#Filling Machine Manufacturers

Explore tagged Tumblr posts

Text

Cup Filler Machines Manufacturer in Haryana

A Cup Filler Machines Manufacturer in Haryana specializes in producing automated machines for filling pre-formed cups with liquids, powders, or granules. These machines ensure precise filling, fast processing speeds, and minimal waste, making them ideal for the food, beverage, and pharmaceutical industries. With a focus on innovation and quality, the manufacturer provides tailored solutions to meet diverse packaging needs.

#Cup Filler Machines Manufacturer in Haryana#Form Fill Seal Machines Manufacturer in Haryana#Auger Filler Machines Manufacturer in Haryana#Automatic Pouch Packaging Machine Manufacturer in Faridabad#Packaging Equipment Manufacturer in Faridabad

2 notes

·

View notes

Text

Dairy Packaging Machine I Dairy Product Packaging Machine I Nichrome Africa

#milk filling machine#milk packaging machine#nichrome mini diary plant in africa#diary plant manufacture in africa#dairy packaging machine#yogurt packaging machine

0 notes

Text

Enhancing Edible Oil Packaging: Nichrome's Advanced Machinery in Bangladesh

The edible oil industry in Bangladesh is witnessing a golden era. From bustling metros to emerging industrial zones, the demand for high-quality oils like soyabean, mustard, palm and other blended varieties is at an all-time high. With the rising health and safety awareness, the preferences of the modern-day consumer have also evolved. This has led to a significant rise in the demand for safer and tamper-proof packaging while packaging edible oils.

In this quality and compliance-driven market, edible oil packaging plays a vital role. It preserves freshness, prevents leakage, and deters contamination, leading towards building a stronger consumer trust with every single pouch or bottle that reaches their hands. This is since today’s consumers look at how the product is packed and carried, and not just at what’s on the cover.

Enter Nichrome, a pioneer in packaging and a trusted partner to some of Bangladesh’s biggest edible oil brands. With our innovative and reliable Nichrome packaging machines, we have set new benchmarks in providing state-of-the-art oil packaging machines that provide high performance, safety and flexibility.

We have been empowering edible oil manufacturers to modernise their packaging operations. Whether you are a large-scale producer or a mid-sized business with growing ambitions, our tailored oil filling machine solutions are built to scale with your success.

Packaging Challenges in the Edible Oil Industry

It is not just about filling and sealing when it comes to packaging edible oils; it is about the fine balance that demands precision, speed, and adaptability. The unique characteristics of oils like mustard, soybean, and vanaspati render standard solutions ineffective. Let’s take a look at the real-world challenges that arise when it comes to packaging these assorted oils:

Handling Viscosity: Thick oils require a specially designed machine that dispenses without creating air pockets or spills. Our high-performing viscous liquid filling machine ensures smooth, uninterrupted flow

Volume Control: Be it filling compact 100ml sachets or big 1-litre pouches, precision is critical in both. Our manual liquid filling machines help you maintain exact volume with minimal wastage.

Precision with Speed: Time is money, especially when consumer demand surges. Therefore, edible oil brands need machines that can seamlessly deliver high-speed performance without compromising on accuracy.

Hygiene & FSSAI Compliance: Every single drop of oil needs to be handled with care. Machines must offer food-grade contract parts, easy cleaning, and a design that can successfully align with strict hygiene standards.

Packaging Versatility: From sachets and spout pouches to rigid bottles, the machinery must adapt to various packaging formats. Our oil packaging machines ensure flexibility with every SKU

In Bangladesh, packaging needs range from traditional to modern, and these challenges can’t be ignored. Fortunately, we at Nichrome have engineered solutions that don’t just meet these industry needs; they surpass them. With a vast range of options from manual liquid filling machines to fully automated oil packing systems, we at Nichrome help edible oil brands overcome these hurdles with efficiency and elegance.

Nichrome’s Solution: Advanced oil packaging machines

As Bangladesh’s edible oil industry keeps on growing in volume and variety, packaging demands are becoming increasingly nuanced. This is exactly we at Nichrome step-in, with our custom packaging solutions that can easily align with the regional needs, packaging formats, and product types. Our oil packaging machines bring precision, consistency, and flexibility to every drop that is being packed.

Key Machines for Oil Packaging:

Our vast portfolio of oil packaging machines is a blend of innovation and adaptability:

Filpack Servo SMD – Ensures smooth and precise fills with zero spills, making it ideal for viscous oils like mustard, vanaspati, or ghee.

Automatic Liquid Packaging Machines – Offers high-speed efficiency with hygienic reliability, most suited for high-volume pouch and sachet operations.

Servo Filling Machines – Provides real-time filling control powered by servo technology, while delivering pinpoint accuracy and consistent fills across batch sizes.

Pouch Liquid Filling Machines – Affordable, scalable, and designed for flexibility in formats and volumes, ideal for startups and mid-scale units.

Technical Features:

Our smart and robust packaging machines don’t just fill but elevate your operation:

Servo-driven filling for high precision and minimal wastage

PLC-based intelligent control system with user-friendly interface

Stainless steel hygienic build to meet food safety regulations

Flexibility across 100ml to 1-litre packs with smooth volume adjustments

Output: Up to 85 packs/min, depending on product and pack size

Adaptability to bottles, sachets, spouted pouches, and other consumer formats

Together, these features ensure that every single Nichrome machine becomes a smart investment for you, maximising output while maintaining the highest quality and hygiene standards. Whether you are producing premium mustard oil or daily-use cooking oil packets, our oil packaging machines deliver the consistency you can easily count on.

Benefits of Using Nichrome Packaging Machines

When you partner with Nichrome, you get more than a machine; you get a head start on the future of streamlined operations and superior product quality. Here’s how:

Improved Production Efficiency: Avoid bottlenecks and get faster fill rates and uninterrupted flow, giving your production line momentum

Minimal Wastage & High Filling Accuracy: With every drop being extremely valuable, our servo-driven technology ensures that each pouch or bottle receives exactly the right amount

Leakage Prevention: Strong and even seals keep oil fresh, making leakage a thing of the past

Reduced Labour Dependency: Automation reduces operational costs, eliminates manual errors, and increases daily output without requiring an increase in your workforce

Quick Format Changeovers: From volume to pack types, easily adapt to market shifts in real-time with our advanced and flexible packaging machines

Compact Design: Our machines can deliver industrial-grade performance in a small footprint as they are designed for the space-starved production units, even in urban Bangladesh.

With all these advantages, we at Nichrome don’t just improve the way you pack oil, but instead enable you to transform your entire production lifecycle into a more profitable, precise and progressive one.

Supporting a Growing Industry: Nichrome in Bangladesh

As the edible oil sector in Bangladesh is rising to meet the growing domestic consumption and global export demand, oil packaging has become a strategic differentiator. In this shift, Nichrome stands strong beside growth, empowering businesses with technology, training and trust.

With us you get:

Local Support: Our local presence ensures seamless onboarding, with a team of experts for installation, hands-on training, and ongoing maintenance right here in Bangladesh.

Strong Customer Base: From leading FMCG giants to agile small-scale entrepreneurs, our Nichrome packaging machines power a wide spectrum of edible oil producers.

Wide Range of Options: Machines like Sprint 250 Plus, Excel 400, and Filpack Servo are the backbone of efficient oil packaging machines, delivering speed, hygiene, and impressive ROI.

In short, we are not just selling machines, we are fuelling an entire packaging revolution across the country.

Future Trends in Edible Oil Packaging

As consumer preferences are shifting and technology is advancing, the edible oil packaging landscape is also rapidly evolving, and we at Nichrome are proud to be at the forefront of this transformation. Beyond simply meeting today’s packaging needs, we are engineering solutions for tomorrow’s challenges. Nichrome packaging machines are designed not just for efficiency and hygiene, but for adaptability in a tech-driven and sustainability-conscious world.

Smart Packaging Integration: The future is interactive. Thanks to the implementation of QR codes, barcodes, and batch traceability functionalities, oil packaging now has the potential to carry important product information, best-before dates, and even brand history directly to the consumers

Artificial Intelligence for Quality Control: We're employing artificial intelligence to track fill quantity, detect leaks, and validate packaging integrity—all in real time, with no human error.

Fortified Oil Support: As the market demand for fortified oils and vitamin-enriched oils is increasing in Bangladesh, Nichrome machines provide batch-wise consistency and regulatory compliance for each pouch or bottle.

The future is smart, sustainable, and sensitive to both market trends and consumer wellbeing. We at Nichrome are paving the path forward, one intelligent innovation at a time.

Conclusion

In the fast-paced edible oil sector of Bangladesh, the consumer demand is soaring, hygiene has become non-negotiable, and competition is fierce. Under this scenario, the difference between good and memorable often lies in your packaging line. With fortified and value-added cooking oils gaining ground, good packaging has now become a strategic advantage more than just an operational need.

At Nichrome, we understand that every drop counts; therefore, our oil packaging is about helping your business stay ahead. Whether you are filling mustard oil in a small unit or packaging refined soybean oil for urban supermarkets, we deliver solutions that are tailored to your needs. Our oil filling machines, automatic liquid packaging machines, and pouch liquid filling machines are engineered to meet the real-world challenges by handling viscosity, reducing spillage, and maintaining hygiene with clockwork precision.

With our local presence in Bangladesh, we ensure smooth operations round the clock, be it installation, training or after-sales services. We are proud to partner with several leading FMCG brands and fast-growing SMEs across the country, offering reliable automation solutions that scale with your ambition.Whether you’re a new entrant or a market leader, we empower you to rise, adapt, and lead with smart, scalable, and high-performance Nichrome packaging machines. From compact units like the Filpack Servo SMD to versatile solutions like the Excel 400, we help you unlock operational excellence without overshooting your budget.

#manual liquid filling machines#Filpack Servo SMD#Pouch Liquid Filling Machines#oil packaging#oil filling machines#edible oil packaging#Nichrome packaging machines#oil packaging machines#oil filling machine#viscous liquid filling machine#packaging solutions#Automatic Liquid Packaging Machines#Automatic Liquid Packaging Machine#Ghee packing machine manufacturer#Oil packing machine manufacturer#Edible oil packing machine#Oil packing machine manufacturers#Oil packaging machines#Cooking oil packing machine#Oil pouch packing machine#Oil filling machine#Edible oil filling machine manufacturers#Oil filling machine manufacturer#Edible oil filling machine#Automatic oil filling machine

0 notes

Text

Eco-Friendly Agrochemical Packaging: How India’s Manufacturers Can Stay Ahead of Global Sustainability Trends

The rising agricultural demand and growing awareness of modern farming practices have led to the flourishing of the Indian agrochemical sector and increased export opportunities. However, this growth has come at a time when environmental sustainability is under strict global scrutiny. As agrochemical usage increases, so does the volume of packaging waste, prompting regulatory bodies and environmentally conscious consumers to challenge traditional packaging materials.

#agrochemical#agrochemical packaging#intelligent packaging lines#agrochemical manufacturers#packaging machine manufacturer#Vertical Form Fill Seal (VFFS) Machines#liquid packaging machines#End-of-line Automation#agrochemical packaging solutions#end-to-end packaging solutions#track-and-trace technology innovations#powder filling machine#bulk bag filling machine#automatic carton box packing machine#powder bottle filling machine#case packer manufacturers india#automatic case erector#carton box packing machine#carton packing machine#automatic bottle filling machine#horizontal flow wrap machine#bottle filling machine

0 notes

Text

Induction Sealing Machine Price Starts at ₹4,999 – Sonic Industries

Looking for the best induction sealing machine price in India? Sonic Industries offers induction sealers starting at just ₹4,999 up to ₹1,04,720, suitable for all bottle types and industries. Combine it with solutions from a trusted liquid filling machine manufacturer for a complete packaging line.

#induction sealing machine price#induction sealer#bottle sealing machine#liquid filling machine manufacturer

0 notes

Text

Top Tube Filling Machine Manufacturer in Mumbai | Rahul Packaging

Rahul Packaging is a trusted tube filling machine manufacturer in Mumbai, offering high-performance, durable, and customizable filling solutions for pharmaceuticals, cosmetics, food, and chemical industries. Our machines ensure precise filling, sealing, and coding for plastic, laminated, and aluminum tubes. Backed by years of engineering excellence, we deliver quality, reliability, and expert support to meet your production needs.

0 notes

Text

Top Packaging Machines for All Industries | Munky Packaging Machine

Looking for a High-Quality Packaging Machine to Streamline Your Business? Munky Packaging Machine Offers Durable, Efficient, and Versatile Solutions for a Wide Range of Industries Including Food, Agriculture, Chemicals, and Fmcg. Our Machines Are Designed for Precision, Speed, and Hygiene, Ensuring Your Product Is Packed Perfectly Every Time. Whether You're Packaging Powders, Granules, or Liquids, We Have the Right Equipment to Meet Your Needs. with Advanced Technology and a Strong Support System, Munky Ensures Minimal Downtime and Maximum Productivity. Choose a Packaging Machine That Boosts Efficiency and Reduces Labor Costs. Visit Our Website or Call to Get Started Today.

Call Now:- 9599919442

#Packaging Machine#Packing Machinery#Automatic Packing Machine#Chips Packing Machine#Filling Machine#Best packaging machine for small businesses#Industrial packaging machine manufacturers in India#High-speed packing machinery for FMCG industry#Packing machinery for spices and powders#Automatic packing machine for granules and powders#Affordable automatic packing machine in India#Fully automatic chips packing machine in India#Chips packing machine for small scale industry#Auger filler filling machine for masala and flour#Liquid filling machine with automatic capping

0 notes

Text

How to Maintain Hygiene in a Bottled Water Plant

In today’s fast-paced world, where access to clean drinking water is becoming increasingly important, the demand for bottled water continues to rise.

But with this growing demand comes a major responsibility—hygiene.

Whether you operate a packaged drinking water plant or a mineral water plant, maintaining high standards of hygiene is not just a legal requirement, it's a moral obligation to the health and safety of your customers.

Clean water can turn into a health hazard if the bottling process is not hygienically maintained.

Consumers trust your mineral water bottle for purity—so that’s exactly what you need to deliver every time.

In this blog, we'll break down the essential practices, tips, and guidelines to ensure your bottled water plant stays hygienic and safe.

1. Understand the Importance of Hygiene in Bottled Water Production

Let’s start with why hygiene matters so much.

Contaminated water, even after treatment, can become a source of illness if it's bottled or stored in unsanitary conditions.

Pathogens, bacteria, and chemical residues can infiltrate at any point—whether through unclean machinery, poor handling, or improper storage.

Maintaining hygiene not only ensures public safety but also protects your brand reputation and prevents expensive recalls or penalties from regulatory bodies.

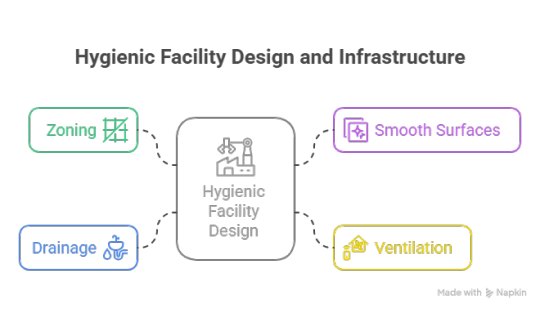

2. Facility Design and Infrastructure

A hygienic plant starts with proper design. Here’s what to keep in mind:

Zoning:

Divide the facility into clean and non-clean areas. Water treatment and bottle filling zones must be strictly restricted.

Smooth Surfaces:

Walls and floors should be made of non-porous, easy-to-clean materials. Avoid cracks where mold or bacteria can grow.

Ventilation:

Install proper air filtration systems to avoid airborne contaminants.

Drainage:

Water should flow away from production areas. Poor drainage is a major hygiene hazard.

Pro Tip: If you’re consulting a mineral water plant manufacturer, ensure they help you design a layout that supports sanitary flow—from raw water entry to bottled product exit.

3. Equipment Sanitation

All machinery—whether it’s for RO purification, UV disinfection, or ozone dosing—must be regularly cleaned and sanitized.

Regular Cleaning Schedules:

Create a Standard Operating Procedure (SOP) for cleaning each machine. Whether it’s the bottle washer, filler, capper, or labelling unit, each piece must be cleaned daily or weekly depending on usage.

Use Food-Grade Cleaners:

Avoid industrial chemicals that may leave residues. Use only certified, food-grade sanitizing solutions.

Maintenance Logs:

Keep a documented log of every cleaning and maintenance task for audits and compliance checks.

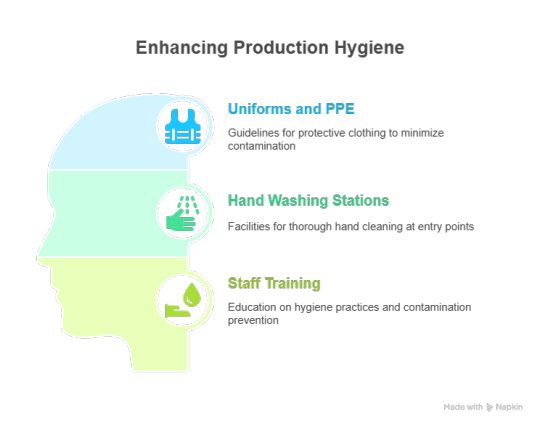

4. Staff Hygiene and Training

People are one of the most common sources of contamination in any production environment.

Uniforms and PPE:

Employees must wear clean uniforms, gloves, masks, and hairnets. Footwear should be exclusive to the production zone.

Hand washing Stations:

Install hand washing units at all entry points. Include soap, hand sanitizer, and disposable towels.

Staff Training:

Train your employees on personal hygiene, cross-contamination prevention, and equipment handling. Refresher sessions every 3-6 months are ideal.

Remember: In any mineral water plant, staff plays a crucial role in maintaining cleanliness. Empower them with knowledge.

5. Water Source and Pre-Treatment

Before even entering the bottling line, your raw water must go through stringent checks.

Source Quality:

Whether it’s borewell, municipal, or spring water, test the source regularly for chemical and biological contamination.

Laboratory Testing:

A well-equipped in-house lab or partnership with an accredited third-party lab can ensure water parameters are consistently within safe limits.

Filtration and Disinfection:

Use multi-stage purification methods: sand filter, carbon filter, RO (reverse osmosis), UV, and ozone. This not only enhances taste and purity but also meets BIS standards.

6. Bottle and Cap Hygiene

Often overlooked, bottles and caps can be a major source of contamination if not handled correctly.

Bottle Washing:

Whether you're using PET or glass, each bottle must be thoroughly cleaned before filling. Automatic rinsing machines using treated water and sanitizing agents are ideal.

Cap Sterilization:

Caps can carry microbes, especially if stored improperly. Use UV sterilizers or chemical sanitizers before capping the bottle.

Storage of Empty Containers:

Store bottles and caps in a dust-free, insect-proof room.

7. Filling and Packaging

This is where the product is most vulnerable. One small lapse can contaminate the entire batch.

Clean Room Environment:

Bottle filling areas must be sealed and maintained as sterile zones. Use laminar airflow cabinets if possible.

Automated Systems:

Minimize manual handling during filling, capping, and labeling to reduce contamination risk.

Temperature Control:

Maintain a cool and dry environment. High temperatures can breed bacteria, especially in sealed containers.

8. Pest Control and Waste Management

Uncontrolled waste and pests can destroy even the best hygiene practices.

Pest Control:

Implement regular pest control treatments through certified agencies. Keep detailed records.

Waste Segregation:

Separate recyclable, biodegradable, and hazardous waste. Ensure timely disposal of sludge, rejected water, and used filters.

Clean Environment:

Don’t just clean machines—clean floors, walls, storage racks, and air vents too.

9. Compliance with Government Regulations

In India, every mineral water plant must comply with BIS (Bureau of Indian Standards) norms and FSSAI (Food Safety and Standards Authority of India) regulations.

Regular Inspections:

Schedule internal audits and be ready for surprise inspections from regulatory bodies.

Maintain Documentation:

Keep records of water tests, batch production, cleaning logs, staff training, and pest control for at least a year.

10. Quality Assurance and Final Testing

After bottling, before sending it to the market, test your water again.

Microbiological Testing:

Ensure no pathogens like E. coli, Salmonella, or coliforms are present.

Final Approval:

Send samples from each batch to an external lab for validation.

Storage Before Dispatch:

Keep finished bottles in a cool, dry, and dust-free storage room. Avoid direct sunlight.

Conclusion

Maintaining hygiene in a bottled water plant isn’t just about compliance—it’s about protecting your brand, your customers, and your peace of mind.

From sourcing water to delivering the final mineral water bottle to the end user, every step should reflect your commitment to quality.

Partnering with a reliable mineral water plant manufacturer can make this easier. The right supplier will not only help you with top-grade machinery but also guide you on plant layout, hygiene protocols, and compliance.

By following the best practices shared above, you can ensure that every bottle that rolls off your production line is a symbol of trust, purity, and care.

Are you planning to set up a new mineral water plant or upgrade your existing one?

Let's discuss how you can implement hygienic systems that are efficient and regulation-ready.

#mineral water plant#mineral water plant manufacturer#water bottle filling machine#mineral water filling machine#packaged mineral water#water bottle making machine

0 notes

Text

12 Compelling Benefits of Semi Automatic Filling & Sealing Machine in India’s Dairy Industry

Semi automatic filling & sealing machines, provided by leading filling and sealing machine manufacturer, optimize the utilization of packaging materials, effectively minimizing waste. These cutting-edge machines guarantee precise sealing, eliminating the necessity for excessive material usage. By curbing material waste, dairy manufacturers not only save costs but also align themselves with sustainable practices.

The expertise of a trusted filling and sealing machine manufacturer ensures that the semi-automatic filling & sealing machines not only enhance operational efficiency but also contribute to environmental responsibility in the dairy industry.

0 notes

Text

Granule Filling Machine

We are a Granule Filling Machine Manufacturers & Exporters in Gujarat, India. The Granule Filling Machine is a high-precision, versatile solution designed for the efficient filling of various granular products ranging from seeds, grains, and spices, to powdered material. Developed to handle multiple packing sizes with consistent speed and accuracy, it is an option that fits well in small as well as large-scale production lines. Being multifunctional, the reliability and ease of operation enhance the assurance that each package is filled accurately, reducing waste and optimizing the filling process.

Designed for industrial application, the Granule Filling Machine features smooth operation with minimal need for manual intervention but still assures the highest quality. It is a robust machine that can support a range of granular products that cut across various fields.

#Granule Filling Machine#Granule Filling Machine exporters#Granule Filling Machine Manufacturers#Granule Filling Machine exporters in Gujarat#Granule Filling Machine Manufacturers in Gujarat#Granule Filling Machine exporters in India#Granule Filling Machine Manufacturers in India

0 notes

Text

Innovations in Dairy Product Packaging Machines: Enhancing Shelf Life and Hygiene for Africa’s Dairy Sector

The Dairy industry in Africa is milking every opportunity to expand, driven by the rising population, increasing health and wellness awareness, and growing urbanisation. This has been stemming from the increasing demand for safe, fresh, and longer-lasting dairy products, be it milk, yogurt, and margarine, to flavoured milk, cream or even dairy powders.

However, how can you ensure a higher-quality product from farm to fridge in a continent where climate, infrastructure, and logistics can pose significant challenges? The answer to this problem is “Smart Dairy Packaging” with Nichrome. With 40+ years of pioneering experience in dairy packaging machines, we at Nichrome are at the frontlines of delivering innovative, efficient, and hygienic dairy solutions that are at par with the unique needs of the African markets.

With our smart and high-performing milk packaging machines and yogurt packaging machines, we, as the leading milk pouch packing machine manufacturers, are empowering African dairy producers to overcome bottlenecks in every segment.

Ready to pour into the details? Let’s dive into the creamy layers of dairy packaging innovation.

Types of Dairy Products and Their Packaging Needs

From farm-fresh milk to creamy yogurts and margarine, and powdered dairy goodness, every dairy product comes with its packaging personality. The key to delivering high-quality dairy products lies in understanding the unique packaging required and then tailoring packaging machines to handle them with precision, care, and hygiene. Our specialised range of dairy packaging machines caters to the entire dairy spectrum.

Let’s unpack the packaging needs of different dairy products and how Nichrome has been rising to the challenge:

Milk: Pouches and bottles that preserve liquid purity

Milk needs airtight, leak-proof and contamination-free packaging as it is highly perishable. Whether it’s pouches for rural markets or bottles for the urban retail, our milk packaging machines offer unmatched speed, precision, and hygiene.

Sprint 250 Plus and Excel Plus milk pouch packing machines – Ideal for small to large-scale milk packing needs.

Automatic lines with milk bottle filling machines - milk bottling in glass or PET bottles

Pouches are formed, filled, and sealed with minimal human contact, with hygienic processing.

Flavoured Milk: Keeping it Tasty & Cool

The delicious flavoured milk is a growing category among African youth. The products require tamper-evident packaging that preserves flavour and nutrients.

Our viscous liquid filling machines ensure accurate filling of flavoured milk varieties.

Multi-purpose milk filling machines can accept pouches, PET bottles, and Tetra Pak substitutes.

Advanced packaging maintains shelf stability without requiring preservatives.

Yogurt & Curd: Thick, Creamy, and Contained

Viscous and semi-solid, curd, and yogurt need extra care. We provide yogurt packaging machines with soft filling technology that prevents air pockets or spoilage.

Servo-driven filling provides hygiene and consistency.

Suitable for cups, pouches, or sachets.

Tamper-proof sealing ensures freshness and trust.

Ghee, Margarine, & Cream: The Rich Delights

For more viscous milk products such as cream, margarine, and ghee, accuracy and hygiene are important. Our milk products packaging machines provide heat-sealed, aseptic packaging that provides maximum shelf life.

Thicker consistencies with specific nozzles.

Perfect for pouch, jar, and cup packaging.

High-temperature packaging films prolong freshness.

Dairy Powders: Light but Strong

Milk powder, whey, and baby formula need protective packaging that is oxygen and moisture-proof.

Dry powder filling machines provide vacuum sealing and nitrogen flushing for extended shelf life.

Case packaging and retail-ready SKUs available.

Assists dairy processors in meeting export requirements.

Whatever your product pours, scoops, flows, or sprinkles, Nichrome has a dairy and milk packaging machine that can do it fast, hygienically, and accurately. From optimizing shelf life to optimizing operational efficiency, Nichrome's flexible packaging machines have Africa's dairy treats ever ready to serve, fresh and fabulous.

Major Packaging Challenges for Dairy Products

With the growth of the dairy business in Africa comes the need to keep packaging at the level required to meet demand, sanitation, and sustainability requirements. Dairy packaging is not a matter of simply covering milk—it's about purity, preventing loss, and defending brand reputation. But for the vast majority of dairy farmers on the continent, the path from cow to consumer is not without its complications.

The following are the biggest challenges that African dairies face, and how we help solve those:

Hygiene Maintenance - Milk and milk products are nutrient-rich but prone to bacterial contamination. Our milk filling machines are equipped with Clean-In-Place (CIP) facilities and stainless-steel construction to provide utmost sanitation.

Spoilage Prevention - Temperature fluctuation during storage and transport is prevalent throughout Africa. Nichrome battles this with air-tight, leak-proof pouches and high-barrier packaging films.

Handling Different Consistencies - From thin milk to thick ghee, yogurt, or margarine, every single product has a special flow. Our milk packaging machines feature speciality nozzles and programmable filling logic to accommodate any viscosity.

Affordability & Flexibility - Small dairies require scalable solutions. We provide milk packing machines and semi-automatic lines that are affordable to tight budgets without sacrificing performance.

It's obvious, dairy packaging in Africa is not a mass market phenomenon. It takes flexibility, dependability, and creativity. We at Nichrome not only get these issues, but we also address them. With a range of dairy packaging machines that are ideally suited to African conditions, we provide producers with the equipment they need to succeed in a competitive, fast-moving market. Because at Nichrome, we don't merely package dairy—we empower it.

Advanced Features in Nichrome's Dairy Packaging Machines

When it comes to packaging milk in a tough and dynamic market such as Africa, efficiency is not sufficient; you require smart, flexible, and forward-looking machines. At Nichrome, innovation is infused in each nut and bolt. Our milk & dairy packaging machines raise the bar on automation to deliver smarter, more efficient solutions that meet real-world requirements.

Here’s the breakdown of the features that set Nichrome's milk packing machines apart:

Automatic Pouch Filling & Sealing

Automatically operated models are the Sprint 250 Plus, Filpack Servo 12K, and Filpack CMD.

Provide uniform pouch sealing with minimal operator interference.

Servo-based operations produce fault-free sealing at high speeds.

Bottle & Jar Filling Lines

From bottling milk to curd in jars, we champion all the varied formats.

Modular systems allow easy integration into existing plants.

General-purpose for flavoured milk, yogurt, and margarine.

Hygienic CIP Systems

Equipments have Clean-In-Place capability for sanitary processing.

Conserves time, water, and detergent compared to hand washing.

Proper Filling for Viscous & Liquid Products

The milk filling machines employ piston and servo-based technology.

Oversees everything from raw milk to cream, yogurt, and margarine.

Reduces overfill loss and is cost-effective.

Packaging Material Compatibility

It accommodates high-barrier laminates, mono-material films, and recyclable ones.

Ensures safety without compromising on sustainability.

Compatible with all standard widths and thicknesses of film rolls.

In brief, our dairy products packaging machines do not just process your product; they process your problems. Whether it is keeping things clean, making things more precise, or making things more efficient, our machines are designed to keep pace with today and expand for tomorrow.

From small regional African dairy farmers to large-scale cooperatives, we offer precision, flexibility, and innovation in an amalgamation that makes packaging not only a process, but a source of differentiation.

Advantages of Applying Contemporary Dairy Packaging Machines

With Africa's dairy industry going into high gear to respond to growing demand, traditional methods no longer cut it. Outdated packaging technology not only keeps your production on ice but also amplifies the chances of spoilage and contamination, delivering a blow to your bottom line and consumer trust.

That is where Nichrome's second-generation dairy packaging solutions step in. Designed to combine hygiene with high-speed functionality, our machines are made to serve African dairies of all sizes, whether packaging raw milk in pouches or flavoured yogurt and margarine in cups.

Here's why it's a cream-of-the-crop choice to upgrade to Nichrome:

Long Shelf Life - Whether milk pouch packaging, yogurt cups, or margarine packs, Nichrome provides packaging that holds spoilage at bay.

Consistent Quality - Each packet is sealed, filled, and trimmed with machine accuracy.

Speed & Efficiency – Our automatic packaging machines produce thousands of pouches an hour, achieving a high throughput rate.

Fewer Wastages - Precise filling results in less wastage and higher output from your material.

Multi-SKU management - Convert SKUs on the fly. One milk packaging machine will switch between SKUs with minimal downtime.

Compliance & Certifications – Our packaging solutions enable compliance with FSSAI, ISO, and international standards of hygiene.

Energy-Efficient Operations - New drives and smart control panels lower energy use and boost plant ROI.

These advantages extend far beyond the pack—they enable your dairy plant to become a wise, forward-looking facility. In a business where margins count and quality sells, Nichrome puts you ahead of the competition. You need to grow efficiently, safely, and intelligently. Whether you're supplying urban supermarkets or rural cooperatives, with Nichrome, your packaging line is a productivity powerhouse.

Conclusion: Channelling Innovation into Africa's Dairy Future

Africa's milk industry is poised for a packaging revolution. With growing urbanization, cold chains, and dairy consumption, the demand for milk product packaging that is innovative, efficient, and hygienic also increases.

With state-of-the-art dairy packaging machines, we at Nichrome haven’t just kept pace but forged ahead. Whether it's milk pouch solutions or milk filling machines, our machines empower African dairies to dispense quality, safe products with speed and panache.

So, are you also looking to upgrade your milk packaging line or introduce a new dairy brand? As a new entrant or legacy co-op, Nichrome Africa offers the best of Indian technology for African conditions.

Call us today to discover a full range of dairy products packaging machines and experience the intelligent packaging first-hand.

Let's change the way Africa consumes milk. Pouch by pouch.

#dairy packaging machines#milk packaging machines#yogurt packaging machines#milk pouch packing machine manufacturers#dairy packaging#dairy packaging machine#milk packaging machine#milk pouch packing machines#milk bottle filling machines#liquid filling machines#milk filling machines#yogurt packaging machine#milk products packaging machines#Dry powder filling machines#nichrome dairy packaging machines#automatic packaging machines#milk packaging line

0 notes

Text

Eco-Friendly Agrochemical Packaging: How India’s Manufacturers Can Stay Ahead of Global Sustainability Trends

The rising agricultural demand and growing awareness of modern farming practices have led to the flourishing of the Indian agrochemical sector and increased export opportunities. However, this growth has come at a time when environmental sustainability is under strict global scrutiny. As agrochemical usage increases, so does the volume of packaging waste, prompting regulatory bodies and…

View On WordPress

#agrochemical#agrochemical manufacturers#agrochemical packaging#agrochemical packaging solutions#Automatic Bottle Filling Machine#automatic carton box packing machine#automatic case erector#bottle filling machine#bulk bag filling machine#carton box packing machine#carton packing machine#cartoning machine#case packer manufacturers india#End-of-line Automation#end-to-end packaging solutions#horizontal flow wrap machine#intelligent packaging lines#Liquid packaging machines#packaging machine manufacturer#powder bottle filling machine#Powder filling machine#Secondary Packaging#track-and-trace technology innovations#Vertical Form Fill Seal (VFFS) Machines

0 notes

Text

Automatic Capsule Filling Machine Manufacturer | IRM Enterprise Pvt. Ltd

Looking for a reliable Automatic Capsule Filling Machine Manufacturer? IRM Enterprise Pvt. Ltd. is a trusted name in the pharmaceutical machinery industry, offering high-performance automatic capsule filling machines designed for precision, speed, and efficiency. Our machines are ideal for pharmaceutical, nutraceutical, and herbal product manufacturers, providing consistent filling of powder, granules, or pellets into capsules of various sizes. With robust construction, user-friendly operation, and low maintenance requirements, IRM’s capsule fillers meet global quality standards and help streamline production processes. Choose IRM Enterprise Pvt. Ltd. for dependable, innovative, and cost-effective capsule filling solutions. Perfect for businesses aiming to scale up with automation and accuracy.

Visit: https://www.karnavatiengineering.com/cf-125.aspx?pid=118

#Automatic Capsule Filling Machine Manufacturer#Capsule Filling Machine Manufacturer#Automatic Capsule Filler#Capsule Filling Machine#Capsule Filler Machine#Pharmaceutical Capsule Filling Machine#Capsule Filling Equipment#High-Speed Capsule Filling Machine#Capsule Filling Machine India#Automatic Capsule Filling Machine Supplier

0 notes

Text

Top Tube Filling Machine Manufacturer in Mumbai | Rahul Packaging

Looking for a reliable tube filling machine manufacturer in Mumbai? Rahul Packaging offers high-performance tube filling machines for pharmaceuticals, cosmetics, food, and more. Our solutions ensure precision, hygiene, and efficiency. Explore semi-automatic and automatic models built to meet industry standards. Visit rahulpackaging.com for advanced packaging solutions.

0 notes

Text

The Power of Automation: How This Machine Ensures Unmatched Accuracy in Rinsing, Filling & Capping

Seppa Solutions has defined a completely new, innovative machine, a Rinser Filler Capper Machine, which would reinvent industrial production in any factory. The machine ensures well-laid cleaning procedures, eliminating all kinds of dust particles and impurities. The ultrasonic cleaning is helping to prolong the lifespan of the machine and helps to create better quality products. Rinser methods can be customized by producers to help align them with their unique product specifications for optimum outcomes on various manufacturing lines. This machine has a user-friendly interface that encourages operators to monitor and set changes to reduce downtime and enhance productivity. Its uses are found across many industries, such as electronics, beverages, and pharmaceuticals. The Seppa Solutions Filler capper machine is a fully refined filling equipment that, with a few parameters, increases and reduces waste while managing to fill just about every container with the best accuracy possible. Its method of filling and capping is automated; thus, it can be used in different applications with almost all types of containers and can easily be cleaned and maintained, making it versatile to use in a variety of industries.

#rfc machine manufacturer#rinser filler capper machine manufacturer#rinser machine#rfcmachine#filler capper machine#filler machine#filler capper#non contact filling machinery

0 notes

Text

The Ultimate Guide to Choosing a Reliable Web Sealer Manufacturer in Maharashtra

In the competitive world of packaging, businesses require robust and efficient sealing solutions to ensure the safety and durability of their products. A Web Sealer Manufacturer in Maharashtra plays a crucial role in providing high-performance sealing machines that enhance packaging efficiency across various industries. Whether you are in the food, beverage, pharmaceutical, or e-commerce sector, a web sealer can streamline your packaging process and improve productivity.

What is a Web Sealer?

A web sealer is a highly efficient packaging machine designed to wrap and seal products using shrink films. This machine ensures that products are securely packed, preventing damage during transportation and storage. It is commonly used for bundling multiple items together, making it ideal for industries that require bulk packaging solutions.

Why Choose a Web Sealer from a Leading Manufacturer in Maharashtra?

When investing in a web sealer, choosing the right manufacturer is crucial. Maharashtra is home to some of the most reputed web sealer manufacturers offering advanced technology and high-quality equipment. Here are some key reasons why businesses should opt for a trusted Web Sealer Manufacturer in Maharashtra:

High-Quality Machines – Manufacturers in Maharashtra offer web sealers built with durable materials, ensuring longevity and efficient performance.

Customizable Solutions – Depending on your industry requirements, leading manufacturers provide tailor-made web sealer machines to fit your needs.

Cost-Effective Packaging – A reliable web sealer minimizes product damage and reduces manual labor costs, enhancing overall business profitability.

Energy-Efficient Models – Modern web sealers come with energy-saving features, ensuring optimal operation while keeping electricity consumption low.

After-Sales Support – Reputable web sealer manufacturers in Maharashtra provide excellent after-sales services, including maintenance, training, and spare parts availability.

Industries Benefiting from Web Sealer Machines

Various industries benefit from using web sealers for their packaging needs. Some of these industries include:

Food & Beverage: Ensuring freshness and secure transportation of packaged food and drinks.

Pharmaceuticals: Safely sealing medicines and healthcare products for contamination-free delivery.

E-commerce & Retail: Securing packaged goods for online orders and store displays.

Automobile & Electronics: Protecting automotive components and electronic gadgets from external damage.

Factors to Consider When Buying a Web Sealer

If you are planning to invest in a web sealer, consider these essential factors to ensure the best purchase:

Machine Size & Compatibility: Ensure the sealer fits your production line and packaging requirements.

Speed & Efficiency: Opt for a machine that offers high-speed sealing for increased productivity.

Material Compatibility: Check if the sealer is compatible with different types of shrink films.

Ease of Maintenance: Look for a machine that is easy to clean, repair, and maintain.

Automation Level: Choose between manual, semi-automatic, or fully automatic models based on your operational needs.

Conclusion

A Web Sealer Manufacturer in Maharashtra provides businesses with state-of-the-art packaging solutions to enhance efficiency and productivity. Investing in a high-quality web sealer can significantly improve your packaging process, ensuring product safety, reducing waste, and increasing overall profitability. If you are looking for the best web sealer for your business, connect with a leading manufacturer today and take your packaging operations to the next level!

#Soda Bottle filling machine Supplier in Maharashtra#Soda pet bottle filling machine Trader in Maharashtra#Rotary soda pet bottle filling plant Manufacturer in Maharashtra#Web sealer Manufacturer in Maharashtra#Sugercan juice machine Manufacturer in Maharashtra

0 notes