#Gantry Robot Systems

Explore tagged Tumblr posts

Text

Introductions

Analise adjusts her tight cooling suit and leans out of the cockpit of her Minotaur protomech. Outside, technicians make sure her long ranged autocannon was tightly fixed and the ammo feed is clear.

One of the technicians, Dary, climbs up on the cockpit access gantry. They reach up and pull the EI interface headband out of its storage rack, and remove the plastic covers on the leads.

Analise leans down so they can slide the band over her head. They test the connection, then hop down.

“Connection secure!”

One of the technicians on the autocannon gives a thumbs up. “Weapon secure.”

A soft warmth fills the cockpit.

“Reactor online! All systems are a go.”

Analise retreats into the small padded space of her cockpit, buckles herself in, and curls up into a ball.

Robotic arms close the heavy chest plate of the protomech with a thud, and the click of the heavy bolts, and for a moment, claustrophobia and darkness overwhelms Analise.

A voice fills her cockpit, dampened by the safety padding.

“Beginning stage one EI integration.”

Suddenly a dim red glow lights the cockpit, casting dark shadows between the cushions.

“Occipital lobe signal confirmed, cerebrum signal confirmed.”

The darkness of the cockpit fades from Analise’s view, replaced by the harsh lighting of the hangar. Analise’s perception of her own body fades, instead replaced by metal strength and myomer muscles. She looks down at her left hand, closing the lump of armor into a fist, then opening it. Her right hand she clenches around the grip of her LB-2X autocannon, instinctively knowing the number of rounds in her ammunition drum.

She leans the cannon back on her shoulder and gives a thumbs up.

“Everything feels alright. The loose plate has been fixed. She rolls her shoulder and shakes her horned head back and forth.

“Time to kill some Spheroids.”

36 notes

·

View notes

Text

Revolutionizing Construction: The Power of 3D Concrete Printing in Construction Technology

Introduction

In the ever-evolving landscape of construction technology, one innovation stands out as a game-changer: 3D concrete printing. This revolutionary technique is reshaping the way we approach construction projects, offering unprecedented speed, efficiency, and creative possibilities. In this article, we delve into the intricacies of 3D concrete printing and its profound impact on the construction industry.

Understanding 3D Concrete Printing

What is 3D Concrete Printing?

At its core, 3D concrete printing is a cutting-edge construction method that utilizes robotic arms or gantry systems to layer concrete in precise patterns, creating three-dimensional structures layer by layer. This departure from traditional construction methods not only accelerates the building process but also allows for intricate and customized designs that were previously challenging to achieve.

How Does it Work?

The process involves a blend of concrete, often enhanced with additives for improved strength and durability, being extruded through a nozzle in a controlled manner. The nozzle is guided by a computerized model, ensuring precision in the deposition of each layer. As the layers stack, a solid, fully functional structure emerges.

Advantages of 3D Concrete Printing

Speed and Efficiency

One of the most significant advantages of 3D concrete printing is its remarkable speed. Traditional construction methods can take months, if not years, to complete a project. In contrast, 3D printing can construct buildings in a matter of days or weeks, significantly reducing construction timelines.

Cost-Effective Construction

By minimizing material waste and accelerating the building process, 3D concrete printing translates into cost savings. The efficiency of this technology contributes to a reduction in labor costs and the overall expenses associated with traditional construction methods.

Design Freedom and Customization

Architects and builders now have unparalleled design freedom with 3D concrete printing. Complex and innovative architectural designs that were once impractical or prohibitively expensive can now be brought to life. This opens up new possibilities for creativity and customization in construction projects.

Applications of 3D Concrete Printing

Residential Construction

The residential construction sector is witnessing a surge in 3D-printed homes. From affordable housing projects to luxurious custom-designed residences, 3D concrete printing offers a versatile solution that aligns with various housing needs.

Infrastructure Projects

Large-scale infrastructure projects, such as bridges and tunnels, can benefit from the efficiency and precision of 3D concrete printing. The technology's ability to produce large and intricate structures with minimal manual intervention makes it an attractive choice for such endeavors.

Sustainable Construction

The environmental impact of traditional construction methods is a growing concern. 3D concrete printing addresses this by reducing material waste and incorporating sustainable concrete mixes. The result is a more eco-friendly construction process that aligns with global sustainability goals.

Challenges and Future Outlook

Technological Challenges

While 3D concrete printing holds immense promise, it is not without its challenges. Refinement in printing materials, addressing structural integrity concerns, and overcoming scale limitations are areas where ongoing research and development are crucial.

Future Prospects

As technology advances, we can anticipate further refinement and widespread adoption of 3D concrete printing. The integration of smart technologies, such as sensors and automation, will likely enhance the precision and capabilities of 3D printing systems, opening doors to even more ambitious construction projects.

Conclusion: Paving the Way for the Future

In conclusion, 3D concrete printing is more than just a technological advancement; it's a catalyst for change in the construction industry. Its ability to reshape the way we build, offering speed, cost-effectiveness, and design flexibility, positions it as a cornerstone for the future of construction. As the technology matures, we can expect 3D concrete printing to become an integral part of construction projects, defining a new era in the built environment.

3 notes

·

View notes

Text

User Reviews Glossary

My SakuAtsu cyberpunk sci-fi story User Reviews takes place in the Hub, a Metro run by the Corp, in a future not too far away.

This glossary can help you speak like a true Hub citizen, and fool most securoBots.

adorb: adorable. A cuter version of something.

android: humanistic Bot.

anonyBand: a necklace that scrambles a person's facial features, making them unreadable in both surveillance camera footage and IRL.

art bomb: an illegal street art installation by graf artists.

atomWash: using an atomizer to get clean.

atomizer: A type of shower, that uses a fine mist to clean.

auDisc: Audio discs, similar to CDs.

bagPants: baggy pants.

the Belt: the drivable street encircling the Hub.

bopBots: AI tasked with inventing Popular Music.

bot: robotic laborer.

candEcube: Corp-produced candy, small cubes made of artificial flavors and sweeteners.

closed-loop: non-networked system.

cof: coffee.

cleanBot: a general use Bot, similar to a housekeeper.

the Collective: an illegal underground artists colony.

Cons: the right-of-center groups who are pro-Corps and run most of the Metros with an iron fist.

the Continental Amalgamation: the equivalent to the US, with a lot less cities and states.

Corp: the corporation in charge of the Hub.

CorpsCorps: the Corps' private army.

Creem: cof whitener.

critThink: critical thinking. Outlawed in the Hub.

cyclo-drive: getting excited.

daffy: dumb.

denary: group of ten.

dFunct: not working. Used as an expletive.

DivZero: short for "dividing by zero," this is a term used to identify an idiot. Used as an expletive.

DnD: do not disturb. An iNet setting that makes you unavailable to others.

E-skl: school.

eco: okay.

eco mode: chill.

error: something gone wrong, used as an expletive.

face2: party.

Fact™: a Corp truth. Registered trademark.

fitPants: pants that are tighter around the leg.

floorSweep: the most common consumer Bot. Functions as a vacuum cleaner.

flux: irregular electricity. Used as an expletive.

foodOp: restaurants. Also known as FOs.

foodPrep: yet another amazing Corp invention, the foodPrep is the only appliance you'll ever need. Designed to cook Readys ready in under two minutes! The Corp foodPrep. Get yours today!

foodPrep area: new name for "Kitchen."

fritzed: something is messed up.

fritz up: to mess something up.

furnsTop: a place that sells furniture and other household items.

ganked: yanked or grabbed.

gantry: hoisting machine.

ghostBoard: an interface for planning and programming on the iNet. Can be set to public or private mode.

graf: graffitti.

greyfiber: a recycled material used for fabric-type purposes.

holoProj: holographic projector, plays simCasts.

hoverCar: individual vehicles. They travel along synthment within the Hub and on smoovPaths between Metros.

Hub: the Hub is one of many Metros that make up the cityStates of the Continental Amalgamation.It is the nation's premier post-creativity society.

iDent: identity file.

iNet: what we would call the internet. Most use it in the form of contact lenses. A few old-timers still use glasses. All normal Hub citizens rely on it for day-to-day tasks.

IRL: in real life, not on the iNet.

iTap: How users of the iNet "click" on various screens within the program, by looking at them.

K: currency used by the Hub.

K-count: how much money a person has.

kak: excrement. Used as an expletive.

lastGen: digital location device, password and key. Used to mark secure areas and also to let people in those secure areas.

Libs: the left-of-center groups that have absconded to the subUrbs. They fight wars of attrition with the Cons who run the Metros.

mBandit: Metro bandits; people who invade Metros for personal gain.

med: hospital.

medBot: robot doctor.

Meeting: illegal spiritual gathering.

Metros: city-states of the Continental Amalgamation.

mono: monorail that circles the Hub.

netFile: every human's digital record. Their identification, online footprint, records and messages, all in one!

netMances: the premier iNet dating app. 90% of successful relationships start on netMances.

nCurrNc: untraceable currency. Best used for illegal income and payments.

nGupLink: clean energy source, what the citizens of the Hub rely on for their power.

Night Market: the illegal event thrown by the Collective, to purchase non-Corp-produced goods.

nMessage: encrypted messaging system. Only for sale illegally.

off prog: going off program can mean a variety of things: getting sick, mental instability, engaging in unauthorized behavior.

offline: someone staring, or even completely unconscious.

on prog: acting in a way that is expected.

outSide: the area beyond the Peri of the Hub.

paPocks: pants pockets. In most bagPants and fitPants.

peri: the perimeter of the Hub, a wall designed to keep the citizens safe.

plasti-gel: plastic gel that conforms to a variety of shapes and sizes. Used for bespoke products.

plasticine: the most used building material in the Hub. It is made out of recycled plastics and can be recycled itself, in perpetuity.

rRoom: restroom.

Readys: Corp-manufactured instant dinners, coming in five whole flavors, not including soupCups! Cooked in a foodPrep in two minutes and nutritionally balanced, Readys are all the food you need!

reEducation: the Corps' most common method of punishing illegal behavior.

reFrige: refrigerator.

roze: when someone is feeling good.

roze-pozy: when someone is feeling really good.

securoBot: security guard robot.

sensaRig: used in conjunction with the simSuit and the articulating simSkin scales, a sensaRig is a full virtual reality pod in which a person can experience another person's vidStream completely. Attachments are available to enjoy taste, smell, and all tactile sensations.

sexClub: a Corp-run sexual activity center to keep Hub citizens satisfied.

simCast: a three-dimensional version of the simScreen.

simScreen: a screen that can run a simulation visible to its audience.

simSkin: the tiles that transmit feeling when a person uses their sensaRig.

simSuit: a thin, nearly transparent fabric, worn under the simSkin tiles of a sensaRig.

skeek: creep

smartMug: a cof cup that can keep your beverage at your desired temp.

smoovPaths: interMetro highways. In disrepair.

socFeeds: iNet social media.

spark off: to make someone angry.

spizzy: cool.

spizzy as zizzy: really cool.

spline: a smooth motion.

streamedy: iNet comedy.

streetClean: these Bots keep the streets clear of any chunks that have been worn away, as well as cleaning up any recycling or illegal street art.

subUrbs: the living areas outSide the Hub. The domain of the Libs.

Sucra™: artificial sweetener.

swiggled: covered.

synthment: what the streets of the Hub are made of.

sys online: systems online. A question meaning, "are you okay?" or an answer meaning, "I'm okay."

T: t-shirt.

Toothy: a toothbrush Bot.

UBI: universal basic income, a way to guarantee all Hub citizens the K they need to buy the products the Corp sells.

upLink: a transmission to or from the iNet.

unders: underwear.

uvBlock: sunscreen.

valet: a general use Bot, similar to a butler.

vidChat: video chat. Audio-only upLinks are also available.

vidScreen: a screen that can project video.

vidStream: programming on the iNet.

wayFrees: freeways.

zero: idiot

5 notes

·

View notes

Text

Gantry Robot manufacturers in India

Discover top gantry robot manufacturers in India offering high-precision, customizable automation solutions for efficient material handling and industrial applications.

0 notes

Text

What is the Real Cost of Owning a Laser Cutter Machine in the USA?

Investing in a laser cutting machine is a major decision for any shop or manufacturing operation. While the sticker price of a new SLTL cutting machine ranges from USD 90,000 to USD 250,000 depending on power and bed size, the true cost of ownership extends far beyond that initial purchase. In this article, we’ll break down the key factors—purchase price, installation expenses, facility requirements, operating costs, consumables, maintenance, and depreciation—to help you calculate total cost of ownership (TCO) for a laser cutter in the USA.

1. Initial Purchase Price

SLTL cutting machines come in a variety of configurations. Entry-level systems (1 kW–2 kW, 4 ft × 4 ft beds) typically start around USD 90,000. Mid-range machines (2 kW–4 kW, 4 ft × 8 ft or 5 ft × 10 ft beds) run from USD 120,000 to USD 160,000. High-end systems (6 kW–12 kW, 6 ft × 12 ft or 8 ft × 20 ft beds) can exceed USD 250,000. Factors that influence price include:

Laser Power (kW): Higher power means faster cutting and thicker-plate capability but costs more.

Bed Size (ft × ft): Larger beds require more steel and larger motion systems, increasing frame and gantry costs.

Automation and Material Handling: Features like automatic sheet loaders or robotic unloaders can add USD 20,000–USD 50,000.

Control Software and Optics: Advanced nesting software, IoT monitoring, and premium optics packages add another USD 5,000–USD 20,000.

Brand, Warranty, and Service: SLTL machines include standard warranties, but extended warranties and nationwide service contracts add USD 10,000–USD 20,000 annually (Source: https://www.laseruser.com/laser-equipment/laser-cutting-machines-pricelist/ and https://www.sltl.com/en-in/products/laser-cutting-machine-fiber).

. Installation and Training

Once the machine is purchased, installation and training costs must be factored in:

Site Preparation: You may need concrete floor reinforcement, a dedicated 3-phase electrical cut-in (480 V), and compressed-air hookups. Costs can range from USD 5,000 to USD 15,000, depending on local contractor rates and the complexity of electrical upgrades.

Machine Setup and Calibration: Professional installation by factory-trained technicians typically runs USD 5,000–USD 10,000. This includes leveling, alignment, testing, and basic adjustments to ensure optimal cut performance.

Operator and Maintenance Training: On-site training for operators and maintenance staff adds USD 3,000–USD 7,000. Comprehensive training cuts down learning curves, reduces early-stage errors, and improves uptime (Source: https://www.sltl.com/en-in/services/laser-machine-installation-training).

3. Facility and Utilities

Laser cutters have specific facility requirements beyond standard workshop space:

Space Requirements: A 4 ft × 8 ft laser table needs roughly 15 ft × 20 ft of clear floor area for the machine, operator access, and material handling. Larger machines (6 ft × 12 ft beds) require 20 ft × 30 ft or more. Real-estate costs vary widely; in some regions, industrial rent can exceed USD 1.50 per square foot per month.

Electrical Consumption: A medium-duty 2 kW fiber laser system typically consumes 25–30 kW during cutting. Running an 8 hr shift at USD 0.10 per kWh equates to about USD 20–USD 24 daily in electricity. Over 250 operating days, that’s roughly USD 5,000–USD 6,000 per year. Higher-power lasers (6 kW–10 kW) can double or triple those figures.

Cooling and HVAC: Fiber lasers use closed-loop water chillers or industrial chillers. A dedicated chiller can consume 5 kW–10 kW continuously, adding another USD 1,000–USD 2,500 annually in electricity. HVAC modifications—such as increased air conditioning capacity—can add USD 3,000–USD 8,000 to initial capital costs.

Fume Extraction: Proper ventilation is mandatory. A 600–800 CFM extraction unit with multi-stage filters costs USD 2,000–USD 5,000. Annual filter replacements and duct cleaning add USD 1,000–USD 2,000 per year (Source: https://www.accurl.com/blog/fiber-laser-cutting-safety/).

4. Consumables and Operating Costs

Your laser cutter relies on various consumables that wear out or require regular replacement:

Nozzles and Protective Glass: Nozzles typically last 100–300 hours depending on material and power settings. At USD 100–USD 200 per nozzle, and assuming 2–3 nozzles replaced monthly, that’s USD 2,400–USD 7,200 annually. Protective cover glasses run USD 50–USD 100 each; you may change one per month, costing USD 600–USD 1,200 per year.

Focus Lenses and Mirrors: OEM focus lenses cost USD 1,000–USD 2,000 and often last 800–1,200 cutting hours. Plan on one replacement every 5–8 months in heavy use, i.e., USD 1,500 × 2 = USD 3,000 annually. High-quality mirrors also degrade, costing USD 1,500–USD 2,500 each; replacing mirrors once a year could add USD 1,500–USD 2,500.

Assist Gases: Cutting mild steel usually uses oxygen; stainless steel and aluminum require nitrogen. High-purity nitrogen (99.998 percent) costs USD 1.50–USD 3.00 per cubic foot. A 2 kW system might use 50–100 scfh during cutting. Over 2,000 cutting hours, that equates to USD 9,000–USD 18,000 annually. Some shops use nitrogen generators to reduce costs, but generator capital can be USD 20,000–USD 40,000 with maintenance expenses.

Electricity for Running the Laser Source: As covered above, estimate USD 5,000–USD 6,000 per year for a 2 kW system; a 6 kW system could consume USD 15,000–USD 18,000 yearly.

Combined annual consumable and operating costs for a mid-range 4 kW laser could reach USD 30,000 or more (Source: https://www.laseruser.com/laser-equipment/laser-cutting-machines-pricelist/).

5. Maintenance and Service Contracts

Regular maintenance keeps your machine running reliably, but it carries its own costs:

Preventive Maintenance Visits: Factory technicians typically charge USD 1,500–USD 3,000 per visit, and recommended schedules are twice a year for medium-use machines. That’s USD 3,000–USD 6,000 annually.

Spare-Part Kits: Annual spare-part kits (including O-rings, seals, sensors, filters) cost USD 2,000–USD 5,000 depending on machine complexity.

Service Contracts: Extended service agreements covering travel, labor, and parts often start at USD 10,000–USD 20,000 per year. These contracts guarantee response times (4 hr–8 hr) and may include software updates, on-site repairs, and wear-part discounts.

If you skip a service contract, unplanned service calls can cost USD 5,000–USD 10,000 per visit, plus lndustrial Laser Cutting Machines | USA Sheet Metal Cutter

ost production.

Source: https://www.sltl.com/en-us/services/laser-machine-maintenance/

6. Depreciation and Financing

The capital cost of a laser cutter is depreciated over its useful life (5–7 years for tax purposes). Depreciation expense can be USD 15,000–USD 50,000 per year depending on machine price. If financed, interest charges add to overall cost:

Depreciation (Straight Line): A USD 150,000 machine depreciated over 7 years yields an annual depreciation of USD 21,428.

Lease or Loan Interest: If you finance USD 150,000 over 5 years at 5 percent interest, total interest paid is approximately USD 20,000, or USD 4,000 yearly (Source: https://www.sba.gov/funding-programs/loans).

Thus, annual non-cash costs (depreciation + interest) for a USD 150,000 machine could be USD 25,428.

7. Total Cost of Ownership (TCO) Example

To illustrate, consider a mid-range SLTL 4 kW, 5 ft × 10 ft machine purchased at USD 160,000. Below is a rough TCO estimate for Year 1:

Annual Cost Breakdown:

Depreciation (7 years): $22,857

Loan Interest (5 years at 5%): $3,000

Electricity (20 kW average draw): $10,000

Chiller Electricity (7 kW): $2,500

Assist Gas (Nitrogen + Oxygen mix): $12,000

Nozzles and Cover Glass: $4,000

Focus Lenses and Mirrors: $4,500

Filters, Seals, and Other Consumables: $3,000

Preventive Maintenance Visits: $5,000

Service Contract: $15,000

In this example, the first-year TCO approaches USD 260,357—well above the USD 160,000 purchase price. Subsequent years (excluding installation and facility mods) may run roughly USD 80,000–USD 100,000 annually depending on usage (Source: https://www.accurl.com/blog/fiber-laser-cutting-safety/ and https://prathamtech.com/blogs/use-original-spare-parts/).

8. Optimizing Your TCO

Match Power to Your Needs: Avoid over-specifying power. A 2 kW system may suffice if you rarely cut beyond 12 mm steel.

Invest in Automation: Higher upfront costs for loaders and part unloaders pay off if labor is expensive and you need high uptime.

Budget for Consumables: Negotiate bulk-purchase discounts on nozzles, lenses, and filters. Consider nitrogen generators if cutting large volumes of stainless.

Schedule Preventive Maintenance: Stick to OEM recommendations to prevent costly unplanned repairs.

Monitor Energy Usage: Use variable frequency drives (VFDs) on chillers and ensure proper system insulation to reduce power draw.

Conclusion

The real cost of owning a laser cutter in the USA extends well beyond the purchase price of USD 90,000–USD 250,000. When you factor in installation, facility upgrades, utilities, consumables, service contracts, depreciation, and financing, annual TCO can exceed USD 80,000–USD 100,000 for a mid-range system. Careful planning—matching machine power to your application, investing in preventive maintenance, and managing consumable usage—will help you optimize your investment and ensure a strong return over the life of your SLTL laser cutting machine.

0 notes

Text

Automation Boom Fuels Growth in Motion Control Drive Market to $8.4 Billion by 2031

The global motion control drive market encompassing servo drives, stepper drives, and variable frequency (VFD) drives was valued at US$ 4.9 billion in 2022. Driven by the surge in automation, robotics, and precision motor control requirements, the market is forecast to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 through 2031, reaching US$ 8.4 billion by the end of the forecast period. Motion control drives regulate voltage, current, speed, and position of motors in applications ranging from CNC machining and semiconductor manufacturing to packaging, automotive, and materials handling.

Market Drivers & Trends

Automation & Industry 4.0 Adoption: Increasing deployment of automation across manufacturing verticals is fundamentally reshaping production lines. Motion control drives, which ensure precise and synchronized movements in robotic arms, conveyor systems, and automated assembly lines, are integral to Industry 4.0 ecosystems.

Integration of IoT & AI: Smart factories require drives that can self-diagnose, self-tune, and communicate performance data. The integration of Internet of Things (IoT) connectivity and artificial intelligence (AI) within drives enables predictive maintenance, reduced downtime, and optimized energy usage.

Compact & Modular Designs: Space constraints and the need for flexible machine layouts have spurred demand for compact drive systems. Solutions such as Bosch Rexroth’s ctrlX DRIVE and Rockwell Automation’s ArmorKinetix series offer modular, scalable form factors that simplify installation and support mobile and portable applications.

Energy Efficiency & Sustainability: With global pressures to reduce energy consumption and carbon footprints, manufacturers are adopting high-efficiency drives that minimize losses and recover regenerative energy—key considerations for sectors like automotive, aerospace, and materials handling.

Latest Market Trends

Self‑Tuning Servo Drives: Advanced digital servo drives can now autonomously adjust motor, drive, and feedback parameters to optimize performance. These self‑tuning capabilities reduce the need for manual calibration of control loops and enhance overall system robustness.

Multi‑Axis Synchronization: As multi-axis robots and gantry systems grow more prevalent, drives capable of precise, coordinated control across several axes are in high demand. Enhanced synchronization features enable smoother motion profiles and greater throughput.

Embedded Safety Functions: Functional safety is increasingly embedded into drive platforms, offering integrated safety monitoring, safe torque off (STO), and safe motion functions. This reduces the footprint and complexity of additional safety components in automated machinery.

Cloud‑Based Drive Management: Vendors are launching cloud‑connected platforms for remote configuration, firmware updates, and performance monitoring, enabling centralized management of distributed drive fleets.

Key Players and Industry Leaders

The motion control drive market remains fragmented, with a diverse set of global and regional players competing on innovation, customization, and service:

ABB Ltd.

Siemens AG

Rockwell Automation Inc.

Bosch Rexroth

Mitsubishi Electric Corporation

Schneider Electric SE

Delta Electronics, Inc.

OMRON Corporation

YASKAWA Electric Corporation

Toshiba Corporation

Allied Motion, Inc.

Advanced Micro Controls, Inc.

Fuji Electric Co., Ltd.

Emerson Electric Co.

HIWIN Corporation

Nidec Motor Corporation

These companies remain at the forefront through continuous R&D investment, strategic acquisitions, and partnerships to expand product portfolios and regional footprints.

Unlock crucial data and key findings from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=52011

Recent Developments

August 2023: Kollmorgen expanded its AKD2G servo drive portfolio, introducing higher amperage models with enhanced safety features and SD card backup, plus a graphical display for simplified multi-axis setup.

May 2023: ABB completed the acquisition of Siemens’ low-voltage NEMA motor business, strengthening its portfolio of integrated motor‑and‑drive solutions for North American markets.

2022: WEG acquired Gefran’s Motion Control Business Unit, gaining full ownership of variable frequency drives, DC converters, and specialized servo drives to bolster its automation offerings.

June 2021: Bosch Rexroth launched its ctrlX DRIVE system—a compact, scalable drive platform designed for easy integration into mobile and space-optimized machinery.

August 2023: Rockwell Automation unveiled Allen‑Bradley ArmorKinetix servo drives that mount directly to motors, simplifying machine assembly and improving performance flexibility.

Market Opportunities

Emerging Economies: Rapid industrialization in Southeast Asia, Latin America, and parts of Eastern Europe is driving demand for mid‑range automation solutions—an opportunity for manufacturers to introduce cost‑effective drive systems.

Smart Manufacturing Upgrades: Legacy factories undergoing digital transformation need retrofit‑friendly drive solutions with IoT connectivity and embedded safety, presenting a sizable aftermarket for system integrators.

Sustainable Energy Projects: Renewable energy installations, including solar trackers and wind turbine pitch control systems, require robust drives optimized for harsh environments and long service intervals.

Customized Solutions: Increasingly, end‑users demand turnkey, application‑specific drive packages—bundling drives with built‑in safety, condition monitoring, and domain‑specific software tools.

Future Outlook

Over the next decade, the motion control drive market will continue to evolve along several axes:

Digitalization: Drives will become central nodes in digital value chains, sending real‑time telemetry to cloud‑based analytics platforms for AI‑driven optimization.

Integration: We can expect tighter integration of drives with higher‑level controllers—blurring the lines between PLC, motion controller, and drive in next‑generation architectures.

Safety & Compliance: As regulatory standards evolve, drives will natively support functional safety protocols (e.g., TÜV‑certified safety functions) to simplify machine approvals.

Miniaturization: Advances in power electronics will permit further size reduction, enabling distributed, embedded drive solutions in compact robotics and wearable exoskeletons.

Buy this Premium Research Report and access vital insights and analysis – https://www.transparencymarketresearch.com/checkout.php?rep_id=52011<ype=S

Market Segmentation

By Type: AC Drives, DC Drives

By Product Type: Servo Drives, Stepper Drives, VFD Drives

By Axis: Single‑Axis, Multi‑Axis

By Precision: Very High Precision, High Precision, Standard

By End‑Use: Semiconductor & Electronics, Food & Beverage, Aerospace & Defense, Automotive, Paper & Printing, Pharmaceuticals, Metals & Machinery, Others

Regional Insights

Asia Pacific: Held the largest share in 2022, driven by heavy investments in manufacturing automation and robotics in China, Japan, South Korea, and India. China’s shrinking labor force and rising robotics installations (81,600 units in 2021, up 30%) underpin strong demand.

North America: Growth fueled by automotive electrification, semiconductor fab expansions, and food & beverage upgrades—coupled with strategic investments by ABB and Rockwell.

Europe: Focus on Industry 4.0 and sustainability is driving adoption of energy‑efficient drives, particularly in Germany, Italy, and the U.K.

Latin America & MEA: Emerging manufacturing hubs in Brazil, Mexico, and UAE present opportunities for mid‑tier drive manufacturers.

Why Buy This Report?

Comprehensive Analysis: Detailed market segmentation, quantitative forecasts (US$ Bn & million units), and historical data spanning 2017–2022.

Strategic Insights: In‑depth qualitative analysis, including drivers, restraints, opportunities, key trends, Porter’s Five Forces, value chain, and competitive landscape.

Company Profiles: Thorough profiles of leading players—covering corporate strategy, financials, product portfolios, M&A, and recent developments.

Decision‑Making Support: Actionable recommendations for new market entrants, technology licensors, system integrators, and investors seeking to capitalize on emerging applications and regional growth hotspots.

Multi‑Format Delivery: Available in PDF and Excel formats, facilitating integration with internal reporting and strategic planning processes.

Explore Latest Research Reports by Transparency Market Research: SMT Equipment Market: https://www.transparencymarketresearch.com/smt-equipment-market.html

Motion Control Drive Market: https://www.transparencymarketresearch.com/motion-control-drive-market.html

3D Printing Medical Devices Market: https://www.transparencymarketresearch.com/3d-printing-medical-devices-market.html

Nano Positioning Systems Market: https://www.transparencymarketresearch.com/nano-positioning-systems-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Palletizing automates stacking and shipping prep, reducing labor and injury risk. From robots to gantry systems, automation scales with your needs. Discover how to boost productivity at the end of your line.

0 notes

Text

How Robotic Water Blasting Systems Are Revolutionizing Industrial Cleaning?

In the evolving landscape of industrial maintenance, one innovation is making waves—literally. Robotic water blasting systems are quickly redefining what’s possible in heavy-duty cleaning, offering unmatched precision, efficiency, and safety. As industries demand faster turnaround times, improved worker safety, and environmentally conscious solutions, robotic water blasting has emerged as a breakthrough technology leading the charge.

This blog will explore how robotic water blasting systems work, their core advantages over traditional methods, real-world applications across industries, and what this means for the future of industrial and commercial water blasting.

What is Robotic Water Blasting?

Robotic water blasting, also known as automated hydroblasting, utilizes high-pressure water delivered through remotely controlled robotic systems to clean, strip, or prepare surfaces. These systems can be mounted on tracks, arms, or scaffolding and are equipped with intelligent software that allows precise, repeatable motion over a targeted surface area.

Unlike manual water blasting, which requires operators to handle heavy hoses and equipment, robotic systems do the dirty work with minimal human intervention. This not only reduces labor fatigue and risk but also achieves a higher degree of consistency and efficiency.

How Does Robotic Water Blasting Work?

At its core, the process involves ultra-high-pressure (UHP) water—often in excess of 30,000 PSI—delivered through robotic arms or rigs fitted with specialized nozzles. These robots are guided by pre-programmed paths or operated remotely, ensuring accurate and thorough coverage across the intended area.

Key Components Include:

Robotic Arm or Gantry System: Provides controlled, multi-axis movement.

UHP Pump System: Delivers water at extremely high pressures for coating, rust, or debris removal.

Control Interface: Allows operators to program or manually direct operations.

Filtration and Recovery Units: Capture wastewater and debris for environmental compliance.

Many advanced systems include sensors, cameras, and AI to adapt to surface irregularities or optimize spray patterns in real-time.

Why Robotic Water Blasting Is a Game-Changer?

1. Enhanced Safety

Industrial cleaning can be dangerous. High-pressure hoses, confined spaces, and elevated work areas present significant risks. Robotic systems allow operators to remain at a safe distance, significantly reducing exposure to physical strain, accidents, and hazardous environments.

2. Superior Consistency and Accuracy

Humans are prone to fatigue and inconsistencies, especially during long cleaning sessions. Robotic systems maintain precise pressure, speed, and spray angles, ensuring uniform cleaning and surface preparation every time. This leads to better outcomes, especially in industries with strict quality or safety standards.

3. Faster Turnaround Times

Because robotic water blasting operates with continuous accuracy, projects are completed faster. This is critical for industries where downtime is costly—such as manufacturing, petrochemical, shipping, or aviation.

4. Environmental Advantages

Robotic systems are designed with integrated recovery and filtration features, which means wastewater and debris are immediately collected, treated, and disposed of responsibly. Compared to abrasive blasting or chemical cleaning, robotic water blasting generates minimal environmental impact.

5. Cost Efficiency Over Time

Although the initial setup may cost more than traditional methods, robotic water blasting reduces labor hours, material usage, rework, and liability—making it a more cost-effective long-term solution.

Applications Across Key Industries

Robotic water blasting is not a niche solution—it’s a versatile powerhouse that serves a wide array of industrial and commercial water blasting needs.

1. Oil & Gas

Offshore rigs, pipelines, storage tanks, and refineries face harsh conditions and complex maintenance requirements. Robotic systems are used to remove marine growth, scale, and coatings, ensuring safe operations without exposing personnel to toxic or flammable environments.

2. Shipyards and Maritime

From hull cleaning to ballast tank maintenance, robotic hydroblasting ensures thorough, uniform cleaning even in tight or submerged areas. It eliminates the need for manual scraping or sandblasting, reducing both labor costs and dry dock times.

3. Power Plants and Utilities

Cooling towers, boilers, and condensers often develop scale or rust that impacts efficiency. Robotic systems can access and clean internal surfaces with minimal dismantling—saving significant time and labor.

4. Manufacturing and Processing

Heavy machinery and production lines accumulate grime, grease, or chemical residues that can hinder performance or contaminate products. Robotic water blasting restores surfaces to a like-new condition without halting production lines for long periods.

5. Infrastructure and Civil Works

Highways, bridges, tunnels, and dams benefit from robotic water blasting for surface prep, graffiti removal, or structural cleaning. These systems are often used during restoration or repainting projects to meet regulatory standards.

The Role of Commercial Water Blasting in Modern Facility Maintenance

As property managers, contractors, and industrial leaders seek smarter, safer cleaning methods, robotic water blasting is also becoming integral to commercial water blasting operations.

Whether it’s a multi-storey car park, shopping mall, or high-rise commercial building, robotic systems make it possible to clean vertical walls, ceilings, and even delicate cladding with remarkable speed and safety. By combining the brute power of high-pressure water with the finesse of robotic precision, building maintenance is evolving into a high-tech operation.

Common Misconceptions About Robotic Water Blasting

“It’s too expensive for smaller jobs.”

While the initial investment is higher, robotic systems can be scaled and configured for medium-sized projects, especially those requiring repeat cleanings.

“It’s only useful for heavy industry.”

Robotic systems are used in commercial, municipal, and even heritage restoration projects thanks to adjustable pressures and programmable controls.

“Manual labor is more adaptable.”

Modern robotic systems offer unparalleled flexibility, adapting to surface geometry and material type with built-in sensors and feedback systems.

The Future of Industrial Cleaning

As industries continue to adopt automation, robotic water blasting is poised to become a standard practice. Integrations with AI, real-time monitoring, and IoT connectivity are just beginning to scratch the surface of what’s possible.

Imagine systems that can:

Autonomously map surface irregularities

Predict wear patterns

Schedule proactive maintenance

Optimize water and energy use on the fly

These advancements won’t just reduce downtime—they’ll reshape how industries think about maintenance entirely.

Choosing the Right Robotic Water Blasting Partner

Not all service providers have the capability or expertise to execute robotic water blasting effectively. When considering a partner, look for:

Experience with robotic systems and high-risk environments

Certified operators and safety compliance

Advanced recovery and filtration equipment

Proven results in your specific industry

You want a team that understands both the technology and your operational needs—someone who sees robotic water blasting not just as a tool, but as a strategic asset.

Final Thoughts

Robotic water blasting is more than just the next step in industrial cleaning—it’s a revolution in how we approach surface preparation, maintenance, and restoration. With its blend of efficiency, safety, and precision, it outperforms traditional methods in nearly every metric.

From rugged refineries to pristine commercial buildings, this technology is transforming industries one blast at a time. If you're ready to modernize your approach and embrace smarter solutions, robotic water blasting could be your competitive edge.

Get In Touch:

Name: Spray and Wash Solutions

Address: 8C Piermark Drive, Rosedale, Auckland 0632, New Zealand

Phone: +64 800 881 123

MAP: https://maps.app.goo.gl/LUz3qFAfD9A3zUw28

1 note

·

View note

Text

The Role of Precision Bearings in Healthcare Industry

Medical devices significantly assist health professionals in diagnosis, treatment, and patient care. For example, surgical robots are employed to perform minimally invasive procedures, as they can offer enhanced dexterity and improve patient outcomes. This device makes the procedure less painful for patients, ensuring faster recovery.

However, these robots require precise motion control, to ensure accuracy when performing medical procedures for optimal performance and patient safety. The controlled movement of their robotic arms and instruments is attributed to precision bearings.

Applications of Precision Bearings in Medical Devices

Bearings find applications in a range of medical devices. Here are a few examples:

Diagnostic Equipment

The accuracy of MRI machines, ultrasound devices, and CT scanners depends on the smooth rotation of the gantry and imaging components, which is made possible by bearings, providing medical professionals with clear images for diagnostic purposes.

In MRI machines, ceramic hybrid or stainless steel bearings are used to maintain smooth gantry rotation, while CT scanners employ angular contact ball or tapered roller bearings for seamless gantry rotation and table movement. On the other hand, ultrasound machines use radial ball or linear bearings to ensure smooth transducer movement and scanning mechanism.

Prosthetics and Orthopedic Devices

Bearings also assist in the smooth movement and articulation of prosthetic limbs, orthopedic implants, and joint replacement systems. In devices like knee and hip implants, bearings made from biocompatible materials such as titanium or ceramic ensure durability and stability. Their low friction and wear-resistant properties enhance patient mobility and comfort.

In artificial limbs, thrust bearings or spherical plain bearings are used to provide smooth joint movement and mobility. Orthopedic implants employ radial ball or roller bearings, while orthotic devices mostly rely on linear bearings.

Surgical Robotics

The seamless movement of surgical instruments and robotic arms is made possible by miniature bearings with high precision and low friction, which provide surgeons greater control when performing intricate procedures. The bearings help minimize tissue damage, speed up recovery, and enhance patient outcomes.

Robotic arm manipulators use angular contact ball or crossed roller bearings to ensure joint articulation and movement. Surgical robot end effectors rely on thrust or needle roller bearings for instrument manipulation and tool handling. And robotic surgical platforms employ linear or spherical roller bearings to correct patient positioning during surgeries. Premier Bearings is one of the top bearing distributors in India. If you are looking for high-quality bearings, please visit us at https://www.premierbearing.com/.

#Top bearing distributors in India#Industrial Bearing Distributors in India#Schaeffler Authorized Distributor in India#FAG Bearings Distributor in India

0 notes

Text

Coordinate Measuring Machine Market Emerging Opportunities and Future Outlook 2025 to 2033

Introduction

The Coordinate Measuring Machine (CMM) market has witnessed significant growth over the past decade, driven by increasing demand for precision measurement in various industries, including automotive, aerospace, healthcare, and manufacturing. As industries continue to evolve towards automation and quality control, CMMs are becoming an essential tool for ensuring dimensional accuracy and product reliability. This article explores key industry trends, growth drivers, challenges, and forecasts for the CMM market up to 2032.

Download a Free Sample Report:-https://tinyurl.com/mvtttbn2

Market Overview

Coordinate Measuring Machines are devices used to measure the physical geometrical characteristics of objects. These machines use coordinate technology to provide precise and accurate measurements, making them indispensable in quality assurance and product inspection. The global CMM market is expected to experience steady growth due to advancements in metrology technology and increasing adoption in various sectors.

Market Size and Growth Projection

The global CMM market was valued at approximately $3.5 billion in 2022 and is projected to reach $6.5 billion by 2032, growing at a CAGR of around 6.5% during the forecast period (2023-2032). This growth is attributed to advancements in automation, growing demand for precision engineering, and increased adoption of Industry 4.0 technologies.

Key Market Trends

1. Integration of Artificial Intelligence and Automation

Artificial Intelligence (AI) and machine learning are revolutionizing the CMM industry by enhancing automation, reducing human intervention, and improving measurement accuracy. AI-driven CMMs are equipped with self-learning capabilities, enabling them to optimize measurement processes and detect deviations more effectively.

2. Adoption of Portable and Optical CMMs

Traditional stationary CMMs are increasingly being replaced by portable and optical CMMs due to their flexibility and ease of use. Optical CMMs, such as laser scanners and white light scanners, are gaining popularity as they provide non-contact measurement capabilities, reducing the risk of damage to delicate components.

3. Rising Demand in Automotive and Aerospace Industries

The automotive and aerospace industries are among the largest consumers of CMMs. With stringent quality standards and the need for precise component measurements, these industries are heavily investing in advanced metrology solutions. The increasing production of electric vehicles (EVs) and lightweight aircraft components further propels the demand for CMMs.

4. Growth of Industry 4.0 and Smart Manufacturing

Industry 4.0 has revolutionized manufacturing by integrating smart technologies, IoT-enabled devices, and real-time data analytics. CMMs equipped with connectivity features enable seamless integration with manufacturing execution systems (MES), allowing real-time monitoring and improved decision-making processes.

5. Expansion of 3D Measurement Technologies

3D measurement technology is becoming a critical component of modern CMMs. Advancements in 3D scanning, digital twin technology, and automated robotic inspection systems are enhancing the capabilities of CMMs, making them more efficient and accurate.

Market Segmentation

By Type

Bridge CMM – Most common type, known for high accuracy.

Gantry CMM – Used for measuring large components.

Horizontal Arm CMM – Ideal for automotive and aerospace applications.

Portable CMM – Increasingly adopted for on-site inspections.

By Application

Automotive – Quality control and component measurement.

Aerospace – Aircraft component inspection and precision engineering.

Healthcare – Medical device and prosthetics manufacturing.

Manufacturing & Heavy Equipment – Industrial machinery and tools measurement.

Electronics – Semiconductor and PCB inspection.

By Region

North America – Leading market due to technological advancements.

Europe – Strong presence of automotive and aerospace industries.

Asia-Pacific – Fastest-growing region, driven by manufacturing expansion.

Latin America & Middle East – Emerging adoption of industrial automation.

Challenges in the CMM Market

High Initial Investment and Maintenance Costs

CMMs require a substantial initial investment and regular maintenance, which can be a barrier for small and medium enterprises (SMEs). The cost of skilled labor for operating these machines also adds to the overall expense.

Integration with Existing Manufacturing Systems

Many manufacturers face challenges in integrating CMMs with their existing production lines. Legacy systems may not support the latest automation technologies, requiring additional investment in upgrades and training.

Competition from Alternative Measurement Technologies

Non-contact measurement technologies, such as laser scanning and structured light systems, are providing competition to traditional CMMs. Companies need to continuously innovate to stay competitive in the market.

Future Outlook and Forecast to 2032

The CMM market is set to witness continued growth, driven by increasing demand for precision engineering and automation. Some key developments expected in the coming years include:

Advancements in AI and Machine Learning – Enabling more efficient, self-correcting measurement systems.

Expansion of 5G and IoT Integration – Improving real-time data analysis and cloud connectivity.

Rising Adoption in Healthcare and Biomechanics – Supporting medical research and prosthetic manufacturing.

Growing Customization and Modular CMM Solutions – Meeting diverse industry-specific measurement needs.

Increased Government Regulations and Quality Standards – Driving demand for high-precision inspection systems.

Conclusion

The Coordinate Measuring Machine (CMM) market is poised for substantial growth over the next decade, driven by technological advancements, increasing adoption in key industries, and the rise of smart manufacturing. While challenges such as high costs and integration issues persist, ongoing innovations in AI, IoT, and automation will play a crucial role in shaping the future of the CMM industry. Businesses that embrace these advancements and invest in modern CMM solutions will gain a competitive edge in the evolving industrial landscape.Read Full Report:-https://www.uniprismmarketresearch.com/verticals/semiconductor-electronics/coordinate-measuring-machine.html

0 notes

Text

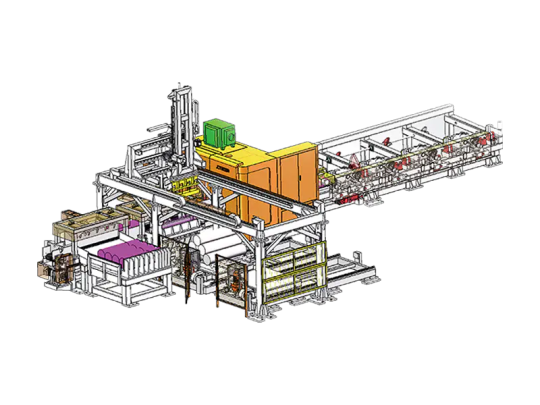

Automated Production Line Demonstration

We have developed a series of specialized loading and unloading production lines according to many special performance requirements based on the actual and latest needs of different industries. This intelligent production line is based on our company's S series circular saw and then develops and configures different supporting equipment for various users' requirements.

At present, the main supporting equipment includes a material analyzer, steel marking machine, bar surface cutting fluid drying device, bar diameter monitoring system, single and double head chamfering machine, automatic weighing system, equal weight control system, automatic stacking device, flexible material unloading device, supporting unloading and collecting device, gantry robot unloading and stacking device, oxidation bar peeling device, automated warehousing system, etc.

Among them, the automated warehousing system provides big convenience for the material loading of the circular saw and greatly improves the automation level of the entire production line. It is not only fast, reliable, and space-saving, but also increases the efficiency of the production line many times. Various forms of loading and unloading material stations are optional. The graphical visualization system manages input and output orders to make it easy for workers to use; It connects to systems such as ERP and downstream equipment to realize material management and factory intelligence.

Office Location No.661 Jiyi Road, Wanghai Hi-tech Industrial Park, Haiyan, Jiaxing City, Zhejiang Province

Company Email [email protected] [email protected]

Contact Us +86-0573-86035661

0 notes

Text

The Importance of Palletizing Systems in Mass Production

In large-scale production, efficiency is everything and the ultimate goal is to reduce time and maximize output at every production stage. Here, palletizing systems play a vital role, giving companies a headway to optimize their processes and stay competitive.

What Are Palletizing Systems?

Palletizing systems automate stacking items – like boxes, bags, or drums – onto pallets for secure shipping and storage. Once a manual, labour-heavy task, modern pallet handling systems are fully automated systems that increase safety and precision, reducing the risk of injury and ensuring a smoother workflow.

Benefits of Palletizing Systems for Large-Scale Production

Alligator Automations, the leading provider of palletizing solutions, offers a range of innovative systems designed to meet the specific needs of large-scale production facilities.

Here’s why integrating palletizing systems into your operation is a wise decision:

Increased Productivity: Automated palletizing solutions are much faster and more efficient than manual processes, boosting production rates and scalability.

Lower Labor Costs: Automation reduces dependency on large labour teams, requiring only a few skilled operators for oversight.

Higher Safety Levels: Palletizing robots minimize the risks of heavy lifting, reducing strain injuries and ensuring a safer workspace.

Enhanced Accuracy and Consistency: Integrated robotics and vision systems provide precise placement, secure stacking, and easier transport.

Space Optimization: Our usage of industrial palletizing technology arranges pallets for ideal shelf positioning, maximizing storage space.

Improved Hygiene: In industries like food and pharmaceuticals, palletizing solutions eliminate human contact, supporting high hygiene standards.

Core Functions of Palletizing Systems

Alligator Automations offers specialised palletizing systems designed to accommodate a wide range of products and their configurations. Our systems handle items like paint buckets, drums, and shrink packs using palletizing robots, adaptive grippers, and integrated vision systems for precise product handling. We also include robotic palletizers capable of complex stack patterns thus allowing for different pallet configurations improving packing density and stack strength.

Palletizing Systems provided by Alligator Automations

Robotic Palletizing: Ideal for high production needs, robotic palletizers offer flexibility for handling various products with minimal adjustments.

Gantry Palletizing: Designed for heavy-duty applications, gantry systems can accurately place large items across expansive areas.

High-Level Palletizing: Built for deep stacking, these robust systems maximize vertical space efficiently.

Low-Level Palletizing: Suitable for lower-capacity lines, these systems organize items neatly as they move along the infeed conveyor.

Hybrid Palletizing: Combining robotic and high-level features, hybrid systems deliver both precision and high-speed stacking.

Use of Palletizing Systems:

Palletizing systems offer a versatile solution across a wide range of industries:

Beverage Manufacturing: From stacking bottles and cans to palletizing kegs, automated systems ensure efficient palletizing in the beverage industry.

Consumer Goods: Whether it’s packaging household items, electronics, or toys, palletizing robots can handle a variety of product types quickly and efficiently.

Agriculture: Palletizing helps streamline bulk packaging of crops, seeds, and farming supplies, reducing manual handling and supporting safe transport.

Chemicals & Fertilizers: In this industry, palletizing is critical for safely managing hazardous and bulky products, ensuring safe, stable stacking of chemicals and fertilizers.

Oil & Paints: Palletizing solutions accommodate various container types, improving safety, organization, and efficiency in stacking oil drums and paint cans.

Alligator Automations: Your Partner in Palletizing Solutions

Alligator Automations provides a comprehensive range of palletizing solutions, including robotic palletizers, gantry palletizers, low level palletizers, high-level palletizers and hybrid palletizers. We utilize cutting-edge technology like vision systems, adaptive grippers, and advanced programming to offer exceptional flexibility and fast cycle times.

Our systems are designed to handle various product types, sizes, and configurations. Additionally, they offer features like automatic slip sheet placement, seamless data integration, and an IoT-enabled platform for real-time monitoring and improved reporting.

Contact Alligator Automations today to discuss your specific needs and discover how our innovative palletizing solutions can transform your production line.

0 notes

Text

Gantry Robot manufacturers in India

Strategi automation solutions is a leading Gantry robot manufacturer in India that offers advanced automation solutions designed for high-precision material handling and industrial applications. These systems feature multi-axis movement, robust construction, and customizable designs, making them ideal for industries such as automotive, electronics, packaging, and heavy engineering. With a focus on efficiency, reliability, and integration flexibility. Strategi automation provide cost-effective solutions that boost productivity, reduce manual labor, and support seamless workflow automation.

#gantry#robot#manufacturers#india#bangalore#mysore#strategiautomation#companies#automation solutions

0 notes

Text

Gantry Robot Manufacturers In Canada

A Step-by-Step Guide to Implementing Gantry Robotics in Your Facility

If you’re considering integrating gantry robots into your facility, you’re on the path to enhancing productivity, precision, and efficiency. Gantry Robot Manufacturers in Canada offer a wide range of solutions tailored to various industrial applications. Whether you’re in manufacturing, logistics, or any other sector, gantry robots can significantly boost your operations. This comprehensive guide will walk you through the steps to successfully implement gantry robotics in your facility.

Understanding Gantry Robotics

Gantry robots are automated systems designed to move along a fixed frame, allowing for precise and controlled movements in multiple axes. These robots are ideal for tasks that require high accuracy, such as:

Material handling

Welding

Cutting

Assembly

Inspection

0 notes

Text

What is a Cartesian robot, and how is it utilized in automation?

A cartesian robot is also known as a Gantry robot. It is a type of robotic system which moves in straight lines along the orthogonal axes. It is commonly referred to as the X, Y and Z axes. These robots are bolts on a coordinate system. They follow Cartesian geometry, and therefore, they have their name.

It involves movements in right-angled directions. Each axis of movement is powered by either a motorized system or a linear actuator. It enables the robot to move accurately in a predictable and controlled manner.

Critical characteristics of Cartesian robots

The following are the essential characteristics of cartesian robots.

Structure

Caterina robots consist of three linear actuators positioned perpendicular to each other. This enables the robot to move in three-dimensional space. Some designs might include an additional rotational axis, referred to as the "R-axis." It helps enhance the robots' capability.

Design simplicity

The construction is straightforward; therefore, cartesian robots are relatively simple to function, design, and maintain compared to the other types of Industrial robotics. Such simplicity also translates to excellent eater reliability and lower costs.

Scalability

The linear axes of a cartesian robust can be scaled and customized to meet particular operational needs. The length of each axis can be shortened or extended on the basis of the size of the work area, making it significantly adaptable to different applications.

High precision

Cartesian robots are known for their precision and accuracy. It makes them ideal for tasks that require meticulous positioning and movement. The linear motion control of the linear robot helps it follow predefined paths with minimal errors, contributing to high repeatability. Cartesian robots are widely employed in industrial automation due to their affordability, cost-effectiveness, and ease of integration.

Their linear action is perfect for many different kinds of jobs, especially those that need basic, repeated movements. The following are some of the leading automation applications for Cartesian robots:

Material Management

Every Cartesian robot is extensively utilized in material handling applications. They can handle delicate parts with greater accuracy and reproducibility, lowering the possibility of damaging the materials. They are employed in sectors where precision and consistency are essential.

3D printing

3D printing is one of the most renowned uses for Cartesian robots. This makes it possible to precisely deposit material in layers to form intricate patterns and motifs. Cartesian robots are perfect for usage in tiny desktop 3D printers and extensive industrial additive manufacturing equipment because of their precision and scalability. The printed products' structural integrity and dimensional precision are guaranteed by their exact movement along the three axes.

Final words

Cartesian robots are a vital component of the automation landscape. Their adaptability across various sectors is demonstrated by their application in palletizing, automated inspection, 3D printing, material handling, and CNC machining.

As automation technology advances, Cartesian robots are expected to significantly enhance operational precision and efficiency in manufacturing and other industries. Reach out to Igus for the best products and services. We ensure you the most affordable yet proficient and effective products. So, contact us and communicate your requirements without any delay!

0 notes

Text

Types of Industrial Robots and Their Role in Automated Manufacturing

In the contemporary manufacturing environment, the integration of industrial robots has significantly transformed production processes, driving enhanced efficiency, accuracy, and flexibility. The evolution of robotics technology has introduced various types of industrial robots, each tailored to meet distinct automation requirements. This article explores the different types of industrial robots, their specific applications, and the critical role of automation advisory and technology scouting in optimizing manufacturing operations.

Overview of Industrial Robots

Industrial robots are categorized based on their design, functionality, and intended applications. The primary types include articulated robots, SCARA robots, delta robots, cartesian robots, and collaborative robots (cobots). A thorough understanding of these robot types is essential for selecting the most appropriate robot for a given manufacturing task.

1. Articulated Robots

Articulated robots are the most prevalent type of industrial robot, characterized by their rotary joints that provide a wide range of motion. Typically, these robots feature four to six axes, enabling them to perform tasks with high precision and flexibility. Due to their versatility, articulated robots are commonly employed in operations such as welding, assembly, material handling, and machine tending. Their ability to maneuver in complex angles makes them indispensable in industries like automotive and aerospace.

2. SCARA Robots

Selective Compliance Articulated Robot Arm (SCARA) robots are designed for tasks that demand rapid and precise movements within confined spaces. These robots have a fixed base and three vertical joints, which make them particularly suitable for pick-and-place operations, assembly, and packaging. SCARA robots are favored for their rigid structure, which ensures stability and accuracy in repetitive tasks, often in electronics and consumer goods manufacturing.

3. Delta Robots

Delta robots, also known as parallel robots, have a distinctive spider-like design featuring three arms connected to a common base. These robots are renowned for their exceptional speed and precision, making them ideal for high-speed applications such as picking, packing, and sorting. Industries like food processing, pharmaceuticals, and electronics frequently utilize delta robots due to their ability to perform quick and accurate movements, essential for maintaining production efficiency.

4. Cartesian Robots

Cartesian robots, or gantry robots, operate on three linear axes (X, Y, and Z) and are recognized for their simplicity and precision. These robots are often employed in applications such as CNC machining, 3D printing, and automated storage and retrieval systems. Cartesian robots are valued for their straightforward design and ease of programming, making them a preferred choice for tasks that require linear motion and high accuracy.

5. Collaborative Robots (Cobots)

Collaborative robots, commonly referred to as cobots, are engineered to work alongside human operators, enhancing both productivity and safety in manufacturing settings. Cobots are equipped with advanced sensors and safety mechanisms that enable safe interaction with human workers. These robots are widely used in assembly, quality inspection, and material handling, where human-robot collaboration can streamline workflows and improve overall efficiency.

Applications of Industrial Robots

The diverse range of industrial robots is applied across various sectors of manufacturing, with each type of robot excelling in specific tasks that contribute to overall production effectiveness.

Welding: Articulated robots are highly valued in welding applications due to their precision and ability to handle complex welding tasks in industries such as automotive and aerospace.

Assembly: SCARA robots and cobots are ideal for assembly processes, where their speed and accuracy are crucial for efficiently assembling components.

Material Handling: Cartesian and articulated robots are often used for material handling tasks, including moving heavy items, loading and unloading machinery, and palletizing products in distribution centers.

Packaging: Delta and SCARA robots are commonly employed in packaging operations, where their quick and precise movements are essential for sorting, packing, and labeling products.

Quality Inspection: Cobots are increasingly used in quality inspection, where their ability to work alongside human inspectors enhances the detection of defects and ensures high product quality.

The Role of Automation Advisory and Technology Scouting

Choosing the appropriate type of industrial robot for a specific application requires careful consideration of factors such as the nature of the task, production demands, and budget constraints. This is where automation advisory services and technology scouting play a pivotal role.

Automation Advisory

Automation advisory involves consulting with experts who assess manufacturing operations and recommend the most suitable automation solutions. These experts analyze production processes, identify bottlenecks, and suggest ways to integrate robots to improve efficiency. By leveraging insights into the latest robotic technologies, manufacturers can optimize their production processes, achieving enhanced performance and cost efficiency.

Technology Scouting

Technology scouting focuses on researching and identifying emerging robotic technologies that can benefit manufacturing operations. Staying informed about the latest advancements enables manufacturers to adopt cutting-edge solutions that drive innovation and improve competitive advantage. Technology scouting also helps in identifying scalable robotic solutions that can evolve with a company’s production needs, ensuring long-term growth and sustainability.

Conclusion

The integration of various types of industrial robots has significantly impacted manufacturing by enhancing efficiency, precision, and flexibility. Articulated robots, SCARA robots, delta robots, cartesian robots, and cobots each serve unique functions across different industrial applications. Utilizing automation advisory and technology scouting ensures that manufacturers select the right robots for their specific needs, optimizing production processes and maintaining a competitive edge. As technology continues to advance, the role of industrial robots in manufacturing will only become more crucial, driving innovation and fostering growth across the industry.

Robotic & Automated Solutions provides expert guidance in harnessing effective advisory services and automation technologies, drawing from extensive experience in industrial automation to support manufacturers in achieving their strategic objectives.

0 notes