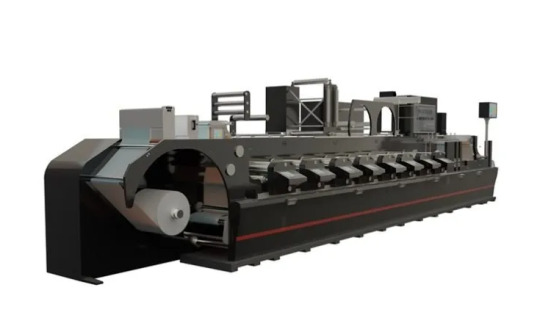

#Flexo Label Printing Machine

Explore tagged Tumblr posts

Text

You’re Invited!

Join WEBTECH at Bharat Print Expo 2025 (BIEC, Bengaluru)

Dates: 24th – 26th April, 2025

Venue: BIEC, Bengaluru

Stall No.: Hall 3, Stall B140

We are thrilled to invite you to visit us at the Bharat Print Expo 2025, where WEBTECH will be unveiling :

- The Latest Generation of our Fully Servo Flexographic Label Printing Machine in a striking new color and design, built for a 450 mm working width.

Come witness the machine that’s setting new benchmarks in precision and speed across India’s flexo printing industry. Engineered for excellence, our new Flexo Press is receiving overwhelming appreciation for its performance, innovation, and efficiency—earning its place as one of the best presses in the country.

Don’t miss this opportunity to experience cutting-edge printing technology in action and explore how WEBTECH can support your future growth.

We look forward to welcoming you!

YouTube : https://youtu.be/inPLvt1TgzM?si=NiuTaCm3QG0uGdjv

Visitor's Online Registration Link : https://www.bharatprintexpo.com/mod_login/visitor_login.php

Team WEBTECH

-"Crafted for Performance, Designed for Precision"

099997 79973

Please Subscribe to our YouTube Channel for more latest updates :

https://www.youtube.com/channel/UCKpciPWoG7D-AMaTOHbmbPg/videos?view_as=subscriber

#bharat#print#expo#label printing#packaging labels#flexo printing machine#webtech#flexographic label printing machine#fully servo#flexo innovation#label#flexo#Bengaluru

0 notes

Text

Elevate Your Production Standards with UV Graphic’s Expertise

Machines that cure are crucial for fast, effective hardening or drying of different materials such as inks, coatings, adhesives in various industries. Such machines cure by applying heat, UV, or other forms of energy so that they assure durability with high finish quality. These machines find extensive applications in industries printing, packaging, automobiles, and electronics.

UV Graphics-the supreme manufacturer of curing machines, produces the avant-garde products matching the expectations of the modern-day industries. The curing machines-a perfect example of precision and speed; even energy efficiency is guaranteed, every time-one can expect flawless output under flexible variable conditions. Some of the features include adjustable intensity of curing, automated controls, and adaptability to various substrates that truly define invaluable wealth to any production line.

Choosing UV Graphic means an acquisition of sophistication in technology, which is further strengthened by unmatchable support for any kind of business. It is because of innovation and quality that UV Graphic endeavors toward simplifying processes within an organization while excelling at achieving high achievements. From equipment to machines based on UV curing or rather on thermal curing systems, realize your modern machines of performance, reliability, and trusted partnership in the manufacturing sector.

#uv curing systems#curing machine manufacturer#rotary hot foil stamping#flexo printing machines manufacturer#gravure printing machines manufacturer#label punching machines manufacturer

0 notes

Video

youtube

Height-LED UV Curing System Hybrid, Designed for Gidue 430 6-color Flexo Press

Instant on/off;

Each lamp can be controlled individually;

Mercury lamp for UV varnish + LED lamps for UV ink;

Mercury lamp and LED lamp use same cassett, easy for installation;

Pin fixing firmly;

Save 70% energy, environmentally friendly;

Cold light source, suitable for heat-sensitive materials

Height-LED looks forward to working with you.

WhatsApp: +8618924582621

Email: [email protected]

#youtube#UV#pprinting#uuva#flexoprinting#flexoprinter#flexo printing machine#varnish#pcb#led#leduv#uvled#label#sticker#tag#Height-LED#HeightLED#nilpeter#mark andy#mps#gallus#arsoma#bobst#gidue#omet#lombardi

1 note

·

View note

Text

How to Choose the Right Flexo Printing Machinery

Investing in the right flexographic (flexo) printing machine is an important decision for any printing or packaging business. The right equipment can improve print quality, speed up production, and reduce operating costs. However, with many options available in the market, choosing the right machine can be challenging.

In this blog, we’ll help you understand what to look for when selecting a flexo printing machine. Whether you're a startup or an established business, working with experienced flexo printing machine manufacturers and choosing a trusted printing machine manufacturer in India can make a big difference.

Understand Your Business Needs

Before you start comparing machines, it's important to know what you need. Consider the type of material you plan to print on—paper, plastic, film, foil, or labels. Also, think about your production volume, color requirements, and the level of automation you need. If your jobs involve short runs with frequent changes, you’ll need a machine that allows quick setup and easy plate changes.

Look for Print Quality and Speed

Flexo printing machines are known for high-speed printing, but print quality should never be compromised. Choose a machine that offers sharp image clarity and consistent ink distribution. A good machine should balance speed and quality to help you meet deadlines without sacrificing output.

Evaluate Machine Features and Technology

Modern flexo machines come with advanced features like automatic tension control, drying systems, and computer-based controls. These features reduce manual work and increase efficiency. Machines with servo drives and automatic registration systems help improve precision and reduce material waste.

When choosing a machine, look for features that match your workflow and production goals. It’s best to select a machine that offers room for upgrades or customization if your needs grow in the future.

Consider After-Sales Support and Maintenance

Even the best machine will require maintenance over time. That’s why after-sales support is crucial. Work with flexo printing machine manufacturers that offer training, spare parts, technical guidance, and quick service response. This will help reduce downtime and keep your production running smoothly.

Choose the Right Manufacturer

Partnering with a reliable printing machine manufacturer in India ensures that you receive a machine that’s built to last. Look for manufacturers with proven experience, good client reviews, and a strong focus on quality. Companies like NBG Printographic Machinery Co. Pvt. Ltd. have decades of experience and offer advanced flexo printing solutions for various printing needs. Their machines are built with precision, using modern technology and durable materials, making them a preferred choice for clients in India and abroad.

Plan Your Budget Wisely

Cost is always a factor, but it's important to focus on value—not just price. A cheaper machine might cost more in the long run due to breakdowns, poor print quality, or limited features. On the other hand, a well-designed, efficient machine might offer faster returns through increased productivity and lower maintenance costs.

Ask the manufacturer about total cost of ownership, including installation, training, spare parts, and support.

Final Thoughts

Choosing the right flexo printing machinery takes careful planning and research. Understand your needs, compare machine features, and work with a trusted printing machine manufacturer in India who offers long-term value and support.

Flexo printing is a smart investment for packaging and label production, but the success of that investment depends on the machine you choose. Reliable flexo printing machine manufacturers can help you find the perfect fit for your business—improving quality, efficiency, and profitability.

Ready to take the next step? Explore the latest flexo printing machines at NBG Printographic Machinery Co. Pvt. Ltd. and find the perfect solution for your printing needs.

0 notes

Text

Precision Printing Solutions with Singla Engravures LLP

In the dynamic world of printing and packaging, precision and consistency are non-negotiable. Singla Engravures LLP stands as a pioneer among printing cylinder manufacturers in India, known for delivering high-performance cylinders that meet international standards. Whether it’s for gravure or flexo printing, their advanced technology and skilled craftsmanship ensure a perfect print—every time.

Meeting Industry Demands with Reliable Cylinder Technology

Modern printing demands speed, detail, and repeat accuracy. Many businesses face production challenges due to poor-quality cylinders that wear quickly or deliver inconsistent results. Singla Engravures addresses these challenges with cylinders engineered to last, customized to fit any press, and built to support long production runs without compromising quality.

How Singla Engravures Manufactures Precision Printing Cylinders

Every order begins with a careful understanding of your printing needs. The cylinders are crafted using modern electroplating and laser engraving technology to produce sharp images and clean transitions. Singla’s deep experience in the industry has earned them a trusted name among printing cylinder manufacturers in India, with a commitment to innovation and quality at every stage of production.

Why Businesses Trust Singla Engravures

When you partner with Singla, you’re not just buying cylinders—you’re investing in reliability. Their products support faster production cycles, reduce machine downtime, and deliver unmatched image consistency. With a legacy of excellence and a focus on quality, Singla provides:

Precision-fit cylinders for rotogravure and flexo machines

Advanced surface treatments for durability

High-definition engraving for fine detail printing

On-time delivery across India

Tailored solutions for unique production environments

Start Scaling Your Print Performance with Singla

Whether you're in the packaging, labeling, or textile industry, Singla Engravures has the tools to take your production to the next level. As one of the most reliable printing cylinder manufacturers in India, their custom solutions help businesses improve efficiency, maintain consistency, and deliver superior print quality to clients around the world.

Frequently Asked Questions

What printing services does Singla specialize in? Singla Engravures specializes in manufacturing rotogravure and flexo printing cylinders with high precision.

Are your printing cylinders compatible with modern machines? Yes, our cylinders are designed to fit seamlessly with modern flexographic and gravure printing presses.

Do you offer customization? Absolutely. Each cylinder is customized based on your machinery specs and the type of material being printed.

What makes your cylinders stand out? Our cylinders are long-lasting, precision-engineered, and made using state-of-the-art engraving technology.

Can I place a bulk order? Yes. We cater to both small and large-scale orders with consistent quality across each unit.

Highlights of Singla Engravures LLP

Two decades of experience in cylinder engineering

In-house laser engraving and electroplating

Fast turnaround times and pan-India delivery

Dedicated support for commercial and industrial printing

Precision-focused production with global quality standards

Contact Singla Engravures LLP

Website: www.singlaengravuresllp.com Email: [email protected] Phone: +91 93131 83167

0 notes

Text

Flexo Printing Machines in Delhi in Delhi NCR

When it comes to choosing between Flexo Printing and Offset Printing for packaging, both technologies are a leverage for businesses. They are both effective printing methods used in the packaging industry. But with their differences, one might be able to make a better choice according to their specific packaging needs.

SBS is indeed a leader in manufacturing packaging machines. Through such state-of-the-art manufacturing, businesses have been able to acquire modern equipment like the Best Flexo Printing Machines in Delhi, the Best Paper Cup Making Machines in Delhi, Biodegradable Bag Making Machines in Delhi, and Non-Woven Bag Making Machines in Delhi. This blog will discuss the significant differences between Flexo Printing and Offset Printing, how these processes benefit a business, and which option is best suited for your packaging needs by 2025.

What is Flexo Printing?

Flexographic printing refers to Flexo printing, which is a fairly advanced, high-speed, and economical printing technology that uses soft and flexible relief plates for transferring inks to almost all substrates such as paper, plastic, and film. This printing method is primarily used for developing packaging materials, such as labels, bags, boxes, and wraps.

The Flexo Printing Machine Manufacturing in Delhi is from SBS Machinery; it is supposed to deliver highly efficient print with a wider range of materials, including biodegradable ones. A flexo printing machine configures itself to be able to print on any kind of packaging substrate. This makes it a suitable equipment option for businesses that want to create package decorations in complicated designs, bright colors, and the same standard results.

What is Offset Printing?

Offset printing is an ancient printing process that is still popular and is widely adopted for bulk jobs like books, magazines, and even commercial packaging. The offset method consists of the transfer of the ink from a printing plate to a rubber-like blanket which in turn transfers the ink to paper or any other substrate. The offset printing is exceptional for high-quality images and sharpness making it very appropriate for any project that demands fine details and exact color reproduction.

This modality can be used in packaging but offset printing is mainly used for cartons and paper products such as labels. It is the least versatile in printing applications probably due to its restricted capacity to print on flexible materials like plastics or films compared to Flexo printing.

Key Differences Between Flexo and Offset Printing

1. Flexibility of Substrates

Flexo Printing: From all other uses, this is best suited for high-volume, seamless production. Thus, it is very open in this part of the world. Flexo printing can print both on paper and nonpaper substrates-plastics-metal and foil. This will make it useful in a larger number of applications for package applications, such as bio-degradable bags, paper cups, and non-woven bags. This flexible option on the Flexo printing machine manufacturer in Delhi can communicate wonders for brands looking at print differentiation.

Offset Printing: As effective as offset printing is in high-quality printed materials, this printing technique suffers from the disadvantage of being limited to flat substrates, such as paper or cardboard. But when the company wants the printed paper to be flexible or made of unusual substrates, offset printing will not work.

2. Print Quality and Detail

Flexo Printing: Flexo printing allows vibrant and quality prints, but it gives lesser detailed and sharper results compared to offset printing. However, with various advancements in Flexo printing technology, for instance, that of SBS’s Flexo Printing Machine, the print quality has improved significantly, allowing one to consider Flexo prints as suitable for most packaging applications.

Offset Printing: Offset printing-making machine manufacturer in Delhi is lauded for its fine print quality, especially as regards little details and color reproduction. It is the primary means for packaging that requires highly detailed, high-definition images or logos, luxury packaging, and superior branding.

3. Speed and Efficiency

Flexo Printing: Flexo print can be much faster than offset printing because it operates continuously at very high speeds. This makes Flexo printing a good option for those who want to have large quantities of packaging in the shortest possible time and efficiently. SBS has manufactured Flexo Printing Machine related to high-speed production but quality delivered at speed, which is equally time in delivering this solution.

Offset Printing: Offset printing may be a bit slower in comparison with Flexo printing when it comes to very detailed jobs or jobs with multiple colors. Nevertheless, this printing method is fully utilized for bulk printing jobs, as it is just in terms of setup and drying process that it is ineffective for greater production of packages.

4. Cost

Flexo Printing: flexo printing scores lower setup values, making it “affordable” for a business that has small print runs or frequent design changes. The SBS flexo printing machine thus saves set-up time and costs, giving enterprises a cost-effective answer to all their packaging requirements.

Offset Printing: The setup costs for offset printing are higher, as it requires the use of special plates and considerable preparation. This makes it relatively more expensive for short print runs or custom designs. However, offset printing becomes cost-effective for longer print runs because of its speed.

5. Environmental Impact

Flexo Printing: In general, flexo printing is said to use less harmful materials compared to offset printing. It uses water-based or UV-inked inks as opposed to oil-based inks such as used in the offset type. SBS’s Flexo Printing Machine is one energy-efficient machinery designed for use by all companies beaming towards reduced footprints.

Offset Printing: Offset printing uses inks that are usually oil-based, likely resulting in a relatively higher environmental impact in terms of their inherent chemicals. Nevertheless, advances in offset printing technology have permitted the development of environmentally friendly substitutes, including vegetable-based inks to reduce environmental effects.

Conclusion

The decisive factor when choosing between Flexo printing and Offset printing will be the particular needs of your packaging business. Flexo printing usually ends up being the best option, especially for businesses whose requirements command printing on different types of materials such as biodegradable bags, paper cups, and non-woven bags, bearing versatility, speed, and cost efficiencies. SBS provides Flexo Printing Machines with state-of-the-art technology for producing high-quality, environment-friendly packaging solutions catering to the sustainable vision of modern business operations.

Conversely, if your packaging needs to have fine details, crisp images, and precise color reproductions, Offset printing may suit you well, especially for paper-based products. For most companies that seek innovation and sustainability from their packaging solutions, though, Flexo printing is the ideal option in 2025.

It is great to know that SBS Machinery in Delhi continues to lead by providing the latest technology in packaging machinery that facilitates businesses in producing high-quality and eco-friendly packaging at cost-effective prices. Whether one chooses Flexo or Offset printing, SBS will supply both machines and expertise for meeting the specific packaging requirements.

FAQs

Q1: What is the main difference between Flexo and Offset printing? The main difference lies in the substrates they can print on. Flexo printing is more versatile and can print on a variety of materials like paper, plastic, and metal, while offset printing is limited to paper-based products.

Q2: Which printing method is better for packaging?Flexo printing is generally the better choice for packaging due to its ability to print on a wide range of substrates, including flexible materials. It is ideal for businesses looking to produce high-quality, cost-effective packaging at scale.

Q3: Can SBS machinery support both Flexo and Offset printing? Yes, SBS specializes in providing Flexo Printing Machines, which are designed to handle a variety of packaging materials, including biodegradable and eco-friendly options. SBS does not manufacture offset printers, but their Flexo printing solutions offer a more versatile and eco-friendly approach for packaging.

Q4: Is Flexo printing suitable for high-quality packaging? Yes, Flexo printing offers high-quality results, especially when paired with advanced machines like the SBS Flexo Printing Machine. While offset printing may offer finer detail, Flexo printing produces vibrant, crisp prints suitable for most packaging applications.

Q5: What are the environmental benefits of Flexo printing?Flexo printing uses water-based or UV inks, which are less harmful to the environment than the oil-based inks used in offset printing. Additionally, SBS’s Flexo Printing Machine is designed with sustainability in mind, making it a more eco-friendly choice for businesses.

0 notes

Text

Advanced Inline Flexo Printing Machine for Quality Prints

With precision, efficiency, and cost-effectiveness molded into the advanced designs of Inline Flexo Printing Machines, UV Graphic Technologies Pvt. Ltd. are a front-line service provider in this high-performance domain. A hallmark of our advancements in Flexographic printing is superior print quality to fit packaging, labels, corrugated printing, and flexible packaging industries. Our Inline Flexo Printing Machines deliver maximum productivity with minimal operational costs underpinned by modern technological features, rugged build, and eco-friendly working conditions.

Why Choose Our Inline Flexo Printing Machines?

Our Inline Flexo Printing Machines are engineered with state-of-the-art features to keep pace with the evolving needs of the printing industry. They promise matchless accuracy, speed, and print consistency in short-run and high-volume productions.

Key Features & Benefits:

High-Speed & Efficient Printing –

Designed for continuous operation with the aim of quick turnaround.

Best Print Quality –

Sharp images, vivid colors, and superb ink adhesion.

Wide Variety of Printing Applications –

Compatible with different substrates including paper, plastic, foil, and film.

Eco-Friendly Technology –

Water-based and UV-curable inks are used for printing economically and sustainably.

User-Friendly & Low Maintenance –

Very advanced automation with ergonomic design ensuring ease of use and long-lasting performance.

Applications of Inline Flexo Printing Machines:

Flexible Packaging-

Used for printing on flexible films, pouches, and laminated material.

Label Printing-Crystal-

clear label printing in HD for various industries.

Carton & Corrugated Box Printing-

Great print results for packaging and branding.

Paper & Board Printing-Improves the beauty of paper-based products.

How Our Flexo Machines Enhance Printing Efficiency

Pragmatic drying and curing systems featuring UV curing technology guarantee fast ink drying with minimal machine downtime integrated into the Inline Flexo Printing Machines. The harmonizing element of precision and high-speed operations enables businesses to take their printing process into mass production without compromising quality.

Nurturing Business Growth by Inline Flexo Printing

An investment into flexible printing with high performance will certainly enhance production efficiency and profit margins. With UV Graphic Technologies Pvt. Ltd. 's technology, businesses can achieve high-volume printing with minimal wastage of materials, less time for setup, and least interruptions for operations.

Why Partner with UV Graphic Technologies Pvt. Ltd.?

With several years of research and experience in the specialization of manufacturing Flexographic printing machines, we are devoted to providing you with the most excellent solution for your business. The best new technology has been integrated into our Inline Flexo Printing Machines, ensuring their easy operation, cost-effectiveness, and the highest quality output.

Get in touch with UV Graphic Technologies Pvt. Ltd. and take a giant leap in your printing capabilities. Browse our Inline Flexo Printing Machines for advanced printing technologies that will make a difference in efficiency and quality. Contact our team today for consultancy and pricing.

0 notes

Text

Webtech Group’s live demonstrations at Printpack 2025

Webtech Group, a leading manufacturer of printing and paper-converting machinery, will showcase its range of machines at Printpack 2025, to be held from 1 to 5 February 2024, at India Expo Centre and Mart in Greater Noida. It show demonstrate the fully servo flexographic printing machine in 450 mm working width, thermal roll slitting rewinding machine with single color online flexo printing, honeycomb paper die cutting machine, and servo-controlled label slitter rewinder machine

Along with the showcased machines, the Webtech team will highlight its entire range of products, including fully servo flexographic printing machines, web offset printing machines, slitting rewinding machines, and die cutting machines at its stand. The team will discuss technological advancements, share insights into the industry’s trajectory, and offer tailored solutions.

Singh emphasized the strategic importance of participating in Printpack 2025. “Printpack provides a vital platform to showcase technological advancements to a global audience and expand our clientele. The exhibition offers invaluable insights into emerging trends and challenges, enabling us to enhance our product offerings and stay ahead of market demands,” he said.

By participating in such exhibitions, Webtech aims to solidify its industry presence while forging new relationships with global clients. “For Printpack 2025, we aim to build on our previous successes by introducing our latest fully servo flexographic printing machine and other innovations. We look forward to engaging with industry leaders and further strengthening our position in the market,” Singh added.

Singh highlighted the evolution of the printing and packaging industry, driven by increasing demand for sustainable and flexible packaging solutions. Key advancements, such as fully servo-driven machines, automation, and eco-friendly substrates, are shaping the future of the industry.

“The printing and packaging sector is experiencing robust growth, with sustainability and precision at its core. We are poised to capitalize on these trends by offering innovative and efficient machinery that addresses challenges such as waste reduction and enhance productivity,” Singh explained.

Webtech International Machineries will be present in hall no 5, stands C19 and C28.

0 notes

Text

Pressure Sensitive Labels

Pressure Sensitive Labels

Pressure Sensitive Labels are pre gummed labels available in roll form to be used in a label applicator machine or applied by hand. There are many kinds of pressure sensitive labels such as paper, film, transparent (no look), speciality materials depending on the product and industry. Pressure Sensitive label is one of the most common product decorations for FMCG, Beverages, Spirits and Pharmaceutical industries. Pressure Sensitive labels can be applied on all types of plastic and metal containers, PET and Glass bottles, paper and laminated pouches. Roll Form Pressure Sensitive labels are manufactured in Flexo printing machines and for short quantities they are produced in Digital printing machines. Various embellishments such as spot coating, Hot foil, Embossing and thermo-reactive print are possible on pressure sensitive labels.

Types

Foil labels

No- look labels

Metallic labels

Color Changing labels

Double Side printed labels

Benefits of

Pressure Sensitive Labels

Highly decorative graphics are possible on these labels with multiple embellishments.

Clean finish of the applied labels on the bottle or jar. There are no excess gum leaking from poor application and the alignment of label to the bottle is straight on all the bottles.

No need to invest in complicated equipment to apply labels

No skilled operators needed to apply these labels and savings in man power costs involved in label application quality checks and correction

Numerous substrates options such as paper, plastic and clear films are available in these labels.

0 notes

Video

youtube

Bangladesh customer side high speed satin care label flexo printing machine

#youtube#flexo printing machine#flexo graphic printing machine#label printing machine#flexo label printing machine

0 notes

Text

SANJO PDA1 250 (4COLOUR + FLEXO UV VARNISH) STICKER 🧻 LABEL PRINTING MACHINE FOR SALE FROM MK PRINTECS MACHINERY, INDIA

.

.

.

For More Information Contact Us ;

MK PRINTECS MACHINERY

( ALL KIND OF LABEL, OFFSET, CUTTING & SCREEN PRINTING MACHINE - IMPORTER, EXPORTER & SUPPLIER IN INDIA )

#4/168, Sivakasi - Erichanatham Main Road, Opp. To Ayyan Fireworks,

Aishwarya Nagar, Vellaiya Puram,

Thiruthangal - 626130,

Tamil Nadu, INDIA

Mob : +91 9842985143 | 8531010853 | 7200729855

E-Mail : [email protected]

Click here to call us : https://mkprintecs.com/mani/+919842985143

Web : https://www.mkprintecs.com

.

.

.

#label #printing #machine #machinery #labelprinting #labelprintingmachine #labelmachine #printingmachine #labelprintingmachineforsale #labelprintingmachineforsaleinindia #labelprintingmachinesupplier #labelprintingmachinesuppliers #labelprintingmachinesuppliersinindia #usedlabelprintingmachine #usedlabelprintingmachineforsale #usedlabelprintingmachineforsaleinindia #labelprintingmachineforsmallbusiness #labelprintingmachinedelaer #mk #mkmachinery #stickerprinting #stickerprintingmachine #mkprintecsmachinery #mkprintecs #offsetprintingmachine #screenprintingmachine #cuttingmachine #diecuttingmachine #silkscreenprintingmachine #stickerlabelprintingmachine #stickerlabel #labelsticker

0 notes

Text

🎄 Merry Christmas! 🎄

✨ Wishing you and your loved ones a holiday season filled with joy, peace, and prosperity.

Thank you for your trust and support throughout the year. 🙏

🚀 We look forward to continuing our journey together in the coming year.

Warm regards,

Team Webtech 🤝

www.webtechengg.com

+919999779973

#christmas#merry christmas#x mas#webtech#flexographic label printing machine#flexo#packaging labels#fully servo#flexo printing machine#label#label printing

0 notes

Text

Streamline Your Workflow with Advanced Label Converting Machines by UV Graphic

The label conversion machine does consist of apparatuses for converting printed labels and further processing them into ready to apply products for different industries like packaging, retail, logistics, etc. A label conversion machine sounds quite complex, and it does include die-cutting, slitting, and lamination, apart from rewinding everything-all concerned with production efficiency and accuracy.

The unique and reliable name in the printing and converting industries is UV Graphic. UV Graphic comes with state-of-the-art label converting machines that are designed to enhance productivity and accuracy. The machines work well with many materials ranging from paper and film to metallic substrates; therefore, they are perfect for many labeling needs.

With advanced automation features, UV Graphic's label converting machines produce less waste, need minimized setup time, and run as seamlessly as possible. Be it small run or large production, these machines always ensure accuracy to the highest level with the same results. Choose UV Graphic for an investment in quality and innovation backed by reliability. UV Graphic label converting machines are perfect for customers who want to be ahead in the modern fast-paced market because of the company’s commitment to customer satisfaction and their technology.

#uv curing systems#curing machine manufacturer#flexo printing machines manufacturer#label converting machine

0 notes

Text

Lug Caps Manufacturers Suppliers In India

We have our units located in Site IV Sahibabad Industrial Area, Ghaziabad, UP (Delhi NCR) with a consolidated covered working space of more than 30 thousand square feet. We are well equipped and with all the amenities rendered by UPSIDC. Our units are very well connected to all type of transportations lug caps manufacturers suppliers in india .

We manufacture : .

LUG CAPS in various sizes and colours.

RO CAPS in all sizes & gauges.

SELF ADHESIVE LABELS upto eight colour printing in roll or sheet form.

WETGLUE LABELS of various sizes and colour to cater all types of packaging modes.

ROPP CAPS in different sizes for pharma, distilleries, or all bottle packaging.

PARMESHTHI Enterprises manufactures self-adhesive labels and wet glue labels for variety of bottled or canned products. It also manufactures pp caps for glass or plastic bottles.

In unit 2 plant, the lug caps and dop Caps are also manufactured of various sizes to cater the needs of the customer.

The plant is situated at a very good location and easy approachable by road at Site IV in the Sahibabad industrial area with all amenities provided by lug caps exporters in india.

It is a team of high skilled technical experts, designers and professionals, continuously pouring the essence of their talent and endeavours, delivering the fine quality in large quantity of multi -colour labels.

The processing and production is operational under a 15000sft covered area, equipped with electric generator for an uninterrupted productivity. The sensitive areas are dust proof and air-conditioned.

Added to other machines, it has a fully loaded multicolor LED flexo printing press, first of its kind in India, delivering cost effective and high-quality labels. It drives out 40 thousand meters per day, of printed rolls. The company has its own brand of paper/stock for its labels to challenge the quality, durability, colour stability, gloss and finish of its labels.

The automatic electronic cutters are tuned to recognize and slice the contiguous borders in simple straight line or designer cut finish.

A team of experts equipped with scanners shuffle the production for its continuous integration to table it for packing and dispatch metal caps manufacturer delhi ncr .

P.ent remains its brand of stock, labels, caps.

Company has its own fleet of vehicles to manage the logistics and schedules of deliveries directly to the esteemed clients.Mr. Anuj Jain, the young and dynamic entrepreneur is behind the wheels, steering the organization to build its reputation in shape of reliability and product confidence.

0 notes

Video

youtube

Label Logo UV Dryer Flexographic Flexo Printing Machine 1 2 3 4 5 6 Colo...

0 notes

Text

Bengaluru to host the premiere edition of Bharat Print Expo!

The Total Print and Package Converting exhibition will be held from 24-26 April 2025 at Bangalore International Exhibition Centre, Bengaluru.

"This is not just another printing exhibition," declares Anil Arora, President of ReEnvision Events Private Limited. "India is poised to become the world's third-largest economy within the next five years, and we acknowledge that specific sectors as well as regions of the country have played a crucial role in driving this growth. It is essential that we feature them prominently on our event calendar."

Bharat Print Expo is inspired by the county’s adoption of new Print and Converting technologies, coupled with the surge in e-commerce, evolving lifestyles, urbanization, and heightened awareness about personal health, that has significantly fuelled the expansion of the Print and Packaging sectors. Bengaluru is a city that mirrors its diversity, combining a rich cultural tapestry with advanced technologies. According to the Bengaluru Innovation Report, among the 780 major cities globally, 17 of the 20 fastest growing cities will be in India. Among them, Bengaluru is projected to have the world's fastest GDP growth at 8.5%, maintaining this pace until 2035. The vibrant city will hold the first edition of Bharat Print Expo, driving participation from all across the country along with a global brand presence. The venue selection was made based on a survey conducted among the exhibitors of our current show.

Exhibitor Profile

Bharat Print Expo 2025 will delve into the growing demand and prospects within South India and its surrounding areas. Exhibitors hailing from various parts of the nation will showcase cutting-edge products and solutions spanning the print and related industries, including- Printing Equipment: Offset/ Screen/ Digital/ Flexo/ Gravure; Prepress Equipment; Post-press & Packaging Converting Equipment; Label Converting & Printing Press; Paper Converting Machines; Adhesives & Consumables; Binding & Lamination; Paper, Films, Foils; Ink & Chemicals; Dies, Cutters, Rollers; Corrugated Box Making Machinery; Carton Folding Equipment; Testing Equipment, Inspection Systems & Accessories; Textile Printing Machines; 3D Printers; Wide Format Signage Printers; Plant Automation; Infrastructure, Trade Associations & Financial Organisations and Services & Software.

Visitor Profile

The exhibition will attract visitors from the entire Southern region, with extensive promotional activities planned to reach a wide audience. Targeted visitors from all over Bharat and Sri Lanka will also attend the Show. The profile will broadly include: Commercial Printers, Package Printers & Label Printers; Brand Owners & Print Buyers; Package Converters & Corrugated Box Manufacturers; Textile Printers & Professionals; Signage & Graphic Arts Specialists; Retailers, Manufacturers & Industry Suppliers; Packaging Professionals, Design Houses, Art Directors & Consultants; Trade publications, Advertising, Marketing, Media & PR Agencies; Government Bodies and Trade Associations.

Venue

The Bangalore International Exhibition Centre (BIEC) enhances its 77,000 square meters of covered space with aesthetically and functionally designed exhibition halls, along with vast open areas ideal for showcasing large and heavy machinery. The venue is conveniently linked via the Green Metro Line and is just a 45-minute drive from the airport and a 30-minute drive from the city centre.

Organizer

ReEnvision carries forward the legacy of its group companies that have launched or co-organized India’s most successful events in the printing and packaging sector including India Label Show, Pack Plus and PAMEX. ReEnvision Events Private Limited is a sister organization of Print-Packaging.com Private Limited.

"We are preparing to open bookings for the Show and anticipate a tremendous response from the industry,” concludes Anil Arora.

0 notes