#Flange Terminal Blocks

Explore tagged Tumblr posts

Text

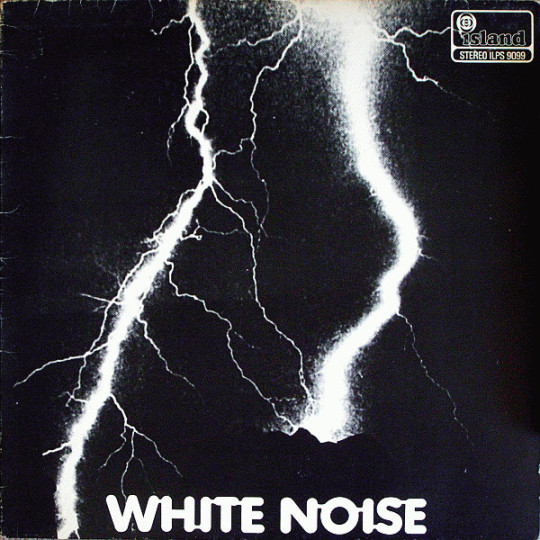

190: White Noise // An Electric Storm

An Electric Storm White Noise 1969, Island

I’ve read a decent amount on how White Noise’s An Electric Storm was made over the course of a year of painstakingly splicing tape by hand in a London flat, but not why they decided to make their pioneering electronic music opus so ooky-spooky. I guess when you coop up folks whose day job is making Dalek noises, you’re going to get something a bit deranged. The opening side’s psych pop is jaunty enough, though there’s often something vacant-eyed in its whimsy, like a carnival in a Stephen King story: your ear is drawn to the incongruous details that hint at some darker working behind the cutesiness. It prepares you well for the flip, where across its 11-minute runtime “The Visitation” opens multiple echo chambers full of sobs, previews the next decade of horror film title themes, and digs pits of gurgling electronic unease that spored whole genres of dark ambient music still evolving to this day. The album ends on a literal (well, fake literal) Satanic ritual in the form of “Black Mass: An Electric Storm in Hell,” which turns jazz drummer Paul Lytton into the Jacob’s Ladder poster. Leader David Vorhaus likes to wryly shake his head recalling how the A&R people at Island Records didn’t “get it” when he turned in the LP, but even as someone who does “get it” I uh get why they didn’t!

youtube

An Electric Storm is chiefly discussed for the means of its production, and that’s fair: despite digital advances in recording technology that make the most advanced techniques found here (phasing, flanging, looping) virtually effortless, it is uncanny hearing them deployed so extensively on music of this vintage. It’s the equivalent of watching a film from the ‘60s and seeing effects that look like The Terminator. The music rarely goes more than a few bars before melting into some other shape (a melodic phrase begun on one instrument is spliced so it resolves on another; the music drops out entirely, replaced by a collage of ratcheting noises, electronic bloops and choking cries somewhere between anguish and laughter). By turning over a third of “My Game of Loving” to cringey orgasm sounds, they even initiate the nascent electronic pop genre into the elite fraternity of styles that are a little too eager to prove they fuck.

The lyrics won’t win any prizes, but I do take issue with how dismissive some writers have been of these songs as songs. An Electric Storm is steeped in the psychedelic tropes of the day, but it doesn’t sound like the work of avid fans of like the Electric Prunes or whatever. One senses that Vorhaus and BBC Radiophonic Workshop regulars Delia Derbyshire and Hodgson have a general but disinterested notion of what the kids are into, and they feed it back to us through the filter of their own predilections. Derbyshire’s two co-writes in particular are anything but generic. The rippling transformations of “Love Without Sound” are as wondrous and eerie as a Winsor McCay Little Nemo strip, but it’s the opiated vocal by the otherwise unknown John Whitman and the strolling melody that ebbs in and out of the collage that give it a dreamy logic. “Firebird” has a Beach Boys-y bounce and gorgeously arranged harmonies to go with an array of synth tones so solid and colourful I want to play with them like toy blocks.

Though it didn’t set the charts ablaze, An Electric Storm developed a reputation as a tripper classic, and I was pretty psyched to find a copy in not too battered condition for a reasonable price at a shop this summer. I’m glad to have it on the shelf, and with the exception of the 45 seconds that makes my neighbours think I’m listening to weird and bad porn, I always enjoy the adventure when I get it on the table.

youtube

190/365

#white noise#david vorhaus#delia derbyshire#bbc radiophonic workshop#dr who#bbc#'60s music#psychedelic pop#tape music#early electronic#electronic music#analog synth#horror music#halloweek

11 notes

·

View notes

Text

Seal It Right : Stainless Steel Blind Flanges for Maximum Piping System Efficiency - Nitech Stainless Inc

Nitech Stainless Inc is a leading Stainless Steel Flanges Manufacturers in India. The company serves the services industries such as oil and gas, chemical, petrochemical, and power generation. They are a reputable Stainless Steel Flanges Manufacturer, offering a variety of flange types that have been tested to meet high-quality and performance requirements.

In the intricate world of industrial piping systems, even the smallest component can play a pivotal role in performance, safety, and efficiency. One such essential component is the Stainless Steel Blind Flanges. Though it might appear as a simple metal disc at first glance, this piece of equipment is indispensable in various industries, including oil & gas, chemical processing, water treatment, and power generation.

What is a Stainless Steel Blind Flange?

A Blind Flanges is a solid, round plate that is used to close the end of a pipe, valve, or pressure vessel. Unlike other flanges, it lacks a bore (hole) in the middle. It essentially serves as a "cap" for a piping system, sealing it off completely.

Made from stainless steel, these flanges offer exceptional corrosion resistance, durability, and strength, making them ideal for demanding environments where exposure to moisture, chemicals, or high pressures is common.

Key Features of Stainless Steel Blind Flanges

Corrosion Resistance: Thanks to their chromium-rich composition, stainless steel blind flanges resist rust and corrosion even in harsh industrial conditions.

High Tensile Strength: Stainless steel grades like 304, 316, and 321 provide superior strength, ensuring long-term structural stability.

Leak-Proof Seal: When properly installed with gaskets, blind flanges provide a tight seal, preventing leaks and ensuring safe system shutdowns or testing.

Versatility: Available in a wide range of pressure ratings (from 150# to 2500#) and sizes, stainless steel blind flanges can be used in everything from small water pipelines to massive oil refineries.

Ease of Maintenance: These flanges allow for easy access to the piping system for cleaning, inspection, and maintenance without dismantling the entire setup.

Common Applications

Pipeline Termination: Used to block off the end of piping systems during maintenance or future expansion.

Hydrostatic Testing: Helps to assess the integrity of a system by allowing pressure tests.

Process Isolation: Enables safe shutdown of sections of a plant or process line for inspection or repair.

Spare Connection Points: Allows for easy future connection to other equipment or systems.

Industries such as petrochemical, marine, pharmaceutical, and food processing regularly use stainless steel blind flanges due to their reliability and hygienic properties.

Stainless Steel Grades Used

304 Stainless Steel: Most commonly used due to its excellent resistance to oxidation and affordability.

316 Stainless Steel: Provides increased resistance to chlorides and acids, making it perfect for marine and chemical applications.

321 Stainless Steel: Stabilized with titanium, it’s perfect for high-temperature environments.

Choosing the right grade depends on the specific environment and operational demands of the application.

We supply Flanges (Country) :

Carbon Steel Flanges Suppliers in UAE

Carbon Steel Flanges Suppliers in Qatar

We supply Flanges :

Flanges Manufacturers Ahmedabad

Flanges Manufacturers Delhi

Why Choose Stainless Steel Blind Flanges from a Trusted Supplier?

Not all blind flanges are created equal. Choosing a reputable supplier ensures:

Compliance with international standards such as ASME, ANSI, and DIN.

Precision machining for tight, reliable sealing

Availability of mill test certifications

Customization options in terms of dimensions and finishes

Conclusion

Choosing the right Stainless Steel Blind Flanges is crucial for ensuring the integrity and safety of your piping systems. As a trusted Stainless Steel Blind Flanges Supplier in India, we are committed to providing high-quality, durable, and corrosion-resistant flanges that meet industry standards. Whether you are looking for reliable Flanges Manufacturers, we offer a comprehensive range of stainless steel blind flanges designed to cater to diverse industrial needs. With our commitment to excellence, you can trust us to deliver top-notch products for the longevity and performance of your systems.

0 notes

Text

A Complete Guide to CPVC Pipe and Fittings and Butterfly Valve Suppliers in Dubai and UAE

When it comes to building reliable plumbing and industrial systems, selecting the right materials and components is crucial. Among the wide range of available options, CPVC pipe and fittings have gained immense popularity for their durability, efficiency, and cost-effectiveness. Likewise, butterfly valves play a significant role in fluid regulation, and finding trustworthy butterfly valve suppliers in Dubai and across the UAE is essential for seamless operations.

In this comprehensive guide, we’ll dive into everything you need to know about CPVC piping systems, the importance of butterfly valves, and how to find the best suppliers without compromising quality or budget.

Understanding CPVC Pipe and Fittings

CPVC (Chlorinated Polyvinyl Chloride) pipes are manufactured through a chlorination process that enhances the material’s heat resistance, chemical stability, and durability. CPVC is widely used for both residential and industrial applications, particularly where hot and corrosive liquids are involved.

Advantages of Using CPVC Pipe and Fittings

Temperature Resistance: CPVC pipes can withstand high temperatures up to 200°F (93°C), making them ideal for hot water distribution.

Corrosion Resistance: Unlike metal pipes, CPVC pipes are highly resistant to corrosion from chemicals and water impurities.

Longevity: A CPVC piping system typically lasts for several decades with minimal maintenance, offering long-term value.

Ease of Installation: Thanks to their lightweight and simple joining methods (solvent welding), CPVC pipes are easy to install, reducing labor costs and time.

Cost-Effective: When evaluating the CPVC pipe price, you’ll find that it offers an excellent balance between affordability and performance.

Smooth Flow: The internal surface of CPVC pipes is smooth, minimizing friction loss and ensuring better flow efficiency.

Common CPVC Fittings

Elbows

Tees

Couplings

Reducers

Flanges

Caps and Plugs

Each fitting plays a specific role in facilitating direction changes, flow control, or system terminations.

Factors Influencing CPVC Pipe Price and Cost

When planning a project, understanding the factors that affect the CPVC pipe price and CPVC pipe cost is important for budgeting accurately. Several aspects can influence the final price:

Pipe Size and Thickness: Larger diameter pipes and thicker walls naturally cost more due to increased material usage.

Quality Standards: Pipes manufactured according to international standards may come at a slightly higher price but offer better performance and safety.

Quantity Purchased: Bulk purchases often attract discounts, reducing the overall CPVC pipe cost for large-scale projects.

Market Demand and Supply: Seasonal trends and supply chain dynamics can cause price fluctuations.

Additional Fittings and Accessories: Fittings, joints, and adhesives add to the overall project cost but are necessary for a complete and durable system.

Always ensure you are purchasing CPVC pipes that meet quality standards rather than going solely for the cheapest option.

The Importance of Butterfly Valves

Butterfly valves are essential components in piping systems that regulate or isolate the flow of fluids. Their simple operation, compact design, and efficiency make them a preferred choice for various industries, including water treatment, oil and gas, HVAC, and food processing.

How Butterfly Valves Work

A butterfly valve consists of a rotating disc mounted on a rod. When the valve is closed, the disc blocks the passageway completely. Rotating the disc allows fluid to pass through, and the amount of flow can be regulated by adjusting the angle of the disc.

Advantages of Butterfly Valves

Space Saving: Butterfly valves are lighter and more compact than many other types of valves.

Cost Efficiency: They generally cost less than gate or ball valves of the same size.

Quick Operation: With a simple quarter-turn (90 degrees), the valve can go from fully open to fully closed.

Versatility: Suitable for a wide range of applications, from large-scale industrial systems to small residential setups.

Finding Reliable Butterfly Valve Suppliers in Dubai and UAE

Given the crucial role butterfly valves play, partnering with reliable butterfly valve suppliers in Dubai and butterfly valve suppliers in UAE is essential. Here are key factors to consider:

Product Range: Look for suppliers offering a comprehensive range of butterfly valves including different sizes, materials (like stainless steel, PVC, or ductile iron), and configurations (wafer, lug, double-flanged).

Compliance and Certifications: Ensure the supplier provides valves compliant with international standards like ISO, API, or ASME.

Availability of Accessories: Good suppliers also offer complementary products like actuators (manual, electric, pneumatic) and other valve control devices.

Technical Support and After-Sales Service: Choose suppliers who offer technical consultation, installation guidance, and maintenance services to ensure system longevity.

Reputation and Reviews: Researching customer feedback and case studies can help you assess the reliability of suppliers.

In Dubai and across the UAE, the demand for high-quality valves is high due to rapid infrastructure development, so taking time to choose the right supplier can save you from future headaches.

Final Thoughts

Whether you’re setting up a residential plumbing system, an industrial fluid management facility, or a commercial project, choosing the right piping materials and components is non-negotiable. CPVC pipe and fittings offer unmatched advantages for hot water and corrosive environments at a reasonable CPVC pipe price and overall CPVC pipe cost. Likewise, butterfly valves remain a top choice for efficient fluid control, and working with reliable butterfly valve suppliers in Dubai or butterfly valve suppliers in UAE can make all the difference.

Always prioritize quality and compliance over cost savings alone. Long-term reliability, safety, and performance are worth the investment. Proper selection, installation, and maintenance will ensure your system runs efficiently for years to come.

#cpvc pipe and fittings#butterfly valve suppliers in dubai#butterfly valve suppliers in uae#cpvc pipe price#cpvc pipe cost

0 notes

Text

What is a GI Flange & Its Purpose? Blind Flange Uses Explained

In the industrial sector, especially in Udhhyog, proper piping system management is critical for operational efficiency. One of the most vital components in these systems is the GI flange (Galvanized Iron Flange), which plays a crucial role in ensuring leak-proof and secure connections between pipes. Among its various types, the blind flange is particularly important in systems that require periodic shutdowns, maintenance, or extensions.

This article will cover the fundamentals of GI flanges, their purpose, and a detailed analysis of blind flanges, including their applications, benefits, and role in Udhhyog industries.

What is a GI Flange?

A GI flange is a type of flange made from galvanized iron, a material that is coated with a layer of zinc to prevent corrosion and rusting. These flanges are widely used in piping and industrial applications where long-term durability and resistance to environmental factors are essential.

Why is Galvanized Iron Used?

Purpose of GI Flanges

GI flanges serve multiple purposes in industrial piping systems, particularly in Udhhyog applications where efficient fluid transport is necessary.

1. Connecting Pipes Securely

Flanges are designed to connect pipes in a system, ensuring a secure and tight seal that prevents leaks. They are bolted together using gaskets, providing a strong joint that withstands pressure fluctuations.

2. Easy Maintenance & Repairs

One of the biggest advantages of using GI flanges is that they allow for easy disassembly and maintenance. Unlike welded connections, flanged joints can be easily detached to inspect or replace components.

3. Flexibility in Piping Systems

GI flanges allow for modifications and extensions in piping networks without the need for extensive reinstallation. This makes them highly suitable for growing industries that may require system expansions.

4. Strength & Leak Prevention

Due to their high-strength material and bolted connections, GI flanges ensure leak-proof joints, essential in applications involving fluids, gases, and steam.

Types of GI Flanges

1. Blind Flange

A blind flange is a solid plate used to block the end of a pipeline. It is commonly used in applications where a pipeline needs to be sealed off permanently or temporarily for maintenance.

2. Slip-On Flange

This type of flange is designed to slide over a pipe before being welded. It is cost-effective and commonly used in low-pressure applications.

3. Weld Neck Flange

These flanges have a long neck and are butt-welded to the pipe, providing high strength and stress resistance, making them ideal for high-pressure applications.

4. Threaded Flange

Threaded flanges have internal threads, which means they can be screwed onto pipes without welding, making them suitable for low-pressure applications.

5. Socket Weld Flange

Designed for high-pressure systems, these flanges have a socket into which the pipe fits before being welded for a secure connection.

Understanding Blind Flanges & Their Uses

What is a Blind Flange?

A blind flange is a flat, circular plate that is bolted to the end of a piping system to block or seal off the flow of fluids or gases. Unlike other flanges, a blind flange does not have a bore (opening), making it ideal for terminating pipelines or isolating sections for maintenance.

Key Characteristics of Blind Flanges

Applications of Blind Flanges in Udhhyog

1. Temporary or Permanent Pipe Sealing

Blind flanges are used to permanently close off pipelines that are no longer in use or to temporarily block sections for future expansion.

2. Maintenance & System Isolation

During repairs or maintenance, certain sections of a piping system need to be isolated. A blind flange provides a reliable shut-off point, allowing workers to safely perform repairs without affecting the rest of the system.

3. Pressure Testing of Pipelines

Blind flanges are commonly used in pipeline pressure testing. By sealing the end of the pipe, it allows the system to be tested for leaks and pressure resistance.

4. Industrial Fluid Control

In industries dealing with oil, chemicals, and water supply, blind flanges help in regulating flow and isolating certain sections when needed.

Advantages of Using GI Blind Flanges

1. Corrosion Resistance

The zinc coating on GI blind flanges prevents rusting, making them ideal for outdoor and humid environments.

2. Cost-Effectiveness

Compared to stainless steel, GI flanges offer durability at a lower cost, making them a preferred choice in many industrial applications.

3. High Durability

Designed to withstand high pressure and harsh conditions, blind flanges ensure long-term reliability in industrial piping systems.

4. Ease of Installation & Maintenance

GI blind flanges are easy to install, remove, and replace, making them convenient for systems that require periodic modifications.

How to Choose the Right GI Flange?

When selecting a GI flange for your industrial needs, consider the following factors:

Conclusion

GI flanges, especially blind flanges, play an integral role in industrial piping systems by ensuring leak-proof connections, safety, and easy maintenance. Their corrosion resistance, affordability, and strength make them a preferred choice for Udhhyog industries dealing with water, chemicals, oil, and gas.

Understanding the purpose and applications of GI flanges can help industries optimize their piping systems, improve safety, and reduce long-term maintenance costs. Whether for sealing pipelines, system isolation, or pressure testing, blind flanges are an essential component in industrial operations.

If you are looking for high-quality GI flanges for your industrial needs, consider Udhhyog’s wide range of durable and cost-effective flanges designed to meet industry standards.

1 note

·

View note

Text

What is a GI Flange & Its Purpose? Blind Flange Uses Explained

In the industrial sector, especially in Udhhyog, proper piping system management is critical for operational efficiency. One of the most vital components in these systems is the GI flange (Galvanized Iron Flange), which plays a crucial role in ensuring leak-proof and secure connections between pipes. Among its various types, the blind flange is particularly important in systems that require periodic shutdowns, maintenance, or extensions.

This article will cover the fundamentals of GI flanges, their purpose, and a detailed analysis of blind flanges, including their applications, benefits, and role in Udhhyog industries.

What is a GI Flange?

A GI flange is a type of flange made from galvanized iron, a material that is coated with a layer of zinc to prevent corrosion and rusting. These flanges are widely used in piping and industrial applications where long-term durability and resistance to environmental factors are essential.

Why is Galvanized Iron Used?

Purpose of GI Flanges

GI flanges serve multiple purposes in industrial piping systems, particularly in Udhhyog applications where efficient fluid transport is necessary.

1. Connecting Pipes Securely

Flanges are designed to connect pipes in a system, ensuring a secure and tight seal that prevents leaks. They are bolted together using gaskets, providing a strong joint that withstands pressure fluctuations.

2. Easy Maintenance & Repairs

One of the biggest advantages of using GI flanges is that they allow for easy disassembly and maintenance. Unlike welded connections, flanged joints can be easily detached to inspect or replace components.

3. Flexibility in Piping Systems

GI flanges allow for modifications and extensions in piping networks without the need for extensive reinstallation. This makes them highly suitable for growing industries that may require system expansions.

4. Strength & Leak Prevention

Due to their high-strength material and bolted connections, GI flanges ensure leak-proof joints, essential in applications involving fluids, gases, and steam.

Types of GI Flanges

1. Blind Flange

A blind flange is a solid plate used to block the end of a pipeline. It is commonly used in applications where a pipeline needs to be sealed off permanently or temporarily for maintenance.

2. Slip-On Flange

This type of flange is designed to slide over a pipe before being welded. It is cost-effective and commonly used in low-pressure applications.

3. Weld Neck Flange

These flanges have a long neck and are butt-welded to the pipe, providing high strength and stress resistance, making them ideal for high-pressure applications.

4. Threaded Flange

Threaded flanges have internal threads, which means they can be screwed onto pipes without welding, making them suitable for low-pressure applications.

5. Socket Weld Flange

Designed for high-pressure systems, these flanges have a socket into which the pipe fits before being welded for a secure connection.

Understanding Blind Flanges & Their Uses

What is a Blind Flange?

A blind flange is a flat, circular plate that is bolted to the end of a piping system to block or seal off the flow of fluids or gases. Unlike other flanges, a blind flange does not have a bore (opening), making it ideal for terminating pipelines or isolating sections for maintenance.

Key Characteristics of Blind Flanges

Applications of Blind Flanges in Udhhyog

1. Temporary or Permanent Pipe Sealing

Blind flanges are used to permanently close off pipelines that are no longer in use or to temporarily block sections for future expansion.

2. Maintenance & System Isolation

During repairs or maintenance, certain sections of a piping system need to be isolated. A blind flange provides a reliable shut-off point, allowing workers to safely perform repairs without affecting the rest of the system.

3. Pressure Testing of Pipelines

Blind flanges are commonly used in pipeline pressure testing. By sealing the end of the pipe, it allows the system to be tested for leaks and pressure resistance.

4. Industrial Fluid Control

In industries dealing with oil, chemicals, and water supply, blind flanges help in regulating flow and isolating certain sections when needed.

Advantages of Using GI Blind Flanges

1. Corrosion Resistance

The zinc coating on GI blind flanges prevents rusting, making them ideal for outdoor and humid environments.

2. Cost-Effectiveness

Compared to stainless steel, GI flanges offer durability at a lower cost, making them a preferred choice in many industrial applications.

3. High Durability

Designed to withstand high pressure and harsh conditions, blind flanges ensure long-term reliability in industrial piping systems.

4. Ease of Installation & Maintenance

GI blind flanges are easy to install, remove, and replace, making them convenient for systems that require periodic modifications.

How to Choose the Right GI Flange?

When selecting a GI flange for your industrial needs, consider the following factors:

Conclusion

GI flanges, especially blind flanges, play an integral role in industrial piping systems by ensuring leak-proof connections, safety, and easy maintenance. Their corrosion resistance, affordability, and strength make them a preferred choice for Udhhyog industries dealing with water, chemicals, oil, and gas.

Understanding the purpose and applications of GI flanges can help industries optimize their piping systems, improve safety, and reduce long-term maintenance costs. Whether for sealing pipelines, system isolation, or pressure testing, blind flanges are an essential component in industrial operations.

If you are looking for high-quality GI flanges for your industrial needs, consider Udhhyog’s wide range of durable and cost-effective flanges designed to meet industry standards.

1 note

·

View note

Text

What is a GI Flange & Its Purpose? Blind Flange Uses Explained

In the industrial sector, especially in Udhhyog, proper piping system management is critical for operational efficiency. One of the most vital components in these systems is the GI flange (Galvanized Iron Flange), which plays a crucial role in ensuring leak-proof and secure connections between pipes. Among its various types, the blind flange is particularly important in systems that require periodic shutdowns, maintenance, or extensions.

This article will cover the fundamentals of GI flanges, their purpose, and a detailed analysis of blind flanges, including their applications, benefits, and role in Udhhyog industries.

What is a GI Flange?

A GI flange is a type of flange made from galvanized iron, a material that is coated with a layer of zinc to prevent corrosion and rusting. These flanges are widely used in piping and industrial applications where long-term durability and resistance to environmental factors are essential.

Why is Galvanized Iron Used?

Purpose of GI Flanges

GI flanges serve multiple purposes in industrial piping systems, particularly in Udhhyog applications where efficient fluid transport is necessary.

1. Connecting Pipes Securely

Flanges are designed to connect pipes in a system, ensuring a secure and tight seal that prevents leaks. They are bolted together using gaskets, providing a strong joint that withstands pressure fluctuations.

2. Easy Maintenance & Repairs

One of the biggest advantages of using GI flanges is that they allow for easy disassembly and maintenance. Unlike welded connections, flanged joints can be easily detached to inspect or replace components.

3. Flexibility in Piping Systems

GI flanges allow for modifications and extensions in piping networks without the need for extensive reinstallation. This makes them highly suitable for growing industries that may require system expansions.

4. Strength & Leak Prevention

Due to their high-strength material and bolted connections, GI flanges ensure leak-proof joints, essential in applications involving fluids, gases, and steam.

Types of GI Flanges

1. Blind Flange

A blind flange is a solid plate used to block the end of a pipeline. It is commonly used in applications where a pipeline needs to be sealed off permanently or temporarily for maintenance.

2. Slip-On Flange

This type of flange is designed to slide over a pipe before being welded. It is cost-effective and commonly used in low-pressure applications.

3. Weld Neck Flange

These flanges have a long neck and are butt-welded to the pipe, providing high strength and stress resistance, making them ideal for high-pressure applications.

4. Threaded Flange

Threaded flanges have internal threads, which means they can be screwed onto pipes without welding, making them suitable for low-pressure applications.

5. Socket Weld Flange

Designed for high-pressure systems, these flanges have a socket into which the pipe fits before being welded for a secure connection.

Understanding Blind Flanges & Their Uses

What is a Blind Flange?

A blind flange is a flat, circular plate that is bolted to the end of a piping system to block or seal off the flow of fluids or gases. Unlike other flanges, a blind flange does not have a bore (opening), making it ideal for terminating pipelines or isolating sections for maintenance.

Key Characteristics of Blind Flanges

Applications of Blind Flanges in Udhhyog

1. Temporary or Permanent Pipe Sealing

Blind flanges are used to permanently close off pipelines that are no longer in use or to temporarily block sections for future expansion.

2. Maintenance & System Isolation

During repairs or maintenance, certain sections of a piping system need to be isolated. A blind flange provides a reliable shut-off point, allowing workers to safely perform repairs without affecting the rest of the system.

3. Pressure Testing of Pipelines

Blind flanges are commonly used in pipeline pressure testing. By sealing the end of the pipe, it allows the system to be tested for leaks and pressure resistance.

4. Industrial Fluid Control

In industries dealing with oil, chemicals, and water supply, blind flanges help in regulating flow and isolating certain sections when needed.

Advantages of Using GI Blind Flanges

1. Corrosion Resistance

The zinc coating on GI blind flanges prevents rusting, making them ideal for outdoor and humid environments.

2. Cost-Effectiveness

Compared to stainless steel, GI flanges offer durability at a lower cost, making them a preferred choice in many industrial applications.

3. High Durability

Designed to withstand high pressure and harsh conditions, blind flanges ensure long-term reliability in industrial piping systems.

4. Ease of Installation & Maintenance

GI blind flanges are easy to install, remove, and replace, making them convenient for systems that require periodic modifications.

How to Choose the Right GI Flange?

When selecting a GI flange for your industrial needs, consider the following factors:

Conclusion

GI flanges, especially blind flanges, play an integral role in industrial piping systems by ensuring leak-proof connections, safety, and easy maintenance. Their corrosion resistance, affordability, and strength make them a preferred choice for Udhhyog industries dealing with water, chemicals, oil, and gas.

Understanding the purpose and applications of GI flanges can help industries optimize their piping systems, improve safety, and reduce long-term maintenance costs. Whether for sealing pipelines, system isolation, or pressure testing, blind flanges are an essential component in industrial operations.

If you are looking for high-quality GI flanges for your industrial needs, consider Udhhyog’s wide range of durable and cost-effective flanges designed to meet industry standards.

0 notes

Text

Blind Flange

A blind flange is a solid steel piece with no bore (interior diameter) and primarily designed to cap off a line.

As the majority of flange connections allow for the passing through of air or fluid via an interior opening, blinds give the ends of pipe connections a well-formed termination point or rerouting of the media in question towards another portion of the pipe assembly.

Opt for a blind flange in these cases, as well as in instances when a pipe line requires a future modification, such as the installation of a valve or fitting to reroute flow.

The majority of blind flanges are of basic constitution, require minimal machining compared to other flanges, and weigh more than most options given the lack of a bore.

Although these are typically provided as blanks to match up to slip on and weld neck flanges, we offer them custom machined as well. Popular alterations include NPT threads in the center, as well as custom bore holes to function as slip on flanges without hubs.

Blind flanges can also be furnished with high hubs on higher pressure applications (most API 6BX blinds have high hubs as a requirement).

The three most popular forms of face connections for blind flanges are typically going to match the mating flange in question.

These include raised face, flat face, and ring joint (RTJ) face seals. The first two are more common in basic sealing applications, with RTJ being the face of choice for higher pressure applications.

In specifications from decades past, including B16.1 and other industrial standard cast steel requirements, blind flanges would often contain a slight recess in the center portion of the raised face.

This recess allowed for the mating of the end of pipe into the connecting flange and allowing for a seal to form between this connecting flange and the blind.

The larger OD blind flanges opted for a concave recess through the body of the blind to create a dished head formation at the top of the flange.

As the older cast iron specification is relatively obsolete, most blind flanges will not be made in these styles. Instead, opt for a modern blind flange with or without a hub.

Ensure the safety and efficiency of your pipeline system with a high-quality blind flange. Designed to handle various pressure ratings and equipped with precision-engineered bolt holes, blind flanges provide a reliable seal for isolating sections, conducting maintenance, or testing.

Their robust design ensures durability and performance under demanding conditions. Don’t compromise on quality when securing your operations. Contact us today to find the perfect blind flange for your system and experience unmatched reliability and peace of mind!

What is a blind flange?

A blind flange is a flat, circular plate used to close or seal the end of a pipe or pipeline. It is commonly used in piping systems to block off flow and prevent the escape of fluids, gases, or other materials.

Blind flanges are available in various sizes and materials to match the specific requirements of the pipeline they are used with.

What are the advantages of blind flanges?

Blind flanges are relatively simple to install and remove compared to welded or bolted pipe closures, and they provide a secure seal for the end of a pipe, preventing leaks and ensuring that the pipeline remains pressurized or safe.

When should I use a blind flange?

When a pipeline is not in use or needs to be closed off temporarily, a blind flange is the ideal solution to seal the end and prevent leaks.

Blind flanges are useful during maintenance operations where sections of the pipeline need to be sealed off while work is carried out on the system.

When should I not use a blind flange?

Blind flanges completely block off the pipe, which makes them unsuitable for applications where continuous flow of liquids or gases is necessary.

In situations where a significant amount of pressure or fluid velocity is present, the blind flange may not provide a reliable seal or could potentially fail under extreme conditions.

What are the different types of blind flanges?

Blind flanges are available in various types, including slip-on flanges, threaded flanges, weld neck flanges, and socket weld flanges.

These types allow for flexibility in choosing the best blind flange depending on the specific requirements of the pipeline system, such as pipe size, pressure, or installation method.

0 notes

Text

Pipe End Cap Alternatives: Exploring Options

Pipe end caps are essential components in piping systems, used to seal or terminate the ends of pipes. While pipe end caps are a common solution, there are several alternatives available, each with its own advantages and disadvantages.

1. Flanges:

Definition: Flanges are circular plates with a raised or recessed surface, used to connect pipes or valves.

Advantages: Flanges offer a strong and reliable connection, allowing for easy disassembly and reassembly. They are also suitable for high-pressure applications.

Disadvantages: Flanges can be more expensive and require additional components, such as gaskets and bolts, for installation.

2. Blind Flanges:

Definition: Blind flanges are similar to regular flanges but have a solid, flat surface without a hole.

Advantages: Blind flanges provide a permanent seal and can be used to isolate sections of a piping system.

Disadvantages: Blind flanges are less versatile than regular flanges and may be more difficult to remove if necessary.

3. Plug Valves:

Definition: Plug valves are valves with a rotating plug that can be inserted into the pipe to block or allow flow.

Advantages: Plug valves offer a reliable and easy-to-operate method for controlling flow. They can also be used as end caps.

Disadvantages: Plug valves may have higher pressure drops than some other types of end caps.

4. Threaded Caps:

Definition: Threaded caps are simple fittings that screw onto the end of a threaded pipe.

Advantages: Threaded caps are easy to install and remove, and they are relatively inexpensive.

Disadvantages: Threaded caps may not be suitable for high-pressure or high-temperature applications.

5. Welding Caps:

Definition: Welding caps are designed to be welded directly to the end of a pipe.

Advantages: Welding caps provide a strong and permanent seal.

Disadvantages: Welding can be time-consuming and may require specialized equipment.

Platinex Piping Solutions

Platinex is a renowned brand offering high-quality stainless steel piping solutions, including pipe end caps and their alternatives. Manufactured by Ratnamani Metals and Tubes Limited (RMTL), a leading Indian stainless steel company, Platinex products are known for their durability, corrosion resistance, and precision manufacturing.

Conclusion

The choice of pipe end cap alternative depends on various factors, such as the application, pressure requirements, and desired level of flexibility. By carefully considering the available options, engineers and technicians can select the most suitable solution for their specific needs.

0 notes

Text

Designing LED Light Boards: A Comprehensive Guide

LED light boards are versatile and energy-efficient lighting solutions used in various applications, from signage and advertising to architectural lighting and interior design. Designing an effective LED light board requires careful consideration of several factors to ensure optimal performance and visual impact. Here are some key aspects to consider when designing LED light boards:

1. Purpose and Application:

Define the purpose of the led light board design and its intended application. Is it for indoor or outdoor use? Will it be used for signage, display, or ambient lighting?

2. Size and Shape:

Determine the dimensions and shape of the LED light board based on the available space and design requirements. Consider aspect ratio, viewing distance, and installation location.

3. LED Selection:

Choose high-quality LEDs that meet the desired specifications in terms of brightness, color temperature, color rendering index (CRI), and beam angle. Select the appropriate LED type (e.g., SMD, COB) based on the application.

4. LED Layout and Spacing:

Plan the layout of LEDs on the board to achieve uniform illumination and minimize dark spots or hotspots. Optimize LED spacing for even light distribution and maximum efficiency.

5. Thermal Management:

Implement effective thermal management solutions to dissipate heat generated by the LEDs and ensure long-term reliability. Use heat sinks, thermal pads, or fans to maintain optimal operating temperatures.

6. Power Supply and Control:

Choose a suitable power supply unit (PSU) capable of delivering the required voltage and current to the LEDs. Consider dimming options, such as PWM or analog dimming, for dynamic lighting control.

7. Optics and Diffusers:

Incorporate optical elements such as lenses, reflectors, or diffusers to control light direction, beam spread, and uniformity. Select diffuser materials and finishes to achieve the desired light diffusion and visual effects.

8. Electrical Wiring and Connectivity:

Ensure proper electrical wiring and connectivity between the LEDs, power supply, and control system. Use high-quality connectors, cables, and terminal blocks for reliable electrical connections.

9. Enclosure and Protection:

Design a durable enclosure or housing to protect the LED light board from environmental factors such as moisture, dust, and impact. Choose materials that are weather-resistant and suitable for the application environment.

10. Compliance and Safety:

Adhere to relevant safety standards and regulations for electrical installations and lighting products. Consider certifications such as UL, CE, or RoHS for compliance with industry requirements.

11. Testing and Optimization:

Conduct thorough testing and optimization of the LED light board prototype to ensure it meets performance specifications and design objectives. Evaluate factors such as brightness, color consistency, energy efficiency, and reliability.

By carefully considering these design principles and best practices, you can create LED light boards that effectively meet the specific requirements of your project while delivering optimal performance, durability, and visual appeal.

For more info. visit us:

Digital sign outdoor

Flange signage

Signage outdoor

0 notes

Text

5 Types of Flanges from Manilaxmi Overseas

Manilaxmi Overseas is a major contributor to Flanges Manufacturer in India and an industry standard of excellence worldwide, having pioneered innovative piping solutions. Their dedication to exacting manufacturing and top-tier quality has won them an unique name in the market as a leading Flanges Supplier in India. Manilaxmi overseas thrives on providing cutting-edge solutions for a wide range of projects in the Middle East, greatly contributing to the region's infrastructure development. Let us delve into the history of this dynamic company, where craftsmanship meets innovation in the domain of piping solutions.

What are Flanges?

Flanges are flat, typically circular components with evenly spaced holes, designed to connect pipes, valves, pumps, and other equipment in a piping system. These connectors provide a reliable and leak-proof joint, allowing for easy assembly, disassembly, and maintenance of the entire system.

Their adaptability makes them important in construction, manufacturing, and infrastructure projects where dependable connections are critical to the proper operation of pipes and other related parts.

Different Types of Flanges

Weld Neck Flanges:

Distinguished by a long neck, offering increased support and stability. Ideal for high-pressure applications and critical conditions.

Slip-On Flanges:

Easy to install and remove, making them cost-effective.Suited for low-pressure and non-critical applications.

Socket Weld Flanges:

Welded directly onto the pipe, providing a strong connection.Suitable for smaller-sized, high-pressure pipelines.

Threaded Flanges:

Features threaded holes for easy installation. Commonly used in low-pressure applications.

Blind Flanges:

Solid plates used to block the end of a pipe securely. Essential for pipeline termination or closure.

Visit Manilaxmi Overseas for Choosing Best Flanges

In conclusion, flanges serve as linchpins in the functionality of piping systems. Understanding the various types and their specific functions is crucial for selecting the right flange for a given application. Proper installation enhances the reliability and longevity of these components, making them indispensable in industries relying on the seamless transportation of fluids or gases.

Manilaxmi Overseas, a reputable Indian manufacturer, is presented with a number of issues and decisions that will have an impact on their business. Maintaining a perfect balance of quality, efficiency, regulations, and environmental responsibility is critical for long-term success in this expanding industry.

As a Flanges Supplier in India, we believe that our customers should benefit fully from our innovative products which are available in various cities. We are also Supply Weld Neck Flange Manufacturer in India and Socket Weld Flange Manufacturer in India.

For more information,

Website: manilaxmioverseas.com

Also, Visit: Slip on Flange Manufacturer in India

0 notes

Text

How to Choose the Best Arduino Screw Terminals for Your Projects

There are different options of screw terminals for Arduino screw terminals, and by selecting the most appropriate screw terminals, you do work with wiring and connecting the components way simpler. Connectivity can be realized easily and quickly through the use of screw terminals, which eliminate the need to solder wires. The screw terminal options you get on the Arduino boards in the market are so many and it is sometimes difficult to choose those that are considered best depending on your needs.

The following blog post will take you through the critical elements to have in mind when deciding to purchase Arduino screw terminals so that you pick the most versatile and long-lasting products for all your DIY electronics projects. No matter what kind you are interested in procuring, whether it is for simple prototyping or for use in a more industrial-type setting, using these tips will make the purchase process much easier and will also ensure that you receive exactly what you want.

Durability

Because you will not want to change scrw terminals very often, go for these made of tough materials, for example, nylon plastic which is resilient to wear and tear. Metal threaded inserts for securing wires also add more strength and longevity compared to plain plastic screws.

For heavy-duty applications with higher voltages or currents, using Arduino screw terminals rated for the required loads will prevent meltdowns. opt for UL-rated industrial ones with casings that can handle exposure to extreme temperatures or environments.

Ease of Installation and Use

For hobbyists and professionals alike, the ease of installation and use is a key consideration. Look for Arduino screw terminals that offer features like:

Color coding for easy identification of connections.

Labels or markings that allow you to note down connection points.

A design that accommodates different wire sizes without the need for additional tools.

These small conveniences can greatly enhance the speed and efficiency of your project assembly and maintenance.

Compact Design

When working with Arduino prototype boards or packing numerous components into an enclosure, compact screw terminal blocks help optimize available space. Look for miniaturized models like 2-pole or 4-pole ones that occupy less area while still allowing sufficient wiring room.

Low profile terminals like the plug-in block types are ideal if you need to stack multiple layers of connections. Slim vertical or horizontal screw terminals also have small footprints perfect for Arduino projects with size constraints.

Compatibility with Your Board

The identification of the compatibility of the screw terminals with the Arduino board is often the first thing to do. Bear in mind that not all terminals are to fit this very board so one has to look for the terminals created explicitly for the given Arduino model. Whether you are working on introducing Arduino DIN rail project, or are rather incorporating Arduino into the larger WiFi PLC system, making sure it fits perfectly will spare you a lot of unpleasant surprises in the future.

Terminal Block Types

Arduino screw terminals come in a variety of connector styles to suit the enclosures and layouts of your projects:

PCB Mount – As the name suggests, these have pins for securely fastening onto PCBs.

Panel Mount – These terminal blocks can be mounted on enclosure walls. They have a flange/frame for screw-fixing onto flat surfaces.

DIN Rail Mount – Designed to snap conveniently onto DIN rails widely used in industrial electronics.

Free-Hanging – No mounting hardware required. You can use them loose by just connecting wires.

Conclusion

Choosing the best Arduino screw terminals gets easy once you evaluate options based on ease of use, durability, size constraints, and terminal block types. erqos offers an extensive range of terminal connectors to suit diverse budgets and project needs. Visit https://erqos.com/ to find the ideal ones to organize and streamline your next Arduino project!

1 note

·

View note

Text

A Comprehensive Overview of High-Pressure Pipe Fittings Hastelloy C276 Pipe Fittings

By joining valves, pipes, pumps, and other machinery using bogus fittings, a pipeline system can be constructed with a diameter ranging from 2 to 4 inches. They are basically the high-pressure pipe fittings and the Hastelloy C276 flanges which are made of stainless steel are durable, long-lasting, and realistically priced. On the other hand, stainless steel's reduced oxidisation resistance could make it incompatible for some applications. Hence, the Nickel Alloy Pipe Fittings are very sustainable as well as wonderful to use for commercial as well as the residential purpose.

It is also important to note that the Nickel 200 Pipe Fittings is well constructed from solid steel blocks that are machined to shape according to specifications, it meets all applicable standards. The device can endure pressures up to the highest class, which is Stainless Steel High Pressure Pipe Fittings as well as also known as Inconel 625 Pipe Fittings. Extreme tension Forged fittings are made by joining two pipe fittings and sealing them with a gasket.

On the other hand, the Incoloy 825 pipe fittings and the Forged fittings come in two varieties: threaded and socket-weld. The pipe is screwed into threaded fittings, whereas the pipes are filledet-welded into socket-weld fittings.

Why High-Pressure Fittings Are Necessary

In many cases, high-pressure fittings are the best option for fluids. They can be found in the following systems and machines:

Skids and panels for gas and oil control

Chemical injection skids

Equipment that uses hydraulic power

Using water jets for cleaning and cutting

Fittings for Stainless Steel Pipes

Fittings of the same or different diameters are used to create couplings, which link two male terminals.

Crosses—The Hastelloy pipe fittings allow you to attach four identical connections to a line of tubing.

Elbows are fittings that join two pieces of tubing at a right angle to one another, allowing the line to be extended.

Nipples are used to join two common male tubing ends when using threaded or coned tubing of varying common lengths.

Reducing Adapters for SS To accommodate fittings and pipes of varying sizes, adapters are manufactured to modify the one end of a pipe. It usually has a male and a female end and is also called diminishing coupling.

Tees—Three identically sized standard connections used to lengthen a tubing line—are the fittings in question.

Advantages of Clamps for High-Pressure Pipes

If a complex threaded connection is required in an industrial setting, these fittings are the way to go. In addition, structural hydrodynamics testing can be done using it.

Chemical fertilizer manufacturing, nuclear power plants, heat exchangers, petroleum gas industries, medical and pharmaceutical sectors, water gas pipe systems, and petrochemical refineries are just a few of the numerous places you could find their use.

A high-pressure pipe fitting is an essential component in numerous applications that demand elevated temperatures. Transporting gases or fluids at high pressure is its primary function.

Read More :-https://www.pipingmaterial.ae/stainless-steel-ferrule-fittings/

0 notes

Link

#terminalblocks#Manufacturing#TerminalParts#ExporterterminalBlocks#PluggableTerminalBlocks#PCBTerminalBlocks#Industrial Terminal Blocks#Flange Terminal Blocks#Left Angle Terminal Blocks#Italy

0 notes

Text

Download MS Blind Flange PDF with Specifications and Uses

MS Blind Flanges (Mild Steel Blind Flanges) are integral components used to seal the ends of pipelines in industrial applications. They are designed to block off flow, allowing for maintenance, testing, or future pipeline expansions.

For complete technical specifications, you can download the MS Blind Flange PDF, which includes dimensions, pressure ratings, and material properties.

What is an MS Blind Flange?

An MS Blind Flange is a solid disk-shaped plate without a bore. It is bolted to the pipe to terminate flow, ensuring that sections of the pipeline remain sealed. This makes them ideal for temporary or permanent closure of piping systems.

Key Features of MS Blind Flanges:

Made from Mild Steel (MS), ensuring durability and affordability.

Available in multiple pressure ratings, including 150#, 300#, 600#, and higher.

Compliant with international standards, such as ASME, ANSI, and IS.

Used in various industries, including oil & gas, power plants, chemical processing, and water treatment.

Specifications of MS Blind Flanges

Understanding the technical specifications of MS Blind Flanges is crucial for selecting the right type for your industrial needs.

1. Material Composition

Mild Steel (MS): Offers strength and cost-effectiveness.

Galvanized Coating (Optional): Provides corrosion resistance.

Custom Fabrication: Available for specialized requirements.

2. Pressure Ratings

ANSI 150# – Low-pressure applications.

ANSI 300# to 600# – Medium to high-pressure pipelines.

ANSI 900# and above – Used in extreme industrial conditions.

3. Dimensions & Standard Sizes

Below is a reference chart of standard MS Blind Flange sizes:Nominal Pipe Size (NPS)Flange Diameter (mm)Bolt Hole Diameter (mm)Number of Bolts1/2"901541"1251942"1501944"2301986"2802288"34522810"405251212"485251214"535291216"595291618"635321620"6853220

Applications of MS Blind Flanges

MS Blind Flanges are widely used across various industries due to their sealing efficiency and ability to handle high-pressure environments.

1. Oil & Gas Industry

Used in pipelines, refineries, and offshore drilling platforms.

Ensures safe isolation during maintenance and testing.

2. Water Treatment Plants

Helps in isolating pipeline sections for repair work.

Used in water distribution systems.

3. Power Generation

Used in steam transmission and cooling water pipelines.

Provides secure pipeline closure.

4. Chemical Processing Plants

Helps in handling hazardous chemicals and gases.

Provides corrosion-resistant sealing solutions.

5. Construction & Infrastructure

Used in HVAC systems, drainage, and plumbing networks.

Ensures safe termination of unused pipelines.

6. Marine & Shipbuilding

Used in ship fuel pipelines and seawater distribution.

Ensures safe handling of high-pressure liquids.

Advantages of MS Blind Flanges

MS Blind Flanges offer several benefits, making them essential in industrial piping systems.

1. High Durability

Made from strong mild steel, ensuring long service life.

2. Leak Prevention

Completely seals off pipelines, preventing leaks and contamination.

3. Cost-Effective Solution

Affordable compared to stainless steel and alloy alternatives.

4. Easy Installation & Removal

Can be bolted or unbolted for maintenance or expansion.

5. Customization Available

Available in different coatings, pressure ratings, and dimensions.

Where to Download the MS Blind Flange PDF?

For complete MS Blind Flange specifications, material properties, and technical drawings, download the MS Blind Flange PDF from Udhhyog, a trusted supplier in Delhi, Haryana, Uttar Pradesh, and Jammu & Kashmir.

Top MS Blind Flange Suppliers:

Udhhyog (Delhi) – Leading supplier of industrial pipe fittings.

B2B Industrial Marketplaces – Online sources for bulk orders.

Local Distributors – Available in major industrial cities.

Conclusion

MS Blind Flanges play a crucial role in sealing, pressure testing, and pipeline safety. Whether used in oil & gas, chemical plants, or water treatment facilities, MS Blind Flanges provide a reliable and cost-effective solution.

For premium MS Blind Flanges, trust Udhhyog, your leading supplier in North India.

#MSBlindFlange#MildSteelFlange#IndustrialFittings#Pipeline#FlangeTypes#Udhhyog#MetalFabrication#Engineering#Welding#Manufacturing#FlangeSpecifications

1 note

·

View note

Text

Download MS Blind Flange PDF with Specifications and Uses

MS Blind Flanges (Mild Steel Blind Flanges) are integral components used to seal the ends of pipelines in industrial applications. They are designed to block off flow, allowing for maintenance, testing, or future pipeline expansions.

For complete technical specifications, you can download the MS Blind Flange PDF, which includes dimensions, pressure ratings, and material properties.

What is an MS Blind Flange?

An MS Blind Flange is a solid disk-shaped plate without a bore. It is bolted to the pipe to terminate flow, ensuring that sections of the pipeline remain sealed. This makes them ideal for temporary or permanent closure of piping systems.

Key Features of MS Blind Flanges:

Made from Mild Steel (MS), ensuring durability and affordability.

Available in multiple pressure ratings, including 150#, 300#, 600#, and higher.

Compliant with international standards, such as ASME, ANSI, and IS.

Used in various industries, including oil & gas, power plants, chemical processing, and water treatment.

Specifications of MS Blind Flanges

Understanding the technical specifications of MS Blind Flanges is crucial for selecting the right type for your industrial needs.

1. Material Composition

Mild Steel (MS): Offers strength and cost-effectiveness.

Galvanized Coating (Optional): Provides corrosion resistance.

Custom Fabrication: Available for specialized requirements.

2. Pressure Ratings

ANSI 150# – Low-pressure applications.

ANSI 300# to 600# – Medium to high-pressure pipelines.

ANSI 900# and above – Used in extreme industrial conditions.

3. Dimensions & Standard Sizes

Below is a reference chart of standard MS Blind Flange sizes:Nominal Pipe Size (NPS)Flange Diameter (mm)Bolt Hole Diameter (mm)Number of Bolts1/2"901541"1251942"1501944"2301986"2802288"34522810"405251212"485251214"535291216"595291618"635321620"6853220

Applications of MS Blind Flanges

MS Blind Flanges are widely used across various industries due to their sealing efficiency and ability to handle high-pressure environments.

1. Oil & Gas Industry

Used in pipelines, refineries, and offshore drilling platforms.

Ensures safe isolation during maintenance and testing.

2. Water Treatment Plants

Helps in isolating pipeline sections for repair work.

Used in water distribution systems.

3. Power Generation

Used in steam transmission and cooling water pipelines.

Provides secure pipeline closure.

4. Chemical Processing Plants

Helps in handling hazardous chemicals and gases.

Provides corrosion-resistant sealing solutions.

5. Construction & Infrastructure

Used in HVAC systems, drainage, and plumbing networks.

Ensures safe termination of unused pipelines.

6. Marine & Shipbuilding

Used in ship fuel pipelines and seawater distribution.

Ensures safe handling of high-pressure liquids.

Advantages of MS Blind Flanges

MS Blind Flanges offer several benefits, making them essential in industrial piping systems.

1. High Durability

Made from strong mild steel, ensuring long service life.

2. Leak Prevention

Completely seals off pipelines, preventing leaks and contamination.

3. Cost-Effective Solution

Affordable compared to stainless steel and alloy alternatives.

4. Easy Installation & Removal

Can be bolted or unbolted for maintenance or expansion.

5. Customization Available

Available in different coatings, pressure ratings, and dimensions.

Where to Download the MS Blind Flange PDF?

For complete MS Blind Flange specifications, material properties, and technical drawings, download the MS Blind Flange PDF from Udhhyog, a trusted supplier in Delhi, Haryana, Uttar Pradesh, and Jammu & Kashmir.

Top MS Blind Flange Suppliers:

Udhhyog (Delhi) – Leading supplier of industrial pipe fittings.

B2B Industrial Marketplaces – Online sources for bulk orders.

Local Distributors – Available in major industrial cities.

Conclusion

MS Blind Flanges play a crucial role in sealing, pressure testing, and pipeline safety. Whether used in oil & gas, chemical plants, or water treatment facilities, MS Blind Flanges provide a reliable and cost-effective solution.

For premium MS Blind Flanges, trust Udhhyog, your leading supplier in North India.

#MSBlindFlange#MildSteelFlange#IndustrialFittings#Pipeline#FlangeTypes#Udhhyog#MetalFabrication#Engineering#Welding#Manufacturing#FlangeSpecifications

1 note

·

View note

Text

Download MS Blind Flange PDF with Specifications and Uses

MS Blind Flanges (Mild Steel Blind Flanges) are integral components used to seal the ends of pipelines in industrial applications. They are designed to block off flow, allowing for maintenance, testing, or future pipeline expansions.

For complete technical specifications, you can download the MS Blind Flange PDF, which includes dimensions, pressure ratings, and material properties.

What is an MS Blind Flange?

An MS Blind Flange is a solid disk-shaped plate without a bore. It is bolted to the pipe to terminate flow, ensuring that sections of the pipeline remain sealed. This makes them ideal for temporary or permanent closure of piping systems.

Key Features of MS Blind Flanges:

Made from Mild Steel (MS), ensuring durability and affordability.

Available in multiple pressure ratings, including 150#, 300#, 600#, and higher.

Compliant with international standards, such as ASME, ANSI, and IS.

Used in various industries, including oil & gas, power plants, chemical processing, and water treatment.

Specifications of MS Blind Flanges

Understanding the technical specifications of MS Blind Flanges is crucial for selecting the right type for your industrial needs.

1. Material Composition

Mild Steel (MS): Offers strength and cost-effectiveness.

Galvanized Coating (Optional): Provides corrosion resistance.

Custom Fabrication: Available for specialized requirements.

2. Pressure Ratings

ANSI 150# – Low-pressure applications.

ANSI 300# to 600# – Medium to high-pressure pipelines.

ANSI 900# and above – Used in extreme industrial conditions.

3. Dimensions & Standard Sizes

Below is a reference chart of standard MS Blind Flange sizes:Nominal Pipe Size (NPS)Flange Diameter (mm)Bolt Hole Diameter (mm)Number of Bolts1/2"901541"1251942"1501944"2301986"2802288"34522810"405251212"485251214"535291216"595291618"635321620"6853220

Applications of MS Blind Flanges

MS Blind Flanges are widely used across various industries due to their sealing efficiency and ability to handle high-pressure environments.

1. Oil & Gas Industry

Used in pipelines, refineries, and offshore drilling platforms.

Ensures safe isolation during maintenance and testing.

2. Water Treatment Plants

Helps in isolating pipeline sections for repair work.

Used in water distribution systems.

3. Power Generation

Used in steam transmission and cooling water pipelines.

Provides secure pipeline closure.

4. Chemical Processing Plants

Helps in handling hazardous chemicals and gases.

Provides corrosion-resistant sealing solutions.

5. Construction & Infrastructure

Used in HVAC systems, drainage, and plumbing networks.

Ensures safe termination of unused pipelines.

6. Marine & Shipbuilding

Used in ship fuel pipelines and seawater distribution.

Ensures safe handling of high-pressure liquids.

Advantages of MS Blind Flanges

MS Blind Flanges offer several benefits, making them essential in industrial piping systems.

1. High Durability

Made from strong mild steel, ensuring long service life.

2. Leak Prevention

Completely seals off pipelines, preventing leaks and contamination.

3. Cost-Effective Solution

Affordable compared to stainless steel and alloy alternatives.

4. Easy Installation & Removal

Can be bolted or unbolted for maintenance or expansion.

5. Customization Available

Available in different coatings, pressure ratings, and dimensions.

Where to Download the MS Blind Flange PDF?

For complete MS Blind Flange specifications, material properties, and technical drawings, download the MS Blind Flange PDF from Udhhyog, a trusted supplier in Delhi, Haryana, Uttar Pradesh, and Jammu & Kashmir.

Top MS Blind Flange Suppliers:

Udhhyog (Delhi) – Leading supplier of industrial pipe fittings.

B2B Industrial Marketplaces – Online sources for bulk orders.

Local Distributors – Available in major industrial cities.

Conclusion

MS Blind Flanges play a crucial role in sealing, pressure testing, and pipeline safety. Whether used in oil & gas, chemical plants, or water treatment facilities, MS Blind Flanges provide a reliable and cost-effective solution.

For premium MS Blind Flanges, trust Udhhyog, your leading supplier in North India.

#MSBlindFlange#MildSteelFlange#IndustrialFittings#Pipeline#FlangeTypes#Udhhyog#MetalFabrication#Engineering#Welding#Manufacturing#FlangeSpecifications

0 notes