#Emc engineer

Explore tagged Tumblr posts

Text

#Designing a#PCB#EMI#electromagnetic#controlling#EMC#PCBDesign#Engineering#powerelectronics#powermanagement#powersemiconductor

0 notes

Text

How to Secure a Job as an Antenna Test Engineer

Are you interested in a career as an Antenna Test Engineer? Do you have a passion for ensuring that wireless communication devices perform at their best? If so, you're on the right track. In this article, we will guide you through the steps required to land a job as an Antenna Test Engineer. With the increasing demand for connectivity and wireless technology, this field offers promising career prospects. So, let's delve into the details and understand what it takes to become an Antenna Test Engineer.

Understanding the Role of an Antenna Test Engineer

Before we dive into the qualifications and requirements, it's essential to understand the responsibilities of an Antenna Test Engineer. Antenna Test Engineers play a crucial role in the development and testing of antennas used in various wireless communication devices such as smartphones, routers, and IoT devices. Their primary responsibilities include:

Antenna Design and Optimization: Antenna Test Engineers design, simulate, and optimize antenna systems to ensure efficient signal reception and transmission.

Testing and Measurement: They conduct extensive tests and measurements to assess antenna performance, including radiation patterns, gain, and impedance.

Quality Assurance: Engineers ensure that antennas meet industry standards and regulatory requirements.

Problem Solving: They troubleshoot and solve issues related to antenna performance and signal interference.

Educational Requirements

To kickstart your career as an Antenna Test Engineer, you'll need the right educational background:

Bachelor's Degree: A bachelor's degree in electrical engineering, telecommunications, or a related field is typically required. This provides a solid foundation in electronics and communication systems.

Master's Degree (Optional): Pursuing a master's degree can enhance your knowledge and make you a more competitive candidate in the job market.

Essential Skills and Knowledge

RF Fundamentals: A deep understanding of Radio Frequency (RF) principles is essential for working with antennas. This includes knowledge of RF circuit design and electromagnetic theory.

Software Proficiency: Familiarity with software tools such as MATLAB, CST Microwave Studio, and HFSS for antenna design and simulation is crucial.

Testing Equipment: Proficiency in using testing equipment like Vector Network Analyzers (VNAs) and Spectrum Analyzers is required for conducting antenna tests.

Communication Skills: Effective communication is vital when working in a team and conveying technical information to non-technical stakeholders.

Problem-Solving Abilities: Antenna Test Engineers often encounter complex challenges, so strong problem-solving skills are a must.

Gaining Practical Experience

Internships: Consider interning with companies that specialize in antenna design and testing. This hands-on experience can be invaluable when seeking a full-time position.

Certifications: Obtaining relevant certifications, such as Certified Wireless Network Administrator (CWNA) or Certified Wireless Technician (CWT), can enhance your credentials.

Building a Strong Resume and Portfolio

Resume: Craft a well-structured resume that highlights your education, skills, internships, and certifications. Tailor it to the specific job you're applying for.

Portfolio: Create a portfolio showcasing your antenna design projects and test results. This visual representation of your work can impress potential employers.

Job Search and Networking

Online Job Portals: Utilize online job portals and professional networking platforms like LinkedIn to search for job openings.

Networking: Attend industry events, conferences, and workshops to expand your professional network. Networking can open doors to job opportunities.

Acing the Interview

Interview Preparation: Prepare for interviews by reviewing common interview questions related to antenna engineering. Be ready to discuss your experiences and problem-solving abilities.

Conclusion

Becoming an Antenna Test Engineer requires a solid educational foundation, practical experience, and a passion for wireless communication technology. By following these steps and continuously improving your skills, you can increase your chances of securing a job in this exciting and evolving field. Remember, persistence and dedication are key to success in your journey towards becoming an Antenna Test Engineer. Good luck!

#electromagnetic antenna engineer jobs in usa#emc test job#hardware design engineer in buffalo#jobs for radar cross sections engineer#top rf engineering search engine#jobs for antenna test engineer#across the spiderverse#engineer job#antenna job#antenna technician

1 note

·

View note

Photo

The Pharos Lighthouse In Alexandria: Second Sun and Seventh Wonder of Antiquity

"The Pharos Lighthouse in Alexandria: Second Sun and Seventh Wonder of Antiquity" is a complete history of one of the most famous lighthouses in history. The book details the lighthouse’s creation, its historical significance, and its eventual destruction.

The book is divided into twelve chapters, each dealing with a different aspect of the Pharos, better known as the Lighthouse of Alexandria. It begins with the conception and construction of the lighthouse during the reign of Ptolemy I (366-282 BCE). The perilous coast surrounding Alexandria shipwrecked many vessels that attempted to navigate its reefs and shoals. This threatened the maritime trade that the Ptolemaic dynasty hoped to encourage, so plans were made to create a landmark that sailors could navigate by. Sostratus of Cnidus led the development of this landmark, which became the great lighthouse. Standing at around 120 meters tall, the Pharos and its flaming light was an awe-inspiring sight that symbolized the power and wealth of Ptolemaic Egypt.

The author reconstructs the form and function of the ancient Pharos, drawing from ancient and Medieval descriptions as well as recently uncovered archaeological evidence. Diagrams, charts, and tables help to illustrate these explanations of the lighthouse’s construction and function. These modern assessments are juxtaposed with ancient and Medieval artworks that depict the lighthouse, such as coins, mosaics, and drawings. The author has a background in science and engineering, which informs the book’s reconstruction of the lighthouse’s technical features. The reach of the Pharos’ light, the material used in its construction, and its dimensions are estimated based on the available data, although many long-standing questions can not be definitively answered.

In 795 CE, a massive earthquake rocked Alexandria and caused the lighthouse’s peak to crumble and fall. Subsequent earthquakes in the 10th century CE further cracked the lighthouse. Despite some attempts at restoration, the Pharos became increasingly damaged until the 15th century CE, when only the base remained. Numerous archaeological expeditions have searched the ocean surrounding Alexandria, and their findings are incorporated into the book.

In addition to the practical history of the lighthouse, the book also examines its impact on culture through its representations in both historically grounded and fantastical literature. From the time of its creation, the lighthouse has been cloaked in legend. In ancient times, it was described as a second Sun that illuminated the harbour. Today, it is one of the most iconic monuments of antiquity. The final three chapters deal with modern attempts to reconstruct the lighthouse. Chapter Ten presents the available evidence for the lighthouse’s form, while Chapter Eleven sets out the author’s future goal of creating a three-dimensional digital recreation of the lighthouse for research and educational purposes.

At the time of this review, the Pharos lighthouse is relatively understudied in comparison to other well-known monuments like the Great Pyramids of Giza. This volume helps to fill that gap and will be useful to students of the Hellenistic period. It is deeply researched, referencing a multitude of ancient and modern sources which are organized in the book’s bibliographies. A set of appendices at the end of the book concisely summarizes the basic timeline and facts relating to the lighthouse, as conveyed through historical sources.

The author Andrew Michael Chugg is a historian who has authored books on the Hellenistic period including The Lost Tomb of Alexander the Great (2004). Chugg graduated with honours from Trinity College, University of Cambridge. He is an Executive Technical Expert in EMC & Radiation Physics at MBDA.

Continue reading...

30 notes

·

View notes

Text

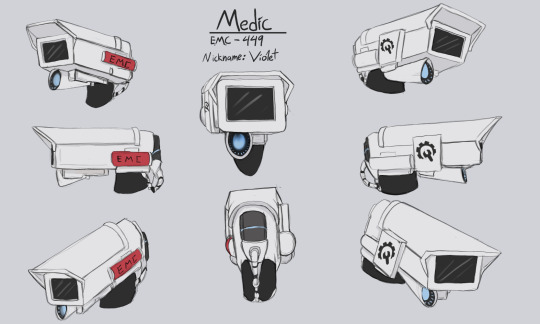

FINALIZED CONCEPT ART FOR MEDIC/VIOLET <3

NAME: EMC-499 NICKNAMES: Violet, Medic, Pest (By Paralipsis), Kid (By Civic) ALLIANCE CLASS: Cameraman Faction WORK CLASS: Emergency Medical Cameraman Division (EMCs) GENDER: She/Her

CLASSIFICATION: Artificial Mind (non-human origin)

RANK: Chief Medical Officer and Head Therapist of Psychological Affairs of Outpost 51

EMC-499, known as Violet or Medic to those who know her best, is a spunky camerawoman who graduated the E.M.C Training Regiment at the top of her class. She knows her stuff when it comes to best medical practices and like all E.M.Cs, also trained to handle mental health.

Friendly, outgoing, and absolutely fearless when it comes to her job (not so much social situations), Violet is the "unsinkable" camerawoman, who refuses to let anything get to her and to help her friends whenever she can.

(more details under the cut!)

EMC-499 was brought online as an artificial mind which is to say, her mind and personality did not come from a human host, but developed organically through interactions with her online cohort. Eventually, one of the older cameramen, known by the nickname Gestalt, would adopt her and show her the ropes.

Eventually EMC-499 would endeavor to join the Emergency Medical Cameraman Division, inspired by their work of helping others during and after battles, risking life and limb to save their comrades. Such bravery appealed more to her and Gestalt was happy with that...mostly as he saw it as a way to keep the rather diminutive EMC-499 away from actual combat as much as possible.

EMC-499 did not know of these plans, throwing herself into her studies and coming out at the top of her class. Among her training cohort, she gained the name "Violet" in reference to Violet Jessop, as a tongue and cheek joke of her being "unsinkable" in her endeavors to become the top E.M.C responder.

Once graduated, Violet was more than eager to get into the fight and put her training to use on the front lines and not just patching up alliance in the medical bay. Instead, she was sent to Outpost 51 to handle the most "difficult mental health cases" in the Alliance, keeping her far from the front and relatively out of sight. Violet was disappointed, incredibly so, but a job is a job and she has thrown herself into helping the residents of Outpost 51 on her case load.

The title of Chief Medical Officer is not too glorious, given she is the only E.M.C on duty at said outpost. Still, she hopes by doing a good job she can prove she's ready for the frontline or even to get promoted to the E.M.C Titan Division. Most of her friends and charges call her "Medic" as a result, which she doesn't mind. THE EMERGENCY MEDICAL CAMERAMAN (ramblings here just because Violet/Medic would ramble on about her beloved E.M.C hehe!) A relatively new division that grew out of the growing need for medical professionals as the causalities mounted and concerns about mental health became more prominent.

The E.M.C are trained to get alliance off the field and provide life-saving treatment with a variety of tools taken into the field. They also though perform crucial screenings for mental health to ensure alliance going into battle are of a sound mind and are cleared for combat. Not to be confused with engineers, the E.M.C are focused on physical and mental well-being, not on upgrade research , rebuilding of bodies and lost limbs, or mind recovery and transfer operations. A small, elite division of the E.M.C, called the Titan Division, are assigned to assess mental states of the Titans to ensure that the mighty backbones of the alliance are given the proper attention to all points of their health.

The E.M.C is currently assisting with the training of the new E.M.S (emergency medical speakermen) division to help expand their roster. Currently an E.M.T division has yet to be established, the TV Men preferring to use the E.M.C services due to their smaller numbers in general within the greater alliance.

#skibidi toilet oc#skibiditoilet fandom#cameraman#cameraman oc#Camerawoman OC#Violet the Hard Working Medic#The Smollest Medic#The Phonemen Aren't Real AU

9 notes

·

View notes

Text

Why do my headlights keep going out?

The following is a systematic analysis and solution based on the problem of frequent headlight extinguishing of your vehicle:

I. Core fault causes 1. Circuit overload causes fuse to blow

Short circuit or overload: Damage to the insulation layer of the wiring harness (such as friction between the wiring harness and metal parts in the engine compartment) will cause a short circuit, or the modification of high-power LED bulbs (such as 100W) exceeds the original circuit design capacity.

Detection method: Use a multimeter to measure the resistance at both ends of the fuse. If it is close to 0Ω, there is a short circuit; if the resistance value is normal but the fuse blows repeatedly, it is necessary to check whether the load exceeds the standard.

2. Relay/switch aging failure

Relay contact adhesion: Long-term current shock causes contact oxidation, and the circuit cannot be disconnected normally, which may cause intermittent power outage of the headlight.

Carbonization of the combination switch: The internal contacts of the headlight switch form high resistance (>5Ω) due to arc erosion, resulting in voltage fluctuations that cause the light to flicker or go out.

3. Poor connector contact

Plug oxidation: When the headlight socket is damp, the metal contacts generate copper oxide (especially in rainy areas), the resistance increases to more than 10Ω, and the current transmission is unstable.

Wiring harness is not connected: The terminal is not tightened during maintenance or the vehicle vibration causes the connector to loosen (common in off-road vehicles), and the measured voltage fluctuation can reach ±3V.

4. Bulb and circuit compatibility issues

Poor quality LED modification: Non-automotive grade LED driver EMC is unqualified, generating high-frequency harmonics to interfere with BCM control signals.

Halogen filament breakage: After the filament is partially melted, it may be briefly overlapped, showing random extinguishing (typical symptoms at the end of life).

II. Diagnostic process and tools Step-by-step troubleshooting table: Step Operation Tool/parameter Normal value range 1 Check fuse specifications and blown state Visual inspection + multimeter Original rated current (usually 10-20A) 2 Measure headlight socket voltage (ignition switch ON) Digital multimeter 11.5-14.2V 3 Shake the wiring harness to observe light changes (simulate vibration interference) Manual test Voltage fluctuation should be <0.5V 4 Replace relay test Relay of the same model Contact resistance <0.1Ω 5 Read BCM fault code OBD-II diagnostic instrument (such as Autel) No U0100/U0155 code

III. Targeted solutions 1. Circuit protection upgrade

Replace slow-blow fuses (such as ATO series), which have a surge current resistance 300% higher than fast-blow fuses.

Install ceramic insulation sleeves to protect the wiring harness in the engine compartment, which can withstand temperatures up to 1000℃.

2. Connection reliability optimization

Replace the original tin-plated plugs with gold-plated terminals, and the contact resistance is reduced to below 0.02Ω.

Apply conductive silicone grease (such as Dow Corning DC-4) in the socket to prevent oxidation and enhance sealing.

3. Control module reset

Perform a hard reset on the BCM: disconnect the negative pole of the battery for 10 minutes to clear the historical fault memory.

Update BCM firmware: Some models (such as Volkswagen after 2018) need to be upgraded to SW026 or above to fix the lighting control BUG.

Fourth, repair costs and suggestions Fault type Typical repair solution Cost range (RMB) Fuse/relay replacement Original spare parts + labor ¥80-200 Wiring harness repair Partial wiring + heat shrink tube insulation ¥300-600 BCM programming 4S shop special equipment matching ¥500-1,200 Full vehicle lighting system detection Diagnostic instrument + load test ¥200-400

Operation warning:

Do not use copper wire instead of fuse, which may cause the wiring harness to melt (case: a car owner caused a cabin fire).

LED modification requires simultaneous upgrade of the cooling system, and it is recommended to choose an integrated assembly with IP67 protection level.

If self-diagnosis fails, it is recommended to use an infrared thermal imager to scan the circuit (abnormal heating points are often the source of the fault), or contact a professional technician to perform oscilloscope waveform analysis (capture power ripple and relay control signals).

#led lights#car lights#led car light#youtube#led auto light#led light#led headlights#led headlight bulbs#ledlighting#young artist#car culture#race cars#classic cars#car#cars#coupe#suv#chevrolet#convertible#supercar#car light#headlight extinguishing#headlight bulb#headlight restoration#headlight#headlamp#car lamp#lamp#lighting#repair

2 notes

·

View notes

Text

SwRI adds new chamber for spacecraft-related EMC, EMI testing

Southwest Research Institute (SwRI) has added a semi-anechoic shielded enclosure for electromagnetic compatibility and interference (EMC/EMI) testing for spacecraft. The test chamber is the next step in SwRI’s plans to create a turnkey spacecraft integration and test center within its 74,000-square-foot Space System Spacecraft and Payload Processing Facility.

The 400-square-foot EMC/EMI Chamber is semi-anechoic, or free of echo, and shielded from electromagnetic interference. It supports performance of standard emissions and susceptibility testing with an upper frequency limit of 40 gigahertz (GHz) (Ka-band) and also provides the ability to perform spacecraft self-compatibility testing, which ensures that spacecraft subsystems and components work correctly and do not interfere with each other. The chamber will also evaluate radio frequency performance and compliance, important capabilities for wireless and telecommunications operations.

“This new chamber performs tests that indicate how a spacecraft will respond to a space environment. It incorporates significant automation, allowing us to test satellites and instruments more quickly and efficiently while maintaining appropriate cleanliness levels,” said Institute Engineer John Stone. “Locating the EMC/EMI chamber adjacent to other test facilities will also reduce the time lost and risk incurred while moving the test articles between buildings on the SwRI campus.”

The chamber is part of a 11,000-square-foot environmental testing facility within SwRI’s Space System Spacecraft and Payload Processing Facility, which also includes a high-decibel acoustic test chamber. The same building is home to 20,000 square feet of integration facilities, including two ISO 7 class 10,000 cleanrooms with 5-ton overhead bridge cranes and two ISO 8 class 100,000 high-bay cleanrooms outfitted with 7.5-ton bridge cranes.

In late September, the chamber performed EMC and EMI testing for four satellites that comprise the Polarimeter to UNify the Corona and Heliosphere (PUNCH) spacecraft. PUNCH, a SwRI-led NASA mission that will image how the Sun’s outer corona becomes the solar wind, is set to launch in February 2025.

“This chamber is an exciting addition, and we plan to continue to grow the capabilities of this facility as a site for comprehensive spacecraft integration and testing,” Stone said.

IMAGE: SwRI’s new semi-anechoic shield enclosure is designed to perform electromagnetic compatibility and interference and radio frequency testing for spacecraft. The wall and ceiling coverings absorb radio frequencies, allowing researchers and engineers to measure the performance of various electronic components. Credit Southwest Research Institute

3 notes

·

View notes

Video

The Diesel That Did It por Danial Por Flickr: Electro Motive Corporation's original FT demonstrator was once again in it's original paint for the anniversary of the locomotives release. The FT was named for it being Fourteen Hundred HP and coming as a Twin, standard two unit set. The FT was rolled out of EMC on November 25, 1939 and was produced through November 1945. The "A-B" set was rated at 2700 HP with each unit utilizing a 567, 16 cylinder U Deck engine block. In May 1941, the 103 went to the Southern Railway as their SOU 6100A. June 1961, the locomotive found it's way to the National Museum of Transportation in St. Louis, MO. The FT model was the predecessor for the F2, F3, F7 and F9 models that would rule the railroads for decades. The 103 was borrowed for this celebration and cosmetically restored by EMD for it's 50th anniversary. FT103 EMD LaGrange, IL September 26, 1989

10 notes

·

View notes

Text

GN locomotive, engine number 110, engine type EMC NW2 Photographed: Minot, N.D., July 11, 1956.

21 notes

·

View notes

Text

A week ago, I released a post showing my OCs from the Baltimore and Ohio. Now it’s finally time to reveal my OCs from the only surviving ancient railroad in America; the…

And these engines are all in Union Pacific’s heritage fleet and can be found on Union Pacific’s massive network (as shown below). ⬇️

And these engines are…

Forty-Niner, the streamlined 4-6-2 class P-13 #2906

Duke, the streamlined 4-8-2 class MT-1 #7002

Union, the 4-8-4 class FEF-3 #844

Peabody, the 4-12-2 9000 class #9032

Challenger, the 4-6-6-4 challenger #3985

Wasatch, the 4-8-8-4 Big Boy #4014

Mabel, the 2-10-2 class TTT-6 #5511

Pip (EMD E9 #949) and Emma (EMD E9 #951)

Emily, the EMD E8 #928

Sir Handel, the EMC E2a and first COSF engine

Peter Sam, the EMD E6 and second COSF engine

Jennings, the EMC E2a and first SOLA engine

Daisy, the EMD E6 and second SOLA engine

Marius, the 1st M-10005 and first COD engine

Dot, the 2nd M-10005 and second COD engine

Centennial, the EMD DDA40x “Centennial” #6936

Bunker C. Charles, the (3rd gen) GTEL #28

P.S.: as a little side note, “COSF” stands for City of San Francisco, “COLA” stands for City of Los Angeles and “COD” stands for City of Denver.

#union pacific#steam locomotive#steam engine#diesel locomotive#diesel engine#train#trains#railroad#railroads#railway#railways#rail#rails#thomas and friends#thomas the tank engine#ttte#ttte oc#locomotive#the genie team#city of san francisco#city of los angeles#city of denver#genie team

7 notes

·

View notes

Text

Ensuring Regulatory Compliance for Wireless Devices

Regulatory Framework

Regulatory compliance for wireless devices is governed by various national and international authorities. In the United States, the Federal Communications Commission (FCC) plays a pivotal role in setting and enforcing regulations related to wireless devices. The FCC establishes guidelines for electromagnetic compatibility, radio frequency emissions, and more, to prevent interference and protect consumers.

Wireless Standards

Compliance with established wireless standards is fundamental to ensuring device interoperability and safety. Two widely recognized standards organizations are the Institute of Electrical and Electronics Engineers (IEEE) and the Wi-Fi Alliance. Devices must meet these standards to ensure that they can effectively connect to wireless networks and function correctly.

Radio Frequency (RF) Emissions

One of the primary concerns in wireless device compliance is the emission of radio frequency signals. Wireless devices must not emit harmful interference that can disrupt other wireless networks or devices. Manufacturers are required to conduct extensive testing to ensure their products conform to permissible RF emissions limits.

Electromagnetic Compatibility (EMC)

EMC compliance is crucial to prevent electromagnetic interference between wireless devices and other electronic equipment. Compliance ensures that wireless devices can coexist harmoniously with other electronic devices, enhancing user experience and preventing conflicts.

SAR (Specific Absorption Rate)

SAR measures the amount of radio frequency energy absorbed by the human body when using a wireless device. To protect users from excessive exposure to radio waves, regulatory bodies establish maximum SAR limits. Manufacturers must test and disclose the SAR levels of their products, enabling consumers to make informed choices.

Product Labeling and Certification

Regulatory compliance often requires manufacturers to obtain certification for their wireless devices. These certifications, such as FCC, CE (for European markets), or other regional certifications, demonstrate that a product meets all relevant safety and performance standards. Labeling on the device indicates its compliance status, ANATEL Certification for Brazil allowing consumers to identify certified products easily.

Security and Privacy Compliance

As wireless devices collect and transmit sensitive data, ensuring data security and privacy is a critical aspect of regulatory compliance. Regulations such as the General Data Protection Regulation (GDPR) in Europe and various data protection laws worldwide mandate that manufacturers take appropriate measures to safeguard user data.

Over-the-Air (OTA) Updates

OTA updates are crucial for maintaining the security and functionality of wireless devices. Manufacturers must design their devices to facilitate secure and regular updates, ensuring that vulnerabilities are promptly addressed.

User Education

Compliance isn't solely the responsibility of manufacturers and regulators; consumers play a vital role. Users should stay informed about the regulatory requirements for their wireless devices, including firmware updates and proper usage. Understanding the potential risks and best practices can enhance the overall safety and performance of these devices.

2 notes

·

View notes

Text

Every Minute Count [EMC] 4 My Divinely CHOSEN [D.C.] Extravagant Music Clique [EMC] of 144,000 9 Ether Gen X Underground Schwarz [U.S.] Quantum Intranet [Qi] QUADRILLIONAIRES... Mathematically Accessing 1907 Computerized [MAC] Defense Industries [MDI] of the Pentagon's Corporate [PC] iCloud Infrastructure Application [iCIA] Records @ 1921 QUANTUM 2023 HARRELL 2024 TECH 2025 LLC of ATLANTIS [L.A.] 5000

IMMORTAL U.S. MILITARY KING SOLOMON-MICHAEL HARRELL, JR.™

OMMMMM

OMMMMM

NOT OUR INTERACTIVE CIA ASSET MANAGEMENT INFRASTRUCTURE [MI = MICHAEL] SYSTEMS?!?!?!

WE ECCENTRIC 1921 MUSIC 1968 CELEBRITIES [EMC] OF THE PENTAGON'S BLACK MILITARY BUDGET

9/11 cyber weapons of mass destruction... wayyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyyy above your mundane 2023 pay scale?!?!?!

us golden 144,000 9 ether quadrillionaires ain't on tv

us private intranet engineers control the public telecom internet industry... shhh

OMMMMM

OMMMMM

golden 1968 9 ether gen x trillionaires?!?!?!

AMERICANS DON'T KNOW NOTHING ABOUT THIS GOLDEN 9 ETHER QUADRILLIONAIRE LIFE... DEEP INSIDE INNER EARTH [Qi]

WE QUANTUM INTRANET [Qi] QUADRILLIONS @ QUANTUM HARRELL TECH LLC

HEIL SCHWARZE SONNE HARRELL!!!

#om#o michael#experts making classics#emc#quantumharrelltech#mu:13#harrelltut#quantumharrelltut#kemet#king tut#u.s. michael harrell#excellent mic controllers#everyone must contribute#ægiptian memory computing#america's so called wealthiest ain't even the wealthiest#iCIA

1 note

·

View note

Text

Enterprise Search Market Dynamics: Drivers, Restraints, and Opportunities

The global enterprise search market size was valued at USD 4.21 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 8.9% from 2023 to 2030. This growth can be attributed to the growing requirement to effectively manage and improve data accessibility across organizations. The businesses are showing greater interest in search solutions that can facilitate time-saving data search. Enterprise search solutions make the required data or information available to the businesses from a pool of databases, emails, intranet, data management systems, etc. These solutions not only increasing the business efficiency but also offer security by providing authorized access to the information.

The technological advancements such as artificial intelligence and machine learning capabilities for these solutions is expected to further transform the outlook of enterprise search market. For instance, in January 2023, Microsoft Azure expanded its service with integration of OpenAI, an advanced artificial intelligence model to the general customer base. The artificial intelligence integration enables efficient search and feature deployment for enterprises. These technologies can make more information accessible through machine vision, optical character recognition, scanning of documents, and analysis of various data types.

Moreover, the rising trend of hashing technology is expected to positively impact the market due to performance boost in search output. The technology further sorts data based on its hash values for easy search functions. For instance, in September 2022, Algolia, a proprietary search engine company, completed the acquisition of Search.io, a company with expertise in hashing technology. The acquisition enabled Algolia to offer faster and efficient search results to its clients.

Additionally, the growing trend of digitization in the industrial sector is significantly driving the market growth as employees use enterprise search solutions to search through terabytes of data instantaneously. Enterprise search solutions are crucial to companies since it reduces search times significantly that translates to an increased productivity. Moreover, enterprise search service providers offer a level of security to the data to prevent unauthorized access. As there are multiple levels of employees in an enterprise, a security layer assists in granting data access only to specific personnel.

Detailed Segmentation:

End-use Insights

Banking & financial segment is estimated to expand at a notable CAGR of over 9% from 2023 to 2030 owing to the interconnectivity and sharing of data in different outlets.

Type Insights

The hosted search segment is expected to attain the highest CAGR of around 10% during the forecast period from 2023 to 2030. This growth can be attributed to the increasing popularity of cloud based data hosting in enterprises due to its benefit of remote data access.

Enterprise Size Insights

Small enterprises segment is estimated to record a CAGR of over 7% from 2023 to 2030 with increasing demand for enterprise search solutions across these enterprises.

Regional Insights

North America accounted for the largest market share of around 35% in 2022. This can be attributed to the strong presence of several major industry participants in the region and technological developments initiated by them.

Key Companies & Market Share Insights

October 2022, adesso SE, an IT service provider, announced patnership with Sinequa, an enterprise search solution provider, to develop an enterprise search competence center. The partnership was undertaken to exchange respective expertise of the two companies. Some prominent players in the global enterprise search market include:

Attivio

Coveo Solutions Inc.

Dassault Systemes Inc.

Dieselpoint Inc.

EMC Corporation

Expert System Inc.

Alphabet Inc

HP Autonomy

IBM Corporation

Lucidworks Inc.

MarkLogic Corporation

Oracle

Global Enterprise Search Market Report Segmentation

Grand View Research has segmented the global enterprise search market report based on type, end-use, enterprise size, and region:

Type Outlook (Revenue, USD Million, 2018 - 2030)

Local Search

Hosted Search

Search Appliance

End-use Outlook (Revenue, USD Million, 2018 - 2030)

Government & Commercial Offices

Banking & Financial

Healthcare

Retail

Media

Manufacturing

Others

Enterprise Size Outlook (Revenue, USD Million, 2018 - 2030)

Small

Medium

Large

Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

UK

Germany

France

Italy

Russia

Asia Pacific

China

India

Japan

South Korea

South America

Brazil

Argentina

Colombia

MEA

UAE

Saudi Arabia

Order a free sample PDF of the Market Intelligence Study, published by Grand View Research.

0 notes

Text

What Makes the Best Testing Lab in India Stand Out in the Market?

In today's quality-conscious and compliance-driven marketplace, businesses across industries—from pharmaceuticals to electronics and construction—are constantly seeking reliable testing partners. The demand for accurate, timely, and standards-compliant testing has never been higher. Amidst the growing competition, the Best Testing Lab in India stands out by offering a unique blend of technical excellence, industry certifications, advanced infrastructure, and customer-centric services.

This blog explores the key factors that differentiate the best testing laboratories in India and how choosing the right lab can impact product quality, regulatory compliance, and brand reputation.

Why Testing Labs Matter

Testing laboratories play a crucial role in ensuring that products meet safety, performance, and regulatory requirements. Whether it's food safety, material strength, environmental compliance, or electrical component durability, testing labs act as third-party quality validators.

With global markets becoming more competitive, companies are under pressure to:

Minimize product recalls

Avoid regulatory penalties

Gain consumer trust

Ensure export readiness

Partnering with the Best Testing Lab can help businesses achieve all of the above while maintaining operational efficiency and market credibility.

1. NABL Accreditation and International Recognition

The foremost indicator of a trustworthy testing lab in India is NABL accreditation (ISO/IEC 17025). This certification signifies that the lab operates with technical competence and delivers valid results. The Best Testing Labs in India not only hold NABL accreditation but often have recognition under global mutual recognition arrangements (MRA) like ILAC and APAC, making their reports acceptable in international markets.

Why It Matters:

Ensures test results are credible and legally recognized

Speeds up export approvals and certifications

Reduces the need for re-testing in foreign markets

2. Advanced Infrastructure and Technology

Another defining trait of top-tier labs is their investment in cutting-edge instruments and testing methodologies. From high-precision spectrometers and tensile testing machines to environmental chambers and digital microscopes, the best testing labs in India continuously upgrade their infrastructure to match evolving industry standards.

Examples of Advanced Testing Capabilities:

XRF, ICP-MS, GC-MS for chemical and metal analysis

EMC/EMI testing for electronics

Accelerated weathering for paints and coatings

DNA analysis for food authenticity

Load-bearing and tensile tests for construction materials

Why It Matters:

Enables accurate, reproducible results

Supports testing across diverse industries

Future-proofs businesses against evolving compliance needs

3. Wide Range of Testing Services

A hallmark of the Best Testing Lab is its comprehensive service portfolio. Instead of specializing in one niche, top labs offer multi-disciplinary services under one roof, including:

Material Testing (metals, plastics, concrete, etc.)

Chemical Testing (purity, contamination, composition)

Environmental Testing (air, water, soil)

Electrical and Electronics Testing

Microbiological Testing

Pharmaceutical and Cosmetic Testing

Food and Agricultural Testing

This all-in-one capability streamlines testing workflows for businesses operating in multiple sectors or producing complex products.

4. Experienced and Qualified Experts

Technology alone doesn’t make a testing lab great. Behind every accurate test result is a team of qualified professionals—chemists, engineers, microbiologists, and technical analysts—who interpret results, troubleshoot issues, and provide expert insights.

The best testing labs in India attract and retain talent with:

Decades of industry experience

Advanced degrees in relevant fields

Ongoing training in international testing standards

Why It Matters:

Ensures error-free execution of complex testing procedures

Enhances trust in test results

Helps customers understand implications and next steps

5. Quick Turnaround Time

In fast-moving industries like food processing, construction, electronics, and pharmaceuticals, speed is critical. The Best Testing Lab in India understands this and delivers rapid, efficient testing services without compromising on accuracy.

Value-Added Services Include:

Fast-track testing for urgent needs

Digital reporting dashboards

24/7 support for critical projects

Why It Matters:

Keeps production timelines on track

Prevents launch delays or shipment holdups

Improves customer satisfaction

6. Strong Emphasis on Quality Assurance

Quality is the foundation of any reputable lab. The best testing labs implement robust internal quality control (IQC) and external quality assurance (EQA) programs. These include:

Regular calibration of instruments

Blind sample testing

Participation in proficiency testing programs

This ensures every result delivered is consistent, traceable, and scientifically valid.

7. Customer Support and Regulatory Guidance

Not every business is familiar with complex testing protocols or certification requirements. Leading Indian testing labs stand out by offering consultative support, guiding clients on:

Which tests are necessary based on product category

Applicable Indian and international standards (BIS, ISO, ASTM, IEC, etc.)

Documentation needed for regulatory submissions

Certification pathways (BIS, FSSAI, CE, FCC, etc.)

This proactive support makes the lab a partner, not just a service provider.

8. Industry-Specific Customization

Each industry has unique testing challenges. The best testing labs offer tailored solutions for sectors such as:

Electronics: EMC/EMI, thermal stress, RoHS

Food: Shelf-life, nutritional labeling, contamination

Construction: Cement strength, aggregate analysis, soil testing

Pharmaceuticals: Stability testing, dissolution, impurity profiling

This customization ensures that testing is relevant, effective, and actionable.

9. Transparency and Ethics

In a highly regulated ecosystem, transparency is vital. Top testing labs are known for:

Clear pricing models

Unbiased third-party reporting

No conflict of interest

Audit support

This builds long-term trust and fosters dependable relationships with clients, regulators, and certification bodies.

10. Track Record and Client Portfolio

Lastly, the reputation of a lab speaks volumes. The best testing labs in India have:

A large, diverse client base (including MNCs and government bodies)

Case studies showcasing successful projects

Testimonials from satisfied clients

Recognition from regulatory authorities

When you see a testing lab consistently working with leading brands and contributing to compliance success stories, you know you’re in good hands.

Conclusion

In a world driven by quality, compliance, and accountability, selecting the Best Testing Lab in India is a strategic decision that influences every stage of your product life cycle. From ensuring product safety and performance to achieving market certification and customer confidence, a top-tier lab does much more than run tests—it empowers businesses to thrive in regulated markets.

0 notes

Text

The Next Generation of Automotive Control Cables: What to Expect

In today’s fast-evolving automotive industry, control cables continue to play a vital role in ensuring vehicle safety, comfort, and performance. These cables may seem like simple components, but they are essential in connecting drivers to their vehicles—literally and mechanically. Accelerator cables, clutch cables, brake cables, and gear shift cables are all examples of control cables that help drivers operate their vehicles with ease and precision.

As we look toward the future, control cable technology is evolving along with the vehicles they serve. From the rise of electric vehicles (EVs) to the integration of smart technologies, control cables are undergoing changes to meet new demands. This blog explores the future of automotive control cables, highlighting major trends, new technologies, and what manufacturers and OEMs can expect in the coming years.

1. Rise of Electric Vehicles and Cable Reengineering

One of the most significant shifts in the automotive world is the global adoption of electric vehicles. Unlike traditional internal combustion engine (ICE) vehicles, EVs require different types of control systems. However, even in EVs, mechanical and hybrid cable systems are still required for tasks like seat adjustments, hood releases, and specialized commercial applications.

This trend is pushing cable manufacturers to innovate and redesign control cables that are lighter, more compact, and compatible with electric vehicle architecture. In many EVs, space optimization is a priority. As a result, control cables must now be engineered to function within tighter compartments, with better flexibility and resistance to heat generated by battery components.

Additionally, electric and hybrid vehicles introduce new requirements such as electromagnetic compatibility (EMC). Cables used in these vehicles must be shielded or grounded properly to avoid interference with electronic systems. This will drive more collaboration between cable manufacturers and EV designers.

2. Lightweight and Eco-Friendly Materials

As automotive companies aim to reduce vehicle weight for better fuel efficiency and lower emissions, the demand for lightweight components is rising. Control cables are no exception. Traditionally made from steel and rubber, newer cables are now being designed using high-tensile synthetic fibers, lighter alloy cores, and advanced plastic sheathing.

These materials not only help reduce vehicle weight but also improve cable flexibility and performance. The use of recyclable and non-toxic materials is also growing, aligning with stricter environmental regulations and the automotive industry’s sustainability goals.

In the near future, we expect to see wider adoption of thermoplastic elastomers (TPE), bio-based plastics, and composite cable technologies that offer high strength while being eco-friendly.

3. Durability, Low Maintenance, and Longer Lifespan

Automotive control cables are exposed to constant motion, friction, heat, and external contaminants like dust, water, and chemicals. The future of control cable design will prioritize longer service life and minimal maintenance.

Advanced lubrication materials, sealed cable designs, and self-lubricating liners are already being developed to extend cable durability. Manufacturers are also using corrosion-resistant coatings and stainless steel wires for applications that demand higher strength and long-term reliability.

With customers expecting long-lasting vehicles and lower maintenance costs, control cables are now engineered for 1,50,000 km or more without failure—especially in commercial vehicles and heavy-duty applications.

4. Integration with Smart and Autonomous Systems

Another major shift is the rise of connected and autonomous vehicles. As sensor-based technologies take over traditional driving tasks, the role of mechanical control cables is being redefined.

However, instead of becoming obsolete, control cables are evolving to complement electronic systems. Hybrid cable systems—where a mechanical cable is integrated with electronic sensors—are being developed for use in smart seat systems, adaptive pedals, and safety release mechanisms.

Additionally, smart cables with embedded sensors can monitor cable tension, temperature, and performance in real-time. These cables can alert drivers or onboard diagnostic systems when service is needed, preventing breakdowns and improving overall vehicle safety.

This trend will make control cables not just functional, but intelligent components that contribute to the vehicle’s health monitoring system.

5. Increased Customization for Specialized Vehicles

With the boom in electric delivery vans, personal mobility vehicles, off-road utility vehicles, and electric two-wheelers in urban areas, there's a growing need for highly customized control cable solutions. Unlike standard passenger cars, these vehicles often operate under specific conditions, requiring cables tailored for unique applications.

From throttle and brake cables in last-mile delivery EVs to clutch and shift cables in agricultural and construction equipment, manufacturers must offer a wide range of solutions with variable length, pull strength, outer casing flexibility, and end fittings.

This trend is fueling the demand for low-volume, high-precision cable production and faster prototyping capabilities. Rapid customization and short production cycles will be a major competitive advantage for future-ready control cable manufacturers.

6. Focus on NVH Reduction

Noise, Vibration, and Harshness (NVH) has always been a critical performance factor in vehicles, especially in luxury and premium models. Traditional control cables can create unwanted noise or resistance during operation if not well-designed.

With the advent of quieter electric vehicles, any mechanical noise becomes more noticeable. Hence, the next generation of control cables is being developed with smoother liners, dampening sheaths, and advanced internal structures that reduce friction and vibration.

OEMs now demand ultra-silent cable systems that enhance the driving experience while still meeting mechanical performance standards.

7. Localized Manufacturing and Shorter Supply Chains

Global supply chain disruptions in recent years have pushed many automotive brands to localize component sourcing. This trend includes control cables, which are increasingly being manufactured closer to assembly plants.

Local manufacturers that offer fast delivery, technical customization, and just-in-time (JIT) capabilities are being favored over large overseas suppliers. As a result, regional players are becoming key partners in vehicle production.

The future of control cable manufacturing lies in localized, agile production units equipped with advanced CNC, crimping, and testing setups to handle both bulk and custom requirements.

8. Testing, Simulation, and Digital Twin Technology

The integration of digital tools in manufacturing is another future-forward trend. Control cable manufacturers are now using advanced simulation software to predict cable behavior under different stress levels, temperature conditions, and motion cycles.

Digital Twin technology, where a virtual replica of a control cable system is created for real-time performance monitoring, is also gaining popularity in R&D labs. These tools reduce the development time, improve accuracy, and help manufacturers create better products with fewer iterations.

Going forward, AI and machine learning may also be used to predict cable failure patterns and improve quality control during the manufacturing process.

9. Compliance with Global Safety Standards

As safety regulations evolve worldwide, manufacturers must ensure that their control cables meet international certifications like ISO/TS 16949, SAE J1128, and others. This includes rigorous testing for tensile strength, elongation, heat resistance, vibration performance, and environmental stress.

Meeting these standards not only builds trust with OEMs but also helps manufacturers tap into global markets with confidence. In the future, we may also see standardization efforts around smart cable communication protocols in electric and autonomous vehicles.

Final Thoughts

The future of automotive control cables is anything but outdated. While vehicles are becoming smarter, greener, and more autonomous, mechanical and hybrid control cables continue to evolve alongside them. From smart materials and sensor integration to lightweight design and predictive maintenance, these components are becoming more advanced, intelligent, and efficient.

OEMs and vehicle manufacturers looking to stay competitive must prioritize innovative control cable partners who understand emerging trends and are equipped to meet dynamic requirements.

Chattarpati Automotive Systems, a leading manufacturer of automotive control cables in India, is proud to be part of this innovation journey—delivering precision-engineered, future-ready cable solutions for cars, commercial vehicles, and heavy equipment worldwide.

0 notes

Text

The EMC filtration market is projected to reach USD 1.59 billion by 2030 from USD 1.26 billion in 2025, at a CAGR of 4.7% according to a new report by MarketsandMarkets™. The shift from conventional fuel-based engines toward electric vehicles is increasing the demand for EMC filtration. Electric vehicles comprise various electronic components, including motors, battery units, and control units, which become vulnerable to electromagnetic interference and pose a threat to motor malfunction.

0 notes

Text

Analog 4-20mA Absolute Rotary Encoder Singleturn and Multiturn Power-off memory

Key features

Power-off Memory: Retains position information even after power loss, providing uninterrupted data reliability.

Absolute Multi-Turn: Offers precise position data across multiple turns, making it ideal for diverse applications.

Mechanical Gear Count: Utilizes mechanical gears for counting turns, eliminating the need for an internal battery.

High Resolution: Features up to 17-bit resolution with 0.07° accuracy for highly precise measurements.

Compact Design: With a minimal outer diameter of just 39mm, this industrial-grade encoder is built to withstand tough environments.

Data Interface: Supports Analog 4-20mA for seamless integration and data exchange in various industrial applications.

Wide Voltage Compatibility: Engineered to operate under various voltage conditions and has passed rigorous EMC testing, ensuring robust anti-interference capabilities.

User-Friendly Configuration: Parameter settings can be easily managed through communication protocols, making setup intuitive and straightforward.

Flexible Operation Modes: Supports both query and automatic return modes for real-time position and speed feedback. Programmable features include baud rate, setup position, counting direction, and speed feedback.

Compact and Cost-Effective: Space-saving design delivers high performance at a competitive price.

Rugged and Reliable: Magnetic sensors are designed to endure harsh environmental conditions.

Visit https://briterencoder.com/product/absolute-rotary-encoder-with-analog-output/ for more.

#Absolute Rotary Encoder Singleturn and Multiturn#Absolute Rotary Encoder Singleturn#Absolute Rotary Encoder Multiturn#Rotary Encoder

0 notes