#EPS Torque Sensor

Explore tagged Tumblr posts

Text

EPS Torque Sensor Market

0 notes

Text

1st gen Subaru Alcyone. Sold as a Vortex in Australia but we never got these FLAT-6 versions, only flat-4 in NA and turbo with choice of FF or AWD

Hyper technology for greater driver loyalty. Intelligent Express.

Alcyone 2.7ℓ FLAT-6

ALCYONE 2700/1800

The Alcyone is a car with a new concept that anticipates the motorization of the near future. Everything about it has been developed to ensure that the driver feels no burden or stress under any driving conditions and always performs at 100% of its potential. It features a number of electronically controlled mechanisms that realize the ultimate in speed through advanced automatic control, including the next-generation 4WD, Active Torque Split 4WD, and the high-performance 2.7-liter FLAT-6. These intelligent mechanisms dramatically improve the vehicle's dynamic performance and create an unprecedented feeling of high-speed movement.

PHOTO: 4WD 2.7L VX Black Mica

Next-generation intelligent mechanisms create a new driving experience.

FLAT-6

2.7ℓ FLAT-6 Engine with EGI System

EGI Horizontally opposed 6-cylinder 2.7-liter engine

Subaru's traditional horizontally opposed engine has been made into a 6-cylinder engine, the FLAT-6, with a large displacement of 2.7 liters. The ideal rotation and vibration characteristics of the horizontally opposed 6-cylinder engine create a smooth rotation feeling. The flat and powerful torque is only possible with a large displacement. And the excellent basic performance has been carefully tuned with the latest electronic control technology to achieve refined speed. The unparalleled individuality invites you to the pleasure that only the Alcyone can provide. (VX)

EGI turbocharged flat-four 1.8-liter engine

The unrivaled horizontally opposed engine is equipped with a high-performance turbo. In addition to smooth and powerful acceleration from low speeds, the response has been greatly improved by the advancement of the EGI system and tuning of the intake system. (VR, VS)

Electronically controlled active torque split 4WD

"Active Torque Split 4WD" maximizes the potential of 4WD. This drive force control system uses a computer to accurately determine the driving situation and road surface conditions, precisely controlling the torque distribution between the front and rear wheels. Always achieving ideal high-speed, easy driving. (VX, VR•AT)

All-range electronically controlled 4-speed automatic E-4AT

Smooth and soft shifting feeling, sharp response, and automatic control of power/economy shifting modes, highly accurate lock-up control, engine brake control, etc. are some of the latest technologies that have been incorporated into the shifting mechanism of this highly functional transmission (VX, VR-AT, VS-AT).

For more reliable operation of automatic transmission vehicles

●Key interlock

•shift lock

•reverse alarm

●AT select indicator is adopted

Electronically controlled air suspension system EP-S

Precise vehicle posture control and vehicle height adjustment. The optimal spring rate setting that makes the most of the characteristics of the air spring and the synergistic effect of the variable damper provide exquisite high-speed stability and a smooth ride.

ABS (4-wheel anti-lock braking system)

The sensor detects wheel lock in advance, which can easily occur when driving at high speeds or when braking suddenly on slippery surfaces.

The ABS detects the vehicle's position and electronically controls the brake pressure, providing excellent danger avoidance capabilities. The 4-sensor diagonal select low system provides excellent control even on roads with different friction coefficients for the left and right wheels.

Electronically controlled motor drive power steering

The latest power steering system uses an electronically controlled motor-driven pump for hydraulic control.

The system determines driving patterns based on vehicle speed and frequency of steering operation. In addition to speed-sensitive control, it also provides optimal steering feel even at a constant speed. (VX)

Cd=0.29*. High performance aerodynamic form

The first Japanese car to break the Coefficient of Air Resistance Co = 0.30 barrier

Breakthrough. Improved maneuverability at high speeds (CD=0.29) and quietness.

PHOTO: 4WD 1.8L VR Medium Gray Metallic/Fine Silver Metallic

9 notes

·

View notes

Text

Automotive Electric Power Steering Market Drivers Transforming Future Vehicle Technologies and Growth Opportunities Globally

The automotive electric power steering market is witnessing significant growth, primarily propelled by various critical drivers that are reshaping the automotive industry. One of the most influential drivers is the increasing demand for fuel-efficient vehicles. Traditional hydraulic power steering systems tend to consume more power and reduce overall fuel efficiency, whereas electric power steering systems consume power only when steering assistance is needed. This feature significantly reduces energy consumption, contributing to better fuel economy, which aligns with growing consumer and regulatory demand for environmentally friendly vehicles.

Another key driver of the automotive electric power steering market is the rising adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs). The transition towards electrification of vehicles is encouraging manufacturers to integrate EPS systems because they are more compatible with electric drivetrains compared to hydraulic systems. EPS can easily be integrated with other electronic vehicle control systems, providing an overall enhancement in vehicle performance and control. As governments worldwide push for stricter emission norms and incentives for electric vehicles, EPS market growth is accelerated by the expanding EV ecosystem.

Safety regulations and advancements in automotive safety technology also significantly drive the EPS market. Modern vehicles are equipped with advanced driver assistance systems (ADAS), such as lane-keeping assist, automated parking, and collision avoidance systems, which rely heavily on precise steering control. Electric power steering systems provide the necessary electronic control interface for these safety features, improving overall vehicle safety and responsiveness. With increasing focus on reducing road accidents and enhancing driver comfort, automotive manufacturers are investing heavily in EPS technology.

Customer demand for enhanced driving comfort and convenience is another important market driver. EPS systems offer improved steering feel and reduced driver fatigue compared to conventional systems. By automatically adjusting steering effort based on vehicle speed and driving conditions, EPS enhances maneuverability in urban environments while providing stability at higher speeds. This adaptability appeals to a wide range of consumers, from everyday drivers to luxury vehicle owners, fueling demand for EPS-equipped vehicles.

Technological advancements in sensor technologies and electronic control units (ECUs) are further driving the adoption of EPS systems. Innovations such as torque sensors, brushless DC motors, and more efficient control algorithms have improved the reliability, responsiveness, and cost-effectiveness of electric power steering. These technological improvements help reduce manufacturing costs and improve system durability, encouraging automakers to adopt EPS as a standard feature even in mid-range vehicles.

Increasing production of passenger cars and commercial vehicles globally supports the automotive electric power steering market growth. Emerging economies are witnessing rapid urbanization and rising disposable incomes, resulting in higher vehicle sales. Automotive manufacturers are incorporating EPS technology across various vehicle segments to meet consumer preferences for fuel economy, safety, and comfort, thus expanding market penetration.

The trend of vehicle electrification is also supported by stringent government regulations on vehicle emissions and fuel economy standards. Many countries have mandated the use of more efficient steering systems that contribute to lowering carbon footprints. Subsidies and incentives for electric vehicle production indirectly promote the adoption of electric power steering systems, as they are integral components of EV platforms.

Furthermore, EPS technology allows easier integration with autonomous and semi-autonomous driving systems, which is an emerging trend in the automotive industry. Self-driving cars require precise steering control that can be electronically managed, making EPS indispensable in the development of autonomous vehicles. This long-term growth prospect also acts as a major driver for research and development investments in EPS.

The shift towards lightweight vehicle components to improve fuel efficiency also benefits the EPS market. Electric power steering systems are generally lighter than hydraulic systems due to the absence of hydraulic pumps and fluid. This weight reduction contributes to overall vehicle efficiency and handling dynamics, encouraging manufacturers to adopt EPS systems in both passenger and commercial vehicles.

In conclusion, the automotive electric power steering market is driven by multiple factors including the increasing demand for fuel-efficient vehicles, rapid growth in electric and hybrid vehicles, stringent safety regulations, customer preference for comfort and convenience, technological advancements, and the rising adoption of autonomous driving technologies. These drivers collectively foster a positive growth environment for EPS manufacturers and automotive companies investing in advanced steering technologies. The ongoing shift towards sustainable mobility and smarter vehicles ensures that the EPS market will continue to expand and evolve in the foreseeable future.

0 notes

Text

0 notes

Text

Electric Power Steering Gear: Enhancing Vehicle Performance and Control

How Does Electric Power Steering Gear Work?

The Electric Power Steering Gear system relies on sensors to detect the driver’s input and road conditions. The electric motor then adjusts the steering effort accordingly, ensuring smooth and responsive handling. Key components include:

Steering Rack and Pinion – Converts the rotational motion of the steering wheel into linear motion to turn the wheels.

Electric Motor – Provides power-assisted steering, reducing the effort required to maneuver the vehicle.

Control Module – Processes data from sensors and adjusts steering assistance in real time.

Torque Sensor – Measures the force applied to the steering wheel and helps regulate assistance levels.

Advantages of Electric Power Steering Gear

Upgrading to an Electric Power Steering Gear offers several benefits:

Improved Fuel Efficiency – EPS systems reduce engine load compared to hydraulic steering, enhancing fuel economy.

Precise Steering Control – Electronic adjustments allow for adaptive steering assistance, improving maneuverability.

Lower Maintenance Costs – Since there are no hydraulic fluids or pumps, EPS systems require less upkeep.

Enhanced Safety Features – Many EPS systems integrate with advanced driver assistance systems (ADAS) for greater road safety.

Find High-Quality Electric Power Steering Gear at Steering Rack China

At Steering Rack China, we provide premium Electric Power Steering Gear solutions designed for various vehicle models. Our products meet rigorous quality standards to ensure durability, reliability, and optimal performance.

Explore our wide range of steering components today at Steering Rack China and experience the benefits of advanced steering technology!

#rack and pinion steering system parts#audi power steering rack#Power Steering Rack and Pinion for Audi#AUDI Steering Gear Assembly Parts

1 note

·

View note

Text

Towards Zero Emission: AEAUTO New Power Steering Solution for Commercial Vehicle

AEAUTO presented the latest electric drive technology to help the commercial vehicle industry move towards a more sustainable future.

Meet the needs of electrification and autonomous driving; Meet the high torque requirements of commercial vehicle steering

Advanced new electric power steering pumb systems for trucks, coaches and city buses provide a solid foundation for electrification and autonomous driving.

AEAUTO new Electric Power Steering system lays the foundation for the electrification transition in the commercial vehicle industry. Suitable for a wide range of medium and heavy duty trucks, coaches and city buses, the EPS system is also one of the key elements in the realisation of the next generation of Advanced Driver Assistance Systems (ADAS), which will drive the vision of autonomous driving in the commercial vehicle industry.

The use of an integrated electric motor instead of a hydraulic pump removes the electric power steering system from the vehicle driveline and eliminates the need for hydraulic fluid assistance. Seamlessly adapted to electric vehicle architectures, the system optimises the driving experience through quiet and smooth electric handling while achieving zero local emissions for pure electric and fuel cell vehicles.The EPS system is available in all powertrain concepts to seamlessly match the architectural requirements of electric vehicles. The modular EPS system, adapted to 24V battery packs, supports power outputs of up to 8,000Nm and has a scalable design to meet the requirements of diverse packages.AEAUTO EPS system is currently available for steer-by-wire, and, thanks to its highly reliable and redundant architecture, as an active electric power steering system, the EPS can be integrated with ADAS to enable safety functions such as Continuous Lane Keeping.

AEAUTO Core Technology of EPS

Heavy commercial vehicles with heavy loads require a steering output torque of 8000Nm, which is achieved through double-winding motor and high-precision variable large transmission ratio deceleration mechanism.

AEAUTO EPS achieves high torque output through dual-winding motors and high-precision variable ratio gearboxes for heavy commercial vehicles with heavy loads and a required steering output torque of 8,000Nm.

24V High power motor: double winding low slot torque, low moment of inertia permanent magnet synchronous motor, output torque of 8000Nm after deceleration.

Patented deceleration mechanism: through high-precision ball screw, planetary wheel and planar secondary enveloping torus worm to achieve a variable transmission ratio of 15~23.

Double winding motor for heavy commercial vehicles + Double MCU+ Double control chip based on functional safety redundant architecture, leading in China.

The steering system is a functional safety component, and the high reliability and safety of electric steering are just necessary.

Highly reliable redundancy design: dual power source + double winding + double MCU+ double control chip based on functional safety redundancy design to ensure high reliability and safety.

Based on the dynamic tracking and feedback control strategy in the loop of the booster value, the response time of angle control is ≤50ms, leading at home and abroad.

The response time of the steering system is very critical for heavy commercial vehicles in high-speed scenarios. With the same steering wheel angle control precision, the shorter the response time, the higher the maximum speed allowed to be reached.

Adopting low rotational inertia permanent magnet synchronous motor with high mechanical sensibility and matching precision, the steering system makes judgment on the control mode through different sensor signals, uses the control algorithm to track the target parameters accurately, and controls the motor to output the ideal assisting torque according to the optimized assisting curve to realize the fast response of EPS assisting.

Advantages Of Electric Power Steering Over Electric Hydraulic Steering

System Efficiency Increased by 30%

No hydraulic link energy consumption loss, high efficiency;

Electric + wire control to meet the needs of heavy commercial vehicles such as electric vehicles and autonomous heavy trucks.

35% Reduction in System Weight

Light weight and small size: Compared with traditional hydraulic or electro-hydraulic steering, electric drive-by-wire steering eliminates 5 components such as hydraulic pump and hydraulic steering device, and is completely driven by motor to achieve steering.

Total System Cost Reduced by 20%

After the cancellation of five components such as hydraulic pump and hydraulic electric power steering gear, the overall cost of parts was greatly reduced after the allocation of R&D investment and mold costs.

AEAUTO EPS has been used in Europe (Norway, Finland) and the Middle East to help achieve low energy consumption and zero emissions in transport, providing an indispensable support for the creation of environmentally friendly societies and the promotion of sustainable development of various industries, as well as providing valuable examples for the development of related fields in other regions of the world.

#aeauto#electric power steering pumb#advantage of electric power steering#electric power steering system

0 notes

Text

Fixing Ford Fusion Power Steering Issues

Power steering is a crucial component for easy vehicle handling, and when it malfunctions, it can make driving a Ford Fusion more difficult and potentially unsafe. Power steering issues can occur in various models of the Ford Fusion, but most commonly involve either the electric power steering (EPS) system or hydraulic power steering (HPS) problems. Let’s explore common power steering issues and how to fix them.

Common Ford Fusion Power Steering Issues

Loss of Power Steering Assist One of the most frequent issues with the Ford Fusion’s power steering is the loss of power steering assist. This often results in a heavier steering feel, especially at lower speeds. This problem is commonly caused by faulty electronic power steering (EPS) motors, a blown fuse, or wiring issues. In some cases, the steering wheel may feel stiff or unresponsive.

Steering Wheel Vibration or Noise If your steering wheel shakes or produces a whining or groaning noise while turning, it may be due to a fluid leak in hydraulic systems or worn-out components in the EPS system. Fluid loss or air bubbles in the system can cause this type of noise and vibration, making driving uncomfortable.

Fluid Leaks (for Hydraulic Systems) For Ford Fusions with hydraulic power steering, leaks are a common problem. Low fluid levels can cause the steering system to become unresponsive. Regularly checking and topping up the fluid can prevent major issues. A mechanic should be called if there is a persistent leak that can’t be fixed with new seals.

How to Fix Ford Fusion Power Steering Issues

Diagnose the Issue The first step is to accurately diagnose the issue. For EPS problems, check for warning lights on the dashboard, particularly the "Power Steering" or "Service Steering" light. Use an OBD-II scanner to check for trouble codes that may indicate faults with the EPS system.

Check Fluid Levels and Leaks If your Fusion uses hydraulic power steering, start by checking the fluid levels. If the fluid is low, top it up with the recommended power steering fluid. If you notice fluid leaks, inspect hoses, seals, and connections for wear or damage, and replace any faulty parts.

Replace Faulty Parts For electric power steering issues, repairing or replacing the EPS motor may be necessary. In some cases, the steering column’s torque sensor or wiring may need to be replaced. If the problem is with the steering pump or hoses in hydraulic systems, these components should be fixed or replaced by a professional mechanic.

Resetting the System After addressing the issue, resetting the EPS system might be required. This can be done by disconnecting the vehicle’s battery for a few minutes to reset the system's electronics.

Conclusion

Fixing power steering issues on a Ford Fusion can range from simple fluid checks to more complex repairs such as replacing the EPS motor or hydraulic system components. Regular maintenance, including checking fluid levels and addressing leaks, can help prevent some of these problems. For more serious issues, it is advisable to seek professional help to ensure your vehicle’s safety and performance are not compromised.

FAQs

1. How do I know if my Ford Fusion has electric or hydraulic power steering? The easiest way to determine which system your Fusion has is by checking the year and model. Most newer models (2011 and beyond) use electric power steering, while older models may still use hydraulic systems. You can also consult your vehicle’s owner’s manual for this information.

2. Can I drive my Ford Fusion if the power steering goes out? If the power steering goes out completely, the vehicle will be harder to steer, especially at low speeds, but you can still drive it. However, it is not recommended to continue driving for long distances, as it could strain other components and pose safety risks. It’s best to have it repaired as soon as possible.

3. How much does it cost to fix power steering on a Ford Fusion? The cost of repairing power steering can vary depending on the problem. For electric power steering issues, repairs may range from $500 to $1,500. For hydraulic systems, fixing leaks or replacing hoses might cost between $150 and $500. Prices may vary depending on labor rates and the specific issue.

0 notes

Text

Electric Power Steering Repairs: What You Need to Know

Electric Power Steering (EPS) has transformed the driving experience, making steering smoother, more responsive, and more efficient. Unlike traditional hydraulic steering systems, EPS relies on electronic components to assist drivers, which reduces engine load and increases fuel efficiency. However, electric power steering systems can develop issues over time, and it’s essential to understand how to handle Electric Power Steering Repairs.

Common Issues in Electric Power Steering Systems

Electric Power Steering is generally low-maintenance, but problems can arise due to electrical faults, sensor malfunctions, or wear and tear on mechanical parts. Here are some common EPS issues to be aware of:

Loss of Power Assist: The most common issue in electric power steering is a sudden loss of power assist, making the steering wheel difficult to turn. This could result from a sensor failure, damaged wiring, or a software glitch.

Intermittent Steering Problems: Sometimes, the power assist might work intermittently, often due to poor electrical connections or overheating in the control unit.

Warning Lights: Modern EPS systems are equipped with diagnostic tools that display warning lights on the dashboard if a fault is detected. Common warning lights may indicate a problem with the torque sensor or the electric motor.

Excessive Steering Wheel Vibration: While it’s natural for a steering wheel to vibrate slightly, excessive vibration can point to a malfunctioning steering rack or alignment issues.

To resolve these issues, prompt Electric Power Steering Repairs are crucial to maintain vehicle safety and handling performance.

Audi Electric Steering Rack Repair: Tailored Solutions for a Premium Brand

Audi is known for its premium engineering, and its electric steering systems are no exception. However, issues can still arise, especially as the vehicle ages. Common signs that your Audi may need Audi Electric Steering Rack Repair include:

Grinding or Knocking Sounds: These sounds could indicate that the electric motor or internal components within the steering rack are wearing out.

Heavy Steering: If your Audi’s steering feels heavier than usual, it may be due to a faulty motor or electronic issue in the steering rack, causing reduced power assist.

Steering Lock: In rare cases, the steering can lock up due to sensor malfunctions or wiring issues within the EPS system.

When dealing with Audi steering systems, a specialized mechanic familiar with Audi’s engineering is essential. Often, minor adjustments or software updates are sufficient, but sometimes the steering rack may need a complete rebuild or replacement.

Power Steering Repair: Diagnosing and Fixing the Issue

Power steering repairs vary depending on the type of system. For traditional hydraulic systems, repairs often involve fluid replacements or fixing leaks, while Power Steering Repair for electric systems might involve reprogramming, component replacements, or motor repair.

A typical diagnostic process includes:

Visual Inspection: A professional will visually inspect the steering rack, connections, and wiring to identify potential problems.

Diagnostic Testing: Mechanics will use specialized diagnostic equipment to scan for error codes in the EPS system and check for specific malfunctions.

Test Drive and Feedback: After repairs or adjustments, a test drive helps ensure that the repair has restored the steering to its intended function.

BMW Power Steering Rack: Maintenance for Precision Driving

BMW’s electric steering system is designed to provide a precise driving experience. The steering rack, specifically, plays a critical role in transferring driver input to the wheels. However, with regular use, certain issues can occur, leading to the need for BMW Power Steering Rack repairs.

Play in the Steering Wheel: If you notice any slack or play in the steering wheel, it’s often due to worn-out components in the steering rack, which can cause misalignment.

Fluid Leaks: Although EPS doesn’t use traditional hydraulic fluid, some BMW models still have fluid-assisted steering racks. If leaks occur, they could lead to premature wear and tear of components.

Error Codes on the Dashboard: BMWs are equipped with sensitive sensors that detect even the slightest issues in the steering rack. Warning lights and error codes can signal when the rack is experiencing malfunctions.

Regular maintenance can extend the life of your BMW’s steering rack, but if issues persist, a professional mechanic experienced with BMW’s EPS systems should handle any necessary repairs.

0 notes

Text

Light Vehicle EPS Market Landscape and Future Growth Insights 2024 - 2032

The Light Vehicle Electric Power Steering (EPS) market has been gaining significant traction in recent years, driven by advancements in technology and increasing demand for fuel-efficient and environmentally friendly vehicles. This article delves into the dynamics of the Light Vehicle EPS market, exploring its components, trends, challenges, and future outlook. The Light Vehicle EPS market is positioned for significant growth as the automotive industry evolves.

Understanding Light Vehicle EPS

What is Electric Power Steering (EPS)?

Electric Power Steering (EPS) is an automotive technology that enhances vehicle control and maneuverability. Unlike traditional hydraulic steering systems, EPS uses an electric motor to assist the driver in steering the vehicle. This system not only reduces the weight of the vehicle but also contributes to improved fuel efficiency.

Components of Light Vehicle EPS

The key components of a Light Vehicle EPS system include:

Electric Motor: Provides the necessary torque to assist steering.

Steering Column: Connects the steering wheel to the steering gear and allows for driver input.

Electronic Control Unit (ECU): Processes input from the driver and adjusts the motor's output accordingly.

Sensors: Detect steering wheel position, vehicle speed, and torque, allowing for real-time adjustments.

Market Overview

Current Market Trends

The Light Vehicle EPS market is witnessing several trends that are shaping its growth:

Growing Adoption of Electric Vehicles (EVs): As EVs become more prevalent, the demand for EPS systems is increasing due to their compatibility with electric drivetrains.

Technological Advancements: Innovations in sensor technology and motor efficiency are enhancing the performance and reliability of EPS systems.

Regulatory Pressure: Stricter emissions regulations are pushing manufacturers to adopt more fuel-efficient technologies, further boosting the EPS market.

Market Segmentation

The Light Vehicle EPS market can be segmented based on:

Type:

Column EPS

Pinion EPS

Rack EPS

Vehicle Type:

Passenger Cars

Commercial Vehicles

Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Key Players in the Market

The Light Vehicle EPS market features several prominent players, including:

Bosch: A leading supplier of automotive technology, Bosch has made significant strides in developing advanced EPS systems.

JTEKT Corporation: Known for its innovative steering solutions, JTEKT is a major player in the EPS market.

TRW Automotive: This company offers a range of EPS systems that cater to various vehicle types.

Challenges Facing the Market

Technical Challenges

Despite the growth potential, the Light Vehicle EPS market faces several challenges:

Complexity of Systems: The integration of advanced electronics and software can lead to increased complexity, requiring higher levels of expertise in design and manufacturing.

Cost Constraints: The initial investment for EPS systems can be high, posing challenges for manufacturers, especially in budget segments.

Market Competition

The market is also characterized by intense competition, with numerous companies striving to develop innovative and cost-effective solutions.

Future Outlook

Growth Projections

The Light Vehicle EPS market is expected to continue its upward trajectory, driven by factors such as:

Increasing Vehicle Electrification: As more manufacturers shift toward electric and hybrid vehicles, the demand for EPS systems will rise.

Technological Innovations: Ongoing advancements in EPS technology, including the integration of artificial intelligence and machine learning, will further enhance system capabilities.

Conclusion

With increasing focus on sustainability and efficiency, the EPS system stands out as a crucial technology for modern vehicles. As challenges are addressed and innovations continue to emerge, the future of the Light Vehicle EPS market looks promising.

0 notes

Text

Electric Power Steering Market: Taking a Smooth Turn

With a shift in the automotive industry toward more fuel-efficient and smarter vehicles, the electric power steering market has a huge potential to grow in the upcoming years. Consumers have started preferring the electric power steering (EPS) system over the traditional Hydraulic Power Steering (HPS) system when they decide to buy a new vehicle, as EPS provides an enhanced and smooth driving experience.

The EPS system does not require a mechanical connection between the steering and the wheels. In the electric power steering system, when the steering is turned, a torque sensor on the steering column detects this movement and sends information to the Powertrain Control Module (PCM), which is the control unit of the car. This control unit then sends electricity to the motor placed at the end of the steering column. Once the motor receives the correct voltage signal, its gears start rotating, which controls the movement of the car's rack and ensures that the front wheels move in the desired direction!

Integration with other Automotive Systems: One of the biggest benefits of adopting the EPS system is that it can be integrated with other automotive systems, which is the need of the hour. Lane departure warning (LDW), automated parking and electronic stability control (ESC) are recent trends of the automotive industry that are compatible with the EPS system. The diverse applications of EPS in other automotive systems increase vehicles’ overall safety and enable more sophisticated steering assistance.

Integration with Autonomous Driving System: Another major industry trend is autonomous driving systems, and the EPS is crucial here, too! An Autonomous Driving System (ADS) requires electric power steering, as it allows the car to steer itself without the driver's assistance.

Why the Electric Power Steering Market is Growing: Advantages Offered by Electric Power Steering System

The EPS system is becoming popular as it offers many advantages when compared to the traditional hydraulic power steering system. HPS has a complicated design and consumes more power than electric power steering. Growing environmental concerns have given rise to the adoption of EPS as they consume less fuel than their traditional counterpart. According to some estimates, EPS can save up to 90% of the energy used by the HPS system. Moreover, the EPS system does not require hydraulic fluids, which results in reduced maintenance costs. Electric power steering also helps in reducing the weight of the vehicle as it uses electric motors instead of hydraulic pumps.

Governments and regulatory organizations in many countries have enforced strict guidelines related to CO2/CO emissions, fuel efficiency and vehicle safety, that mandate manufacturers to integrate cutting-edge technologies in steering mechanisms. For example, in case of frontal impact, collapsible electric power steering (CEPS) collapses the steering column and provides additional safety to the driver by reducing the risk of chest and head injuries.

Gain deeper insights on the market and receive your free copy with TOC now @:Electric Power Steering Market Report

Challenges

The EPS industry has its challenges too—limited aftermarket presence being the first. The EPS components have a relatively small aftermarket, which poses a challenge to vehicle owners looking for repairs or improvements. Secondly, despite being simple in design, the repair and maintenance of electric power steering is little complex. Since the market is evolving fast, specialized skills and equipment are required for proper servicing. This can lead to higher maintenance costs for the owner. EPS’s dependency on electrical systems is another major threat to the market growth, as electrical failures can affect steering performance, raising concerns regarding safety.

Global Overview

The global electric power steering market had a size value of more than USD 25.32 billion in 2023. This is anticipated to reach around USD 40 billion by 2030, growing at a compound annual growth rate of 6.6% from 2024 to 2030. The market has witnessed tremendous transformation in the recent few years. With the growing popularity of hybrid and electric vehicles, EPS system is delivering lightweight and energy-efficient solutions. Due to the emerging economies of the Asia Pacific, the EPS industry accounted for the largest revenue generation in this region in 2023. The rapidly growing demand for the solution from countries such as India and China, where the rising population provides a large customer base, has given a boost to the electric power steering market.

Europe is another key market for EPS due to the presence of significant manufacturers in the region. For example, the rising demand for ADAS and the push toward autonomous vehicles in Germany have given a push to the adoption of EPS by the major automakers operating in the country, such as Volkswagen Group, BMW AG, and Mercedes-Benz. Moreover, organizations such as the International Council on Clean Transportation (ICCT) and the European Union (EU) have implemented stringent emission and fuel efficiency standards that encourage the adoption of EPS technology. North America has a significant presence of larger vehicles such as trucks and SUVs. These heavy vehicles require better safety features, such as precise and responsive steering systems. EPS technology plays a crucial role here.

Innovations in the industry

The EPS industry is evolving rapidly. Key players are coming up with innovative and latest technologies to stay ahead of their competitors. In April 2023, Nexteer Automotive launched the Modular Rack-Assist Electric Power Steering system (mREPS) to provide cost-effective, modular EPS solutions. The mREPS system offers advanced steering systems in heavier vehicles, including EVs. Similarly, in September 2022, Hitachi Astemo introduced a Steer-by-Wire prototype, which actuates the tires through the electric control of steering wheel inputs.

JTEKT Corporation, GKN Automotive Limited, Hitachi Astemo, Ltd., Denso Corporation, Nexteer Automotive, NSK Ltd., Robert Bosch GmbH, Hyundai Mobis, Mitsubishi Electric Corporation and ZF Friedrichshafen AG, are some of the leading companies in the electric power steering market.

Contact:

Grand View Research, Inc.

Phone: 1-415-349-0058

Toll-Free: 1-888-202-9519

Email: [email protected]

Web: https://www.grandviewresearch.com

Explore Horizon, the world's most expansive market research database

#ElectricPowerSteering#EPSMarket#AutomotiveIndustry#SteeringSystems#VehicleTechnology#AutomotiveInnovation#ElectricVehicles#AutomotiveComponents#EPS#AutomotiveSafety#SteeringMechanisms#VehicleControl#AdvancedSteering#AutomotiveTrends#PowerSteering#ElectricSteering#AutomotiveElectronics#AutomotiveMarket#CarSteering#VehicleSteeringSystems

0 notes

Text

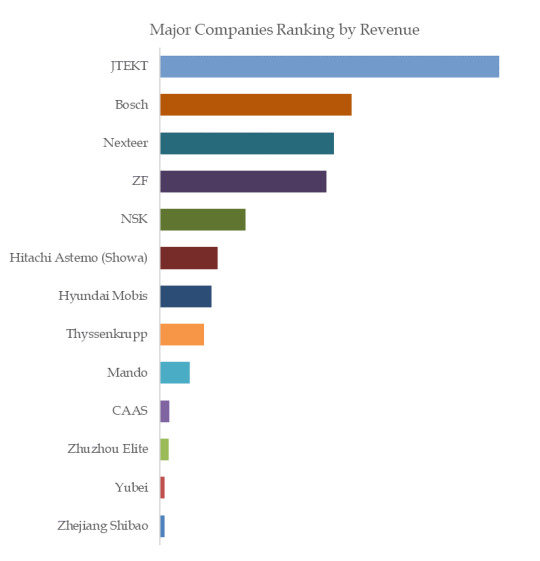

Global Top 13 Companies Accounted for 79% of total Electric Power Steering System (EPS) market (QYResearch, 2021)

Automotive Electronic Power Steering is a very popular steering system, a power steering system that directly relies on the motor to provide auxiliary torque; Currently, most of the vehicle are installed the electronic power steering system, and the electronic power steering system can reduce about 5% fuel consumption.

According to the new market research report “Global Electric Power Steering System (EPS) Market Report 2023-2029”, published by QYResearch, the global Electric Power Steering System (EPS) market size is projected to reach USD 20.38 billion by 2029, at a CAGR of 2.7% during the forecast period.

Figure. Global Electric Power Steering System (EPS) Market Size (US$ Million), 2018-2029

Figure. Global Electric Power Steering System (EPS) Top 13 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Electric Power Steering System (EPS) include JTEKT, Bosch, Nexteer, ZF, NSK, Hitachi Astemo (Showa), Hyundai Mobis, Thyssenkrupp, Mando, CAAS, etc.

In 2022, the global top five players had a share approximately 79.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

#Global EPS Torque Sensor Market Size#Share#Trends#Growth#Industry Analysis#Key Players#Revenue#Future Development & Forecast

0 notes

Text

A steering gear motor is an electric motor that provides the power to turn the wheels of a vehicle. It's part of a car's steering system, which translates the driver's input from the steering wheel into controlled turning of the front wheels.

There are two main types of steering gear motors:

* Hydraulic steering gear motor: This type of motor uses hydraulic fluid to create the power needed to turn the wheels. The motor is connected to a hydraulic pump, which generates the pressurized fluid. The fluid is then directed to a hydraulic cylinder, which pushes or pulls on the steering linkage to turn the wheels.

* Electric power steering (EPS) motor: This type of motor uses an electric motor to directly provide assistance to the steering system. The EPS motor is mounted on the steering column and works in conjunction with a torque sensor that detects the driver's input. The EPS motor then provides additional torque to the steering shaft, making it easier for the driver to turn the wheels.

Hydraulic steering gear motors are generally used in larger vehicles, such as trucks and SUVs, where more power is needed to turn the wheels. EPS motors are becoming increasingly common in cars of all sizes, as they offer several advantages over hydraulic systems, including improved fuel efficiency, better responsiveness, and a more natural steering feel.

0 notes

Text

Guiding the Decade: Navigating the Brush Motor Control Unit Market's Journey Towards Tomorrow's Control

The market for brush motor control units is anticipated to reach a value of US$ 1,968.3 million in 2023 and US$ 3,236.9 million by 2033. During the projection period, sales of brush motor control units are anticipated to grow significantly at a CAGR of 5.1%.

The brush motor control unit provides precise speed control, and it has an electric power system (EPS) that controls the torque of the motor drive. The brush motor control unit system makes precise current adjustments based on torque signals detected by torque sensors. As a result, it provides vehicle drivers with some steering assistance during vehicle operation.

Ready to make informed decisions for your business? Get our market overview sample and discover growth opportunities today https://www.futuremarketinsights.com/reports/sample/rep-gb-4183

Brush Motor Control Unit Market Overview

The brush motor control unit provides precision control of the speed, and it has an electric power system (EPS), which is responsible for controlling the torque of the motor drive. Brush motor control unit system makes precise current adjustments based on the steering of torque signals; which are detected by torque sensors. It thus offers vehicle drivers a little steering assistance in the vehicle operation.

Brush motor control unit consumes energy only when the steering assist is necessary. The brush motor control unit system is comparatively more fuel efficient than the conventional hydraulic power steering systems.

The electrical control unit (ECU) of the brush motor control unit calculates the torque necessary for the steering assist from the engine speed and the torque sensor signal, etc. and ultimately supplies the maximum electric power to the brush motor control unit. Choosing a right type of motor control unit is critical for the overall performance of vehicle or machine in which it is used in as a component.

Brush Motor Control Unit Market: Market Dynamics

The increasing demand for fuel-efficient automobiles coupled with the fact that the fuel reserve levels are going down constantly; is fueling the growth of the brush motor control unit market. The increasing demand for cost-effective automotive parts coupled with the fact that the companies are constantly trying to reduce their operational and overall cost of production; is contributing to the growth of brush motor control unit market.

However, the high initial cost of investment is a restraining factor. Another challenge faced in the expansion of the brush motor control unit market is the wide acceptance and proven performance of hydraulic steering systems. The launch of the brushless motor control units is a threat to the brush motor control unit market as they have less cost of maintenance (brushes require maintenance).

The use of brush motor control units in the cabin pressure, navigation and target servos, trim controls, utility actuation, and valve drives, etc., is one of the prevailing trends. Companies are also manufacturing brush motor control units with a range of magnetic materials such as samarium cobalt alloys and neodymium.

These units have weight with a durable performance which makes these ideal for use in a helicopter and small aircraft applications. There is an increasing preference for the brush motor control unit because it can alter or vary the speed-torque ratio in all possible ways.

0 notes

Text

Working Process of Electric Power Steering

The electrical power steering system relies on the sensors and the electric motor. When the driver turns the wheel, the steering sensor senses the turn. This sensor is attached to the steering column and sends the electric message to the ECU.

Read more - What is Electric Power Steering? Best for Car or Not?

Then, the EPS control unit, also known as the electronic control module (ECM), processes information from various sensors, including the torque sensor, steering angle sensor, and vehicle speed sensor. Based on these inputs, the control unit determines the appropriate level of assistance needed and sends commands to the electric motor.

Then the electricity takes the specific amount of electricity from the battery and generates the electricity into it. The electric motor needs to produce the torque as given the sense from the steering sensor. Then this torque is delivered through the torque sensor and the actuators.

The gears are placed on a shaft, that is attached to the electric motor. Then the pinion(where the motor output shaft connects the system) rotates and transfers the torque to the rack. This transfer of torque then turns the rack and the vehicle turns left or right

#engineering#motorcycle#car#transmission#gearbox#engine#automobile#automotive#notes#automatic transmission#steering#power steering

1 note

·

View note

Text

https://ecudepot.com/product/audi-c7-b8-eps-test-platform/ Bench test platform for AUDI A4 Q5 A6 A7 A8 Electric power steering rack, diagnose, delete fault code, flash the firmware on bench, can use original torque sensor or this Torque sensor simulate driver box to check the mechanical structure actions.

audieps #audij500 #B20000 #b200049 #audipowersteering #auditorque #ODIs #porsche95b #audia4 #audia6 #audib8

0 notes