#Erw pipe

Text

What are the benefits of MS Pipe angle and MS Pipe beam?

MS angle, also known as mild steel angle, is a type of L-shaped cross-section that has several applications in the building industry. MS angles, also known as metal angles, are typically used to create right angles with two equal sides with the same width and length. Equal angles are those in which each side is the same length, and unequal angles are those in which one or more of the sides is longer than the other.

While Tube Trading Co. is just one of many MS angle manufacturers in India, it is widely recognized as a leading supplier of MS Pipe angle in Vadodara. MS angles are easy to weld, drill, as well as cut to a desirable size, making them versatile for a wide range of applications. They also have exceptional mechanical qualities.

Applications of MS Angle:

Angles made of mild steel (MS) are produced using two materials, either high-strength low alloy steel or hot-rolled carbon steel, which gives them a great deal of stability for use in a variety of structural applications as well as other general fabrication and maintenance activities. It finds widespread applicability across a variety of engineering fields, including commercial, industrial, and domestic settings.

MS Angle is highly recyclable, and as a result, it is regarded as an economically viable material for the production of a wide variety of tiny and big components in virtually every industry. MS angles have a very broad range of applications since they may be utilized in a variety of contexts to perform a variety of functions to meet your needs.

The construction of bridges, buildings, as well as other types of structures, farm equipment and machinery, precipitators, transmission lines and towers, transportation corners and frames, border frames, as well as a variety of other applications are just some of the common industries that make use of MS angle.

Tube Trading Co. is one of the most reliable sources for all of your requirements if you are looking for a trusted distributor of MS Pipe angle in Vadodara, and if so, you should consider using their services.

Advantages of MS Angles:

In light of what has been discussed thus far, it should come as no surprise that the malleability and high degree of versatility inherent to MS angles confer a plethora of advantages.

The pipe angles made from Mild Steel are also available in a variety of grades, dimensions, as well as surface treatments. It has a lower carbon percentage, which makes it simpler to deal with because it can be easily drilled, cut, and welded to suit a vast range of applications, especially construction because of its tenacity. Additionally, it has a lower carbon content, which makes it more environmentally friendly. MS angles have a superb surface finish, and they are available in mild to high steel, all of which contribute to their popularity as a material for the construction of dependable building frames and structures. It is also quite versatile in nature, and as a result, it is regarded as a "green material" for the fabrication of all construction-related components because of this quality.

Therefore, regardless of the kind of building work you could be doing, you should think about using MS angle because it has such a vast array of different mechanical qualities. When it comes to acquiring items made of mild steel, it is usually suggested to purchase from reputable manufacturers and suppliers.

MS Beams:

Mild steel, often known as MS, is a common and flexible building material that may be found in the construction of large structures like skyscrapers and residential buildings alike. The Mild Steel used in construction is designed to withstand significant weight. MS Pipe beam in Vadodara is available in a variety of dimensions, and its application is determined by the needs of the construction. In order to protect a structure from being damaged by severe weather, it is common practice to make use of MS beams while constructing roof structures and the frames of homes. The ability of MS pipes and beams to be bent and shaped is an important factor in the construction industry's reliance on the usefulness of these materials.

Features of Mild Steel pipes:

● High tensile strength

● Made of a low % of Carbon

● Easily welded

● Budget-friendly

● Long-life

Primary Applications of MS Pipe Beams:

● General engineering purposes

● Mechanical purposes

● Structural purposes

● Water treatment plants

● Chemical processing plants

Advantages of MS Beams:

● Recyclable:

In contrast to the majority of other materials used in construction, structural mild steel may be recycled. This contributes significantly to the reduction of waste produced by construction.

● Durable:

Mild Steel beams and other structural components made of Mild steel are known to have a higher tensile strength that can withstand heavy weight, which contributes to their remarkable durability. It is more resistant to fracture under pressure than a mass of stone or wood of the same volume would be under the same conditions. One of the benefits that make structural mild steel structures ideal for the building of big skyscrapers and bridges is the fact that they can withstand wear and tear for a long time.

● Rust and Corrosion resistance:

The life expectancy of construction materials such as wood is poor because of the increased likelihood that they would rot sooner. Because of the chemical structure of mild steel beams, these components are resistant to rust and corrosion, which are two factors that could otherwise reduce the structure's longevity. Because of this benefit, the life expectancy of structures that are created using mild steel beams supplied by Tube Trading Co. - an excellent supplier and distributor of MS Pipe beam in Vadodara is higher when compared to other construction materials.

#MS Pipe angle in Vadodara#MS Pipe beam in Vadodara#Businss#Industry#MS angle#MS pipe#MS steel#seamless pipe#GI pipe#stainless steel pipe#spiral welded pipe#IBR pipe#ERW pipe#pipes for fire fighting work

7 notes

·

View notes

Link

Structurally sound The DFT method was used to create Apollo Fabritech ERW steel tubes in square sections ranging from 20x20 to 300x300 and rectangle sections ranging from 25x20 to 400x200 for a variety of applications.

2 notes

·

View notes

Text

How to find square pipe dealers in Vadodara?

What are square pipes?

Square pipes are a type of structural steel tubing with a square cross-section. They are typically made from hot-rolled or cold-rolled steel and are used for a variety of construction and engineering purposes. Some common uses for square pipes include framing, fencing, handrails, and support structures.

Square pipes manufactured by an excellent supplier of Square pipe beam in Vadodara, Tube Trading Co., are generally stronger and more rigid than round pipes, making them well-suited for use in construction and engineering applications where strength and stability are important. They are also relatively easy to cut and weld, which makes them a popular choice for many types of projects.

Square pipes are typically measured by their width, which is the distance across the flat sides of the square cross-section. The thickness of the pipe walls is also an important consideration, as it determines the strength and rigidity of the pipe. Square pipes are available in a range of sizes and thicknesses to suit different applications.

How to find the best square pipe dealer in Vadodara?

There are several ways you can find the best square pipe dealer in Vadodara:

- Search online directories or business listings:

There are several online directories and business listings that can help you find square pipe dealers in Vadodara. You can try searching for "square pipe dealers in Vadodara" or "steel supply companies in Vadodara" to find a list of businesses that may be able to help you.

● Contact local steel supply companies or construction material suppliers:

If you know of any local steel supply companies or construction material suppliers in Vadodara, they may be able to point you in the direction of square pipe dealers in the area.

● Ask for referrals from other professionals:

If you know other professionals in the construction or engineering fields in Vadodara, they may be able to provide you with recommendations for reputable square pipe dealers in the area.

● Connect with professional companies or industrial associations:

There may be industry associations or professional organizations in Vadodara that can provide you with information about square pipe dealers in the area. You can try contacting these organizations to ask for recommendations or to find out if they have a list of recommended suppliers.

● Check with local hardware stores or building supply stores:

Local hardware stores or building supply stores may carry square pipes or be able to order them for you. They may also be able to provide you with information about where to find square pipe dealers in the area.

Applications of Square pipes:

Some common applications for square pipes include:

- Framing:

Square pipes are often used as framing members in construction, such as for building walls, floors, and roofs.

- Fencing:

Square pipes are often used to create fencing and gates, as they provide a strong and durable structure that can withstand wind and other forces. If you are looking to build a fence around your property, get the best quality square pipe beams from the most distinguished exporter of Square pipe beam in Vadodara, Tube Trading Co.

- Handrails:

Square pipes are often used to create handrails for stairs, balconies, and other structures, as they provide strong and stable support for people to hold onto.

- Support structures:

Square pipes can be used to create support structures for a variety of applications, such as bridges, towers, and other large structures.

- Industrial equipment:

Square pipes are used in the construction of various types of industrial equipment, such as conveyor systems, cranes, and material handling systems.

- Agricultural equipment:

Square pipes are often used in the construction of agricultural equipment, such as feeders, wagons, and trailers.

- Automotive:

Square pipes are used in the construction of various types of automotive parts and components, such as roll cages and chassis.

Benefits of using Square Pipes:

Square pipes are known for their strength, rigidity, and versatility. Some of the key benefits of square pipes include:

- Strength:

Square pipes are generally stronger and more rigid than round pipes, making them well-suited for use in construction and engineering applications where strength and stability are important.

- Versatility:

Square pipes can be used in a wide range of applications, from framing and fencing to support structures and industrial equipment.

- Easy to cut and weld:

Square pipes are relatively easy to cut and weld, which makes them a popular choice for many types of projects.

- Durability:

Square pipes are typically made from high-quality steel, which makes them resistant to wear and tear and able to withstand harsh environments.

- Corrosion resistance:

Square pipe beams supplied by a trusted distributor of Square pipe beam in Vadodara can be treated with a variety of coatings and finishes to improve their corrosion resistance, making them suitable for use in outdoor or coastal environments.

- Sustainability:

Square pipes are made from recyclable materials and can be recycled at the end of their useful life, making them a sustainable choice for many applications.

Final Thoughts:

Square pipes are known for their strength, rigidity, and versatility, and are used in applications such as framing, fencing, handrails, and support structures. Square pipes are relatively easy to cut and weld and can be treated with a variety of coatings and finishes to improve their corrosion resistance. Square pipe beams offered by a noteworthy supplier of Square pipe beam in Vadodara are made from recyclable materials and can be recycled at the end of their useful life, making them a sustainable choice for many projects. Overall, square pipes are a popular choice for many constructions and engineering applications due to their strength, versatility, and cost-effectiveness.

#Square pipe dealer in Vadodara#IBR Pipe#ERW Pipe#Jindal Pipe#MS Steel#MS angle#Square pipe beam in Vadodara#Spiral welded pipe

5 notes

·

View notes

Text

Exploring The Benefits of ERW Pipe

Looking for high-quality ERW pipes? This Is a type of steel pipe that is manufactured using high-frequency induction welding technology? This process involves the use of a current to heat the edges of the steel strip and fuse them together, for your industrial needs, our assortment of ERW pipes is strong and dependable. Examine our selection right now! Visit our website for more information: https://www.husteel-group.com/products/erw-steel-pipe.html

0 notes

Text

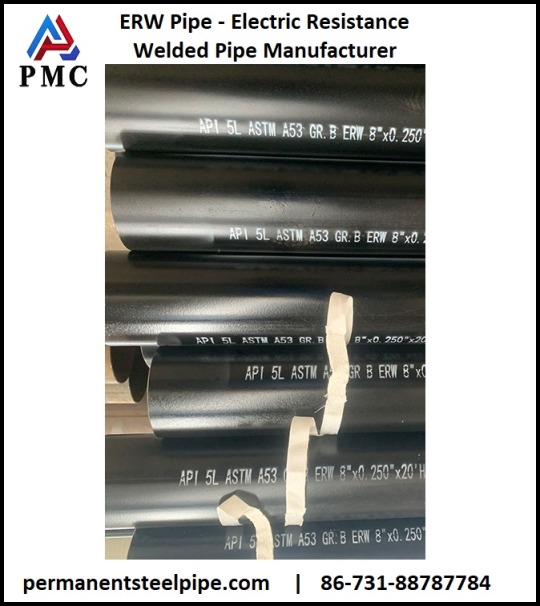

ERW Pipe - Electric Resistance Welded Pipe Manufacturer

Permanent Steel manufacturer of Electric Resistance Welded Pipe and supply worldwide. It is used For ERW Line Pipe, Casing, and Structure Tube. Its surface is Lightly oiled, Hot dip galvanized, and Electro galvanized. It comes with Plastic plugs on both ends, two tags on each bundle, and wrapped in waterproof paper. For more details call us at 86-731-88787784.

0 notes

Text

Erw vs Spiral Pipe : Difference

Pipes are a fundamental component in various structures, serving critical roles in plumbing, HVAC systems, and fluid exchange applications. In industries like oil & gas and petrochemicals, pipes play a crucial role in transferring crude oil products. When it comes to pipeline networks and selecting the right pipes for the job, the debate between ERW pipes and spiral pipes emerges due to their unique characteristics, including pressure resistance and performance.

Let’s delve into the essential differences between these two pipe types, from their manufacturing processes to their pressure resistance and overall performance.

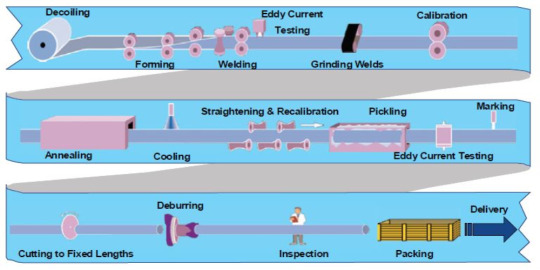

Manufacturing Process:

Conversely, spiral pipes begin with an unrolled steel coil unwound using a roller machine. Spiral pipes require a welding wire or filler to fuse the metals together while forming a helix-like structure. The ends of the strips are joined using a submerged arc welding technique, and each welded portion is inspected to ensure there are no defects. Similar to ERW pipes, spiral pipes undergo ultrasonic testing and other non-destructive tests to examine their physical properties, weld quality, and chemical composition.

Pressure Resistance:

During production and end-use, both ERW pipes and spiral pipes experience residual stress, which refers to stress present on the pipes even in the absence of external forces. ERW pipes tend to have lower residual stress due to the longitudinal and straight seam electric welding, as well as the post-processing methods applied. This is critical for storage and use since the single seam does not compromise the pipe’s quality.

In contrast, the spiral rotation in spiral pipes may lead to higher residual stress, potentially pushing the pipe beyond its yield limit. The presence of multiple seams can significantly impact the pipe’s load-bearing capabilities, especially when subjected to tensile, circumferential stresses, and other forces. Additionally, the use of fillers and welding rods in spiral pipes may introduce weld defects and physical deformations.

Performance:

Considering the above factors, ERW pipes tend to outperform spiral pipes in various applications. The single seam in ERW pipes allows for a consistent flow of different fluids, reducing the likelihood of leaks and bursts. In contrast, the multiple seams in spiral pipes can lead to inconsistent pressure changes, affecting specific portions or the entire pipe.

Furthermore, the multiple welded seams in spiral pipes may cause issues with calcium build-ups and chemical deposits, compromising the pipe’s corrosion resistance and longevity. ERW pipes, lacking weld filler raw materials and flux, offer more consistent weld quality, better surface finish, and improved corrosion resistance.

Key Takeaway:

The choice between ERW pipes and spiral pipes comes down to their manufacturing process, pressure resistance, quality, and overall performance. ERW pipes, produced through electric resistance welding from rolled steel coils or strips, offer enhanced performance and consistency compared to spiral pipes with submerged arc welding on multiple weld seams.

Looking for high-quality Spiral pipes, ERW pipes and Seamless Pipe? Kalpataru Piping Solutions selection can meet your industry’s pipeline supply and requirements. Click here to learn more!

0 notes