#Ethylene Vinyl Acetate

Text

Ethylene Vinyl Acetate Market Poised to Grow on Back of High Demand from Solar Panel Manufacturing Industry

Ethylene vinyl acetate (EVA) is a copolymer of ethylene and vinyl acetate which finds extensive usage as an encapsulant in photovoltaic (PV) module manufacturing. As an encapsulant, EVA protects PV cells from moisture and helps in improving their performance. It provides excellent adhesion to both front glass as well as back sheet. The global solar panel market has been growing rapidly over the past few years owing to supportive government policies and initiatives encouraging the adoption of renewable energy. With increasing deployment of solar panels worldwide, demand for EVA from this application segment is projected to surge substantially.

The global ethylene vinyl acetate market is estimated to be valued at US$ 1710.66 Mn in 2024 and is expected to exhibit a CAGR of 3.4% over the forecast period 2024 to 2031, as highlighted in a new report published by Coherent Market Insights.

Market Dynamics:

The high demand from solar panel manufacturing is one of the major drivers propelling the growth of ethylene vinyl acetate market. Solar panel encapsulants account for over 40% of the overall EVA consumption. The government targets to increase usage of renewable sources of energy along with falling prices of solar panels have boosted the solar energy market size significantly. According to the International Renewable Energy Agency (IRENA), globally over 100 GW of solar PV was added in 2021 alone. This rising deployment of solar panels directly translates to increased consumption of EVA. Apart from this, EVA finds wide applications in hot melt adhesives, packaging, and cables. The growth in end-use industries is further augmenting demand.

SWOT Analysis

Strength: Ethylene Vinyl Acetate (EVA) is used as an effective polymer in several end use industries such as solar panels, medical devices, and footwear. EVA provides excellent flexibility, transparency, and reliability in production processes. EVA products show consistent performance even in extreme temperatures due to their durable nature.

Weakness: Fluctuating raw material prices impact the cost of EVA production. Rising crude oil prices increase the commodity prices of ethylene and vinyl acetate, making EVA slightly expensive. EVA has poor mechanical properties and low melting point in comparison to other polymers.

Opportunity: Surging demand for renewable energy sources is driving the solar PV industry. EVA encapsulants protect photovoltaic cells from moisture and UV damage, thereby enhancing module efficiency. Growing medical devices market especially for implants and prosthetics boosts EVA usage.

Threats: Strict regulations regarding toxic emissions can adversely impact manufacturing units. Intense competition from substitute polymers may reduce EVA consumption gradually.

Key Takeaways

The global ethylene vinyl acetate market size is expected to witness high growth backed by increasing solar installations and growing medical device industry. The global ethylene vinyl acetate market is estimated to be valued at US$ 1710.66 million in 2024 and is expected to exhibit a CAGR of 3.4% over the forecast period 2024 to 2031.

Asia Pacific dominates the global market due to large solar PV sector and rapidly expanding construction industry in China and India. Key regional players are expanding their production capacities to meet local demand.

Key players operating in the ethylene vinyl acetate market are DuPont, ExxonMobil, FPC, Hanwha Group, LyondellBasell, Sipchem, and Formosa Plastics. They are focusing on developing novel EVA grades with enhanced properties to strengthen their market position. Technological innovation and partnerships remain crucial for gaining competitive edge. New product launches with optimized performance characteristics could boost revenues. Collaboration with end users aids in developing customized polymer solutions.Get more insights on this topic:https://www.newswirestats.com/ethylene-vinyl-acetate-market-size-and-outlook/

#Ethylene Vinyl Acetate#Ethylene Vinyl Acetate Market#Ethylene Vinyl Acetate Market size#Ethylene Vinyl Acetate Market share#Coherent Market Insights

0 notes

Text

EVA Price, Trend, Prices, Demand & Market Analysis | ChemAnalyst

The Ethylene Vinyl Acetate (EVA) market have witnessed dynamic fluctuations in recent times, influenced by a myriad of factors spanning from raw material costs to global demand trends. EVA, a copolymer of ethylene and vinyl acetate, is a versatile material extensively used in various industries such as packaging, footwear, and solar cell encapsulation, among others.

One key determinant of EVA prices is the cost of its raw materials, primarily ethylene and vinyl acetate monomers. Ethylene, derived from petrochemical sources, is sensitive to crude oil prices, geopolitical events, and supply chain disruptions. Fluctuations in these factors directly impact the overall production cost of EVA. Similarly, the pricing dynamics of vinyl acetate, often tied to ethylene, can also be influenced by factors such as market demand for acetic acid and the availability of feedstocks.

Global demand trends play a pivotal role in shaping the EVA market landscape. The packaging industry, a major consumer of EVA, has experienced increased demand due to the rise in e-commerce activities and the need for efficient and sustainable packaging solutions. Additionally, the footwear industry's growth has contributed to the escalating demand for EVA in shoe soles and midsoles. Solar energy applications, where EVA is used as an encapsulant in photovoltaic modules, have also emerged as a significant driver for market demand.

Market dynamics are further influenced by regulatory changes and environmental considerations. As sustainability becomes a focal point for industries, there is a growing preference for eco-friendly materials, including EVA. Manufacturers are under increasing pressure to adopt green practices, impacting production processes and costs. Additionally, regulatory changes related to product standards and safety can influence market dynamics and prices.

Get Real Time Prices of Ethylene Vinyl Acetate (EVA): https://www.chemanalyst.com/Pricing-data/ethylene-vinyl-acetate-74

The COVID-19 pandemic has introduced a layer of complexity to the EVA market. Disruptions in the global supply chain, production slowdowns, and fluctuations in demand have all contributed to uncertainties in pricing. While certain sectors experienced a surge in demand for EVA-based products, others faced challenges due to lockdowns and restrictions.

Competitive dynamics among key market players also influence EVA prices. Industry consolidation, technological advancements, and innovations in manufacturing processes can impact production efficiency and costs. As companies strive to differentiate themselves, factors such as product quality, brand reputation, and customer service can play a crucial role in shaping market prices.

Currency exchange rates represent another variable impacting the EVA market. As a globally traded commodity, fluctuations in currency values can influence import and export dynamics, subsequently affecting prices. Exchange rate volatility can introduce uncertainties for both producers and consumers in the EVA market.

The future trajectory of EVA prices is likely to be shaped by a combination of these factors. Industry participants are closely monitoring global economic trends, geopolitical developments, and advancements in production technologies to make informed decisions. Sustainability initiatives, market regulations, and shifts in consumer preferences will continue to be key determinants, steering the EVA market in new directions.

The Ethylene Vinyl Acetate (EVA) market is subject to a complex interplay of factors that collectively influence pricing dynamics. From raw material costs and global demand trends to regulatory changes and competitive forces, stakeholders in the EVA market navigate a dynamic landscape. As industries evolve and prioritize sustainability, the EVA market is poised for further transformation, presenting challenges and opportunities for manufacturers, suppliers, and consumers alike.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Spenco Propel + Carbon Performance Shoe Insoles for Women and Men, Men's

Please see the>>

0 notes

Text

Ethylene Vinyl Acetate Is Used in Various Industries

By 2030, the ethylene vinyl acetate market is set to hit $13,149.7 million from $7,060.8 million in 2019, advancing at a 7.2% CAGR between 2021 and 2030. During covid-19 epidemic has reduced the growth of the food service industry by around 30%, resulting in a $925 billion loss. However, other parts of the business expanded at previously unheard-of rates, including online meal delivery, which climbed saw a 30% rise in 2020 from the 20% growth registered in 2019.

Ethylene vinyl acetate foam has a fine, homogenous cell structure that makes it processable in the same way that other thermoplastics are. It keeps its pliability and resilience and rebounds rapidly from compressions. Ethylene vinyl acetate foam is incredibly versatile, having a plethora of usages that most of us take for granted. Such foam is used in a variety of applications, including packaging, construction and building, marine, electronics, healthcare, sports, footwear, and leisure.

When segmented by end use, renewable energy is predicted to develop at the highest rate in the ethylene vinyl acetate market. This is owing to a growing transition away from conventional sources and toward renewable energy, as well as technological developments. Similarly, the above-28% VA category will likely grow rapidly throughout the forecast period. The significant surge in demand for solar panels will be the primary reason for this.

Ethylene vinyl acetate foam can endure large forces since it is extremely robust and tough. It's also resistant to the elements and can endure other potentially dangerous substances like fuel oils and chemicals. Its manufacture is simple and identical to that of thermoplastics due to its molecular makeup. There are several applications for this foam. While its usage in many sectors is well known, there are a variety of other applications that will be developed in the future years.

Hence, due to the increasing solar photovoltaic installation snowballing the demand for ethylene vinyl acetate.

0 notes

Text

Ethylene Vinyl Acetate (EVA) EVA with 6% – 10% vinyl acetate content is commercially used for film applications. Films manufactured using EVA copolymers became the most widespread due to their properties, such as lower melting point, higher transparency, high impact resistance, thermal stability, elasticity, and hygienic characteristics

#Ethylene Vinyl Acetate Market#Ethylene Vinyl Acetate#Ethylene Vinyl Acetate Market size#Ethylene Vinyl Acetate Manufacture#Ethylene Vinyl Acetate Market Report#Ethylene Vinyl Acetate Market Overview#Ethylene Vinyl Acetate Market Outlook#Ethylene Vinyl Acetate Market Trends#Ethylene Vinyl Acetate Market Share#Ethylene Vinyl Acetate Market Driver#Ethylene Vinyl Acetate Market Demand#Ethylene Vinyl Acetate Market growth#Ethylene Vinyl Acetate Market insights#Ethylene Vinyl Acetate Industry#Ethylene Vinyl Acetate Market Forecast#Ethylene Vinyl Acetate Market Analysis#Global Ethylene Vinyl Acetate Market#Ethylene Vinyl Acetate Industry Trends#Ethylene Vinyl Acetate Market Growth#Ethylene Vinyl Acetate Market CAGR#Ethylene Vinyl Acetate Market in Europe#Ethylene Vinyl Acetate Market in USA#Ethylene Vinyl Acetate Market in Asia Pacific

0 notes

Text

#Ethylene Vinyl Acetate Pricing Report 2024#Ethylene Vinyl Acetate pricing chart#Ethylene Vinyl Acetate price news

0 notes

Text

Ethylene Vinyl Acetate Market Global Demand Analysis & Opportunity Outlook 2035

Research Nester’s recent market research analysis on “Ethylene Vinyl Acetate Market: Global Demand Analysis & Opportunity Outlook 2035” delivers a detailed competitors analysis and a detailed overview of the global ethylene vinyl acetate market in terms of market segmentation by type, application, end-use industry, and by region.

Growing Agriculture Activities to Boost the Growth of the Global Ethylene Vinyl Acetate Market

The global market for ethylene vinyl acetate is set to grow on account of growing agriculture activities. EVA is a component of agrochemicals such as pesticides, insecticides, and herbicides. The main benefits of using EVA include requiring fewer soil applications, providing plants with a constant and frequent supply of nutrients, reducing nutrient loss due to leaching, being easier to handle than fertilizers, helping to prevent root damage caused by high salt concentrations, and lowering production costs.

Additionally, a large increase in demand for ethylene vinyl acetate resins from the paper and packaging industries is the primary driver driving the expansion of the global market for these resins. Additionally, the creation of bio-based ethylene vinyl acetate resin, an environmentally friendly substance, is anticipated to open up significant market expansion prospects throughout the projection period. The market is expected to have slower growth as a result of the increasing accessibility of low-cost substitutes such as linear low-density polyethylene (LLDPEs).

Some of the major growth factors and challenges that are associated with the growth of the global ethylene vinyl acetate market are:

Growth Drivers:

Rise in the Use of Ethylene Vinyl Acetate in Footwear

Growth in the Application of Ethylene Vinyl Acetate in the Packaging Sector

Challenges:

Unfortunately, a growing number of firms are currently experiencing the drawbacks of EVA. In addition, EVA (Ethylene Vinyl Acetate) is a wear-resistant polymer, but when processing temperatures are too high, it can release corrosive breakdown products. As a result, market demand is geared towards restraint.

Request Report Sample@

https://www.researchnester.com/sample-request-5173

By end-use industry, the market for ethylene vinyl acetate is segmented into pharmaceutical, packaging, building & construction, agriculture, and footwear. Out of these, the footwear segment is estimated to have significant growth over the forecast period. In order to make vegan shoes, EVA is now widely used. The name of the plastic made by fusing ethylene and vinyl acetate is EVA. They combine to create a material that can be used to create the soles of EVA trainers. It is also recognized as an environmentally friendly material because it doesn't use chlorine in the production process and is easily recycled into new things (playgrounds, mats, and more).

By region, the market for ethylene vinyl acetate in Europe is expected to grow over the forecast period. A growing number of packaged food and personal care companies are expressing a need for smaller packaging sizes in this region. During the projection period, it is expected that this tendency would intensify, driving up market demand for EVA in this region.

This report also provides the existing competitive scenario of some of the key players of the global ethylene vinyl acetate market which includes company profiling of The Dow Chemical Company, ExxonMobil Corporation, Arkema, SABIC, Hanwha Solutions Chemical Division, LG Chem Ltd., China Petrochemical Corporation, Versalis S.p.A., Braskem S.A., TotalEnergies, and others.

Access our detailed report at:https://www.researchnester.com/reports/ethylene-vinyl-acetate-market/5173

0 notes

Text

Global Ethylene Vinyl Acetate Market Is Estimated To Witness High Growth Owing To Increasing Demand for Sustainable Packaging Solutions

The global Ethylene Vinyl Acetate (EVA) Market is estimated to be valued at USD 1,349.71 million in 2021 and is expected to exhibit a CAGR of 4.89% over the forecast period 2022-2030, as highlighted in a new report published by Coherent Market Insights.

A) Market Overview:

Ethylene Vinyl Acetate (EVA) is a copolymer of vinyl acetate and ethylene, which gives it excellent flexibility, clarity, impact resistance, and low-temperature properties. EVA is widely used in various industries such as packaging, automotive, footwear, solar panels, and agriculture. Its advantages include excellent adhesion, low-temperature flexibility, good toughness, and filling properties. The growing need for sustainable packaging solutions and the increasing demand for EVA-based products are key factors driving the market growth.

B) Market Key Trends:

One key trend in the global EVA market is the increasing demand for sustainable packaging solutions. With the rising awareness about environmental issues and the need to reduce plastic waste, there is a growing demand for eco-friendly packaging materials. EVA-based films and sheets are widely used in the packaging industry due to their excellent properties such as transparency, flexibility, and recyclability. For instance, EVA films are extensively used in food packaging applications as they provide a barrier against moisture, oxygen, and UV light, thereby extending the shelf life of the packaged products.

C) PEST Analysis:

Political: There are no significant political factors impacting the EVA market.

Economic: The economic growth in developing countries is driving the demand for EVA-based products in various industries.

Social: The increasing awareness about environmental issues is leading to a shift towards sustainable packaging solutions.

Technological: Technological advancements in EVA production processes and product innovation are driving market growth.

D) Key Takeaways:

- The Global Ethylene Vinyl Acetate Market Size is expected to witness high growth, exhibiting a CAGR of 4.89% over the forecast period. The increasing demand for sustainable packaging solutions is driving market growth.

- Asia Pacific is the fastest-growing and dominating region in the EVA market, owing to the rapid industrialization and growing demand from industries such as packaging, automotive, and footwear.

- Key players operating in the global EVA market include Arlanxeo, Asia Polymer Corporation, Benson Polymers Limited, Braskem, Celanese Corporation, Clariant AG, Dow, ExxonMobil Corporation, Hanwha Solutions/Chemical Corporation, Innospec Inc., LyondellBasell Industries Holdings BV, Repsol, Sipchem, SK Global, Sumitomo Chemical Co. Ltd, and Tosoh Corporation.

In conclusion, the global Ethylene Vinyl Acetate (EVA) market is expected to witness significant growth due to the increasing demand for sustainable packaging solutions. The market is driven by the advantages offered by EVA, such as flexibility, impact resistance, and low-temperature properties. Asia Pacific is the fastest-growing region due to rapid industrialization and high demand from various industries. Key players in the market are focused on technological advancements and product innovation to stay competitive in the market.

#Ethylene Vinyl Acetate Market#Ethylene Vinyl Acetate Market Demand#Ethylene Vinyl Acetate Market Outlook#Ethylene Vinyl Acetate Market Insights#Ethylene Vinyl Acetate Market Analysis#adhesion#packaging#footwear#solar cells#polypropylene#Coherent Market Insights

0 notes

Link

Vinyl Acetate - Ethylene Copolymer Emulsion Market Report: 2023-2029 Vinyl Acetate - Ethylene Copolymer Emulsion Market (Newly published report) which covers Market Overview, Future Economic Impact, Competition by Manufacturers, Supply (Production), and Consumption Analysis Get

0 notes

Text

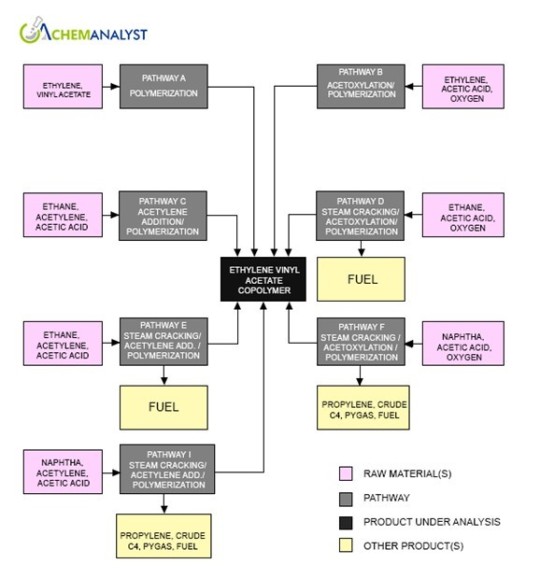

Decoding the Manufacturing Process of Ethylene Vinyl Acetate (EVA): Technologies Adopted by Industry Leaders

Ready to dive into the world of cutting-edge polymers? Today, we're shining the spotlight on Ethylene Vinyl Acetate, or EVA – the superhero of polymers! So, what's the deal with EVA? Well, it's not your average resin – oh no! It's a super-special copolymer of vinyl acetate and ethylene, packed with some seriously awesome properties. We're talking flexibility that'll make your jaw drop, the ability to brave even the chilliest temperatures, and toughness that can stand up to any chemical thrown its way. In this blog, we will read more about EVA and unleash the secrets this material holds along with its manufacturing process in detail. So, what are we waiting for? Let’s dive into it!

Introduction

EVA, a polymer blend of ethylene and vinyl acetate, stands out among plastics due to its distinctive properties. Its composition grants it a range of advantages that distinguish it in various applications. Regarding production, EVA boasts ease of processing. It lends itself well to molding, extrusion, or foaming, enabling diverse shapes and configurations and enhancing design possibilities. This versatility renders it indispensable across industries, spanning from packaging to healthcare.

EVA has the following characteristics:

Flexibility: EVA remains pliable and doesn't become stiff or brittle. For example, in cold weather conditions, materials like EVA can still bend and stretch without breaking, making them ideal for applications where flexibility is crucial, such as in footwear or packaging.

Resilient: Resilience refers to the ability of a material to return to its original shape or form after being stretched, compressed, or deformed. In the case of EVA, its resilience means that it can withstand pressure or impact without permanently deforming. This property makes it suitable for products that undergo repetitive stress or impact, like athletic gear or cushioning materials.

Tough at low and moderate temperatures: EVA maintains its strength and durability even when exposed to low or moderate temperatures. It can withstand external forces or impacts without breaking or cracking, ensuring the integrity of the material. This toughness makes it suitable for various applications, including outdoor equipment, automotive parts, or industrial components.

Crack resistant: EVA's crack resistance means that it can endure bending, stretching, or impact without developing cracks or fractures. This property is crucial for ensuring the longevity and reliability of products made from EVA, such as footwear, toys, or packaging materials.

Manufacturing Process

There are several ways to create EVA through the copolymerization of ethylene and vinyl acetate, including solution polymerization, suspension polymerization, bulk polymerization, and emulsion polymerization.

In solution polymerization, a solvent is used alongside a catalyst to facilitate the reaction between ethylene and vinyl acetate. The preferred solvents are alcohols with four or fewer carbon atoms, or mixtures where these alcohols are the main component. Examples include methanol, ethanol, and propanol, with methanol being the most favorable choice. While any radical initiator can technically be used as a catalyst in EVA production, some options are more favorable. This invention particularly highlights azo compounds as preferred catalysts. Two specific examples of suitable azo compounds are 2,2'-azobis-(2,4-dimethylvaleronitrile) and 2,2'-azobis-(2,4,4-trimethylvaleronitrile).

There are several options for feeding vinyl acetate and the catalyst into the reaction vessel:

Pre-mix: Combine all three (vinyl acetate, solvent, and catalyst) beforehand and feed them together.

Separate Feed 1: Dissolve the catalyst in the solvent, then feed the vinyl acetate and solvent separately.

Separate Feed 2: Feed the vinyl acetate separately from a pre-mixed liquid containing the catalyst and solvent.

Separate Feeds (Preferred): Introduce separate streams of a pre-mixed liquid containing vinyl acetate and solvent, and another pre-mixed liquid containing the catalyst and solvent.

The ideal polymerization temperature falls within a range of 40°C to 80°C. Temperatures below 40°C require a longer reaction time, necessitating an increased amount of catalyst, which can complicate control of the process. Conversely, exceeding 80°C makes controlling the polymerization difficult.

The average time the reaction mixture spends within the vessel (residence time) is preferably between 2 and 8 hours, with a narrower preference of 2 to 6 hours. A residence time shorter than 2 hours requires adjustments like increasing the reaction temperature or catalyst amount, both of which can make control of the polymerization more challenging. After the EVA copolymerization process, the resulting product undergoes further processing to create usable forms.

The first step involves using an alcohol solution (or an alcohol-water solution) of the EVA copolymer that has been saponified (a chemical treatment). This solution serves as the base for creating strands. These strands are then formed by extruding the alcohol solution into a solidifying liquid, typically water or a water-alcohol mix. The solidified strands are cut into pellets and rinsed with water.

Following rinsing, the pellets can optionally undergo a chemical treatment. This may involve immersing them in a water-based solution containing acids or their salts. Examples of suitable chemicals include formic acid, acetic acid (preferred choice), adipic acid, other carboxylic acids, phosphoric acid, boric acid, or their salts.

Finally, the dried pellets are ready for melt-molding into various desired products. The preferred temperature range for melt-molding is between 160°C and 260°C. During molding, various additives can be incorporated as needed. Additionally, the EVA copolymer can be blended with other thermoplastic resins for further modification. There are numerous melt-molding methods available, including injection molding, compression molding, and extrusion molding. Extrusion molding offers even more possibilities, with techniques like T-die, blow molding, pipe extrusion, wire extrusion, irregularly shaped die extrusion, inflation, and more. The processed EVA can be molded into various final products, either by itself (films, sheets, tapes, bottles, pipes, filaments, irregularly shaped extrusions) or through co-extrusion with other thermoplastic resins.

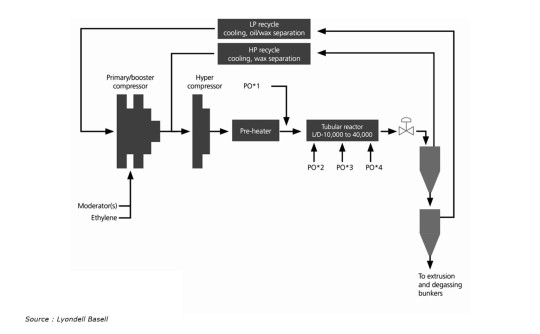

Lyondell Basell uses the Lupotech process to produce EVA. The overall EVA production process can be segmented into several distinct process units: Pre-compression of ethylene, compression to reach reaction conditions, the polymerization reaction itself, separation of polymer from gas, recycling of unreacted gases, extrusion, pelletizing, degassing, storage, and packaging.

In the Lupotech T tubular reactor, the entire flow of ethylene is received from the hyper compressor, entering the first reaction zone preheated to temperatures ranging between 150–170°C and under pressures ranging from 2000 to 3100 bar. For the synthesis of copolymers, specific comonomers like vinyl acetate or acrylic-based monomers are introduced. The reaction is initiated by injecting organic peroxides into the reactor at various points following each reaction peak, which optimizes the temperature profile of the reaction mixture.

On the other hand, in the Lupotech A autoclave reactor, compressed ethylene from the secondary compressor is directed through flow splitters to designated points within the reactor. An organic liquid peroxide initiator is introduced to sustain a continuous polymerization reaction within controlled temperature zones. Additionally, a comonomer modifier is injected to regulate product properties. The effluent from the reactor is then discharged through a product cooler into the high-pressure separator.

Applications of Ethylene Vinyl Acetate (EVA):

Footwear

Ethylene Vinyl Acetate (EVA) is a superstar material in the footwear industry. Thanks to its impressive cushioning, shock absorption, and flexibility, EVA is a go-to material for crafting comfortable and supportive insoles, midsoles, and outsoles. This makes it a popular pick for a wide range of footwear, from athletic shoes that help you conquer your workout to comfy sandals and casual shoes for everyday wear.

Sports Goods

EVA shines in the world of sports and recreation due to its exceptional cushioning and impact resistance. This makes it a hero material for various equipment, including sports padding, helmet liners, yoga mats, exercise mats, and protective gear like knee pads and shin guards. By absorbing shock and blows, EVA helps athletes of all levels train and perform safely and comfortably.

Automotive

Cars are another place where EVA shows off its versatility. Inside the vehicle, EVA contributes to comfort and functionality. Floor mats made from EVA are a common sight, and it's also used to create supportive headrests, attractive door panels, and even instrument panels. Beyond comfort, EVA's presence extends to essential car parts like gaskets, seals, and insulation materials.

Packaging

Because EVA plastic is lightweight, flexible, and great at absorbing shock, it's a champion in the world of packaging. Commonly found as foam inserts, protective packaging for delicate items, and padding materials for electronics, EVA helps keep your valuable products safe and sound during transport.

Solar Panels

Ethylene vinyl acetate is a key player in solar panel technology. This material boasts excellent properties for solar applications. It allows sunlight to pass through easily (good radiation transmission) and resists degradation from sunlight over time (low degradability). In the solar panel manufacturing process, EVA acts as a glue (encapsulating agent). When heated and applied, it forms a protective layer (sealing and insulating film) that encases the delicate solar cells within the panel. This layer safeguards the cells and keeps them functioning optimally.

Market Outlook:

The footwear industry reigns as the main driver of the global market for Ethylene Vinyl Acetate (EVA). This dominance is expected to continue due to the ever-growing global population. EVA's winning formula for footwear lies in its impressive combination of properties: high resistance, excellent grip, crack resistance, thermal insulation, shock absorption, chemical resistance, vibration dampening, and low water absorption. Beyond footwear, EVA finds another key application in the solar energy sector. Here, it serves as an adhesive that encapsulates photovoltaic (PV) modules within solar panels. This not only provides structural support but also ensures electrical isolation, further fueling the demand for EVA.

Ethylene Vinyl Acetate (EVA) Major Manufacturers

Significant companies in the Global Ethylene Vinyl Acetate (EVA) market are ExxonMobil Corporation, Sinopec, Hanwha Total Petrochemical, Formosa Plastics Corporation, BASF-YPC, The Dow Chemical Company, Celanese, Shaanxi Yanchang Zhongmei Yulin Energy Chemical Co., Ltd, Asia Polymer Corporation, PJSC Kazanorgsintez, and Others.

Conclusion:

Ethylene Vinyl Acetate (EVA) is a versatile polymer with numerous useful applications. EVA is a material that can morph into many shapes and structures. It is great when it comes to resisting water and moisture, providing cushioning and shock absorption, insulating against heat, and lasting a long time. This winning combination, especially its lightweight design with shock-absorbing capabilities, makes it a superstar in the world of sports footwear. You'll find EVA in various parts of athletic shoes, from outsoles and midsoles to insoles. But its popularity goes beyond just sports shoes; it's become a common element in all types of footwear. EVA's versatility extends beyond shoes as well, finding use as padding and interfacing in various applications. The increasing popularity of Ethylene Vinyl Acetate (EVA), propelled by its exceptional friction coefficient and long-lasting nature, is fueling its utilization in the production of footwear. This trend is anticipated to significantly boost the global Ethylene Vinyl Acetate (EVA) demand.

0 notes

Text

EVA is ethylene vinyl acetate, a material that has good radiation transmission and low degradability to sunlight. This is a thermoplastic polymer, which is used in solar modules as an encapsulating agent since, by applying heat to the assembly, it forms a sealing and insulating film around the solar cells.

#Ethylene Vinyl Acetate Resins Market Analysis#Ethylene Vinyl Acetate Resins Market Demand#Ethylene Vinyl Acetate Resins Market Revenue#Ethylene Vinyl Acetate Resins Market Forecast#Ethylene Vinyl Acetate Resins Market Growth

0 notes

Text

Vae Emulsion Market - Growth, Trends, COVID-19 Impact, Forecast Upto 2030

The assessment conducted by Market Research Future (MRFR) has found out that the Global VAE Emulsion Market is expected to mark a CAGR of 5.44% during the forecast period 2022 to 2030. The market has been estimated to scale a valuation of USD 4,910.1 Mn towards the end of the review period. The key advantages offered by vinyl-acetate-ethylene (VAE) include adhesion, durability, and water resistance. These features are obtained from the copolymerization of ethylene & vinyl acetate and are expected to exhibit proliferating applications for accelerated revenue creation. In the upcoming years, the demand for epichlorohydrin in the production of epoxy resin is likely to emerge as one of the prominent factors anticipated to catapult the VAE Emulsion Market on an upward trajectory.

VAE emulsion has penetrated major industry verticals such as automotive, construction, wood-based packaging, etc. The growth of these end-users is projected to catalyze the demand for VAE in the years to come. This, in turn, is expected to have a positive influence on the growth pattern of the market over the next couple of years. The ever-increasing production of automobiles backed by rising purchasing power is anticipated to provide impetus to the growth of the VAE Emulsion Market in the forthcoming years.

Market Segmentation:

The global VAE Emulsion Marketis segmented on the basis of type and application.

By type, ordinary VAE emulsion held 68.17% share in the market in 2017. This can be credited to its affordability and low volatile organic compounds (VOC) content. On the other hand, the waterproof VAE emulsion segment can exhibit 5.67% CAGR during the review period owing to its ability to bond polyvinyl chloride films.

On the basis of application, paints & coatings accounted for 43.77% share of the VAE Emulsion Market in 2017. Demand for the polymer as a binder in paints and coatings combined with the rise in residential construction activities can drive the segment during the forecast period. On the other hand, the re-dispersible powders segment can exhibit 5.56% CAGR during the assessment period.

Key Players:

The noted players operating in the Global VAE Emulsion Market are Wacker Chemie AG (Germany), Dairen Chemical Corporation (China), Celanese Corporation (U.S.), China Petrochemical Corporation (China), H.B. Fuller Company (U.S.), Vinavil S.p.A. (Italy), Shanxi Sanwei Group Co., Ltd. (China), Benson Polymers Limited (India), U.S. Adhesives, Inc. (U.S.), and Richest Group Limited (China).

Region:

The VAE Emulsion Market based on the region divided into North America, Asia-Pacific, Europe, the Middle East, and Africa, and Latin America. The global VAE Emulsion Market is dominated by Asia-Pacific with 43.32% owing to the growing demand for paints and coatings in various countries like India, China, and South Korea. Also, investments made in a huge amount by the government for improving the infrastructure of the cities for growth of economics drives the demand of VAE Emulsion Market Size. This region is expected to grow at a CAGR of 6.2% at a reach value of USD 2,221.1 million during the forecasted period.

Owing to the increasing need for special formulations for enhancing the appearance of the buildings in the Middle East and Africa region, the growth of the vinyl-acetate ethylene emulsion market will increase in this region and is expected to show a high CAGR of 5.35% during the forecasted period from 2021 to 2030.

Latest Industry News:

Germany-based global chemical company Wacker has announced its participation in the Middle East Coatings Show (MECS) 2019 for the introduction of its sustainable construction solutions including, but not limited to, interior paint, based on Wacker’s VAE technology, which has seven times lower volatile organic compounds (VOC) content compared to conventional paints.

Celanese Corporation, a global chemical and specialty materials company, has completed the acquisition of, one of India’s largest engineering thermoplastics (ETP) compounders, Next Polymers Ltd.

Get Complete Report Click Here: https://www.marketresearchfuture.com/reports/vae-emulsion-market-7714

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

#VAE Emulsion Market#Vinyl acetate ethylene Market#Global VAE Emulsion Market Research#VAE Emulsion Market Analysis#VAE Emulsion Market Trends

0 notes

Text

Ethylene Vinyl Acetate Market Advanced technologies & growth opportunities in global Industry by 2022 to 2028

The Ethylene Vinyl Acetate market report provides information and statistics on market shares, size, restraining factors, and driving factors for the forecast period 2021 to 2028. It also mentions the role of main market players in the Chemicals industry. The report on Ethylene Vinyl Acetate market evaluates the value of the market report, keeping in mind the application and regional segments, market share, and size while forecasting the market for each product type and application of the Ethylene Vinyl Acetate market in different segments of the report. The research report also mentions some sections of the Ethylene Vinyl Acetate market including opportunities, growth, trend, size, demand, and technology used by prominent players of the market. Then, it gives detailed profiles of the key players as a part of the competitive landscape of the Ethylene Vinyl Acetate market.

Get Sample Copy @ https://iconmarketresearch.com/inquiry/sample/IMR1711

The study of the report divides it into several sub-segments and represents the whole Chemicals industry. An estimation of the revenue generated by the entire Chemicals industry and its sub-segments are also provided in the report. It decides the factors that affect the demand of the Chemicals industry rapidly, including methods of development, growth networks, and the product model. The report also points out the greatest prospects for the growth of the Chemicals market such as forecasting the growth of the market, the launch of new goods, and analysis of the product demand, purchase decisions, several economic factors that are important to determine the trend of Ethylene Vinyl Acetate market, and the attractiveness of the market. The report on the Ethylene Vinyl Acetate market will help in assisting the stakeholders in identifying high-potential customers, such as distributors and manufacturers.

The main aim of the Ethylene Vinyl Acetate report is to give the map of the growth for the Ethylene Vinyl Acetate market that will help in providing the clients with the required information for the formulation strategies to meet their respective business goals. The report also provides deep knowledge of the Ethylene Vinyl Acetate for the previous year as well as for the forecast years and what the CAGR level of the market is going to be. This report is a synopsis of what the market conditions are going to be while also giving information regarding the market’s definition, classifications, applications, and engagements are. This report also aims to analyze the Ethylene Vinyl Acetate market’s developments including the market improvement, market position, and others which are usually done by the prominent players and brands of the chemicals industry. This report also consists of all the market drivers and restraints which are obtained through SWOT analysis. The report also has the CAGR values of the Ethylene Vinyl Acetate market for the base years 2021, the historic year 2020, and forecast years 2021-2028.

0 notes

Text

0 notes

Text

Ethylene Vinyl Acetate (EVA) Resins & Films Market Analysis Forecast to 2022-2031

Kenneth Research has released a report titled “Ethylene Vinyl Acetate (EVA) Resins & Films Market: Global Demand Analysis & Opportunity Outlook 2031” which also includes some of the prominent market analyzing parameters such as industry growth drivers, restraints, supply and demand risk, along with the impact of COVID-19 and a detailed discussion on the latest trends and future opportunities that are associated with the growth of the market.

The solar PV installed capacity worldwide, according to the statistics by the International Renewable Energy Agency (IRENA), grew from 72216 MW in the year 2011 to 843086 MW in the year 2021.

Access full Report Description, TOC, Table of Figure, Chart, etc.@https://www.kennethresearch.com/sample-request-10352389

The demand for solar panels worldwide is increasing at a significant pace. This can majorly be attributed to the increasing concern for greenhouse gas (GHG) emissions and the rising focus of the government of nations to promote the adoption of green energy. With the surge in demand for solar panels, there is a rising need amongst the solar PV manufacturers for raw materials to manufacture these components. As EVA resins & films are widely used in the manufacturing of solar PV panels, hence, the demand for the chemical compound amongst the solar PV panel manufacturers is anticipated to grow, and in turn, drive the growth of the global ethylene vinyl acetate (EVA) resins & films market.

The global ethylene vinyl acetate (EVA) resins & films market is anticipated to grow with a CAGR of 5.9% over the forecast period, i.e., 2022 – 2031. The market is estimated to garner a revenue of USD 12127.4 Million by the end of 2031. Additionally, in the year 2021, the market registered a revenue of USD 6863.6 Million. The market is segmented by application into food & beverage packing, hot melt adhesives, wires & cables, foams, inks, bitumen additives & asphalt modifiers, pharmaceutical, EVA film, and others, out of which, the EVA films segment is projected to garner the largest revenue of USD 5387.1 Million by the end of 2031. Moreover, the segment generated a revenue of USD 3006.5 Million in the year 2021.

By region, the global ethylene vinyl acetate (EVA) resins & films market is segmented into five major regions including North America, Europe, Asia Pacific, Latin America and Middle East & Africa region, out of which, the market in the Asia Pacific is expected to garner the largest revenue of USD 7437.1 Million by the end of 2031. Moreover, the market in the region generated a revenue of USD 4051.9 Million in the year 2021.

Browse Full Report @

https://www.kennethresearch.com/report-details/ethylene-vinyl-acetate-eva-resins-films-market/10352389

The research is global in nature and covers detailed analysis on the market in North America (U.S., Canada), Europe (U.K., Germany, France, Italy, Spain, Hungary, Belgium, Netherlands & Luxembourg, NORDIC [Finland, Sweden, Norway, Denmark], Poland, Turkey, Russia, Rest of Europe), Latin America (Brazil, Mexico, Argentina, Rest of Latin America), Asia-Pacific (China, India, Japan, South Korea, Indonesia, Singapore, Malaysia, Australia, New Zealand, Rest of Asia-Pacific), Middle East and Africa (Israel, GCC [Saudi Arabia, UAE, Bahrain, Kuwait, Qatar, Oman], North Africa, South Africa, Rest of Middle East and Africa). In addition, analysis comprising market size, Y-O-Y growth & opportunity analysis, market players’ competitive study, investment opportunities, demand for future outlook etc. has also been covered and displayed in the research report.

However, the availability of low-cost substitutes is projected to hinder the market growth in the coming years.

This report also provides the existing competitive scenario of some of the key players of the global ethylene vinyl acetate (EVA) resins & films market, which includes company profiling of Arkema, International Polymers Corporation (IPC), Exxon Mobil Corporation, LyondellBasell Industries Holdings B.V., Braskem, LG Chem, Celanese Corporation, Hanwha Solutions Chemical Division Corporation, Folienwerk Wolfen GmbH, SANVIC Inc. (KANEKA CORPORATION), LOTTE Chemical Corporation, Dr. Dietrich Mueller GmbH, Lucent CleanEnergy, SK geo centric Co., Ltd., Changzhou Betterial Film Technologies Co., Ltd., Zhejiang Sinopont Technology Co., Ltd., JIN HEUNG INDUSTRIAL CO., LTD., INTERLAYER SOLUTIONS, Mitsui Chemicals, Inc., Japan Coating Resin co., ltd., The Dow Chemical Company, 3M, and others.

The profiling enfolds key information of the companies which comprises of business overview, products and services, key financials and recent news and developments. Conclusively, the report titled “Ethylene Vinyl Acetate (EVA) Resins & Films Market: Global Demand Analysis & Opportunity Outlook 2031”, analyses the overall global ethylene vinyl acetate (EVA) resins & films industry to help new entrants to understand the details of the market. In addition to that, this report also guides existing players looking for expansion and major investors looking for investment in the global ethylene vinyl acetate (EVA) resins & films market in the near future.

Request Sample Report@ https://www.kennethresearch.com/sample-request-10352389

Kenneth Research is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment, etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision so as to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 313 462 0609

#Ethylene Vinyl Acetate (EVA) Resins & Films Market#Ethylene Vinyl Acetate (EVA) Resins & Films Market size#Ethylene Vinyl Acetate (EVA) Resins & Films Market share#Ethylene Vinyl Acetate (EVA) Resins & Films Market trends

0 notes