#DistilledWaterStorageTanks

Text

Kingspan Diesel Storage Solutions

Market of Diesel Storage Tanks in India

The global fuel and storage industry is growing rapidly. India is the world’s third-largest oil consumer, which used 35.2 million tonnes of diesel from January to May in 2018. This figure had risen by 6% from the corresponding period last year. More than half of India’s population is employed in the farm sector, which depends on diesel to fuel the pumps for land irrigation.

This industrial growth has led to an increase in demand and supply of advanced storage solutions. Production of diesel is witnessing a significant growth due to its demand from end-use industries. Many storage solution manufacturers are now incorporating new strategies, improvised designs and advanced techniques in their processes.

Product Insights

Storage tanks or fuel tanks are used for storage and dispensing of diesel. They are also useful for transporting them safely to desired areas. Increasing urbanization has made India a leading economy and an elevated consumer of diesel in the past few decades.

As established global market leaders, Kingspan offers a diverse range of innovative and environmentally responsible steel and plastic Diesel Storage solutions. These tanks are ideal for a wide variety of industrial, agricultural, road haulage, mining, manufacturing, and construction applications. The tanks are constructed differently for different liquids in accordance with the needs and storage capacity.

The advanced storage tanks are intelligently created, offering the following advantages-

Leak-proof bunded (double) casing for storage of diesel with dispensing pumps to ensure no loss due to spillage.

In-house telemetry, which ensures that the readings are always accurate and there is no loss due to pilferage.

Lightweight and easy to transport and store.

Compliant with global certifications of safety.

2-year warranty on the tank body and 1-year warranty on pumps and nozzles.

Cost effective with savings over the life of the tank.

Product Portfolio

Kingspan’s steel and plastic storage solutions offer diesel dispensing and management systems in capacities ranging from 200 to 100,000 litres.

1. Kingspan TruckMaster

Usage- Safe transportation of diesel fuel

Capacity- 200, 300, 430 and 900 litres

Warranty- 5-year conditional tank warranty

2. Kingspan FuelMaster

Usage- Storage, dispensing and protection of diesel fuel

Capacity- 2,500 and 5,000 litres

Warranty- 5-year conditional tank warranty

3. Kingspan DieselPRO

Usage- Shipping and transportation of diesel to remote locations with standard 10ft, 20ft and 40ft container footprint options

Capacity - 12,000, 30,000 and 66,000 litres

UL142 complaint

Quality Assurance

Quality of the diesel storage tanks is a major concern as they carry hazardous fluids and are always at risk. It can only be assured by adopting and being awarded appropriate certifications.

For over 40 years, Kingspan has designed and manufactured innovative ways to store and dispense diesel. They have pioneered the world’s first environmentally responsible bunded tank, leading change in the sector, ensuring trust and reliability and setting industry standards around the world.

Shubham Acqualink has been awarded the BS EN ISO 9001:2000 certification for quality assurance. The certification demonstrates the ability to consistently provide the product that meets customer and applicable regulatory requirements and aims to enhance customer satisfaction through the effective application of the system, including processes for continual improvement of the system and the assurance of conformity to customer and applicable regulatory requirements.

Application Insights

Each series of tanks offer a variety of applications, depending on the usage requirements.

The Kingspan TruckMaster range is specifically designed for the safe transportation of diesel fuel. It offers a lightweight, robust and portable solution for convenient refueling on-site.

The Kingspan FuelMaster range offers a robust and convenient on-site storage solution. This range has been specifically designed for the secure storage, dispensing and protection of diesel fuel.

The Kingspan DieselPRO range of self-bunded containerized steel tanks has been specifically designed for shipping and transportation to remote locations with standard 10ft, 20ft, and 40ft container footprint options.

Shubham Acqualink (India) Pvt. Ltd. (SAIPL) is an 18-year-old company focused on water storage and water management solutions. It manufactures high-quality Zincalume Steel Bolted panel tanks with Liner in India under technical collaboration with Kingspan Water & Energy, Australia and is exclusively responsible for promoting the Kingspan Rhino Tanks, Kingspan Diesel and AdBlue Storage Tanks in the Indian sub-continent.

SAIPL also separately provides Glass Fused Steel tanks for very critical storage & Bio-gas applications as well as ultra large (up to 80 lac litre) storage tanks in collaboration with YHR Beijing, China.

#DistilledWaterStorageTanks#WaterSprinklerTank#VerticalStorageTank#OilStorageTanks#DieselStorageTank#WaterStorageTanks#StainlessSteelWaterTank#SteelWaterTank#IndustrialWaterStorageTank#UndergroundWaterTanks#DMWaterTank#ZincAluminiumWaterTank#OverheadTanks#MSwaterTanks#LiquidTanks#FabricatedTanks#ShubhamAcqualink

1 note

·

View note

Text

Industry Applications of Kingspan RHINO Tanks

Introduction

Shubham Acqualink (India) Pvt. Ltd. (SAIPL) manufactures high-quality Kingspan RHINO Tanks in India under technical collaboration with to Kingspan Water & Energy Australia, and is exclusively responsible for promoting the Kingspan RHINO Tanks in the Indian sub-continent.

For the past 25 years, Kingspan Rhino has been manufacturing high quality, long-lasting water tanks, and accessories. Today, Kingspan Rhino continues to be a market leader and trusted the source of expert advice in liquid storage solutions for the residential, commercial and rural sectors. Kingspan Rhino Tanks offers high-quality steel water tanks and accessories that are built to last. Utilizing many advanced design features and materials, Kingspan Rhino tanks are strong, fully customizable, and corrosion resistant and carry the highest structural wind rating in the market. Kingspan Rhino Tanks are bolted-panel/inner liner design pre-fabricated, site-assembled tanks.

Applications

Kingspan Rhino Tanks can provide storage solutions across various application areas like:

Drinking/Potable Water - ANSI/NSF – 61 certified INFINITY ™ liner ensures that water stored inside remains safe for drinking for a long time.

Fire Water storage - Modular design, quick installation, durable and customization of nozzles make this ideal for fire water storage.

Raw Water Storage - Tough liner can handle pH from 2-12 and temp from -20 deg C to + 60 deg C making it ideal for raw water storage.

RO/DM Water Storage - Tough Metallocene contact layer (molecular density > Kevlar) makes the liner safe for storing aggressive liquids like DM water.

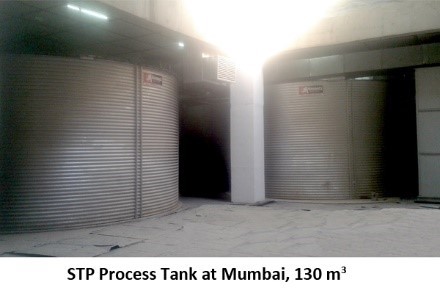

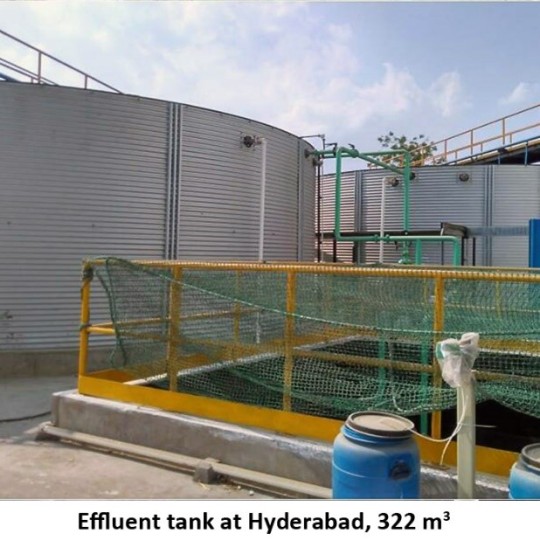

STP/ETP Aeration and Clarifier Tanks – Tough, long lasting, UV stabilized and inert liner ensure that these tanks work excellently even when kept open as no algae/fungus formation happens, ideal for Aeration/ Clarifier application.

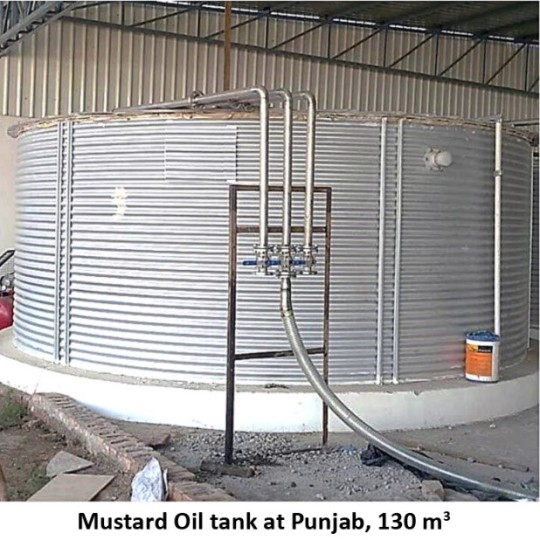

Vegetable Oil Storage- Potable water certified liner ensures it is safe to store edible oils.

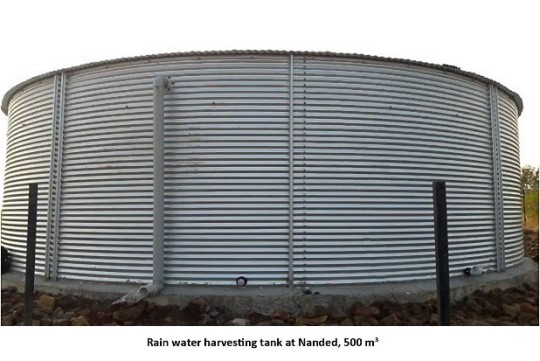

Rain Water Harvesting- Dome-shaped roof with rain saver caps help to capture rainwater falling on the roof and store directly in the tank.

Benefits

Quick to Install. Tanks up to 100 KL can be installed at the site into 2-3 days and made ready to store water.

Relocatable. Can be knocked down and re-assembled at a different site one day.

Low Maintenance. The inner liner which holds the liquid is a unique 5 layered, reinforced liner with Metallocene layer. Metallocene doesn’t allow any algae or fungal formation on it, making it practically maintenance free.

Potable Water certified. Certified to stringent ANSI/NSF-61 standards

Durable. The design life of 50-60 years. Outer structure made from highly corrosion resistant and strong Zincalume Steel corrugated panels manufactured by Tata BlueScope.

Light weight and can be installed in the remotest locations easily.

Cost effective.

Warranty - 3 years pro-rata warranty for clear treated water.

#DistilledWaterStorageTanks#RainWaterHarvesting#VegetableOilStorageTanks#STP/ETPAerationandClarifierTanks#RO/DMWaterStorageTanks#RawWaterStorageTanks#FireWaterstorageTanks#ShubhamAcqualink

0 notes

Text

Glass-Fused-To-Steel-Tanks

Introduction & Specifications

Glass-Fused-To-Steel-Tanks technology was brought to India, exclusively by Shubham Acqualink (India) Pvt. Ltd; the leader in Zincalume® Steel Bolted liner tanks in India. It has tied up with YHR of Beijing, China to bring GFST technology to India. The glass-fused-to-steel technology conveys more prominent lifetime value than welded or concrete tanks. Two materials are fused together to accomplish the best properties of both – the quality and adaptability of steel joined with the corrosion resistance of glass.

Glass-Fused-To-Steel-Tanks are available in sizes ranging from 100 m3 to 10000 m3. YHR has a strong pedigree of over 6000 GFS tanks constructed and operated globally in the past 13 years.

Why choose Glass-Fused-To-Steel Technology

i. Faster Construction Speed

Since all the tank steel plates and accessories are prefabricated in a factory and easily assembled, Glass-fused tanks can be installed in many types of weather conditions which site constructed steel and concrete tanks cannot. Tanks are assembled with a jacking system that progressively elevates the structure without the need for expensive cranes and extensive scaffolding. This construction method enables rapid, logical progress for timely completion.

ii. Convenient & Safe Installation Work

Most of the work is done on the ground hence there is more safety and less risk of working onsite. Other tanks involve long development period.

iii. Super Anti Corrosion Performance

GFTS Coating Thickness: 0.25~0.45mm, double sides coating PH application range:

Standard coating pH value: 3~11; well qualified for biogas application.

Special glass coating PH: 1-4.

Adhesive power: 3,450 N/cm;

GFTS Coating Elasticity: the same to the steel plate, in 500 kN/mm;

Service Life is greater than 30 years.

iv. Better And Easy Quality Control

All items prefabricated and assembled on site, unlike pouring or welding on site. Can be installed in any weather. Not dependent on workers skill, sense of responsibility or mood.

v. Less & Easy Civil Work

Concrete and welded tanks can have long lead and construction times. Glass Fused Tanks are easy to install because of construction is done on the ground with less manpower and fewer machines.

vi. Low Maintenance Cost

High yield strength steel and enameled coating with high abrasion-proof. Concrete tanks are expensive, usually take longer to construct than Glass-fused tanks. Concrete tanks always need a maintenance because design specification of concrete tanks allows for some level of cracking, leaking.

vii. Beautiful Appearance Which Makes Your Plant Value-Added

Assurance you will receive the highest engineered quality, best service, longest product life, and greatest value in liquid storage tanks.

viii. Reasonable Price Compared With Concrete Tank

Concrete and welded tanks can have long lead and construction times. Glass Fused Tanks are easy to install because of construction is done on the ground with less manpower and fewer machines.

Glass-Fused-To-Steel-Tanks are useful for effluent & sewage treatment, biogas & bio-methane generation, molasses and another ultra large liquid storage, municipal wastewater, industrial wastewater, drinking water, sludge disposal, livestock effluent, landfill leachate, kitchen waste, and agricultural organic waste, both in India & globally.

Technical expertise of YHR combined with execution excellence of Shubham Acqualink will create a win-win for our esteemed clients.

#DistilledWaterStorageTanks#ShubhamAcqualink#VerticalStorageTank#Glass-Fused-To-Steel#Glass-Fused-To-Steel Technology#YHR

0 notes