#automatic packaging machines

Text

Ensuring Seed Quality in Bangladesh with Nichrome's Advanced Packaging Technology

In the vibrant agricultural landscape of Bangladesh, the quality of seeds plays a crucial role in determining the success of crops. High-quality seeds lead to better germination rates, robust plants, and bountiful harvests. Recognizing the critical importance of seed quality. As a leading packaging manufacturer in Bangladesh, we design seed packaging machines to preserve and enhance seed integrity from the moment they are packed until they are sown.

Nichrome's Advanced Seed Packaging Technology: Unique Features

Our seed packaging machines with cutting-edge technology are tailored to meet the specific needs of seed preservation. Here are some unique features of our filling and packaging machines that ensure seed integrity and quality:

Hermetic Sealing: Our automatic sachet packaging machines provide airtight sealing to protect seeds from moisture, pests, and contaminants. This feature is crucial in Bangladesh's humid climate, where moisture can quickly degrade seed quality.

Controlled Atmosphere Packaging: To further safeguard seed viability, our vertical form fill seal machines can modify the packaging atmosphere, reducing oxygen levels and maintaining a low moisture environment. This helps in extending the shelf life of seeds.

Accuracy in Filling: Ensuring that each packet contains the exact amount of seeds with minimal variation is essential for maintaining uniformity and quality. Our automatic filling and packaging machines ensure precision that guarantees accurate seed count and weight.

Robust Packaging Materials: We use high-quality, durable materials for seed packaging that offer excellent barrier properties against environmental factors. These materials are also resistant to punctures and tears, ensuring the seeds remain protected throughout their journey.

Automated Quality Checks: Nichrome’s machines are integrated with advanced sensors and automated quality control systems to detect and reject any defective packages. This ensures that only the best quality seeds reach the farmers.

User-Friendly Interface: Our small packaging machines feature an intuitive interface that simplifies operation and maintenance. This ensures that even operators with minimal technical expertise can manage the packaging process efficiently.

Benefits of Maintaining Seed Quality from Packaging to Planting

Enhanced Germination Rates: High-quality seeds with intact germination capabilities lead to higher germination rates, ensuring that more plants grow successfully, maximizing crop yield.

Uniform Crop Growth: Consistent seed quality results in uniform plant growth, which is vital for efficient field management and harvesting processes.

Pest and Disease Resistance: Seeds that are well-preserved and protected during packaging are less likely to carry pests or diseases, reducing the risk of crop failure and the need for chemical treatments.

Economic Gains for Farmers: Quality seeds contribute to higher crop yields and better-quality produce, which can command higher prices in the market, leading to improved economic stability for farmers.

Seed Longevity: Proper packaging extends the shelf life of seeds, allowing farmers to store seeds for longer periods without compromising quality. This is particularly beneficial in managing planting schedules and preparing for adverse weather conditions.

Conclusion

In conclusion, maintaining seed quality from packaging to planting is essential for the prosperity of Bangladesh's agriculture. Our advanced packaging technology offers a comprehensive solution to preserve seed integrity, contributing to higher crop yields, better farmer incomes, and sustainable farming practices.

Partner with Nichrome and invest in the future of agriculture in Bangladesh!

#sugar packaging machines#automatic sugar packaging machines#Vertical Form fill seal machine#sachet filling machines#pouch filling machines#VFFS machine#automatic sugar filling machines#packaging machines in Kenya#commercial food packaging machine#automatic packaging machines

0 notes

Text

#integrated packaging solutions#automatic packaging machines#packaging machine manufacturers#food packaging machine

0 notes

Text

Preserving Purity: Nichrome's Milk Packing Machines Nurturing Growth in African Dairy Industry

In the heart of Africa, where the sun-kissed savannas meet bustling cities, a revolution is quietly unfolding in the dairy industry. At the forefront of this transformation are the ingenious milk packaging machines by Nichrome, seamlessly blending technology and tradition to ensure the freshest milk reaches every corner of the continent.

In the rolling hills of Kenya, where the Maasai's cattle graze under the vast African sky, the significance of milk is deeply ingrained in the culture. Enter the stage, the milk packaging machine in Kenya, a silent hero empowering local dairy farmers to share the goodness of their produce with the world.

Advantages of having Nichrome’s milk packing machines for Dairy Industry

Preservation of Freshness:

Nichrome's milk filling machines are designed with a primary focus on preserving the freshness of milk. Advanced technology ensures that each package seals in the natural goodness, extending the shelf life and maintaining the quality of the dairy product.

Precision and Efficiency:

The precision engineered into Nichrome's milk pouch packaging machines guarantees an efficient and accurate packaging process. From the milk filling machine to the VFFS packaging machine, every component works seamlessly to minimize wastage, enhance productivity, and optimize resources.

Versatility in Packaging Formats:

Nichrome understands the diverse needs of the dairy industry. Our milk packaging machines offer versatility in packaging formats, accommodating various sizes and types of milk containers, from pouches to bottles. This adaptability is crucial for meeting market demands and consumer preferences.

Automation for Increased Productivity:

Embracing automation, Nichrome's machines significantly increase productivity and reduce operational costs. The integration of smart technology not only streamlines the packaging process but also minimizes the risk of errors, ensuring consistency and reliability in every package.

Reduced Downtime and Maintenance:

Nichrome's dedication to reliability extends to the durability of their machines. With robust construction and advanced engineering, these milk packaging machines are built to withstand the rigors of continuous operation, minimizing downtime and maintenance costs.

Vertical Form Fill Seal Machines by Nichrome

In the realm of innovative packaging solutions, Nichrome's Vertical Form Fill Seal (VFFS) technology emerges as a meaningful change, redefining efficiency, versatility, and reliability in the packaging industry.

Filpack CMD ALPHA

FILPACK CMD Alpha is another efficient packaging solution for milk and other liquids. Built shorter than conventional machines, it also occupies less floor space as no side opening is required. The impulse seal system is controlled through solid state control technology, and there is a specially designed film roll unwinding mechanism for smooth bag pulling.

FILPACK CMD Alpha offers twin heads so you can pack two different products at the same time. You can even conduct maintenance on one track while the other is in operation.

Filpack Servo 12K

This machine is the fastest milk pouch packaging machine, with a speed of 12,000 packs/hour. It can pack CSPP pouches of 200 ml, 500 ml and 1000 ml with equal ease and accuracy. FILPACK SERVO 12K is a heavy duty machine with simple maintenance-friendly construction. It is built for hygiene with product contact parts of stainless steel and a UV film sterilisation system for the packaging material.

Independent balance tanks offer flexibility to manage single or different products simultaneously.

Conclusion:

The future is bright for Africa's dairy sector, with the milk packaging machine in Kenya and beyond playing a pivotal role. Nichrome's continuous innovation ensures that the freshness of Africa's milk becomes a global standard, fostering a legacy that transcends borders.

In conclusion, as Africa's dairy industry evolves, Nichrome's milk packaging machines emerge as catalysts for positive change. They are not just machines; they are enablers of dreams, custodians of purity, and architects of a future where every sip of milk tells a story of growth and prosperity.

#milk filling machine#powder filling machines#vertical form fill seal machines#powder packaging machine#milk packaging machine#milk pouch packing machine#automatic filling machine#automatic packaging machines

0 notes

Text

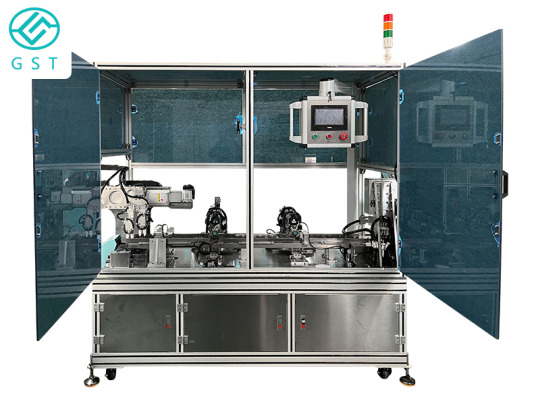

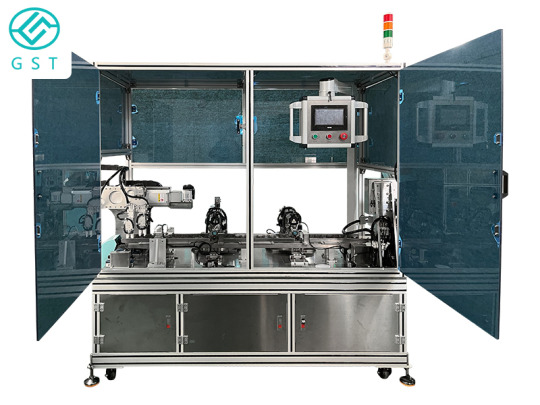

Selection experience of automatic packaging machine

For mechanical equipment products such as automatic packaging machines, there must be a reasonable structure before they can be put into use. The reason why the equipment is required to have a reasonable structure is mainly because: The safety of the structure is reasonable. As a mechanical equipment product, the automatic packaging machine is very easy to have problems in use when there are problems with its own structure, especially easy Because of the poor performance of the relevant structure, it will cause safety problems, and once this happens, it will bring great economic losses to everyone. Therefore, in order to ensure the safety of the equipment, it is required to have a reasonable structural design. Next, Guanshentai Automation Equipment will share with you the selection experience of automatic packaging machines.

1. Choose an automatic packing machine according to what you use and what you pack. There are three main types of automatic packaging machines in the market, one for pp tape, one for pet tape, and one for steel tape. Users can roughly determine the type of automatic packaging machine to be used according to the packaging they want to use.

2. Select the device according to the output. Any kind of automatic packaging machine can be divided into semi-automatic packaging machine, automatic packaging machine and fully automatic packaging machine. The user can roughly determine what type of automatic packaging machine to choose based on the output.

3. Choose the model according to the enterprise brand. The main problem of this kind of purchase method research is through the word-of-mouth effect. Generally, the development of a big brand with more seniority is a more trustworthy one. Users can buy with more confidence, and the sales management staff will also make suitable recommendations for you.

The above content is an introduction to the selection experience of automatic packaging machines. In the process of selecting equipment, it is necessary to pay attention to a variety of different situations, not only to understand the internal technology of the equipment, but also to understand the external functions. We have to pay more attention to different aspects. Only after you can better understand these aspects, then we can make a good selection of equipment so that we can play the expected functions and functions.

0 notes

Text

youtube

2 notes

·

View notes

Text

#Pouch filling#Automatic packaging#Vertical form fill seal (VFFS)#Horizontal form fill seal (HFFS)#Multih uch packaging materials#Pouch packaging designs#Pouch packaging industry#Pouch packaging equipmen#ead weigher#Auger filler#Rotary packing machine#Bagging machine#Packaging automation#Pouch sealing#Sachet packing#pouch packing machine#buy pouch packing machine#pouch packing machine seller#pouch packing machine manufecturer#automatic packing machine#FFS packing machine#chips packing machine#namkeen packing machine#snacks packing machine

2 notes

·

View notes

Text

#packaging#automatic packing machine#silica gel#wrapping#diy#expedition#crafts#masking tape#duct tape marketing#adhesive#wooden pallets#stretch film#bubble wrap#dunnage packaging market

2 notes

·

View notes

Text

0 notes

Text

Mineral Water Bottling Plant, Mineral Water Bottling Plant Manufacturer - kceindia.com

Mineral Water Bottling Plant : We are Mineral Water Bottling Plant Manufacturer, Mineral Water Bottling Plant Supplier in Navi Mumbai, India. Call Now.

Mineral Water Bottling Plant, Industrial Water Bottling Plant, Mineral Water RO Plant, Mineral Water Plant, Mineral Water Plant Machine, Mineral Water Packaging Plant, Mineral Water System, Industrial Mineral Water Plant, Mineral Water Treatment Plant, Packaged Drinking Water Plant, Fully Automatic Bottle Filling Machine, Fully Automatic Bottle Blowing Machine, SS Vessel, SS Storage Tanks, SS Housing For Filter, SS Membrane Housing, SS Piping, Dosing Pump, Roller Conveyor, Ozonation Generator, Post Filtration System, Leather Softeners, Water Softeners in Sanpada, navi mumbai, mumbai, india.

#Mineral Water Bottling Plant#Industrial Water Bottling Plant#Mineral Water RO Plant#Mineral Water Plant#Mineral Water Plant Machine#Mineral Water Packaging Plant#Mineral Water System#Industrial Mineral Water Plant#Mineral Water Treatment Plant#Packaged Drinking Water Plant#Fully Automatic Bottle Filling Machine#Fully Automatic Bottle Blowing Machine#SS Vessel#SS Storage Tanks#SS Housing For Filter#SS Membrane Housing#SS Piping#Dosing Pump#Roller Conveyor#Ozonation Generator#Post Filtration System#Leather Softeners#Water Softeners in Sanpada#navi mumbai#mumbai#india

0 notes

Text

Elevate your business with cutting-edge technology and expertise of the best Carbonated Soft Drink Plant Manufacturers in Ahmedabad leading the way. For more information visit: https://www.marutimacpack.com/

#Carbonated Soft Drink Plant Manufacturers in Ahmedabad#Automatic Carbonated Soft Drink Machine#Water Bottle Packaging Machine#Automatic Soda Soft Drink Packaging Plant Manufacturers#Carbonated Soft Drink Plant Manufacturers#Automatic Soda Soft Drink Packaging Plant

1 note

·

View note

Text

#pharmaceutical packaging machine#table top blister packaging machines#vertical form fill seal machine#automatic packaging machines#liquid filling machine#filling and packaging machine#pouch sealing machine

0 notes

Text

#integrated packaging solutions#automatic packaging machines#packaging machine manufacturers#innovative packaging solutions#packaging machine manufacturer#food packaging machine

0 notes

Text

Maximizing Operational Efficiency with Nichrome’s Sugar Packaging Machines

In today's competitive market, operational efficiency is the key to success for any business. For companies in the sugar industry, finding reliable and efficient packaging solutions is crucial. Nichrome’s state-of-the-art sugar packaging machines offer a perfect blend of innovation and efficiency, designed to meet the unique demands of the industry. By investing in our automatic sugar packaging machines, businesses can streamline their operations, reduce waste, and boost productivity.

Benefits of Nichrome’s Vertical Form Fill Seal Machine for Sugar Industry:

The Vertical Form fill seal machine is one of Nichrome’s flagship products, renowned for its efficiency and versatility. Here are some key benefits:

1. Enhanced Speed and Productivity

Our VFFS machines are designed to operate at high speeds, significantly boosting production rates. This is crucial for businesses that need to package large volumes of sugar or other granular products quickly and efficiently. The increased throughput ensures that customer demands are met promptly, improving overall business efficiency.

2. Versatility in Packaging

The VFFS machine is highly versatile, capable of handling various packaging materials and formats. With a wide range of fillers we give you the flexibility of packaging sugar in sachets, pouches, or other forms. Our sachet filling machines and pouch filling machines are designed to adapt to your specific needs. This flexibility allows businesses to cater to different market segments and customer preferences with ease.

3. Precision and Accuracy

Accuracy in packaging is vital to maintaining product consistency and customer satisfaction. Under the VFFS machine we manufacture automatic sugar filling machines equipped with advanced filling mechanisms that ensure precise measurement and filling of sugar. This reduces product wastage and enhances cost-efficiency by ensuring that each package contains the exact amount of product.

4. Improved Product Quality and Shelf Life

Packaging plays a crucial role in protecting the product and extending its shelf life. Our automatic packaging machines ensure airtight sealing, which helps in preserving the freshness and quality of sugar. This is particularly important in maintaining the product’s integrity during transportation and storage, thereby reducing spoilage and returns.

5. Ease of Operation and Maintenance

Our sugar filling machines are designed with user-friendly interfaces, making them easy to operate and maintain. Minimal training is required for operators, which means businesses can quickly implement the machines into their production lines without extensive downtime. Furthermore, the machine’s design facilitates easy cleaning and maintenance, ensuring that it remains in optimal working condition with minimal effort.

6. Enhanced Safety Features

Safety is a critical concern in any manufacturing process. We ensure that our VFFS machines are equipped with advanced safety features to protect operators and ensure safe operation. Features like automatic shut-off in case of malfunctions, safety guards, and easy-access panels for maintenance contribute to a safer working environment.

Packaging Machines in Kenya: Meeting Local Needs

Kenya’s sugar industry is growing rapidly, and so is the need for efficient packaging solutions. Nichrome’s packaging machines in Kenya are designed to meet the specific needs of local businesses. Whether you’re a small-scale producer or a large manufacturing unit, we offer a range of packaging machines designed to scale with your operations.

Our commercial food packaging machine from Nichrome is another excellent option for businesses looking to maximize efficiency. We design these machines to handle various packaging materials and formats, ensuring that your sugar products are packaged securely and attractively.

Conclusion

Investing in Nichrome’s sugar packaging machines is a strategic move for any business looking to enhance operational efficiency. With a range of automatic packaging machines tailored to the needs of the sugar industry, Nichrome stands out as a leader in innovation and reliability. Whether you are looking for a sugar filling machine or a comprehensive commercial food packaging machine, we have the solution to help your business thrive.

Embrace the future of packaging with Nichrome and see the difference it can make in your operational efficiency.

#sugar packaging machines#automatic sugar packaging machines#Vertical Form fill seal machine#sachet filling machines

0 notes

Text

What are the advantages of automatic packaging machine

With the continuous acceleration of the industrialization process, labor costs and production efficiency are also constantly improving, and automatic packaging machines are widely used in industrial mechanized packaging production lines. The materials of automatic packaging machines are generally made of stainless steel, and are currently widely used in biopharmaceutical, chemical, food and other industries. So what are the advantages of the automatic packaging machine?

What are the advantages of the automatic packaging machine?

1. High efficiency

In the past, the production efficiency of traditional manual packaging was relatively slow and it was easy to lose materials. Using a fully automatic packaging machine instead of manual packaging can efficiently complete the entire production process of feeding, measuring, bagging, printing date, and product output. This mechanized assembly line produces high measurement accuracy, fast efficiency, saves materials and reduces labor costs.

2. Reduce labor intensity

The automatic packaging machine replaces manual packaging to free workers from heavy work. First of all, manual packaging like some small-sized products is labor-intensive and not easy to package; secondly, some products will produce dust, radioactivity, and irritation during the production process, which are toxic to the human body. The production of this machine can effectively solve these problems.

3. Energy saving and environmental protection

Generally speaking, fully automatic packaging machines with good service have the function of automatic detection. Therefore, for those products that are unqualified, the machine can intelligently automatically screen and repackage them again, which improves the pass rate without wasting materials. It is also easy to maintain and operate, reducing production costs to a large extent.

4. Safety and health

Manual packaging is difficult to avoid contact between people and production products due to manual participation, which may contaminate products and make it difficult to guarantee production quality. The automatic packaging machine has no manual participation in the whole process of automatic production from feeding material to finished product. This packaging production line reduces the bacterial pollution in the packaging process and provides a good guarantee for the enterprise.

The above are the main advantages of the fully automatic packaging machine. With the continuous improvement of the level of mechanized packaging, choosing a cost-effective automatic packaging machine is a wise choice for industrial enterprises. It is believed that in the era of industrialization, the automatic packaging machine can better serve the enterprise and improve the production level.

0 notes

Text

Pouch Packing Machine & Collar Type Pouch Packaging Machine

Pouch Packing Machine: The Ultimate Guide to Finding the Right Manufacturer and SupplierAre you in search of a reliable pouch packing machine manufacturer and supplier in Delhi, Bihar, Bhopal, Varanasi, or Ghaziabad? Look no further! In this comprehensive guide, we will walk you through everything you need to know to make an informed decision and ensure you get the best pouch packing machine for your specific needs. What to Look for in a Pouch Packing Machine Manufacturer and Supplier? When choosing a pouch packing machine manufacturer and supplier, there are several key factors to consider: Experience: It is essential to choose a manufacturer and supplier with years of experience in the industry. This ensures that they have the necessary expertise to provide high-quality machines that meet your requirements. Expertise: Look for a manufacturer and supplier who specializes in pouch packing machines. This shows that they have in-depth knowledge of the product and can offer customized solutions to suit your needs. Authority: Seek out a manufacturer and supplier who is well-established and has a strong reputation in the market. This indicates that they are trustworthy and reliable. Trust: It is crucial to partner with a manufacturer and supplier you can trust to deliver on their promises and provide ongoing support and service. Pouch Packing Machine Manufacturer and Supplier in Delhi In Delhi, there are several reputable manufacturers and suppliers of pouch packing machines. One of the leading companies in the area is XYZ Pouch Packing Machines. With over 20 years of experience in the industry, they offer a wide range of high-quality machines to meet various packaging needs. Whether you are looking for a small-scale machine for your startup or a large-scale automated system for a manufacturing facility, XYZ has got you covered. Pouch Packing Machine Manufacturer and Supplier in Bihar, Bhopal, Varanasi, and Ghaziabad In Bihar, Bhopal, Varanasi, and Ghaziabad, finding a reliable pouch packing machine manufacturer and supplier is crucial for businesses looking to streamline their packaging process. One such company is ABC Packaging Solutions, known for its innovative and efficient machines. From vertical form-fill-seal machines to horizontal flow wrappers, ABC offers a diverse range of options to cater to different packaging requirements. Conclusion In conclusion, when searching for a pouch packing machine manufacturer and supplier, it is essential to consider factors such as experience, expertise, authority, and trust. By choosing a reputable company with a proven track record, you can ensure that you get a high-quality machine that meets your specific needs. Whether you are based in Delhi, Bihar, Bhopal, Varanasi, or Ghaziabad, there are several reliable manufacturers and suppliers to choose from. Invest in the right pouch packing machine today and take your packaging process to the next level!

#pouch packing machine#collar pouch packing machine#fully automatic pouch packaging machine#business#manufacturer#agarbatti making machine#machine learning

0 notes

Text

Performance and Quality: We present the quality and high performance together thanks to the materials supplied from the brands that leader of it’s sector

Fast and Easy Maintenance : Only one person is enough to fast, easy, and fully automatic usage of the machine thanks to the filling settings system on the touch screen.

Multi Format : You can have the most suitable format thanks to our wide – scale,the diameter changing depends on your request, and our flowmetric and volumetric systems depends on your product type.

Maximum Security : Maximum Security : Your safety is provided by plexiglass protection cabin frames and protection switches on the door during and after the filling.

Maximum Hygiene : When the sterilization of the machine is provided by Hepa filter, the inner cleaning of the machine after the filling is provided by the CIP system. The sterilization of the filling cups is provided by the UV Lamp unit. All the materials of the machine are stainless steel and the conformity of food is provided by materials have food conformity certificate.

ADDRESS: İvedik Osb Mah. 1371 Sok. No:23 Ostim/ANKARA

TELEFON: +90 (312) 395 02 78

EXPORT: +90 (542) 675 12 07

E-POSTA: [email protected]

E-POSTA: [email protected]

#honey#icecream#filling#packaging#pdmmachinery#turkey#yoghurt#ayran#performans#kalite#quality#performance

#dondurma#dolum#paketleme#pdm#makina#pdmmakina#ankara#türkiye#yoğurt#ayran#meyvesuyu#reçel#juice#jam

www.pdmmakina.com.tr

#Performance and Quality: We present the quality and high performance together thanks to the materials supplied from the brands that leader o#Fast and Easy Maintenance : Only one person is enough to fast#easy#and fully automatic usage of the machine thanks to the filling settings system on the touch screen.#Multi Format : You can have the most suitable format thanks to our wide – scale#the diameter changing depends on your request#and our flowmetric and volumetric systems depends on your product type.#Maximum Security : Maximum Security : Your safety is provided by plexiglass protection cabin frames and protection switches on the door dur#Maximum Hygiene : When the sterilization of the machine is provided by Hepa filter#the inner cleaning of the machine after the filling is provided by the CIP system. The sterilization of the filling cups is provided by the#ADDRESS: İvedik Osb Mah. 1371 Sok. No:23 Ostim/ANKARA#TELEFON: +90 (312) 395 02 78#EXPORT: +90 (542) 675 12 07#E-POSTA: [email protected]#E-POSTA: [email protected]#honey#icecream#filling#packaging#pdmmachinery#turkey#yoghurt#ayran#performans#kalite#quality#performance#dondurma#dolum#paketleme

0 notes