#Dip Pipes Suppliers

Text

#Teflon Lined Pipes#Concentric Eccentric Reducers#PTFE Slide Bearings#PTFE Lined Pipes#PTFE Expansion Joints#PTFE Pipes And Fittings#Lined Pipe Fittings#Lined Pipe Manufacturers#Sparger Manufacturer In India#Dip Pipes Suppliers#PTFE Lined Pipe Manufacturer#PTFE Lined Pipe Suppliers#PTFE Lined Pipes and Fittings#PFA molded fittings near me

1 note

·

View note

Text

Siren in batdr 😺☝️

Picture 1 is her as an entity in batdr. She can only move through a puddle due to her structure as a mermaid. Audrey encounters her in an inky river somewhere (my memory's fuzzy and i dunno if theres an inky river in batdr but if there isnt, well lets just pretend there is) and she is given choices of whether to talk to her or ignore her banter.

A. If Audrey chooses to ignore her, Siren will get angry and will disappear into the dark puddles. Only to appear again occasionally to jumpscare audrey (kinda like slicer but more vicious and vocal)

B. If Audrey chooses to go and talk to her, she will ask Audrey to do something to her bidding (havent thought what thatll be but maybe something in relation to getting a bendy plush or smth? And a radio maybe) And when she returns with the required items, Siren will immediately be the supplier of Audrey in batdr: supplying her with inky hearts, coins, upgrades, batteries, and even the canister(she can only two tho). But this transaction can only happen once in every encounter. She can also be a jack of all trades, she can help audrey occasionally whenever she's stuck in a level, low power of the gent pipe, distract the keepers or any enemies nearby. Usually she'd do this by randomly popping from an inky puddle or when audrew looks on her back to see siren out in her puddle.

She is one of the experiments who escaped The Pit. She loathes Twisted Alice and loves to dive in when audrey battles Alice. Whenever she says goodbye to audrey after the trade, she says "Your welcome for that, my little goldenfish. Oh! And dont forget to say hi to my darling devil!" She waves briefly and then disappears into the puddle, then the Ink Demon will be heard nearby, initiating the usual warning from the game.

Picture 2 depicts another version of Siren--except she replaces Audrey as the protagonist. Her weapon is changed from a gent pipe into a fountain pen. Upgraded in a different way, she would need to dip it into an ink puddle that is charged with electricity. It causes the pen to enlarge and strengthen itself. There are certain stations for this upgrade tho, like the gent pipe upgrade station. It just doesnt have a manual compared to the pipe. The metap tip will have some electrical shock and it can be pulled out to reveal thick ink inside that can be used to temporarily blind or immobilize enemies (its sticky). She doesnt have the banish ability and will be replaced by Soul Snatch, she can snatch an enemy's life in one touch. She will still have the flow ability from Porter (changed from yellow to black) and the travel ability from Heidi tho.

The ink demon aint merging with her in the end tho, lets say... just a change of heart.

Oh i forgot to say, they cannot both exist at once. So no one meets the other.

#bendy and the dark revival#batdr#sirensea#self insert#my sona#i dunno what else to tag yo#oc lore#??? lol

14 notes

·

View notes

Text

Octavia and the Terrible, Horrible, No-Good, Very Bad Day

This is my bard's backstory. It starts about 24 hours before she wakes up on the Mind Flayer ship, and just goes downhill.

____________________________________________________

Octavia de’Mire (pronounced ‘deh-meer’, thank you very much) had woken up to a horrible crick in her neck, discovered she’d forgotten to clean her flute the night before, and- And there was a rat chewing a hole through the toe of her boots. Her only pair of good boots, which were also her only pair of shitty boots.

“Get!” She rolled out of bed onto the floor, startling the rat and herself, and let out a curse as pain flared in her neck.

Her foot has been tangled in blankets kicked to the foot of her pallet.

So it’s going to be that kind of morning.

She hauled herself to her feet and stared at herself in the mirror she’d nailed to a barrel. What she saw was fixable, even if the boots weren’t. “You know you’ve got this. Boots won’t matter if you’re good enough. Might even be charming.”

Her reflection told that she really should brush her hair. And that she looked nervous.

Tavi scoffed at herself. Appearances only mattered on the job when Angus got a bee in his bonnet and wanted his bards to match the decor, except she wasn’t going down to the Plunging Neckline today. She needed to put her best foot- or in this case, non-eaten boot, forward.

Angus wouldn’t forgive her for playing hooky. This had to work.

So she dipped her rag into yesterday’s bucket of water and washed off last night’s face paint, gave the rest of herself a quick wash, and combed her hair back as best she could.

Her costume- technically it was a handful of different pieces of costumes she’d gone searching through the brothel’s wardrobes for. It was a ridiculous pair of striped pants, a frilly white shirt that had a suspicious stain, and a patterned vest that covered the stain. And her now-holey boots. And a belt that had probably not originally meant for holding pants up.

It looked like a clown had tried to make interesting clothes out of old jousting flags. Did everything match? No. Did Tavi care? Marginally. She looked like the bards illustrated in the fancy books she’d seen as a child, and that would work. She looked like she’d put everything together with intention.

That was what mattered. Looking intentional. Like she belonged. Like she chose to dress like a grubby bard.

She reached for her flute and grimaced. It should’ve been polished last night, but Angus had her stay late for a well-paying patron who apparently had a hankering for a harpsichord, and she was his only bard who could play it half-decent.

The filigree was dull with fingerprints, yesterday’s lipstick smudged on the mouthpiece. The flute deserved better, and probably knew it.

It would have to do.

Tavi slipped out of her room and crept down the hall to the window over the kitchen roof. A glance out revealed Angus having a heated conversation with the baker’s boy who was delivering the day’s bread next door.

Probably how Angus wanted to pay the bare minimum for the crusts. A coin pinched was a coin saved, he said. It made him insufferable to the suppliers. Few seamstresses even considered taking commissions from him because he’d argue over the price by the stitch and no self-respecting seamstress would let anyone out in something that was held together with hopes and dreams.

The baker’s boy was not having whatever Angus was insisting on.

So she couldn’t sneak out on the roof, but she could instead just go out the front door.

The stairs creaked faintly as she slowly descended. The downstairs hall stank of stale pipe smoke, and leftover cheap perfume. The threadbare rug, once red and now a sad, faded pink, had sawdust piled in the middle of it to absorb someone’s emptied stomach.

Probably a good thing she was leaving early. Angus would have one of his bards (that sounded like there were a lot of bards. But really, it was just the two of them, Tavi and Adolphus) clean up the vomit, because his other employees were too precious for such a demeaning task.

She almost felt bad for Adolpus, but chances were he was the one who’d thrown up, because the kid held his watered-down ale like a sieve.

Tavi made it to the foyer before she was caught.

“What in the hells are you wearing?” The voice’s owner snorted in lazy laughter.

Dammit.

“Good morning to you, too, Bea.” Tavi sketched a small bow to the centerpiece of the Plunging Neckline, currently sprawled on a chaise lounge with a little teacup of coffee and yesterday’s newspaper.

Bea sneered at her name. She’d started trying to only go by her stage name, Begonia. Tavi refused, mostly just to piss her off. Bea had started out as a bard, like Tavi, but she’d decided she’d rather be one of Angus’ ‘flowers’ as he called them. There wasn’t anything wrong with that, in Tavi’s opinion. Her distaste of Bea came entirely from Bea’s snooty attitude that she was now better than the bards.

They all provided pretty services. Tavi’s were pretty on the ears. Bea’s were pretty on the eyes.

“And what are you doing dressed like that?” Bea’s eyebrows migrated down. “No, wait, where are you going? Angus didn’t say you had the day off.”

The accusation hung in the air.

Tavi shifted towards the door. “That’s my business.”

Her eyes shifted to the holey boot. “Sure, what little of it you get. I take it tips haven’t been good?”

“We both know Agnus gives me the worst rooms.”

Angus had been trying for the better part of a decade to get Tavi to quit, because young bards like Adolphus were easy to take advantage of and he could save money by paying them with exposure. Tavi got five gold coins a week, a private room, and she got to keep half her tips.

“Hm. Pity. I’m the best performer, and I get the best tips. I’m sure once you improve they’ll get better.” Bea innocently tucked a fiery curl behind one ear, looking the perfect portrait of friendliness.

Tavi didn’t have time for veiled insults. “Fuck you too, Bea.” She stormed out the front door of the Plunging Neckline, and right into a puddle of what she was praying was water and not horse piss.

Her sock in the holed boot was now wet. Disgusting.

She steeled herself and started towards Bloomridge Park, trying to polish her flute on her sleeve.

It wasn’t doing much.

She veered around a carriage of someone far more important than she was, and ignored the cries of newspaper hawkers going on about some murder.

Murder wasn’t that uncommon. Half the time it was because someone drunk got offended at a drunk someone else or something, and one healer later the dead soul was being brought back. Whoever had been killed this time would either be in a better place, or be brought back thanks to a fair amount of gold.

She slowed on the sidewalk, seeing the line outside the park’s gate. A bright red pavilion was erected in the middle, the line snaking out and spilling down the block. Damn, and it was still early morning. Everyone else here seemed to have the same idea of getting up with the sun. She joined the back of the line, behind a woman in a brilliant blue outfit that shimmered as she moved.

Her own outfit was already drab, but now it just seemed pathetic in comparison.

The woman turned around to take in Tavi. Her expression said everything manners wouldn’t let her. She carried a lyre gilded in gold. It looked expensive, probably worth more than she’d ever see in her lifetime.

Perhaps this wasn’t the best idea. Maybe she should’ve practiced more. Or picked a better outfit.

Tavi returned to trying to shine up her flute on her sleeves.

The line shifted forward.

Her wet sock squished. It was definitely not water that she’d stepped in.

The blue woman plucked at her lyre, humming. Further ahead someone had a massive drum slung over their chest and was louding banging out a beat. A lute, some violins, a pan flute were further up. Everyone was practicing as they slowly moved closer to the pavilion.

Tavi pursed her lips and played a soft lullaby to warm up.

The lyre woman turned around, appraising Tavi again. “Nervous?”

She nodded.

“First time?”

Tavi paused her playing, trying to see what this woman’s angle was. She’d dismissed her earlier, but now was trying to be kind. Time to play stupid. “No, I've been nervous before.”

The eavesdropping violinist behind her burst out into laughter.

The lyre woman raised a manicured eyebrow. “First time auditioning for a lord?”

Tavi sighed and lowered her flute. “It’s that obvious?”

“There’s a certain… quality they’ll be expecting.” Her eyes strayed over Tavi’s wrinkled and overly-frilly shirt and mismatched vest and trousers, and then settled on the flute. “That is a magnificent instrument.” There was an implication in her words.

The flute was gilded in silver, filigree swirls around the holes and mouthpiece. The lower keys had little leaves engraved. It was far nicer than anything Tavi had ever owned. It spoke of quality, and Tavi didn’t look like the sort who had ever owned anything quality.

“It was my mother’s.” Tavi shifted to the side, ignoring the lyre woman as she continued to warm up.

The line moved forward again. And again. The violinist and her took turns saving each other’s spots to go run to a food cart or find a bathroom.

Again the line would move, again, and each time Tavi hated her holey boot and foul sock. There was no time to run back to her tiny room in the Plunging Neckline for a clean sock that would just get dirty again.

The sun climbed higher over the city, and made it abundantly clear that summer was on the way.

She wished she’d brought a hat. Tomorrow she would have a sunburn red enough to make her look like a tiefling.

They were close enough that Tavi could see into the pavilion by the time mid-afternoon hit.

She was thoroughly tired of hearing the violinist behind her play the same three songs over and over. The drummer with the wardrum had vanished into the tent and the cobblestones had stopped vibrating. The woman in front of Tavi looked as though she was miserable in the heat. Tavi felt only mildly warm, because she wasn’t wearing a taffeta confection covered in (probably fake) sapphires.

The park trees offered some shade from the sun.

And Tavi’s shoulder had been an unfortunate victim of the birds living in the trees.

Another shift forward.

Then they were in the tent, and Tavi understood why the lyre woman had put up with the heavy dress.

In the red half-light through the pavilion canvas, it was hard to see where the jewels were attached, so it looked like the night sky fashioned into clothing. The sapphires were stars, twinkling and inviting. The sweat made her skin look dewy-

A servant nodded for the woman to go around the cloth partition.

Tavi took a shaky breath and flexed her tired fingers. She was sunburnt, sweaty, and the bird crap on her shoulder was not going to be easy to wash out. But this was what she’d been practicing months for.

She couldn't recall the last five minutes. Nerves were making her fingers twitchy. She was next and good gods, what was she doing here, she played in the background of the second-worst brothel in the city-

The lyre woman began her audition. And she could play the lyre better than anyone Tavi had ever heard.

She risked a look around the partition and steeled herself.

A thickset, stern-looking woman sat behind a desk, frowning and unimpressed.

Oh, this had been a terrible idea. Tavi was not meant to be ambitious. Hadn’t she learned her lesson last time?

I’m an idiot.

The lyre player finished her song-

How was she done already?

And then it was Tavi’s turn. She took a deep breath and shook off the nerves. She’d played thousands of times.

Tavi strode around the partition and dropped into a bow. “I’m Octav-”

“Just play.” The woman waved a hand laden with triangular silver jewelry.

She stood tall and brought her flute up. Song of Balduran was a simpler song, but it was one of those songs that would worm its way into your head for hours. It was a favorite song of the city; everyone knew it and she’d passed countless taverns with the patrons belting out the words and echoing down alleys. Nop one could go a day in Balder’s Gate and not hear it.

“Thank you, you can stop.”

Tavi pulled away from the flute in the middle of the second verse.

The woman waved her hand. “You can go. Next.”

The world went silent. No, it was the blood rushing through her ears. Her hands had gone numb. She found herself outside of the pavilion, legs carrying her back towards the Plunging Neckline because she couldn’t think of anywhere else to go. Embarrassment and shame and other, harder-to-identify emotions were clawing at the lump in her throat.

They hadn’t wanted her. She hadn’t passed the audition. She’d skipped work for nothing, and Angus-

Oh gods, what had she done? Her heart and stomach seemed to be trading places; her heart sinking and bile rising. She hadn’t done enough, she wasn’t good enough. And she’d played as well as she ever had.

Tavi’s hands were shaking. She couldn’t think. The pain of tears prinkled behind her eyes, making her squint in the early dusk.

Had the woman even been listening-

She’d failed spectacularly. Her head felt hot, hands clammy, her hands wouldn’t stop shaking so she gripped her flute tighter.

“And look who’s back.”

Tavi brought herself back to her surroundings. She’d made it back to the Plunging Neckline and Angus was leaning against the front window, blocking the gawking passerby from catching a look at whoever was meant to be dancing.

Somewhere, Fate was probably laughing at the cruel joke of the situation.

“Angus, I can-”

“Nope, I ain’t gonna hear it. What’s the point of letting you live here if you ain’t even gonna do your job?” He spat at her feet. “Consider yourself now lookin’ for employment. An’ don’t use me as a reference.”

Tavi felt like she’d been hit with a fireball. “What?” she repeated. That couldn’t have been her voice, it was too thin, too high- Oh dear. She was going to cry.

“I’m no longer employin’ you. I’m terminating your job. Canceling your position. However you wanna put it, just don’t come back for nothing.” Angus generously spat at her feet again.

She caught the sight of Bea watching her with a smirk in the window.

Angus waved at her. “Now shoo, you’re blockin the door from cust’mers.”

Tavi opened and shut her mouth. Everything had gone silent because her ears were ringing. Heart pounding. Her skin felt tingly and both too hot and too cold, fingers numb again.

Fired.

A failure.

Shame burned at her throat. Or perhaps it was bile, and she was going to vomit up her heart.

She didn’t have anywhere else to go. Her clothes, her books, the good pillow she’d bought with a month’s worth of wages. “I need my stuff-”

Angus paused in the doorway. “Forfeit for the day’s work. And for takin’ costumes.” He looked over his shoulder at her. “You took advantage of me, so it’s all fair. I coulda called the Fists. Now get or I will call ‘em.”

Tavi took a step back, and another, and another, until she realized she’d made it back to Bloomridge Park, watching the great pavilion be taken down. She entered through a different gate, and stood there, trying to breathe and tell herself that it would be alright.

Except she had nothing to her name, save her flute and the ridiculously stupid over-the-top bard costume.

A tear leaked out. She was going to cry, and she didn’t care. Tavi slipped deeper into the park, to one of the private fountains that would muffle her tears. Dusk was being evicted as night fell. She sunk down in front of the fountain and let out the sobs.

Come on, think!

Her mind lost the battle to her emotional turmoil. She could think about what to do later. A good cry would sort her out emotionally-

Tavi whipped her head around, ponytail flying and crick in her neck protesting, as she listened. She could have sworn she’d heard something over the gurgling fountain.

Hadn’t the newsboy that morning mentioned a murder?

It had probably been a rat in the bushes, if she’d even heard anything. But still, this wasn’t a safe place to be, even if she didn’t have anywhere else to go.

Tavi stood-

And everything went black.

3 notes

·

View notes

Text

Leading Copper Earthing Electrode Manufacturer in India

Veraizen Earthing is the biggest copper earthing electrode manufacturer in India. Copper Earthing Electrodes are also made of Hot Dip Galvanized Pipes, with a copper termination and 20 mm copper inside. Copper Earthing Electrodes Suppliers offers a variety of Copper Earthing Electrode products, including electrogrip 60mm 3 metre, electrogrip 40mm 3 metre, electrogrip 50mm 3 metre, electrogrip 80mm 3 metre, electrogrip 90mm 3 metre, and electrogrip 40mm 2 metre pure copper earthing electrodes.

The leading copper earthing electrode supplier in India is Veraizen Earthing.We are also a top provider of pure copper electrodes, copper-bonded electrodes, and copper plates.We have established a good reputation in the local and international markets via strong business ethics and high-quality products such as the Copper Earthing Electrode. We transport our items all across the world. They are popular among our regular clients because of their long lifespan and affordable cost.We also produce and market copper-bonded solid electrodes, earth rods, solar earthing, and chemical earthing. We Supply Lightning Arrester Manufacturers in Mumbai and Lightning Arrester Manufacturers in Kolkata.

#Copper Earthing Electrodes manufacturers in india#Copper Earthing Electrodes Supplier in india#Copper Earthing Electrodes Suppliers#Lightning Arrester Manufacturers in Mumbai#Lightning Arrester Manufacturers in Kolkata

0 notes

Text

Carbon Steel ASTM A105 Flanges Manufacturers In India

Carbon Steel ASTM A105 Flanges Manufacturers In India,Supplier In india ,Stockist In India,Exporter In India

Introduction:- Carbon Steel ASTM A105 Flanges Manufacturers In India

India is emerging as a significant hub for the production of Carbon Steel ASTM A105 flanges, catering to a variety of industries such as oil and gas, petrochemicals, power generation, and construction. These flanges are integral to piping systems, providing robust connections that ensure safety and efficiency in high-pressure and high-temperature environments.

Manufacturers in India utilize advanced manufacturing techniques and adhere to stringent quality standards to produce ASTM A105 flanges that meet international specifications. This commitment to quality ensures that their products are reliable and durable, capable of withstanding demanding operational conditions.

The growing industrial landscape in India, combined with an increasing focus on infrastructure development, has led to a rising demand for high-quality flanges. Indian manufacturers are well-equipped to meet this demand, offering a diverse range of flanges, including slip-on, weld neck, threaded, and blind types.

This introduction sets the stage for a closer examination of the features, applications, and leading manufacturers of Carbon Steel ASTM A105 flanges in India, highlighting their role in supporting the

Product Overview:-.

ASTM A105 Flange is a specification for flanges. Specifications can include flanges of various grades made of stainless steel. The flange is made of forged Carbon Steel ASTM and is intended for high temperature use. Shasan Piping Solution is a leading manufacturer and supplier of ASTM A105 flange types.

This material contains carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum, and vanadium. These are called Carbon Steel ASTMs because other materials contain less than 1% of the composition. There are different types, including SA105N blind flanges, which are used to close pipelines. The flange also has excellent strength properties. The minimum yield strength of the flange is 250 MPa and the minimum tensile strength is 485 MPa. It is a hard material with a Brinell hardness of 187.

Specifications:-

Specification Format of SA105N Blind Flange

Specifications

ASTM A182, ASME SA182

Size

1/2″ to 48″

Standards

ANSI B16.47 Series A & B, MSS SP44, AWWA, Custom Drawings, ASA, ANSI B16.5, API-605.

Pressure Ratings

Class 400, Class 150, Class 1500, Class 300, Class 900, Class 2500, Class 600

Flange Face Type

Flate Face, Raised Face, Ring Type Joint

Coating/Surface Treatment

Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated.

Benefits:-

There are various pressure classes such as class 150, 300, up to 2500, and PN6 to PN64. A105 flanges of class 300 and below do not require heat treatment, but high pressure class can be heat treated. Flanges with a nominal internal diameter greater than 4 inches are heat treated as annealing, normalizing, normalizing and tempering, or normalizing and tempering. ASTM A105 pipe flanges can also be forged. This material is suitable for welding applications. When welding materials, boilers, and pressure vessels, guidelines consistent with ASME standards must be followed. Flanges are both bolted and bolted. ASTM A105 N threaded flanges are useful when welding or screwing methods are not suitable. Threaded flanges can be used on threaded pipes to create connections without welding. Please contact us for flange pricing and details.

Conclusions:-

In summary, Carbon Steel ASTM A105 flanges are a vital component in modern piping systems, known for their strength, durability, and versatility. Their compliance with the ASTM A105 specification guarantees high-quality performance in demanding environments, making them a preferred choice in industries such as oil and gas, petrochemical, and construction.

Email Id:- [email protected]

Contact No:-8879709191

0 notes

Text

Threaded Flanges Specifications

Specifications

Platinex Piping Solutions LLP stands out as a premier manufacturer and exporter of threaded flanges, adhering to ASME/ANSI B16.5 standards in India. Specializing in high-quality threaded or screwed flanges crafted from carbon, alloy, and stainless steel, our offerings cater to diverse industrial needs. Our threaded flanges facilitate seamless assembly in low-pressure piping systems without necessitating welding, ensuring efficient connections with pipes and equipment. Although welding around the joint is possible post-assembly, it’s not recommended for optimal performance. Renowned for their versatility, threaded flanges, also known as screwed flanges, feature threaded bores, enabling welding-free installation akin to slip-on flanges.

Flange face types encompass Flate Face (FF), Raised Face (RF), and Ring Type Joint (RTJ), with surface treatments including anti-rust paint, zinc plating, and hot dip galvanization.

Additionally, we provide value-added services like CNC machining and customized flanges. The different types of threaded flanges are:

Plain Threaded Flanges

Female Threaded Flanges

Male Threaded Flanges

0 notes

Text

Orifice Flanges Exporters in India

Introduction

Universe Metal & Alloys has extensive experience in manufacturing and supplying all types of pipe fittings. The entire manufacturing process is supported by trained professionals who have extensive experience in handling different types of pipe fittings and other products.

Description

Universe Metal & Alloy stands tall as one of the leading Manufacturers, Suppliers, Stockists, and Exporters of Orifice Flanges in India. With a rich legacy and a commitment to quality, we have carved a niche for ourselves in the competitive metal market. Our dedication to Suppliers to international and national quality standards sets us apart, making us a trusted name in the industry.

At Universe Metal & Alloy, we take pride in our Stainless Steel Orifice Flanges, which are meticulously designed and developed to meet the diverse needs of various industries. Crafted with precision and excellence, our ASTM A182 Stainless Steel Orifice Flanges are renowned for their durability and reliability, making them ideal for a wide range of piping applications across sectors such as Chemical, Petrochemical, Building, Construction, and more.

Benefits:

Accuracy and Reliability: Orifice flanges provide precise flow measurement, which is essential for process control and optimization.

Versatility: Suitable for a wide range of applications, including water, oil, gas, and steam.

Cost-Effective: They offer an economical solution for flow measurement, especially in large-scale industrial applications.

Durability: Made from robust materials, these flanges can withstand harsh operating conditions, ensuring long-term performance.

Ease of Installation and Maintenance: Orifice flanges are designed for easy integration into existing piping systems and require minimal maintenance.

Specification:

ASME B16.5 Orifice Flange Size Chart1/2" (15 NB) to 48" (1200NB) DN10~DN5000grooved Orifice flange StandardsANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092Spectacle Flange Pressure Rating ANSIClass 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Spectacle FlangeSpectacle Flange Pressure Calculation in DIN6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Spectacle FlangeJIS5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Spectacle FlangeUNI6Bar 10Bar 16Bar 25Bar 40Bar grooved Orifice flangeEN6Bar 10Bar 16Bar 25Bar 40Bar Forged grooved Orifice flangeCoatingOil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized ASME B16.5 Orifice FlangeMost common types of Orifice FlangeForged / Threaded / Screwed / PlateTest CertificatesEN 10204/3.1B

Raw Materials Certificate

100% Radiography Test Report

Third Party Inspection Report, etcProduction technique

Forged, Heat treated and machined

Connect Type/ Flange Face TypeRaised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, GrooveSpecial designAs per your drawing

AS, ANSI, BS, DIN and JIS

15 NB (1/2″) to 200 NB (8″)

Equal and Reducing ConfigurationsTestDirect-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detectorEquipmentPress machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etcOriginIndian / West Europe / Japan / USA / KoreanManufacturer of

ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

Spectacle Flange: -BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange

B.S: BS4504 , BS3293, BS1560, BS10

AS 2129: Table D; Table E; Table H

ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

ANSI : ANSI B16.5, ANSI B16.47(API605), MSS SP44, ANSI B16.36, ANSI B16.48

ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48

American standard (ANSI)

German (DIN)

British standard (BS)

DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 Forged grooved Orifice flange

The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276

grooved Orifice flange Uses & application

Bitumen upgraders.

Heavy oil refineries.

Nuclear power (mostly seamless).

Petrochemicals and acids.

Export toIreland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc

Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175

Product Overview:

At Universe Metal & Alloys, our orifice flanges are designed and manufactured to the highest standards. Each product undergoes rigorous quality control to ensure it meets the specific requirements of our clients. Our orifice flanges are suitable for a variety of applications, including chemical processing, petroleum refining, power generation, and water treatment. With a commitment to excellence, we provide detailed product information, technical support, and competitive pricing to meet the needs of our customers.

Conclusion:

Orifice flanges are an indispensable component for accurate flow measurement in industrial piping systems. Universe Metal & Alloys is dedicated to delivering high-quality orifice flanges that meet the exacting standards of various industries.

For more information or to place an order, please contact us at [email protected] or call us at +91-22-66363360 / 66393788.

0 notes

Text

Flanges Stockist in Oman

A350 LF2 flanges are designed for low-temperature applications. These flanges are made from carbon steel or low alloy steels. There are A350 LF2 Class 1 and Class 2 flange types. Both types require a notch toughness test to ensure they meet the necessary quality standards. The ASTM A350 LF2 flanges come in various shapes, sizes, dimensions, and grades. We are a manufacturer and supplier of all these different types. Our company has been in operation for many years, producing various types of flanges in different material grades.

The ASTM A350 LF2 manufactured flanges are stronger because they are made from a single piece of metal, making them suitable for applications requiring high strength. Purchase directly from ASTM A350 LF2 Class 1 flange manufacturers in Dubai. These flanges can also be easily welded with piping systems. For applications requiring durability and hardenability, the ASME A350 LF2 flanges are suitable. In certain conditions, killed carbon products are preferred. For such applications, we supply A350 LF2 killed carbon steel flanges to meet the requirements. Different dimensions and scales are also available. Please feel free to contact us to learn more or to inquire about our products. All forgings provided by the SA 350 Gr LF2 Cl1 flange manufacturer are typically ultrasonically tested.

Specification Chart of ASTM A350 LF2 Flanges

Size Chart:

1/2″ to 48″ (15 NB to 1200 NB)

Pressure Rating Chart:

ANSI: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS

DIN Pressure Calculation: PN6, PN10, PN16, PN25, PN40, PN64 (6 Bar, 10 Bar, 16 Bar, 25 Bar, 40 Bar, 64 Bar)

JIS: 5 K, 10 K, 16 K, 20 K, 30 K, 40 K, 63 K

Manufacturer Standards:

UNI, BS, AS2129, ANSI, DIN, GOST, JIS, SABS, NFE, AWWA, EN, etc.

Testing Methods:

X-ray detector

Ultrasonic flaw detector

Direct-reading spectrograph

Magnetic particle detector

Hydrostatic testing machine

Coating Options:

Zinc plated

Yellow transparent

Cold and hot dip galvanized

Anti-rust paint

Oil black paint

Common Types:

Threaded / Screwed

Forged

Plate

Equipment Used:

Press machine

Bending machine

Sand-blasting machine

Pushing machine

Electric bevelling machine, etc.

UNI / EN Pressure Ratings:

6 Bar, 10 Bar, 16 Bar, 25 Bar, 40 Bar

Connection / Flange Face Types:

RF (Raised Face)

Small Tongue

RTJ (Ring Type Joint)

FF (Flat Face)

LJF (Lap Joint Flange)

Large Tongue & Groove

Origin:

West Europe, Japan, India, USA, Korea

Standards:

API7S-43, API605, ISO70051, JISB2220, API7S-15, ANSI/ASME B16.5, BS4504, BS 10, EN-1092, DIN, B16.47 Series A & B, MSS S44, BS1560-3.1, B16.48, EN1092

#ASTM A350 LF2 Flanges Manufacturers in UAE#ASTM A350 LF2 Flanges Suppliers in UAE#ASTM A350 LF2 Flanges Stcokists in UAE#ASTM A350 LF2 Flanges Exporters in UAE#CS Flanges in UAE

0 notes

Text

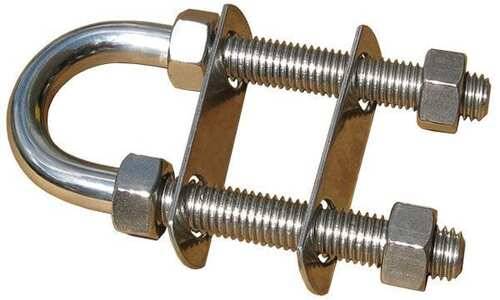

U Bolt Dynamics: Crafting Precision Fasteners for Every Need

In the world of construction, automotive manufacturing, and countless other industries, the unsung heroes are often the smallest components. Among these, U bolts hold a place of critical importance. These U-shaped fasteners are pivotal in their role, offering not just support but also ensuring safety and longevity in various applications. From securing pipelines beneath city streets to holding together the framework of skyscrapers, U bolts are integral to structural integrity and function. In this blog post, we will dive deep into the world of U bolts, exploring their types, manufacturing processes, selection criteria, and how U bolt suppliers play a crucial role in providing high-quality fasteners for every need.

Understanding U Bolts

Understanding U bolts goes beyond recognizing their simple U-shaped design. These essential fasteners play a pivotal role in various industries, offering crucial support and stability. To ensure the right fit and performance, it's vital to source U bolts from reputable U bolt suppliers. These suppliers specialize in providing a wide range of U bolts, tailored to specific needs and applications.

By understanding the nuances of U bolts and partnering with reliable U bolt suppliers, businesses can ensure the structural integrity and safety of their projects. From construction to automotive manufacturing, the importance of high-quality U bolts cannot be overstated, making the choice of supplier a critical decision in any procurement process.

Design Features: U bolts are characterized by their U-shaped design, which allows for easy clamping around cylindrical or square objects.

Material Varieties: These fasteners are available in a range of materials, including stainless steel, carbon steel, and galvanized steel, each offering distinct properties suited to different applications.

Application Specifics: U bolts find application in diverse industries such as construction, automotive, marine, and telecommunications, where they are used for securing various components like pipes, poles, and equipment mounts.

Load Capacity Considerations: Choosing the right U bolt involves assessing factors such as the anticipated load and the material being clamped, ensuring that the bolt can withstand the required forces without failure.

Surface Finish Options: To enhance durability and corrosion resistance, U bolts can be finished with coatings such as zinc plating, epoxy coating, or hot-dip galvanizing, depending on the environmental conditions they will be exposed to.

Thread Specifications: U bolts feature threads on both ends, allowing for easy installation and adjustment. Thread size and pitch must be selected carefully to ensure compatibility with nuts or other fastening components.

Customization Possibilities: Some applications may require U bolts with specific dimensions, angles, or configurations. Customization services offered by suppliers allow for the creation of tailored solutions to meet unique project requirements.

Supplier Expertise: Working with experienced U bolt suppliers ensures access to high-quality products, technical support, and reliable delivery, essential elements in achieving successful project outcomes.

Types of U Bolts

When it comes to securing various components in different industries, U bolts are indispensable. These fasteners come in a variety of types, each designed to suit specific applications and requirements. Understanding the different types of U bolts is essential for selecting the right one for a particular project. Here, we'll delve into some common types of U bolts and how they are used across various industries.

Round Bend U Bolts: As the name suggests, round bend U bolts feature rounded bends on both ends, making them ideal for securing cylindrical objects such as pipes, tubes, or cables. They provide a snug fit around the rounded surface, ensuring stability and preventing slippage. Round bend U bolts are commonly used in plumbing, electrical, and automotive applications.

Square Bend U Bolts: Square bend U bolts are designed for clamping square or rectangular objects securely. Their square-shaped bends provide a tight grip, making them suitable for applications where stability and alignment are crucial. These U bolts are often used in construction, scaffolding, and equipment mounting.

Long Tangent U Bolts: Long tangent U bolts feature extended legs and threads, offering increased clamping force and versatility. They are designed to accommodate thicker materials or multiple components, providing a secure hold even under heavy loads. Long tangent U bolts find application in structural steelwork, bridge construction, and machinery assembly.

Custom U Bolts: In some cases, standard U bolts may not meet the specific requirements of a project. Custom U bolts are tailored to precise specifications, including dimensions, materials, and thread configurations. This customization allows for optimal performance and ensures a perfect fit for unique applications. Custom U bolts are often used in industries such as aerospace, marine, and renewable energy, where standard fasteners may not suffice.

When sourcing U bolts for a project, it's crucial to partner with reliable U bolt suppliers. These suppliers offer a wide range of U bolts in various types, sizes, and materials to meet diverse needs. With their expertise and extensive inventory, U bolt suppliers play a vital role in ensuring that projects are equipped with high-quality fasteners that deliver reliable performance and durability.

Manufacturing Excellence

In the realm of industrial hardware, where precision meets durability, the significance of U bolts cannot be overstated. These unassuming yet essential components serve as the backbone of various applications, from construction to automotive engineering. At the heart of every sturdy structure and reliable machinery lies the reliability of U bolts. In this landscape of manufacturing excellence, the role of U bolt suppliers emerges as pivotal players, ensuring that the foundation of industries remains steadfast.

Manufacturing excellence isn't merely about producing goods; it's a commitment to quality, innovation, and reliability. U bolt suppliers embody this ethos by consistently delivering products that meet and exceed industry standards. Their dedication to precision engineering ensures that each U bolt is crafted with meticulous attention to detail, guaranteeing optimal performance in diverse environments.

One of the hallmarks of manufacturing excellence in the realm of U bolt suppliers is their ability to tailor solutions to meet specific customer needs. Whether it's a bespoke design for a unique application or a large-scale production order, these suppliers exhibit versatility and flexibility in their operations. By leveraging advanced manufacturing techniques and cutting-edge technologies, they empower industries to achieve new heights of efficiency and productivity.

Moreover, manufacturing excellence goes hand in hand with sustainability in today's global landscape. U bolt suppliers recognize their responsibility towards environmental stewardship and adopt eco-friendly practices throughout their operations. From sourcing materials responsibly to optimizing energy consumption, these suppliers strive to minimize their carbon footprint while maximizing value for their customers.

Furthermore, manufacturing excellence isn't confined to the production floor; it extends to every aspect of the supply chain. U bolt suppliers prioritize transparency, reliability, and integrity in their dealings, fostering long-term partnerships built on trust and mutual benefit.

Selection Criteria

When navigating the market for U bolt suppliers, selecting the right partner is crucial for the success of any project or endeavor. Several key criteria should inform this decision-making process to ensure optimal outcomes.

Firstly, expertise and experience play pivotal roles. Assessing a supplier's track record within the industry, including the breadth of their portfolio and the depth of their technical knowledge, provides valuable insights into their capabilities.

Secondly, quality assurance measures are non-negotiable. Look for suppliers who adhere to stringent quality control standards and certifications, ensuring that their U bolts meet or exceed regulatory requirements and industry benchmarks.

Thirdly, responsiveness and communication are vital aspects of a fruitful partnership. Opt for suppliers who prioritize clear and prompt communication channels, fostering transparency and alignment throughout the procurement process.

Additionally, consider factors such as reliability, scalability, and cost-effectiveness when evaluating potential suppliers. A dependable partner with the capacity to scale operations according to your needs, while offering competitive pricing, can significantly enhance project feasibility and success.

Ultimately, the selection of U bolt suppliers should be a well-informed decision, guided by comprehensive assessment against these critical criteria. By prioritizing expertise, quality, communication, reliability, and cost-effectiveness, stakeholders can forge enduring partnerships that drive efficiency, innovation, and success.

Choosing the right U bolt for a specific application requires careful consideration of several factors:

Material: Depending on the environment, a U bolt may need to be made of weather-resistant materials like stainless steel.

Size and Load Capacity: The size and thread design must be suitable for the load it is expected to bear.

Shape: The shape of the U bolt must match the object it is clamping.

Finish: The right finish can greatly extend the lifespan of a U bolt by protecting it against corrosion.

U Bolt Suppliers: Ensuring Quality and Variety

Finding the right U bolt for your project involves more than just understanding the types and manufacturing processes. It requires access to a reliable supplier who can provide high-quality fasteners tailored to your specific needs. U bolt suppliers play a critical role in the ecosystem, ensuring that customers have access to a wide variety of fasteners that meet strict quality standards.

Reputable U bolt suppliers are characterized by their extensive inventory, which includes bolts of different sizes, shapes, and materials. They often offer custom manufacturing services for projects that require unique specifications. Additionally, top suppliers ensure that their products are tested for strength and durability, providing customers with the confidence that their fasteners will perform as expected.

Comprehensive Material Selection: U bolt suppliers meticulously source materials, including high-grade steel and other alloys, to ensure durability and performance across diverse applications.

Advanced Manufacturing Techniques: Leveraging state-of-the-art technologies such as computer-aided design (CAD) and precision machining, suppliers produce U bolts with unparalleled accuracy and consistency.

Rigorous Quality Control Processes: From initial inspection of raw materials to final product testing, suppliers implement stringent quality control measures to maintain the highest standards of quality and reliability.

Customization Capabilities: Recognizing the unique requirements of different industries and applications, U bolt suppliers offer customization options, including varying sizes, coatings, and thread types, to meet specific customer needs.

Diverse Product Range: In addition to traditional U bolts, suppliers often offer a diverse range of related products, such as square U bolts, round U bolts, and specialty configurations, providing customers with comprehensive solutions for their fastening needs.

Read Also: A Journey Through the World of Fastening Systems

The Importance of Quality Control

In the realm of U bolt suppliers, quality control isn't just a checkbox; it's a cornerstone of reliability, safety, and customer satisfaction. These seemingly small components play a significant role in supporting crucial infrastructure across various industries, from construction to transportation. As such, ensuring their quality is paramount.

Quality control measures within U bolt manufacturing encompass a spectrum of processes, from material selection to final inspection. Suppliers must meticulously vet raw materials, utilizing only the highest-grade steel or other suitable materials to withstand the rigors of their intended applications.

Precision engineering is another crucial aspect of quality control. U bolts must adhere to precise dimensional specifications to ensure proper fit and functionality. Advanced manufacturing techniques, such as computer-aided design (CAD) and computer numerical control (CNC) machining, enable suppliers to achieve unparalleled accuracy and consistency.

Furthermore, rigorous testing protocols are employed to validate the performance and durability of U bolts. This may include stress testing, corrosion resistance assessments, and fatigue analysis to simulate real-world conditions and ensure long-term reliability.

The importance of quality control extends beyond individual components to the overall reputation and trustworthiness of U bolt suppliers. By prioritizing quality at every stage of the manufacturing process, suppliers demonstrate their commitment to excellence and customer satisfaction, ultimately fostering enduring partnerships and driving industry advancement.

Conclusion

U bolts may be small, but their impact on the safety and integrity of structures and machinery is immense. Understanding the types of U bolts, their manufacturing process, and how to select the right one for your needs is crucial. Equally important is choosing a supplier that can provide high-quality, durable fasteners tailored to your project's requirements.

As industries continue to evolve and new challenges arise, the demand for precision-engineered fasteners like U bolts will only grow. By partnering with reputable U bolt suppliers, businesses can ensure that they are equipped with the best fasteners for the job, contributing to the overall success and longevity of their projects.

In a world where the strength and stability of our constructions, vehicles, and machinery are paramount, U bolts stand out as a critical component. Ensuring that these essential fasteners are of the highest quality and perfectly suited to their intended application is not just a matter of efficiency but of safety and reliability. As we have seen, the dynamics of U bolts encompass a wide range of considerations, from their design and manufacture to the crucial role played by suppliers in delivering precision fasteners for every need. By paying close attention to these aspects, we can continue to build, create, and innovate with confidence, knowing that our smallest components are more than capable of holding together our grandest designs.

Read Also: A Closer Look at Industry-Leading Carriage Bolt Makers

#bolt supplier#manufacturer#business#u bolt manufacturers#U-bolt Suppliers#U-bolt exporters India#U Bolts Manufacturer#U Bolts Manufacturers India

0 notes

Text

DIN 2391 ST37 Pipe Supplier In India

Sachiya Steel International Is One Of The Leading Exporter And Supplier Of ST37 Pipe In India, ST 37 steel is a kind of low carbon steel with carbon content of less than 0.17%, Silicon less than 0.35, Manganese more than 0.35, P and S each maximum up to 0.0. 4. DIN 2391 ST37 Pipe is also widely applied everyday uses and structural applications where high strength is not so important. DIN 2391 ST37 Steel Pipe is made up of carbon, nitrogen, phosphorus and sulfur. The material is strong and corrosion resistant and strong. Sachiya Steel International is a leading supplier of the DIN 2391 ST37 pipes in different standards, dimensions and shapes. The minimum yield strength of the pipes is 235MPa and the minimum tensile strength is 470MPa. The Carbon Steel DIN 2391 ST 37 Pipes can be processed as hot rolled, cold rolled, cutting, grinding, machining and forming operations.

The pipe’s outer diameter ranges from 4mm to 60mm. The wall thickness of the DIN 2391 ST37 Welded Pipe ranges from 0.5mm to 8mm and the length ranges up to 6000mm. There are different pressure grades of the pipes with different schedules. The ST37 Steel Pipe schedules are according to the wall thickness and the outer diameters. These are high wear and tear pipes that are used under high stress applications. The application include the petroleum industries, oil and gas industries, food processing, chemical, power generation, transmission lines and in general purpose piping applications. The ST 37 Steel Grade Seamless Pipe has high impact strength so that it can be used under high impact prone outdoor applications as well. Please feel free to contact us for more information on the DIN 2391 ST37 Carbon Steel Pipes and their pricing.

ST 37 carbon steel properties are as per this, Tensile strength 480 N/mm2, Elongation as 6% for cold drawn, provided with three types of surface treatment – galvanized, black or pre-painting. Owing to its chemical content, ST-37 EN10305 Carbon Steel Precision Pipe doesn’t have corrosive resistance and will get rusty within few days. Therefore , hot-dip galvanized or pre-painting is done sometimes in order to protect the steel from corrosion.

For More Info Visit our Website: https://steeltube.co.in/din-2391-st37-pipe-supplier-in-india/

Email Us: [email protected]

Contact Us: 97690 56007

0 notes

Text

Top Quality Copper Earthing Electrode Manufacturer in India

Veraizen Earthing is the largest copper earthing electrode manufacturer in India. Copper Earthing Electrodes are also constructed from Hot Dip Galvanized Pipes, with a copper termination and a 20 mm copper inside. Copper Earthing Electrodes Suppliers provides a wide range of Copper Earthing Electrode products, including the electrogrip 60mm 3 metre, electrogrip 40mm 3 metre, electrogrip 50mm 3 metre, electrogrip 80mm 3 metre, electrogrip 90mm 3 metre, and electrogrip 40mm 2 metre pure copper earthing electrodes.

The best copper earthing electrode supplier in India is Veraizen Earthing.We are also a leading supplier of pure copper electrodes, copper-bonded electrodes, and copper plates.We have built a good name in the local and worldwide markets via strong business ethics and high-quality items like the Copper Earthing Electrode. We ship our products all over the world. They are popular with our regular customers due to their extended lifespan and low cost.We also manufacture and sell copper-bonded solid electrodes, earth rods, solar earthing, and chemical earthing. We Supply Lightning Arrester Manufacturers in Mumbai and Lightning Arrester Manufacturers in Kolkata.

#Copper Earthing Electrodes manufacturers in india#Copper Earthing Electrodes Supplier in india#Copper Earthing Electrodes Suppliers#Lightning Arrester Manufacturers in Mumbai#Lightning Arrester Manufacturers in Kolkata

0 notes

Text

Chhajed Steel & Alloys Pvt.Ltd is a manufacturer & Exporters of Nickel 201 Pipe & Tubes. We offer Nickel Alloy Tubes across the globe with the help of state of art technology.

Hot Dipped Galvanizing and thickness are its unique characteristics. Epoxy and FBE Coating increases the quality of these pipes & tubes. The other types of these pipes & tubes are Fabricated /Seamless / Welded/ ERW to meet the industrial market.

Our Nickel Alloy Pipes & Tubes are highly customizable. It is a popular choice of our customers, you can avail these Pipes and Tubes at ease with the most reasonable price. The alloy is dual certified. Good mechanical properties provide it with excellent resistance to many corrosive environments. It is widely used to handle caustic soda. Where product purity is a priority, Nickel 201 is especially useful. The Nickel 201 Pipes UNS N02201 is manufactured to sustain very high pressure and product warranty.

Our product includes tubes and pipes, Nickel 201 Pipes, Nickel 201 Tubes, Nickel 201 Seamless Pipes & Tubes etc. These products are available at the best possible prices which is another important feature exhibited by our products range.

NICKEL 201 SEAMLESS & NICKEL 201 WELDED PIPES & TUBES SPECIFICATION:

Grade: Nickel 201 (UNS N02201)

Size: Seamless 1/2" - 10" , Welded 1/2" - 48"

Types: Seamless / ERW / Welded / Fabricated / LSAW Pipes

Form: Round, Square, Rectangular, Hydraulic Etc.

Nickel 201 Pipes, Nickel 201 Tubes, Nickel Alloy Werkstoff Nr.2.4068 Seamless Pipes & Tubes, Nickel 201 Welded Pipes Supplier, Nickel Alloy 201 EFW / ERW Pipes & Tubes Exporter in India.

0 notes

Text

Carbon Steel ASTM A105 Flanges Suppliers In India

Carbon Steel ASTM A105 Flanges Manufacturers In India,Supplier in India ,Stocklist in India,Exporter In India

Introduction Carbon Steel ASTM A105 Flanges Manufacturers In India,

Introduction:-

ASTM A105 is an American standard specification for carbon steel flanges and fittings, which has been widely adopted in India due to its proven performance and reliability. These flanges are manufactured according to the ASTM A105 standard, ensuring they meet the required specifications for strength, durability, and quality

While ASTM A105 flanges offer many benefits, it is important to consider the specific requirements of the application. For highly corrosive environments or extreme temperature conditions, alternative materials like stainless steel or alloy steel flanges might be more suitable.

Product Overview:-

ASTM A105 Flange is a specification for flanges. Specifications can include flanges of various grades made of stainless steel. The flange is made of forged Carbon Steel ASTM and is intended for high temperature use. Shasan Piping Solution is a leading manufacturer and supplier of ASTM A105 flange types.

TThis material contains carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum, and vanadium. These are called Carbon Steel ASTMs because other materials contain less than 1% of the composition. There are different types, including SA105N blind flanges, which are used to close pipelines. The flange also has excellent strength properties. The minimum yield strength of the flange is 250 MPa and the minimum tensile strength is 485 MPa. It is a hard material with a Brinell hardness of 187

Specifications:-

Specifications

ASTM A182, ASME SA182

Size

1/2″ to 48″

Standards

ANSI B16.47 Series A & B, MSS SP44, AWWA, Custom Drawings, ASA, ANSI B16.5, API-605.

Pressure Ratings

Class 400, Class 150, Class 1500, Class 300, Class 900, Class 2500, Class 600

Flange Face Type

Flate Face, Raised Face, Ring Type Joint

Coating/Surface Treatment

Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated.

Benefit:-

India is home to several prominent manufacturers of Carbon Steel ASTM A105 flanges, catering to the diverse needs of various industries such as oil and gas, petrochemical, chemical processing, and power generation. Here's a brief overview of some notable manufacturers. In India, numerous manufacturers produce high-quality Carbon Steel ASTM A105 flanges, catering to a wide range of industrial applications. These manufacturers are known for their adherence to international standards, competitive pricing, and the ability to provide customized solutions to meet specific needs

Conclusions:-

There are various pressure classes such as class 150, 300, up to 2500, and PN6 to PN64. A105 flanges of class 300 and below do not require heat treatment, but high pressure class can be heat treated. Flanges with a nominal internal diameter greater than 4 inches are heat treated as annealing, normalizing, normalizing and tempering, or normalizing and tempering. ASTM A105 pipe flanges can also be forged. This material is suitable for welding applications. When welding materials, boilers, and pressure vessels, guidelines consistent with ASME standards must be followed. Flanges are both bolted and bolted. ASTM A105 N threaded flanges are useful when welding or screwing methods are not suitable. Threaded flanges can be used on threaded pipes to create connections without welding. Please contact us for flange pricing and details.

Email Id :- [email protected] Contact No:- 88879709191

0 notes

Text

Blind Raised Face Flanges (BLRF) Sellers

About the product

Blind raised face flanges are essential components in piping systems, offering a sealing mechanism at the end of a pipeline or vessel. This is a kind of round plate without a central post, but with suitable screw holes. These BLRF flanges are available in different sizes, grades, specifications,, and strengths as per customer requirements. These flanges find application in industries such as oil and gas, chemical processing, and power generation. Their ability to withstand high pressures and temperatures, resist corrosion, and facilitate easy installation and maintenance makes them indispensable in critical industrial environments.

In strict adherence to industry standards such as ASME B16.5, ASME B16.47, MSS SP44, ANSI B16.36, and ANSI B16.48, our blind raised face flanges assure unparalleled performance and reliability. Further elevating our offerings, we provide various flange face types, including flat face (FF), raised face (RF), and ring type (RTJ). Committed to ensuring prolonged longevity and resilience against corrosion, our products undergo a meticulous coating and surface treatment process, encompassing options such as anti-rust paint, oil black paint, yellow transparent, zinc plated, as well as cold and hot dip galvanized finishes. Entrust Platinex Piping Solutions LLP for blind raised face flanges of superior quality, surpassing industry standards and expectations with each product.

Specifications

Platinex Piping Solutions LLP stands at the forefront as a distinguished manufacturer, supplier, and exporter of Blind raised flanges, meticulously crafted from premium-quality raw materials. Our BLRF Flanges, available in stainless steel and alloy steel variants, epitomize excellence in quality and durability. Engineered to impeccably seal pipelines, valves, and pumps, these flanges also serve as adept inspection covers. Our blind flanges feature a circular plate construction with no central opening and all necessary screw holes to expertly secure the ends of your piping system. Tailored to meet the discerning requirements of our esteemed clientele, our BLRF Flanges are available in a diverse range of sizes, grades, specifications, and thicknesses. Specifications include sizes ranging from ½” (15 NB) to 48 (1200 NB) and classes spanning 150 LBS to 2500 LBS, alongside DIN Standard ND-6,10, 16, 25, 40, among others.

Grades in Blind Raised Face Flanges

Stainless Steel Blind Raised Face Flanges

⇒ ASTM A403 WP Gr. 304

⇒ASTM A403 WP Gr 304H

⇒ASTM A403 WP Gr 309

⇒ASTM A403 WP Gr 310

⇒ASTM A403 WP Gr 316

⇒ASTM A403 WP Gr 316L

⇒ASTM A403 WP Gr 317L

⇒ASTM A403 WP Gr 321

⇒ASTM A403 WP Gr 347

⇒ASTM A403 WP Gr 904L

Carbon Steel Blind Raised Face Flanges

Low Temperature Carbon Steel Blind Raised Face Flanges

Alloy Steel Blind Raised Face Flanges

Duplex Steel Blind Raised Face Flanges

Nickel Alloy Blind Raised Face Flanges

Types of blind raised face flanges (blrf)

Blind raised face flanges come in two primary types:

standard duty and

heavy duty

Standard duty flanges, commonly forged from steel or carbon steel, offer lower pressure ratings, typically up to 300 psi. Heavy-duty blind flanges with increased sealing surface, on the other hand, have higher pressure ratings reaching up to 1,000 psi and are typically made of stainless steel or alloy materials for added durability. These flanges provide a secure connection between pipe sections, ensuring integrity in various pressure systems.

Additionally, they offer versatility, with the capability to function effectively in both high-pressure and low-pressure environments.

Platinex Piping also offers Socket raised face flanges, orifice flanges, and various grades to cater to diverse project requirements. Whether for standard or heavy duty applications, blind raised face flanges offer quick assembly times and reliable connections, making them indispensable in industrial settings. With options like Carbon Steel Blind Raised Face Flanges and Duplex Steel Blind Raised Face Flanges, Platinex Piping ensures that customers receive top-quality products tailored to their specific needs, ensuring efficiency and safety in their operations.

ANSI B16.5 BLIND FLANGES APPLICATION

The ANSI B16.5 blind flanges find extensive applications across diverse industries, renowned for their exceptional performance and reliability. Platinex Piping offers a wide range of flat face blind flanges, distributed through a global network of stock-keeping branches. These versatile flanges serve various purposes in industries, such as

Oil and Gas Pipeline

Chemical Industry

Plumbing and Structural Pipe

Heating

Water Supply Systems

Power Plant

Paper & Pulp Industry

General Purpose Applications

Fabrication Industry

Food Processing Industry

Manufacturing Standards

Platinex Piping offers a comprehensive range of blind raised face flanges crafted from high-quality materials to ensure superior performance and durability across diverse industrial applications. Our Stainless Steel Blind Raised Face Flanges include ASTM grades such as A182, A240 F 304, 304L, 316, and more, providing excellent corrosion resistance and longevity. For Carbon Steel Blind Raised Face Flanges, we provide options like ASTM A105/A105N, A350 LF2, and A694 F52, suitable for high-pressure environments. Alloy Steel Blind Raised Face Flanges, featuring ASTM A182 grades like F5, F9, and F22, offer exceptional strength and reliability. Additionally, our Nickel Alloy Blind Raised Face Flanges, Copper Alloy Blind Raised Face Flanges, and Duplex Steel Blind Raised Face Flanges cater to diverse project requirements with materials such as Monel, Inconel, Hastelloy, Cu-Ni alloys, and more. With a commitment to quality and precision, Platinex Piping ensures that our blind raised face flanges meet industry standards and exceed customer expectations for performance and longevity.

These flat steel blind flanges serve a variety of purposes, from sealing pipelines, valves, and pumps to use as inspection covers. With precise engineering and meticulous attention to detail, our blind flanges guarantee seamless integration into piping systems, facilitating smooth operations and maintenance. We pride ourselves on offering BLRF flanges in various sizes, grades, specifications, and thicknesses, tailored to meet the unique requirements of our clients. Trust Platinex Piping Solutions LLP for superior quality Blind Raised Face Flanges that exceed expectations in performance, durability, and reliability.

Use of The Product

Blind raised face flanges exporters in India play a crucial role in various piping applications, offering versatile solutions for both temporary and permanent closures of piping systems. These flanges serve as essential connection points, facilitating future expansions of the piping network while ensuring secure seals. ASME B16.5 Blind Flanges are particularly instrumental in creating pressure vessels for containing substances such as oil, gas, and water, effectively preventing hazardous leaks or spills. Additionally, they enable seamless liquid or gas transfer through pipes by establishing reliable connections between pipe sections. The versatility of blind flanges extends to terminating piping systems, as they lack a hub or bored center, presenting a solid face with a matching thickness, face type, and bolting pattern. They can effectively seal nozzle openings on pressure vessels, maintaining system integrity and safety standards. Available in both raised face (RF) and flat face (FF) styles, blind flanges are designed to prevent the flow of liquid, gas, or air, making them ideal for applications requiring a complete seal. These flanges find utility in various scenarios, including pressure testing, providing access points in piping systems, temporary sealing during maintenance or repairs, and long-term termination of piping systems. Bolted rather than welded in place, blind flanges offer easy accessibility for system upkeep, inspections, or future expansions. When paired with a gasket, they create a robust seal, effectively filling the space between flange faces to prevent any potential leaks, ensuring operational safety and efficiency.

Why platinex for the product

Platinex Piping Solutions LLP stands out as the premier choice for Stainless Steel Blind Raised Face Flanges, Alloy Steel Blind Raised Face Flanges, and Nickel Alloy BLRF Flanges. As an esteemed manufacturer, supplier, and exporter, we prioritize quality and reliability in every aspect of our products. Our extensive range of flanges conforms to industry standards including ASME B16.5, ASME B16.47, ASTM A182, A105, A350, SB564, SB160, and SB472, ensuring compliance and performance excellence. Crafted from high-quality raw materials, our Blind Raised Face Flanges offer unparalleled durability and functionality.

Stainless Steel Blind Raised Face Flanges, Alloy Steel Blind Raised Face Flanges Manufacturer & Exporter.

ASME B 16.5, ASME B 16.47, ASTM A182, 105, 350, SB564, 160, 472 Blind Flanges, Nickel Alloy BLRF Flanges Suppliers.

Platinex Piping Solutions LLP is one of the leading Manufacturers, Supplier and Exporters of Blind Raised Face Flanges using high quality raw materials. These BLRF Flanges are made using premium quality materials. These flat face steel blind flanges are used to blank off pipelines, valves and pumps, it can also be used as an inspection cover. A blind flange is used to close ends of piping systems. It is a kind of round plate with no center hold but with all the proper bolt holes. These BLRF Flanges is available in various size, grades, Specification & thickness as per the clents requirments.

0 notes

Text

Supplier of Puddle Flange in Telangana

Supplier of Puddle Flange in Telangana:

Meghmani Metal Industries:

An ISO Certified 9001:2015 Engineering Company based in Ahmedabad. Renowned for premium-quality manufacturing and supply of Puddle Flange.

Expertise in ferrous and non-ferrous metal products. Specialized products include Stainless Steel Pipes, Stainless Steel Tubes, Steel Flanges, Steel Butt Welding, Steel Pipe Fittings, Steel Rods, Wires, Coils, Flats, Structural components, etc.

Puddle Flange Applications:

Widely utilized in plumbing, gas injection, and various areas such as tanks, floors, manholes, shafts, walls, and pools.

Puddle Flange Specification:

Product Name: Puddle Flange / Puddle Pipe

Steel Grade: Copper, Ductile Iron, Cast Iron, Carbon Steel, Stainless Steel, etc.

Standards: Compliant with AISI, ASTM, BIS, DIN, GB, JIS, EN10249, EN10248, ASTM A328, ASTM A105, ASTM A350, and more.

Size: Available in various sizes from 19mm to 2000mm and customizable sizes.

Length: Ranges from 50mm to 12 meters.

Finishing: Options include black, painted, or galvanized, as well as stainless steel, copper, black oxidized, and hot-dip galvanized.

Trade Terms: Acceptable trade terms include FOB, CRF, CIF, and EXW.

Supply in Telangana:

We Provide Supplier of Puddle Flange in Telangana, serving locations including Hyderabad, Warangal, Nizamabad, Khammam, Karimnagar, Ramagundam, Mahbubnagar, Nalgonda, Siddipet, Miryalaguda, Suryapet, Jagtial, Bhongir, Kamareddy, Mancherial, Wanaparthy, and Jangaon.

For further inquiries and information, please don't hesitate to contact us.

Read the full article

#Bhongir#Hyderabad#India#Jagtial#Jangaon#Kamareddy#Karimnagar#Khammam#Mahbubnagar#Mancherial#Manufacturer#Miryalaguda#Nalgonda#Nizamabad#PuddleFlange#Ramagundam#Siddipet#Stockiest#supplier#Suryapet#Telangana#Wanaparthy#Warangal

0 notes

Text

Nitrous Oxide Cylinder, 0.95L whipped cream charger

100 Bulbs (50 Pack X 2) Pure N2O Cream Chargers

DSW is a professional nitrous oxide canisters manufacturer and supplier of 0.95L/2.2L Nitrous Oxide cylinders and 0.95L whipped cream chargers that enjoy a high reputation in quality and delivery.

Categories: Gases, Nitrous Oxide gasTags: 580G Nitrous Oxide Cylinder, whip cream chargers, whipped cream chargers

Description

0.95L whip cream chargers suppliers

Established in 2006, DSW is one of China’s premier gas manufacturers & suppliers, Offering an annual production capacity of 1.1million tonnes of carbon dioxide (CO), 60k tonnes of nitrous oxide (N2O), and 400 million 8g cream chargers – DSW stands ready to meet growing demands for quality gases.

DSW is a professional cream chargers manufacturer and supplier of 0.95L/2.2L Nitrous Oxide cylinders and 0.95L whipped cream chargers that enjoy a high reputation in quality and delivery.

Ammonium nitrate gas produces an inhalant with exhilarating or anesthetic properties when heated. It can be used as both an anesthetic agent and aerosol propellant (commonly referred to as laughing gas) and also referred to as laughing gas.

supreme whip cream chargers specification

What Is an N2O Whip Cream?

A nitrous oxide cartridge is a small metal canister filled with nitrous oxide and fitted with a small nozzle at one end for whipping cream. Nitrous oxide helps thicken and stabilize it to produce delicious, creamy results! When used to create fluffy clouds of fluffy foam.

These small chargers are budget-friendly solutions for in-home kitchens; restaurants and cafes typically opt for larger tanks containing 580g of nitrous oxide.

What does a whip cream charger do?

Each 0.95L Canister contains 580g of the highest culinary grade n20 gas available and considerably reduces wastage vs. 75 standard Cream Chargers per 1 of our units.

DSW tanks have .95 liters of FDA lab-certified culinary food-grade nitrous oxide gas.

Enjoy delicious whipped cream. Conforms to Standards – The charger canister conforms with Manufacturing International Standards such as ISO 9001 and ISO 14001, so you can be sure it is of outstanding quality.

The advantages of the ammonium nitrate method are high purity, high capacity, and environmental protection. We are the largest N2O producer of ammonium nitrate method in China.

We can provide 0.95L-3.3L industrial grade, food grade, medical grade, and electronic grade nitrous oxide; the purity range is 99.5%-99.9995%.

A whipped cream charger is a steel cylinder that’s also referred to as a cartridge. Whipped cream chargers are filled with nitrous oxide or N2O. The charger is tasked with destroying and creating the whipped cream using a sharp pin inside the dispenser.

Consequently, what is the purpose of whipped cream chargers, which are steel cylinders, also known as cartridges? Whip cream canisters are filled with nitrous oxide or N2O. Using a sharp pin inside the dispenser, the charger is responsible for whipping and creating the cream.

Here are some ways chefs and cooks use whipped cream canisters in their kitchens:

Decoration: Use a piping bag with a star tip to pipe fresh whipped cream onto cakes or cupcakes.

Filling: Use a piping bag to serve doughnuts with whipped cream or fill for cream puffs or eclairs.

Topping: Top pie slices or cheesecakes with a dollop of whipped cream, or use it as a topping for milkshakes or frappes.

Cocktails: Add a whipped cream topping to cocktails like Irish coffees, or use it as a mixer for drinks like the White Russian.

You can use your whipped cream to top off cakes, cupcakes, pies, and other desserts. You can also use it to fill and decorate cakes and cupcakes.

Frosting: You can use whipped cream instead of frosting on cakes and cupcakes. It’s a great way to cut down on sugar and calories.

Cream filling: You can use whipped cream to fill cakes, cupcakes, and other pastries.

Snacks: You can use whipped cream to make fruit dips, chocolate dipping sauce, and other tasty snacks.

0 notes