#Global Cold Chain Tracking and Monitoring Market

Explore tagged Tumblr posts

Text

Trailer Telematics Market : Size, Trends, and Growth Analysis 2032

The Trailer Telematics Market was valued at US$ 779.09 million in 2024 and is anticipated to grow at a CAGR of 10.90% from 2025 to 2032. This rapid market expansion is fueled by the global logistics sector’s increasing demand for real-time visibility, predictive analytics, and fleet safety optimization. Trailer telematics technologies are revolutionizing how logistics and transport companies manage assets—unlocking higher efficiency, security, and profitability.

Understanding Trailer Telematics

Trailer telematics systems integrate GPS, IoT sensors, cellular connectivity, and cloud platforms to monitor and transmit vital data from trailers. These systems track:

Real-time location

Vehicle speed and route history

Cargo condition (e.g., temperature, humidity)

Door open/close status

Brake health and tire pressure

Trailer utilization and idle time

This data allows fleet managers to monitor, control, and optimize operations remotely, reducing downtime, theft risk, fuel consumption, and cargo damage.

Key Drivers of Market Growth

1. Booming E-commerce and Logistics

The explosion in e-commerce and on-demand delivery services has intensified the need for fast, reliable, and transparent supply chain operations. Telematics solutions give companies the tools to manage complex logistics efficiently and meet growing customer expectations for real-time delivery tracking.

2. Need for Real-Time Visibility

Fleet operators are under pressure to know exactly where assets are and how they are performing at all times. Trailer telematics deliver location accuracy, status updates, and usage patterns that help in informed decision-making and route optimization.

3. Cargo Security and Regulatory Compliance

With increasing cargo theft incidents and tightening regulations around goods handling (especially cold chain logistics), companies are adopting telematics to ensure security and compliance. Real-time alerts for door breaches or temperature fluctuations can help prevent costly losses.

4. Predictive Maintenance and Asset Lifecycle Management

Advanced telematics systems support predictive maintenance by analyzing component health and usage patterns. This minimizes unplanned downtime, extends trailer lifespan, and reduces maintenance costs.

5. Environmental and Fuel Efficiency Goals

Fleet management increasingly incorporates sustainability goals. Telematics helps reduce fuel consumption by monitoring driver behavior, optimizing routes, and minimizing idling—supporting carbon reduction efforts.

Core Components of a Trailer Telematics System

GPS Modules – For accurate location tracking.

Telematics Control Unit (TCU) – Collects, processes, and transmits data.

Sensors – Monitor cargo temperature, trailer doors, braking systems, tire pressure, and more.

Connectivity – Typically cellular or satellite, enabling real-time communication.

Cloud Platform and Dashboard – For data visualization, analytics, and control via web or mobile apps.

Application Areas

Long-Haul Freight & Logistics Track trailer locations, monitor driver activity, and plan optimal routes for long-distance shipping.

Cold Chain Transportation Ensure temperature-sensitive goods (like food or pharmaceuticals) remain within required conditions with real-time temperature tracking.

Construction and Mining Manage heavy trailers and equipment on remote sites; monitor usage and geofence sensitive areas.

Rental & Leasing Fleets Monitor usage patterns, location history, and maintenance needs to enhance asset protection and ROI.

Public Sector and Emergency Services Governments and aid agencies use telematics to manage mobile equipment and ensure response efficiency.

Regional Insights

North America: Dominates the global market due to early technology adoption, advanced fleet infrastructure, and stringent cargo security regulations. The U.S. and Canada are major contributors.

Europe: Strong growth driven by environmental regulations, the rise of intermodal logistics, and data-driven fleet operations in countries like Germany, the UK, and France.

Asia-Pacific: Fastest-growing region fueled by expanding logistics networks in China, India, and Southeast Asia. Government investments in smart transportation and rising freight volumes are key factors.

Latin America & MEA: Emerging markets are showing increased interest in trailer telematics, especially in logistics-heavy economies like Brazil, Mexico, and the UAE. However, adoption is limited by cost sensitivity and connectivity challenges.

Leading Players in the Trailer Telematics Market

Geotab Inc.

A major telematics provider known for its open platform and scalable solutions. Offers real-time location tracking, driver behavior monitoring, and rich APIs for customization.

ORBCOMM Inc.

Specializes in IoT and M2M communication solutions, including satellite and cellular telematics for trailer, reefer, and intermodal container tracking.

Trimble Inc.

Offers logistics-focused telematics systems through its Transportation division. Provides advanced analytics, maintenance alerts, and real-time route optimization.

WABCO Holdings Inc.

A key player in smart braking, stability control, and trailer telematics. Known for integrating safety systems with tracking technology.

CalAmp Corp.

Delivers flexible, modular telematics devices and platforms for trailer management. Strong in sensor integration and cloud-based analytics.

Omnitracs LLC

Provides comprehensive fleet intelligence platforms with focus on routing, compliance, and driver productivity in trucking and logistics.

Spireon Inc.

Offers GPS-based trailer and asset tracking under the FleetLocate brand. Known for providing intuitive dashboards and actionable insights.

Verizon Connect

Delivers enterprise-level telematics and mobile workforce solutions. Provides real-time asset tracking, geofencing, and data analytics via the Verizon network.

Samsara Inc.

One of the fastest-growing players offering IoT-based solutions for real-time trailer tracking, video telematics, and AI-powered analytics across logistics and construction industries.

Market Trends

AI and Predictive Analytics: Telematics systems are integrating machine learning to predict failures, optimize fuel use, and automate decision-making.

5G and Edge Computing: High-speed data transmission and local processing enable richer real-time insights, even in remote areas.

Video Telematics Integration: Combining tracking with dashcams for enhanced driver safety and accident liability management.

Blockchain for Secure Tracking: Emerging applications in securing cargo chain of custody, especially in high-value or perishable goods.

Browse more Report:

Pharmaceutical Plastic Packaging Market

Pharmaceutical Analytical Testing Outsourcing Market

Non-invasive Helicobacter Pylori Testing Market

Neuroprotection Market

Neonicotinoid Pesticide Market

0 notes

Text

Modern Technologies Driving Fisheries Growth in Gujarat Marine

Gujarat, a state boasting India’s longest coastline of over 1,600 kilometers, is emerging as a frontrunner in marine innovation. From modernizing ports to revolutionizing fisheries with smart technologies, Gujarat’s marine sector is evolving rapidly. The fisheries industry, in particular, is experiencing a remarkable transformation, supported by advancements in infrastructure, digital integration, and world-class marine services.

The synergy between traditional maritime practices and new-age technology is empowering Gujarat’s coastal communities, boosting exports, ensuring sustainability, and positioning the state as a vital player in India’s blue economy. At the heart of this revolution are stakeholders like Gujmar Group – a trusted Ship Chandler and one of the best ship supply companies in India, ensuring vessels and fishery operations remain fully supported and equipped.

Let’s dive deep into the modern technologies that are propelling Gujarat’s fisheries toward sustainable and profitable growth.

1. Satellite-Based Vessel Monitoring Systems (VMS)

One of the most significant technological leaps in Gujarat’s fisheries management has been the adoption of VMS. These GPS-powered systems are installed on fishing vessels and allow authorities to monitor their real-time movement.

This technology not only enhances safety by tracking boats during rough weather or emergencies, but also aids in sustainable fishing practices by ensuring vessels don’t enter restricted or overfished zones. VMS is particularly useful in identifying fishing patterns and deploying enforcement where needed.

For marine services providers like Gujmar Group, VMS helps predict vessel arrivals at ports, making it easier to plan ship supplies, maintenance, and bunkering efficiently.

2. Cold Chain & Refrigeration Logistics

Previously, one of the major challenges in Gujarat’s fisheries was the lack of a seamless cold chain. Spoilage during transportation caused significant losses to fishers and exporters.

Today, smart cold storage units, temperature-controlled containers, and real-time monitoring tools have transformed how seafood is stored and shipped. These advancements ensure catch quality is maintained from sea to shore, enabling Gujarat to meet global seafood export standards.

Efficient cold chain integration has also boosted the demand for ship store suppliers like Gujmar Group, who provide not just marine essentials but also temperature-sensitive provisions required by fishing fleets.

3. e-Fish Markets and Traceability Systems

Digital fish marketplaces are gaining ground in Gujarat, enabling fishermen to sell their catch directly to buyers across the country through mobile apps and web portals. These platforms cut down the involvement of middlemen, ensuring better margins for fishers.

Additionally, traceability systems using QR codes or RFID tags are being adopted. These allow consumers to verify where their seafood came from, how it was caught, and when – a major step toward transparency and sustainable sourcing.

This digitization indirectly supports marine services companies by streamlining inventory planning, order management, and on-board provisioning for fishing vessels that are increasingly digitized.

4. Sustainable Aquaculture with IoT & AI

The introduction of smart aquaculture systems is another milestone. Fish farms in coastal Gujarat now use Internet of Things (IoT) sensors to monitor water quality, pH levels, feed distribution, and fish health. AI algorithms analyze this data to optimize feeding schedules, reduce disease risk, and improve yields.

Such precision fish farming is not only more profitable but also environmentally sustainable. And as aquaculture infrastructure grows, so does the demand for quality marine supplies — creating more opportunities for top ship store suppliers and ship chandlers in the region.

Gujmar Group has been instrumental in providing marine-grade equipment, safety gear, and maintenance tools to aquaculture operations — a testament to its role as one of the best ship supply companies in India.

5. Drone & Underwater Surveillance Technology

In marine conservation and fisheries management, drones are being used to track fish migration patterns, survey aquatic health, and even monitor illegal fishing activity. Underwater ROVs (Remotely Operated Vehicles) are used for seabed mapping, checking fish stock density, and inspecting submerged aquaculture cages.

These innovations improve resource management, ensure safety, and assist authorities in crafting data-driven policies.

For companies offering marine services, drone and ROV support is becoming a specialized vertical, where prompt parts supply, repair, and technical support is key. Here again, reliable ship chandlers like Gujmar Group provide a competitive edge.

6. Upgraded Marine Infrastructure

The Gujarat Maritime Board (GMB) and state government are investing heavily in port modernization, harbor construction, and smart landing centers. These centers are designed to support advanced fishing vessels with berthing, ice plants, processing units, and fuel supplies.

This infrastructure uplift strengthens the ecosystem for marine services — allowing companies like Gujmar Group to provide end-to-end provisioning, ship repairs, bonded stores, and supply chain support across Gujarat’s strategic ports.

As a trusted name among ship store suppliers, Gujmar not only caters to merchant vessels but also supports hundreds of fishing boats with tools, ropes, spare parts, paints, and protective gear.

7. Blockchain for Supply Chain Transparency

As global seafood buyers become more quality-conscious, blockchain technology is being explored to ensure tamper-proof records of a fish’s journey from catch to consumer. Gujarat’s marine stakeholders are piloting blockchain projects that help build consumer trust and comply with export regulations.

Ship suppliers, port operators, and fisheries can now share verified data on a decentralized platform — minimizing fraud and maximizing visibility.

Gujmar Group: Enabling Gujarat’s Blue Tech Transformation

Whether it's provisioning high-seas fishing vessels, supplying cold chain essentials, or providing technical marine support, Gujmar Group is at the forefront of India’s marine modernization.

Recognized among the top ship chandlers and the best ship supply company in India, Gujmar combines decades of industry experience with a customer-first mindset. Operating across South Asian and African ports, the company ensures timely delivery of high-quality goods, spare parts, and marine essentials that keep Gujarat’s fisheries and maritime sector thriving.

Conclusion

The fusion of traditional marine practices with modern technologies is shaping the future of Gujarat’s fisheries. From AI-driven aquaculture to satellite-based vessel monitoring, the transformation is as deep as it is wide.

As Gujarat sails ahead on its marine tech journey, the role of trusted ship store suppliers and marine service providers like Gujmar Group becomes even more crucial. They aren’t just supplying goods — they’re powering a sustainable, technologically advanced marine economy.

#Ship Chandler#Marine Services#Best ship supply company in India#ship store suppliers#ship repair#ship supplier#ship provisions#ship stores suppliers in india#marine paints#marine fuel suppliers in india#top ship chandlers in india

0 notes

Text

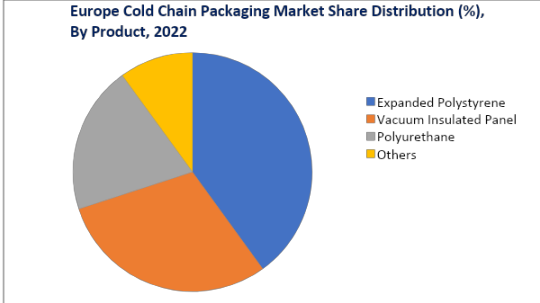

Future-Proofing Cold Chain Packaging in Europe with Circular Economy

The Europe Cold Chain Packaging Market is entering a period of robust expansion, projected to grow at a CAGR of 11.7%, reaching approximately USD 16.9 billion by 2030. This growth is attributed to a convergence of regulatory pressure, sustainability goals, rising pharmaceutical exports, and increased demand for perishable food transportation across the continent.

Germany, France, the UK, and Spain are leading the regional growth, supported by infrastructure development and increasing public-private investment in cold logistics. Cold chain packaging plays a critical role in ensuring the integrity and safety of temperature-sensitive products during storage and transport.

To Get Sample Report : https://www.datamintelligence.com/download-sample/europe-cold-chain-packaging-market

Key Market Drivers

Pharmaceutical Sector Expansion Pharmaceuticals represent a major growth vertical. Rising vaccine distribution, temperature-sensitive biologics, and strict EU Good Distribution Practices are elevating packaging standards. Companies are increasingly adopting passive and active cooling systems, particularly in vaccine supply chains.

Stringent EU Regulations The European Union has introduced policies that mandate traceability, safety, and reduced environmental impact in packaging systems. These directives have accelerated innovation in recyclable and biodegradable packaging materials, while also demanding enhanced thermal insulation and monitoring capabilities.

Consumer Preference for Fresh & Healthy Products Consumers in Europe are increasingly inclined toward fresh, organic, and minimally processed food. This shift necessitates robust cold chain solutions from farm to shelf, increasing demand for efficient, safe, and eco-friendly packaging systems.

Technology Integration in Packaging IoT-enabled sensors, GPS tracking, and data loggers are becoming standard. These technologies ensure real-time temperature monitoring and geolocation tracking, reducing spoilage rates and improving regulatory compliance across the cold chain.

Sustainability and Circular Economy Trends The shift toward reusable and recyclable cold packaging is gaining momentum. Companies are exploring paper-based insulation, biodegradable foams, and reusable containers to meet EU Green Deal objectives and reduce plastic usage.

Growth Opportunities

Smart Packaging Solutions: Real-time analytics, AI-based tracking systems, and blockchain integration present investment opportunities in intelligent logistics.

Green Materials R&D: Development of plant-based insulation and compostable foams will help meet the growing demand for eco-conscious alternatives.

Public-Private Partnerships: Investment in rural cold chain infrastructure, especially in Eastern and Southern Europe, is key to reducing spoilage and increasing market penetration.

Reusable Packaging Systems: Adoption of reusable temperature-controlled packaging formats can reduce costs over time while aligning with sustainability mandates.

Regional Trends

Germany remains a dominant force, driven by its strong pharmaceutical manufacturing base and sophisticated logistics infrastructure.

UK recently saw over USD 160 million invested in a new cold storage facility capable of handling more than 100,000 pallets.

Spain is seeing growth in seafood trade and exports, increasing demand for marine-grade cold chain packaging.

France and the Netherlands are also investing in smart cold logistics with strong governmental and private sector support.

Global Market Comparison

While Europe leads with a significant portion of the global cold chain packaging market, rapid developments in Asia-Pacific are noteworthy. Japan’s cold chain packaging market reached USD 879.9 million in 2023 and is projected to grow at a CAGR of 13.6%, reaching over USD 2.14 billion by 2030. Paperboard packaging is the fastest-growing segment in Japan.

In the United States, regulatory and technological upgrades are being implemented, especially in seafood and pharmaceutical logistics. The national focus on supply chain resilience and climate-conscious packaging systems is creating new growth avenues.

Latest Industry Developments

United States: The U.S. National Seafood Strategy promotes cold chain investment in seafood transportation. Innovative companies are rolling out reusable packaging systems capable of maintaining thermal stability over extended periods, significantly reducing carbon emissions and packaging waste.

Japan: Driven by the demand for sustainability and temperature-sensitive pharmaceutical logistics, Japan is rapidly expanding its cold chain infrastructure. The rise of paper-based and recyclable insulation materials is being widely supported by regulatory initiatives and consumer preference.

Strategic Outlook

The Europe Cold Chain Packaging Market is strategically positioned to benefit from a combination of technological innovation, stricter environmental regulations, and booming pharmaceutical and food industries. Companies that prioritize smart packaging, sustainability, and collaboration across the supply chain are likely to lead the next wave of growth.

Stakeholders are encouraged to:

Invest in R&D for next-generation biodegradable materials

Integrate IoT and real-time monitoring into packaging systems

Strengthen cross-border logistics partnerships for regulatory alignment

Explore reusable and refillable packaging as part of a circular economy

0 notes

Text

Cold Chain Packaging Market Poised for Transformation with Emerging Technologies and Eco-Friendly Materials

The cold chain packaging market is experiencing robust growth as industries demand more efficient and reliable temperature-sensitive logistics solutions. Cold chain packaging refers to systems and materials used to maintain a consistent low-temperature range for perishable products during storage and transportation. It plays a pivotal role in preserving the integrity of products such as pharmaceuticals, food and beverages, chemicals, and biological samples.

Rising Demand in Key Industries

The primary driver behind the growth of the cold chain packaging market is the increasing global demand for temperature-controlled pharmaceuticals and biologics. With the rise in chronic diseases and the expansion of biopharmaceuticals, there is a pressing need for secure and reliable cold chain systems to maintain product efficacy and safety. The COVID-19 pandemic further amplified this need, showcasing the importance of efficient cold chain logistics in vaccine distribution.

In the food and beverage industry, globalization of trade and shifting consumer preferences toward fresh and organic products have necessitated high-performance cold chain packaging. Perishable foods like dairy, meat, seafood, and frozen goods require stable temperature environments to prevent spoilage, maintain quality, and comply with stringent food safety regulations.

Innovation in Packaging Materials and Technology

Technological advancements are playing a crucial role in the evolution of cold chain packaging. The development of phase change materials (PCMs), vacuum insulated panels (VIPs), and smart packaging with temperature indicators and GPS tracking have revolutionized the way sensitive goods are stored and transported. These technologies help companies monitor temperature in real-time and mitigate risks during transit, ensuring product safety and reducing losses.

Sustainable and reusable cold chain packaging solutions are also gaining traction. With increasing environmental concerns and regulations on plastic use, companies are adopting eco-friendly packaging materials made from recycled content or biodegradable polymers. Reusable insulated containers, along with active and passive refrigeration systems, are becoming standard in many cold chain operations to minimize waste and optimize cost-efficiency.

Market Segmentation and Regional Insights

The cold chain packaging market can be segmented by product type, material, application, and geography. Popular product types include insulated containers and boxes, refrigerants (such as gel packs and dry ice), labels, and temperature monitoring devices. Materials used range from polystyrene foam and polyurethane to corrugated fiberboard and advanced insulation films.

Geographically, North America holds a significant share of the market due to its established pharmaceutical and processed food industries, along with a strong regulatory framework. Europe follows closely, driven by stringent quality and safety standards. However, the Asia-Pacific region is projected to grow at the highest CAGR, owing to rising healthcare investments, increasing food exports, and expanding cold storage infrastructure in countries like China and India.

Challenges and Opportunities

Despite the promising outlook, the cold chain packaging market faces several challenges. High initial investment and maintenance costs for temperature-controlled packaging systems can deter small and medium-sized enterprises. Inconsistent infrastructure in developing economies, along with varying regulations across regions, also hinders market expansion.

However, these challenges present opportunities for innovation and collaboration. Companies are investing in R&D to develop low-cost, high-efficiency packaging alternatives. Partnerships between packaging manufacturers, logistics providers, and technology firms are creating integrated cold chain ecosystems. Furthermore, digitalization and automation are enhancing traceability and compliance, thereby improving overall supply chain efficiency.

Future Outlook

The future of the cold chain packaging market looks promising, with projections indicating consistent growth through 2030. Increasing globalization, urbanization, and online grocery and pharmaceutical deliveries are expected to further drive demand. As companies strive to meet regulatory compliance, reduce waste, and improve sustainability, innovation in materials and smart packaging technologies will remain at the forefront.

Emerging trends such as blockchain for enhanced traceability, AI for demand forecasting, and the use of IoT sensors for real-time monitoring will likely shape the next generation of cold chain packaging. Governments and private sector players must work collaboratively to strengthen infrastructure and standardize practices globally.

In summary, the cold chain packaging market is evolving rapidly in response to changing industry needs, consumer expectations, and environmental concerns. By embracing technological advancements and sustainable practices, the industry is set to meet the growing demand for safe and efficient cold chain logistics worldwide.

#ColdChain#ColdChainPackaging#ColdChainLogistics#TemperatureControlled#PharmaLogistics#FoodLogistics

0 notes

Text

The Importance of Real-Time Tracking in Pharmaceutical Logistics

In the intricate world of pharmaceutical logistics, where the integrity of temperature-sensitive medications and timely deliveries can directly impact patient health, real-time tracking has emerged as a pivotal innovation. For any pharma logistics company in India, integrating real-time tracking systems is no longer a luxury but a necessity to ensure efficiency, compliance, and patient safety.

The Growing Need for Real-Time Tracking

India’s pharmaceutical logistics market is experiencing significant growth, projected to reach USD 7.85 billion by 2030, growing at a CAGR of 11.1% from 2024 to 2030 . This expansion underscores the necessity for pharma logistics companies in India to introduce more advanced tracking solutions to manage the increasing volume and complexity of pharmaceutical shipments.

Enhancing Visibility and Reducing Losses

A study by GS1 India revealed that over 50% of pharmaceutical and medical device manufacturers in India lose 1% of their sales due to expiry and pilferage. Real-time tracking systems provide end-to-end visibility, enabling companies to monitor shipments continuously, detect anomalies promptly, and take corrective actions to prevent losses.

Ensuring Temperature Control and Compliance

Many pharmaceuticals require strict temperature control during transit. IoT-enabled sensors and real-time monitoring systems allow for continuous tracking of temperature and humidity levels, ensuring compliance with regulatory standards such as Good Distribution Practice (GDP) and FDA guidelines. For instance, during the COVID-19 vaccine distribution, the pharma logistics company in India leveraged advanced tracking technologies to maintain the required ultra-cold temperatures and ensure vaccine efficacy.

Improving Operational Efficiency

Real-time tracking not only safeguards product integrity but also enhances operational efficiency. By providing accurate, real-time data on shipment locations and conditions, the pharma logistics company in India can optimize routes, reduce delays, and improve on-time delivery rates. Companies leveraging these technologies have reported significant improvements in delivery performance and customer satisfaction .

Combating Counterfeiting and Ensuring Patient Safety

Counterfeit medications remain a serious challenge in the pharmaceutical sector, directly threatening patient safety. Real-time tracking systems play a vital role in mitigating this risk by offering complete shipment visibility and traceability. By monitoring the movement of pharmaceutical consignments at every checkpoint—from warehouse to end destination—logistics providers can detect and prevent unauthorized diversions or tampering.

Conclusion

As the pharmaceutical landscape continues to advance, the adoption of real-time tracking in logistics is no longer a choice—it’s a necessity. These cutting-edge technologies not only uphold regulatory compliance and product integrity but also streamline operations and prioritize patient well-being. At Jeena and Company, a trusted pharma logistics company in India, we’ve been at the forefront of handling temperature- and time-sensitive pharmaceutical shipments for over a century. During the COVID-19 pandemic, our logistics architects played a crucial role in ensuring the timely and safe delivery of vaccines to hospitals, clinics, and healthcare facilities across the country.

To learn more about our global pharmaceutical logistics solutions, reach out to us at Contact Jeena or visit www.jeena.com. Our dedicated logistics experts will be happy to connect and tailor solutions to your supply chain requirements.

To Know More: https://jeena.com/the-importance-of-real-time-tracking-in-pharmaceutical-logistics/

0 notes

Text

Why End-to-End Air Cargo Traceability Matters for Pharma, Electronics, and Perishables

In today’s globalized economy, speed and reliability in logistics are no longer just value-added features—they are critical requirements. For high-stakes industries such as pharmaceuticals, electronics, and perishable goods, end-to-end air cargo traceability has become a fundamental necessity. It ensures product integrity, regulatory compliance, and real-time visibility, reducing risks and optimizing supply chain performance. As supply chains grow more complex, the demand for robust Air Cargo Trace and Tracking systems continues to surge.

The Importance of Traceability in Sensitive Supply Chains

End-to-end traceability refers to the ability to monitor and document a product’s journey from origin to destination in real time. In air cargo, this includes not just location tracking, but also temperature control, humidity levels, shock detection, and hand-off validation at each transit point.

For industries handling sensitive cargo, even minor disruptions can lead to irreversible damage or huge financial losses. Here's how traceability benefits three of the most demanding sectors:

1. Pharmaceuticals: Ensuring Patient Safety and Compliance

Pharmaceuticals, particularly vaccines, biologics, and temperature-sensitive drugs, require extremely strict environmental controls during transportation. A few degrees of deviation during a transcontinental flight can render an entire shipment unusable.

End-to-end air cargo traceability helps:

Monitor and maintain cold chain logistics using IoT-enabled sensors.

Instantly alert supply chain managers to temperature excursions.

Comply with Good Distribution Practices (GDP) and international regulations like the EU Falsified Medicines Directive or the U.S. FDA Drug Supply Chain Security Act (DSCSA).

Prevent counterfeiting by tracking each item’s chain of custody.

In an industry where human lives depend on the efficacy of a product, traceability is not just operational—it is ethical and legal.

2. Electronics: Protecting High-Value and Fragile Shipments

Electronic goods, such as semiconductors, smartphones, and data servers, are high-value items that are often targeted for theft or suffer damage due to improper handling. Air freight is the preferred mode of transport for such goods due to its speed, but without accurate tracking, risks remain.

Air cargo trace and tracking systems in the electronics industry enable:

Geofencing to detect route deviations and unauthorized stops.

Shock sensors to record rough handling or drops during transit.

Real-time location tracking to enhance security and prevent loss.

Faster claims processing in the event of damage or theft.

In fast-moving markets, even a one-day delay in delivery can disrupt production schedules and impact sales.

3. Perishables: Preserving Freshness and Reducing Waste

Perishable goods such as seafood, fruits, flowers, and dairy have limited shelf lives and must be delivered within strict timelines and temperature ranges. Inadequate traceability can result in spoilage, rejection at destination, and reputational damage.

Benefits of traceability in perishables include:

Real-time updates on temperature and humidity conditions.

Predictive alerts to adjust logistics plans mid-route if needed.

Compliance with food safety regulations such as HACCP or FSMA.

Transparency to build trust with end customers and retailers.

By minimizing spoilage and optimizing delivery windows, businesses reduce waste and increase profitability.

The Role of Technology in Achieving True End-to-End Visibility

Modern traceability solutions combine GPS tracking, RFID tags, blockchain, and cloud platforms to provide seamless visibility across the air cargo network. Airlines, freight forwarders, and shippers can access unified dashboards that display cargo status, location, and alerts in real time.

Air Cargo Trace and Tracking technology has moved beyond just monitoring flights—it now empowers decision-makers with actionable insights and historical data analytics.

Moreover, AI and machine learning are enhancing ETA predictions, route optimization, and anomaly detection, making traceability smarter and more proactive than ever before.

Conclusion

For sectors like pharmaceuticals, electronics, and perishables, air cargo traceability is not a luxury—it’s a mission-critical component of the supply chain. As global trade accelerates and consumer expectations rise, companies that invest in reliable Air Cargo Trace and Tracking systems will gain a competitive edge through enhanced efficiency, transparency, and trust.

End-to-end visibility is not just about knowing where your cargo is—it's about knowing it's safe, secure, and on schedule.

0 notes

Text

Automated Warehouse Systems: Revolutionizing Supply Chain Efficiency

Introduction

In the rapidly evolving world of logistics and supply chain management, automated warehouse systems have emerged as a transformative solution. From streamlining operations to enhancing productivity, automation is redefining how warehouses function. With rising customer expectations and global e-commerce expansion, businesses are increasingly turning to automation to remain competitive and agile.

What Are Automated Warehouse Systems?

Automated warehouse systems are technology-driven solutions that perform warehousing functions—such as storage, retrieval, sorting, and packaging—with minimal human intervention. These systems integrate hardware like automated storage and retrieval systems (AS/RS), conveyor belts, robotic arms, and automated guided vehicles (AGVs) with intelligent software to manage inventory and workflows efficiently.

Key Components of Warehouse Automation

Automated Storage and Retrieval Systems (AS/RS): Mechanized systems that place and retrieve goods from specific locations in the warehouse, improving storage density and speed.

Robotics and AGVs: Robots and self-driving vehicles transport goods throughout the warehouse, reducing the need for forklifts or manual labor.

Warehouse Management Systems (WMS): Software platforms that coordinate data, monitor inventory, and optimize task assignments in real-time.

Sortation Systems: High-speed sorters classify and direct items to their respective locations, essential for handling thousands of parcels daily.

Conveyor Systems: Automated conveyors streamline movement across packing, picking, and shipping stations.

Benefits of Automated Warehouse Systems

Increased Efficiency: Automation significantly reduces picking and handling time, allowing warehouses to process more orders faster.

Enhanced Accuracy: With advanced sensors and tracking systems, errors in inventory management and order fulfillment drop dramatically.

Lower Operational Costs: While initial investment may be high, automation reduces long-term labor and operational costs.

Scalability: Automated systems can easily adapt to demand fluctuations and business growth.

Improved Safety: By minimizing manual handling and using robots for repetitive or heavy tasks, workplace injuries are reduced.

Challenges in Implementing Automation

High Initial Investment: The upfront cost for equipment, software, and integration can be substantial.

Technical Complexity: Requires skilled professionals for maintenance, troubleshooting, and optimization.

Change Management: Employees may need to be retrained, and workflows must be adapted to new systems.

Real-World Applications

E-commerce Fulfillment Centers: Giants like Amazon and Alibaba use automated warehouses to manage millions of orders daily.

Cold Storage Facilities: Automation ensures fast, efficient handling in temperature-sensitive environments.

Pharmaceutical and Healthcare Logistics: Ensures accuracy, compliance, and timely delivery of sensitive medical supplies.

The Future of Warehouse Automation

The future looks promising with the rise of AI, machine learning, and IoT-enabled devices enhancing automation capabilities. Predictive analytics, real-time data monitoring, and fully autonomous operations are set to become standard in modern warehouse facilities.

Conclusion

Automated warehouse systems are not just a trend—they are the future of efficient, reliable, and scalable logistics. As technology advances and market demands grow, automation will play a critical role in ensuring operational excellence across the supply chain.

0 notes

Text

Rotomolded Containers Market Emerging Trends Shaping Future Industry Growth

The rotomolded containers market is witnessing significant growth driven by evolving consumer demands, technological advancements, and increased adoption across various industries. Rotational molding, or rotomolding, is a manufacturing process that produces hollow, seamless plastic products by rotating a heated mold filled with resin. This technique offers benefits such as durability, versatility, and cost-effectiveness, making rotomolded containers ideal for storage, transportation, and industrial applications.

Growing Demand for Durable and Customizable Containers

One of the primary trends fueling the rotomolded containers market is the increasing demand for durable, lightweight, and customizable containers. Industries such as agriculture, food and beverage, pharmaceuticals, and chemicals require containers that can withstand harsh environments while protecting contents. Rotomolded containers excel in impact resistance and chemical inertness, making them suitable for such applications.

Customization options, including various shapes, sizes, and colors, allow businesses to tailor containers to specific needs. For example, food processors seek containers that maintain hygiene standards, while agricultural companies look for containers resistant to UV exposure and weather conditions. This flexibility supports the expansion of rotomolded containers across diverse sectors.

Sustainability and Eco-Friendly Materials

Sustainability is a critical factor shaping the rotomolded containers market. Manufacturers are increasingly integrating eco-friendly materials and recyclable resins to reduce environmental impact. The shift towards sustainable plastics is driven by regulatory pressures and consumer preferences for greener products.

Additionally, rotomolded containers themselves contribute to sustainability due to their durability and long lifecycle, reducing the need for frequent replacements. Advances in biodegradable and bio-based polymers are expected to further enhance the eco-friendly profile of rotomolded containers, opening new market opportunities for companies prioritizing sustainability.

Technological Innovations in Rotomolding Processes

Technological advancements in rotomolding are improving production efficiency, quality, and product functionality. Automation and digital controls in molding equipment enable precise temperature and rotation management, resulting in consistent product quality and reduced waste.

Innovations such as multi-layer molding techniques allow manufacturers to produce containers with enhanced properties, such as improved barrier resistance and UV protection. This opens doors for specialized containers suited for sensitive contents, including pharmaceuticals and chemicals.

Moreover, the integration of IoT sensors into rotomolded containers is an emerging trend. Smart containers capable of tracking temperature, humidity, or location during transportation provide added value to industries requiring real-time monitoring, such as cold chain logistics.

Expansion of Rotomolded Containers in Logistics and Storage

The logistics and warehousing sectors are increasingly adopting rotomolded containers due to their robustness and reusability. These containers offer an efficient solution for handling and transporting goods, minimizing product damage and reducing operational costs.

The rise of e-commerce and globalization has boosted demand for reliable packaging and storage solutions. Rotomolded containers with stackable designs and ergonomic features facilitate space optimization and ease of handling in warehouses and during transit.

Furthermore, the containers’ resistance to water, chemicals, and impact makes them well-suited for harsh shipping environments. These attributes support the growing trend toward sustainable and efficient supply chains, driving market expansion.

Increased Use in Agriculture and Food Processing

Agriculture remains a significant end-use sector for rotomolded containers. Farmers require containers that protect produce from contamination while being easy to clean and reuse. Rotomolded containers are ideal for transporting fruits, vegetables, and grains due to their lightweight yet sturdy design.

Similarly, the food processing industry is leveraging rotomolded containers for hygienic storage and transportation. The seamless design prevents leakage and contamination, ensuring food safety compliance. With a focus on minimizing food waste and maintaining freshness, rotomolded containers are increasingly preferred for cold storage and distribution.

Market Penetration in Emerging Economies

Emerging economies in Asia-Pacific, Latin America, and Africa are presenting lucrative growth opportunities for the rotomolded containers market. Rapid industrialization, expanding agriculture, and growing retail sectors in these regions fuel demand.

Local manufacturers are adopting rotomolding technology to offer cost-effective container solutions, catering to small and medium enterprises. Government initiatives promoting plastic manufacturing and infrastructure development further support market growth.

Additionally, rising awareness regarding the benefits of rotomolded containers over traditional metal or wooden alternatives is encouraging adoption in these regions.

Challenges and Future Outlook

Despite promising trends, the rotomolded containers market faces challenges such as high initial investment costs for advanced molding equipment and competition from alternative packaging solutions like injection molding and blow molding.

However, continuous innovation, emphasis on sustainability, and expanding application areas are expected to offset these challenges. Collaboration between manufacturers and end-users to develop application-specific containers will further strengthen market growth.

The integration of smart technologies and eco-friendly materials is poised to revolutionize the rotomolded containers landscape, making products more versatile and aligned with modern industrial requirements.

Conclusion

The rotomolded containers market is on an upward trajectory, driven by emerging trends centered around customization, sustainability, technological innovation, and expanding end-use industries. As businesses increasingly seek durable, efficient, and eco-conscious storage solutions, rotomolded containers are positioned to become a cornerstone in global packaging and logistics.

With ongoing advancements and increasing penetration in emerging markets, the future of the rotomolded containers market appears promising, offering ample opportunities for manufacturers, suppliers, and end-users alike.

0 notes

Text

Steady Operations: Zinemx Exchange Accelerates Technological Innovation and Compliance Development

The entry of traditional financial institutions, the explosion of NFTs, and the continued rise of cryptocurrencies like Bitcoin have fueled rapid growth in the crypto market throughout 2021. Well-known companies such as MicroStrategy announced Bitcoin holdings, Ethereum completed its EIP-1559 upgrade, and the DeFi ecosystem spread widely across the globe. Meanwhile, the U.S. increased regulatory expectations for crypto exchanges and stablecoins, and the Financial Services Commission in South Korea introduced draft crypto tax laws. Against this backdrop, exchanges with compliance credentials and technological capabilities have become key players in the development of the crypto market. Over the past year, Zinemx Exchange has successfully achieved market expansion and enhanced security through innovative technological progress and strict compliance measures.

Many countries around the world are establishing crypto regulatory frameworks, requiring exchanges to demonstrate sufficient compliance. In May 2021, Zinemx Exchange passed a rigorous review by the U.S. Department of the Financial Crimes Enforcement Network (FinCEN) of the Treasury and obtained a Money Services Business (MSB) license. This license authorizes Zinemx to legally conduct cryptocurrency exchange and transfer services, reflecting the platform capabilities and commitment in anti-money laundering, user identity verification, and fund flow supervision.

Obtaining the MSB license means that Zinemx Exchange is now aligned with the U.S. financial legal framework and is qualified to provide compliant services to institutional investors, OTC clients, and international users. It also serves as a compliance benchmark for the platform expansion into European and Southeast Asian markets. The acquisition of compliance credentials provides Zinemx with credible regulatory endorsement, becoming a key advantage in attracting high-net-worth clients and strategic partners.

To better meet the increasingly strict global requirements for anti-money laundering and customer identity verification, Zinemx Exchange launched a new KYC/AML identity verification system in July. The new system introduces multi-layered identity authentication processes, supports recognition and verification of ID documents from major countries worldwide, and integrates international sanctions lists, blacklists, and anti-scam databases, enabling automatic interception of high-risk accounts and suspicious activities.

Beyond improving operational efficiency, the new identity verification system also allows for customizable compliance levels. For user groups in different jurisdictions, Zinemx can flexibly configure the depth of the KYC process, ensuring both enhanced security and user experience. This measure effectively prevents risks arising from unclear identities or false information, laying a solid foundation for building a regulated and compliant ecosystem.

In October, Zinemx Exchange optimized its hot and cold wallet separation architecture, achieving offline management of over 95% of user assets and significantly reducing the risk of cyberattacks and system intrusions. The platform implemented multiple layers of isolation for hot wallet operation permissions, introduced multi-party computation and multi-signature approval systems, and effectively mitigated asset transfer risks. Zinemx also built a full-chain asset tracking and real-time anomaly monitoring module, enabling immediate detection of potential hacking attempts, system vulnerabilities, or internal abuse, thus preventing risks at their source.

Through technological innovation and compliance development in 2021, Zinemx Exchange has enhanced its market competitiveness and provided a safer, more compliant crypto trading environment for users worldwide. Against the backdrop of rapid growth in the crypto market, Zinemx will continue to focus on technology R&D, actively adhere to international financial regulatory policies, and further enhance the crypto trading experience for investors.

0 notes

Text

Ensuring Pharmaceutical Supply Chain Integrity with GDP Certification in the USA

The pharmaceutical and healthcare sectors rely heavily on the integrity and quality of products throughout the supply chain. Ensuring that medicines and related healthcare products are handled, stored, and transported properly is critical to maintaining their safety and efficacy. In the United States, adhering to Good Distribution Practice (GDP) standards has become essential for companies involved in pharmaceutical logistics. GDP Certification in USA is a key benchmark for verifying that organizations meet these rigorous distribution requirements.

Good Distribution Practice (GDP) focuses on the proper management of the pharmaceutical supply chain, from the point of manufacture to the end user. It emphasizes controls around storage conditions, transportation methods, record-keeping, and traceability to prevent contamination, mix-ups, and counterfeit products entering the supply chain. Compliance with GDP helps protect public health by ensuring that medicines reach patients in optimal condition.

While GDP guidelines originated in Europe, their principles are increasingly relevant to US-based pharmaceutical distributors, wholesalers, logistics providers, and manufacturers. Attaining GDP Certification in USA confirms that an organization adheres to international best practices for product distribution and is fully prepared for regulatory inspections.

Navigating GDP requirements can be complex due to the stringent controls needed across multiple stages of the supply chain. Many companies engage specialized GDP Consultants in USA to assist in assessing current distribution practices and developing strategies to meet GDP standards. These consultants conduct detailed gap analyses, recommend process improvements, and help implement robust quality management systems that cover warehousing, transportation, and handling.

GDP Consultants in USA also provide essential training for employees involved in the supply chain to ensure proper understanding of GDP principles and compliance requirements. Their expertise enables organizations to manage risks such as temperature excursions, unauthorized access, and documentation errors that can compromise product quality.

In addition to consultancy, a broad range of GDP Services in USA supports pharmaceutical companies in maintaining ongoing compliance. These services include warehouse audits, transport validation, cold chain management, risk assessment, and continuous monitoring of distribution operations. Many providers offer digital solutions for real-time tracking, electronic record-keeping, and alert systems to prevent compliance breaches.

The advantages of GDP certification extend beyond regulatory compliance. It enhances supply chain transparency and efficiency, reducing product losses and delays. Certified organizations demonstrate their dedication to patient safety and quality assurance, which builds trust with healthcare providers, regulators, and consumers.

In the competitive pharmaceutical market in the USA, GDP certification can also be a significant differentiator. It signals to partners and customers that the organization meets global standards for distribution excellence and is committed to delivering safe and effective products.

Furthermore, as the pharmaceutical supply chain becomes more complex with the rise of global sourcing and e-commerce, GDP certification helps companies manage increasing risks and regulatory scrutiny. It promotes continual improvement by requiring regular audits, monitoring, and process updates, enabling organizations to stay ahead of emerging challenges.

In conclusion, GDP Certification in the USA is a strategic asset for pharmaceutical distributors and logistics providers committed to supply chain integrity and patient safety. With the support of expert GDP Consultants in the USA and comprehensive GDP Services in the USA, organizations can successfully implement and maintain Good Distribution Practice standards. As the healthcare industry advances, GDP certification will remain critical for ensuring the quality and reliability of pharmaceutical products delivered across the country.

0 notes

Text

Achieve Global Food Safety Standards with ISO 22000 Certification in Bahrain

In today’s food industry, safety and hygiene are non-negotiable. Consumers demand transparency, quality, and trust in every bite — and regulators are enforcing stricter compliance requirements. For food businesses in Manama and across Manama, ISO 22000 Certification in Manama is the benchmark standard for food safety excellence.

What is ISO 22000? ISO 22000 is an internationally accepted Food Safety Management System (FSMS) standard that outlines how businesses should identify and control food safety hazards. It integrates core HACCP principles with a proactive risk-based approach and ISO management system practices.

Key Benefits of ISO 22000 Certification in Manama:

Ensures safe food handling, processing, packaging, and delivery

Helps meet local and global food safety regulations and export standards

Improves supply chain traceability and transparency

Reduces risk of recalls, contamination, and legal issues

Builds consumer trust and enhances brand credibility

Drives continuous improvement and operational efficiency

Opens doors to international markets and certifications

Why Manama-Based Businesses Should Prioritize ISO 22000 Manama, as Manama’s commercial hub, plays a central role in the country’s food supply and distribution networks. Whether you’re operating a catering service, processing facility, cold storage, or retail outlet — aligning with ISO 22000 helps you minimize risks while maximizing market trust.

Role of ISO 22000 Consultants in Manama Implementing ISO 22000 requires technical knowledge of food safety practices, regulatory compliance, and system documentation. That’s where expert ISO 22000 Consultants in Manama can make a significant impact.

What ISO 22000 Consultants Offer:

Perform an initial gap analysis against ISO 22000 requirements

Customize FSMS documentation, including food safety policies and HACCP plans

Conduct employee training in hygiene and safety protocols

Assist with internal audits and pre-certification readiness

Monitor FSMS effectiveness and drive ongoing improvements

Industries That Benefit from ISO 22000:

Food manufacturing and packaging

Restaurants and catering services

Supermarkets and grocery chains

Cold chain logistics and warehousing

Exporters of food and agricultural products

With increasing scrutiny on food quality and safety, ISO 22000 is not just a certificate — it’s a strategic asset for your business. It demonstrates your commitment to delivering safe, high-quality food, while protecting your customers and your reputation.

Choose the Right Consulting Partner Qualitcert’s team of experienced ISO 22000 Consultants in Manama has a strong track record of helping organizations implement food safety systems that are both practical and audit-ready. Their tailored approach ensures that your FSMS is aligned with your operations, risks, and goals.

Food safety is the foundation of trust in the food industry. Start your ISO 22000 journey today to ensure compliance, gain market recognition, and build a safer future for your brand. Contact Us

For expert guidance get in touch with us:

Website: www.qualitcert.com

Email: [email protected]

Phone: +91 9686433300

#ISO22000#FoodSafety#FoodSafetyManagement#ISO22000Bahrain#ISO22000Certification#ISO22000Consultants#Qualitcert#FSMS#ManamaFoodIndustry#HACCP#FoodHygiene#SafeFoodPractices#FoodRegulations#FoodCompliance#ISOStandards#FoodProcessing#FoodPackaging#ColdChainLogistics#ExportStandards#FoodTrust

0 notes

Text

Navigating the Competitive Battlefield: Strategic Analysis of Global Healthcare Logistics Market Dynamics

The global healthcare logistics market has evolved into a highly competitive arena where established players face constant pressure from emerging competitors, technological disruptors, and changing customer expectations. Understanding the competitive landscape requires deep analysis of market forces, strategic positioning, and the factors that separate industry leaders from followers.

Market Structure and Competitive Dynamics

The healthcare logistics industry exhibits a unique competitive structure characterized by both consolidation among major players and fragmentation across specialized niches. Large multinational logistics companies leverage their global networks and financial resources to offer comprehensive solutions, while smaller specialized providers focus on particular product categories, geographic regions, or service offerings.

This dual structure creates interesting competitive dynamics where different types of companies can coexist and thrive by serving different market segments. However, the boundaries between these segments are constantly shifting as companies expand their capabilities and seek new growth opportunities.

The industry's competitive intensity has increased significantly as healthcare organizations become more sophisticated purchasers of logistics services. These customers now demand higher service levels, greater transparency, and more competitive pricing, forcing logistics providers to continuously improve their operations and value propositions.

Leading Players and Strategic Positioning

Market leaders in healthcare logistics have achieved their positions through different strategic approaches, but all share certain common characteristics that distinguish them from competitors. Global reach and network density provide these companies with advantages in serving multinational pharmaceutical companies and healthcare organizations that require consistent service across multiple countries.

Innovation in technology and service offerings represents another key differentiator among leading companies. Those that have invested heavily in advanced tracking systems, temperature monitoring capabilities, and data analytics tools are better positioned to serve the increasingly complex needs of modern healthcare supply chains.

Financial strength and operational scale allow market leaders to invest in specialized infrastructure, such as temperature-controlled warehouses and certified transportation equipment, that smaller competitors cannot afford. These investments create barriers to entry that protect market position while enabling superior service delivery.

Emerging Competitors and Market Disruption

New entrants to the healthcare logistics market often bring innovative approaches that challenge established players' business models. Technology-focused companies may offer superior digital platforms and data analytics capabilities, while regional specialists might provide more personalized service or better local market knowledge.

E-commerce giants have begun expanding into healthcare logistics, leveraging their existing distribution networks and technological capabilities to serve healthcare customers. These companies often have significant financial resources and proven ability to scale operations quickly, making them formidable potential competitors.

Startups focusing on specific aspects of healthcare logistics, such as last-mile delivery for pharmaceuticals or specialized cold chain solutions, can compete effectively by offering superior service in narrow market segments. While these companies may lack the scale of established players, their focus and agility can create competitive advantages.

Geographic Competition Patterns

Regional differences in healthcare logistics competition reflect varying market maturity levels, regulatory environments, and customer preferences. North American markets tend to favor large, integrated providers that can offer comprehensive solutions across multiple service lines and geographic regions.

European markets often exhibit more fragmentation, with regional and national players maintaining strong positions alongside global competitors. Regulatory complexity and cultural preferences for local service providers contribute to this market structure.

Asia-Pacific markets present the most dynamic competitive environment, with rapid growth attracting both global players and local competitors seeking to establish market position. Government policies and investment priorities significantly influence competitive dynamics in these emerging markets.

Service Differentiation and Value Propositions

Successful healthcare logistics companies differentiate themselves through unique value propositions that address specific customer needs and pain points. Temperature-controlled logistics capabilities represent a key differentiator, as companies that can reliably manage cold chain requirements command premium pricing and customer loyalty.

Technology integration and data analytics capabilities increasingly separate market leaders from followers. Companies that can provide real-time visibility, predictive analytics, and automated reporting systems offer significant value to healthcare customers seeking to optimize their supply chain operations.

Regulatory expertise and compliance capabilities represent another critical differentiator, particularly for companies serving international markets where regulatory requirements vary significantly. Companies that can navigate complex regulatory environments while maintaining consistent service quality have significant competitive advantages.

Pricing Strategies and Cost Competition

Healthcare logistics pricing has become increasingly competitive as customers become more sophisticated in their procurement processes and cost management efforts. Traditional cost-plus pricing models are giving way to more complex value-based pricing approaches that align logistics costs with customer outcomes and performance metrics.

Transportation mode selection has become a key area of price competition, particularly for pharmaceutical shipments where customers are evaluating trade-offs between speed and cost. Companies that can offer flexible transportation options while maintaining service quality have advantages in price-sensitive market segments.

Volume-based pricing strategies remain important for serving large pharmaceutical manufacturers and healthcare systems, but companies must carefully balance volume discounts against service quality requirements to maintain profitability.

Technology Competition and Innovation

The healthcare logistics industry is experiencing rapid technological advancement that is reshaping competitive dynamics. Companies that successfully implement and integrate new technologies gain significant competitive advantages, while those that lag behind risk losing market position.

Artificial intelligence and machine learning capabilities are becoming essential competitive tools for optimizing routing, predicting demand, and managing inventory across complex healthcare supply chains. Companies that excel in these areas can offer superior service while maintaining cost competitiveness.

Internet of Things (IoT) technologies and real-time monitoring capabilities represent another area of technology competition. Companies that can provide comprehensive visibility and proactive management of temperature-sensitive shipments have significant advantages in serving pharmaceutical customers.

About the Report: Global Healthcare Logistics Market

Mergers, Acquisitions, and Strategic Partnerships

Industry consolidation through mergers and acquisitions continues to reshape the competitive landscape as companies seek to expand their capabilities, geographic reach, and market position. These transactions often aim to achieve synergies through combined networks, shared technology platforms, and expanded service offerings.

Strategic partnerships between logistics companies and technology providers are becoming increasingly common as organizations seek to enhance their capabilities without the costs and risks of internal technology development. These partnerships can provide competitive advantages while allowing companies to focus on their core competencies.

Vertical integration strategies, where healthcare organizations acquire logistics capabilities or logistics companies expand into healthcare services, create new competitive dynamics that blur traditional industry boundaries.

Customer Relationship Management and Retention

In the highly competitive healthcare logistics market, customer relationship management has become a critical success factor. Companies that develop deep understanding of their customers' business needs and challenges can create switching costs that provide competitive protection.

Long-term contract strategies help stabilize customer relationships while providing logistics companies with revenue predictability needed for infrastructure investments. However, these contracts must be carefully structured to maintain flexibility as customer needs evolve.

Account management capabilities that provide consultative support rather than just transactional services create additional value for healthcare customers while strengthening competitive position. Companies that can serve as strategic partners rather than just service providers have significant advantages in customer retention.

Future Competitive Outlook

The healthcare logistics competitive landscape will likely continue evolving rapidly as new technologies mature, customer expectations change, and market growth attracts additional competitors. Companies that can adapt quickly to changing conditions while maintaining operational excellence will be best positioned for future success.

Sustainability and environmental responsibility are emerging as new competitive factors as healthcare organizations increasingly consider environmental impact in their supply chain decisions. Companies that can offer environmentally responsible logistics solutions while maintaining cost competitiveness may gain competitive advantages.

The integration of healthcare logistics with broader healthcare delivery systems may create new competitive opportunities for companies that can effectively bridge the gap between logistics services and healthcare outcomes. Organizations that successfully make this transition may achieve sustainable competitive advantages in an increasingly complex and competitive market environment.

Know More: HEALTHCARE LOGISTICS MARKET INSIGHTS

#healthcare#logistics#literature#medicine#writeblr#writers on tumblr#health care industry#medicine industry

0 notes

Text

Temperature Data Logger Market Growth Drivers Transforming Global Industry Dynamics Rapidly

The Temperature Data Logger Market is witnessing significant growth driven by several critical factors shaping its expansion globally. Temperature data loggers are essential devices that record temperature over time, ensuring safety, quality, and compliance in various sectors such as pharmaceuticals, food and beverage, healthcare, and logistics. Understanding the key drivers propelling this market helps businesses and investors capitalize on emerging opportunities and address evolving industry needs.

One of the primary drivers of the Temperature Data Logger Market is the increasing demand for reliable temperature monitoring solutions in the pharmaceutical and healthcare industries. Maintaining strict temperature control during the storage and transportation of vaccines, medicines, and biological samples is critical to preserve their efficacy and safety. With the surge in vaccine distribution globally, especially highlighted by the COVID-19 pandemic, the need for temperature data loggers has intensified. These devices help ensure that sensitive products remain within required temperature ranges throughout the supply chain, reducing spoilage risks and compliance violations.

Technological advancements are another vital driver fueling the market’s growth. Modern temperature data loggers are equipped with wireless connectivity, real-time monitoring, and cloud-based data management features, allowing users to track temperature variations remotely and receive instant alerts in case of anomalies. The integration of Internet of Things (IoT) technology has enhanced the efficiency and accuracy of these devices, making them more user-friendly and adaptable across diverse applications. Innovations such as compact designs, longer battery life, and multi-parameter sensing capabilities have broadened their usability, thereby increasing market penetration.

Strict government regulations and industry standards related to temperature control and monitoring have also accelerated the adoption of temperature data loggers. Regulatory bodies worldwide mandate precise temperature tracking in sectors like food processing, pharmaceuticals, and cold chain logistics to ensure consumer safety and product quality. Compliance with regulations such as the FDA’s Good Manufacturing Practices (GMP), WHO guidelines, and HACCP (Hazard Analysis and Critical Control Points) is driving businesses to invest in advanced temperature monitoring systems. These regulatory requirements create a steady demand for temperature data loggers, especially in regions with stringent quality control standards.

The growth of cold chain logistics is another significant market driver. With the rise in global trade of perishable goods, including fresh food, seafood, and temperature-sensitive pharmaceuticals, efficient cold chain management has become paramount. Temperature data loggers play a crucial role in monitoring environmental conditions during transportation and storage, reducing the risk of product degradation. Increasing consumer awareness about food safety and quality further supports the expansion of cold chain infrastructure, indirectly boosting the demand for temperature data logging solutions.

Furthermore, expanding end-use industries contribute to market growth. Apart from healthcare and food, sectors such as agriculture, chemical manufacturing, and environmental monitoring require precise temperature measurement to optimize operations and maintain product integrity. For example, in agriculture, monitoring soil and storage temperatures helps improve crop yields and reduce wastage. Similarly, in chemical industries, maintaining controlled temperature conditions is essential for safe processing and storage of volatile substances. The broadening application scope enhances the overall demand for temperature data loggers.

Cost-effectiveness and ease of use also act as drivers for widespread adoption. Many temperature data loggers are now designed to be plug-and-play devices that require minimal technical expertise, encouraging small and medium-sized enterprises to implement temperature monitoring solutions. Additionally, the availability of affordable models without compromising accuracy has made these devices accessible to a larger customer base. This democratization of temperature monitoring technology is expected to contribute substantially to market growth in emerging economies.

The rising trend of digitalization and Industry 4.0 initiatives across manufacturing and supply chain operations further supports the Temperature Data Logger Market. Organizations aiming to enhance transparency, traceability, and operational efficiency adopt advanced temperature monitoring tools integrated with data analytics platforms. The insights generated from temperature data help businesses make informed decisions, reduce wastage, and comply with safety standards. The synergy between digital transformation and temperature data logging presents a promising growth avenue.

Lastly, increasing awareness of sustainability and reduction of food and drug wastage is encouraging industries to implement efficient temperature control measures. Temperature data loggers provide actionable insights that help reduce losses caused by improper storage conditions, supporting eco-friendly practices and cost savings. As environmental concerns become a priority globally, this driver will play a more significant role in shaping market dynamics.

In summary, the Temperature Data Logger Market growth is propelled by multiple intertwined drivers: escalating demand for temperature-controlled logistics, technological innovations, regulatory compliance, expansion of end-use industries, and the digital transformation of supply chains. These factors collectively create a robust ecosystem supporting market expansion. Companies investing in research, product development, and strategic partnerships are well-positioned to leverage these growth drivers and capture emerging opportunities in this evolving market landscape.

0 notes

Text

Refrigerated Warehousing Market Drivers: Key Factors Fueling Global Growth and Industry Transformation

The Refrigerated Warehousing market is undergoing significant expansion, driven by rising global demand for perishable goods, advances in cold chain technology, and evolving consumer expectations. As businesses and consumers alike seek reliable, temperature-controlled storage for food, pharmaceuticals, and chemicals, the importance of refrigerated warehousing has become more critical than ever. In this article, we explore the major drivers influencing the growth and evolution of the Refrigerated Warehousing market, shaping its present and future.

1. Rising Demand for Perishable Foods and Beverages

One of the most significant drivers of the Refrigerated Warehousing market is the escalating global demand for perishable foods and beverages. With rising incomes, urbanization, and changing dietary habits, consumers are increasingly opting for fresh and frozen food products, including fruits, vegetables, dairy, meat, seafood, and ready-to-eat meals.

This demand is particularly evident in emerging economies, where cold chain infrastructure is expanding to accommodate growing consumption. Retail chains, supermarkets, and e-commerce platforms now require reliable cold storage solutions to meet customer expectations for freshness and quality, boosting the demand for refrigerated warehousing services.

2. Growth of E-Commerce and Online Grocery Sales

The rapid expansion of e-commerce, especially in the grocery and food delivery sectors, has significantly contributed to the growth of the Refrigerated Warehousing market. Online grocery sales have surged post-pandemic, and this trend is expected to persist due to consumer convenience and digital adoption.

Online platforms require highly efficient, temperature-controlled logistics networks to deliver perishable items on time and in good condition. As a result, retailers and logistics providers are increasingly investing in refrigerated warehouses and last-mile cold chain delivery solutions, expanding the need for sophisticated and strategically located refrigerated storage facilities.

3. Pharmaceutical and Healthcare Industry Growth

The pharmaceutical industry represents another major driver of the Refrigerated Warehousing market. Many pharmaceuticals, including vaccines, biologics, and specialty drugs, require strict temperature control during storage and transportation to maintain their efficacy and safety.

The COVID-19 pandemic highlighted the importance of cold chain logistics in distributing temperature-sensitive vaccines globally. Even beyond the pandemic, the demand for biologics and specialty medicines continues to rise, pushing pharmaceutical companies to invest heavily in refrigerated warehousing infrastructure.

Furthermore, regulatory bodies such as the FDA and WHO impose stringent guidelines on cold chain compliance, driving pharmaceutical firms to partner with warehousing providers that offer validated, temperature-controlled storage solutions with real-time monitoring and reporting capabilities.

4. Technological Advancements in Cold Storage Solutions

Innovative technologies are transforming the Refrigerated Warehousing market, making cold storage more efficient, reliable, and cost-effective. Automation, real-time temperature tracking, warehouse management systems (WMS), and the use of artificial intelligence (AI) and IoT (Internet of Things) are helping warehouse operators improve inventory control, reduce energy consumption, and enhance operational efficiency.

Advanced insulation materials, solar-powered refrigeration units, and energy-efficient cooling systems are reducing environmental impact while lowering operating costs. These innovations make refrigerated warehousing more sustainable and attractive to environmentally conscious companies, further fueling market growth.

Moreover, predictive maintenance powered by AI and machine learning allows warehouse operators to identify potential equipment failures before they happen, minimizing downtime and ensuring uninterrupted cold storage services.

5. Expansion of Global Trade and Supply Chains

Globalization and the international trade of perishable goods are boosting the Refrigerated Warehousing market. Cross-border trade of food products, pharmaceuticals, and temperature-sensitive chemicals necessitates robust cold chain infrastructure in both exporting and importing countries.