#Grain temperature sensor

Explore tagged Tumblr posts

Text

Enabling magnetostrictive strain-sensitivity synergy in polycrystalline Fe₈₁Ga₁₉ alloys

Magnetostrictive Fe-Ga alloys with low temperature dependence, high permeability, and good mechanical properties have gained increasing attraction among various magnetostrictive materials. In particular, polycrystalline Fe-Ga alloys exhibit wide potential in applications such as sensors, actuators and implants owing to their structural variety and low production costs. Nevertheless, polycrystalline Fe-Ga alloys are limited by a tradeoff between large magnetostrictive strain and high sensitivity due to their inverse relationships with magnetic anisotropy. This prompts swift actions to overcome the bottleneck between magnetostrictive strain and sensitivity for wider range of applications. The magnetostrictive strain of Fe-Ga alloys is closely associated with the grain and domain structures, while the essence of magnetostrictive sensitivity lies in the ease for the motion of magnetic domains during the magnetization process. This process is subjected to various factors, including domain structure, dislocation density and grain boundary.

Read more.

#Materials Science#Science#Magnetism#Iron#Gallium#Magnetostriction#Polycrystals#Additive manufacturing#Materials processing

8 notes

·

View notes

Text

Image Calibration Details

A dark calibration image is a dark image produced by capping off the lens of a camera to record just the thermal readings or thermal noise of the camera sensor. The dark image is captured with the same settings and conditions (Camera settings; ISO, exposure time, etc. Conditions; temperature, time, etc.) as the regular images that the dark will be used to calibrate. By capturing a dark image, you can subtract the thermal noise from the regular images in post-production. It helps to improve the quality of the final image by improving contrast and reducing noise/grain.

A flat calibration image is a blank, uniformly brightened image that is used in cohesion with an image of similar conditions to fix imperfections in the main image. Problems a flat calibration image may solve include darkness around the edges, unwanted debris, pixel inconsistencies and noise or grain. When calibrating with a flat, the pixels are divided into the existing pixel's values.

When combining darks or flats for use in calibration, the median combine type is better than the average combine type because it is more likely to sand out outlying pixel values like overly bright pixels, dark spots, etc. It does this by sorting the pixel values of each pixel of each frame then picks the middle value, essentially ignoring the brightest and darkest values. Contrarily, averaging adds all the brightness values of each pixel then divides them by the number of frames, making this method of combining easily thrown off by outliers.

2 notes

·

View notes

Text

What Every Farmer Should Know About Advanced Grain Bin Ventilation Solutions

Grain storage management has become a vital component of farming success, requiring more than traditional practices to ensure long-term grain quality. Effective Grain Bin Management begins with understanding how airflow impacts storage conditions over time. Without proper airflow control systems in place, grain bins can quickly become high-risk areas for spoilage and grain loss. The right fan ventilation system plays a crucial role in protecting grain from harvest through to storage. For farmers who understand the value of preserving their products, investing in reliable ventilation is essential. Properly managed airflow supports uniform grain conditions and strengthens the quality and value of stored grain throughout the entire storage cycle.

Here is more detailed information:-

Smart Fan Control Systems for Grain Bin Ventilation Offer Reliable and Targeted Airflow

Modern grain storage requires more than just ventilation fans. It demands controlled airflow that actively manages temperature and moisture inside the bin. When grain bins are equipped with intelligent fan control systems, airflow can be directed precisely where and when it is needed. These systems respond to actual internal conditions rather than relying on guesswork or fixed schedules. By utilizing accurate sensors and fully automated controls, fans can turn on and off at the optimal time and with the appropriate intensity to maintain grain conditions and minimize unnecessary energy consumption.

Reducing Moisture Risks in Grain Storage with Precise Air Movement and Fan Timing

Grain spoilage often begins when moisture levels inside the bin are no longer in balance. If the grain becomes too damp, it risks developing mold. At the same time, overly dry conditions lead to shrinkage and a reduction in quality. Precision fan control systems prevent this by measuring the temperature and relative humidity of both the grain and outside air, ensuring the fan runs only when drying conditions are safe. The Grain Bin Automated Fan Control video clearly illustrates how this system operates in real-world situations to protect stored grain. This reduces the risk of rewetting and maintains consistent conditions across the bin. It also helps minimize fan runtime, which contributes to improved energy efficiency during extended storage periods.

Improving Grain Quality with Fan Efficiency and Condition-Based Controls

Grain bin ventilation that operates without monitoring or feedback can result in uneven conditions inside the bin and wasted energy. Advanced control systems optimize how and when fans operate, helping to eliminate common risks such as over-drying or over-conditioning. These systems are designed for farmers who want to protect their harvest while reducing unnecessary operating costs. By focusing airflow where it is most needed, these intelligent systems maintain consistent grain temperature and moisture levels without requiring frequent manual adjustments. With proper settings in place, grain storage becomes more reliable, safer, and easier to manage year-round.

Final Remarks

Farmers who depend on grain storage for a large portion of their annual success need systems that support reliability control and grain integrity. Smart grain bin ventilation is not just an upgrade but a direct investment in harvest preservation. With condition-based fan systems that adapt to changing environments inside and outside the bin, stored grain remains in optimal condition for more extended periods. Precision control means safer storage, better energy use, and greater peace of mind during every season. Reliable grain preservation begins with proper fan control and dependable ventilation performance from the start of storage through delivery.

Footnote

Safeguard every harvest with high-performance grain bin fan control systems that apply proven grain management techniques to reduce waste. Select airflow solutions designed to safeguard yield quality at every stage.

0 notes

Text

Grain Storage Silos Manufacturers | Uplex Infra Project Pvt. Ltd.

In the agricultural sector, proper grain storage is vital for maintaining quality, reducing losses, and ensuring a consistent food supply chain. As one of the leading Grain Storage Silos Manufacturers, Uplex Infra Project Pvt. Ltd. is committed to delivering advanced and efficient storage solutions tailored to the needs of farmers, grain traders, and food processing industries.

What Are Grain Storage Silos?

Grain storage silos are large, vertical structures used for storing bulk quantities of grains such as wheat, rice, corn, barley, and pulses. These silos are designed to protect grains from external factors like moisture, pests, and temperature fluctuations that can degrade the quality of stored produce. Unlike traditional storage methods, silos provide a controlled environment that significantly extends the shelf life of grains.

Importance of Quality Grain Storage

Inadequate storage can result in substantial post-harvest losses. Grains are highly sensitive to humidity, insects, and fungi. Without proper protection, stored grain can spoil quickly, leading to financial losses and food insecurity. This is where modern grain silos come in—they help maintain optimal storage conditions, minimize losses, and enable efficient handling and transportation of grain.

Why Choose Uplex Infra Project Pvt. Ltd.?

At Uplex Infra Project Pvt. Ltd., we are recognized among the top Grain Storage Silos Manufacturers in India. Our team combines industry expertise, innovative engineering, and high-grade materials to build silos that meet global standards. Whether you require small farm silos or large-capacity silos for industrial use, we provide customized solutions to suit every requirement.

Key Features of Our Grain Silos:

Durable Construction: Built from galvanized steel or high-strength alloy for long-lasting performance.

Modular Design: Easy to install, expand, or relocate as per project needs.

Ventilation System: Prevents mold growth and maintains consistent air circulation.

Temperature & Moisture Control: Ensures grain remains fresh and contamination-free.

Pest-Proof Design: Reduces infestation risks and ensures hygienic storage.

Automated Monitoring: Advanced systems for tracking grain conditions in real-time.

Types of Grain Silos We Manufacture

Flat Bottom Silos Ideal for long-term storage of large quantities of grain, flat bottom silos are equipped with temperature sensors, aeration systems, and grain sweep augers for efficient management.

Hopper Bottom Silos These silos are perfect for short-term storage and easy unloading. The conical bottom allows for smooth grain discharge, reducing manual handling and contamination risks.

Mobile Silos Designed for temporary or portable grain storage, these silos are compact, flexible, and suitable for remote locations or mobile grain handling operations.

Applications of Grain Storage Silos

Grain silos are widely used across various industries:

Agriculture: For seasonal harvest storage and management.

Food Processing: Ensuring consistent grain supply for mills and processing units.

Export & Import Facilities: For large-scale grain handling and international shipping.

Government Procurement Centers: Maintaining food reserves and public distribution stocks.

Commitment to Quality and Innovation

Uplex Infra Project Pvt. Ltd. places strong emphasis on quality assurance, using cutting-edge technology and adhering to global standards in every project. From design and fabrication to installation and maintenance, our solutions are engineered for maximum reliability, safety, and efficiency.

Conclusion

With increasing demand for efficient grain storage systems, choosing the right silo manufacturer is crucial. As a trusted Grain Storage Silos Manufacturer, Uplex Infra Project Pvt. Ltd. is proud to support the agricultural backbone of the nation with innovative and durable storage solutions. We understand that every grain counts, and our silos are built to ensure not a single one goes to waste.

If you're planning a grain storage project, get in touch with Uplex Infra Project Pvt. Ltd. today for expert consultation and cost-effective solutions designed for long-term value.

1 note

·

View note

Text

Rotary Dryers Market: Emerging Trends Shaping the Industry Landscape

The rotary dryers market has witnessed significant evolution over recent years, driven by growing industrialization and the rising demand for efficient drying technologies across multiple sectors. Rotary dryers, widely used in industries such as mining, agriculture, chemical processing, and food production, play a critical role in reducing moisture content in bulk solids, thereby improving material quality and facilitating further processing. As industries seek higher productivity, sustainability, and automation, several emerging trends are shaping the rotary dryers market’s trajectory.

Increasing Demand Across Diverse Industries

One of the primary drivers of growth in the rotary dryers market is the expanding use of drying technology across various sectors. The mining and minerals industry requires rotary dryers to process ores and minerals, removing moisture to enhance handling and extraction. Similarly, in agriculture, rotary dryers are instrumental in drying grains, seeds, and biomass, reducing spoilage and improving storage life.

The chemical and pharmaceutical sectors are also adopting rotary dryers to handle sensitive materials that require controlled drying environments. This diversification of applications is broadening the market base and encouraging manufacturers to innovate to meet industry-specific demands.

Advances in Energy Efficiency and Sustainability

Energy consumption is a critical consideration in drying processes, as traditional rotary dryers can be energy-intensive. The market is seeing a shift toward more energy-efficient designs and the integration of renewable energy sources to reduce operational costs and environmental impact.

Modern rotary dryers are increasingly incorporating advanced heat recovery systems, optimized airflow designs, and variable speed drives to enhance efficiency. Additionally, the use of solar energy and waste heat utilization is becoming more prevalent, aligning with global sustainability goals and regulatory pressures to reduce carbon footprints.

Integration of Automation and Smart Technologies

The adoption of automation and smart technologies is revolutionizing the rotary dryers market. Automation enhances process control, reduces human error, and improves operational safety. Smart rotary dryers equipped with sensors and IoT (Internet of Things) capabilities provide real-time data on temperature, moisture content, and airflow, enabling predictive maintenance and process optimization.

These intelligent systems help operators fine-tune drying parameters, leading to improved product quality and reduced energy usage. Moreover, remote monitoring and control features allow for greater flexibility and responsiveness in managing drying operations, which is particularly valuable in large-scale industrial setups.

Customization and Modular Designs

As industries demand more specialized drying solutions, manufacturers are focusing on customizable and modular rotary dryer designs. Customization allows users to tailor dryer size, drum speed, heating methods, and material handling systems according to their unique process requirements.

Modular rotary dryers provide flexibility in installation and scalability, enabling businesses to expand or modify their drying capacity with minimal downtime. This approach not only reduces initial investment but also facilitates easier maintenance and upgrades, driving wider adoption across small and medium enterprises.

Focus on Product Quality and Uniform Drying

Uniform drying and maintaining product quality are critical factors influencing market trends. Innovations in drum design, such as improved flights and lifters, enhance the lifting and cascading of materials inside the dryer, promoting even heat distribution and consistent drying.

Enhanced control over drying parameters also helps prevent overheating or under-drying, which can compromise product integrity. These improvements are particularly significant for sensitive products in the food, chemical, and pharmaceutical sectors, where moisture levels directly affect shelf life and efficacy.

Growing Emphasis on Environmental Regulations

Stringent environmental regulations are prompting manufacturers and end-users to adopt cleaner and more eco-friendly drying solutions. Emission control technologies, such as dust collectors and scrubbers, are increasingly integrated with rotary dryers to minimize air pollution.

Furthermore, the use of low-emission fuels and the optimization of combustion processes help reduce greenhouse gas emissions. Compliance with environmental standards is not only a regulatory requirement but also a competitive advantage as industries strive for sustainable operations and corporate social responsibility.

Expanding Market in Emerging Economies

Emerging economies in Asia-Pacific, Latin America, and Africa present significant growth opportunities for the rotary dryers market. Rapid industrial growth, urbanization, and increased agricultural production in these regions are driving demand for efficient drying technologies.

Local manufacturers and international players are investing in these markets by establishing production facilities, forging partnerships, and offering cost-effective solutions tailored to local needs. The rise in infrastructure development and the adoption of advanced manufacturing processes are expected to further boost market expansion.

Challenges and Future Outlook

Despite promising growth prospects, the rotary dryers market faces challenges such as high initial investment costs, maintenance complexities, and fluctuating energy prices. Addressing these issues through technological advancements and service improvements will be crucial for sustained growth.

Looking ahead, the market is expected to benefit from continued innovation in energy-efficient designs, smart automation, and sustainable practices. The integration of AI and machine learning for predictive analytics and process optimization may emerge as a game-changer, enhancing operational efficiency and reducing downtime.

Conclusion

The rotary dryers market is undergoing dynamic changes driven by technological innovation, sustainability imperatives, and diverse industry needs. Emerging trends such as energy efficiency, automation, customization, and compliance with environmental regulations are shaping the future of rotary drying technology. As industries continue to prioritize quality, efficiency, and sustainability, rotary dryers will remain a vital component in material processing across the globe, offering significant growth opportunities for manufacturers and end-users alike.

0 notes

Text

What Makes Aluminium the Future of Window & Door Design

The design language of modern architecture is shifting toward openness, light, and sustainability—and the materials used must rise to meet these evolving expectations. In this context, what makes aluminium the future of window and door design is its unique ability to combine sleek aesthetics with long-lasting performance. From towering skyscrapers to elegant contemporary homes, aluminium is fast becoming the material of choice for architects and homeowners alike, setting a new benchmark in both form and function.

Let’s dive in.

1. Sleek, Minimal, and Maximized

Aluminium’s natural strength allows for slimmer frames without compromising on stability. That means more glass and less frame—a dream come true for modern designs that emphasize light, space, and connection with nature.

Whether you're looking for floor-to-ceiling sliders, panoramic windows, or corner glazing with uninterrupted views, aluminium offers the structural flexibility to make it happen.

Architect's Choice: Thin frames = bolder views. Aluminium lets you design without limits.

2. Made for Harsh Weather

India’s climate is nothing if not diverse. From coastal humidity to dry heat, monsoon downpours to winter chills—aluminium performs in every condition.

It doesn’t swell, warp, rot, or crack. Aluminium is naturally corrosion-resistant and doesn’t degrade under UV exposure or pollution—making it a perfect fit for homes, offices, and high-rise buildings across the country.

Low Maintenance: A simple wipe-down keeps aluminium looking new for years.

3. Energy-Efficient & Eco-Friendly

Aluminium may be a metal, but today’s systems are anything but outdated. Thanks to thermal break technology—a layer within the frame that blocks heat transfer—modern aluminium windows and doors can offer exceptional insulation.

When paired with double or triple glazing, they help regulate indoor temperature, cutting down on energy bills and your carbon footprint.

What’s more? Aluminium is 100% recyclable and doesn’t lose its properties through recycling, making it one of the most sustainable materials in construction.

Green Fact: Recycling aluminium uses only 5% of the energy it takes to produce it from raw materials.

4. Customized to Match Any Design

Aluminium is incredibly adaptable. Want a matte black industrial look? A brushed silver finish for an office? A wood-grain texture for a heritage bungalow?

With powder coating, anodizing, and wood-textured laminates, aluminium frames can be tailored to match virtually any aesthetic. And these finishes aren’t just pretty—they’re long-lasting, fade-resistant, and easy to clean.

Style with substance—your frames can now be a design statement, not just a structural element.

5. Strength Meets Security

Security is as important as style—and aluminium delivers both.

Aluminium frames support advanced locking systems, reinforced joints, and impact-resistant glass. Whether it's a home in the suburbs or a retail store in a busy city, aluminium systems offer a secure envelope for your space.

Combine them with smart locks or sensor-based access systems, and you've got a door or window that’s ready for the future.

Peace of mind has never looked this sleek.

The GREFET Advantage

At GREFET, we believe in building systems that blend engineering and elegance.

Every GREFET aluminium window or door system is:

Precision-crafted for strength and durability

Designed for thermal and acoustic performance

Customizable to suit unique architectural needs

Built to meet global standards of safety and sustainability

We partner with architects, builders, and homeowners to deliver products that don’t just meet expectations—they redefine them.If you're designing for tomorrow, choose materials that will stand the test of time. Choose aluminium. Choose GREFET.

#aluminium windows India#modern door design#energy-efficient windows#GREFET aluminium systems#architectural aluminium#custom aluminium doors#sustainable window materials#aluminium sliding doors#best window material India#future of window design

0 notes

Text

How AI and Automation Are Transforming the Processing of Ferro Titanium Scrap and Powder!

In today’s fast-evolving metallurgical landscape, the demand for efficiency, precision, and quality is greater than ever. Industries working with specialty alloys—especially steelmakers, aerospace manufacturers, and defense contractors—depend on high-purity ferroalloys like Ferro Titanium Scrap and Ferro Titanium Powder for superior performance.

But as demand rises, so do expectations. Clients now seek not only quality materials but Consistency, Traceability, and Speed. This is where technology is making a massive impact.

Enter AI (Artificial Intelligence) and Automation—two game-changing forces that are transforming how ferro titanium is processed, refined, and delivered.

The Traditional Challenge

Historically, processing Ferro Titanium Scrap involved labor-intensive manual sorting, inconsistent blending, and trial-and-error methods in quality control. This led to:

Variable purity levels

Delays in production

High material waste

Unreliable delivery timelines

For clients who need high-performance alloys, this uncertainty simply isn't acceptable. Manufacturers needed a smarter, faster, and more reliable solution. That’s exactly what modern technology is providing.

Smart Sorting with AI Vision Systems

One of the most significant improvements comes in the scrap sorting phase.

Using AI-powered vision systems combined with robotics, manufacturers can now scan and sort ferro titanium scrap in real-time, based on:

Size and shape

Surface texture

Contaminant detection

Alloy composition (via integrated spectroscopy)

This level of precision ensures only the right quality scrap goes into the melting or powdering process. The result? Better input quality, reduced contamination, and lower rejection rates in the final product.

Automation in Powder Production

When it comes to producing Ferro Titanium Powder, the consistency of grain size, composition, and particle distribution is critical. Automated systems now control everything from:

Feeding of scrap

Melting and alloying

Powder atomization

Drying and sieving

Sensors and feedback loops allow these systems to self-adjust in real time, ensuring consistent quality from batch to batch.

For clients, this means they receive uniform powder ideal for applications like welding electrodes, deoxidizers, and additive manufacturing—without surprises.

AI-Powered Quality Control

In the past, quality control relied heavily on manual sampling and periodic lab analysis. Today, smart sensors and AI-driven quality monitoring systems can inspect every batch of ferro titanium in real time.

These systems monitor parameters like:

Chemical composition

Temperature during processing

Impurity levels

Microstructure alignment (in powders)

Using machine learning algorithms, the system can predict deviations before they occur and auto-correct the process. This predictive capability significantly reduces downtime, scrap rates, and customer complaints.

Meeting Rising Client Expectations

Clients today don’t just want material—they want certainty. They expect:

Traceability of every batch

Guaranteed consistency

Shorter lead times

Custom alloy solutions

Technology enables all of this. With data tracking systems, every piece of ferro titanium scrap or powder can be traced from its origin to the end user. Automation shortens production cycles. AI makes precision possible at scale.

This not only builds trust but also allows manufacturers to offer tailored solutions that align with the specific needs of each client.

Environmental Benefits

AI and automation don’t just help improve output—they reduce environmental impact as well. Smart processing reduces waste, optimizes energy use, and minimizes emissions.

When scrap is sorted accurately and powder production is tightly controlled, less material is wasted, and fewer resources are consumed.

This commitment to sustainability is another factor today’s clients actively look for when selecting suppliers.

Smarter Forecasting and Supply Chain Management

Modern tech isn’t limited to the shop floor. With AI-driven analytics, manufacturers can now predict market trends, client demands, and raw material needs with far greater accuracy.

Inventory management, lead times, and resource planning all become more efficient. This means fewer delays, better pricing, and on-time delivery—key factors that clients care about deeply.

The Competitive Edge

Suppliers who embrace technology gain a massive competitive edge. By offering ferro titanium scrap and powder processed through intelligent systems, they meet the exacting standards of top-tier clients in sectors like:

Aerospace

Automotive

Welding and fabrication

Marine and defense

These industries depend on reliable alloy inputs, and they partner with suppliers who bring both innovation and consistency to the table.

Final Thoughts: It's Time to Think Smart

The ferroalloy industry is no longer just about mining, melting, and mixing. It’s about precision, predictive control, and performance—powered by smart technologies.

If you’re a manufacturer or supplier of Ferro Titanium Scrap and Ferro Titanium Powder, the future belongs to those who invest in automation and AI. And if you’re a buyer, now is the time to partner with suppliers who are forward-thinking, digitally equipped, and quality-driven.

#FerroTitaniumScrap #FerroTitaniumPowder

0 notes

Text

Harnessing Heat: A Practical Guide to Industrial Drying

Why Industrial Drying Matters

Industrial drying removes moisture from raw or finished goods, guarding product quality while cutting storage weight. The industrial drying process supports food safety, extends material life and drives energy savings across factories.

Key Benefits at a Glance

Quality retention – Moisture invites mould and corrosion; swift moisture removal keeps goods sound.

Energy efficiency – Dry goods store, ship and handle with less effort, slashing fuel usage.

Process speed – Dry lines run quicker, boosting throughput and meeting tight lead times. (60 words)

Core Principles of Industrial Drying

Heat Transfer

Warm air or radiation draws water from the product surface. Engineers pick temperatures that lift moisture yet shield texture and colour.

Mass Transfer

Fans sweep moist air away, replacing it with fresh, dry air. This cycle keeps evaporation brisk and continuous.

Moisture Diffusion

Water inside the material moves toward the surface. Correct airflow and product thickness shorten this path, cutting cycle time.

Popular Industrial Drying Solutions

Convective Systems

Hot air passes over moving belts or trays. Simple design, low upkeep and strong reliability suit textiles and grains.

Conductive Systems

Products rest on heated plates or drums. Direct contact gives quick, even warmth. Users favour this method for films, paper and thin sheets.

Infra-red Units

Infra-red waves penetrate surfaces, warming water molecules from within. This option trims drying stages for coatings and paints.

Selecting the Right Approach

When choosing among varied industrial drying solutions, weigh these factors:

Material traits – Porous goods dry faster than dense metals.

Desired moisture level – Food often needs near-zero water, while timber may keep slight moisture for flexibility.

Energy budget – Gas, steam and electric each carry distinct running costs and carbon footprints.

Space limits – Tower dryers suit small footprints; tunnel units need long floor space.

Steps to Optimise an Existing Line

Audit Current Performance

Measure inlet and outlet moisture, temperature and airflow. Data pinpoints bottlenecks.

Upgrade Airflow Control

Variable-speed fans match demand in real time, trimming waste heat.

Install Moisture Sensors

Inline sensors give instant feedback, letting operators fine-tune set-points.

Improve Insulation

High-grade panels lock heat inside the chamber, lowering fuel burn.

Safety and Environmental Notes

Follow local emission rules. Fit filters to capture volatile compounds. Train staff to spot fire risks, especially with dust-laden products.

Future Trends in Industrial Drying

Engineers push boundaries with hybrid methods that blend infra-red and convection. Heat-pump technology also rises, recycling latent heat once lost to exhaust streams. These advances promise leaner, greener factories.

Conclusion

Mastering industrial drying unlocks consistent quality, lean energy use and swift production. By grasping core principles and matching them with smart industrial drying solutions, managers build resilient systems ready for market shifts and stricter climate goals. Continuous measurement, staff training and strategic upgrades keep every drying line efficient, safe and future-proof.

0 notes

Text

Agriculture Warehouse: Powerful Strategies & Modern Solutions in 2025

Introduction to Agriculture Warehouses

In today's fast-evolving agricultural landscape, agriculture warehouses have become indispensable. These structures are more than just storage spaces; they are central to efficient food distribution, reduced waste, and supply chain stability. The concept has evolved from traditional barns to cutting-edge facilities equipped with the latest technologies that ensure produce is preserved at its peak.

Historically, farmers relied on underground pits or mud structures to store grains. However, these were prone to pest infestations, theft, and climatic damage. The shift towards scientifically designed warehouses was fueled by the growing need for food safety, export readiness, and supply chain efficiency.

Types of Agriculture Warehouses

Cold Storage Warehouses

Ideal for perishable items like fruits, vegetables, and dairy, cold storage warehouses use refrigeration to extend shelf life and maintain quality.

Dry Storage Warehouses

Used for grains, pulses, and non-perishables, these agriculture warehouses maintain ambient conditions to prevent moisture buildup and pest invasion.

Controlled Atmosphere Storage

These high-tech warehouses control oxygen, carbon dioxide, and humidity levels—especially useful for apples, kiwis, and long-storage crops.

Importance of Warehousing in Agriculture

Warehousing plays a critical role in reducing post-harvest losses, which account for nearly 30% of food wastage in developing countries. Here's why it's essential:

Food Security: With growing populations, having stockpiled food reserves ensures availability during lean seasons.

Stabilizing Prices: Warehousing enables farmers to sell produce when prices are favorable.

Export Readiness: Properly stored products meet international standards and remain viable for longer export timelines.

Key Features of a Modern Agriculture Warehouse

Modern warehouses incorporate advanced features like:

Climate Control Systems: Regulate temperature and humidity to protect sensitive produce.

Ventilation: Ensures airflow, reducing mold and fungal growth.

Security: Surveillance cameras, access controls, and fire safety mechanisms reduce risk.

These enhancements are pivotal in preserving product integrity and maximizing shelf life.

Site Selection and Layout Planning

Choosing the right location can make or break a warehouse’s efficiency.

Accessibility to Farms and Markets: Reduces transport time and cost.

Soil and Drainage: Affects the building's stability and longevity.

Zoning and Legal Clearances: Avoids future regulatory hurdles.

A well-planned layout supports smooth loading, unloading, and storage operations with optimal space utilization.

Technologies Transforming Agriculture Warehousing

Digitalization is revolutionizing warehousing operations:

IoT Sensors: Monitor temperature, moisture, and gas levels in real-time.

Automation: Robots and conveyors reduce manual labor and errors.

Smart Packaging: Tracks product quality from storage to delivery.

These innovations improve traceability and reduce wastage.

Inventory Management in Warehouses

Efficient inventory systems like FIFO (First In, First Out) and LIFO (Last In, First Out) help in timely product rotation. Real-time monitoring systems enable:

Faster dispatch

Lower spoilage rates

Improved traceability and compliance

Warehouse Management Software (WMS) further enhances operational accuracy.

1 note

·

View note

Text

Cutting-Edge Illumination: The Best LED Headlight Technology of 2025

The year 2025 marks a significant leap forward in automotive lighting, with LED headlight technology reaching unprecedented levels of sophistication and performance. Gone are the days of dim, yellowish halogen bulbs struggling to pierce the darkness. Today, cutting-edge LED innovations are delivering unparalleled brightness, precision, and efficiency, transforming the way we see and are seen on the roads, including the diverse driving conditions encountered in Jhargram. This article delves into the best LED headlight technologies of 2025, highlighting the advancements that are illuminating our drives with remarkable clarity and safety.

One of the most significant advancements in 2025 is the refinement of high-intensity LED chips. Manufacturers are now producing smaller, more powerful LEDs that deliver significantly higher lumen output while maintaining exceptional energy efficiency. This translates to brighter headlights that illuminate a wider and longer area of the road, crucial for spotting potential hazards well in advance, whether it's navigating through foggy conditions or encountering unexpected obstacles on rural roads around Jhargram. These advanced chips also allow for more precise control over light distribution.

Coupled with these high-performance LEDs are innovative optical designs. The reflectors and lenses within the headlight assembly are engineered with meticulous precision to shape and direct the light beam with greater accuracy than ever before. Multi-faceted reflectors and complex lens geometries work in tandem to create a sharp, well-defined beam pattern that maximizes visibility on the road while minimizing glare for oncoming traffic. This focus on beam control is a critical safety feature, ensuring that drivers in Jhargram and elsewhere can benefit from enhanced illumination without compromising the vision of others.

Adaptive Driving Beam (ADB) technology represents another cutting-edge innovation gaining prominence in 2025. These intelligent headlight systems utilize sensors and cameras to detect the presence of other vehicles and automatically adjust the light beam to avoid dazzling other drivers. This can involve dynamically dimming specific sections of the high beam or even creating "light tunnels" around oncoming vehicles, allowing the driver to maintain optimal illumination of the rest of the road. ADB systems are particularly beneficial on winding roads and during nighttime highway driving, providing a significant boost to safety and comfort.

Matrix LED technology takes adaptive lighting a step further. These systems consist of multiple individually controllable LED segments within the headlight unit. This allows for even finer-grained control over the light distribution. For example, the system can selectively dim or turn off individual LEDs to precisely "shape" the light beam around multiple oncoming or preceding vehicles simultaneously, offering even greater precision in preventing glare while maintaining maximum illumination of the surrounding environment. This level of sophisticated light control enhances visibility in complex traffic scenarios.

Beyond beam control, advancements in thermal management are crucial for the performance and longevity of LED headlights. BEST LED HEADLIGHT BULBS 2025 generate significant heat, which, if not properly dissipated, can lead to reduced brightness and a shortened lifespan. Cutting-edge LED headlight systems incorporate sophisticated cooling solutions, including active cooling fans, advanced heat sink designs utilizing materials with high thermal conductivity, and intelligent thermal management circuitry. These systems ensure that the LEDs operate within their optimal temperature range, maintaining consistent performance and extending their lifespan, even in the hot and humid climate experienced in Jhargram.

The integration of digital control systems is also a hallmark of the best LED headlight technology in 2025. Microprocessors and sophisticated software algorithms manage the brightness, beam pattern, and adaptive features of the headlights in real-time, based on input from various vehicle sensors. This allows for seamless and dynamic adjustments to the lighting based on driving conditions, speed, and the presence of other vehicles.

Finally, the aesthetic design and integration of LED headlights have also evolved significantly. Manufacturers are creating sleek and stylish headlight units that seamlessly integrate with the overall design language of modern vehicles. The compact nature of LEDs allows for greater flexibility in design, leading to distinctive and visually appealing lighting signatures.

In conclusion, the best LED headlight technology of 2025 represents a significant leap forward in automotive illumination.

1 note

·

View note

Text

Nutrifit

Welcome to the first blog post of Nutrifit. If you have ever wished a sports scientist, dietitian, and recovery coach could travel with you on every run, ride, or yoga flow, our little ring is about to grant that wish.

Wrists jostle, chest straps chafe, and phones weigh pockets down. A ring, however, sits close to the arteries in your finger, quietly reading heart-rate variability, skin temperature, micro-vascular oxygen, and subtle muscle tremors. By embedding multilayer photonics, a haptic motor, and edge-AI in a band lighter than a nickel, NutriFit records the signals that matter while you almost forget it is there.

Finish any activity and open the companion app. A single swipe delivers an actionable four-part briefing that feels like a coach’s personalized note. First comes nutrition: the algorithm converts metabolic expenditure into precise macro and micronutrient targets, recommending carbohydrate-rich grain bowls after hill repeats or leucine-dense proteins when heavy squats dominate your session. Next arrives recovery: a real-time fatigue score—built from variability, temperature, and tremor signals—suggests breath-work, contrast baths, foam-rolling drills, and sleep hygiene tweaks calibrated to your physiology rather than generic averages. Preparation follows: tomorrow’s calendar dictates mobility flows, priming sets, and hydration reminders so you start warm instead of warming up. Finally, performance: inertial sensors reconstruct technique, nudging cadence, grip width, or knee tracking to squeeze extra efficiency from the same effort.

These prescriptions are powered by machine-learning models trained on motion libraries from ultrarunners, powerlifters, weekend warriors, desk workers, and adaptive athletes, allowing NutriFit to scale advice from first couch-to-5K strides to podium ambitions—or even to optimize the noble discipline of a restorative nap. Every suggestion links to a bite-sized scientific explainer and peer-reviewed citation, delivering clarity without drowning you in jargon. Privacy, meanwhile, is non-negotiable: each reading is encrypted on the ring and synced with zero-knowledge keys; your physiological story is shared only with the coaches or physicians you explicitly approve, never sold to advertisers.

In the coming months this blog will unpack sensor teardowns, share beta-tester diaries, showcase culturally diverse meal plans, debut new app features, and open limited pre-orders. If you want early-bird pricing and a voice in shaping the future of wearable intelligence, join the insider list at nutrifit.io/earlyaccess today. Strap in—rather, ring up. The journey toward smarter movement, faster recovery, and tastier fuel begins now, and we’re thrilled you’re here for the first step. Welcome to NutriFit, where a tiny circle carries truly giant ambitions for athletes and everyday movers alike, worldwide community. Join us. On this exciting data-driven wellness adventure together.

Monday, April 28, 2025

1 note

·

View note

Text

Silos Market Forecasted to Hit $2.8 Billion by 2034 with Steady 6.4% CAGR

Silos Market is charting a path of significant growth, with its valuation expected to rise from $1.5 billion in 2024 to an estimated $2.8 billion by 2034. This surge, marked by a robust CAGR of 6.4%, is largely driven by the escalating demand for efficient and sustainable storage solutions across key industries such as agriculture, construction, food and beverage, and manufacturing. Silos are no longer just simple storage structures — they’ve evolved into high-tech systems integrated with advanced monitoring tools, ensuring optimum preservation of grains, cement, chemicals, and more.

At the heart of this market lies its diversity. From tower and bunker silos to more advanced modular and portable versions, the market is being reshaped by innovation. The agriculture sector continues to dominate, accounting for a whopping 45% market share, followed by the food and beverage industry. These storage systems help minimize post-harvest losses, optimize supply chains, and ultimately bolster food security on a global scale.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS26211

Market Dynamics

Several dynamic forces are shaping the trajectory of the silos market. One of the primary drivers is the global increase in grain production and the resulting need for reliable, long-term storage. Cement silos are also on the rise, reflecting the ongoing boom in infrastructure and construction activities worldwide.

Technological innovation is another significant factor. The integration of IoT-enabled sensors and automated material handling systems has transformed silo storage into an intelligent, data-driven process. These advancements not only enhance efficiency but also enable real-time condition monitoring, reducing spoilage risks and optimizing space usage.

Sustainability is increasingly playing a central role. With environmental regulations tightening, companies are adopting eco-friendly materials like fiberglass and aluminum for silo construction. These changes are not only reducing the environmental footprint but are also creating opportunities for product differentiation and premium pricing.

Key Players Analysis

The competitive landscape of the silos market includes a mix of established leaders and emerging innovators. Key companies like AGCO Corporation, Silos Cordoba, and Sioux Steel Company are leveraging their expertise to deliver cutting-edge solutions with durability and scalability at the core.

Meanwhile, emerging players such as Silo Tech Innovations and Agro Sphere Solutions are pushing the envelope with custom solutions, IoT integration, and eco-conscious designs. These players are contributing significantly to market dynamism through strategic collaborations, product innovations, and targeted regional expansions.

Regional Analysis

North America stands at the forefront of the silos market, led by the United States’ tech-driven agricultural sector and investments in automated farming solutions. Europe trails closely behind, with countries like Germany and France emphasizing sustainable practices and advanced storage systems due to stringent food safety regulations.

Asia-Pacific is a rising star in this space. Rapid urbanization, industrialization, and increased agricultural output in nations like China and India are spurring silo demand. Latin America, particularly Brazil and Argentina, is also witnessing a rise in modern silo installations to reduce post-harvest losses and meet export demands.

Recent News & Developments

Recent developments in the silos market spotlight a shift toward smarter, more resilient systems. Innovations in material science have led to stronger, lighter, and more cost-effective silos. Smart silos equipped with IoT sensors for temperature and humidity control are gaining traction, enhancing efficiency in agricultural and industrial applications.

Additionally, partnerships between global leaders and local governments are fueling large-scale projects aimed at strengthening food storage infrastructure. The trend of customizing silo solutions to adapt to varied climates and terrain is another noteworthy development reshaping the industry landscape.

Browse Full Report : https://www.globalinsightservices.com/reports/silos-market/

Scope of the Report

This comprehensive report on the silos market offers in-depth insights into global and regional trends, technological advancements, and competitive dynamics. It analyzes key market segments — including type, product, service, material, technology, and end user — while highlighting growth opportunities, challenges, and regulatory impacts.

Our data-driven approach ensures accurate forecasts, market share analysis, and strategic recommendations. Whether you’re a farmer, a construction company, or a tech innovator, this report provides the intelligence needed to make informed decisions in a rapidly evolving storage solutions market.

Discover Additional Market Insights from Global Insight Services:

Military Vehicle Electrification Market : https://www.globalinsightservices.com/reports/military-vehicle-electrification-market/

Baggage Handling System Market : https://www.globalinsightservices.com/reports/baggage-handling-system-market/

Electric Forklift Market : https://www.globalinsightservices.com/reports/electric-forklift-market/

Unmanned Underwater Vehicles (UUV) Market : https://www.globalinsightservices.com/reports/unmanned-underwater-vehicles-uuv-market/

Crane and Hoist Market :https://www.globalinsightservices.com/reports/crane-and-hoist-market/

#silosmarket #storagesolutions #agtech #grainstorage #agribusiness #constructiontech #smartfarming #iotsolutions #sustainablestorage #cementindustry #agribusinessnews #precisionagriculture #supplychainoptimization #infrastructuregrowth #globalagrimarket #constructionboom #foodsecurity #postharvestsolutions #agriculturetrends #materialinnovation #smartstorage #techintegration #farmtech #iotenabled #agricultureequipment #modularstorage #futureoffarming #sustainableagriculture #smartinfrastructure #constructionupdates #agrinews #grainsilos #cementstorage #bunkersilos #silotechnology #asiapacificgrowth #northamericamarket #latamagriboom #europemarket #ecoagriculture #storageinnovation

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

The Impact of Temperature on Water Activity Measurements

Water activity is a key factor in many industries, like food safety, pharmaceuticals, and agriculture. It tells us how much "free" water is available in a product for things like bacteria or mold to grow. But did you know that temperature can change water activity measurements? In this article, we’ll explore how temperature affects water activity, why it matters, and how to handle it when using a water activity meter. Whether you’re a food producer, a scientist, or just curious, this guide will break it all down in simple terms.

What Is Water Activity?

Before we dive into temperature, let’s define water activity (often shortened to "aw"). Water activity measures how much water in a product is available to support life—like microbes or chemical reactions. It’s not the same as moisture content, which is just the total amount of water present. Water activity ranges from 0 (completely dry) to 1 (pure water). For example, fresh meat has a high water activity (around 0.99), while crackers are much lower (around 0.3).

Tools called water activity meters measure this value. They’re used in labs, factories, and even small businesses to keep products safe and stable. But here’s the catch: temperature can mess with those measurements if you’re not careful.

Why Temperature Matters for Water Activity

Temperature affects water activity because it changes how water behaves in a material. When things heat up or cool down, water molecules move differently. This can make the water activity reading higher or lower than it really is. Let’s break it down:

1. Warmer Temperatures Increase Water Activity

When you heat a sample, water molecules get more energy and move around faster. This can make more water "available," raising the water activity reading. For example, a piece of bread at 75°F might show a water activity of 0.75, but at 100°F, it could jump to 0.80. That’s a big deal if you’re trying to stop mold from growing!

2. Cooler Temperatures Lower Water Activity

On the flip side, cold temperatures slow water molecules down. This can make less water seem "free," lowering the reading. Imagine testing frozen dough—it might show a lower water activity than the same dough at room temperature.

3. Temperature Affects the Meter, Too

Water activity meters use sensors to detect water vapor. These sensors are sensitive to temperature. If the meter or the sample isn’t at the right temperature, the results can be off. Some meters even have built-in temperature controls to fix this problem.

Real-World Examples of Temperature’s Impact

Let’s look at how this plays out in everyday situations:

Food Safety: In food production, like making jerky or cheese, water activity keeps bacteria in check. If you test a warm sample fresh from the oven, the reading might be too high. Cooling it first gives a more accurate result.

Pharmaceuticals: Medicines like tablets need low water activity to stay stable. Testing them in a hot lab could trick you into thinking they’re unsafe.

Grain Storage: Farmers use water activity to prevent mold in stored grains. A cold silo might show a safe reading, but warmer weather could raise the risk.

How Temperature Changes Water Activity in Science

Scientists have studied this for years. Research shows that even small temperature shifts—like 5°F—can change water activity by 0.01 to 0.03 units. That might sound tiny, but in industries where safety depends on exact numbers, it’s huge. For example, mold grows above a water activity of 0.70. A wrong reading could mean spoiled food or wasted money.

One study (like the kind you’d find on ScienceDirect) tested how temperature affects water activity in sugary solutions. At 68°F, the water activity was 0.85. At 86°F, it climbed to 0.87. The heat made water molecules more active, shifting the balance.

How to Control Temperature for Accurate Measurements

To get reliable water activity readings, you need to manage temperature. Here’s how:

1. Match the Sample and Meter Temperature

Let your sample sit until it’s the same temperature as the meter. Most meters work best around 70°F to 77°F (room temperature). If your sample is hot or cold, wait 10-15 minutes before testing.

2. Use a Temperature-Controlled Meter

Some high-end water activity meters have built-in heaters or coolers. They keep the sample at a steady temperature, like 77°F, so you don’t have to guess.

3. Test at a Standard Temperature

Pick one temperature—like 77°F—and stick to it for all your tests. This makes your results consistent and easier to compare.

4. Avoid Extreme Conditions

Don’t test samples straight from a freezer or oven. Extreme heat or cold throws off the meter’s sensors and gives bad data.

Why This Matters for Businesses

If you run a business, temperature’s effect on water activity can save—or cost—you a lot. Here’s why:

Product Quality: Wrong readings can lead to soggy crackers or moldy cheese. Customers won’t be happy.

Safety Rules: The FDA and other agencies set water activity limits for safe food. Messed-up measurements could break those rules.

Money: Throwing out bad batches hurts your wallet. Accurate tests prevent waste.

For example, a bakery might test cookies at 90°F and see a water activity of 0.65—too high for a long shelf life. Cooling them to 70°F might drop it to 0.60, which is safer and better for sales.

Common Questions About Temperature and Water Activity

Does Every Product React the Same Way?

No! Foods with lots of sugar or salt (like candy or jerky) change more with temperature than something simple, like plain rice. It depends on the ingredients.

Can I Fix a Bad Reading?

If you suspect temperature messed up your test, let the sample stabilize and try again. Use a thermometer to double-check.

What’s the Best Temperature for Testing?

Most experts recommend 77°F (25°C). It’s a standard that works for most products and meters.

Tips for Using a Water Activity Meter

Here are some quick tips to handle temperature like a pro:

Store your meter in a stable, room-temperature spot.

Check the manual—some meters need warm-up time.

Test samples in small batches to avoid heat buildup.

Keep a log of temperatures with your readings for better tracking.

The Future of Water Activity Meters

Technology is making water activity meters smarter. New models can adjust for temperature automatically, using sensors to correct readings on the fly. Some even connect to apps, so you can monitor results from your phone. As these tools improve, businesses and labs will get faster, more accurate data—no matter the temperature.

Conclusion

Temperature has a big impact on water activity measurements. It changes how water behaves in a product and how meters read that water. By understanding this, you can take control—whether you’re keeping food safe, making medicine, or storing crops. Use the right tools, test at a steady temperature, and double-check your work. That way, you’ll get results you can trust every time.

Want to learn more about water activity or how to pick the best meter? Keep exploring—it’s a small step that can make a big difference!

0 notes

Text

Smart Farming in Iowa: The Power of a Grain Moisture Sensor

The Problem: Storage Losses Are Eating Into Profits

You've harvested a great crop, but what happens next can make or break your season. Improper storage, especially with unchecked moisture, leads to spoilage, shrinkage loss, mold, and reduced grain value. Many Iowa farmers face this silent profit drain every year, often without realizing the full impact until it's too late.

The Solution: Monitor Moisture, Maximize Returns

Instead of risking spoilage or over-drying, more farmers are turning to technology to take control of grain conditions. That's where a Grain Moisture Sensor Iowa solution comes into play—giving you the data you need to store smarter, act faster, and protect your bottom line through every stage of storage.

Say Goodbye to Guesswork

Moisture can fluctuate quickly inside a grain bin, especially in Iowa's variable climate. With a moisture sensor in place, you're no longer relying on manual checks or gut instinct. Instead, you get accurate readings that help you decide when to run fans, aerate, or transfer grain. This means less guesswork and more control, reducing the chances of grain loss due to poor timing.

Real-Time Alerts That Work for You

Modern sensors aren't just accurate—they're smart. Set your own temperature and moisture thresholds, and you'll get alerts when conditions shift. You'll know what's happening inside your bin, whether in the field or at home. These updates allow you to take immediate action, preventing problems before they grow. It's even more powerful when paired with a grain bin monitoring system that watches every layer of your stored crop, keeping you informed 24/7.

Built Tough for Iowa Conditions

Iowa farmers deal with everything from humid harvest seasons to freezing storage months. That's why today's sensors are made to last through heat, cold, and heavy use. They're durable, reliable, and simple, whether installing in older bins or installing a new system. These tools are built with long-term performance in mind, offering peace of mind during your most critical storage windows.

Your Grain Deserves Better

Grain is a valuable asset that deserves more than a "wait and see" approach. Moisture sensors allow you to fine-tune storage conditions and prevent damage before it starts. You're managing your grain proactively instead of reacting to issues after the fact. This kind of control turns a good harvest into a great return by preserving grain quality from bin to buyer, and that makes a real difference in your yearly revenue.

Conclusion

Whether you manage a few thousand bushels or full commercial bins, moisture monitoring is a no-brainer. A small investment significantly impacts your operation's efficiency and grain value. It's time to invest in a grain bin monitoring system Iowa farmers rely on to protect their grain and profits, season after season.

0 notes

Text

Latest Innovations in Capacitive Proximity Sensors Technology – 2025 Update

Capacitive proximity sensors have come a long way in recent years, and 2025 is shaping up to be a breakthrough year for the technology. Known for their ability to detect a wide range of materials including plastic, glass, liquids, and powders without direct contact, capacitive sensors have become a staple in industries like automation, packaging, agriculture, and consumer electronics. Let’s dive into the latest innovations in capacitive proximity sensors that are driving new possibilities in 2025.

Smarter Self-Calibration Systems

One of the standout innovations in 2025 is the advancement in self-calibrating capacitive proximity sensors. These next-gen sensors can automatically adjust their sensitivity to changing environmental conditions such as temperature, humidity, or dust. This not only reduces false triggers but also extends the sensor’s life in harsh or variable environments. It’s a huge win for industries operating in fluctuating conditions, like food processing and outdoor automation systems.

Miniaturization Meets High Performance

As devices get smaller, the demand for compact sensors has increased. Capacitive proximity sensors in 2025 have been miniaturized without compromising sensitivity or range. New chip designs allow for ultra-compact sensors ideal for medical devices, mobile robotics, and consumer electronics. These tiny yet powerful sensors are helping manufacturers pack more functionality into less space.

Wireless Integration for IoT Applications

Capacitive proximity sensors are no longer standalone devices. In 2025, many models now feature built-in wireless connectivity options like Bluetooth Low Energy (BLE), Zigbee, and Wi-Fi. These sensors can seamlessly communicate with other IoT devices, enabling real-time monitoring, diagnostics, and predictive maintenance. This innovation is particularly useful in smart factories and remote systems where wired connections are impractical.

Artificial Intelligence for Better Signal Processing

AI is playing a big role in sensor technology this year. Capacitive sensors equipped with AI algorithms can now filter out noise and learn from their environment to improve detection accuracy. They can distinguish between actual targets and interference from moisture, static, or vibrations. This level of intelligence enhances reliability in complex environments like automotive manufacturing and pharmaceutical packaging.

Longer Detection Ranges with Lower Power Usage

Traditionally, capacitive sensors have had limited detection ranges, especially with non-metallic objects. However, recent breakthroughs in sensing technology have led to increased range capabilities while simultaneously reducing power consumption. This is a game-changer for battery-operated devices and mobile equipment, where energy efficiency is crucial.

Broader Material Compatibility

2025 also brings improvements in material detection. New sensor designs can more accurately detect low-dielectric materials such as foam, dry bulk solids, and certain plastics. This allows capacitive proximity sensors to be used in more niche applications, including agriculture (for grain level monitoring) and recycling plants (for sorting non-metallic materials).

Conclusion

The latest innovations in capacitive proximity sensors technology are pushing the boundaries of what’s possible. With smarter calibration, AI-enhanced accuracy, wireless capabilities, and compact design, 2025’s sensors are more adaptable, efficient, and powerful than ever. Whether you’re upgrading a smart factory or building next-gen robotics, these new developments make capacitive sensors a key component for innovation in the years ahead.

0 notes

Text

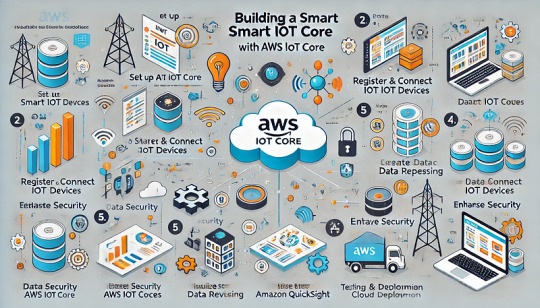

Building a Smart IoT Application with AWS IoT Core

The Internet of Things (IoT) has revolutionized industries by enabling devices to connect, communicate, and make intelligent decisions. AWS IoT Core provides a robust platform to build, manage, and secure IoT applications at scale. This guide outlines the key steps to develop a smart IoT application using AWS IoT Core.

What is AWS IoT Core?

AWS IoT Core is a managed cloud platform that enables connected devices to interact securely with cloud applications and other devices. It supports MQTT, HTTP, and WebSocket protocols for device communication.

Key Features of AWS IoT Core

✅ Secure device communication via X.509 certificates. ✅ Supports real-time data processing with AWS Lambda and Amazon Kinesis. ✅ Integrates seamlessly with AWS services like DynamoDB, S3, and CloudWatch. ✅ Offers Device Shadow for offline state management.

Step 1: Set Up AWS IoT Core

Sign in to the AWS Management Console.

Navigate to AWS IoT Core.

In the left menu, go to Manage → Things.

Click Create Thing and provide:

Name: A meaningful identifier for your IoT device.

Device Shadow: Enable it if you want AWS IoT to store device state information.

Click Next, generate certificates, and download them securely for authentication.

Step 2: Register and Connect IoT Devices

Go to Secure → Certificates in AWS IoT Core.

Upload the certificate generated during Thing creation.

Attach an IoT Policy that grants permissions for device connectivity.

Install the certificate and private key on your IoT device.

Use the MQTT protocol to connect your device using the provided endpoint.

Example Code (Python — MQTT Connection):pythonimport paho.mqtt.client as mqttclient = mqtt.Client() client.tls_set("path/to/AmazonRootCA1.pem", certfile="path/to/device-certificate.pem.crt", keyfile="path/to/private.pem.key") client.connect("your-iot-endpoint.amazonaws.com", 8883) client.publish("iot/topic", "Hello from IoT Device!")

Step 3: Create an IoT Rule for Data Routing

In AWS IoT Core, navigate to Act → Rules.

Click Create a rule and define the following:

Name: Provide a meaningful name.

SQL Statement: Use SQL-like syntax to filter data from specific MQTT topics.

Example Rule Statement:sqlSELECT temperature, humidity FROM 'iot/sensor/data' WHERE temperature > 30

Choose an Action, such as:

Sending data to Amazon S3 for storage.

Triggering AWS Lambda for real-time processing.

Publishing alerts to Amazon SNS for notifications.

Step 4: Implement Data Storage and Processing

Use Amazon DynamoDB to store structured IoT data for real-time queries.

Utilize AWS Lambda to process data and trigger automated actions.

Leverage Amazon Kinesis for real-time analytics and dashboards.

Step 5: Visualizing Data with Amazon QuickSight

In Amazon QuickSight, create a new dataset using data stored in Amazon S3 or DynamoDB.

Build interactive dashboards to track device performance, environmental conditions, or system health.

Use visual charts to analyze patterns, trends, and anomalies.

Step 6: Enhancing Security

Use AWS IoT Device Defender to monitor security threats.

Enable AWS IoT Policies to manage fine-grained permissions for each device.

Secure communication using TLS 1.2 encryption and X.509 certificates.

Step 7: Testing and Deployment

Simulate multiple devices to validate your application’s scalability.

Monitor data flow in AWS IoT Core’s Test console.

Deploy the application using AWS IoT Greengrass for edge computing scenarios.

Conclusion

Building a smart IoT application with AWS IoT Core empowers developers to connect devices securely, process data in real-time, and build scalable solutions. By integrating AWS services like Lambda, DynamoDB, and QuickSight, you can create powerful IoT applications that drive actionable insights.

WEBSITE: https://www.ficusoft.in/aws-training-in-chennai/

0 notes