#Emergency Spill Response Industry Report

Text

Almost every week, oil spills are reported somewhere in the world. From ships dumping contaminating ballast water or breaking down on coral reefs, to direct attacks on oil pipelines and tankers. The larger the spill, the bigger the media attention.

This year alone, off the coast of Trinidad and Tobago, a Bellingcat investigation found that 1,000 tonnes of oil contaminated protected wetlands and wildlife sanctuaries after a barge capsized. In the Middle East, the Houthis targeted the Liberia-flagged tanker, Chios Lion. Carrying a cargo of crude oil, the strike resulted in a 200-kilometre-long oil slick. And in South-East Asia, in late July, the tanker, MT Terra Nova, carrying 1.4 million litres of industrial oil, capsized off the coast of Manila in the Philippines, causing a four-km-long engine oil spill.

The sheer scale of ocean oil pollution is staggering. In Europe, a suspected 3,000 major illegal oil dumps take place annually, with an estimated release of between 15,000 and 60,000 tonnes of oil ending up in the North Sea. In the Mediterranean, figures provided by the Regional Marine Pollution Emergency Response Centre estimate there are 1,500 to 2,000 oil spills every year.

The impact of any single oil spill on a marine or coastal ecosystem can be devastating and long-lasting. Animals such as birds, turtles, dolphins and otters can suffer from ingesting or inhaling oil, as well as getting stuck in the slick. The loss of water and soil quality can be toxic to both flora and fauna. Heavy metals enter the food chain, poisoning everything from plankton to shellfish, which in turn affects the livelihoods of coastal communities dependent on fishing and tourism.

However, with a wealth of open source earth observation tools at our fingertips, during such environmental disasters it’s possible for us to identify and monitor these spills, highlight at-risk areas, and even hold perpetrators accountable.

4 notes

·

View notes

Text

Note that the studies that were released by companies affiliated with polluters happened in 2019, during the trump administration.

Excerpt from this story from Inside Climate News:

On a Southern California spring morning in 1973, a tanker truck driver jackknifed his rig and dumped the agricultural fumigant he was transporting onto a city street. A Los Angeles Fire Department emergency response team spent four hours cleaning up the chemical, 1,3-dichloropropene, or 1,3-D, a fumigant sold as Telone that farmers use to kill nematodes and other soil-dwelling organisms before planting.

Seven years after the spill, two emergency responders developed the same rare, aggressive blood cancer—histiocytic lymphoma—and died within two months of each other. In 1975, a farmer who’d accidentally exposed himself to 1,3-D repeatedly through a broken hose was diagnosed with another blood cancer, leukemia, and died the next year.

Within a decade of the men’s deaths, described as case studies in JAMA Internal Medicine, the National Toxicology Program, or NTP, reported “clear evidence” that 1,3-D causes cancer in both rats and mice. The finding led the U.S. Environmental Protection Agency to classify the chemical as “likely to be carcinogenic to humans” the same year, 1985. So it wasn’t a surprise when researchers at the University of California, Los Angeles reported in 2003 that Californians who’d lived at least two decades in areas with the highest applications of 1,3-D faced a heightened risk of dying from pancreatic cancer.

Yet EPA’s Office of Pesticide Programs’ Cancer Assessment Review Committee, or CARC, concluded in 2019 that 1,3-D—originally embraced by tobacco companies for its unparalleled ability to kill anything in soil that might harm their plants—isn’t likely to cause cancer after all.

In doing so, EPA, whose mission is to protect human health and the environment, rejected the human evidence, calling the UCLA study “low quality.” It also dismissed the authoritative NTP study and studies in lab animals that documented 1,3-D’s ability to damage DNA, a quintessential hallmark of cancer.

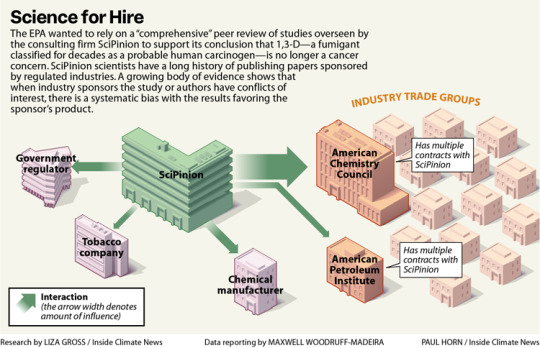

Instead, EPA’s CARC relied on studies provided by Dow AgroSciences (now called Corteva), the primary manufacturer of 1,3-D, and proposed a review of evidence linking the fumigant to cancer by SciPinion, a consulting firm hired by Dow, as an external peer review of its work. The decision to entrust external review to a Dow contractor has drawn repeated criticism, including from the agency’s watchdog, the Office of Inspector General, or OIG.

“During EPA’s search of the open literature, a comprehensive third-party peer review of the cancer weight-of-evidence assessment that considered toxicokinetics, genotoxicity and carcinogenicity data for 1,3-D was conducted and published in 2020 by SciPinion,” said agency spokesperson Timothy Carroll. EPA argued that the SciPinion review satisfied the criteria for an external review, Carroll said, and that another panel would have arrived at the same conclusion, given the specialized expertise required.

The OIG had recommended EPA conduct an external peer review of its 1,3-D cancer risk assessment in a 2022 report that outlined several problems with the agency’s process. An external review, the OIG said, requires “independence from the regulated business,” again noting the deficiency in a new report released in early August.

The scientists who run SciPinion have long consulted for manufacturers of harmful products, often publishing studies that deploy computer models to question the need for more protective health standards.

4 notes

·

View notes

Text

Simple Steps to Strong Safety Management

Process safety management (PSM) is essential for ensuring workplace safety, especially in industries dealing with hazardous materials or complex processes. Having a robust safety management system helps reduce risks and prevent accidents. Whether you’re just starting or looking to improve your safety measures, these simple steps can help you build a strong safety management plan that protects both workers and operations.

Identify Potential Hazards

The first step in any safety management system is identifying potential hazards. Conduct regular risk assessments to uncover areas where safety issues could arise. Look at all possible risks, from equipment malfunctions to human errors. By understanding what could go wrong, you can put measures in place to prevent incidents. This proactive approach is crucial to the foundation of Process Safety Management.

At The Safety Master, we help organizations conduct thorough safety audits to ensure all risks are identified and controlled. Our expert team provides customized solutions to meet the unique needs of each company, making workplaces safer and more efficient.

Implement Safety Protocols

Once hazards have been identified, it's important to establish clear safety protocols. These protocols should outline steps for preventing accidents and responding to emergencies. Whether it’s wearing protective gear, following machine operation guidelines, or conducting regular equipment checks, clear instructions help everyone stay safe.

These protocols must be easily accessible and regularly updated to adapt to new technologies or changes in the work environment. At The Safety Master, we help businesses implement strong safety protocols based on industry best practices and process safety management guidelines.

Train Employees

Training is a vital part of any safety management system. Employees must know how to recognize risks and follow safety procedures properly. Regular training sessions ensure that everyone remains updated on the latest safety practices. It's not enough to just train employees once; consistent refresher courses keep safety top of mind.

By offering tailored training programs, The Safety Master ensures that your workforce is fully equipped to handle safety concerns, reducing the likelihood of accidents and improving overall compliance with safety standards.

Encourage Reporting

Creating a culture where employees feel comfortable reporting safety concerns is essential for improving safety management. Workers on the frontlines often notice issues that management might miss. By encouraging them to report unsafe conditions or incidents, you create an open environment focused on continuous improvement.

Organizations that promote open communication often prevent accidents before they happen. The Safety Master promotes this culture by helping companies establish anonymous reporting systems, ensuring that all safety concerns are addressed in a timely manner.

Regular Inspections and Audits

A strong safety management system requires continuous monitoring and improvement. Conduct regular inspections and safety audits to ensure that all systems are functioning correctly and that safety measures are being followed. Regular reviews of safety protocols can help identify areas for improvement.

At The Safety Master, we offer comprehensive safety audits to help businesses stay compliant with regulations while continuously improving their safety performance. Our audits are tailored to your industry, ensuring that your process safety management systems are always effective.

Create an Emergency Response Plan

Even with the best safety protocols in place, emergencies can still happen. It’s important to have a well-prepared emergency response plan that outlines steps to take in case of fire, chemical spills, or other dangerous situations. Make sure all employees are familiar with the plan and conduct regular drills to ensure everyone knows what to do during an emergency.

Having a solid emergency plan in place minimizes the impact of unexpected incidents and ensures the safety of your workforce. The Safety Master specializes in helping businesses develop and implement effective emergency response plans tailored to their specific operations.

Continuous Improvement

Safety management is not a one-time task; it requires ongoing attention and refinement. Regularly review your safety practices and update them as needed. New technologies, changing industry standards, and evolving work environments all require flexibility in your safety management system.

Continuous improvement is key to staying ahead of potential risks. The Safety Master works with companies to regularly assess and update their process safety management systems, ensuring that they remain strong, efficient, and effective over time.

Conclusion

Building a strong safety management system is crucial for protecting workers and ensuring smooth operations. By following these simple steps—identifying hazards, implementing safety protocols, training employees, encouraging reporting, conducting audits, preparing emergency plans, and focusing on continuous improvement—you can create a safer workplace.

Process safety management is at the heart of this process. It helps prevent accidents before they happen and ensures compliance with industry regulations. If you’re looking for expert guidance on improving your safety management system, The Safety Master is here to help. Our team of experienced professionals provides tailored solutions that meet the specific needs of your organization, helping you create a safer and more efficient workplace.

By investing in strong safety management, you not only protect your employees but also enhance the long-term success of your business.

0 notes

Text

How House of Expertise Customizes Safety Solutions for Different Types of Construction Projects

Ensuring safety on construction sites is paramount, and it requires a tailored approach to address the unique needs of each project. The House of Expertise excels in providing customized safety solutions for various types of construction projects. By leveraging their extensive experience and expertise, they help ensure that construction sites in Dubai, Abu Dhabi, and across the UAE adhere to the highest safety standards.

Understanding the Unique Needs of Construction Projects

The Complexity of Construction Sites

Construction projects vary widely in scope, scale, and complexity. Whether it's a high-rise building, a residential development, or an infrastructure project, each type has its unique safety challenges. Understanding these nuances is crucial for developing effective safety solutions.

Factors Influencing Safety Requirements

Several factors influence the safety requirements for a construction project:

Type of Construction: Different types of projects, such as commercial, residential, or industrial, have distinct safety needs.

Project Size and Scope: Larger projects with multiple phases or complex operations require more comprehensive safety measures.

Site Conditions: The geographical location, weather conditions, and environmental factors of the construction site impact safety planning.

Regulatory Requirements: Compliance with local regulations and industry standards is essential for safety.

Customized Safety Solutions for Diverse Construction Projects

Risk Assessment and Management

Risk assessment is the cornerstone of any effective safety plan. Safety consultants in Dubai and Abu Dhabi begin by evaluating the specific risks associated with a construction project. This involves:

Identifying Hazards: Potential hazards are identified based on the type of construction, site conditions, and activities involved.

Evaluating Risks: The likelihood and impact of each hazard are assessed to prioritize safety measures.

Developing Risk Mitigation Strategies: Tailored strategies are created to manage and minimize identified risks.

Designing Site-Specific Safety Plans

Once the risks are assessed, safety consultants design site-specific safety plans. These plans are customized to address the unique needs of the construction project and may include:

Emergency Response Plans: Tailored to the specific site conditions and potential emergencies, such as fires, chemical spills, or structural collapses.

Safety Training Programs: Customized training for workers based on the project’s requirements and hazards. This includes general safety training and specialized training for specific tasks or equipment.

Personal Protective Equipment (PPE): Recommendations for appropriate PPE based on the hazards present on the site.

Implementing Safety Measures

Effective implementation of safety measures is crucial for maintaining a safe construction site. Safety consultants assist in:

Site Inspections: Regular inspections to ensure compliance with safety plans and to identify any emerging hazards.

Safety Audits: Comprehensive audits to evaluate the effectiveness of safety measures and to recommend improvements.

Incident Reporting and Analysis: Procedures for reporting and analyzing incidents to prevent future occurrences and improve safety practices.

Compliance with Local and International Standards

Adhering to Regulatory Requirements

Safety consultants in Abu Dhabi and Dubai ensure that construction projects comply with local regulations and international safety standards. This includes:

Understanding Local Regulations: Familiarity with the specific safety regulations and codes applicable to construction projects in the UAE.

Compliance with International Standards: Incorporating international safety standards and best practices to ensure a high level of safety.

Collaboration with Regulatory Authorities

Collaboration with regulatory authorities is an integral part of the safety management process. Safety consultants work closely with these authorities to:

Obtain Necessary Permits: Ensuring that all required safety permits are obtained before commencing work.

Address Compliance Issues: Quickly addressing any compliance issues or concerns raised by regulatory authorities.

Benefits of Customized Safety Solutions

Enhanced Safety Performance

Customized safety solutions lead to improved safety performance on construction sites by addressing specific risks and ensuring that all safety measures are relevant and effective.

Increased Compliance

Tailored safety plans help ensure compliance with both local regulations and international standards, reducing the risk of penalties and project delays.

Improved Worker Safety

By addressing the unique hazards associated with each project, customized safety solutions contribute to a safer working environment for construction workers.

Efficient Risk Management

Customized solutions enable more effective risk management by focusing on the specific risks associated with the project, leading to better overall safety outcomes.

Conclusion

The House of Expertise plays a crucial role in enhancing construction site safety by providing customized solutions tailored to the unique needs of different projects. Their approach, which involves thorough risk assessment, site-specific safety planning, and strict adherence to regulatory standards, ensures that construction projects in Dubai, Abu Dhabi, and across the UAE are managed safely and effectively. By leveraging the expertise of safety consultants in Dubai and Abu Dhabi, construction projects can achieve higher safety standards, reduce risks, and ensure compliance with both local and international regulations.

0 notes

Text

Industrial Absorbents Market worth $5.2 billion by 2028

The report "Industrial Absorbents Market by Material type (natural organic & inorganic, synthetic), Product (pads, booms & socks), Type (universal, oil-only, HAZMAT), End-use industry (oil & gas, chemical, food processing), and Region - Global forecast to 2028", size is projected to grow from USD 4.3 billion in 2023 and reach USD 5.2 billion by 2028, at a CAGR of 4.0% from 2023 to 2028. The exponential growth of the industrial absorbents market is intricately linked to the amplified concern for our ecological well-being. Heightened environmental consciousness has spurred a global call for action, with industries increasingly recognizing the critical role they play in preserving ecosystems. As regulatory bodies tighten the reins on spill management, demanding stringent adherence to laws addressing oil and chemical spills' deleterious effects, industries are compelled to seek effective solutions.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=101269725

Furthermore, the pivotal role of industrial absorbents lies in their ability to align with these regulations, providing efficient spill containment and cleanup measures. Moreover, as corporations embrace sustainability as a core value, the use of absorbents becomes not just a compliance necessity but a strategic move towards responsible business practices. By safeguarding ecosystems, complying with regulations, and showcasing a commitment to environmental responsibility, the surge in demand for industrial absorbents is propelled by a collective drive to protect the planet while maintaining operational integrity.

The synthetic segment to lead the industrial absorbents market during 2023-2028.

The synthetic segment holds the top position in the industrial absorbents market due to its substantial demand across key industries like oil & gas, chemicals, food processing, and healthcare. Synthetic absorbents offer a range of advantages, including versatility in handling various types of spills, cost-effectiveness, and high absorbency rates. Their ability to efficiently manage oil, chemical, and hazardous material spills makes them preferred choices across diverse industries. Additionally, advancements in manufacturing technology have led to the development of synthetic absorbents with enhanced properties such as higher absorbency capacities and eco-friendly formulations. These factors collectively position the synthetic segment at the forefront of the industrial absorbents market, driving its growth and widespread adoption in spill management applications.

The pads segment will lead the industrial absorbents market during the forecast period.

Based on products, the pads segment is expected to be the largest segment of the industrial absorbents industry due to its practicality, convenience, and versatility. Pads offer a quick and efficient solution for spill containment and cleanup across various industries. They are easily deployable, making them ideal for both planned and emergency spill response scenarios. Moreover, pads come in different sizes and absorbency capacities, catering to a wide range of spill types and volumes. Their ease of use, effectiveness in absorbing liquids like oil, chemicals, and water, and compatibility with different surfaces contribute to their widespread adoption. As industries prioritize efficient and reliable spill management solutions, the pads segment stands out for its effectiveness, driving its leading position in the industrial absorbents market.

Oil-only is expected to register the highest growth during the forecast period.

During the forecast period, oil-only is expected to register the highest growth in the industrial absorbents foam market. Industries dealing primarily with oil-based products, such as petroleum, automotive, and manufacturing sectors, require specialized absorbents tailored specifically for oil spills. These oil-only absorbents are designed to selectively absorb oil while repelling water, making them highly effective in situations where oil spills pose a significant risk. Additionally, the increased focus on environmental protection has amplified the demand for dedicated oil-absorbing solutions, as they aid in preventing oil contamination in water bodies and ecosystems. The versatility and effectiveness of oil-only absorbents in managing oil-based spills are expected to drive their heightened adoption and subsequent growth in the industrial absorbents market during the forecast period.

The oil & gas segment is estimated to account for the largest share during the forecast period.

The oil & gas sector stands as the leading end-use industry segment in the industrial absorbents market due to its significant demand for synthetic absorbents. Oil & gas operations, covering downstream, midstream, and upstream phases, necessitate spill control products to mitigate spill risks. Spills in this industry involve liquid hydrocarbons released into the environment. These spills stem from crude oil leakage in tankers, offshore platforms, drilling rigs, and wells, along with refined petroleum products or heavy fuels from ships. Industrial absorbents aid oil & gas companies in managing spill aftermath, facilitating liquid recovery and disposal.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=101269725

North America will lead the global industrial absorbents market during the forecast period.

Stringent regulations set by environmental agencies like the EPA, specifically for spill control in oil & gas and chemical industries, have propelled the North American industrial absorbents market's expansion. Nonetheless, the market in North America is expected to experience a moderate growth rate in the forecast period due to reduced major oil spills and a stabilized demand for spill control products in the US. Additionally, there's a growing awareness of environmental concerns, prompting industries to adopt better spill management practices. The need for these absorbents is also influenced by their effectiveness in containing and managing spills, especially in sectors prone to oil and chemical spills.

Moreover, innovations and advancements in absorbent technology are contributing to the market's growth, enhancing the efficiency and effectiveness of these products. Overall, the combination of regulatory pressures, environmental awareness, and technological advancements is fueling the expansion of the industrial absorbents market in North America.

Some of the leading manufacturers of industrial absorbents profiled in this report are 3M Company (US), Brady Corporation (US), Decorus Europe Ltd. (UK), Johnson Matthey Plc (UK), Kimberly-Clark Professional (US), Meltblown Technologies Inc. (US), Monarch Green, Inc. (US), New Pig Corporation (US), and Oil-Dri Corporation of America (US).

0 notes

Text

Essential Items In Spill Kits In Melbourne: What Can Be Carried

In Melbourne, a city known for its diverse industrial landscape, the management of hazardous materials and liquids is of paramount importance. Spill kits are indispensable tools in preventing and managing spills, whether in a manufacturing plant, laboratory, or transport vehicle. These kits are designed to contain and clean up spills, protecting both the environment and human health. In this blog, we will explore the essential items that can be carried in spill kits in Melbourne, ensuring compliance with safety regulations and readiness for emergencies.

Introduction to Spill Kits

Spill kits are comprehensive packages containing various tools and materials designed to manage spills of hazardous substances. The composition of these kits can vary depending on the specific requirements of the industry or environment in which they are used. In Melbourne, spill kits are crucial in a range of settings, from industrial sites to healthcare facilities, due to the city's extensive use of chemicals, oils, and other potentially dangerous materials.

Key Components of Spill Kits

Absorbent Materials: Absorbents are the core component of any spill kit. They are specifically designed to soak up liquids, preventing them from spreading and causing further contamination. Common absorbents include pads, socks, pillows, and loose materials. Each type serves a unique purpose, such as pads for flat surfaces, socks for creating barriers, and pillows for large-volume spills. These materials are typically hydrophobic, allowing them to absorb oil-based substances while repelling water.

Personal Protective Equipment (PPE): Safety is a top priority when dealing with hazardous spills. Spill kits in Melbourne often include personal protective equipment (PPE) such as gloves, goggles, face masks, and protective clothing. This equipment is essential for protecting responders from exposure to harmful substances, preventing skin contact, inhalation, or eye injuries. The inclusion of PPE ensures that clean-up operations can be conducted safely and efficiently.

Containment Tools: Containment is a crucial aspect of spill management. Spill kits include various tools designed to contain and control the spread of spills. These may include drain covers, booms, dikes, and berms. Booms and socks, for instance, can be placed around a spill to prevent it from spreading, while drain covers block the flow of contaminants into drainage systems. These tools are particularly important in preventing environmental contamination in urban areas like Melbourne.

Disposal Bags and Containers: After the clean-up, the safe disposal of contaminated materials is vital. Spill kits typically come with heavy-duty disposal bags and containers to safely store used absorbents and PPE. Proper disposal is crucial to comply with environmental regulations and to prevent secondary contamination. In Melbourne, businesses must adhere to strict waste management guidelines, making the inclusion of disposal materials in spill kits a necessity.

Instruction Manual and Spill Response Plan: A well-prepared spill kit includes an instruction manual and a spill response plan. These documents provide clear guidelines on how to use the kit's contents effectively and outline the steps to take during a spill event. The response plan may include emergency contact numbers, procedures for evacuating the area, and instructions for reporting the incident to local authorities. Having a clear plan ensures a coordinated and efficient response, minimising the impact of the spill.

Conclusion

In conclusion, spill kits are an essential part of any emergency response plan in Melbourne, providing the necessary tools to manage and contain hazardous spills. The key components of these kits, including absorbents, PPE, containment tools, and disposal materials, are designed to protect both the environment and human health. Whether dealing with oil, chemicals, or other hazardous substances, having a well-equipped spill kit on hand is crucial for ensuring safety and compliance with local regulations. By understanding the importance and functionality of spill kits, businesses and individuals can be better prepared to handle spill incidents effectively, minimising their impact on the environment and public safety.

0 notes

Text

In today’s fast-paced industrial environment, safety is not just a regulatory requirement but a critical component of operational success. Chemical safety training programs are essential for organizations that handle hazardous materials, ensuring that employees are well-prepared to manage risks associated with chemical exposure. In Greater Noida, a hub for various industries, the importance of comprehensive chemical safety training cannot be overstated.

Understanding the Need for Chemical Safety Training

Chemical safety training is crucial for preventing accidents, ensuring regulatory compliance, and maintaining a safe workplace. Chemicals used in industries, laboratories, and even in households can pose serious risks if not handled properly. The primary objective of Chemical Safety Training Program in Greater Noida is to educate employees about the hazards of chemicals they may encounter and the best practices for managing those hazards.

Key Components of a Chemical Safety Training Program

Regulatory Compliance: Training programs are designed to ensure compliance with local and international regulations, such as the Occupational Safety and Health Administration (OSHA) standards and the Globally Harmonized System (GHS) of Classification and Labeling of Chemicals. Understanding these regulations helps in avoiding legal repercussions and ensures that the workplace meets safety standards.

Chemical Hazard Identification: Participants learn to identify different types of chemical hazards, including physical hazards (flammable, explosive) and health hazards (toxic, corrosive). This includes understanding Material Safety Data Sheets (MSDS) and Safety Data Sheets (SDS), which provide critical information about chemical properties and safety measures.

Proper Handling and Storage: Effective training covers the correct procedures for handling and storing chemicals. This includes using appropriate personal protective equipment (PPE), proper labeling of chemical containers, and safe storage practices to prevent leaks, spills, and reactions.

Emergency Response: A significant part of chemical safety training involves preparing employees for emergency situations. This includes training on how to respond to chemical spills, leaks, and exposure incidents. Employees are taught how to use emergency equipment, follow evacuation procedures, and report incidents promptly.

Safe Disposal Practices: Proper disposal of chemicals is crucial for environmental protection and safety. Training programs include guidelines on how to dispose of chemicals responsibly, including waste segregation and the use of licensed disposal services.

Benefits of Chemical Safety Training

Reduced Accidents and Injuries: Well-trained employees are less likely to experience accidents or injuries related to chemical exposure. This leads to a safer work environment and reduced downtime due to accidents.

Regulatory Compliance: Ensuring that employees are aware of and adhere to safety regulations helps organizations avoid fines and legal issues, contributing to a more compliant and responsible workplace.

Enhanced Productivity: A safe work environment contributes to higher employee morale and productivity. When employees feel safe and well-prepared, they can focus on their tasks without the distraction of safety concerns.

Environmental Protection: Proper handling and disposal of chemicals prevent environmental contamination, aligning with sustainability goals and contributing to corporate social responsibility.

Implementing a Training Program in Greater Noida

Organizations in Greater Noida can benefit from specialized chemical safety training programs tailored to their specific needs. Local training providers offer customized programs that address the unique challenges and requirements of different industries. These programs can be conducted on-site or at dedicated training facilities, ensuring convenience and accessibility for businesses.

Conclusion

Chemical safety training is an investment in the well-being of employees and the overall safety of the workplace. For businesses implementing a robust Chemical Safety Training Program in Greater Noida program is not just a regulatory requirement but a proactive approach to preventing accidents and ensuring operational efficiency. By prioritizing chemical safety, organizations can foster a safer work environment, comply with regulations, and contribute to the well-being of their employees and the community.

0 notes

Text

Premier Hazardous Environmental Waste Transportation Services in New York, NY: Why RES Is Your Best Choice

Handling hazardous environmental waste is a critical responsibility for businesses across various sectors, and ensuring its safe and compliant transportation is paramount. For businesses in New York, NY, RES offers premier hazardous environmental waste transportation services designed to meet the highest standards of safety, compliance, and efficiency. With our expertise and dedicated approach, RES ensures that hazardous waste is managed responsibly from collection to final disposal. Here’s why RES stands out as the top choice for Hazardous environmental waste transportation services New York NY,

The Critical Role of Hazardous Waste Transportation

Hazardous environmental waste encompasses a range of materials, including chemicals, industrial byproducts, and medical waste, that pose potential risks to human health and the environment. Proper transportation of these materials is essential for several reasons:

Safety: Hazardous waste can be harmful if not handled correctly. Effective transportation methods help prevent exposure, spills, and accidents, ensuring the safety of personnel and the public.

Regulatory Compliance: New York and federal regulations mandate strict guidelines for the handling and transportation of hazardous waste. Non-compliance can result in severe penalties and legal repercussions. Professional services ensure that all regulatory requirements are met.

Environmental Protection: Proper waste management helps protect natural resources and ecosystems from contamination. Safe transportation practices reduce the risk of environmental damage and support sustainable waste management.

Why Choose RES for Hazardous Environmental Waste Transportation in New York, NY?

RES is a leading provider of hazardous environmental waste transportation services in New York, NY, offering comprehensive solutions tailored to the needs of businesses and organizations. Here’s what makes RES the ideal choice for your hazardous waste transportation needs:

Advanced Equipment and Vehicles: RES utilizes specialized equipment and vehicles designed for the safe and efficient transportation of hazardous materials. Our fleet includes advanced containment systems to prevent leaks and ensure secure handling throughout transit.

Expert Knowledge of Regulations: Navigating the complex regulations governing hazardous waste can be challenging. RES’s team is well-versed in federal, state, and local regulations. We ensure that all necessary permits and documentation are in place to achieve full compliance.

Customized Solutions: We recognize that different types of hazardous waste require specific handling procedures. RES provides tailored transportation solutions based on the nature of the waste, including its type, quantity, and storage needs.

Emergency Response Preparedness: In the unlikely event of an incident or spill, RES is equipped with a comprehensive emergency response plan. Our trained professionals are ready to manage any situation swiftly and effectively, minimizing risks and ensuring safety.

Commitment to Sustainability: At RES, we are dedicated to environmentally responsible practices. We employ sustainable methods in our transportation processes, including optimizing routes and minimizing emissions, to support environmental conservation efforts.

How RES Ensures Safe and Compliant Hazardous Waste Transportation

Thorough Assessment and Planning: Before transportation, RES conducts a detailed assessment of the hazardous waste to determine the appropriate containment and handling measures. This planning phase ensures that all safety and compliance aspects are addressed.

Trained and Certified Personnel: Our team undergoes rigorous training and certification in hazardous waste management. We stay current with industry best practices and regulatory updates to provide the highest level of service and safety.

Detailed Documentation and Reporting: Accurate documentation is crucial for hazardous waste transportation. RES maintains comprehensive records of all transportation activities, including waste manifest forms and tracking reports, to ensure transparency and regulatory compliance.

Customer-Centric Support: RES prioritizes exceptional customer service. We offer regular updates on the status of your waste transportation and are available to answer any questions or concerns you may have throughout the process.

Contact RES for Expert Hazardous Waste Transportation Services

For reliable and professional hazardous environmental waste transportation services in New York, NY, RES is your trusted partner. Our commitment to safety, regulatory compliance, and environmental stewardship ensures that your hazardous waste is managed efficiently and responsibly.

Reach out to RES today to learn more about our hazardous waste transportation services and how we can assist with your waste management needs. With RES, you can have peace of mind knowing that your hazardous materials are handled by experts who prioritize safety and compliance. Let us take care of your hazardous waste transportation needs so you can focus on what matters most to your business.

#Hazardous environmental waste transportation services Pennsylvania PA#Hazardous environmental waste transportation services New York NY

0 notes

Text

The global demand for gene editing in oil and gas was valued at USD 50.4 million in 2022 and is expected to reach USD 167.52 million in 2030, growing at a CAGR of 16.20% between 2023 and 2030.The oil and gas industry, a cornerstone of global energy supply, has continuously evolved through technological innovations. Recently, a groundbreaking development has emerged that promises to reshape the landscape: gene editing. Although primarily associated with biotechnology and healthcare, gene editing is finding novel applications in the oil and gas sector, offering unprecedented opportunities for efficiency, environmental sustainability, and cost reduction.

Browse the full report at https://www.credenceresearch.com/report/gene-editing-in-oil-and-gas-market

The Advent of Gene Editing in Oil and Gas

Gene editing, particularly through CRISPR-Cas9 technology, has revolutionized the way genetic information is manipulated. This technology allows precise alterations to the DNA of organisms, enabling the enhancement of desirable traits and suppression of undesirable ones. In the context of oil and gas, gene editing is being harnessed to optimize microbial processes critical to various stages of oil extraction, refining, and pollution mitigation.

Microbial Enhanced Oil Recovery (MEOR)

One of the most promising applications of gene editing in the oil and gas industry is Microbial Enhanced Oil Recovery (MEOR). MEOR involves the use of microorganisms to increase the amount of oil that can be extracted from reservoirs. Traditionally, this process relied on naturally occurring microbes with limited efficiency. However, with gene editing, scientists can enhance the metabolic pathways of these microbes, making them more effective in breaking down oil and reducing viscosity.

By modifying the genetic makeup of these microorganisms, researchers can tailor them to thrive in extreme conditions typical of oil reservoirs. Enhanced microbes can produce biosurfactants, biopolymers, and gases such as CO2 and methane, which aid in mobilizing trapped oil. This not only boosts oil recovery rates but also extends the lifespan of existing reservoirs, reducing the need for new drilling operations and thereby mitigating environmental impact.

Bioremediation of Oil Spills

Oil spills pose a significant threat to marine and terrestrial ecosystems. Traditional cleanup methods are often labor-intensive, costly, and inefficient. Gene editing offers a novel solution through the development of genetically modified microbes that can rapidly degrade hydrocarbons. These engineered organisms can be deployed to contaminated sites, where they break down oil into less harmful substances at an accelerated rate.

For instance, researchers have successfully edited the genes of certain bacteria to enhance their ability to metabolize complex hydrocarbons. These modified bacteria can be introduced into oil spill sites, where they effectively degrade the oil, significantly reducing the environmental damage and cleanup costs. This bioremediation approach not only offers a more effective solution but also minimizes the ecological footprint of oil spill response efforts.

Biofuel Production

The shift towards sustainable energy sources has led to increased interest in biofuels. Gene editing is playing a crucial role in optimizing the production of biofuels from biomass. By altering the genetic pathways of algae and other microorganisms, scientists can enhance their ability to produce lipids and other biofuel precursors. These genetically modified organisms (GMOs) can be cultivated in bioreactors, producing biofuels that can be blended with traditional fuels or used independently.

In the oil and gas industry, the integration of biofuels offers a pathway to reduce carbon emissions and dependency on fossil fuels. Genetically engineered algae, for example, can be optimized for higher lipid content and faster growth rates, making biofuel production more economically viable. This not only contributes to a more sustainable energy mix but also aligns with global efforts to combat climate change.

Challenges and Ethical Considerations

While the potential benefits of gene editing in the oil and gas industry are substantial, several challenges and ethical considerations must be addressed. The release of genetically modified organisms into the environment raises concerns about unintended ecological impacts and the potential for gene transfer to non-target species. Rigorous testing and regulatory frameworks are essential to ensure the safe and responsible application of gene editing technologies.

Moreover, public perception and acceptance of GMOs remain contentious issues. Transparent communication and engagement with stakeholders, including environmental groups and local communities, are crucial to build trust and acceptance of these innovative solutions.

Key Players

ExxonMobil

Chevron

Shell

BP p.l.c.

Equinor

Others

Segmentation

By Biomedical Research And Therapeutics

Gene Therapy

Cancer Treatment

By Agriculture And Crop Improvement

Crop Modification

Livestock Improvement

By Pharmaceutical Development

Drug Discovery

Vaccine Development

By Functional Genomics

Understanding Gene Function

Genome-Wide Screening

By Bioproduction And Industrial Processes

Biofuel Production

Enzyme Engineering

By Disease Modeling And Drug Testing

Creating Disease Models

Drug Screening

By Synthetic Biology

Creating Synthetic Organisms

Biofabrication

By Environmental Conservation

Conservation Genetics

Biocontrol

By Neuroscience

Functional Neurogenomics

Neurological Disorder Research

By Infectious Disease Control

Vector Control

Antiviral Strategies

By Region

North America

The U.S.

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/gene-editing-in-oil-and-gas-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

How to Choose Reliable Ammonia Suppliers in India for Your Business

Choosing a reliable ammonia supplier is crucial for businesses that depend on this essential chemical for their operations. Whether you are in agriculture, manufacturing, or other industries, the quality and consistency of ammonia supply can significantly impact your business’s performance. Here’s a comprehensive guide to help you select trustworthy suppliers of ammonia in India.

1. Understand Your Ammonia Needs

Before you begin your search for suppliers of ammonia in India, it’s essential to assess your specific requirements. Consider the following factors:

Type and Grade of Ammonia: Determine whether you need liquid ammonia, anhydrous ammonia, or ammonia solution. Different industries and applications require different grades and types of ammonia.

Quantity Requirements: Estimate your monthly or annual ammonia needs. This will help you choose a supplier who can meet your volume demands consistently.

Delivery Schedule: Consider your delivery requirements, including frequency and timing. Reliable suppliers should be able to accommodate your schedule.

2. Research Potential Suppliers

Once you have a clear understanding of your ammonia needs, start researching potential suppliers. Look for suppliers of ammonia in India who have a proven track record of reliability and quality. Here are some tips to help you with your research:

Industry Reputation: Check the reputation of the supplier in the industry. Look for reviews, testimonials, and case studies from other businesses that have worked with them.

Certifications and Compliance: Ensure that the supplier adheres to industry standards and holds necessary certifications. Compliance with safety and environmental regulations is crucial for ensuring the quality and safety of the ammonia they supply.

Experience and Expertise: Consider the supplier’s experience in the industry. Established suppliers with years of experience are more likely to offer reliable and consistent services.

3. Evaluate Quality and Safety

Quality and safety are paramount when choosing suppliers of ammonia in India. Here’s how you can evaluate these aspects:

Product Quality: Ensure that the ammonia supplied meets industry standards and specifications. Ask for product certificates and test reports to verify the quality.

Safety Measures: Ammonia is a hazardous chemical, so it’s essential to choose suppliers who prioritize safety. Check their safety protocols, including handling, storage, and transportation procedures.

Emergency Response: A reliable supplier should have a robust emergency response plan in case of accidental spills or leaks. Ensure that they provide necessary safety data sheets and training for handling ammonia.

4. Assess Customer Service and Support

Good customer service and support are vital for a smooth supply chain. Consider the following aspects when evaluating potential ammonia suppliers:

Communication: Choose suppliers who are responsive and easy to communicate with. They should be able to address your queries and concerns promptly.

Technical Support: Suppliers should offer technical support to help you with any issues related to ammonia usage or handling.

Flexibility and Adaptability: The supplier should be able to accommodate changes in your requirements and provide solutions to any challenges that arise.

5. Compare Pricing and Payment Terms

Cost is an important factor, but it should not be the only criterion for choosing suppliers of ammonia in India. Compare the pricing of different suppliers and consider the following:

Cost Structure: Understand the cost structure, including the price of ammonia, delivery charges, and any additional fees.

Payment Terms: Review the payment terms and conditions. Choose suppliers who offer flexible payment options and transparent billing practices.

Value for Money: Evaluate the overall value provided by the supplier, including product quality, service, and support, in addition to the price.

6. Check for Supply Chain Reliability

A reliable supply chain is essential for ensuring a consistent supply of ammonia. Consider the following factors:

Supply Chain Network: Evaluate the supplier’s supply chain network and logistics capabilities. Ensure that they have a robust system in place for sourcing, storage, and distribution.

Contingency Plans: Check if the supplier has contingency plans in case of supply disruptions. They should be able to manage unforeseen issues and ensure continuity of supply.

Track Record: Look into the supplier’s track record for on-time delivery and reliability. Past performance can be a good indicator of their ability to meet your needs.

7. Request References and Visit Facilities

To further validate the reliability of potential suppliers, request references from other businesses that have worked with them. Additionally, consider visiting the supplier’s facilities to get a firsthand look at their operations. This will give you insights into their quality control processes and overall business practices.

8. Negotiate and Finalize the Agreement

Once you have shortlisted potential suppliers of ammonia in India, negotiate the terms of the agreement. Ensure that the contract includes:

Product Specifications: Clearly define the type, grade, and quantity of ammonia to be supplied.

Delivery Terms: Specify delivery schedules, locations, and any associated costs.

Quality Assurance: Include clauses related to product quality, safety standards, and compliance.

Payment Terms: Outline payment terms, including pricing, payment schedules, and any discounts or incentives.

9. Monitor Performance and Provide Feedback

After finalizing the agreement, it’s important to continuously monitor the supplier’s performance. Provide feedback on their service and address any issues promptly. Building a strong relationship with your supplier can lead to better service and reliability over time.

Conclusion

Choosing reliable suppliers of ammonia in India is crucial for maintaining the efficiency and safety of your operations. By understanding your needs, researching potential suppliers, evaluating quality and safety, and considering customer service, pricing, and supply chain reliability, you can make an informed decision. Always prioritize suppliers who demonstrate a commitment to quality, safety, and reliability. A well-chosen supplier will contribute to the smooth functioning of your business and help you achieve your operational goals effectively.

0 notes

Text

Smart Tank Level Monitoring Using IoT

In the age of digital transformation, the Internet of Things (IoT) is revolutionizing how we manage and monitor various systems. One critical application of IoT is tank level monitoring, which is essential for efficient resource management across numerous industries. From water storage to fuel management, accurate monitoring of tank levels can prevent wastage, reduce costs, and improve safety.

Understanding IoT Tank Level Monitoring

What is IoT Tank Level Monitoring?

IoT tank level monitoring involves the use of connected sensors and technology to track the amount of liquid or material within a tank. This system provides real-time data on tank levels, enabling better decision-making and resource management. By integrating IoT technology, users can receive instant updates and insights, enhancing operational efficiency and responsiveness.

Components of an IoT Tank Level Monitoring System

Sensors: These are the core components of the system, responsible for measuring the tank’s content. Common types include ultrasonic sensors, which use sound waves to gauge levels, and radar sensors, which utilize electromagnetic waves for precise measurements.

Connectivity: The data collected by sensors is transmitted to a central system via various connectivity options like Wi-Fi, cellular networks, or satellite. This ensures that data is always accessible, regardless of location.

Data Processing: Once transmitted, the data is processed and analyzed. This can be done locally on-site or through cloud-based platforms, providing users with comprehensive insights and actionable information through dashboards and reports.

Benefits of IoT Tank Level Monitoring

Enhanced Efficiency

IoT tank level monitoring enables real-time data access, allowing for more efficient resource management. By continuously tracking tank levels, businesses can optimize their operations, ensuring that resources are used effectively and that supplies are replenished on time.

Cost Savings

One of the most significant benefits of IoT tank level monitoring is cost savings. By preventing overflows, leaks, and other issues, businesses can reduce wastage and avoid costly emergency responses. Additionally, optimizing tank usage helps in managing inventory more effectively, lowering operational costs.

Improved Safety

Monitoring tank levels in real-time helps in identifying potential problems before they escalate. For example, early detection of low levels or leaks can prevent accidents and hazardous situations, thereby enhancing overall safety for both personnel and the environment.

Environmental Impact

Efficient tank management also contributes to environmental sustainability. By minimizing wastage and preventing spills, businesses can reduce their environmental footprint and comply with regulations aimed at protecting natural resources.

Key Features to Look for in IoT Tank Level Monitoring Systems

Accuracy and Reliability

The primary function of a tank level monitoring system is to provide accurate measurements. Therefore, it is crucial to choose systems with high precision and reliability. Look for sensors that are well-calibrated and capable of delivering consistent performance.

Real-Time Monitoring

Immediate updates on tank levels are essential for effective management. Systems that offer real-time data allow for prompt responses to any changes or issues, ensuring that operations remain smooth and efficient.

Ease of Integration

The IoT monitoring system should seamlessly integrate with existing infrastructure. Compatibility with other systems and ease of installation are key factors to consider, as they impact the overall efficiency and cost of implementation.

User-Friendly Interface

A clear and accessible dashboard is vital for interpreting the data effectively. The interface should be intuitive, allowing users to easily navigate through the information and make informed decisions based on the data presented.

Applications of IoT Tank Level Monitoring

Water Management

In residential and municipal settings, IoT tank level monitoring helps in managing water resources efficiently. By keeping track of water levels in storage tanks, authorities can ensure a consistent supply, detect leaks, and prevent shortages.

Agriculture

In agriculture, IoT tank level monitoring is used to manage irrigation systems. By integrating with smart irrigation systems, farmers can monitor water levels in irrigation tanks to ensure that crops receive the optimal amount of water. This leads to better yields and resource conservation, as water is used more efficiently and precisely based on the crops' needs.

Future Trends in IoT Tank Level Monitoring

Advancements in Sensor Technology

The field of sensor technology is constantly evolving. Future advancements may include more accurate sensors with extended ranges and improved reliability. These developments will enhance the effectiveness of tank level monitoring systems and expand their applications.

Integration with Other IoT Systems

As IoT technology continues to advance, integration with other smart systems will become more prevalent. For example, combining tank level monitoring with predictive maintenance and smart grid systems can further optimize resource management and operational efficiency.

Conclusion

IoT tank level monitoring offers significant benefits, including enhanced efficiency, cost savings, improved safety, and reduced environmental impact. By leveraging real-time data and advanced technology, businesses and municipalities can manage their resources more effectively and address potential issues before they become critical. As IoT technology continues to evolve, the capabilities and applications of tank level monitoring systems are likely to expand, providing even greater opportunities for optimization and innovation.

0 notes

Text

Occupational Health and Safety Course

Occupational health and safety (OHS) courses play a crucial role in equipping individuals and organizations with the knowledge and skills necessary to maintain safe working conditions and prevent workplace injuries and illnesses.

Understanding Occupational Health and Safety Courses

Occupational health and safety courses cover a wide range of topics, tailored to different industries and job roles. These courses typically include:

1. Risk Assessment and Management: Teaching individuals how to identify potential hazards in the workplace, assess risks, and implement effective risk management strategies.

2. Legal Requirements: Educating participants about relevant laws and regulations pertaining to workplace safety, ensuring compliance and understanding of responsibilities.

3. Health and Wellness: Addressing physical and mental health issues that may arise in the workplace, promoting overall well-being among employees.

4. Emergency Preparedness: Providing training on how to respond to emergencies such as fires, chemical spills, or medical incidents, ensuring swift and effective action.

Benefits of OHS Courses

1. Reduced Workplace Accidents:

By educating employees about potential hazards and safe practices, OHS courses help minimize accidents and injuries. This leads to fewer lost workdays, lower insurance costs, and improved productivity.

2. Improved Compliance:

Organizations that invest in OHS training demonstrate their commitment to safety compliance, which can mitigate legal risks and regulatory penalties.

3. Enhanced Employee Morale:

When employees feel safe at work, morale improves. OHS courses empower individuals to take responsibility for their safety and that of their colleagues, fostering a positive work environment.

4. Cost Savings:

Preventing workplace accidents not only saves lives but also reduces financial burdens associated with worker compensation claims, medical expenses, and equipment damage.

5. Enhanced Organizational Reputation:

Investing in OHS training demonstrates to clients, partners, and the public that an organization prioritizes safety. This enhances reputation and can be a competitive advantage in winning contracts and attracting talent.

6. Reduced Turnover and Absenteeism:

Safe workplaces contribute to employee satisfaction and retention. OHS courses educate employees on preventing injuries and illnesses, leading to lower absenteeism and turnover rates.

7. Crisis Management Skills:

OHS courses often include training on crisis management and response strategies. This prepares employees to handle unexpected events effectively, minimizing disruptions and ensuring swift recovery.

8. Cultural Transformation:

Comprehensive OHS training fosters a culture where safety is ingrained in everyday practices. This cultural shift encourages proactive hazard reporting, peer-to-peer safety reminders, and continuous improvement in safety standards.

Implementing OHS Training Programs

Effective implementation of OHS courses involves several key steps:

- Assessment: Conducting a thorough assessment of workplace hazards and risks to tailor training programs accordingly.

- Integration: Incorporating OHS training into onboarding processes and regular professional development sessions and Environment Management

- Evaluation: Continuously evaluating the effectiveness of training programs and making adjustments as necessary to address emerging risks or compliance updates.

Certainly! Let's expand further on the importance and benefits of occupational health and safety (OHS) courses in today's workplace, as well as delve deeper into the implementation and impact of these courses.

Impactful Implementation Strategies

1. Tailored Training Modules:

Designing OHS courses that are specific to the industry, job roles, and even individual workplaces ensures relevance and applicability. Customization can address unique risks and challenges faced by different sectors.

2. Technology Integration:

Utilizing e-learning platforms, virtual reality (VR) simulations, and mobile apps enhances accessibility and engagement in OHS training. These technologies provide interactive learning experiences and practical simulations of hazardous scenarios.

3. Leadership Commitment:

Strong leadership support and participation in OHS training programs reinforce the importance of safety throughout the organization. Executives and managers setting an example by attending courses themselves can inspire broader employee buy-in.

4. Continuous Improvement:

Nebosh courses should evolve alongside changing workplace conditions, technological advancements, and regulatory updates. Regular reviews and updates to training content ensure its effectiveness and alignment with current best practices.

Long-Term Benefits and Sustainability

- Sustainable Development Goals (SDGs):

Investing in OHS aligns with global sustainability goals, particularly those related to health, well-being, and safe working environments (e.g., UN SDG 3 and 8).

- Global Standards and Certifications:

Achieving internationally recognized OHS certifications (e.g., ISO 45001) through comprehensive training programs demonstrates a commitment to high standards of workplace safety on a global scale.

Conclusion

In conclusion, the significance of occupational health and safety courses in modern workplaces cannot be overstated. Beyond compliance and cost savings, these courses contribute to organizational resilience, employee satisfaction, and sustainable business practices. By embracing OHS training and Nebosh Cources as a strategic investment, organizations not only protect their workforce but also position themselves as leaders in safety and well-being.

Continued innovation in OHS education and a steadfast commitment to ongoing improvement will ensure that workplaces remain safe, productive, and resilient in the face of evolving challenges and opportunities.

#WorkplaceSafety#OHSTraining#HealthAndSafety#OccupationalHealth#SafetyTraining#NEBOSH IGC#NEBOSH courses#ISO Lead Auditor Certification#Lead Auditor Training

0 notes

Text

Lab Pack Services

In today's industrial and commercial landscapes, the proper handling and disposal of chemicals have become increasingly crucial. Businesses across various sectors, from laboratories to manufacturing plants, often deal with a wide array of chemicals that require careful management throughout their lifecycle. This is where professional lab pack services play a vital role. Lab pack services involve the meticulous packaging, transportation, and disposal of chemicals, ensuring compliance with environmental regulations and maintaining safety standards. This article explores why hiring a professional for lab pack services is essential, particularly focusing on the complexities involved in handling different chemicals safely.

The Importance of Professional Lab Pack Services

Chemicals used in industries and laboratories range from solvents and acids to reactive substances and hazardous materials. Proper management of these chemicals is not only a legal requirement but also crucial for protecting human health and the environment. Professional lab pack services offer specialized expertise in managing chemical inventories, identifying hazardous materials, and executing safe disposal procedures.

Expertise in Chemical Identification and Classification

One of the primary reasons to enlist professional lab pack services is their expertise in chemical identification and classification. Different chemicals react differently with each other and require specific handling protocols to prevent accidents or environmental contamination. Professionals are trained to classify chemicals according to regulatory standards (e.g., EPA, OSHA) and can accurately assess risks associated with each substance.

Compliance with Environmental Regulations

Environmental regulations governing the disposal of hazardous waste are stringent and vary by locality. Professional lab pack service providers are well-versed in these regulations and ensure that all disposal activities comply with federal, state, and local laws. They handle necessary permits, paperwork, and reporting, minimizing the risk of fines or legal liabilities for businesses.

Safety Protocols and Risk Mitigation

Handling hazardous chemicals poses inherent risks, including toxicity, flammability, and reactivity. Professional lab pack technicians are trained in safety protocols designed to mitigate these risks effectively. They utilize specialized equipment and personal protective gear to safeguard themselves and others during chemical handling, minimizing the potential for accidents or injuries.

Customized Packaging and Transportation Solutions

Proper packaging and transportation of chemicals are critical to preventing spills, leaks, or exposure during transit. Professional lab pack services offer customized packaging solutions tailored to the specific properties of each chemical. They use certified containers, absorbents, and secondary containment measures to ensure compliance with transportation regulations and to safeguard against accidental releases.

Emergency Response Preparedness

Despite meticulous planning, emergencies can occur during chemical handling or transportation. Professional lab pack service providers are trained in emergency response protocols and have the resources to quickly address spills, leaks, or other incidents. Their prompt and effective response helps mitigate potential environmental damage and ensures the safety of personnel and the surrounding community.

Specialized Equipment and Facilities

Handling hazardous chemicals requires specialized equipment and facilities that meet safety and regulatory standards. Professional lab pack service providers invest in state-of-the-art equipment, such as chemical resistant gloves, spill containment kits, and ventilation systems, to facilitate safe handling and disposal. They also operate licensed facilities equipped for proper storage and treatment of hazardous waste.

Documentation and Record-Keeping

Maintaining accurate documentation throughout the chemical disposal process is essential for regulatory compliance and liability protection. Professional lab pack services meticulously record details such as chemical inventories, disposal methods, and waste manifests. This documentation not only ensures transparency but also facilitates audits and regulatory inspections without delays or complications.

Cost-Effectiveness and Efficiency

While hiring professional lab pack services involves an initial investment, it often proves cost-effective in the long run. Professionals streamline the disposal process, minimize downtime associated with regulatory compliance tasks, and reduce the risk of costly fines or legal penalties for non-compliance. Their expertise also maximizes resource utilization and minimizes the environmental impact of chemical disposal.

Conclusion

In conclusion, professional lab pack services play a crucial role in the safe and compliant management of hazardous chemicals across industries. By leveraging specialized expertise, safety protocols, and regulatory knowledge, these services ensure that businesses meet environmental obligations while safeguarding human health and safety. From chemical identification and classification to customized packaging and emergency response preparedness, professionals mitigate risks and provide peace of mind. Businesses that prioritize safety, compliance, and environmental stewardship benefit significantly from partnering with experienced lab pack service providers.

1 note

·

View note

Text

Building a Strong Safety Management Plan

Creating a strong safety management plan is crucial for any organization that wants to ensure a safe and productive workplace. A well-structured plan not only protects employees but also enhances operational efficiency and complies with regulations. Let’s explore how to build a robust safety management plan with a focus on Process Safety Management (PSM) and the support of experts like The Safety Master.

Understanding Process Safety Management (PSM)

Process Safety Management (PSM) is a systematic approach to managing safety in industries where processes involve hazardous chemicals or operations. The goal of PSM is to prevent accidents and incidents that could harm people, property, or the environment. A solid safety management plan incorporates the principles of PSM to create a safer working environment.

Key Elements of a Strong Safety Management Plan

Leadership and Commitment Leadership is the cornerstone of any safety management plan. Management must demonstrate a strong commitment to safety by setting clear goals, providing resources, and leading by example. When leadership prioritizes safety, it creates a culture where everyone understands the importance of adhering to safety protocols.

Hazard Identification and Risk Assessment Identifying potential hazards and assessing risks is a fundamental part of PSM. This involves evaluating processes, equipment, and chemicals used in your operations. Regular inspections and risk assessments help to uncover potential dangers before they lead to incidents. Using tools like safety audits and hazard analysis can guide these evaluations effectively.

Standard Operating Procedures (SOPs) Clear and concise Standard Operating Procedures (SOPs) are essential for ensuring consistent safety practices. SOPs should detail how tasks are to be performed safely, including steps for handling emergencies. Regularly updating SOPs and ensuring that all employees are trained on them can help maintain safety standards.

Training and Competence Proper training ensures that employees understand safety procedures and can recognize hazards. Training should be ongoing and include both initial training for new hires and refresher courses for current employees. Competency assessments can verify that employees have the necessary skills and knowledge to perform their jobs safely.

Emergency Preparedness Preparing for emergencies involves having clear procedures in place for dealing with accidents, spills, or other incidents. This includes having emergency response plans, conducting drills, and ensuring that all employees know their roles in an emergency. A well-prepared workforce can respond quickly and effectively to minimize the impact of emergencies.

Communication Effective communication is key to a successful safety management plan. Regular meetings, safety briefings, and feedback mechanisms help ensure that safety information is shared and understood. Encourage open communication where employees feel comfortable reporting hazards or safety concerns without fear of retaliation.

Monitoring and Review Continuous monitoring and review are essential to maintain and improve safety standards. Regular inspections, audits, and performance reviews help identify areas for improvement. Tracking safety metrics, such as incident rates and near-misses, can provide valuable insights into the effectiveness of your safety management plan. Major Point: Integrating PSM into Your Safety Management Plan

Integrating Process Safety Management into your safety management plan is crucial for managing complex processes safely. PSM focuses on preventing catastrophic accidents related to hazardous chemicals, and its principles should be embedded in every aspect of your safety plan. Key components of PSM include:

Process Hazard Analysis (PHA): Identifying and evaluating potential hazards associated with processes.

Operating Procedures:

Documenting safe procedures for operating and maintaining processes.

Training and Certification: Ensuring that employees are trained and competent in process safety.

Mechanical Integrity:

Maintaining and inspecting equipment to prevent failures.

Management of Change (MOC):

Managing changes to processes or procedures to ensure safety is maintained.

By incorporating PSM principles, you create a comprehensive safety management plan that addresses not only general safety practices but also the specific risks associated with your processes.

In conclusion

A strong safety management plan is essential for protecting your organization and its employees. By focusing on key elements like leadership, hazard identification, SOPs, training, emergency preparedness, and communication, and integrating PSM principles, you can create a safer and more efficient workplace. The Safety Master is here to support you every step of the way, ensuring your safety management plan is robust and effective.

For more information on how The Safety Master can assist with your safety management needs, visit our website or contact us today. Together, we can build a safer future for your organization.

0 notes

Text

What Services Does House of Expertise Provide in the Field of Safety Consultancy?

In today's fast-paced and highly regulated environment, ensuring the safety of your workplace or facility is paramount. The role of safety consultants is crucial in helping businesses comply with regulations, protect their employees, and maintain operational efficiency. House of Expertise is a leading provider of safety consultancy services in the UAE, with a strong presence in both Dubai and Abu Dhabi.

Understanding the Role of Safety Consultants

Safety consultants play a vital role in identifying, evaluating, and mitigating risks in various industries. They ensure that businesses adhere to local and international safety standards, helping to prevent accidents and minimize the impact of potential hazards. House of Expertise stands out as a key player in this field, offering a wide array of services tailored to meet the unique needs of their clients.

Safety Audits and Risk Assessments

One of the primary services provided by House of Expertise is conducting safety audits and risk assessments. These are essential for identifying potential hazards in the workplace, evaluating the level of risk, and recommending appropriate control measures. Whether it's a manufacturing plant, a construction site, or an office building, the safety consultants in Dubai and Abu Dhabi from House of Expertise meticulously examine every aspect of the facility to ensure compliance with safety regulations.

The process begins with a thorough inspection of the premises, followed by interviews with employees and a review of existing safety protocols. The consultants then prepare a detailed report, outlining the identified risks and providing actionable recommendations to mitigate them. This service is invaluable for businesses aiming to create a safe working environment and avoid costly penalties for non-compliance.

Fire Safety Consultancy

Fire safety is a critical concern for any business, and House of Expertise excels in this area as well. As leading fire safety consultants UAE, they offer comprehensive fire safety services, including fire risk assessments, fire evacuation planning, and the design of fire protection systems. Their expertise ensures that businesses are well-prepared to handle fire emergencies, minimizing damage and safeguarding lives.

House of Expertise's fire safety consultants conduct a thorough analysis of the building's layout, materials, and existing fire protection systems. They then provide recommendations for improvements, such as installing fire alarms, sprinkler systems, and emergency lighting. Additionally, they assist in the development of fire evacuation plans, ensuring that all employees are aware of the proper procedures in case of a fire.

Safety Training and Education

In addition to risk assessments and fire safety consultancy, House of Expertise offers a wide range of safety training programs. These programs are designed to equip employees with the knowledge and skills they need to maintain a safe working environment. From basic safety awareness courses to specialized training in fire safety, chemical handling, and first aid, their offerings cater to various industries and job roles.