#Geotechnical Deformation Monitoring Devices

Explore tagged Tumblr posts

Text

Monitoring and Inspection Methods for Reinforced Soil Slopes

Reinforced Soil Slopes (RSS) are an essential component of modern geotechnical engineering, providing stability and support in various construction projects, including highways, railways, and urban developments. Ensuring the long-term stability and safety of these structures requires regular monitoring and inspection. Effective monitoring and inspection methods are crucial to identify potential issues early and to maintain the integrity of the slopes. This article explores the key methods used for monitoring and inspecting reinforced soil slopes.

Importance of Monitoring and Inspection Monitoring and inspection of reinforced soil slopes are vital for several reasons. Firstly, they help in the early detection of potential failures or deformations, allowing for timely intervention. Secondly, they ensure compliance with design specifications and performance standards. Lastly, regular monitoring contributes to the safety of the infrastructure and the surrounding environment by preventing catastrophic failures.

Visual Inspections Visual inspection is the most straightforward and widely used method for monitoring reinforced soil slopes. This involves regular site visits by trained engineers who visually assess the slope for signs of distress, such as cracks, surface erosion, or unusual vegetation growth. Visual inspections are cost-effective and provide immediate information about the condition of the slope. However, they may not always detect underlying issues that are not visible on the surface.

Inclinometers Inclinometers are devices used to measure the angle of slope movement and deformation over time. These instruments are installed in boreholes along the slope and provide continuous data on the lateral movements within the slope. By monitoring these movements, engineers can detect any shifts or trends that might indicate instability. Inclinometers are particularly useful for slopes that are suspected to be at risk of failure due to lateral movements.

Piezometers Piezometers measure the pore water pressure within the soil, which is a critical factor in slope stability. High pore water pressure can reduce the shear strength of the soil, leading to slope failure. By monitoring the pore water pressure, engineers can assess the effectiveness of drainage systems and detect any changes that might threaten the stability of the reinforced soil slopes. Piezometers can be installed at various depths to provide a comprehensive understanding of the subsurface water conditions.

Settlement Gauges Settlement gauges are used to measure the vertical displacement or settlement of the soil. These gauges can detect any subsidence or heave in the slope, which could indicate potential stability issues. By monitoring vertical movements, engineers can ensure that the reinforced soil slopes are performing as expected and take corrective actions if necessary.

Geotechnical Instrumentation and Remote Sensing Advanced geotechnical instrumentation, such as extensometers and strain gauges, can provide detailed information on the deformation and stress within the soil. These instruments are installed within the slope and connected to data loggers, which record the measurements over time. Remote sensing techniques, such as LiDAR (Light Detection and Ranging) and UAV (Unmanned Aerial Vehicle) surveys, can also be employed to monitor large areas efficiently. These technologies allow for the collection of high-resolution data and can identify changes in the slope that might not be visible to the naked eye.

Ground Penetrating Radar (GPR) Ground Penetrating Radar is a non-invasive method used to detect subsurface anomalies and changes in soil composition. GPR can identify voids, changes in soil density, and other factors that might affect the stability of reinforced soil slopes. By using GPR, engineers can gain insights into the internal structure of the slope and detect potential issues before they become critical.

Data Analysis and Interpretation The data collected from various monitoring instruments must be analyzed and interpreted by geotechnical engineers to assess the stability of the reinforced soil slopes. This involves comparing the measured data with design specifications and historical performance data. Advanced software tools can assist in analyzing the data and predicting future behavior of the slopes. Regular reporting and documentation of the monitoring results are essential for maintaining a comprehensive understanding of the slope's condition over time.

Conclusion Monitoring and inspection of reinforced soil slopes are crucial for ensuring their long-term stability and safety. A combination of visual inspections, inclinometers, piezometers, settlement gauges, geotechnical instrumentation, remote sensing, and Ground Penetrating Radar provides a comprehensive approach to monitoring these structures. By employing these methods, engineers can detect potential issues early, maintain compliance with design standards, and ensure the safety of the infrastructure and the surrounding environment. Effective monitoring and inspection not only extend the lifespan of reinforced soil slopes but also contribute to the overall reliability and resilience of modern construction projects.

0 notes

Text

Geotechnical Deformation Monitoring Devices Market is Expected to Grow at a Healthy CAGR with Top players: Geotechnical Instrumentation, RST Instruments, Roctest, Sherborne Sensors, GaiaComm

The recently Published Report titled Geotechnical Deformation Monitoring Devices Market is Expected to Grow at a Healthy CAGR with Top players: Geotechnical Instrumentation, RST Instruments, Roctest, Sherborne Sensors, GaiaComm by Axel Reports offers a comprehensive picture of the market from the global view point as well as a descriptive analysis with detailed segmentation, complete research and development history, latest news, offering a forecast and statistic in terms of revenue during the forecast period from 2021-2027. The report covers a comprehensive analysis of key segments, recent trends, competitive landscape, and key factors playing a substantial role in the market are detailed in the report. The report helps vendors and manufacturers to understand the change in the market dynamics over the years.

Get Sample Copy of this Report with the Latest Market Trend and COVID-19 Impact: https://axelreports.com/request-sample/117485

Global Market Segmentation by Top Key-Players: Geotechnical Instrumentation RST Instruments Roctest Sherborne Sensors GaiaComm Geosense 3D Laser Mapping Fugro N.V Keller Group Geokon Incorporated Durham Geo Slope Indicator Nova Metrix Geocomp Corporation Sisgeo COWI A/S Measurand Marmota Engineering Canary Systems Soldata Mine Design Technologies

NOTE: Consumer behaviour has changed within all sectors of the society amid the COVID-19 pandemic. Industries on the other hand will have to restructure their strategies in order to adjust with the changing market requirements. This report offers you an analysis of the COVID-19 impact on the Geotechnical Deformation Monitoring Devices market and will help you in strategising your business as per the new industry norms.

Report offers: 1. Insights into the intact market structure, scope, profitability, and potential. 2. Precise assessment of market size, share, demand, and sales volume. 3. Authentic estimations for revenue generation and Geotechnical Deformation Monitoring Devices Market development. 4. Thorough study of Geotechnical Deformation Monitoring Devices Market companies including organizational and financial status. 5. Perception of crucial market segments including, forecast study. 6. Acumen of upcoming opportunities and potential threats and risks in the market.

Market segments by Types of, the report covers- Manual Deformation Monitoring Devices Automatic Deformation Monitoring Devices Market segments by Applications of, the report covers- Civil Engineering Mechanical Engineering Construction Geology Others

The report diversifies the global geographical expanse of the market into five prominent regions as:

North America (United States, Canada and Mexico)

Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe)

Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia)

South America (Brazil, Argentina, Colombia, and Rest of South America)

Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa)

Key Elements Discussed In The Report: The report then discusses important dynamics on the business drivers that have a major impact on the performance are given in the report. The business drivers are important to the business operations and financial results of the industry. All the drivers are determined in the research study using market analysis. The report is comprehensive coverage of the existing and potential markets along with their assessment of their competitive position in the changing market scenario. It scrutinizes in-depth global market trends and outlook coupled with the factors driving the global Geotechnical Deformation Monitoring Devices market, as well as those hindering it.

Get Up to 30% Discount on the first purchase of this report @ https://axelreports.com/request-discount/117485

Moreover, the report throws light on the pinpoint analysis of global Geotechnical Deformation Monitoring Devices market dynamics. It also measures the sustainable trends and platforms which are the basic roots behind the market growth. With the help of SWOT and Porter’s five analysis, the market has been deeply analyzed. Consumer behavior is assessed with respect to current and upcoming trends. The report takes a detailed note of the major industrial events in past years. These events include several operational business decisions, innovations, mergers, collaborations, major investments, etc.

Customization of the Report: This report can be customized to meet the client’s requirements. Please connect with our sales team ( [email protected]), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +18488639402 to share your research requirements.

ABOUT Axel Reports:

Axel Reports has the most comprehensive collection of market research products and services available on the web. We deliver reports from virtually all major publications and refresh our list regularly to provide you with immediate online access to the world’s most extensive and up-to-date archive of professional insights into global markets, companies, goods, and patterns.

Contact: Axel Reports Akansha G (Knowledge Partner) Office No- P 221 Pune, Maharashtra 411060 Phone: US +18488639402 Web: https://axelreports.com/

1 note

·

View note

Text

This report studies the Geotechnical Deformation Monitoring Devices market size (value and volume) by players, regions, product types and end industries, history data 2018-2022 and forecast data 2023-2030; This report also studies the global market competition landscape, market drivers and trends, opportunities and challenges, risks and entry barriers, sales channels, distributors and Porters Five Forces Analysis.

0 notes

Text

Geotechnical Deformation Monitoring Devices Market Competitive Landscape, Manufacturers Analysis and Overview Forecast by 2024

Geotechnical Deformation Monitoring Devices Market Competitive Landscape, Manufacturers Analysis and Overview Forecast by 2024

Chicago, United States, Nov 14, 2019 — The Global Geotechnical Deformation Monitoring Devices Marketreport offers a high-quality, accurate, and comprehensive research study to equip players with valuable insights for making strategic business choices. The research analysts have provided deep segmental analysis of the global Geotechnical Deformation Monitoring Devices market on the basis of type,…

View On WordPress

#Geotechnical Deformation Monitoring Devices#Geotechnical Deformation Monitoring Devices Industry#Geotechnical Deformation Monitoring Devices Market#Geotechnical Deformation Monitoring Devices Market Analysis#Geotechnical Deformation Monitoring Devices Market CAGR#Geotechnical Deformation Monitoring Devices Market Competitive Landscape#Geotechnical Deformation Monitoring Devices Market Forecast#Geotechnical Deformation Monitoring Devices Market Growth#Geotechnical Deformation Monitoring Devices Market Share#Geotechnical Deformation Monitoring Devices Market Size#Geotechnical Deformation Monitoring Devices Market Trend#Geotechnical Deformation Monitoring Devices Revenue

0 notes

Text

2017-2022 Global Geotechnical Deformation Monitoring Devices Market Analysis : Marmota Engineering, Canary Systems, Soldata, Mine Design Technologies

2017-2022 Global Geotechnical Deformation Monitoring Devices Market Analysis : Marmota Engineering, Canary Systems, Soldata, Mine Design Technologies

Worldwide Geotechnical Deformation Monitoring Devices Market 2017presents a widespread and fundamental study of Geotechnical Deformation Monitoring Devices industry along with the analysis of subjective aspects which will provide key business insights to the readers. Global Geotechnical Deformation Monitoring Devices Market 2017 research report offers the analytical view of the industry by…

View On WordPress

0 notes

Text

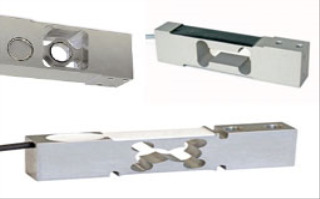

Everything You Need to Know About Load Cells and Their Technology

In the dynamic industrial world, load cells are one of the most ubiquitous components that cannot be overlooked. Wondering what load cells are? Well, they fall under the umbrella of transducers or electro-mechanic sensors that helps convert force into electrical output. The cell functions to measure weight or force and it has an effective design that depends on the electricity flow and material deformation. Load cells are versatile devices offering accurate performance across diverse applications. All commercial and industrial processes use load cells as an effective way to measure weights and forces across systems.

Load Cell Technology

There are different types of load cells. While the resistive load cells work on the principle of piezo-resistivity, the capacitive load cells function on the principle of the change of the capacitance. Typically, capacitance is a system’s ability to hold a certain amount of charge when the voltage is applied to it. Also, load cell designs can also be differentiated as per the type of output signals generated (hydraulic, pneumatic, electric) or according to the way how they detect weight (compression, bending, tension, shear, etc).

Load cells find their uses in geotechnical fields. They are typically used to monitor deep sea foundations in excavation bracing like struts, anchors or tiebacks, soldier pile, and retaining walls. Load cells can also be used to keep tabs on tunnels and shafts. Working on the classic principle of Wheatstone bridge, load cells need the application of voltage to opposite nodes.

How do load cells work?

Load cells involve the use of geotechnical instruments and they can’t wok without being paired up with sensors. One of these sensors is the strain gauge. Strain gauges are fundamentally thin elastic materials made up of stainless steel. They are fixed inside the load cells and they have a specific resistance directly proportional to its width and length. When the force is applied on the load cell, it stretches or bends causing the strain gauge to move and when the cross-section and length of the strain gauge alters, its electrical resistivity also gets changed, thereby changing the overall output voltage.

Environmental Conditions

The load cell may face versatile environmental conditions. However, you must ensure to protect it from the exterior environment to make sure it has an efficient performance for the intended usage timeline. A few load cells are in potted form and their cavities get filled with resin material or epoxy to cover the anodic components. The protection helps guard the circuit system from humidity and outside damage while dissipating heat.

A few load cells also exhibit hermetic seals to enable environmental protection. Fully welded seals provide a robust and airtight enclosure that helps the load cell to stand up during challenging environments.

You may find FM and ATEX certificates for certain load cell types that indicate it is safe to use the equipment in dangerous or explosive environments.

Conclusion

You must ensure that the load cell gets properly installed and aligned to make the most of its performance. You can follow the manufacturer’s recommendations to get the best results from the reliable device and ensure long-lasting usage.

Source: https://packagingmachinesaustralia.blogspot.com/2022/08/everything-you-need-to-know-about-load.html

0 notes

Text

Geotechnical Deformation Monitoring Devices Market Major Manufactures, Trends, Demand, Share, Analysis To 2025

Geotechnical Deformation Monitoring Devices Market Report

On a global scale, the Geotechnical Deformation Monitoring Devices market is currently showing significant development. The Geotechnical Deformation Monitoring Devices marketis experiencing a growth velocity due to the new product prototype versions, world market dynamics, topological variations, economic statistics, product demands and…

View On WordPress

0 notes

Link

Electronic total station is an optical or electronic instrument, used in modern surveying & building construction. It is used in geotechnical monitoring such as building a structure like tunnels below the ground, and to provide a firm foundation above the ground. Its main functions are angle measurement, coordinate measurement, distance measurement, and data processing. It is widely used by civil engineers for topographical surveying. Its main applications are mining, mechanical & electrical construction, and meteorology. The key advantages are high accuracy of measurement, eliminates manual errors of reading & recording, speeds up field work, and provides accurate calculation of coordinates.

According to study, “World Electronic Total Station Market Research Report 2024(covering USA, EU, China, South East Asia, Japan and etc)” the key companies operating in the world electronic total station market are South Surveying & Mapping Instruments Co. Ltd., Hexagon AB, Dad, Foif, Tjop, Boif, Topcon Corp., Leica, Trimble Inc., Suzhou FOIF Co. Ltd., Changzhou Dadi Surveying Science & Technology Co., Ltd., Stonex, CST/Berger, Kara Company, Kwipped, Axis- GPS and Surveying Instruments, Celtic Surveys, Ti Asahi Co. Ltd, Advanced Surveying Instruments India Pvt. Ltd., GENEQ Inc., Maple International Instruments Inc., Hi-Target Surveying Instrument Co., Ltd., Guangdong Kolida Instrument Co., Ltd. Key players are developing robotic electronic total station with unique features, making it easy for users to operate it and get the correct data.

Based on type, electronic total station market is segmented into manual total station and robotic total station. Based on component type, market is segmented into Electronic Distance Measurement (EDM), microprocessor, electronic theodolite, storage unit and others (display, accessories, and prism). Based on product type, market is segmented into building & construction total station, surveying & engineering total station, construction & surveying total station, laser stations and engineering & monitoring total station. Based on offering, market is segmented into services and hardware. Services include calibration, repairs, rentals, and on-site training. Based on methods, market is segmented into triangulation and traverse. Based on distribution channel, market is segmented into wholesalers, supermarkets/hypermarkets, retailers and online retail. In addition, based on application, market is segmented into large-scale construction on the ground, precision engineering surveying, underground tunnel construction and deformation monitoring field.

The electronic total station market is driven by increase in 3D modelling in surveying technology, followed by rise in need for modernized construction plan, modernization of tools & techniques in surveying sector and growth in demand for fast & precise measurement in rail application. However, high cost associated with the device and lack of awareness on latest measurement may impact the market. Moreover, integration of terrestrial laser scanners and enhancement in accuracy & improvement in performance are key opportunities for market.

Based on geography, China country holds major share in electronic total station market owing to increase in investments in construction & engineering sector and presence of major companies in the country. USA country is expected to witness substantial growth due to growth of transportation & construction sector over the forecast period. In upcoming years, it is estimated that the market will be reached at rapid pace on account of rise in demand from transportation sectors.

To know more, click on the link below:-

Global Electronic Total Station Market

Contact Us:-

Ken Research

Ankur Gupta, Head Marketing & Communications

+91-9015378249

0 notes

Text

Geotechnical Deformation Monitoring Devices Market Global Locations 2019 - HeyReport

Geotechnical Deformation Monitoring Devices Market Global Locations 2019 – HeyReport

Global Geotechnical Deformation Monitoring Devices ResearchReport is top of its kind research report that includes current competitive analysis as well as valuable insights to industries and clients. And a strategy to penetrate or expand in a geotechnical deformation monitoring devices industry. This has assessed capacity utilization rate, gross, volume, cost, price data, import/export,…

View On WordPress

0 notes

Text

2015-2023 World Geotechnical Deformation Monitoring Devices Market Research Report by Product Type, End-User / Application and Regions / Countries

2015-2023 World Geotechnical Deformation Monitoring Devices Market Research Report by Product Type, End-User / Application and Regions / Countries

Get Market Research publishes the following report: 2015-2023 World Geotechnical Deformation Monitoring Devices Market Research Report by Product Type, End-User / Application and Regions / Countries

Summary

Date Published: 2018-03-06 00:00:00

Pages: 132

Category: Machinery and Equipment

This report includes market status and forecast of global and major regions, with introduction of vendors,…

View On WordPress

#2015-2023 world geotechnical deformation monitoring devices industry analysis#2015-2023 world geotechnical deformation monitoring devices market data#2015-2023 world geotechnical deformation monitoring devices market growthrate#2015-2023 world geotechnical deformation monitoring devices market research#2015-2023 world geotechnical deformation monitoring devices market size#2015-2023 world geotechnical deformation monitoring devices market structure#2015-2023 world geotechnical deformation monitoring devices market study#2015-2023 world geotechnical deformation monitoring devices market trends#growth drivers and issues

0 notes

Text

FBG sensors: a comprehensive review

A fiber Bragg grating is an optical interferometer embedded in an optical fiber. At the same time, fiber optics combined with certain substances (usually germanium) can change its refractive factor when the fiber is exposed to ultraviolet light. If such a fiber is illuminated with ultraviolet light with a specific spatial periodic structure, the optical fiber becomes a kind of diffraction grating. In other words, this optical fiber will almost completely reflect the light of a certain, predetermined range of wavelengths, and transmit light of all other wavelengths.

The FGB application includes the following fields:

• Point sensors (that is able to measure deformation, temperature, pressure, tilt, displacement), embedded in composite materials and others;

• Laser systems and amplifiers (filters, mirrors);

• Telecommunications (dispersion compensation modules, WDM technology);

• Research and development.

For decades, electrical sensors (tensor-resistive, string, potentiometric, etc.) have been the main method of measuring physical and mechanical phenomena. Despite their widespread use, electrical sensors have several disadvantages, such as loss during signal transmission, sensibility to electromagnetic interference, the need to organize a spark-resistant electrical circuit (if there is a danger of explosion). These mentioned above limitations make electrical sensors unsuitable or difficult to use for a number of applications.

The use of fiber optic sensors is an excellent solution to these problems. In fiber optic sensors, the signal is light in the optical fiber instead of electricity in the copper wire at traditional electrical sensors.

Over the past twenty years, a huge number of innovations in optoelectronics and in the field of fiber optic telecommunications has led to a significant reduction in prices for optical components and to a significant improvement in their quality. This factor allows fiber optic sensors to move from the category of experimental laboratory tools to the category of widely used devices in various areas.

A fiber Bragg grating or FBG acts as a sensitive element of point fiber optic sensors, which is capable to reflect certain wavelengths of light and transmit all others. This effect is achieved by periodically changing the refractive index in the core of the fiber optics.

When the laser light passes through an optical fiber, a part of it is reflected from the fiber grating at a certain wavelength. This peak of reflected light is registered by measuring equipment. As a result of the numerous parameters influence, the interval between the FBG bundles and the refractive index of the fiber optics change.

Consequently, the wavelength of the light reflected from the fiber Bragg grating changes. In addition, it is possible to determine the exact characteristics of the changes by changing the wavelength. In fiber optic sensors based on Bragg gratings, the measured value is converted to a Bragg wavelength offset. The recording system converts the wavelength offset into an electrical signal.

The sensing element of such FBG sensor does not contain electronic components and therefore it is completely passive, which means it can be used in the area of increased explosiveness, aggressiveness, strong electromagnetic interference. Numerous fiber Bragg gratings can be installed on a single fiber, each of which gives a response at its own wavelength. In this case, instead of a point sensor, we get a distributed sensing system with multiplexing along the wavelength.

The use of the light wavelength as an information parameter makes the FBG sensor insensitive to the long-term changes of the parameters of the source and radiation detector, as well as random attenuation of power in the optical fiber.

The following types of fiber optic sensors based on FBG technology are used for automated monitoring:

FBG strain sensors;

FBG displacement sensors;

FBG temperature sensors;

FBG pressure sensors;

Fiber optic tilt sensors;

Fiber optic acceleration and vibration sensors;

Data recorders for fiber optic sensors;

Additional equipment for data recorders.

The principle of FGB sensor operation is based on the modulation of one or several properties of a propagating light wave (intensity, phase, polarization, frequency), which change occurs with a change in the measured physical quantity.

The basis of fiber-optic sensing technology is optical fiber - a thin glass thread that transmits light through its core. The optical fiber consists of three main components: core, shell, and coating. The shell reflects the scattered light back into the core, allowing light to pass through the core with minimal loss.

It can be achieved by a higher refractive index in the core relative to the shell, resulting in a complete internal reflection of light. The outer coating protects the fiber optics from external influences and physical damage. It can consist of several layers depending on the required protection.

The advantages of FBG sensors include:

• Wide sensing range;

• Possibility to integrate the FBG sensing system into the object structure;

• Full fire and explosion safety;

• Long distance signal transmission;

• Integration of several fiber optic sensors in one channel;

• Insensitiveness to electromagnetic and radio frequency influences;

• No need for recalibration (stable over time under constant external conditions).

At the moment, most of the sensors used in the world are electrical sensors. As it was mentioned above, in optical sensors based on fiber Bragg gratings, the signal is light passing through an optical fiber (instead of an electric current passing through a copper wire). This fundamental difference allows FBG sensors to overcome many problems typical for electrical sensors.

Optical fibers and sensors are non-conductive, electrically passive and immune to electromagnetic interference. Monitoring with a tunable high-power laser system allows sensing over long distances with virtually no signal loss. In addition, each optical channel is able to monitor a variety of FBG sensors unlike the electrical channel, which significantly reduces the size and complexity of such a sensing system.

Optical sensing systems are ideal for use in conditions where conventional electrical sensors (strain gauge, string, thermistor, etc.) can be difficult to use (long distances, EM fields, explosion safety, etc.). It is easy to switch to fiber optic solutions since the installation and operation of optical sensors are similar to traditional electrical sensors.

Understanding the principles of FBG operation and the benefits of Bragg grating sensor application can greatly facilitate the solution of various problems in the field of sensing measurement (for example, monitoring of structures).

Nowadays FBG sensors are applied in various fields that require precise and fast measurements. Fiber Bragg sensing systems can be used in aeronautic, automotive, civil engineering structure monitoring, undersea oil exploration, in the mining industry, geotechnical engineering, structural engineering, tunnel construction engineering, etc.

The most promising application of FBG sensors is medicine. Now FBG technology is highly used for fiber-based biomedical sensing including biosensing, safety or security, and structural health monitoring. FBG sensors offer a new and effective way of real-time measurements. They can be applied in laser systems, medical tiny intra-aortic probes and body sensors for biochemical analysis making. For example, today fiber Bragg gratings apply optical-fiber sensing probes that are able to dissolve due to such ability as controlled solubility in a physiological environment. Thus, FBG technology enables safer diagnostic of sensitive human organs and there is no need for a surgical extraction. The development of FBG continues, and it is possible that very soon new FBG sensors with improved characteristics appear. If you want to obtain a highly efficient sensing system, you should choose Optromix company. Optromix is a manufacturer of innovative fiber optic products for the global market. The company provides the most technologically advanced fiber optic solutions for monitoring worldwide. Optromix is a fast-growing vendor of fiber Bragg grating (FBG) products line such as fiber Bragg grating sensors, FBG interrogators and multiplexers, distributed acoustic sensing (DAS) systems, distributed temperature sensing (DTS) systems. If you are interested in FBG sensors and want to learn more, please contact us at [email protected]

0 notes

Text

Geotechnical Deformation Monitoring Devices Market Segmentation, Manufacturing Cost Analysis Iincluding Key Raw …

Geotechnical Deformation Monitoring Devices Market offers comprehensive analysis of industry status and outlook of major regions based on of key players, countries, product types, and end industries.... TRY OUR MEDIA SEARCH ENGINE - https://nzrtnetworksearch.blogspot.com/ from NZRT NETWORK https://nzrtnetworkmedia.wordpress.com/2018/07/21/geotechnical-deformation-monitoring-devices-market-segmentation-manufacturing-cost-analysis-iincluding-key-raw/ via IFTTT

0 notes

Text

Geotechnical Deformation Monitoring Devices Market Industry 2018-2023 Analysis, Trends and Forecasts

Geotechnical Deformation Monitoring Devices Market Industry 2018-2023 Analysis, Trends and Forecasts

The Global and Chinese Geotechnical Deformation Monitoring Devices Market, 2013-2023 Industry Research Reports an exhaustive study on the present market scenario of the global Geotechnical Deformation Monitoring Devices industry with a special focus on the China market of this industry.

The report summarizes key statistics of the Geotechnical Deformation Monitoring Devices and the overall status…

View On WordPress

#Geotechnical Deformation Monitoring Devices#Geotechnical Deformation Monitoring Devices forecast#Geotechnical Deformation Monitoring Devices Industry#Geotechnical Deformation Monitoring Devices market#Geotechnical Deformation Monitoring Devices Market Growth#Geotechnical Deformation Monitoring Devices Market report

0 notes