#FlowMetermanufacturer

Explore tagged Tumblr posts

Text

Water treatment in the water and wastewater industry involves a series of processes designed to purify water, making it safe for consumption or suitable for release back into the environment. It typically includes several stages, such as pre-treatment (screening, sedimentation), primary treatment (physical separation of solids), secondary treatment (biological processes to remove organic matter), and finally, disinfection (using chemicals or UV light to eliminate pathogens). Advanced techniques like membrane filtration and reverse osmosis are also used to achieve higher purity standards. Overall, water treatment aims to ensure the supply of clean, safe water and minimize environmental impact from wastewater.

0 notes

Text

Burak Metering - Your Premier Choice for Flowmeter Solutions

Choose Burak Metering as your premier choice for Flowmeter Solutions. As distinguished Flow Meter Suppliers and Manufacturers, we guarantee top-tier quality and performance

0 notes

Text

Process Control Devices Mumbai - Leaders in Flow Meter Technology

Discover the latest in flow meter technology with Process Control Devices (PCD). As Flow Meter Manufacturers in Mumbai, we set the standard for precision and innovation in industrial measurement.

0 notes

Text

How RPD Gas Meters Support Industrial Compliance

In highly regulated industries such as oil & gas, power generation, and chemical processing, accurate measurement and reporting of gas flow is not optional it’s essential. Rotary Positive Displacement (RPD) gas meters play a key role in this process, offering reliable, real-time data to help industries maintain compliance with stringent environmental and operational standards.

Ready to upgrade your gas flow monitoring system? Browse our latest RPD gas meters built for compliance and accuracy.

Unlike other flow metering technologies, RPD gas meters measure volumetric flow with remarkable precision. This level of accuracy is crucial for audits, energy reporting, and billing, particularly when regulatory frameworks demand transparent and verifiable gas usage records. As industries work to meet ISO standards, government regulations, and internal safety benchmarks, RPD gas meters provide the assurance that every cubic meter of gas is accounted for.

Flow meter suppliers and manufacturers now offer advanced RPD gas flow meter solutions with integrated diagnostics and compatibility with SCADA systems. This not only improves data accessibility but also supports predictive maintenance and early detection of anomalies that could lead to compliance risks.

Moreover, the growing emphasis on sustainability has made energy efficiency a compliance issue as well. RPD meters help monitor consumption patterns and reduce waste, enabling better fuel management and lower emissions. Whether you are reporting to environmental agencies or conducting internal efficiency reviews, these meters ensure your data stands up to scrutiny.

Speak to an expert get tailored advice from a trusted flow meter supplier for your specific industry needs.

0 notes

Text

Gas India Expo 2023

#Gasindiaexpo2023#2daysleft#gasindustry#manasmicro

#2days Left for Mega International Event on Natural and Industrial Gases Production, Processing, Refining Refueling, Gas Technologies, Gas Equipment, and Allied Industries at GAS India Expo 2023 | 6–8 July 2023 | India Expo Mart, Greater Noida, U.P., India, with Concurrent Events - World Gas Summit 2023 and NGV India 2023

https://manasmicro.com/gas-india-2023/

#gas#india#gasindiaexpo#gasindustry#industrialgases#event#noida#exhibitions#manasmicro#flowmeterexpert#flowmetermanufacturer#flowmeters#gasflowmeter#airflowmeter

0 notes

Link

0 notes

Text

Economical Flow meter

For any flow meter, uninterrupted operation is important. If there is no obstruction in the flow path within the meter, the meter can live longer. Mechanical flow meters, by their design, work with a flow element that is supposed to obstruct the flow.

Mechanical flow meter sensors can get damaged, choked, or deformed. This causes errors and reduces the life and reliability of these meters.

It is wiser to switch over to Electromagnetic flow meters in such cases, as these flow meters do not obstruct the flow and hence can give long life and reliable results over a long period.

Manas offers Economical Electromagnetic flow meters that are just the perfect choice!

https://manasmicro.com/elect.../economical-flow-meter-smart/

#manasmicro#flowmetermanufacturer#supplier#economicalflowmeter#waterflowmeter#digitalflowmeter#residentialuses#longlife#savewater#electromagneticflowmeter#ultrasonicflowmeter#btumeter#steamflowmeter#ThermalMassFlowMeter#massflowmeter#electromagnetic flow meter

0 notes

Text

Compressed Air Flow Meter Manufacturer and Supplier in Kolkata

Kolkata is the capital of the state of West Bengal located in eastern India. The city formerly known as Calcutta is the biggest metropolitan city in that part of the country. Having one of the oldest ports, Kolkata is the port of communication for the country’s entire northeast and happens to be the primary financial, business and industrial hub of east India.

The city has a great cultural heritage and an important centre of literary and artistic excellence. Kolkata also has many heritage structures, monuments, museums and buildings of historical importance. The art institutes and galleries across the city hold many exhibitions. Other cultural centres also conduct music festivals, concerts and other recitals in the city.

Compressed Air Flow Measurement in Chemical Industry in Kolkata

Kolkata celebrates the festival of Durga Puja with great pomp and splendor. Pandals are constructed and gatherings happen in the streets across the city with people assembling in large numbers and engaging themselves in celebration.

The industrial setup of Kolkata covers a wide range of industries from large, medium to small scale. Some of the major industries include steel, mining, metals and minerals, jute, textiles, information technology and agriculture. Kolkata also has companies and units that are manufacturers and suppliers of a wide range of equipment used in different sectors of business.

Compressed air is used for multiple purposes and applications in the chemical industry. A few of the examples of usage are

Generate nitrogen by filtering it from the air using a membrane which is then used for different chemical applications

Create a clean and safe area for different processes to function

Accelerate the drying process of many materials

Used in equipment that supplies production lines

Reduce the volume of gases for storage

Cleaning of equipment and other needs

Powdery substances and granules are conveyed through compressed air along with processing points

Measurement and monitoring of the compressed air is critical due to many reasons like

Reliable supply of compressed air to ensure the quantity and quality is not affected and diluted

Satisfy different types of compressed air requests

0 notes

Text

Compressed Air Flow Meter Manufacturer and Supplier in Pune

Pune is the second most important city in the state of Maharashtra in India, which is located in the western part of the country. The city is one of the biggest information technology and automobile hubs of India and is also well known for being a major centre for educational institutions. In the software industry, the city is the base for many companies that deliver services to clients across the globe. The manufacture of automobiles and other equipment is a huge industry in Pune with several German companies having a big presence and industrial setup.

The presence of educational institutions makes Pune to be referred to as the Oxford of the East with hundreds of colleges, universities, research institutes located in the city. Some of the most important and prominent institutes in the city offer courses on combat intelligence, military intelligence, business administration, management studies, human resource development and other research subjects.

Compressed Air Flow Measurement in Pulp and Paper Industry in Pune

The many world-class manufacturing units in Pune cater to the needs of clients both domestically and internationally. Considering the high quality of products manufactured, there is a large number of exports to countries across the world. Being quite close geographically to Mumbai, the financial capital of India has also helped in the overall development when looking at things from a financial perspective. Among the various industries are manufacturers and suppliers of small and medium-scale products.

The Paper and pulp industry has a lot of steps and processes that are executed during the manufacture of paper, paper pulp and other similar materials. Wood is the most commonly used source or fuel from which paper and related products are made. Combustion control and compressed air are two vital elements of the overall manufacturing process.

The efficient combustion process is about finding the right ratio between oxygen and air, which helps to reduce the cost spent on fuel required to produce energy. Proper measurement and control of the process also helps in better adherence to safety and reduced emissions of toxic substances.

Compressed air is used to cool down the paper after it is pressed and also as part of multiple other procedures. The quality of air needs to be monitored and regulated to ensure that it doesn’t get contaminated by both external and internal influencers. Oil-free air compressors are used to achieve some of these requirements. Contaminated air used during the process can lead to the end product getting spoiled due to unexpected contact or other reasons.

0 notes

Text

Compressed Air Flow Meter Manufacturer and Supplier in Visakhapatnam

Visakhapatnam is one of the oldest and biggest port cities located in the state of Andhra Pradesh in the southern part of India. The city also has one of the finest shipyards and the port has a lot of cargo activity happening throughout the year making it one of the busiest in the country. Many other government industrial establishments are located in the city that contribute to its massive industrial setup.

The city formerly and more commonly known as Vizag is famous for its natural beauty and lovely beaches making it one of the most sought-after tourist destinations of the state. Many temples, monuments and other places of worship in the city add to the historical and religious importance making it a memorable place to visit.

Compressed Air Flow Measurement in Oil and Gas Industry in Visakhapatnam

On the industrial side, there is a massive presence of different government and private companies across sectors like thermal power plants, steel manufacturing, petroleum, pharmaceuticals, fishing and many other industries. The industrial set up across the city has helped in creating numerous job opportunities for the local population and also people from other parts of the country. Besides, there are many small and medium scale industrial units also that are manufacturers and suppliers of various equipment and products in Visakhapatnam.

Compressed air is one of the most important utilities essential to operations in a refinery along with water, natural gas and electricity. Compressed air is required during the execution of many processes in the oil and gas industry. It acts as a medium for the transfer of energy that is required to power different types of equipment. During operation of machinery required for the production of gases and liquids, it helps to control precise measurement and calibration.

From the point where oil and gas are explored from the wells, undergo various processes and transferred to the stage where it can be used for power generation, the application of compressed air is manifold. Hydrocarbons are unearthed as part of exploration after which crude oil is processed and made safe for petrochemical processes. This is subsequently transferred via huge pipes, tankers etc. to the various oil refineries from where it is distributed for market needs like power generation industries. Throughout the different stages of oil and gas applications, the usage of compressed air is extensive.

Measurement of compressed air has to be accurate and reliable in all the processes involved to generate the best results during production, avoid safety hazards and meet all other guidelines as appropriate.

0 notes

Text

How Does A Thermal Dispersion Flow Meter Work?

In spite of the fact that there are many technologies available to measure the flow rate of air and gas, most of these methods measure the flow rate at the actual operating pressure and temperature, and they will require pressure and temperature correction before the mass flow can be calculated.

According to tradition, the biggest advantage of thermal dispersion flow measurement over volumetric gas flow measurement is the inherent ability to directly measure the mass flow without the need for pressure and temperature correction as with volumetric gas flow measurement. Besides offering a more useful flow measurement, thermal products also have the benefit of being very cost-effective due to their high efficiency. In addition, magnetrol thermal mass flow dispersion meters also provide the opportunity for users to conduct calibration verification in the field, a feature that is becoming increasingly important to process industries.

Thermal Dispersion Flow Meter

According to the thermal dispersion principle of operation, the rate of heat transfer by a flow stream is proportional to the mass flow of that flow stream, and that is one of the key features of thermal dispersion technologies. By measuring the cooling effect as the mass (molecular) flow is passed by the heated sensor, it is possible to measure the flow rate of the mass (molecular) flow. It consists of two main components: the sensor itself and the signal processor.

It is the reference that measures the temperature of the gas in relation to the reference.

There is also a second element, which is heated by a variable electrical power in order to maintain the desired temperature difference between the two sensors at all times.

In the illustration below, we see the amount of power that is required to maintain a constant temperature difference between the two sensors at the same time. There is limited cooling involved in the operation of a low mass flow system, and the power required for the system is minimal. It is important to note that as the mass flow increases, more power is required. With this feature, the flow sensitivity is low and the turndown capability is high, resulting in excellent performance.

0 notes

Text

Vortex Flow Meter

The Heavy Steam is produced with the boiler by including heat. It is an extremely effective and also conveniently regulated warm transfer tool. It is frequently utilized for delivering power from the boiler to any type of detailed location in the plant where it is used to warmth air, water, or process applications. The heavy steam is a vapor type of water with heat and stress problems.

As we understand that gauging energy consumption is an essential element to enhance energy performance. Effective as well as exact dimension through the steam meter is a must to establish the central heating boiler effectiveness excess usage or any type of loss at the same timeline to reduce the reduction in the plant running cost as well as product top quality. Commonly one of the most typical techniques of vapor metering was via differential pressure measurement. The numerous kinds of differential stress strategies utilized for vapor metering were orifice plate, venture meter, and also V-cone meter. As differential stress tools have reduced turn down with high-pressure loss which makes dimension challenge. Mistakes take place as a result of absolutely no and also span drift when the temperature/pressure problems rise and fall past the design parameters. The vortex circulation meter is known to be an extremely precise tool for heavy steam flow dimensions. Vortex heavy steam flow meter has lining dimension, big turndown ratio, high accuracy, and low-pressure drop. To meet the needs of customer Burak metering manufacture a vortex circulation meter. BA-VFM with stress as well as temperature level compensation to give exact circulation outcome with a selection of heat ranges up to 350 deg c.

0 notes

Text

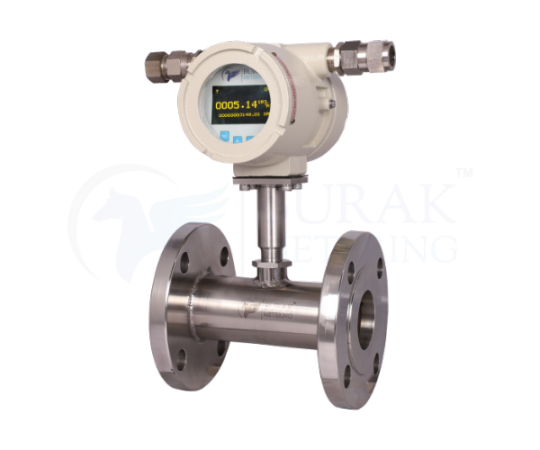

Compressed Air Flow Meter - New

BURAK Metering is a manufacturer, supplier, and exporter of compressed air flow meters in India.

Just how does a compressed air flow meter job? The meter works utilizing 2 temperature sensors, one warmed and also the various other fixed. Mass circulation is symmetrical for the power needed to keep a continuous temperature difference between these sensors in a flow of gas.

The compressed air flow meter is additionally a transmitter, which converts the determined specification right into a standard electric signal. The transmitter can therefore be integrated into systems (e.g. pressed air systems), making it a key instrument in measuring and also controlling modern technology.

0 notes

Text

Compressed Air Flow Meter - New

BURAK Metering is a manufacturer, supplier, and exporter of compressed air flow meters in India.

Just how does a compressed air flow meter job? The meter works utilizing 2 temperature sensors, one warmed and also the various other fixed. Mass circulation is symmetrical for the power needed to keep a continuous temperature difference between these sensors in a flow of gas.

The compressed air flow meter is additionally a transmitter, which converts the determined specification right into a standard electric signal. The transmitter can therefore be integrated into systems (e.g. pressed air systems), making it a key instrument in measuring and also controlling modern technology.

0 notes

Text

Compressed Air Flow Meter - New

BURAK Metering is a manufacturer, supplier, and exporter of compressed air flow meters in India.

Just how does a compressed air flow meter job? The meter works utilizing 2 temperature sensors, one warmed and also the various other fixed. Mass circulation is symmetrical for the power needed to keep a continuous temperature difference between these sensors in a flow of gas.

The compressed air flow meter is additionally a transmitter, which converts the determined specification right into a standard electric signal. The transmitter can therefore be integrated into systems (e.g. pressed air systems), making it a key instrument in measuring and also controlling modern technology.

0 notes

Text

Thermal Dispersion Mass Flow Meter

Thermal mass flow meters are well known as thermal dispersion mass flow meters. It comprises a descent of instruments for the measurement of the total mass flow rate of primary gases flowing through closed conduits pipes and ducts.

They are mainly used in air and gas flow measurement applications. There are two main types of thermal flow meters, Thermal Dispersion/Immersible Type, and Capillary Tube Type.

Thermal Dispersion/Immersible Type is generally used to measure the high flow rate in pipes and ducts whereas the Capillary Tube Type is used to measure the low flow of gas. BURAK is a manufacturer, supplier, and exporter of thermal mass flow meters in India.

0 notes