#Engineering Plastic Market

Text

Engineering Plastic Market Trends, Key Players, DROT, Analysis & Forecast Till 2030

Engineering plastics are a group of plastic materials such as polystyrene, PVC, polypropylene and polyethylene, and others. These materials have superior properties such as higher impact strength, high abrasion, wear, and fatigue resistance. It has better mechanical and thermal properties. Engineering Plastics are expensive and are manufactured for special purpose applications only. These are usually thermoplastic materials. Hence these materials can be easily processed with conventional plastic processing machinery.

According to a recent study report published by the Market Research Future, the global market for engineering plastic is booming and expected to gain prominence over the forecast period. The Global Engineering Plastic Market is projected to be worth USD 115.10 Billion by 2030, registering a CAGR of 7.2% during the forecast period (2021 - 2030).

High growth in the automotive industry is the major factor driving the growth of the market. It has slightly similar properties to metals and is lightweight. Hence, these materials have been largely substituting some metal components in auto as well as industrial machinery and help in weight reduction. Additionally, the high demand for electronics and electrical appliances among the consumers also fuelling the growth of the market. However, higher costs, fluctuating prices of crude oil, and regulatory challenges regarding CO2 emissions are some factors that may hamper the growth of the market.

Market Segmentation:

The Global Engineering Plastic Market is segmented in MRFR’s report on the basis of Product, Application, and Region.

By Product, the market is segmented into polyamide, acrylonitrile butadiene styrene (ABS), thermoplastics, polyesters, polycarbonates, and others. Among these, the ABS segment accounts for the largest share on the basis of product due to the high demand for it. ABS is in high demand as it has properties such as chemical resistance, high-temperature resistance, mechanical potency, and several others.

Applications of Engineering Plastics are found in construction, electrical & electronics, automotive, consumer goods, and others. The automotive segment is the largest consumer of Engineering Plastic as they have extensive applications in the automotive industry. Used for the production of lighting components, connectors, and other automotive parts, Engineering Plastics is expected to witness increased demand from this segment due to the increasing demand for personal transportation vehicles.

Regional Segmentation divides the global market into North America, Europe, Asia Pacific, and the Rest of the World.

Global Key Players and Competition Analysis

The key players in the engineering plastic market are BASF SE (Germany), Covestro (Germany), Solvay S. A. (Belgium), Celanese Corporation (U.S.), E. I. du Pont de Nemours and Company (U.S.), LG Chem Ltd. (South Korea), Saudi Basic Industries Corporation (Saudi Arabia), Evonik Industries AG (Germany), Lanxess AG (Germany), and Mitsubishi

Browse the market data and information spread across 111 pages with 27 data tables and 15 figures in the report “Engineering Plastic Market Research Report - Global Forecast to 2030” in-depth alongside a table of content (TOC) at: https://www.marketresearchfuture.com/reports/engineering-plastic-market-2161

Contact us:

Market Research Future (part of Wantstats Research and Media Private Limited),

99 Hudson Street, 5Th Floor,

New York, New York 10013

United States of America

+1 628 258 0071

Email: [email protected]

2 notes

·

View notes

Text

Analyzing the Engineered Plastics Market: Trends and Growth Potential

Engineered plastics, also known as engineering plastics market, are a group of plastic materials that have enhanced mechanical and thermal properties, making them suitable for more demanding applications than standard plastics. These materials are used in a wide range of industries, including automotive, aerospace, electronics, and healthcare. This article explores the current trends, driving forces, challenges, and future prospects of the engineered plastics market.

Understanding Engineered Plastics

Engineered plastics are polymers that exhibit superior strength, heat resistance, and durability compared to commodity plastics. Common types of engineered plastics include polycarbonate (PC), acrylonitrile butadiene styrene (ABS), polyamide (PA or nylon), polyoxymethylene (POM or acetal), and polyphenylene oxide (PPO). These materials are used in applications that require high performance and reliability.

Key Market Drivers

Growth in End-Use Industries: The expansion of industries such as automotive, aerospace, electronics, and healthcare is a major driver for the engineered plastics market. These industries demand materials that can withstand harsh environments, offer high precision, and contribute to lightweighting and energy efficiency.

Technological Advancements: Innovations in polymer science and manufacturing processes are enhancing the properties of engineered plastics. Advances such as reinforced composites, biodegradable polymers, and 3D printing materials are broadening the application scope of engineered plastics.

Environmental Regulations and Sustainability: Stringent environmental regulations and the growing emphasis on sustainability are driving the demand for engineered plastics. These materials are often recyclable, contribute to energy savings through lightweighting, and can replace metal parts, reducing the overall environmental impact.

Market Segmentation

The engineered plastics market can be segmented based on type, application, and region.

By Type:

Polycarbonate (PC): Known for its high impact resistance and transparency, used in automotive parts, electronics, and medical devices.

Acrylonitrile Butadiene Styrene (ABS): Offers good toughness and rigidity, used in automotive components, consumer electronics, and toys.

Polyamide (PA or Nylon): Known for its strength and wear resistance, used in automotive parts, textiles, and industrial applications.

Polyoxymethylene (POM or Acetal): Provides high stiffness and dimensional stability, used in precision parts like gears and bearings.

Polyphenylene Oxide (PPO): Offers high thermal stability and electrical insulation, used in electrical and electronic components.

By Application:

Automotive: Engineered plastics are used for components like fuel systems, interior and exterior parts, and under-the-hood applications.

Aerospace: These materials are used in lightweight structural components, interior parts, and insulation.

Electronics: Used in housings, connectors, and circuit boards.

Healthcare: Employed in medical devices, surgical instruments, and diagnostic equipment.

Industrial: Used in machinery parts, gears, bearings, and conveyor systems.

By Region:

North America: Driven by advancements in technology and the presence of key end-use industries.

Europe: Emphasis on sustainability and high-performance materials.

Asia-Pacific: Rapid industrialization and growth in automotive and electronics industries.

Latin America and Middle East & Africa: Emerging markets with increasing demand for high-performance materials.

Challenges in the Market

Despite the positive growth outlook, the engineered plastics market faces several challenges:

High Costs: The production and raw material costs for engineered plastics are higher than for commodity plastics, which can limit their adoption in cost-sensitive applications.

Regulatory Compliance: Meeting stringent environmental and safety regulations requires continuous innovation and investment in research and development.

Market Competition: The market is highly competitive, with numerous players offering a wide range of products. Differentiating based on quality, performance, and sustainability is crucial for gaining a competitive edge.

Request for a sample of the report browse through- https://univdatos.com/get-a-free-sample-form-php/?product_id=23691

Future Prospects

The future of the engineered plastics market is promising, with several growth opportunities on the horizon:

Advancements in Composite Materials: The development of reinforced composites and hybrid materials will enhance the performance characteristics of engineered plastics, expanding their application range.

Growth in Emerging Markets: Emerging economies in Asia-Pacific, Latin America, and Africa present significant growth opportunities. Increasing industrialization and infrastructure development in these regions will drive the demand for engineered plastics.

Sustainability Initiatives: The push for sustainability will continue to drive innovations in biodegradable and recyclable engineered plastics. These materials will play a crucial role in reducing the environmental impact of various industries.

Conclusion

The engineered plastics market is set for robust growth, driven by the expansion of end-use industries, technological advancements, and sustainability trends. While challenges such as high costs and regulatory compliance persist, innovations in composite materials and the growth of emerging markets offer substantial opportunities. As industries evolve, engineered plastics will continue to play a vital role in delivering high-performance, durable, and sustainable solutions.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

Electric Vehicle Engineering Plastics Market Analysis, Trends, Report 2023-2030

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the Global Electric Vehicle Engineering Plastics Market size by value at USD 14.62 billion in 2023. During the forecast period between 2024 and 2030, BlueWeave expects the Global Electric Vehicle Engineering Plastics Market size to boom at a robust CAGR of 23.76% reaching a value of USD 68.21 billion by 2030. The Global Electric Vehicle Engineering Plastics Market is driven by various factors. Consumer demand for lighter BEVs (battery electric vehicles)/PHEV (plug in hybrid electric vehicles) and HEVs (hybrid electric vehicles), coupled with the need for enhanced plastic performance in challenging environments, is increasing the demand for plastics in the sector. Growing environmental concerns and strict emission regulations promoting electrification and weight reduction are also significant drivers for the market.

By volume, BlueWeave estimated the Global Electric Vehicle Engineering Plastics Market size at 3.2 million tons in 2023. During the forecast period between 2024 and 2030, BlueWeave expects the Global Electric Vehicle Engineering Plastics Market size to expand at a CAGR of 24.88% reaching the volume of 5.1 million tons by 2030. The greater use of anti-microbial polymers in EVs contributes to market growth. Major countries like United States, United Kingdom, India, Japan, China, Germany, and Canada show the most potential for industry expansion. Plastics offer advantages, such as customizability, formability, affordability, and performance, making them suitable for EV applications. They also contribute to weight reduction, part consolidation, and noise and vibration dampening, further driving their demand for EVs.

Opportunity – High focus on reducing carbon footprints through engineering plastics

The escalating global concern over carbon footprints drives the Global Electric Vehicle Engineering Plastics Market. Electric vehicles (EVs) are hailed as environmentally friendly alternatives, necessitating the adoption of lightweight engineering plastics to meet sustainability targets. By enhancing vehicle efficiency and curbing energy consumption, these materials contribute to reduced carbon emissions both in production and operation phases. The eco-conscious transition fosters a heightened demand for innovative engineering plastics, fueling the expansion of the Global Electric Vehicle Engineering Plastics Market.

Sample Request @ https://www.blueweaveconsulting.com/report/electric-vehicle-engineering-plastics-market/report-sample

Impact of Escalating Geopolitical Tensions on Global Electric Vehicle Engineering Plastics Market

Escalating geopolitical tensions can significantly impact the Global Electric Vehicle Engineering Plastics Market. Trade restrictions, tariffs, and disruptions in the supply chain can raise material costs and hinder market growth. For instance, during the US-China trade war, tariffs on imported goods led to increased costs for electric vehicle components. Similarly, political tensions between countries can disrupt the flow of critical raw materials used in engineering plastics production, affecting supply stability. Additionally, heightened geopolitical uncertainties may discourage investment in electric vehicle infrastructure and research, slowing down technological advancements. These factors collectively can create challenges for market players, affecting their production capabilities and profitability, and ultimately impeding the growth trajectory of the global electric vehicle engineering plastics market.

Global Electric Vehicle Engineering Plastics Market

Segmental Coverage

Global Electric Vehicle Engineering Plastics Market – By Plastic

Based on plastic, Global Electric Vehicle Engineering Plastics Market is divided into Acrylonitrile Butadiene Styrene (ABS), Polyamide (PA), Polycarbonate (PC), Polyvinyl Butyral, Polyurethane (PU), and Other (Polypropylene, Polyvinyl Chloride, Polymethylmethacrylate, High-Density Polyethylene, Low-Density Polyethylene, and Polybutylene Terephthalate) segments. The polyamide (PA) segment is the leading plastic in the Global Electric Vehicle Engineering Plastics Market. Polyamide, commonly known as nylon, is a versatile engineering plastic valued for its high strength, durability, and thermal resistance, making it ideal for various automotive applications. Its widespread usage in EV components, such as battery casings, connectors, and structural parts contributes significantly to its dominance in the market segment. With its favorable properties and extensive application scope, polyamide emerges as a prominent choice in the electric vehicle engineering plastics market, reflecting its pivotal role in advancing the automotive industry's transition towards sustainable mobility solutions.

Global Electric Vehicle Engineering Plastics Market – By Component

Based on component, Global Electric Vehicle Engineering Plastics Market is divided into Dashboard, Seat, Trim, Bumper, Body, Vehicle Type, Engine, Lighting, and Wiring segments. The body segment is the largest component in the Global Electric Vehicle Engineering Plastics Market. The segment encompasses a wide range of components, including the vehicle's structural framework, exterior panels, and other crucial elements that contribute to the overall design and functionality of the vehicle. As electric vehicles continue to gain popularity and manufacturers prioritize lightweight materials for improved efficiency, the demand for engineering plastics in body-related applications is expected to remain substantial, making it a significant portion of the market.

Competitive Landscape

Global Electric Vehicle Engineering Plastics Market is fiercely competitive. Major companies in the market include Covestro AG, Celanese Corporation, DuPont de Nemours, Inc., Evonik Industries AG, LANXESS Deutschland GmbH, Mitsubishi Engineering-Plastics Corporation, BASF SE, LyondellBasell Industries Holdings B.V., Sabic, Dow, Sumitomo Chemicals Co. Ltd, and Asahi Kasei. These companies use various strategies, including increasing investments in their R&D activities, mergers, and acquisitions, joint ventures, collaborations, licensing agreements, and new product and service releases to further strengthen their position in the Global Electric Vehicle Engineering Plastics Market.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

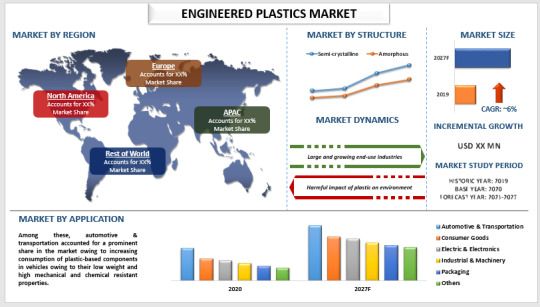

The global engineered plastics market is likely to showcase a growth of around 6% during the forecast period.

0 notes

Photo

(via Industry Experts, Inc Predicts Global Engineering Plastics Market to Reach 34 Million Tonnes by 2029)

0 notes

Text

Engineering Plastics Market Overview, Top Key Players, Outlook, and Research Report 2024-2032

According to IMARC Group latest report titled “Engineering Plastics Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032”, offers a comprehensive analysis of the industry, which comprises insights on engineering plastics market research report. The report also includes competitor and regional analysis, and contemporary advancements in the global market.

The global engineering plastics market size reached US$ 121.9 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 218.9 Billion by 2032, exhibiting a growth rate (CAGR) of 6.6% during 2024-2032.

Request a Free Sample Report: https://www.imarcgroup.com/engineering-plastics-market/requestsample

Engineering plastics, also known as high-performance plastics, are a class of polymers designed to exhibit superior mechanical, thermal, and chemical properties, making them ideal for a wide range of industrial applications. These plastics are characterized by their exceptional strength, toughness, and resistance to wear, impact, and high temperatures. Common types include polyamide (nylon), polycarbonate, polyacetal, and polyphenylene sulfide. Engineering plastics find widespread use in automotive components, electrical and electronic devices, aerospace applications, medical equipment, and various industrial machinery. Their versatility allows for the production of lightweight yet durable parts, contributing to advancements in technology, design flexibility, and improved efficiency across diverse sectors. The engineering plastics market continues to expand as industries seek materials that meet stringent performance requirements in demanding environments.

Market Trends:

The global market is majorly driven by the escalating demand for high-performance materials across diverse industries. Primarily, the automotive sector drives this market, seeking lightweight alternatives to traditional materials for improved fuel efficiency and reduced emissions, catalyzing the market. Engineering plastics, such as polyamide and polycarbonate, are instrumental in manufacturing components like engine parts, interior components, and structural elements. Furthermore, the electronics and electrical industry's relentless pursuit of miniaturization and enhanced performance fuels the demand for engineering plastics with excellent electrical insulation properties, thermal stability, and resistance to harsh environmental conditions. The expansion of consumer electronics, electric vehicles, and advancements in 5G technology further amplify this need. Additionally, the aerospace sector relies on engineering plastics for their exceptional strength-to-weight ratio, contributing to fuel efficiency and durability in aircraft components. Besides, the healthcare industry benefits from the biocompatibility and sterilizability of certain engineering plastics, promoting their use in medical devices and equipment. As sustainability gains prominence, engineering plastics play a pivotal role by offering recyclability and reduced environmental impact compared to traditional materials, strengthening the market. The market is also influenced by continuous innovations in polymer chemistry, allowing for the development of new formulations with improved properties.

View Full Report with TOC & List of Figure: https://www.imarcgroup.com/engineering-plastics-market

Competitive Landscape

3M Company

AdvanSix

Arkema S.A.

Avient Corporation

BASF SE

Celanese Corporation

Daicel Corporation

DuPont de Nemours Inc.

Eastman Chemical Company

Ineos Limited

LANXESS Aktiengesellschaft

Solvay S.A.

Key Market Segmentation:

Our report has categorized the market based on region, type, performance parameter and application.

Breakup by Type:

Polyamide

ABS

Thermoplastic Polyesters

Polycarbonates

Polyacetals

Fluoropolymers

Others

Breakup by Performance Parameter:

High Performance

Low Performance

Breakup by Application:

Packaging

Building and Construction

Electrical and Electronics

Automotive

Consumer Products

Others

Breakup by Region:

North America (United States, Canada)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Asia Pacific (China, Japan, India, Australia, Indonesia, South Korea, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1–631–791–1145 | United Kingdom: +44–753–713–2163

0 notes

Link

Asia Pacific is projected to lead the global Engineering Plastics market owing to advancement in the technology and presence of key industrial players...

#adroit market research#engineering plastics#engineering plastics 2020#engineering plastics size#engineering plastics share

0 notes

Text

#Engineering Plastic Market Segmentation#Engineering Plastic Market Growth#Engineering Plastic Market Analysis#Engineering Plastic Market Insight#Engineering Plastic Market Forecast#Engineering Plastic Market Index#Engineering Plastic Market Trends#Engineering Plastic Market Opportunities

0 notes

Text

Shaping Tomorrow: Insights into the Thermoplastic Polyester Engineering Resins Market

The thermoplastic polyester engineering resins market was USD 3,912.2 million in 2022, and it will touch USD 5,896.6 million, advancing at a 5.4% compound annual growth rate, by 2030.

The growth of the industry is attributed to the increasing utilization of these resins for various nonstructural applications as they can be utilized without filters and are usually tougher and more ductile than…

View On WordPress

#advanced polymers#aerospace applications#automotive industry#engineering plastics#engineering resin market#high-performance polymers#Industrial applications#market growth#material innovation#plastic components#plastic industry#plastic materials#polymer engineering#resin manufacturing#sustainable materials#thermoplastic polyester engineering resins#thermoplastic properties#thermoplastic technology

0 notes

Text

Global Engineering Plastics Market Is Estimated To Witness High Growth Owing To Growing Demand for Sustainable Materials

The global engineering plastics market is estimated to be valued at US$ 115.0 billion in 2021 and is expected to exhibit a CAGR of 6.6% over the forecast period 2022-2030, as highlighted in a new report published by Coherent Market Insights.

A) Market Overview:

Engineering plastics are a group of lightweight, high-performance materials that possess excellent mechanical, thermal, and chemical properties. These plastics are widely used in various industries such as automotive, electrical and electronics, consumer goods, and medical devices. They offer advantages such as high strength-to-weight ratio, resistance to impact and chemicals, and excellent dimensional stability. The need for engineering plastics arises from the demand for lightweight and durable materials to replace traditional metals and other plastics in various applications.

B) Market Key Trends:

One key trend driving the growth of the Engineering Plastics Market is the increasing demand for sustainable materials. With growing environmental concerns, there is a shift towards eco-friendly and recyclable materials in various industries. Engineering plastics such as bio-based polymers and recycled plastics offer a sustainable alternative to conventional materials. For instance, DuPont offers engineering plastics made from renewable resources, such as corn and sugarcane, which reduce carbon footprint and dependency on fossil fuels. This trend is expected to drive the demand for engineering plastics in the coming years.

D) Key Takeaways:

Paragraph 1: The global engineering plastics market is expected to witness high growth, exhibiting a CAGR of 6.6% over the forecast period, due to increasing demand for sustainable materials. For example, companies like BASF SE and Arkema Group are focusing on developing bio-based and recycled engineering plastics to meet the growing demand from environmentally conscious consumers.

Paragraph 2: Asia Pacific is expected to be the fastest-growing and dominating region in the engineering plastics market. The region is witnessing rapid industrialization and urbanization, leading to increased demand for engineering plastics in various sectors such as automotive and electrical and electronics.

Paragraph 3: Key players operating in the global engineering plastics market include Arkema Group, Asahi Kasei Corporation, BASF SE, Celanese Corporation, Covestro, DSM N.V., DuPont, Lanxess, LG Chem., Mitsubishi Engineering-Plastics Corporation, Saudi Basic Industries Corporation (SABIC), Solvay SA, Teijin, Toray, and Victrex Plc. These players are focusing on product innovations, strategic collaborations, and mergers and acquisitions to strengthen their market position.

In conclusion, the global engineering plastics market is poised for significant growth due to the increasing demand for sustainable materials. Key trends such as the development of bio-based and recycled plastics and advancements in manufacturing processes will drive market growth. The Asia Pacific region is expected to dominate the market, supported by rapid industrialization. Key players in the market continue to invest in research and development to offer innovative solutions to meet customer demands.

0 notes

Link

#adroit market research#engineering plastics#engineering plastics 2020#engineering plastics size#engineering plastics share

0 notes

Text

Organic Influencer Marketing Strategies for Small and Medium-sized Law Firms

Organic influencer marketing can be a powerful tool for law firms to enhance their online presence and reach a wider audience. Read more on our social media marketing services! https://www.medresponsive.com/blog/leveraging-organic-influencer-marketing-boost-small-and-medium-sized-law-firms/

#social medica marketing services#plastic surgery seo company#legal marketing services#organic search engine optimization services

0 notes

Text

The Business Research Company offers engineering plastics market research report 2023 with industry size, share, segments and market growth

#engineering plastics market#engineering plastics market size#engineering plastics market share#engineering plastics market report#engineering plastics market research#engineering plastics market data#engineering plastics market growth#engineering plastics market analysis#engineering plastics market segments#engineering plastics market forecast#engineering plastics market overview#engineering plastics market outlook#engineering plastics industry#engineering plastics industry report#engineering plastics industry research

0 notes