference that can disrupt sensitive signals. Capacitors are used to filter out this noise, providing clean power and ensuring accurate readings from sensors and control systems.

Energy Storage: Capacitors serve as energy storage devices in industrial applications. They can quickly store and release energy, making them ideal for applications requiring rapid bursts of power, such as motor startups or short-term energy backup systems.

Enhancing Efficiency and Reliability

By incorporating capacitors into industrial automation systems, several benefits can be realized:

Improved Equipment Performance: Capacitors help maintain stable voltage levels, preventing equipment damage and downtime due to voltage fluctuations.

Energy Savings: Power factor correction reduces energy wastage, leading to lower utility bills and improved overall efficiency.

Extended Equipment duration: By reducing stress on electrical components, capacitors contribute to the longevity of industrial machinery and electronics.

Enhanced Process Control: Clean power and reduced electrical noise ensure accurate data acquisition and precise control over industrial processes.

Emergency Backup: Capacitors can provide short-term energy backup during power outages, allowing critical processes to continue uninterrupted.

Conclusion

In conclusion, capacitors play a vital role in enhancing automation in industrial processes. From power factor correction to voltage regulation and noise reduction, these small yet powerful components contribute to the efficiency, reliability, and longevity of industrial systems. By understanding the importance of capacitors and integrating them effectively, industries can unlock new levels of productivity and performance in their automation endeavors.

#industrial automation#industrial equipment#auto2mation#industrial spare parts#industrial and marine automation#industrial and marine automation equipment#industrial automation equipment#capacitors

0 notes