#EvaporationSystems

Text

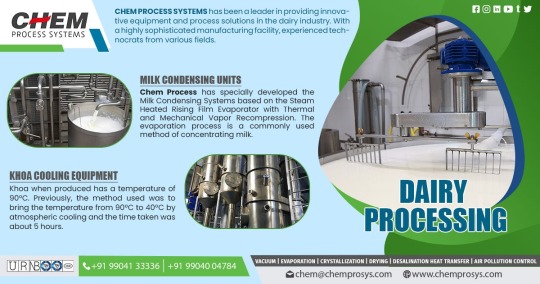

Dairy Processing Plant Solution

Chem Process Pvt. Ltd. Is Provided Dairy Processing Plant Solution across in India.

Chem Process Pvt. Ltd. is based in Ahmedabad, Gujarat, India.

We are specializes in Desalination, Ejectors, Vacuum Systems, Dryers, Distillation, Gas Extraction and Generation, Evaporation Systems, Power Plant Equipment,

Specialized Fabrication, MVR Type Evaporation Systems, Crystallizers, Filters, Ethylene Glycol Vacuum Systems, and more.

We leads in delivering innovative equipment and process solutions for the dairy industry.

With a state-of-the-art manufacturing facility and experienced technocrats, we excel in designing, engineering, and supplying solutions to enhance processes,

improve efficiency, and ensure sustainability. Our focus on hygiene and food safety sets us apart.

We create energy-efficient, affordable, and economical Milk Condensing Units tailored for small and medium-scale operations.

Chem Process has engineered Milk Condensing Systems utilizing the Steam Heated Rising Film Evaporator with Thermal Vapour Compression.

This evaporation technique is widely employed for milk concentration. Various evaporator types, including Steam Heated Falling Film Evaporators with

Single to Multi Effect, are available in the market with different capacities.

We used various Machines:

Ejectors And Vacuum Systems

Dryers

Evaporation Systems

Chem Process Pvt. Ltd. has specially developed the Milk Condensing Systems and Khoa Cooling Equipment in Dairy Processing Plant Solution.

Chem Process Systems Pvt. Ltd. Is Provided Dairy Processing Plant Solution across in India.

For further details and inquiries, please feel free to contact us.

Read the full article

#affordable#Ahmedabad#ChemProcessPvt.Ltd.#createenergy-efficient#Crystallizers#DairyProcessingPlant#DairyProcessingPlantSolution#Desalination#Distillation#Dryers#economicalMilkCondensingUnits#Ejectors#EjectorsAndVacuumSystems#EthyleneGlycolVacuumSystems#EvaporationSystems#Filters#GasExtractionandGeneration#Gujarat#improveefficiency#India#KhoaCoolingEquipment#MilkCondensingSystems#MVRTypeEvaporationSystems#PowerPlantEquipment#SpecializedFabrication#supplyingsolutionstoenhanceprocesses#VacuumSystems

0 notes

Text

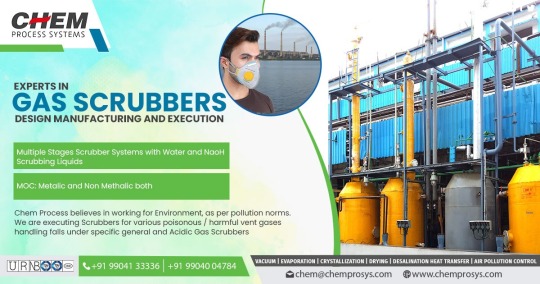

Gas Scrubber Manufacture

Gas Scrubber Manufacture

Chem Process Systems is an ISO 9001:2015 and OHSAS 18001:2007 certified company, and We are Manufacturer and Supplier of Gas Scrubber in Ahmedabad, Gujarat, India.

Our extensive product range includes Desalination, Ejectors And Vacuum Systems, Dryers, Distillation, Gas Extraction and Generation, Evaporation Systems, Power Plant Equipment, Specialized Fabrication, MVR Type Evaporation Systems, Crystallizers, Filters, Ethylene Glycol Vacuum Systems, and more.

Gas scrubbers are effective air pollution control devices that utilize a high-energy liquid spray to eliminate aerosol and gaseous pollutants from an air stream.

People commonly use gas scrubbers to control the release of gas emissions into the environment.

The fundamental wet scrubber comprises a vessel with the appropriate cross-sectional area to maintain the correct air velocity, a packing media depth for distributing scrubbing solutions like caustic or base solutions that can capture and neutralize gases, a recirculation system to supply the proper volume of solution throughout the packing, and a demister pad or mist eliminator to prevent excessive scrubbing solution from re-entering the exhaust stack.

The gas stream traverses through a bed of structured or randomly packed media.

Pall rings serve as the packing media, absorbing a maximum amount of gas components while inducing minimal static pressure drop.

Scrubber spray chambers and nozzles are meticulously designed to thoroughly saturate the media.

An ample number of nozzles ensures comprehensive packing irrigation, preventing any dry areas within the packed bed.

Features

Less operation and maintenance cost

Less residence time

High efficiency

Trouble free Operation

Gas scrubbers necessitate routine maintenance, encompassing the replacement or replenishment of scrubbing liquid, cleaning of packing materials, and component inspections to ensure proper functionality.

Chem Process Systems is a Manufacturer and Supplier of Gas Scrubber in Ahmedabad, Gujarat, India.

Read the full article

#absorbingamaximumamountofgas#Ahmedabad#ChemProcessSystems#cleaningofpackingmaterials#Crystallizers#Desalination#Distillation#Dryers#EjectorsAndVacuumSystems#EthyleneGlycolVacuumSystems#EvaporationSystems#Exporter#Filters#GasExtractionandGeneration#GasScrubberManufacture#Gasscrubbersareeffectiveairpollutioncontrol#gasstreamtraverses#Gujarat#Highefficiency#India#Lessoperationandmaintenancecost#Lessresidencetime#Manufacturer#MVRTypeEvaporationSystems#PowerPlantEquipment#scrubbingliquid#SpecializedFabrication#Supplier#TroublefreeOperation

0 notes

Text

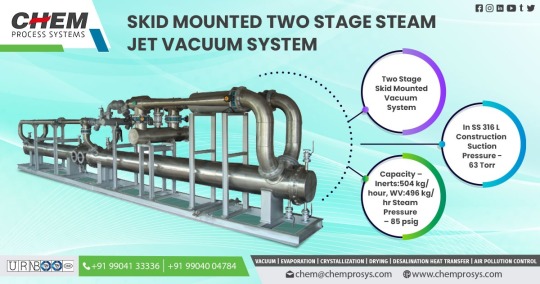

Skid Mounted Two Stage Steam Jet Vacuum System

Chem Process Systems an ISO 9001-2015 and OHSAS 18000-2007 certified company, is a leading Manufacturer and Supplier of Skid Mounted Two Stage Steam Jet Vacuum System in India.

We offer a wide range of rugged, reliable, and efficient ejectors for various industrial applications.

Our extensive product range includes Desalination, Ejectors And Vacuum Systems, Dryers, Distillation, Gas Extraction and Generation, Evaporation Systems, Power Plant Equipment, Specialized Fabrication, MVR Type Evaporation Systems, Crystallizers, Filters, Ethylene Glycol Vacuum Systems, and more.

Key Features:

Compact Design: Our skid-mounted configuration ensures a small footprint, making installation in tight spaces easy while maintaining accessibility for maintenance.

Employing a two-stage design, our system enhances performance, achieving deeper vacuum levels for efficiently removing gases and vapors.

Steam-Powered: Our system uses high-pressure steam as its energy source, ensuring energy efficiency and environmental friendliness. It easily integrates into existing steam systems.

State-of-the-art control systems equip our skid-mounted vacuum system, enabling easy operation, monitoring, and precise adjustment of vacuum levels and process parameters.

Low Maintenance: Minimal maintenance requirements reduce downtime, ensuring continuous operation and cost-effectiveness.

Applications include Vacuum Distillation, System Pre-Evacuation, System Operating Vacuum Maintenance, Pumping System Priming, Vacuum Liquid Pumping, and Laboratory use.

Chem Process Systems stands as a trusted Manufacturer and Supplier of Skid Mounted Two Stage Steam Jet Vacuum System.

For in-depth information and expert guidance, we invite you to connect with Chem Process Systems or our dedicated team.

Read the full article

#Ahmedabad#ChemProcessSystems#CompactDesign#Crystallizers#Desalination#Distillation#Dryers#efficientejectors#EjectorsAndVacuumSystems#EthyleneGlycolVacuumSystems#EvaporationSystems#Exporter#Filters#GasExtractionandGeneration#Gujarat#India#Lowmaintenance#Manufacturer#MVRTypeEvaporationSystems#PowerPlantEquipment#PumpingSystemPriming#reliable#rugged#SkidMountedTwoStageSteamJetVacuumSystem#SpecializedFabrication#Steam-Powered#Supplier#SystemOperatingVacuumMaintenance#SystemPre-Evacuation#VacuumDistillation

0 notes

Text

Surface Condenser

Chem Process Systems Pvt. Ltd. is an ISO 9001-2015 firm.

Chem Process Systems Pvt. Ltd. is manufacture and supply Desalination, Ejectors And Vacuum Systems, Dryers, Distillation, Gas Extraction and Generation, Evaporation Systems, Power Plant Equipment, Specialized Fabrication, MVR Type Evaporation Systems, Crystallizers, Filters, Ethylene Glycol Vacuum Systems, and other products.

Surface condensers are commonly used in large power plants and refrigeration systems.

We have created expertise in the technology for versatile yet stiff surface condensers that can function under a variety of settings, forged with passion and devotion to offering the best to our clients.

To keep up with the ever-changing technology, we are constantly on the lookout for new ideas and incorporating innovative equipment and tools into existing plant structures in order to improve our technology and productivity and deliver a product designed and fabricated to the highest standards for its ultimate area of installation and usage.

We have designed and fabricated condensers for up to 220 TPH Capacity and fabricated rectangular condensers for up to 650 TPH.

We have delivered surface condensers to practically every industry and region in the world, including special certifications such as ASME U-Stamp, CE-PED, DOSH, CSA.

Available Types of Condenser

Top steam Inlet

Axial steam Inlet

Dual steam inlet

Chem Process Systems Pvt. Ltd. is a Manufacturer and Supplier of Surface Condenser.

For comprehensive details and expert guidance, we encourage you to engage in a conversation with Chem Process Systems or our dedicated team.

Read the full article

#Ahmedabad#AxialSteamInlet#ChemProcessSystemsPvt.Ltd.#Crystallizers#Distillation#Dryers#DualSteamInlet#EjectorsAndVacuumSystems#EthyleneGlycolVacuumSystems#EvaporationSystems#ever-changingtechnology#Filters#GasExtractionandGeneration#Gujarat#India#Manufacturer#ManufacturerandSupplierofSurfaceCondenser#MVRTypeEvaporationSystems#PowerPlantEquipment#SpecializedFabrication#Supplier#SupplierofSurfaceCondenser#SurfaceCondenser#TopsteamInlet

0 notes

Text

Agitated Nutsche Filter Dryer

Chem Process Systems Pvt. Ltd. is ISO 9001-2015 certified company.

Chem Process Systems Pvt. Ltd. is manufacture and supply Desalination, Ejectors And Vacuum Systems, Dryers, Distillation, Gas Extraction and Generation, Evaporation Systems, Power Plant Equipment, Specialized Fabrication, MVR Type Evaporation Systems, Crystallizers, Filters, Ethylene Glycol Vacuum Systems, and other products.

The Agitated Nutsche Filter is a machine that uses positive pressure to filter solids from a slurry.

A screen or cloth forces the slurry's liquid through to capture the solids.

In sterile applications, our machines are suitable, and we offer specific designs that can be installed in clean rooms.

The Agitated Nutsche Filter Dryer is high-quality equipment developed for solid-liquid separation processes in the pharmaceutical, chemical, fine chemical, and food industries using filtration under pressure and vacuum drying.

Features

Filtering surface from 0.5 m² to 15 m².

Operation capacity 10000Lit.

Batch-wise operation.

Design with absolute vacuum – Drying under vacuum and ultra vacuum.

Heating/ cooling of the body and/or agitator.

Operating pressure of 3 bar(g)

Operation Temperatures up to 200º C.

Design according to ASME VIII div.1 – AD-2000 – EN-13445.

Filter in textile, synthetics, metal, multilayer (sintered) or ceramic.

Bottom sealing system SUPERCLAMP.

Application

Pharmaceuticals

Chemical Industry

Food and Beverage

Petrochemical

Spciality Chemical

Biotechnology

Fine chemical

Agrochemicals

Chem Process Systems Pvt. Ltd. is a Manufacturer and Supplier of Agitated Nutsche Filter Dryer.

For comprehensive details and expert guidance, we encourage you to engage in a conversation with Chem Process Systems or our dedicated team.

Read the full article

#AgitatedNutscheFilterDryer#Ahmedabad#ChemProcessSystems#ChemProcessSystemsPvt.Ltd.#chemical#Crystallizers#Desalination#Distillation#Dryers#Dryingundervacuumandultravacuum#Ejectors#EthyleneGlycolVacuumSystems#EvaporationSystems#Filters#finechemical#GasExtractionandGeneration#Gujarat#High-performanceAgitatedNutscheFilterDryer#India#Manufacturer#MVRTypeEvaporationSystems#pharmaceutical#PowerPlantEquipment#SpecializedFabrication#Supplier

0 notes

Text

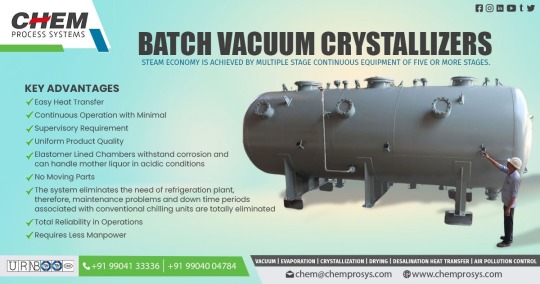

Batch Vacuum Crystallizer

Chem Process Systems is manufacture and supply Desalination, Ejectors And Vacuum Systems, Dryers, Distillation, Gas Extraction and Generation, Evaporation Systems, Power Plant Equipment, Specialized Fabrication, MVR Type Evaporation Systems, Crystallizers, Filters, Ethylene Glycol Vacuum Systems, and other products.

Chem Process Systems is ISO 9001-2015 certified company.

Industries use the Batch Vacuum Crystallizer, a specialized apparatus, to induce the formation of solid crystals from a solution or suspension.

It operates in batches under reduced pressure, controlling temperature and agitation to produce high-quality crystals for various applications.

Why Choose Our Batch Vacuum Crystallizers?

Solution Preparation: Introduce a solution or suspension containing the substance for crystallization into the crystallizer.

Crystallization Under Vacuum: The crystallizer operates in a vacuum environment, which lowers the pressure and reduces the boiling point of the solvent.

Precise Temperature Control: Precise temperature control fosters desired crystal growth and prevents the presence of impurities.

Crystal Separation: After completing crystallization, separate solid crystals from the remaining liquid, usually by filtration or centrifugation, producing the purified product.

Application

Pharmaceutical Manufacturing

Chemical Processing

Food and Beverage Production

Specialty Chemicals

Petrochemicals

Chem Process Systems is a Manufacturer and Supplier of Batch Vacuum Crystallizer.

For comprehensive details and expert guidance, we encourage you to engage in a conversation with Chem Process Systems or our dedicated team.

Read the full article

#BatchVacuumCrystallizer#ChemProcessSystems#Crystallizers#Desalination#Distillation#Dryers#EjectorsAndVacuumSystems#EthyleneGlycolVacuumSystems#EvaporationSystems#Filters#GasExtractionandGeneration#manufacture#Manufacturer#ManufacturerandSupplierofBatchVacuumCrystallizer#MVRTypeEvaporationSystems#PowerPlantEquipment#SpecializedFabrication#Supplier

0 notes

Text

Concentration Plant

Chem Process Systems Pvt. Ltd. is ISO 9001-2015 and OHSAS 18000-2007 certified.

We manufacture and supply Desalination, Ejectors And Vacuum Systems, Dryers, Distillation, Gas Extraction and Generation, Evaporation Systems, Power Plant Equipment, Specialized Fabrication, MVR Type Evaporation Systems, Crystallizers, Filters, Ethylene Glycol Vacuum Systems, and other products.

Chem Process Systems Pvt. Ltd. is a market leader in the production of Concentration plants, in which we use various heat and crystallization technologies separately or in combination to meet the needs of our clients.

Chem Process Systems Pvt. Ltd. is unrivaled in recognizing chemical reactions, physical and thermal changes, and phase identification, with over 100 installations in India and throughout the world.

Companies, in general, use powdered or solidified chemicals and dilute or liquefy them by adding water, solvents, or other fluids/liquids.

Following use, the companies would like to collect the extra water or secondary liquid at predetermined concentrations.

The chemical, pharmaceutical, agricultural, and fertilizer industries widely use fluidic chemicals.

These fluids can either be any Oil based viscous product, Acids or Alkalis

Chem Process has supplied plants for different applications like :

Sulfuric Acid Concentration

Amino Acid Concentration

Nitric Acid Concentration

Spent Acid Concentration

Organic Concentration

NaOH Concentration

KOH Concentration and many many more

Chem Process Systems Pvt. Ltd. is a Manufacturer and Supplier of Concentration Plant.

For comprehensive details and expert guidance, we encourage you to engage in a conversation with Chem Process Systems or our dedicated team.

Read the full article

#ChemProcessSystemsPvt.Ltd.#Crystallizers#Desalination#Distillation#Dryers#EjectorsAndVacuumSystems#EthyleneGlycolVacuumSystems#EvaporationSystems#Filters#GasExtractionandGeneration#MVRTypeEvaporationSystems#OrganicConcentration#PowerPlantEquipment#SpecializedFabrication#SpentAcidConcentration#SulfuricAcidConcentration

0 notes

Text

Liquid Jet Ejector Vacuum System

Chem Process Systems is a Manufacturer and Supplier of Liquid Jet Ejectors.

Chem Process Systems is accredited to ISO 9001-2015 and OHSAS 18000-2007.

We are Manufacturer and Supplier of Liquid Jet Ejectors, Desalination, Ejectors And Vacuum Systems, Dryers, Distillation, Gas extraction and Generation,

Evaporation Systems, Power Plant Equipment, Specialized Fabrication, MVR Type Evaporation Systems, Crystallizers, Filters, Ethylene Glycol Vacuum Systems etc.

The uniquely designed Liquid Jet Ejectors operate with water, solvent, or any other transparent liquid and generate vacuum equal to the liquid's vapor pressure.

In distillation and evaporation applications, they best suit situations with low non-condensable and high condensable loads.

To maintain liquid temperature in compliance with vacuum requirements, an external heat exchanger can be provided.

Combining a liquid jet ejector with a steam jet ejector system can achieve a higher vacuum level.

For ease of installation, the entire system can be supplied as a pre-assembled skid mounted unit.

How to work

Liquid jet ejectors are jet pumps, motivated by a high pressure liquid.

They use the kinetic energy of the pressure liquid to entrain gases and vapors, slurries and other liquids or granular solids and then discharge the resultant mixture against a counter pressure.

Advantage of our liquid Jet Ejectors

Maintenance free

Easy to operate

Facilitate for low level installation

Simple in design

Reliable in operation

No moving parts, hence minimal maintenance

Inline mixing of liquid and gas

Virtually silent operation

Suitable for hazardous areas

Custom designed

Chem Process Systems is a Manufacturer and Supplier of Liquid Jet Ejectors.

For comprehensive details and expert guidance, we encourage you to engage in a conversation with Chem Process Systems or our dedicated team.

Read the full article

#ChemProcessSystems#Crystallizers#Desalination#Distillation#Dryers#EjectorsAndVacuumSystems#EthyleneGlycolVacuumSystems#EvaporationSystems#externalheatexchanger#Filters#GasExtractionandGeneration#LiquidJetEjectorVacuumSystem#LiquidJetEjectors#Manufacturer#MVRTypeEvaporationSystems#PowerPlantEquipment#Supplier

0 notes

Text

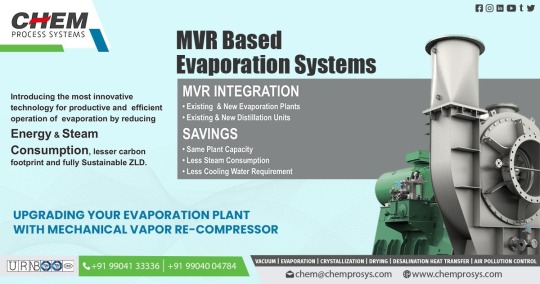

MVR Based Evaporation System

Chem Process Systems is accredited to ISO 9001-2015 and OHSAS 18000-2007 and Supplier of MVR Based Evaporation System.

We are Manufacturer and Supplier of Desalination, Ejectors And Vacuum Systems, Dryers, Distillation, Gas extraction and Generation, Evaporation Systems,

Power Plant Equipment, Specialized Fabrication, MVR Type Evaporation Systems, Crystallizers, Filters, Ethylene Glycol Vacuum Systems etc.

Chem Process System are designs, installs, and commissions Mechanical Vapor Recompression technology-based Evaporator systems.

The evaporated vapour goes via a compressor or high pressure fan, increasing the pressure by a factor of 1.2 to 2.0.

The higher pressure of the vapour allows it to supply the necessary energy and temperature difference for evaporation.

Mechanical recompression evaporation may be less expensive than TVR evaporation.

The MVR design, used for pre-concentration instead of a membrane system, operates efficiently and demands minimal maintenance.

The great efficiency of a Chem MVR Evaporator System can contribute significantly to your energy savings program.

Features

Calandria deaeration, as well as easy examination and cleaning.

The static liquid distribution system ensures that all tubes in the calandrias receive the same amount of liquid at all times and can withstand large changes in

liquid flow and flash vapor.

Chem's freestanding form saves floor area requirements and building expenses while also being adaptable for installation in existing structures.

Controlled vapor velocities with tangential input and outflow ensure minimal pressure losses, resulting in efficient liquid-vapour separation.

Automated CIP producers significantly reduce cleaning costs.

Instrumentation is tailored to the needs of the customer, including PLC controllers that can maximize product and quality.

Chem Process Systems is a Manufacturer and Supplier of MVR Based Evaporation System.

For comprehensive details and expert guidance, we encourage you to engage in a conversation with Chem Process Systems or our dedicated team.

Read the full article

#ChemProcessSystems#Crystallizers#Desalination#Distillation#Dryers#EjectorsAndVacuumSystems#EthyleneGlycolVacuumSystems#EvaporationSystems#Filters#GasExtractionandGeneration#Gujarat#India#Manufacturer#minimalpressurelosses#MVRBasedEvaporationSystem#MVRTypeEvaporationSystems#PowerPlantEquipment#resultinginefficientliquid-vapourseparation.AutomatedCIPproducers#SpecializedFabrication#Supplier

0 notes

Text

Gas Extraction and Generation

Chem Process Systems is an ISO 9001-2015 and OHSAS 18000-2007 certified company.Chem Process Systems are manufacturer and supplier of Desalination, Ejectors And Vacuum Systems, Dryers, Distillation, Gas extraction and Generation, Evaporation Systems, Power Plant Equipment, Specialized Fabrication, MVR Type Evaporation Systems, Crystallizers, Filters, Ethylene Glycol Vacuum Systems etc.

We are Manufacture and Supplier of Two types of Pressure Swing Adsorption Systems.PSA Oxygen Generation plantWe use PSA (Pressure Swing Adsorption) technology in our Oxygen Gas Plant.

We produce cost-effective oxygen gas plants requiring minimal maintenance, ensuring timely and desired results.

Our Generators absorb nitrogen using two absorption vessels loaded with the most efficient zeolite molecular sieves for nitrogen absorption.

Zeolite molecular sieves fill two towers, adsorb nitrogen, and then discharge waste.PSA Nitrogen Generation plantOur nitrogen plant, powered by PSA technology, comprises twin towers, each packed with a special grade of carbon molecular sieves.

We provide a PSA Nitrogen Gas Plant if a higher pressure is required at the discharge.

We can normally provide a discharge pressure of about 6 kg/cm2g with our PSA system, but we can increase it to a higher pressure of 150 kg/cm2g depending on the client's needs.Chem Process Systems is a manufacturer and supplier of Gas Extraction and Generation.

For comprehensive details and expert guidance, we encourage you to engage in a conversation with Chem Process Systems or our dedicated team.

Read the full article

#Ahmedabad#ChemProcessSystems#cost-effectiveoxygengasplants#Crystallizers#Desalination#Distillation#Dryers#EjectorsAndVacuumSystems#EthyleneGlycolVacuumSystems#EvaporationSystems#Filters#GasExtractionandGeneration#Gujarat#India#Manufacturer#MVRTypeEvaporationSystems#OxygenGasPlant#PowerPlantEquipment#PSAtechnology#SpecializedFabrication#Supplier

0 notes

Text

Agitated Thin Film Dryers-Chem Process System

Agitated Thin Film Dryers-Chem Process System

Chem Process Systems manufactures and supplies a comprehensive range of equipment, including Agitated Thin Film Dryers, Ejectors, Vacuum Systems, Distillation Units, Gas Extraction and Generation Systems, Evaporation Systems, Power Plant Equipment, Specialized Fabrication, MVR Type Evaporation Systems, Crystallizers, Filters, and Ethylene Glycol Vacuum Systems.The Agitated Thin Film Dryer (ATFD) is pivotal for vacuum drying heat-sensitive products and ensuring full solvent recovery.

This high-throughput system efficiently operates under vacuum conditions, employing indirect heating and drying in inert environments. This approach is particularly effective for heat and oxygen-sensitive products.Our vertical ATFD design caters to a wide spectrum of process fluids, including liquids, slurries, and pastes. By enabling a continuous single-pass operation, these process fluids are transformed into free-flowing solids.

Our dryers are widely used across various industries to convert liquids, slurries, and pastes into free-flowing solids through continuous single-pass operation.

The self-cleaning heating surfaces of our dryers minimize maintenance requirements for moving parts over the long term.

Advantages:

Excellent heat conductivity (k-value), even with highly viscous and contaminated products

The synergy of low operating capacity and brief dwell time results in minimal thermal stress, elevating overall performance significantly.

High evaporation rates attributed to highly turbulent film and significant temperature differences

Gentle evaporation resulting from short residence times, rapid conveyance in the heated zone, and constant product film renewal

Furthermore, applying vacuum operation leads to lowered boiling points, yielding a substantial overall process efficiency improvement.

Thin film thickness without hydrostatic height

High turndown ratio and flexibility for varying requirements

Low operating pressure, reaching as low as 1 micron to lower boiling temperature

These systems find application in Zero Liquid Discharge systems for drying concentrated effluents, preventing thermal degradation by reducing impurities, and enhancing the removal of highly volatile components from viscous products.

Furthermore, they aid in producing continuous dry powder, concentrating Vegetable Extracts, Animal Products, sugars, Bio-Acids, Bio-alcohols, and more.

Chem Process Systems proudly serves as a Manufacturer and Supplier of Agitated Thin Film Dryers.For comprehensive details and expert guidance, we encourage you to engage in a conversation with Chem Process Systems or our dedicated team.

Read the full article

#AgitatedThinFilmDryers#AgitatedThinFilmDryers-ChemProcessSystem#Ahmedabad#AnimalProducts#ATFD#Bio-alcohols#ChemProcessSystem#continuousdrypowder#Crystallizers#EthyleneGlycolVacuumSystems#EvaporationSystems#Filters#Gujarat#India#pastes#slurries#sugars

0 notes

Text

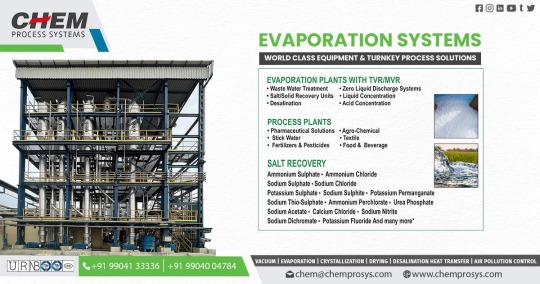

Manufacturer and Supplier of Evaporation System

Chem Process Systems is an established leader in the supply of process equipment for Vacuum, Evaporation, Crystallization, Drying and Heat Transfer applications.

Evaporation starts with inputs in a liquid form and outputs are more concentrated but still liquids in a pump able state.

It is important that the product under evaporation is subject to minimum thermal degradation, hence bespoke design of equipment is mandatory to ensure that the temperature and time of exposure minimal.Chem Process's evaporation technology provides a proven solution, where they reuse the condensates as make-up water and recycle the recovered crystalline products for profitable industrial production.We offer complete solutions by combining evaporation with other options of pre and after treatment.

Having supplied more than 100 plants in process industries for the treatment of various industrial effluents and concentration of many liquids, the field experience from the design and manufacture along with continued research and development have resulted in a unique expertise in this technology.

Evaporator Types:

Falling film

Natural circulation

Rising film

Forced circulation

Plate type

Horizontal Wetted Tube

Combination types

Thermal vapour compressions, TVR

Mechanical vapour compression, MVRProduct concentration

Evaporator Applications

Product concentration

Dryer feed pre-concentration

Volume reduction

Water/solvent recovery

Features

Heat source: They utilize the heat source to vaporize the liquid. This can be a steam boiler, a hot oil bath, or an electric heater.

Condenser: The condenser is used to condense the vapor back to a liquid. This can be a water-cooled condenser, an air-cooled condenser, or a vacuum condenser.

Separator: The separator is used to separate the condensed liquid from the gas. This can be a simple settling tank or a more complex centrifugal separator.

Control system: The control system controls the temperature and flow of the liquid and gas. This can be a simple on/off controller or a more complex PID controller.

Chem Process Systems is a Manufacturer and Supplier of Evaporation System.

For further details and professional assistance, it is recommended to have a conversation with Chem Process Systems or their team.

Read the full article

#EvaporationSystem#Fallingfilm#HorizontalWettedTube#ManufacturerandSupplierofEvaporationSystem#SupplierofEvaporationSystem

0 notes