#FlowSensors

Explore tagged Tumblr posts

Text

#FlowSensors#IndustrialAutomation#SensorTechnology#AutomationEngineering#FluidMeasurement#ProcessControl#FluidFlow#IndustrialSensors

0 notes

Text

GE Original ECG Trunk Cable, 3-lead w/integrated grabber leadwire, IEC, 3.6m/12ft. REF: 2106309-002

#ecgmachineend#philipsvm6monitor#americanstandardecgleads#temperatureprobe#geb1800anesthesiamonitor#blackbloodpressuretubewithonemaleandonefemaleconnector#ecgmachineendwithblack6-pin#flowsensor#philipsmp80monitor#medicalequipmentsupply

0 notes

Text

Cardone® Mass Air Flow Sensor

-Reman Mass Air Flow Sensor -Remanufactured Mass Air Flow Sensor -Mass Air Flow Sensor, Air Flow Sensor, Air Flow Meter, MAFS, VAFM, Air Flow

https://www.usautopartscar.com/dp/A17460007

0 notes

Text

3 Tips When Buying a Liquid Flow Meter

Choosing a mass flow meter requires a bit of knowledge about what is being measured. Both gas and liquid can be quantified using gauges that compute the flow at kilograms per second or liters per second in relation to the density of the material. Each device is different and you can't use the same meter for both wastewater plant and potable water, for example. But choosing one that's perfect for you will not be as difficult if you follow the tips below.

Make a checklist

What is the material to be measured: is it liquid or gas? If so, what type of liquid or gas are you working with? Is the liquid dirty or clean? Do you want the process the information manually or remotely? What about the temperature conditions of the plant and the material, are they hot or cold? Measuring hot water may need a gauge that will compensate for the change in temperature to get an accurate reading. Make sure you consider in your checklist the following: the liquid viscosity, corrosive and conductive properties, toxicity if applicable, and type of piping. When dealing with gases, make sure you list down if it's wet, corrosive, toxic, combustible, or clean.

There are numerous mass or water flow meters to choose from such as coriolis, differential pressure, energy, magnetic, open channel, optical, massive displacement, thermal, turbine, ultrasonic, variable area and vortex. Each has its own advantages and disadvantages.

Narrowing down prospects

There are so many companies offering these devices but the best manufacturers have the best engineers to help your identity plant specifications through an easy-to-follow guide will help determine the perfect product for your needs. You also want a company with strong local presence with qualified partners in North and South America, Asia, Europe, Africa and the Middle East. This is to minimize the potential shut-down time when the mass flow meters encounter a snag since the manufacturer can immediately send in engineers. Also, the manufacturer should be able to offer you a competitive rate along with technical training of your staff, application assistance or taking care of the repair and maintenance.

Saving on costs

The process of listing down the plant specifications will entail cost, if you consider the number of manpower hours alone. Then you have to find the perfect technology that fits your need. An educated estimate would place the expense somewhere between 30 to 40% of the sales cost.

Mark Alan has provided more information about measurement technologies. He has more knowledge and gives the good information about vortex mass flow meter, best flow meter valve and more. For more info - proteusind.com.

6 notes

·

View notes

Text

Flow Sensors Market Expected To Reach USD 7.48 Billion By 2020

The Global Flow Sensors Market is expected to reach USD 7.48 billion by 2020, according to a new study by Grand View Research, Inc. Increasing quest for new energy sources along with renewable energy development is expected to drive the flow sensors market over the forecast period. Regulations governing the industry have been favorable in stimulating market growth for different types of sensors. For example, standards laid by the EPA for power plants have increased the demand for gas flow sensors which are effective in monitoring gas leakage. Various initiatives are taken into consideration for energy conservation and efficiency over the years worldwide. For instance, Omron Corporation offers high performance MEMS flow sensors to optimize air conditioning energy efficiency.

Further, the industry has witnessed high demand from numerous end-use industries. For example, in the automotive sector, active and passive safety sensors have witness tremendous growth due to the growing need for accident mitigation systems. Emission of hazardous gases has led to the framing of legislations for emission control and resulted in the need for monitoring the concentration of exhaust gases.

To request a sample copy or view summary of this report, click the link below: http://www.grandviewresearch.com/industry-analysis/flow-sensors-market

Further key findings from the study suggest:

The flow sensors market is expected to witness considerable growth over the forecast period. The need for new energy sources, including oil and gas exploration, and the growing significance of developing of renewable energy sources are expected to be key market drivers.

The process industries segment is poised for significant growth over the next few years, and accounted for over 25% of the overall market in 2013. Growing number projects and the establishment of new process plants along with reinvestments in plant modernization, renovation and capacity expansion are expected to fuel the market demand.

North America emerged as the dominant regional market in 2013 accounting for more than 30% of the overall market in the same year. Surging demand owing to rebound in automotive and machinery production along with regulatory mandates are expected to spur the regional market growth over the next six years.

Key industry players include Emerson Electric Company, First Sensor AG, Gems Sensors & Controls, Keyence Corporation, Omron Corporation etc. Manufacturers focus on investing in R&D activities as accuracy and reliability are major product selection criteria. Further, industry participants emphasize on product differentiation in order to avoid price competition.

See More Reports of This Category: https://www.grandviewresearch.com/industry/sensors-and-controls

About Grand View Research:

Grand View Research, Inc. is a U.S. based market research and consulting company, registered in the State of California and headquartered in San Francisco. The company provides syndicated research reports, customized research reports, and consulting services. To help clients make informed business decisions, we offer market intelligence studies ensuring relevant and fact-based research across a range of industries, from technology to chemicals, materials and healthcare.

0 notes

Photo

Irrigation sensors and irrigation system Due to urbanization, water cost and its scarcity are increasing day by day. So smart use of water in #irrigationsystem becomes as important as never. As for irrigation system is concerned, Soil moisture sensor, flow sensor, rain sensor are the smart products that can help to conserve water and save money. So let's understand about them. 1. Soil moisture sensors sense the moisture content in soil and send water requirement to the controller and concerned irrigation valves. According to received data from moisture sensor, controller adjust/suspend/ override the preset irrigation schedule. 2. #Flowsensor suspend irrigation system automatically in case of broken pipes and heavy leakages. Moreover you can get water usage data and flow rate data for years. 3. #Rainsensor measures the rainfall quantity and accordingly controller adjust the watering duration as per landscape water requirement. Now technology is more affordable and not limited to golf courses and commercial buildings. You can easily install for your residence and socities. Please inbox your enquiries at [email protected] AND visit our company profile through www.blurain.in (at Gurgaon, Haryana) https://www.instagram.com/p/BzqZZd-A-Fu/?igshid=1e5y2fp12nqou

0 notes

Text

Jual Pom Bensin Mini Murah Terbaru

Selamat datang di situs kami yang merupakan pom mini Center terbaik di Indonesia, Anda bisa mendapatkan berbagai jenis model mini pom terbaru yang memiliki kualitas terjamin, selain itu pom mini yang disediakan oleh kami sangat murah tapi tidak murah, Kami berada di Kota Tasikmalaya, Tapi Anda tidak perlu khawatir, Anda bisa mendapatkan pom mini Asli ini di manapun Anda berada, Planet Pom Mini akan mengirimkan barang ke tempat Anda dengan ONGKIR GRATIS, gratis untuk pengiriman pom mini ke tempat Anda , itulah keunggulan kami dalam menjual barang Pom Mini online.

Jenis pom mini Yang Kami Jual

1. Mini Digital Noozle 1 Portable Pom

Spesifikasi unit mesin digital pom 1 nozzle mini terdiri dari bingkai pelat pencairan pertama seperti yang ditunjukkan pada gambar foto. Kemudian bagian atas disusun serangkaian CPU atau mesin penghitung komputer dalam bentuk MCB dan komponen elektronik yang terhubung ke display, keypad, dan segmen ketujuh. Sementara bagian bawah terdiri dari mesin penghisap pompa bensin, sensor counter, selang, dan pipa sambungan serta drum penyimpanan bahan bakar bensin 210 liter.

Di luar ada selang 4 meter yang terhubung ke 1 noozle dan dihiasi dengan kaca film manis serta kation dan stiker. Kreasi tambahan untuk penampilan yang lebih menarik dapat ditambahkan ke aksesori ornamen lainnya. Planet Pom Mini mengutamakan kualitas mesin dibanding penampilan luar. Namun, kami selalu memprioritaskan permintaan pembeli dalam hal pemesanan.

Harga satuan mesin pom mini noozle 1 portabel adalah Rp. 10.900.000, - dengan sensor aliran. Jika permintaan ini tentu saja berbeda lagi. Nilai harga jualnya sangat murah karena sudah termasuk ongkos kirim ke tempat (khususnya wilayah Jawa Barat dan Jawa Tengah termasuk Sukabumi, Tangerang, Karawang, Bogor, Depok, Bekasi, Cikarang, Subang, Pamanukan dan kota-kota regional lainnya) , selain harga jual satuan pertamini 1 noozle dikatakan super murah karena juga termasuk pelatihan cara mengatur tempat dan garansi selama 3 bulan.

2. Mini Digital Pom 1 Penanaman Nozzle

Penanaman nozzle Pom mini 1 hampir sama dengan penanaman mini pom tipe portabel. Perbedaannya adalah jika nozzle mini pom 1 portabel dilengkapi dengan roda, sedangkan versi penanaman tidak dilengkapi dengan roda. Dan tangki penyimpanan bahan bakar ditanam.

Anda dapat memiliki jenis mini pom digital ini dengan harga Rp12.000.000 Plus ONGKIR GRATIS.

3. Pom Mini 2 Noozle Model Minimalis Portable

Berbagai input dan saran selama proses pembuatan unit mesin dari pembeli selalu ditampung. Permintaan untuk 2 item mesin mini pom digital noozle tersedia dengan harga terendah tetapi kualitas adalah dominasi harapan kebanyakan orang. Langkah nyata adalah mewujudkan permintaan dengan menjadikan unit mesin Pertamini 2 model minimalis noozle.

Rangkaian di unit mesin portabel 2 noozle sebenarnya sama dengan mini pom standar. Satu-satunya perbedaan adalah ketinggian dengan perbedaan 30 cm. Ketinggian mesin ini hanya 1,5 meter. Selain ketinggian tempat penyimpanan drum 150 liter tempat biasa 210 liter.

Kehadiran unit stock engine 2 noozle portabel menjawab semua permintaan dan harapan penjual atau pengecer bensin literer. Harga mesin Pertamini diatur pada Rp.13.500.000 (Tiga Belas juta lima ratus ribu rupiah) Jabotabek OTR, Bandung, Jawa Barat, Priangan, Jawa Tengah. Harga ini sudah termasuk biaya pengiriman dan garansi 3 bulan. Pembayaran dilakukan setelah pengiriman selesai.

4. Penanaman Digital Noozle 2 pom mini

Harga paket untuk mesin Pom Mini / 2oz Noozle hose yang dibuat di rumah produksi kami termasuk biaya pengaturan, konsultasi teknis, memegang drum, selang dan biaya transportasi untuk pengiriman di wilayah Jawa Barat seperti Sumedang, Tasikmalaya, Ciamis, Kota Sukabumi, Majalengka , Kuningan, Purwakarta, Tangerang, Bekasi, Cianjur, Bandung, Kabupaten Bogor, Cilacap, Purwakarta, dan daerah Cirebon.

Harga Harga 2 oz Mini Pertamini Pom Machine 2 di Planet Pom Mini produksi unit mesin pertamini dan suku cadang:

Harga mesin pertama 2 noozle minimal order harga Rp. 13.500.000, - menggunakan flow sensor meter plus pengaturan dan biaya pemasangan, pengiriman di Jawa Barat dan Jawa Tengah.

Harga mesin cashing mini pom 2 noozle adalah harga standar Rp. 19.000.000, menggunakan alat pengukur sensor aliran, termasuk biaya pemasangan dan pengiriman hingga ke tempat khusus di Jawa Barat dan Jawa Tengah.

Harga mesin cashing mini pom 2 noozle adalah harga standar Rp. 19.000.000, menggunakan alat pengukur sensor aliran, termasuk biaya pemasangan dan pengiriman hingga ke tempat khusus di Jawa Barat dan Jawa Tengah.

Harga jual mesin pertamini 2 noozle diklasifikasikan sebagai yang termurah karena juga termasuk drum berukuran 210 liter dan juga jaminan kerusakan hingga 3 bulan. Harga dua majelis noozle pertama dijual dalam 2 pilihan paket: Rp. 13,5 juta Flowsensor meter minimalis dan Rp. 19 juta rupiah menggunakan kerangka sensor aliran standar. Tahapan pembayaran melalui mekanisme pembayaran setelah barang sudah terpasang.

5. Mini 3 Noozle Digital Portable Pom terbaru

Spesifikasi untuk mesin asuransi adalah sebagai berikut:

Tubuh yang terbuat dari plat besi 100 persen tidak menggunakan serat Cat menggunakan cat terbaik dan dilapisi dengan lapisan mengkilap yang membuatnya lebih tahan lama dan berkilau Alat ukur yang digunakan adalah Sensor Aliran dengan menggunakan sistem sirkulasi untuk membuatnya lebih lama karena menghilangkan tekanan sistem, dan lebih akurat dalam hal literasi. Menggunakan produk selang hitam dari Italia Boot Nozzle dan Nozzle Sistem pemasangan di daleman menggunakan bahan besi terbaik sehingga lebih tahan lama dan tahan lama Ditanggung oleh jaminan sebagai tanggung jawab kualitas yang kami berikan Mengenai harga mesin pertamini digital 3 Nozzle terbaru 2018 adalah Rp. 21.000.000 / unit dari hampir semua distributor Pertamina. Inilah yang menggunakan mesin sensor aliran.

Harga ini adalah harga yang termasuk pengiriman ke daerah tertentu seperti Jawa Barat, Jawa Tengah, Sumatra, dan Jambi. Sedangkan untuk wilayah lain, harga dapat berubah tergantung jarak.

Itu adalah jenis pom mini yang kami sediakan di Planet Pom Mini, jika Anda tidak mengerti atau tidak mengerti penjelasan di atas, Anda dapat menghubungi kami melalui SMS: WA:

Keuntungan Membeli Pertamini di Planet Pom Mini Factory LAYANAN PERTAMINI dan perbaikan SUKU CADANG PERTAMINI: Jika mesin pertamini Anda rusak, pertamini elektrik dan PERTAMINI DIGITAL, Anda dapat menghubungi kami.

JAMINAN ALAT PERTAMINI DAN MESIN PERTAMINI. Pabrik Planet Pom Mini menjamin pertama kali Anda membeli di tempat kami jika ada cacat material atau kesalahan dalam pekerjaan pabrik, bukan karena kesalahan pengguna atau kerusakan material karena cacat instalasi.

PERTAMINI SUKU CADANG. Kami menyediakan Semua Jenis Pertamini Suku Cadang Terbaru dan Terlengkap dari Planet Pom Mini Assemblies. Teknologi Sensor Aman Digital Pertamini Mudah digunakan. Operasi sederhana sangat mudah untuk dilengkapi dengan pengaturan buku dan video manual, dapat diatur dengan harga sendiri, kalibrasi sendiri

Pertamini digital canggih. ada fitur Sales print-out, dan rekam jejak penjualan (berfungsi sebagai laporan untuk mengetahui berapa liter yang terjual per hari), dapat mengendalikan total penjualan.

Melayani pengiriman ke semua wilayah dijamin cepat. Pembelian dapat dengan mudah dibayarkan, Tunai Saat Pengiriman / Pesanan Pembayaran di Alamat Tujuan. Sistem Pertamini Digital Portable. cukup tekan, bensin otomatis mengalir ke sepeda motor dan mobil pelanggan seperti di pompa bensin.

1 note

·

View note

Photo

L3p showing us all how its done ...⠀ ⠀ EKWB Cpu Block⠀ EKWB GPU Blocks ⠀ EKWB Backplates⠀ EKWB Radiators⠀ EKWB Pumps⠀ EKWB Liquid⠀ Intel i7 5930K⠀ Asus X99 Deluxe⠀ LG 34U95-P 34″ 3440×1440⠀ Nvidia Geforce Reference GTX980 X2⠀ Nvidia 2-Way SLI Bridge⠀ Corsair Dominator Platinum 64GB DDR4 2400Mhz⠀ Corsair Dominator Platinum Light Bars⠀ Corsair Force Series™ LX 512GB X2⠀ Corsair HXi Series HX1000i⠀ Corsair White sleeved Cable Kit⠀ Corsair Vengeance K70 RGB⠀ Corsair Vengeance M65 RGB⠀ Corsair Commander Mini⠀ Corsair Link Lighting Node⠀ Corsair SP120 LED White 8x⠀ Parvum Custom lasercut frame⠀ Nanoxia CoolForce PETG Pipe⠀ Bitspower Fittings⠀ Bitspower Reservoirs⠀ Bitspower Pumptops⠀ Bitspower Flowsensors⠀ ⠀ #n3xuscomputing #technology #buildapc #custompc #gaming #gamingpc #pcgaming #desktop #computer #pcmasterrace #pcgoals #officialsetups #battlestation

10 notes

·

View notes

Text

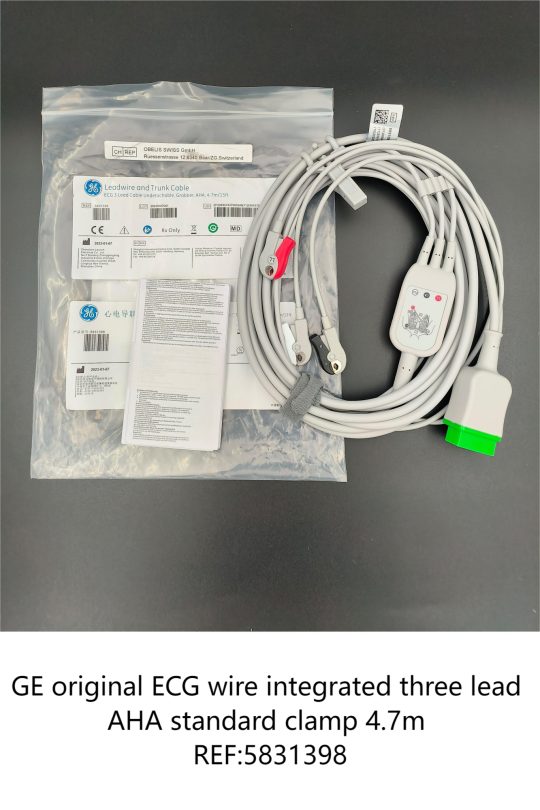

GE original ECG wire integrated three lead AHA standard clamp 4.7m REF:5831398

#internaltemperatureprobe#single-rowecgleads#capnography#flowsensor#fetalmonitor#siemens#finger-sleevespo2sensor#defibrillationcable#b450#b40

0 notes

Text

GE Original Datex-Ohmeda, BELLOWS SUBASSY ADULT ABA W/DISK-RING-BUMPERS.REF: 1500-3378-000#medicalconsumableswholesale #gesolar8000monitor #philipsmonitoraccessories #flowsensor #hospitalequipment

0 notes

Text

GE Original D-fend Water Trap,black REF:876446-HEL#flowsensor #gedash2500monitor #ivy #side-flow #beijingfutianelectronicmedical

0 notes

Text

Explore the Compact Liquid Flow Meters That Are Best For Industrial Usage

Prior to giving conclusions on the best compact liquid flow meters for industrial usage, you must understand about them and their applications. The turbine flow meter contains rotor blades positioned on a shaft at an angle. The liquid passing through these blades leads them to turn the rotor shaft. A mechanical reader can sense the shaft’s rotation. Concerning the blades, a magnetic reader identifies the movements through the magnetic pulses. For non-lubricating fluids, specific considerations are granted. Generally, these blades are greases in case the meter is designed for calibrating such type of fluid. In calibrating the natural gas’ transmission, the blades can simply bear temperatures of up to 60oC. In terms of using a clean or corrosive liquid, a turbine flow meter appears to be compact. These types of liquids incorporate water, petroleum, and chemicals. The size of the pipe must not be more than a diameter of 24 inches. The installation needs a sturdy building made of concrete, for large flow meters. The turbine flow meter’s precision deteriorates in the case of the flow rate not being very high. In addition, you are unable to use this type of meter for liquids streaming at rates higher than specified. In a nutshell, this damages the rotor blades or wears them out. The flow meter gets worn out by non-lubricating fluids causing inappropriate readings. Likewise, the meter can’t sense the dirty fluids’ transmission. Another useful flow meter is a magnetic meter that calibrates the fluid flow through a concept termed as Faraday’s Law. You will not find any moving parts in this meter. This scientific concept works on the standard that when the liquid particles pass through a magnetic field, voltage is produced and this voltage is in proportion to the velocity of the flow. This signal is detected by an electronic reader and also is processed by it. Quite different from a turbine meter, this specific flow meter is perfect for assessing water, extremely corrosive diluted acids, and dirty fluids. Nevertheless, you can’t use it for purified water and hydrocarbons. Due to its technology and design, a magnetic flow meter can be utilized in a vast range of industrial applications. This meter is capable of measuring the movement of corrosive, abrasive, dirty, and clean water based or other conductive liquids. It can’t measure gas as they are non-conductive. When you need low maintenance operations, these meters perform the best. For pressure drops in liquids, you can use it as the best option. Dirty water is released by many industrial applications as a part of the waste. And it is seen in applications like processing of chemicals, minerals, power production, and paper processing. Sewage and water utility organizations utilize this kind of flow meter. Verdict According to the discussion done above, the magnetic flow meters can be considered to be the most compact liquid flow meters for industrial operations. These meters are capable of measuring any type of liquid flow, be it dirty or clean. Most of the industries use chemicals or water in various forms. They require an accurately measured inflow and outflow also. Hence, you always must have a full pipe for the liquid to be accurately measured.

0 notes

Text

Flow Meters for Maintaining Temperature

Proteus Industries provides a reliable flow measurement solution to any oil, gas, liquid or steam operation. The quality of our flow meters can truly be seen at gathering facilities where a custody transfer of millions of gallons of products is required for transfer from one place to another on a daily schedule.

An example of this is crude oil. A gathering station pumps up to 10,000 gallons of crude oil every minute. If a flow meter had a measurement error of just 0.02%, it will result in a loss of 68 barrels every day. A single barrel costs $40, so this will translate to a loss of $1 million every year.

Taking steps to ensure that you are getting a reliable flow measurement solution is key to avoiding disastrous mistakes. One of accomplishing this is by taking steps to prevent measurement inaccuracy. This can be achieved by ensuring that instrumentation is calibrated properly before it enters operation.

In today’s market, companies have access to numerous types of measurement devices. Some of these are Rota meters, vortex, ultrasonic and Coriolis flow meters. All these types of flow meters are advanced technologies. However, their benefits can only be gained if they are put to use properly. Most errors in reliable flow measurement solution occur during preoperational phases. This will eventually lead to complications down the road; incurring very high maintenance costs and next-to-no downtime.

Since flow meters are in continuous operation, drifting (a very serious issue) is highly possible. Periodic proving of your flow meter is essential to identify the drift and correct it. A flow meter will calculate volume by producing pulses in relation to the quantity of fluid passing through it. When there are more pulses, it means the volume is higher. This is meter proving and it is a form of calibration that relies on this concept to maintain accuracy by making comparisons between known liquid volumes that traverse the prover to the volume shown by testing flow meter. Data that is obtained during a proving test may be used to calculate corrections. This enables the operator to alter meter readings so that they represent real flow rates.

Routine calibration or meter proving helps to protect against inaccurate measurements occurring from natural mechanical wear and tear, pipe blockages, product build up and changes in the proeprties of the product over time.

Proteus Industries Inc’ flow meters provide a reliable flow measurement solution, time and time again. Give us a call today to learn more about best water cooling flow meter and Best meters monitor cooling flow.

0 notes

Text

Manufacturers of Flow Control Solutions for Semiconductor and Fab Equipment

Manufacturing is defined as the process which is used to convert raw materials into finished products. The operation of manufacturing can be viewed as a system with supplies and raw materials serving as its input and the finished products serving as outputs. In the manufacturing of semiconductor, the input materials include dopants, metals, semiconductor materials, and insulators. While, the output materials include ICs, printed circuit boards, IC packages and several other electronic systems and products such as digital cameras, computers and cellular phones. The types of processes that are used in semiconductor manufacturing includes oxidation, etching, crystal growth, planarization, deposition processes, and photolithography.

Proteus Industries focuses on the requirement, types of flow controllers, characteristics, and gases currently utilized in semiconductor industry. The importance of flow control in semiconductor equipment processes is vital to the repeatability, manufacturing, and capability of integrated circuits. Today, in semiconductor industries different kinds of flow control solutions are becoming dominant. Thermal bases flow control solution is the most common variety in the whole industry. There are two types of sensors which are used in different industries like MEMS-based sensors and Coriolis. These sensors are not fully developed but can be found in semiconductor application in the future. Continued technological advancements, improvements, and feature sizes in semiconductor chip manufacturing have seen the arrival of faster, smaller, and newer fluid handling component. In addition, the trend shifting in the industry from single wafers to batch process has effected the components of the traditional gas system. The requirements of the performance had not been developed for the mass flow control in the semiconductor industry, materials that are applied set forth a specification to test and define the requirements. The technique best duplicates the behavior of gas which is trying to enter into a wafer process chamber.

Surrogate gasses which are normally referred to as calibration gases are used to best duplicate the nameplate gas. Mass flow control as calibrated for the nameplate gas which is the actual process gas. The relationship of calibration gases to name plate gas is utmost in understanding how to calibrate a mass flow control. These relationships are polynomial equations and nonlinear which can be created to best fit the function of this relationship. In addition, the relationships of nitrogen with all the gases are important, so that testing of mass flow control combined in to semiconductor equipment can be tested before the shipment and installation in the fab.

The evaluation of performance is extremely necessary for understanding which mass flow control system are best for a particular semiconductor process. The requirements of testing allows suppliers ranking, and interactive development of mass flow control with the instrument manufacturers. The improvements in diagnostics, digital communication, and calibration have improved the capability of mass flow control and allow process control methods to be applied. This process allows continuous improvements, which are necessary in the development of semiconductor process.

Flow Control of Gas in Semiconductor Manufacturing

The semiconductor manufacturing process includes a stage in which the process gas is delivered to the tool according to a program that state a flow for a time period. This rate of flow is obtained by a mass flow controller, which is supplied with gas at a controlled pressure. The delivery of gas for semiconductor manufacturing by using a flow control system is possible in a flow mode for delivering a batch and likewise in a no-flow mode.

The Market of Mass Flow Control (MFC)

The market for water, air, fluid, and gas control and treatment will rise to $493 billion in 2017, which is not only based on expansion of the economy of the world but also on the response to the new regulatory developments and the rise of new technologies and industries. The MFC market is expected to grow at a CAGR of 5.5% between 2018 and 2023 and it is expected to increase from USD 1,119.5 million in 2018 to USD 1,495.1 million by 2022. The main factors influencing the growth of the market are the strategies, such as agreements, expansions, product launches, partnerships by the people operating in the MFC market as well as the increasing demand for mass controllers in the semiconductor industry for several applications.

Proteus Products

Our products are manufactured in California, Silicon Valley, USA and we offer five-year warranty for Flow Meters and Switches:

1. WeldSaver 3- DeviceNet and Vortex Flow Sensors.

2. WeldSaver 3- DeviceNet and Discrete I/O.

3. WeldSaver 5 & 6.

Proteus provides a full line of instruments and flow control solutions for the semiconductor and fabrication equipment industry.

0 notes

Photo

Florite Flow Monitoring and Control Instruments - Proteus Industries

www.proteusind.com : Florite Flow Monitoring and Control Instruments - Developed to manage the special needs of flow measurement and control engineers, these flexible and reliable flow computers can be easily adapted to your unique application. Monitor instantaneous and total flow

Flow, temperature and pressure can be monitored with FluidVision® 4000 instruments

Multi-channel controls – Up to 8 input/output channels

Batch control

Multiple alarm functions

Data logging

#FlowMonitoring#FloriteFlowMonitoringAndControlInstruments#FlowMeter#FlowSensor#FlowSwitches#ControlInstruments

1 note

·

View note

Audio

Water Flow Measurement in Remote Locations

Portable flow meters are used in various circumstances and can provide many benefits over fixed flow meters. While there are circumstances where a fixed unit will be better suited (such as when data logging is necessary), the portable instruments are often being put into play to bring cost savings and flexibility. https://proteusind.com

0 notes