#steel building

Text

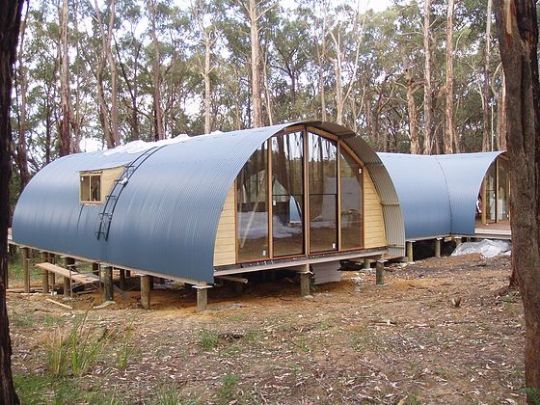

Quonset huts are on my mind again and it seems that there are two schools of thought for building large(ish) homes with them:

The American approach is often one big arch split into two full levels.

Where as the Australians appear to prefer two or more connected arches for a wide single floor with high ceilings.

There is also the option of building over another structure like a basement or walkout.

8 notes

·

View notes

Text

Structural Steel Buildings: A Durable and Versatile Solution

Structural steel buildings have emerged as a popular choice for various construction projects due to their exceptional strength, durability, and versatility. Steel, known for its remarkable properties, offers numerous advantages over other building materials, making it an ideal choice for a wide range of applications, from commercial and industrial buildings to residential structures. In this article, we will explore the benefits and applications of structural steel buildings.

Strength and Durability: One of the most prominent advantages of structural steel is its unparalleled strength and durability. Steel is an alloy of iron and carbon, which provides it with exceptional load-bearing capacity. Steel structures can withstand extreme weather conditions, including strong winds, earthquakes, and heavy snow loads, making them highly resistant to damage. Moreover, steel does not warp, rot, or corrode like wood or concrete, ensuring the longevity of the building.

Versatility in Design: Structural steel offers immense flexibility in design, allowing architects and engineers to create innovative and aesthetically pleasing structures. The high strength-to-weight ratio of steel enables the construction of long-span structures with large open floor areas, eliminating the need for interior columns and enhancing the usable space. Additionally, steel can be easily modified, expanded, or adapted to accommodate future changes or expansions in the building.

Sustainable and Eco-Friendly: In an era where sustainability is paramount, structural steel buildings are an environmentally friendly choice. Steel is a recyclable material, and most steel used in construction today contains a significant percentage of recycled content. At the end of its life cycle, steel can be recycled indefinitely without losing its properties, reducing the demand for new steel production and minimizing waste. Furthermore, steel buildings can be designed to optimize energy efficiency, using advanced insulation systems and incorporating renewable energy sources.

Cost-Effective: While the initial cost of constructing a steel building may be slightly higher compared to traditional materials, the long-term cost savings outweigh the initial investment. Steel structures require minimal maintenance and have a longer lifespan than other building materials, reducing repair and replacement costs over time. Moreover, steel construction is faster and more efficient, saving on labor costs and minimizing construction delays.

Applications: Structural steel buildings find extensive applications in various sectors. In the commercial sector, steel structures are commonly used for office buildings, shopping malls, and warehouses due to their large spans and versatile design options. In the industrial sector, steel buildings are utilized for manufacturing plants, power plants, and storage facilities, providing the necessary strength and durability for heavy machinery and equipment. Steel is also a popular choice for residential construction, offering modern, open-plan living spaces and customizable designs.

In conclusion, structural steel buildings have revolutionized the construction industry with their exceptional strength, durability, and versatility. From their ability to withstand adverse weather conditions to their design flexibility and sustainability, steel structures offer numerous advantages over traditional building materials. Whether for commercial, industrial, or residential purposes, structural steel buildings provide a cost-effective and reliable solution that meets the demands of modern construction.

4 notes

·

View notes

Text

Leading Prefabricated Manufacturer in Delhi - Coreinfra Solutions India

Coreinfra Solutions India stands as the foremost prefabricated manufacturer in Delhi, renowned for excellence in construction solutions. With a commitment to innovation and sustainability, we deliver top-quality prefabricated products tailored to your unique project requirements. Our extensive range encompasses versatile prefab structures, designed to expedite construction processes while maintaining uncompromised durability and efficiency. Our dedication to quality ensures each prefab unit meets stringent industry standards, offering cost-effective, time-efficient, and eco-friendly construction solutions. Choose Coreinfra Solutions India for your prefabricated needs and experience unparalleled expertise in Delhi's construction landscape.

2 notes

·

View notes

Link

Structurally sound The DFT method was used to create Apollo Fabritech ERW steel tubes in square sections ranging from 20x20 to 300x300 and rectangle sections ranging from 25x20 to 400x200 for a variety of applications.

2 notes

·

View notes

Text

If you're looking for modular houses, Ideal Prefab can be the best option for you in terms of affordable price and quality materials ! The most advantageous aspect of this houses is that there is no design limit. Modular homes have very short construction times. That is why you do not have to wait too long to move into your new home. These structures are also much safer than reinforced concrete structures.

#prefab homes#casas prefabricadas#prefabricated#prefabrik#architecture#home & lifestyle#buildings#steel building#tiny home#tiny living#tiny house

3 notes

·

View notes

Text

Getting to Know the Stages of Steel Building Construction

Building with steel involves a consultation with a steel building construction company to discuss project needs and preferences. This consultation helps develop a plan for your requirements and budget. The process involves careful planning, design, fabrication, and construction, ensuring efficient and satisfactory completion. Lacey Construction Inc. offers assistance throughout the process.

#lacey construction#metal building construction#metal building#steel building#steel building in nebraska

0 notes

Text

A Step-by-Step Guide: Building Brilliance in Steel Warehouse Installations

Steel warehouse buildings have become increasingly popular. It has happened as a result of the growing need for durable and advanced storage solutions. These buildings are an incredible option. They work wonders in different sectors because they are affordable, flexible, and long-lasting.

So, a systematic and thorough strategy is essential to guarantee the robust construction of a steel warehouse structure.

Today, we will discuss the essential phases of creating brilliance in steel warehouse installations in this article below.

Best Steps You Can Take For Advanced Steel Warehouse Installations

These are some of the top steps you can take for robust steel warehouse buildings-

Project Preparation and Design

A state-of-the-art steel warehouse building project starts with careful planning. It also needs deliberate design and graphics. Work with skilled architects for this. Take help from engineers to develop a comprehensive plan that suits your company's requirements. Consider things like storage needs, operational workflows, and potential future expansion. A well-designed steel warehouse will maximize space utilization and improve overall functionality.

Setting Up the Site

Site preparation comes next after the design is complete. It entails providing appropriate drainage, leveling the land, and removing the chosen area. The stability and endurance of the steel warehouse structure depend on a well-prepared site. The installation crew should carry out a comprehensive evaluation to handle any possible issues and modify the design as needed.

Building the Foundation

Any structure, including steel warehouse buildings, is anchored by its foundation. Select the best foundation based on the building specifications and soil conditions. Pier or concrete slab foundations often get used for steel warehouses. Confirm that the foundation is strong enough to hold the weight of the stored items and the steel construction.

Fabrication of Steel Structures

The steel warehouse's structure is its main component. Collaborate with trustworthy steel fabricators who can fulfill project demands while producing top-notch components. Precision in production is essential. Accuracy and efficiency are enhanced using modern fabrication processes like computer-aided design (CAD) and computer numerical control (CNC) machining.

Delivery and Transportation

The steel parts must be delivered to the construction site after production. Communication between the logistics staff and the fabrication plant is crucial. It helps in prompt and secure delivery. Proper handling and packaging practices should be in place to prevent any damage during shipment to ensure that the components reach the site in ideal shape.

On-Site Constructing

The assembly stage starts once the steel components are on location. Throughout the installation procedure, competent construction teams should adhere to safety regulations and the comprehensive blueprints. Large steel parts may need to be lifted and placed using heavy machinery and specialist equipment. Any deviations from the plan should be quickly remedied. It ensures the warehouse's structural integrity, and precise assembly is essential.

Roofing and System Integration

The steel warehouse's cladding and roofing are essential elements that enhance its appearance and usefulness. Select cladding and roofing materials of the highest caliber that meet the unique needs of the warehouse environment. Following the installation of the structural components, the focus shifts to the interior finishing and system integration. Safety and accessibility should be prioritized. Organize the interior space to allow for advanced product storage and retrieval.

Wrapping Up This Here

A systematic and well-thought-out approach is a must-have to create brilliant steel warehouse installations. Every stage of the project, from the initial concept and planning to the last details of interior finishing, is vital to its success.

Businesses may guarantee steel warehouse buildings that satisfy their present demands. They also lay the groundwork for future growth and efficiency by devoting time and attention to each stage.

Lastly, contact TSSC - Technical Supplies and Services Co LLC for solid steel warehouse installation materials and cladding solutions. Check out their digital assets and call them right now!

0 notes

Text

Steel Building Construction Cost – steel buildings

A steel building is a construction with steel external covering and interior support. They are well known for their robustness, versatility, and longevity, serving a variety of purposes. Our specialty at 3s Steel Buildings is the design, construction, and distribution of steel buildings in the Dindigul region. Prefabricated steel members are just one aspect of our services; we also offer full construction, including groundwork, drawings, and calculations as needed.

Elements Affecting a Steel Building's Cost

Numerous factors affect how much a steel building costs. The elements that respond to the query, "What makes steel buildings expensive?" are listed below. To help you budget for the expenses of your next project, it's critical that you comprehend them

.Among the most important components are:Material Costs: The price of a steel construction is mostly determined by the cost of steel, which is perhaps the most important component. Global market factors that affect steel prices include supply, demand, and even geopolitical developments. For example, the demand for steel may rise in response to a global upsurge in infrastructure projects, hence driving up costs. Conversely, prices may decrease if steel production exceeds demand. The cost of the cladding that 3s Steel Buildings uses to create a durable structure is seen here.

Size and Design Complexity: The building's internal design and proportions have a direct bearing on the quantity of steel needed, which adds significantly to the cost. Naturally, a larger construction will require more materials, raising the total cost. Similarly, more labor and maybe more expensive materials will be needed for a complicated design that calls for specialized construction methods or distinctive architectural components, which will raise the cost of the steel building even more.

Labor Charges: The intricacy of the project and the state of the local labor market can have a significant impact on labor expenses. Labor prices may be higher in places where there is a high demand for skilled construction labor. Increasingly complex projects requiring specialized training or certifications may also result in higher labor expenses. A committed crew from 3s Steel Buildings installs and completes building projects for our customers.

Groundwork and Installation Costs: Because ground conditions can differ greatly throughout the Dindigul, the state of the site can have a substantial impact on groundwork costs. These expenses may mount up if the site needs intensive preparation, such as leveling, soil testing, or foundation construction. Additionally, installation prices may increase if the site is challenging to access because it would take more time and effort to move supplies and equipment there. When necessary, 3s Steel structures can offer installation and foundation services.

Furthermore, there are additional, less important elements like:

Type of Steel: The cost may also vary depending on whether hot or cold rolled steel is selected. Despite being stronger and more resilient than cold rolled steel, hot rolled steel is typically more costly. You may read more about the advantages of each here.

Location and Delivery Fees: Depending on how far you are from the supplier, the cost of delivering the steel building components to your site will vary. Delivery costs may be greater to remote regions.Extra Features: Including extra features like insulation, unique doors or windows, or custom finishes will raise the overall cost of the steel construction. This would also contain additional technology like electric wiring and interior designs, which are popular with customers.

0 notes

Text

Largest Car Companies in the World

Want to know more about these brands? Check out this infographic that provides in-depth information about the top cars of these brands, headquarters, founders, etc.

0 notes