#Fully Automatic Core Cutter Machine

Explore tagged Tumblr posts

Text

SP Ultraflex’s live demonstration at drupa 2024

Visitors to SP Ultraflex’s stand (hall no-11, stand no D12) at drupa 2024 will witness the live demonstration of the Roboslit Plus series 1000 mpm dual turret slitter rewinder. Expressing his excitement about drupa 2024, Biku Kohli said, “We are always on the lookout for new vendors, experts in their respective fields, to support us in our innovation projects, and drupa is known to host many such vendors.”

Kohli's participation in the show is fueled by his firm belief in the capability of the technologically advanced slitter rewinding machine, and that it will attract vendors for discussions rather than the team of SP Ultraflex seeking them out.

The machine on display has an operational speed of 1000 MPM. It has a fully automatic job set-up that encompasses the positioning of the web guide sensor, cutters, trim extraction nozzles, and rewind cores, effectively minimizing setup time, material consumption, and operator dependency.

According to Kohli, drupa being the largest exhibition in the printing industry, provides an unparalleled opportunity to maximize global exposure while presenting the latest technology. He said, “drupa 2024 will play a vital role in facilitating our company's growth trajectory by providing a platform for strategic engagement, collaboration, and continuous learning within the dynamic landscape of the flexible packaging and converting industry.”

Apart from new inquiries and projects through showcasing, the latest innovations, Kohli expects to strengthen existing relationships with their valued existing customers a drupa 2024.

0 notes

Photo

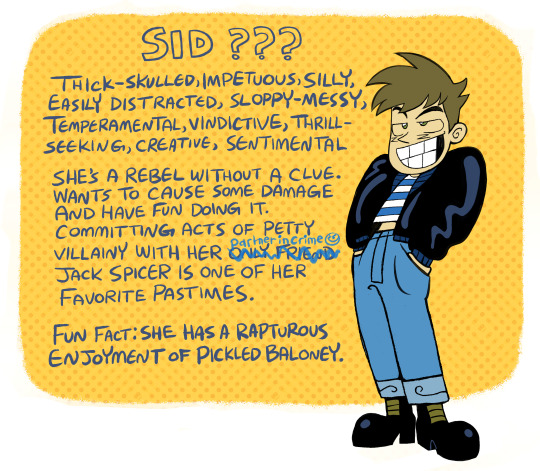

a bio for my xiaolinsona! she’s a work in progress so i’m bound to come back and change it. trivia and more in depth information is under the readmore :)

continued trivia:

she’d show up somewhere near the start of season 4

she’s used a LOT for slapstick. in fact she’s mostly a comic relief character

she’s guided mainly by emotions, is right brain oriented, and is a hands-on learner

there is a running gag where she frequently has bandaids on her fingers, hands, arms, or anywhere really

she’s a massive funk junkie. LOVES disco. she’s also a great dancer

when she comes up with xiaolin showdowns, sometimes she’ll base it off of fun recreational activities or things that seem harmlessly mundane, like mini golf..... tic tac toe.....dance-off...... rock paper scissors..... the showdowns themselves obviously end up being high-stakes and lethal as they always are, except they’re based off of goofy premises

she’s probably musically accented by grunge that’s slightly funky

when it’s funny, she occasionally will use huge words or make jarringly philosophical statements, eg patrick star’s “the inner machinations of my mind are an enigma” cut to footage of milk spilling

shes a lot like charlie kelly. in general. any charlie moment is just. Her. she’s a wild card and screams every line and huffs glue and tries to get the honey out of a hornets nest outside of jacks house because she thinks hornets make honey and she likes ghouls and she genocides the rats in his basement and sleeps ass to ass with him and is illiterate

she likes to do arts and crafts but they almost always come out as abominations. she’ll occasionally borrow some of jack’s tools to construct her latest atrocity, and she’ll refer to them by a wrong/made up name while she’s at it. “the hacksaw duey”, “the electric hole puncher,” ”the automatic pizza cutter”, etc. yes the projects and the bandaids have a direct cause and effect relationship. please refer to this video (and this channel in general)

youtube

imagine her sitting at a table and just doing this in jack’s lair... this video alone can be used to sum up so much of her. the technique. the bandaids. the blatantly wrong information that’s said with such conviction. the dark turn towards the end of the video. “superfluous protrusion.” the way it ends

continued trivia pt. 2, taken from my instagram

(i’ll get into this more further down the post)

fighting style because this is xiaolin showdown:

she has a very nimble, disorienting style of combat. using pokemon stats as an analogy, her highest would be speed by far, followed by attack, with her lowest stats being defense and special attack. this combined with her unrelenting nature makes her an excellent distraction and a general nuisance, but she doesn’t fare well in prolonged head to head battle.

favorite shen gong wu:

monkey staff, mikado arms, fancy feet, neptune helmet, hoduko mouse, woozy shooter (on herself), tongue of saiping, longi kite, indigo pyramid (on jack (cause it’s funny))

*the shen gong wu she’s most skilled with in battle are ones that trip up her opponents and cause status ailments. kinda like a prankster

backstory/analysis:

at her core, she’s a jolly, optimistic, humorous person, but her unruly, isolating childhood put a blow on her psyche. much like jack spicer, she’s been virtually alone her entire life - she was rejected by peers and adult figures alike since earliest childhood, and her home life was turbulent at best.

to ease the pain, at some point, she took on resenting and judging those around her as a means to cope. she has a holden caulfield-esque defense mechanism in play where if everybody sucks for this reason, or that reason, or those reasons, then she has justification for detaching herself from others, and she can derive her only source of self esteem from being better than them. this hurts far less than the devastating truth that she cannot connect with people on account of feeling so worthless and estranged from other human beings that she could never have the chance to be cared about by anyone. deep down, she’s in desperate, thrashing need of support and genuine human connection, and she has a warped perception of how she can achieve that.

she’s taken up evil as a hobby because it nurtures her desire to be destructive and, again, just like jack spicer, she engages in it as a way to feel seen. all press is good press, and the best way to make the headline is to cause some damage. what sets her apart from him in this regard, though, is that she takes all of her pain out on her enemies (in this case, the xiaolin monks) because she can’t stand how well off they are - instead, on the basis of their acceptance of one another, she sees them as goody two-shoes phonies who ought to be knocked down a peg. while evil to jack is both a means of getting much needed attention and a convoluted way of spending time with friends, to sid it’s a way to vent frustrations and a way to, well... still garner attention, but also spend time with a friend, except the friend is jack.

the other half of the reason she partakes in petty villainy is that it’s just... fun. she only got wrapped up in all this because she’d been restlessly putzing around somewhere remote, found a neat doohicky she planned on keeping, and when one thing led to another she wound up in a xiaolin showdown against jack. experiencing the chaos unfold revealed a golden opportunity she couldn’t pass up, so she asked jack to let her come with, debuting their partnership (i talk about this in further detail at the end of the post). goofing off and doing evil with him is so much fun to her! it makes her feel alive, a sensation and state of mind she never could fully achieve before.

noteworthy relationships:

jack:

they have a team rocket thing going on. not in terms of their interpersonal dynamic, but rather their role in the story, how much of a threat they pose as, their schemes, and even their overall attitude are reminiscent of the iconic duo; they’re petty, recurring villains with hearts of gold who aren’t above occasionally siding with the good guys.

even though they both are on the same tier of comic relief and general foolishness, the metaphor i like to draw is that jack is the left brain and sid is the right brain.

their personalities have such chemistry and they’re both so goofy that they effortlessly sync up. everyone thinks it’s REALLY annoying

they’re best friends! they actually care very deeply for one another, even if they might have funny ways of showing it. they may be evil, but they’re mutually the only and closest friend the other has ever had, and with that carries a lot of weight. think of it - the first person you meet who hasn’t been nothing but awful to you likes you and wants to be around you. What a concept

while their relationship is platonic, there are several gags implying a romantic element, even though nothing is ever outright stated. kisses on the cheek, bashfulness, other characters making fun of them (“where’s your DUMB little girlfriend?” “..........she’s not DUMB!!!!!”), domestic references (“am i sleeping on the couch”)..... it’s left ambiguous because it’s hetbait plain and simple. somebody asks them what they even are and they say Partners In Crime wym. jack asks sid What Are We and she fist pumps the flat of her own chest twice, throws a peace sign and says We’re Bros

their nicknames for each other include but are not limited to “jackass, jacky-boy, jack-o-lantern, smarty pants, wiggles, spack jicer, spack, mr spack, spackle”, and “shortstack, pipsqueak, sid the kid, champ, funky monkey, foxy (in a funny way, he’ll say it like Whatcha Up To Foxy ? while she’s like making a mess doing an arts & crafts abomination or just vibing bein her weird lil self.... it comes from a place of playful sarcasm and affection) (champ, funky monkey, and foxy are courtesy of @currentlyfallingthroughspace)

to piggyback off of the left brain vs. right brain metaphor, “heart vs. brain is how they think, right brain vs. left brain is how they act, and two halves of a heart represents their natural dispositions” is how my aforementioned friend put it. they both have a lot of heart and are ooey gooey on the inside, but the difference is that sid can grasp the intricacies of emotional/psychological matters while jack can’t (actually knowing how to EXPRESS this is another topic). it’s in the same way that jack can effectively plan ahead, use logical reasoning, and know where to go and how to get there, but sid is shabby in this department. “one is aware but doesn’t address it until it’s too late, and one can’t see it and doesn’t ask until it’s too late.”

another feature of potential conflict in all incarnations of them is the juxtaposition of sid actually being more down to earth than jack in the grand scheme of things. jack has the potential to go completely overboard, and whether or not he demonstrates the ability to catch himself on the event horizon will ascertain the outcome.

deep down, neither of them are truly evil, and they bring this out in each other as they ultimately contribute to the redemption of one another. how this actually happens is a lot rockier. sid has the intuition and self awareness to become increasingly cognizant of the fact that she engages in schemes as a way to bond with her friend, and, over time, she’s able to recognize that she’s simply been acting out, and she consequently softens up over time - but jack is much denser in this regard. he doesn’t consciously pick up on the same things she does and still believes that she’s drinking the koolaid as much as he is. the crucial dissonance in what matters most that had been incubating under the weight of things left unsaid emerges in a major falling out that challenges the nature of their entire dynamic and respective moral codes. i had a lot of help from the same friend with the following series of events and it’s really something that ought to be gone into detail on its own post, but a whirlwind brief summary is that jack becomes desperate from losing over and over so he comes up with this sinister plan that’s just too far, sid tells him to stop, they get into a nasty fight, sid leaves and makes it clear she’s not coming back, she goes to the xiaolin dragons for help, jack goes on an evil rampage but also loses his grip and has this mental breakdown because he lost the one person who’s ever cared about him (or so he thought), sid has the same brutal separation pangs but it doesn’t change the fact that jack is still doing what he’s doing, sid gets a firsthand view of a fight breaking out between the monks while she’s working with them and has a moment of clarity when she observes how they resolve it in such a healthy way, as they continue to work together and help her through the whole fiasco she realizes they’re not so bad, an entire excruciating series of events that’s genuinely too large to fit on this post unfolds and it ultimately ends with jack actually having to team UP with the good guys to stop what he started, and it ends with them breaking down, apologizing, and beginning their redemption BUT not without the illustration of several lessons that arose out of the complications of the entire thing...... the overarching lesson that’d been entrenched in their entire dynamic from the start, albeit corny, is that caring and being cared for was all they ever needed, and they learn to cultivate that within each other right under their own noses. it would be fun to have them stay as recurring villains forever, but seeing how much good is in their hearts is enough to make you wonder how they were ever evil.

xiaolin monks:

she thinks she hates them, but she doesn’t really. while her opinion of them is marked by resentment and distaste, she also holds them in high regard. a part of her wishes she could be friends with them, but the mental landscape she’s paved for herself doesn’t reveal that as an option. in her mind, she’s already been rejected by them. so why try?

the way she takes her pain out on them - people who had nothing to do with her traumas - can be summed up by the spinel su quote, “why do i want to hurt you so bad? i’m supposed to be a friend. i just want to be a friend.”

she gets chummier with them upon her redemption. out of the group, she gets along best with clay and dojo :)

bonus origin episode

this would be the imaginary early season 4 episode i mentioned at the beginning of the post. it’s more of a loose string of ideas tied together with reckless abandon but hey. the episode would open with jack feeling lonely and down on his luck to establish the theme that he kinda needs a friend (”wuya’s gone, chase trained his cats to get surly with me if i show up, my evil dream team won’t answer my calls....”). his sulking is interrupted by a shen gong wu alert and he’s like. whatever. i don’t need them. i’m still gonna do this on my own. even if it’s. ˡᵒⁿᵉˡʸ. fastforward to the scene i described where sid is putzing around with her doohicky (which i’m considering might be the neptune helmet) all by her sad miserable lonesome when suddenly some flying bloke in a trenchcoat who looks like he hasn’t seen the sun in years shows up telling her she’s got something he needs. she of course responds with something along the lines of “you know what? why don’t you try to take it from me since you want it so bad, mr big stuff,” triggering a xiaolin showdown. this is around the time the xiaolin dragons show up too late - but they’re grateful for somebody having been there to fight jack in time, even if they have no idea who they are. she has no clue what’s going on, but whatever it is, she LOVES it. she goes buckwild. she has a time. jack, on the other hand.... well, understanding how badly he needs that wu is certainly throwing a wrench in it, but he can’t help but feel like he’s having a bit of fun too. well, up until he loses. post-showdown, the monks kinda count their chickens before they hatch so to speak and they rush over to this new kid with a shower of praise, thinking they have a friend on their side. instead, she cuts them off, shouts to the guy who’s gathering his bearings (or lack thereof) - “hey! jack was it?” - and playfully tosses her shen gong wu in the air, catching it. “you look like you need this thing way more than i do. tell you what! take me with and i’ll let you borrow it,” is what she follows it up with, implying she wasn’t really that invested and only saw the whole thing as a fun game. jack and the monks are flabbergasted. what’s more bizarre is she did in fact ask to join him, something nobody’s ever done out of their own volition before. she talks about how boooooooooooring it is here and how that was soooooo much fun and to pleeeeeeeease take her with. he’s really iffy about it and doesn’t know if it’s such a good idea. he tries to make himself look cool, telling her “as IF, shortstack..........im afraid The Jack Rides Alone................................................. but-” and ultimately buckling because he can’t deny that it would be nice to have someone around.

#IM PROBABLY GONNA COME BACK AND CHANGE SO MANY PETTY THINGS BUT I HAD TO RIP OFF THE BANDAID#xiaolin showdown#xiaolin showdown oc#xiaolinsona#draws#btw her last name is question marks because i havent come up with anything yet#i have utmost confidence about this i literally think of her and jack as a duo even though shes not a real character#also it's important to add that i hope it goes without saying that a lot of her qualities arent direct translations of my own#her qualities are based on my own and are in some cases translated to represent how it would manifest in this narrative#sonas are tools u know. not being like THIS IS LITERALLY ME!!! cause its a bit different#for example my own opinions of the other characters and her opinions of the other characters differ. u kno for tha story#xiaolinsonabio

67 notes

·

View notes

Text

Used Welding Tools and Equipment

A number of top-notch companies at some point need welding tools and equipment. Different tools for welding include gas and LPG engine welders, diesel engine welders, stick welders, multi-process welders, spool guns, TIG welders, Automatic wire-feeders and many more. Being very expensive, businesses do not prefer to buy them but instead rent them. Numerous suppliers of welding machines, equipment, and tools provide the service of renting and leasing them.

Welding Equipment and Their Functions:

Gas and LPG welders: these operate with engines offering different wattage and amperages. Allowing users to combine AC or DC welding, you can use it as auxiliary power for grinders, lights, and many other tools.

Positioners and manipulators: a wide range of welding manipulators and tailstock positioners offer higher efficiency and safety. Headstock positioners handle time consuming pieces across a horizontal centerline.

Generators: the generators cater fully engine-driven generators comprising natural gas, diesel, and dual fuel as well.

Specialty equipment: a varied assortment of specialty equipment is useful for manifold purposes such as electrodes ovens, compressors, flux holding ovens, gas cylinder cages and much more.

Induction systems: The induction system is highly efficient and operates on heating without contact.

Advantages of Renting Welding Machines

Reduced costs of equipment and other welding tools.

Minimize costs of machine repairs and maintenance.

Eliminating the need of freight cost, storage and handling requirements.

Use the freed capital in manifold beneficial ways.

Advantageous processes of welding and latest technology used in equipment leads to the growth of business.

No need to pay fees for licensing and other taxes as well.

Benefits from trusted supplier

Though many suppliers are available in market to choose from, yet it is an intelligent option to select most reliable and trusted one for renting or leasing welding machines and other related tools. They offer various benefits to you as:

Wide range of products: They offer a wide range of products for your specific requirements. In case some equipment is not available, they quickly make it available.

Diversity in products: welding tools and equipment comprise welding positioners, welders, and other equipment related to equipment like electrode ovens, pipe bevellers, plasma cutters etc.

Expert assistance: Customers aware of their needs get advice regarding particular product fitting their needs.

Reliable performance of equipment: They have both new and used products but all machines and equipments are engineered and serviced to withstand extremely powerful performance and durability even in harshest conditions

Financing facility: They proffer financing facility for short and long-term rentals of welding machines, tools, and equipment. They have customized programs for lease and fleet outsourcing.

In short, suppliers of used welding machines and tools are highly efficient meeting all your particular needs. Focusing on core business skills, they strive to bring value addition to your business minimizing the inventory costs. Consequently, you can maximize your savings while increasing job productivity of business with renting inventory from such reliable suppliers of business machines, equipment, and tools.

1 note

·

View note

Text

Live at drupa 2024 — SP Ultraflex' Roboslit plus series

At drupa 2024 in Dusseldorf, SP Ultraflex, a specialist in Converting Slitter Rewinders, will conduct a live demonstration of its Roboslit plus series 1000 mpm dual turret slitter rewinder. Biku Kohli, CEO of SP Ultraflex, said, “This model, positioned right at the top of our extensive range, includes a host of features that take output, quality, and operator convenience to the next level within a safe and automated environment that includes end-to-end integrated material handling.”

The machine, which will be on display in hall no-11, stand no D12, has an operational speed of 1000 MPM. It has a fully automatic job set-up that encompasses the positioning of the web guide sensor, cutters, trim extraction nozzles, and rewind cores, effectively minimizing setup time, material consumption, and operator dependency.

Other features include a newly developed low-noise trim extraction system that allows a safer and more comfortable working environment; an automatic off-loader with a secondary pusher that reduces manual effort and enhances workflow efficiency, enabling continuous operation without interruptions; and robust safety features, including an area scanner, doors and guard interlocking, and CCTV cameras to ensure a secure working environment for operators.

Kohli explained the automatic job set-up feature. "It involves the simultaneous alignment of the unwind, cutting, and rewind sections of the machine to the package design through the use of servo-driven pick-and-place mechanisms for the components in the respective sections.” He believes this feature will be one of the key attactions for visitors, who are overwhelmed by the size changes required on their slitter rewinders.

The SP Ultraflex team says the newly designed trim extraction is far more efficient than its predecessor and, as such, can produce the desired suction power at a fraction of the power consumed by a regular trim extraction blower.

Kohli says the printing industry is undergoing rapid and significant changes. In the evolving landscape, he expressed confidence that his team is ready to deliver for converters who demand more efficient solutions with minimal set-up wastage and reduced dependency on operator skills.

He feels drupa 2024 is the largest exhibition in the industry and offers an opportunity to maximize the global exposure of any company. “It will play a vital role in facilitating our company's growth trajectory by providing a platform for strategic engagement, collaboration, and continuous learning within the dynamic landscape of the flexible packaging and converting industry.”

0 notes

Text

Key questions to Ask before buy a wire Cutting and Stripping Machine

A lot of time and effort often goes into finding the right equipment for your facility. Purchasing a new automatic cutting machine is no different. With so many options, where does one start? Asking these five questions during the decision-making process will help ensure you end up with equipment that fits all of your needs.

Will my new cutting and stripping machine be flexible enough to process all of my current and future applications?

Unless you will be running the same few jobs day in and day out, you’ll want a machine that is as flexible as possible. It is best to focus on the extreme ends of the application range in regards to wire and cable size. For example, if the largest wire you currently process is 10 AWG, determine if there is a chance you will need to process 8 AWG or larger wires in the future. You should also determine if there is a chance you will require advanced features like a multi-blade cutter head (for processing multi-conductor cable jackets and inner conductors) or a rotary incision unit to make radial incisions through the various cable-layers when processing coaxial and other multi-layer cables. Being prepared for future needs will allow you to get the most out of your purchase.

How long will changeovers take and are tools required?

Most modern cutting and stripping machines are fully programmable, however, there are always several job specific mechanical parts (guide tubes, blades, etc.) that have to be changed between jobs. Changeover times can be minimized if these changes can be accomplished without requiring tools. The smaller your batch size, the more frequent your changeovers will be. A wire stripping machine with shorter changeover times will provide a quicker ROI and continue to pay dividends over the life of the machine.

What is a realistic production rate that I can expect with my new cutting and stripping machine?

When comparing datasheets for several different wire cutting and stripping machines, you will sometimes see a specification listed for Maximum Transport Speed. A high maximum transport speed does not always correlate to a high production rate, unless you are running longer lengths. The cutting axis and other machine specifications all contribute to the machine cycle time, so it is better to focus on the Maximum Production Rate listed for each wire length and application. It is always best to send wire or cable samples to the machine manufacturer before purchasing to get realistic production rates for your specific application.

What pre- and post-processing accessories are available for my new cut and strip machine?

Keep in mind that typical entry level cut and strip machines cannot be integrated with a full range of pre- and post-processing accessories. Determine what additional operations you’ll need and whether the manufacturer of the cut and strip machine offers fully integrated accessories for those operations. Typical operations include hotstamp or inkjet marking, coiling and stacking to name a few.

Another of the most basic accessories is a prefeeder. They are available in many different sizes and styles. The most basic models feed wire and cable directly by pulling it through motorized belts or rollers. The more advanced automatic wire prefeeder drives the cable reel directly, which is gentler on the wire or cable being fed. The most advanced models also feature a motorized reel lift and full enclosure for maximum safety. Make sure to specify a prefeeder that matches or exceeds the maximum acceleration and feed rates of your new cut and strip machine.

In the world of wire processing equipment, terminal crimping machines are like offensive linemen on a football team. They’re the unsung heroes that perform in the trenches out of the limelight. Applicators don’t get the same buzz and attention as laser wire marking or stripping machines, just like linemen are often overlooked in favor of quarterbacks or running backs.

Crimping presses haven’t changed much in recent years. But the tooling—that’s another story. Today, there are terminal crimping applicators equipped with RFID chips that store and relay setup and maintenance information. There are flexible applicators with multiple feed options. There are applicators with built-in cameras to aid setup. There’s even an applicator made from composite material.

Applicators are used to ensure quality and consistency in wire processing applications. They eliminate many problems that can arise from manual placement since terminals are automatically fed into position. Machine termination also ensures a complete cycle. In addition, crimp quality monitoring systems can be employed to ensure consistency and identify quality issues.

Harness shops usually crimp from hand or lose piece to applicator when they have high capacity. Although all crimping tools are designed to provide repeatable results, the crimper will produce the best throughput when used on a benchtop crimping machine. If used on fully automatic terminal crimping machines, this will be more true.

The automatic wire harness tape winding machine is used for professional wire harness winding and winding equipment. The tapes include duct tape, PVC tape, cloth tape, etc., used for marking, fixing and protection, and are widely used in automotive, aerospace, electronics and other industries.

Fully automatic cable coiling machine is a new model developed in recent years. In order to meet the requirements of high fficiency and high output, fully automatic models generally adopt multi-head linkage design. Most domestic manufacturers refer to Taiwan and other places. The design of the imported machine model adopts the programmable controller as the control core of the equipment, and cooperates with the manipulator, pneumatic control components and executive accessories to complete the functions of automatic wiring, automatic foot wrapping, automatic

0 notes

Text

Hyundai Accent Fob Keys And Remote Program San Antonio TX

Locking yourself out or Losing your vehicle keys at the discount store or driving in a crowded highway may literally be a horrifying situation, and finding an established trained road side assistance that aim to clarify your complications at the earliest as possible 24hr is highly important. As a quality Hyundai Accent lock-smith in San Antonio TX and close by area, San Antonio Key Replacement agents go over the roof twenty four hour 7 day a week 365 days a year assembled with every single software, key programmers and diagnostic equipment needed to rekey, install or replace your car lock, ignition or key on the spot.

Hyundai Accent replacement keys in San Antonio TX

One of the core part of any Hyundai Accent is it's key-lock infrastructure, which should be recovered if blown or lost. When this type of a dispute transpires we, at San Antonio Key Replacement, in San Antonio TX, are fully competent to organize all styles of car ignition, lock or key problems on site.

Hyundai Accent transponder key is especially coded to run an explicit vehicle and our qualified task force can cut and program Hyundai Accent Tibbe, sidewinder, switch blade key or smartkey keys, as well as repair, install or replace any type of locks, ignition and keys on-the-spot non-stop around the clock.

About Hyundai Accent key and lock platform

Hyundai is a Korean vehicle maker of leading cars operates as a Hyundai Motor subsidiary and one of South Korea's greatest auto maker of average motor vehicles all over the world. based in Seoul, penetrated the world in 1946, Hyundai generally employ similar sort of immobilizer mechanism on majority of of their models since 2007.

On decrepit designs, to make an extraneous key on the dash-board, you should have not less than one programmed operational key, nevertheless to make a supplementary key for latest vehicle, an exclusive diagnostic tools and key programmer is required.

Starting from 2007, Hyundai models can employ the Proximity Key for it's a push-to-start ignition or key-less entry as a optional or standard instrumentation.

Ignition repair

When the car doesnt turn over, there might be oodles of problems which may be the reason. Since the fuel pump system and car battery are connected to the ignition lock, the problem might be difficult to investigate by an unqualified personal, yet here are a few frequent problems, which driver might have to cope with.

</p> <h5>key will only turn half way in the ignition</h5> <p> If the ignition key is hard to turn in the ignition, it may be due to a couple of reasons: Often this occurs when the steering is locked by the ignition lock with the car front wheels turned aside (usually when you park on a hill) or if one of the front wheels is pressed with force against something (e.g. sidewalk edge). In this condition, try turning the steering wheel right and left altogether with gently wiggling the ignition gripping the key - which might help in releasing the steering wheel.

</p> <h5>Dead car battery</h5> <p> Another common reason why your ignition lock might go bad is a failure of the car battery. A deflated car battery may happens as a result of electronic wiring or alternator failure. If you have no lights on the dash-board console when you turn the key in the ignition, most chances you should call a vehicle mechanic shop.

The ignition switch is one of the most important part of any vehicle and containing manifold tiny detachments that might be difficult to investigate by an unqualified personal, so the best a person may do bumping into ignition cylinder or key issues is to assure you’re in fact attempting to start your own car and call a car key-smith to arrive to your premise to repair, replace reprogram the ignition or key which will priced as about $150–$350.

Chipped key generate

Car keys, ignition and locks have progressed two decades ago with breakthrough in electric chips and laser cut blades to authorize tasks like mirror adjustment, power windows, automatic door opening and locking, alarm and many more.

Though chipped key is certainly convenient, replacing misplaced keys is no longer a brisk, lowest possible cost drive to the local hardware store or dealership. Incidents such as stolrn transponder key, breaking a flip key remote or losing your proximity key at the beach, on top of cutting a blank key, the key should be compiled to the car by a suitable programming machine done by a locksmith or at the dealer-ship and will empty your pocket with about 180-600$ base on year, model and maker.

Hyundai Accent keyless device

Hyundai Accent keyless device anable a driver to lock and unlock the door to your car besides lighting up the car yet avoiding utilizing a physical key, and since 2007, many Hyundai Accent vehicles in the market come with some kind of a proximity key system that incorporate a short-range remote transmitter.

With a smart-key, opening the door to your Hyundai Accent is normally attained by sending an RF signal from a transponder in the keyless device to a car engine control module on an enciphered channel when you merely walks within the range of 5 feet of the car with the smartkey on a key ring or in the pocket.

This radio-frequency signal and the Hyundai Accent smartkey instrumentation, furthermore enable pushtostart ignition (also known as Crash starting or Push starting). Using this method a car owner is adept of kindling a motor vehicle engine by clicking a push buttons on the dash-board console as opposed to turning a key in a break.

Copy vs lost car keys

The platform of duplicating a vehicle key differ among different models and year of your Hyundai Accent. For some models, dash-board programming could be utilized to duplicate a chipped key. This process ward off the need for extravagant key programmer and codes when programming a new chipped key to the car. Models who don't support Dash-board key duplication outline need to have a surplus key coded employing a suitable key programmer that is available solely to a sanctioned locksmith or Hyundai Accent dealer.

This coding machine costs several grands to own which is the reason making an electrical vehicle key is way more expensive to only cut an old-style metal bladed key.

If you misplaced your last car key you’ll need to get your vehicle towed to the dealer or find a car locksmith to come out to your premise to re-program the immobilized computer to accept the new key and deny the old one. This rekey process requisite proof of ownership documents like title, registration or insurance and will costs $185–$250.

24 hours car lockout

If you locked yourself out of vehicle with the keys inside, you found the right website. Our car popalock ervice can assist you in popping each and every sort of van, truck, semi-trailer or SUV professionally averting harm to door frame, the power locks, windows or electric wiring. Sometimes, in incidents that you wish a key replacement or a key extraction service employing cutters, programmers and diagnostic equipment. Alternatively to towing your car to the vehicle dealer-ship or lock smith store, call us at our call center and our polite local lock-smith agent will come down to you hurriedly to clear up your troubles on premises and put you on your way to your next activity.

Car locks updating

Did you forgot where you put your vehicle key?, acquired a brand new Hyundai Accent ignition and recommend to supplant an older one? or got one of your Hyundai Accent keys taken?, want to certify that no one else glean the proficiency to turn on your car? Good News! You enter the right page, seeing correcting of car locks is one of San Antonio Key Replacement necessary quirk. Our experts can qualify the internal pins in your door or ignition lock, so it would employ the fresh key and disdain the elderly one. Grasp the cell phone and call our customer care office to get your vehicle lock corrected by a proficient locksmith within the least possible amount of time

To sum up

San Antonio Key Replacement virtuoso car lock-smith workers are operational 24 hours a day throughout the week furnished with suitable diagnostic equipment, lock cracking tools and key programmers qualified for all your keys, locks and ignition troubles. Our 24 hrs call centre is ready to help with programming remote, vehicle unlocking, replacing lost keys and more on premises.. If you are gazing for Car key replacement service in San Antonio Texas call (210)598-8120 for a reliable local automotive locksmith, who duplicate and replace trunk, door and ignition keys and remote fob made on the spot.

0 notes

Text

3+ Best FoodSaver V4840 2-in-1 Vacuum Sealer Machine 2020

Best FoodSaver V4840 2-in-1 Vacuum Sealer Machine Reviews FoodSaver V4840 2-in-1 Vacuum Sealer System 2020 - Nowadays, people have started buying vacuum sealer machines to preserve the food for quick preparation. Not only you can store the eatables for longer, but also you can take them with you wherever you need. Now there is no need to buy packed and canned food when you can vacuum seal it at your home. Here is a vacuum sealer machine that will make the task easier and effortless. We are here with FoodSaver v4840 2-in-1 Vacuum Sealer Machine that works exceptionally well and is easy to use the machine.

FoodSaver V4840 2-in-1 Vacuum Sealer System Review 2020

Salient Features This compact vacuum sealer machine has a lot to offer. Moreover, you can take it with you a sit only weighs 10 pounds. Whether you are a frequent traveler or you are a homemaker, you can use this machine to preserve food for your beloved. Air Tight Seal The seals applied by this vacuum sealer are airtight, so the eatables will remain preserved for longer without getting contaminated. Also, the seal locks the moisture outside of the preserving bag, which enhances the shelf life of the food. Fully Automatic FoodSaver v4840 2-in-1 vacuum sealer system is fully automatic and required minimal human intervention. Also, it can sense the bag ad can start creating a vacuum and sealing it with its airtight sealing system. Just place the bag on the machine, and it will do the rest of the job.

Now you can take the food anywhere when it is vacuumed by FoodSaver V4840. Can Even Seal Jars You can even use this machine to seal jars and other containers. All you need is a jar sealer to connect with the primary device. (Jar sealer sold separately) With the jar sealer, you can also vacuum seal canisters and zip bags. There is no need to buy a different vacuum sealer machine, as everything can be done with this 2-in-1 sealer machine. Built-in Roll Storage and Cutter The machine comes with a built-in cutter and roll storage compartment. There is the least wastage of vacuum bags and other stuff when you have FoodSaver V4840 by your side. Dishwasher Safe Cleaning this vacuum sealer is another easy task as packing. The drip tray is removable, and you can wash it in the dishwasher. There is a dedicated switch that will let you know whether the drip tray needs cleaning, so you don't have to check it multiple times. NRTL tested & Certified Device This FoodSaver 2 in 1 vacuum sealer is tested by NRTL and UL, and this means that you can use this vacuum sealer without thinking twice. It is safe to use and doesn't intervene with the flavors and essence of the items packed.

Durable Body The body of this machine is durable, and it will last longer in your kitchen! The buttons are also responsive and are of high quality. Frequently bought together Verdict With FoodSaver V4840, you can automate the sealing process. The machine detects the sealer bag and seals it airtight. Overall, it is an affordable food sealer that can help you in preserving food for longer. FoodSaver v4840 VS v4400 Many buyers get confused between FoodSaver v4840 VS v4400 as both of these sealer machines are best-in-class, and affordable. Buy here in this article, we have explained the core differences between these two machines. Material The first and foremost difference between these machines is the materials. FoodSaver has used stainless steel and plastic to manufacture the body of v4840, whereas v4400 has an entirely plastic body. You will get more durability with v4840. Roller Bag Unit The roller bag unit of v4840 is rapid and efficient as compared to v4400. Still, you will get a lot of with v4400, as it also has an excellent roller bag unit. Space When it comes to space, v4400 is a step ahead of v4840. V4840 has a more significant body and structure, so if you have less space available in your kitchen, then v4400 is an excellent option for you. Also, Read FoodSaver V4400 2-in-1 Vacuum Sealer Machine Bawell Platinum Alkaline Water Ionizer Machine Review Dewalt DWS779 12 Sliding Compound Miter Saw Review OXO Brew 9 Cup Coffee Maker Review 2020 Bawell Platinum Alkaline Water Ionizer Machine Review Bowflex Selecttech 552 Adjustable Dumbbells Review Final Thoughts A vacuum sealer is a must-have appliance for your kitchen to preserve food. Also, you get the benefit of automation and some other essential features. You can choose FoodSaver v4840 2-in-1 Vacuum Sealer Machine over other devices as it is easy to use and comes at a reasonable price. Read the full article

0 notes

Text

Use and maintenance of optical fiber fusion splicer

The optical fiber fusion splicer is an indispensable device in the engineering and maintenance of optical fiber cables. It can complete the connection of single-mode, multi-mode, dispersion-shifted, and non-zero dispersion-shifted fibers. The optical fiber fusion splicer has a precise structure and high price, and there are many places to pay attention to during daily use and maintenance.

The optical fiber fusion splicer should be placed in a special carrying case for transportation, avoiding vibration, bumps and overturns during transportation. It is recommended to keep the outer box for long distance transportation.

The optical fiber fusion splicer is a high-precision device, which has requirements on the use environment (Take the FSM-50S single-core fiber fusion splicer from Japan's Fujikura Corporation as an example. Its use environment is: 0 ~ 5000 meters above sea level, -10 ~ 50 degrees temperature, Humidity 0 ~ 95% without condensation). During daily use, avoid direct sunlight, rain, snow, low temperature, wind and sand, or use tools such as parasols and tents to protect equipment.

There are generally three types of electricity supplied by the optical fiber fusion splicer: AC power, built-in battery and DC power supply. When using a small generator to power the equipment, a regulated power supply should be provided to prevent the surge current from damaging the high voltage package of the equipment. The built-in battery of the fusion splicer is generally a nickel-metal hydride battery, which has a certain memory. If it is used improperly, it will reduce the battery capacity. Before charging, the residual power in the battery should be used up. If the battery is not used for a long time, it should be fully charged and fully charged and discharged once a month.

In field construction, attention should be paid to cleaning. Ensure that the fiber optic clamps, reflectors, and V-grooves are clean. If there are dust or foreign objects, they can be cleaned with anhydrous alcohol cotton. Make it a habit to close the windshield cover to prevent dust and fiber debris from falling into the machine. The general optical fiber splicing machine provides an automatic start function. The machine automatically starts splicing after closing the wind shield. It is recommended to turn off this function.

Optical fiber precision cutting blade is an important part of the fusion splicer, and the quality of optical fiber cutting is an important guarantee for fusion splicing. Keep the fiber presser foot, V-groove and cutting blade clean during use. When it is found that the cutting quality is obviously reduced, you can rotate the cutting blade to the next edge. After the blade has been used for one turn, the blade should be replaced in time. ,

The optical fiber fusion splicer will provide multiple splicing modes corresponding to different optical fibers. You should choose the appropriate fusion splicing mode according to the type of fiber. Non-professionals should not modify the parameters in the mode to avoid affecting the splicing quality.

When the splicer fails, use the self-test function of the splicer to eliminate some problems or find the cause of the problem. If the problem is still not resolved, you should contact the supplier in time and do not disassemble the machine yourself.

It is recommended to do a comprehensive maintenance of the splicer once a year, and conduct a comprehensive inspection and maintenance of the optical path, mechanical transmission, electrodes, batteries, cutters and other parts of the equipment.

0 notes

Text

C140 Light Steel Frame Roll Forming Machine

C140 Light Steel Frame Roll Forming Machine

Light Steel Frame Machine

The Door Frame Forming Machine can produce all frames of building construction.

SURFACE TREATMENT

A: Steel Door Frame Roll Forming Machine Applicable Material

1) Processing material: Q345、G550 galvanized steel strip

2) Material thickness: 0.75-1.2mm

3) Material width: 234mm

B: Light Steel Frame Roll Forming Machine Formed profiles

1) Profile sizes: width 140mm; web 41mm; lip 10-12mm

2) Length: the max 8000mm

3) Length accuracy: ±0.5mm

4) Forming speed: the max speed 35m/min, normally 2-3 tons per day

C: Electric Decoiler

1) Coil OD: Ф1400 mm (the max)

2) Coil ID: Ф508±10 mm

3) The max width: 300mm

4) Coil weight: ≤3000 kg

5) Expending or shrinking method: operate the handle to more the four connection rods to away from or close up to the cored shaft

6) Brake: cored shaft is double hold tightly

7) Driving method: decoil raw material automatically

D: Punching system

1) Punching mould material: Cr12MOV1

2) Multi-purpose punching devices:

Punching device 1 for web notch and lip notch, blanking force 40KN

Punching device 2 for notch, blanking force 30KN

Punching device 3 for dimple, blanking force 10KN

Punching device 4 for service hole, blanking force 10KN

Punching device 5 for lipcut, blanking force 30KN

Punching device 6 for truss notch, blanking force 40KN

3) Every punching device is unipunch, can be controlled independently

4) Distance of punching holes can be adjustable

5) The life of punching mould: 300000-500000 times, 1000000 times for frequently-used mould

E: Roll Forming Parts

1) Feeding device: with four guiding rollers

2) Roll forming device: 12 roller stations, one is to form and adjust the angle ( from 87 to 95) degree of bottom and web

3) Straightening device: with one pair of horizontal shafts and two dangling rollers

4) Profile leading device: with one set of leading rollers

5) Roller material: GCr15

6) Roller processing technic: CNC machining, heat treatment HRC58-60, then processed by CNC lathe, plating finally

7) Shaft material: 40Cr

8) Roller processing technic: CNC machining, quenching and tempering HRC28-32, then processed by CNC lathe, plating and polishing finally

9) Driving method: servo motor

10) Weight: about 3500kg

F: Sheet Forming Machine Cutting System

1) Cutter material: Cr12MOV1.

2) Cutting device: 3 pieces of blades to keep and cut the shape of profile

3) Cutting type: fully automatic cut to any length

G: Production receiving System

1) Receiving table length: 4m

2) Receiving method: receive formed profiles and side-slip them pneumatically to saving table

H: Control System

1) Main control system: One Lenovo laptop and a control box inside of based frames of the machine

2) Producing software: self-developed PLC computer control system with inveter

3) Designing software: Vertext BD type

4) Leaser Printing Device: USA Matthews Leaser Printing Device for painting spray logo and installation indicating number

5) Remote-control device: ireless remote-controller controls machine to go forward or backward or stop

6) Brands of main components: PLC(self-developed), Relay (French Schneider), proximity switch(French Schneider), Encoder(Japanese Omron), Servo Motor (Xinjie) All those components takes with International Warranty Service

I: Servo System and Hydraulic System

1) Servo motor: 5.5kw, taking with precision planetary gear reducer

2) Hydraulic Station: 7.5kw, hydraulic oil injection 200 litre

3) Brands of main components: solenoid valve (Germanic Rexroth)

4) Power supply: 380V, 3 Phase, 50Hz(or as per your request)

J: Attached Components and Spare Parts

1) 2 sets of punching poles and down moulds, one set of tools

2) Protective cover: totally-enclosed type

3) Manual operation

Software VERTEX BD Pro

VERTEX BUILDING DESIGN SOFTWARE SOLUTION about Light Steel Frame Machine

A: The standard package contains:

1) Architectural Design:

Full architectural drawings

3D browser with furniture & accessories

Tools for creating presentable models

(e.g. Fascia, Soffits, Window & Door Trims, Guttering…)

2) 3D Modeling and 2D Drafting

3) DWG, DXF, 3DS, IGES and SAT -interfaces

4) Archiving tools

5) OpenGL-rendering

6) Material database

7) Wall, Floor and Roof panels and roof trusses:

Automatic panel drawings

Automatic truss structure drawings

Automatic joist & rafter layout drawings

8) Bill of materials, Cutting lists

9) First year support and maintenance

10) Add-On modules:

Vertex Standard CSV NC interface

Vertex Truss Design module, (AS/NZS Standards)

B: Software maintenance

The software maintenance agreement includes a hotline support service, a named support person and new software versions. Thus, new features that improve efficiency and ease-of-use are immediately at the disposal of the customer.

First year software support and maintenance is included to software license purchase.

1) 1 day Vertex BD basics and architectural o Drafting

Projects with Vertex BD o Wall design

Floor design o Roof design o Profiles

Drawings

2) 2 days framing training

How to use architectural model

Wall panel design

Roof and floor framing and trusses

Steel Frame Roll Forming Machine Panel drawings

3) Training will be On-Site at customer's premises or at Vertex office in Cleveland, QLD Australia

4) Maximum five (5) people can attend to training

5) Travel expenses will be charged separately

6) Training will be charged in advance

D: Recommendation for Hardware

1) The advised minimum PC configuration for VERTEX use is:

2) PC with Windows 7, Windows 8, Windows 8.1 or Windows 10

3) Pentium IV or AMD Athlon dual-core, 2 GHz,

4) 8 GB RAM

5) 120.0 GB disc

6) Display at 1280x1024 resolution

7) Graphics card with full Open GL support and min 512 Mb memory.

E: Integrated Graphics Cards are not recommended

1) CD/DVD Drive

2) 3 – button mouse

3) Backup system

TECHNOLOGY

Electric Decoiler→Multi-Purpose Punching System→Main Roll Forming Machine→Leaser Printing System→Punching System→Automatic Cutting System→Auto Receiving Table, Servo Motors, Control System with Software, Hydraulic System

0 notes

Text

Daily maintenance of rotary cutting chopper leather All-in-one machine

The Daily maintenance of rotary chopper leather All-in-one is best carried out by a person, from one end understand the machine situation, easy to maintain veneer peeling machine, extend the service life. Veneer peeling machine can use chip-free rolling process, production efficiency high plate utilization, can be different diameter, wall thickness and length of the plate for fixed length cut, to achieve automatic feeding, automatic cutting, is a typical mechatronics products, programmable controller on the hydraulic cylinder, motor, solenoid valve, Sensors and other systems to control, from the material, loading, positioning, into the expected rolling, the entire processing process fully realized the automation. Veneer peeling machine also needs to be equipped with a cumulative count and budget counting device, respectively, the cutting of the workpiece to accumulate and set a count, to facilitate statistical production and counting tool replacement. It is hoped that veneer peeling machine continue to innovate and develop to meet the development of society and People's needs. Card Shaft Speed Rotary coniferous and broad-leaved materials, the speed of the card shaft and the speed of the rotary cut are very different. Coniferous spinning card shaft speed is the fastest 600r/min, wide-leaf rotary cutting card shaft speed of the fastest about 600r/min. Veneer peeling machine has two gearboxes to meet the needs of different diameter wood rotary cuts. Two different speeds can be selected by the operator at the operator station through the control key, because the new veneer peeling machine's card shaft speed is stepless speed regulation, so the speed of the card shaft can be automatically selected between 0 and its maximum speed. In this way, producers can choose any spin speed required for production conditions. Veneer peeling machine easy wear parts have knife holder screw, nut, card shaft and bushing, main slide and slider, ruler frame and knife holder and so on. These parts of wear will reduce the accuracy of the machine tool, affecting the quality of the plate skin, such as uneven thickness of the plate skin, uneven, wave shape, rough damage of the plate skin and so on. Therefore veneer peeling machine need regular maintenance, regular maintenance not only to ensure product quality, but also to improve work efficiency, more can extend the service life of the machine. The Daily maintenance of rotary-cut chopper leather All-in-one includes daily cleaning and lubricating oil and so on. Rotary Cut Chopper leather All-in-one after each use to clean up the above wood chips, in order to prevent wood chips into the plug into the seam, affecting the spin efficiency. In order to prevent veneer peeling machine corrosion, regular lubrication should be added. How much lubricant used in the Rotary chopper leather All-in-one machine should be confirmed according to the type of machine, as well as the viscosity of the oil. The use of lubricating oil is easy to be affected by temperature, so according to the season situation to buy. Rotary cutting Chopper leather All-in-one machine is a wood processing equipment, its degree of automation, on the integration of the material spinning, than the ordinary veneer peeling machine efficiency, suitable for small diameter logs and card veneer peeling machine remaining wood shaft reprocessing, processing Pi Zihou degree from 1.0~2.6mm, processing wood shaft length changes, as well as the size of the wood shaft diameter, the user can be selected according to their own needs, with its spinning wood skin can be used as a wood-based panel sandwich or skin. So the rotary cut chopper leather All-in-one machine is very popular. As a result of the rotary cut chopper leather All-in-one machine often spin hard wood, so a long time will inevitably become dull, work efficiency decline, then we need to maintain it on a daily basis. Card Shaft The diameter of the card shaft reduces the diameter of the wood core and can increase the plate rate. The most direct and intuitive way to reduce the diameter of the wood core is to reduce the diameter of the card shaft, but the diameter of the axle must ensure that there is enough torsion when the wood section is rotated without damaging the end of the wood section. The smaller the diameter of the log, the larger the proportion of its wood core, so the diameter of the rotary wood core of the path material is much more important than that of the large diameter spinning wood core. At present, the diameter of the rotary cutter shaft of the trail material can be as small as 5~6mm. Press Roller As a rotary cutting auxiliary function of the pressure roller, is the formal veneer peeling machine production enterprises to produce veneer peeling machine indispensable components. Its form, length, driving mode and so on are different; Long pressure Roller The full-length roller; The new veneer peeling machine are fitted with a press roller of the same length as the wooden section to prevent the wood section from bending during the rotary cut. The biggest drawback of the traditional veneer peeling machine is that the press roller is not long enough to prevent the bending of the whole spinning wood segment in the direction of length. Once the wood segment is bent, the thickness of the veneer will be uneven (resulting in lip edges) and will accelerate causing the wood segment to break and the wood core to wring.

0 notes

Link

Fabrication, particularly when linked to industry, implies the building of structures, machines, products or other equipment by stamping, cutting shaping, joining and even assembling components from raw materials - most often metals.

It is commonly considered standard to assume that a fabrication operation includes welding also, but I have chosen to separate this out as some welding operations are now very specialist techniques and they merit their own section in this article.Often a small business that specialises in this type of work is known as a fabrication shop, but it should be noted that in most instances the individual parts and metalworking activities will overlap with machine shop work and sheet metal engineering or sheet metal work.

What sounds a simple activity such as cutting metal can mean many different things from shearing, sawing, to cutting torches and water jet cutters and finally to laser cutting tables and plasma cutting. Depending upon the speed and accuracy of what you want, and cost and quality requirements; you will always need to check on the capabilities and capacities of the fabrication facility that you intend to use.

In general terms the Fabrication and welding shop is likely to cover many of the following activities:

Cutting Burning Bending Wheeling Shearing Folding Forming Punching Milling Tapping Turning Welding Soldering Welding

Welding is often a major part of metal fabrication and many formed parts and assemblies will be tack welded together prior to being checked for accuracy and fit.Welding is a fabrication method which is predominantly about joining metals or thermoplastics by causing coalescence which is commonly achieved by melting the parts, adding a filler material to form the weld pool which, when cooled, becomes a very sturdy joint (the weld). This is different to brazing and soldering which does not induce melting of the initial components but melts a material between the components to form a bond between them.

There are lots of different forms of energy which can be used for welding other than the gas flame most of us recognise being also; laser, electric arc, electron beam, friction or ultrasound. Welding is a skilled operation and requires also several safety precautions to avoid burns, shocks, eye damage, fumes etc.

Starting in Blacksmiths shops with forge welding, shielded metal arc welding is probably the commonest form of welding used today as well as the semi and fully automated processes such as gas metal arc welding (MIG) and flux-cored arc welding and as the technology advances ever onwards so too does the welding systems such as laser beam welding and electron beam welding.

MIG welding (Metal Inert Gas) or metal arc welding was originally developed for welding aluminium and other non-ferrous metals. It is usually an automatic or semi-automatic process whereby an electrode joins two pieces of metal as a direct current is continuously passed through a welding gun. This is done at the same time as an inert gas is also passed through the gun which stops any air borne contaminants entering the weld area.

MIG welding allows the welding process to be much faster than other methods which makes it ideal for welding softer metals such as aluminium.It produces continuous welds faster than traditional methods, and produces cleaner welds,As it is very versatile, MIG welding can be used with a wide variety of metals and alloys.Tungsten inert gas welding or TIG welding, for short, is an arc welding process that uses a tungsten electrode to produce the weld.

Similar to MIG welding in that the weld area is also protected from atmospheric contamination via an inert gas (usually Helium or Argon or a combination), and a filler metal is often used, although certain welds, called autogenous welds, do not require this. The constant-current produces energy which in turn, is conducted across the arc through a combination of ionized gas and metal vapours which is known as plasma.

TIG Welding is often used to weld non-ferrous metals such as magnesium, copper alloys and aluminium and thin sections of stainless steel and as the technique gives the experienced welder greater control over the weld it has some advantages over MIG welding in that it can produce even higher quality and stronger welds.

http://welding.onlinetopservices.com/ http://welding.onlinetopservices.com/blogosphere.php http://welding.onlinetopservices.com/sims-metal-management.php http://welding.onlinetopservices.com/how-to-drill-granite.php http://welding.onlinetopservices.com/welding-rod-identification.php http://welding.onlinetopservices.com/metal-sensing-switch.php http://welding.onlinetopservices.com/welded-wire-kennel.php http://welding.onlinetopservices.com/metal-kitchen-wall-art.php http://welding.onlinetopservices.com/higbee-welding.php http://welding.onlinetopservices.com/il-dcfs-infant-fire-drill-evacuation-drill-procedures.php http://welding.onlinetopservices.com/welding-in-purcellville-va.php http://welding.onlinetopservices.com/tips-for-drilling-straight-holes.php http://welding.onlinetopservices.com/article_list.php http://welding.onlinetopservices.com/sitemap.php http://welding.onlinetopservices.com/feed.xml http://welding.onlinetopservices.com/james-weldon-johnson-poems.php http://welding.onlinetopservices.com/small-oxygen-welding-tanks-in-canada.php http://welding.onlinetopservices.com/miller-weld-home-page.php http://welding.onlinetopservices.com/basketball-drills-fifth-grade-girls.php http://welding.onlinetopservices.com/full-metal-alchemist-dvd-series-collection.php http://welding.onlinetopservices.com/kanga-drills.php http://welding.onlinetopservices.com/roberts-welding-llc-and-pa.php http://welding.onlinetopservices.com/metal-door-seals.php http://welding.onlinetopservices.com/welder-closed-loop-water-cooling-system.php http://welding.onlinetopservices.com/esab-tig-welders.php http://welding.onlinetopservices.com/stud-welder-dent-repair-kit.php http://welding.onlinetopservices.com/grey-wolf-drilling.php http://welding.onlinetopservices.com/hyundai-welding-wire.php http://welding.onlinetopservices.com/tradesman-drill-press-parts.php http://welding.onlinetopservices.com/machining-harley-wheels.php http://welding.onlinetopservices.com/metal-detectors-maryland.php http://welding.onlinetopservices.com/the-machining-centre.php http://welding.onlinetopservices.com/thor-38-drill.php http://welding.onlinetopservices.com/dodo-supernatural-metal-polish.php http://welding.onlinetopservices.com/harleydavidson-metal-buckle.php http://welding.onlinetopservices.com/metal-polishing-michigan.php http://welding.onlinetopservices.com/drill-hole-granite.php http://welding.onlinetopservices.com/victim-fabrication.php http://welding.onlinetopservices.com/drill-videos.php http://welding.onlinetopservices.com/metal-floor-registers.php http://welding.onlinetopservices.com/drill-trade-in.php http://welding.onlinetopservices.com/metal-life-of-jesus.php http://welding.onlinetopservices.com/bloomfield-iowa-metal.php http://welding.onlinetopservices.com/cam-lock-weld-plug.php http://welding.onlinetopservices.com/china-drill-oil-in-us-waters.php http://welding.onlinetopservices.com/electric-weld-forged-knife-blades.php http://welding.onlinetopservices.com/san-diego-metal.php http://welding.onlinetopservices.com/lincon-welding.php http://welding.onlinetopservices.com/osroot-aro-drill.php http://welding.onlinetopservices.com/fluency-drill-practice-worksheet.php http://welding.onlinetopservices.com/spindle-controller-for-milltronics-partner-1-cnc-machining-center.php http://welding.onlinetopservices.com/high-fly-fabrication.php http://welding.onlinetopservices.com/dribbling-drills-to-become-ambidextrous.php http://welding.onlinetopservices.com/independent-fabrication-bikes.php http://welding.onlinetopservices.com/ana-drill-fort-nelson.php

0 notes

Text

Mast Motorsports Gets You Into 650 hp and 570 lb-ft of Torque with the 650 Black Label Road and Track LS7

Fifty years ago, we could never have imagined a mill like the Mast Motorsports Black Label LS7 V-8. This Chevrolet Performance LS7 displaces 427 ci, or 7.0 liters, and it’s as compact as the legendary small-block Chevy. It can easily be considered the greatest American V-8 ever. You can drop this guy into nearly any vehicle where space is at a premium—and even where it isn’t—such as our classic 1970 Week To Wicked Chevy C10 shortbed pickup.

Our Week To Wicked C10 truck is a prime candidate for a 700-horse LS7. This big-cube LS7 is good for cruising, hauling, and even towing. It is also good for Saturday night drag racing. And, when you set up the suspension for roadwork, it makes the C10 a darned good canyon cutter for quick passes that will leave Challenger, Cuda, Camaro, and Mustang guys eating their words because you’ve never seen a C10 handle like this one.

We had the good fortune of visiting Mast Motorsports in the small East Texas community of Nacogdoches, a groovy little college town where these folks build massive amounts of power into a variety of mainstream engines like the small- and big-block Chevys, LS GEN IIIs and IVs. Then, they crate these engines up and ship them to locations around the world. The main focus here at Mast Motorsports is Chevrolet power, though there is the occasional Ford or Chrysler build.

What endears us to Mast Motorsports is the close, intimate team spirit that exists here. Mast employs a family atmosphere where everyone on the team looks at what they can do to help each other. As a result, you have close attention to detail from people who care about what they’re doing each day. What this means for you is a professional engine build using the best parts and technique available.

The Black Label LS7’s heart and soul is the new Chevrolet Performance LS7 aluminum block utilizing a Mast Motorsports–engineered camshaft that is custom ground on a three-bolt cam core. The 427’s foundation is a fully machined LS7 7.0L aluminum block with a forged Callies bottom end with Mahle pistons topped off with Mast Motorsports Black Label LS7 285cc cylinder heads and an LS7 intake manifold.

ARP fasteners are used throughout and Mast Motorsports Black Label pushrods ride on GM LS7 hydraulic roller tappets. This custom, handbuilt LS7 engine utilizes a camshaft that delivers great mid- and high-rpm power for the customer who will be aggressively racing their vehicle but who still wants great street manners in a daily driver. The result here is 650 hp from a 4.125-inch bore and 4.000-inch stroke yielding an 11.4:1 compression ratio.

Mast Motorsports can build you this engine or a lower compression LS7 suitable for supercharging, turbocharging, nitrous, or anything else you might have on your mind in a variety of horsepower ranges.

The Mast Motorsports 703-horse LS7 arrived on our doorstep crated just like you see here, ready to be swapped into our Week To Wicked 1970 Chevy C10 shortbed. We like the FAST induction system designed to deliver both low- to midrange torque down low and 650 real-world horsepower at 7,000 rpm in a truck. Even the crate is a nice piece engineered to protect the engine inside.

When we got the Black Label LS7 on an engine stand, we went to work dressing it up with an Eddie Motorsports S-Drive in front, FAST ignition system and controller, Earl’s plumbing, FAST induction with a 102mm throttle body, Hooker cast-iron exhaust headers, and more. We splined this high-end mill into a Performance Automatic 4L80E with the Smart Shift package for a driveline ready to take on just about anything.

The Chevrolet Performance 7.0L LS7 block is one heck of a statement for GM engineers and product planners who have had an eye on improvement ever since the GEN III V-8 first appeared in the Corvette in the late ’90s. Mast Motorsports has given the Black Label block ARP-studded and cross-bolted main caps for unparalleled security. Main caps are an interference fit machined for a perfect fit. They do not move.

You can make 700 hp all day long with the LS7. However, you can’t do it with a stock bottom end with I-beam rods and hypereutectic pistons. The Mast Motorsports LS7 is fitted with a Callies forged steel crankshaft, H-beam rods, and forged Mahle pistons for extraordinary durability. ARP fasteners are used throughout.

Professional engine builder Justin Pixley of Mast Motorsports has already set the crank and checked clearances.

We’ve opted for Mast Motorsports’ own custom cam grind for the Black Label LS7. These are matched components where cam, heads, and compression work together to make 703 hp and 603 lb-ft of torque. Stock GM roller tappets ride on top of these cam lobes, which tells us something about GM durability.

Pixley has lubed the cam journals and is setting the cam at this time. Positioning the cam calls for special attention to detail to avoid damaging cam lobes and journals.

Pixley demonstrates for us how important it is to do a methodical cylinder wall wipedown before block assembly. Freshly machined cylinder walls retain a lot of contaminants, which makes a final wipedown a necessity. Pixley wipes down the cylinder walls with automatic transmission fluid, which is a detergent as well as a lubricant. Look at the contaminants in the cloth.

Piston rings and skirts are dressed with engine assembly lube for adequate lubrication upon startup. Rod bearings and journals are also lubricated with assembly lube.

Rings are compressed with a ring compressor as shown, then, piston and rod are positioned at the bore for installation. Pixley stresses being very methodical to avoid cylinder wall and crank journal damage from the rod.

With rings properly compressed, the piston is pressed into the bore, taking note of where the rod is as we go. Rod is seated comfortably on the crank journal below.

With all eight pistons and rods installed, Pixley hand tightens the rod bolts, then torques them to ARP torque specifications. Once he has torqued all of the rod bolts, he goes back and checks again. All engine fasteners must be checked at least twice for proper torque.

Here’s something very few engine builders do. Pixley stresses checking rod journal side clearances around the circumference of the rod journal on both sides of the rod. Most engine builders do a quick check of connecting rod side clearance. It’s not enough.

Here’s everything that goes behind the timing cover — timing chain and sprockets, cam plate, tensioner, and the oil pump and related parts.

Cam plate screws get thread locker to keep them secure. Note these screws call for a Torx driver.

Cam plate screws get 18 lb-ft of torque. Begin by snugging the center screw, then the two outboard screws. Next, apply torque at the center screw, then the outboards. This approach ensures even tightening.

Timing components are very similar in design to the small-block Chevy with a three-bolt cam and sprocket. Justin examines timing marks and gets them lined up. Cam bolts get torqued to 26 lb-ft.

Camshaft endplay is checked with a dial indicator and found to be within specs. Excessive cam endplay, or not enough, will result in engine damage.

The LS employs a crank-driven gerotor oil pump that is very efficient. Pixley has blueprinted the oil pump with methodical attention to detail.

Mast Motorsports builds all get new sensors, which provide feedback to the ECM for precise engine function.

The windage tray and oil pump pickup are installed in advance of oil pan installation. The windage tray, as its name implies, keeps oil from being drawn into the crank’s rotation.

Mast Motorsports utilizes this sophisticated oil pan, which keeps oil around the pickup under nearly any condition. Isn’t gasket technology wonderful today? We like this composite pan gasket, which keeps oil where it belongs making the LS7 leakproof.

The timing cover and related components are installed next and secured.

The LS7’s hydraulic roller tappets are fitted into these holders and stuffed into the block. The lifters have been soaked in 30 weight engine oil where they will go to work immediately upon fire up.

Lifters and Cometic cylinder head gaskets have been installed. We’re ready for the heads.

The 650 Black Label LS7’s 285cc cylinder heads are methodically assembled using high-end stainless steel valves, Viton valve seals, and premium dual valvesprings.

Viton valve seals are the order of the day these days because they seal better than anything else in the marketplace. We remember a day when Viton seals were a rarity and only on high-end engines. When builders and racers discovered how good they were Viton seals began witnessing more widespread use.

The LS7’s CNC-machined combustion chambers offer excellent quench in a high-swirl design.

The LS7 cylinder head is an obvious improvement over those original cathedral port units employed on the LS1 in 1997.

What makes the LS so loved by many is its wonderful simplicity. Shaft-mounted rockers deliver excellent low-friction function and precise operation. We continue to ask, how do you improve on an already-terrific design?

Pixley puts the final touches on the Black Label LS7 before sending it to the dyno lab for testing and shipment to the customer.

The post Mast Motorsports Gets You Into 650 hp and 570 lb-ft of Torque with the 650 Black Label Road and Track LS7 appeared first on Hot Rod Network.

from Hot Rod Network http://www.hotrod.com/articles/mast-motorsports-gets-650-hp-570-lb-ft-torque-650-black-label-road-track-ls7/ via IFTTT

0 notes

Text

Pontiac Ignition Repair & Key Replacement Downey CA

Pontiac Ignition Repair & Key Replacement Downey CA - CALL (626)800-4410

http://www.downeykeyreplacement.com/pontiac.html

Are you scanning for a responsible Pontiac lock-man service in Downey CA to assist in a ticklish car lockout or lost key circumstance? Great news! If you unintentionally left your keys inside the car or lost the keys to your vehicle in a far province area or late night in a dark ally not able to open your car door and need to get safely back on your way, Downey Key Replacement adroit craftsmanship has spent a lot of energy and time into expanding our expertized mobile car lockman work truck with latest key programmers, high security key cutters and break in and entry tools and moreover extensive range of blank key-fob, transponder and keyless entry keys adequate to line on premises ignition repair, remote fobik key cloning and sidewinder key cutting

Pontiac replacement keys in Downey CA

One of the core part of any Pontiac is it's keys and locks technology, which will have to be re-keyed if misplaced or deteriorated. When this sort of a obstacle appears we, at Downey Key Replacement, in Downey CA, are without reservation experienced to regulate all designs of ignition, lock or key burdens on premises.

Pontiac transponder key is specifically computed to work with a specific car and our professionally trained team can issue Pontiac sidewinder, P.A.T.S, Tibbe or transponder keys, in addition to install, repair or replace any kind of locks, keys and ignition on-the-spot 24 hours every day.

About Pontiac keys and locks instrument

Pontiac is a U.S.A global car-maker stationed in Oakland County, Michigan, America Founded in 1926 by producing common cars.

Pontiac originate accepting transponder chipped keys in 1999. A few outmoded models keys could be conveniently duplicated using dashboard procedure, yet with most later cars the radio frequency message is coded and a unique diagnostic apparatus is required.

Today's cars (since 2007) accepts the Passive Entry Passive Start (PEPS) as smart-key and push to start electronic ignition instrumentation.

Ignition cylinder repair