#Additive manufacturing

Explore tagged Tumblr posts

Text

Nanomanufacturing process slashes chip production costs by 99%

The current microelectronics manufacturing method is expensive, slow and energy and resource intensive. But a Northeastern University professor has patented a new process and printer that not only can manufacture advanced electronics and chips more efficiently and cheaply, it can make them at the nanoscale. "I thought that there must be an easier way to do this, there must be a cheaper way to do this," says Ahmed A. Busnaina, the William Lincoln Smith professor and a distinguished university professor at Northeastern University. "We started, basically, with very simple physical chemistry with a very simple approach." Busnaina runs the National Science Foundation Center for High-rate Nanomanufacturing at Northeastern University.

Read more.

#Materials Science#Science#Manufacturing#Materials processing#Electronics#Northeastern University#Nanotechnology#Additive manufacturing#3D printing

31 notes

·

View notes

Text

Reload day

2 notes

·

View notes

Text

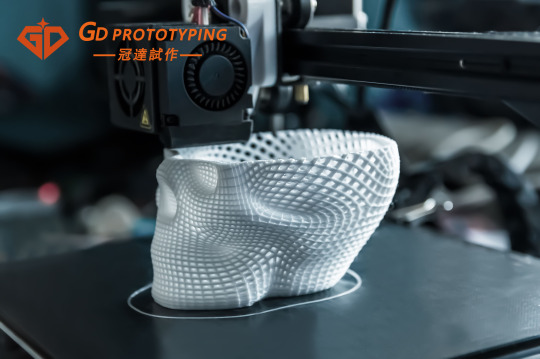

Top 8 Applications of 3D Printing in Medical Industry

3D printing technology, with its highly customizable, responsive and material-saving features, is triggering profound changes in the medical field. Especially in the application of medical models, 3D printing technology shows unparalleled advantages and potential.

Furthermore, 3D printing technology, as an emerging additive manufacturing technology, has made breakthroughs in its application in the medical field in recent years. The application of 3D printing technology in the medical field is becoming more and more widespread. Through the layer-by-layer stacking of digital models, a variety of medical devices, prosthetics, orthotics and other aids, and even human organs, can be accurately printed.

1.Surgical preview model

With 3D printing technology, doctors can create surgical preview models to help them simulate operations before surgery, improving accuracy and safety.

It is important for medical workers to conduct preoperative planning for risky and difficult procedures. In the previous surgical preview process, medical workers often need to obtain the patient's data through CT, magnetic resonance imaging (MRI) and other imaging equipment, and then the two-dimensional medical image using software to convert into realistic three-dimensional data. Today, medical workers can use devices such as 3D printers to print 3D models directly. In this way, it not only can assist the doctor to carry out accurate surgical planning, improve the success rate of surgery, but also to facilitate the communication and exchange between medical workers and patients on the surgical program plan.

2.Surgical guide

Surgical guides can help the surgeon to accurately position and operate during surgery, reducing surgical errors and improving surgical outcomes.

As an auxiliary surgical tool during surgery, surgical guides can help medical workers to accurately implement surgical programmes. Currently, the types of surgical guides have included joint guides, spinal guides, oral implant guides, etc. With the help of 3D printed surgical guides, firstly, the 3D scanning technology can produce three-dimensional data on the patient's affected area, which allows the doctor to obtain the most realistic information, so as to better plan the surgery. Secondly, while making up for the shortcomings of the traditional surgical guide manufacturing process, the size and shape of the guide can also be adjusted as needed.In this way, different patients can have a guide plate that meets their real needs.

3.Dental applications

3D printing technology is also widely used in the field of dentistry to print personalized trays, moulds, etc., to help patients have better dental treatment.

The application of 3D printing in the dental field mainly focuses on the design and production of metal teeth, invisible braces, etc. The emergence of cutting-edge technology of 3D printing creates more possibilities for those who need orthodontic treatment to achieve personalized and customized braces. At different stages of orthodontic treatment, orthodontists need different sets of braces. With the help of 3D printing to create multiple sets of braces needed for orthodontic treatment, it not only helps the healthy development of teeth, but also reduces the cost of braces production. The significance of these digital technologies is that they are gradually making it less necessary for doctors to make models, dentures, etc. by hand, and returning more of their efforts to the diagnosis of oral diseases and the performance of oral surgery itself.

4.Rehabilitation medical equipment

Through 3D printing technology, a variety of rehabilitation medical devices, such as prosthetics and orthotics, can be created to help patients regain function.

The real value of 3D printing for orthopaedic insoles, bionic hands, hearing aids and other rehabilitation devices is not only to achieve accurate customization, but also to allow accurate and efficient digital manufacturing technology to replace the traditional production methods, reducing the cost of individual customized rehabilitation medical devices and shortening the production cycle. 3D printing process is diversified, and there is a wide range of 3D printing materials. SLA light-curing 3D printing technology has the advantage of being able to provide the most efficient and cost-effective 3D printing technology. SLA light-curing 3D printing technology is widely used in rapid prototyping by the medical device industry due to its advantages of fast processing speed, high precision, good surface quality of photosensitive resin material moulding and moderate cost.

5.Medical Equipment Cases

3D printing technology can also be used to create a variety of medical devices, such as surgical instruments and medical equipment, to improve the personalization and accuracy of medical devices.

Take the example of 3D printing for mass customized production in the hearing aid shell industry. In the traditional way, injection moulds need to be made from a model of the patient's ear canal. The final shape of the hearing aid is obtained by drilling sound holes and manually processing the plastic product. If a mistake is made during the process, the mould needs to be recreated. The process of making a hearing aid using a 3D printer, on the other hand, begins with the design of a silicone mould or impression of the patient's ear canal, a step that is done using a 3D scanner. CAD software is then used to convert the scanned data into a design file that can be read by the 3D printer. The designer can then use the software to modify the 3D image and create the final product shape.

6.Precision replication and personalization

3D printing technology is able to accurately restore a patient's anatomy and produce full-size, high-fidelity medical models based on the patient's CT, MRI and other imaging data. These models not only have extremely high geometric accuracy and surface quality, but also reflect the unique physiological characteristics of the patient, providing doctors with real and reliable references.

7.Teaching and training

3D printed medical models also play an important role in medical education and training. By printing out models of various typical cases, medical students can perform practical operations in a simulated surgical environment to enhance their surgical skills and resilience. At the same time, these models can also be used as teaching tools to help students better understand human anatomy and disease principles.

8.Scientific research and experimentation

In the field of medical research, 3D printed medical models also have important applications. Researchers can use these models to conduct experimental studies such as drug screening and biomechanical testing to explore new treatment methods and technologies. In addition, by printing tissue or organ models with specific physiological functions, they can also provide strong support for research in cutting-edge fields such as organ transplantation and regenerative medicine.

In summary, 3D printing technology has a wide and far-reaching significance in the application of medical models. It not only improves the accuracy and efficiency of medical services, but also promotes the innovative development of medical education, research and clinical practice. With the continuous progress of technology and the expansion of application scope, we have reason to believe that 3D printing will play a more important role in the future medical field.

#3d printing#3d printing services#3d printed#additive manufacturing#3d print#medical device machining#medical 3d printing#3d printed parts#3d printing materials market#3d printing market share

4 notes

·

View notes

Text

Additive manufacturing for aerospace part.

Know more about additive manufacturing

#additive manufacturing#3d printing#aerospace#science#materials science and engineering#engineering#materials

6 notes

·

View notes

Text

The AU project leverages the benefits of additive manufacturing , (AM), computational design and the use of composite materials to drive innovation in the medical and healthcare sector. By integrating these advanced technologies, AU aims to:

Optimize pressure distribution and comfort using personalized pressure mapping data.

Reduce weight, product size, and part count, enhancing ergonomics and usability.

Ensure more effective cooling and breathability.

Extend product longevity, performance, and customizability.

Introduce cutting-edge aesthetics to help combat stigma.

Improve sustainability by prioritizing additive over traditional subtractive manufacturing processes.

For more information, get in touch or check out our submission: 🔗 Link

#industrialdesign#product#composites#design#designer#rapidprototyping#3dprinting#additive manufacturing#cushion#computationaldesign

2 notes

·

View notes

Text

Formnext is happening next week! 🌟 Curious about what to expect? Visit our Formnext Highlights Guide to warm up for the event.

4 notes

·

View notes

Text

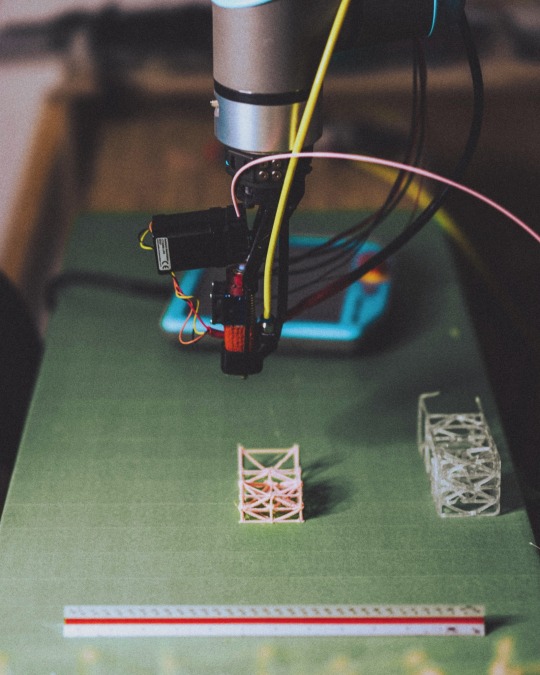

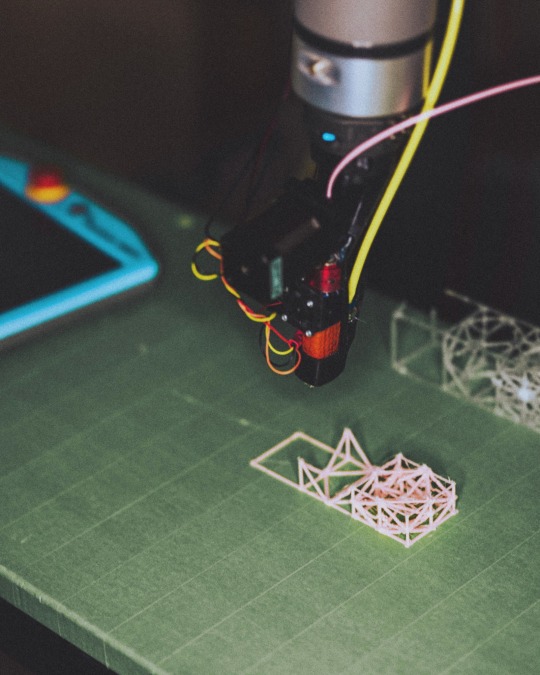

scene setup

#3d printing#digital fabrication#robotic fabrication#additive manufacturing#robots in architecture#3dprint

7 notes

·

View notes

Text

How Israeli Tech is Shaping the Future of Additive Manufacturing Worldwide

Overview of Israel’s Strategic Position in Additive Manufacturing

Israel has rapidly emerged as a global force in additive manufacturing (AM), fortified by a powerful high-tech ecosystem, robust government support, and a legacy of innovation in defense, aerospace, and medical technologies. With the Israel additive manufacturing market valued at USD 221.4 billion in 2024 and forecasted to exceed USD 280.3 billion by 2032, the nation is positioned to lead transformative advances in 3D printing technologies. The Israel additive manufacturing market compound annual growth rate (CAGR) of approximately 7% reflects both escalating domestic demand and global interest in Israeli AM innovation.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40589-israel-additive-manufacturing-market-research

Driving Forces of Growth in Israel's Additive Manufacturing Market

Innovation Across Key Industrial Verticals

Israel additive manufacturing market sector is evolving as a backbone for modernization in:

Aerospace and Defense: Lightweight components, complex geometries, and high-performance materials enable operational efficiency and reduced lead times.

Healthcare: Customized prosthetics, implants, bioprinting, and surgical models offer patient-centric care and improved clinical outcomes.

Automotive and Industrial Manufacturing: Rapid prototyping, tooling, and small-batch production optimize supply chains and cut production timelines.

These sectors benefit from the convergence of additive technologies with AI, machine learning, and advanced robotics, all core competencies of Israel's high-tech sector.

Rising Demand for Customization and Sustainability

The shift toward sustainable manufacturing and personalized solutions is fueling AM adoption. Israeli startups and research institutions are developing biocompatible, recyclable, and multi-material printing solutions that meet stringent regulatory and industry-specific standards.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40589-israel-additive-manufacturing-market-research

Technological Landscape of the Israeli Additive Manufacturing Ecosystem

Polymer-Based Additive Manufacturing

Valued at USD 306.31 million in 2024, this segment dominates due to its cost-effectiveness, versatility, and compatibility with lightweight, complex part production. With an expected CAGR of 17.3%, applications in consumer goods, automotive interiors, and medical devices continue to surge.

Metal-Based Additive Manufacturing

Growing at a robust 20.1% CAGR, metal AM is the cornerstone of defense and aerospace advancements. In 2024, it accounted for USD 180.86 million, projected to exceed USD 775.48 million by 2032. Israel’s focus on titanium, aluminum alloys, and nickel-based superalloys supports structural applications with high thermal and mechanical stability.

Hybrid Additive Manufacturing

By blending subtractive and additive processes, hybrid AM enhances surface finish and dimensional accuracy, critical in precision tooling, aerospace, and dental prosthetics. This segment is rapidly gaining traction due to its versatility and integration into smart manufacturing systems.

Segmental Breakdown of the Israel Additive Manufacturing Market

By Component

Hardware: Represents the largest share, valued at USD 1,137.28 million in 2024, supporting high-throughput production and industrial-scale fabrication.

Software: Fueled by AI-powered design, generative modeling, and process simulation, this segment is experiencing 19.9% CAGR, revolutionizing digital twin applications and real-time process monitoring.

Services: The on-demand printing ecosystem is expanding, empowering SMEs to access advanced AM capabilities with minimal capital expenditure.

By Deployment Model

In-House Manufacturing: With a Israel additive manufacturing market valuation of USD 317.09 million in 2024, large enterprises prefer internal AM operations for confidentiality and operational control.

Service-Based Models: Growing at 19.4% CAGR, third-party service bureaus are crucial in democratizing access to advanced AM technologies for startups and research institutions.

By Functionality

Prototyping: Dominates with USD 340.60 million in 2024, essential for R&D, iterative design, and proof-of-concept validation.

Production: The rising shift to end-use part manufacturing is catalyzing growth in this segment, valued at USD 197.73 million in 2024.

Tooling: Customized, high-durability tooling supports faster transitions from design to production across various industrial sectors.

By Printer Size

Small/Compact Printers: Most accessible and dominant segment, valued at USD 253.09 million in 2024, ideal for labs, healthcare, and educational institutions.

Medium and Large Printers: Increasingly adopted in industrial manufacturing, these enable batch production and larger component fabrication.

End-Use Industries Driving Adoption

Aerospace & Defense

USD 159.32 million in 2024, this sector prioritizes weight reduction, material performance, and supply chain agility. With Israel’s defense sector being R&D intensive, 3D printing significantly enhances manufacturing autonomy and mission-readiness.

Healthcare & Medical

USD 131.40 million in 2024, growing due to demand for patient-specific devices, bioprinted tissues, and anatomical models. With innovations in regenerative medicine, Israel is at the forefront of personalized healthcare.

Industrial & Automotive

Israel’s industrial ecosystem leverages AM for lightweighting, thermal management, and low-volume production, especially in EV components and robotics enclosures.

Strategic Movements and Competitive Intelligence

Leading Israel Additive Manufacturing Market Participants

Stratasys: A global pioneer, deeply rooted in Israel, with continuous development in multi-material, high-resolution systems.

XJet: Revolutionizing ceramic and metal printing with NanoParticle Jetting™ technology.

Nano Dimension: Innovator in multi-layer electronics and PCB printing, driving miniaturization and functional integration.

Recent Developments

XJet (June 2024): Launched new ceramic printers with applications in automotive and aerospace, enhancing resolution and mechanical strength.

Nano Dimension (Sept 2024): Acquired startups to advance multi-material electronics printing, expanding their capabilities in embedded sensor systems.

Challenges and Strategic Opportunities

Major Israel Additive Manufacturing Market Challenges

Capital Intensity: High upfront costs limit adoption, especially among SMEs.

Talent Gap: Scarcity of AM-trained professionals hampers rapid scaling.

Scaling Complexity: Transitioning from prototype to full production requires new QA methodologies and workflow optimization.

Strategic Israel Additive Manufacturing Market Opportunities

Workforce Development: Partnerships with universities and technical institutes to offer AM-centric curricula.

Material Innovation Hubs: Support from government and private sectors to develop high-strength composites, bioresorbable materials, and nanostructured alloys.

Sustainability Mandates: Incentives for closed-loop manufacturing systems, energy-efficient printers, and recyclable materials.

Future Outlook: Israel’s Role in Global Additive Manufacturing Leadership

Israel is poised to lead the next frontier of digital manufacturing, where data-driven fabrication, machine learning-enhanced design, and autonomous production lines define industry 4.0. With unmatched cross-sector collaboration between startups, research centers, and government agencies, the nation’s AM sector is evolving from rapid prototyping to full-fledged production infrastructure.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40589-israel-additive-manufacturing-market-research

Conclusion

Israel additive manufacturing market is entering a golden era, driven by its technological prowess, strategic policy initiatives, and vibrant innovation culture. As the global demand for agile, sustainable, and customized manufacturing solutions intensifies, Israel is uniquely equipped to lead the charge. Enterprises, investors, and policy makers must align to fully harness this momentum and establish Israel as a global additive manufacturing powerhouse.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#Israel#Additive Manufacturing#3D Printing#Israeli Tech#Advanced Manufacturing#Industrial 3D Printing#Aerospace#Medical Devices#Defense Technology#Innovation#Startups#Tel Aviv#Prototyping#Manufacturing Industry#AM Materials#Digital Manufacturing#Smart Manufacturing#High-Tech Industry#Metal 3D Printing#Polymer Printing#R&D#Technology Trends#Engineering#Robotics#Supply Chain#Product Development

1 note

·

View note

Text

2 notes

·

View notes

Text

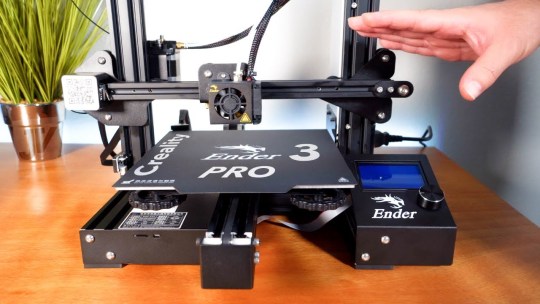

Mastering the Art of 3D Printing with Ender 3 Pro: Tackling Print Bed Adhesion Woes

So you got an Ender 3 pro? and you are having issues Embarking on a journey into the world of 3D printing can be an exciting yet challenging endeavour, especially when faced with print bed adhesion issues. If you find yourself grappling with stubborn prints sticking a bit too well, fear not. In this guide, we will delve into the nuances of optimizing your Ender 3 Pro, addressing common…

View On WordPress

4 notes

·

View notes

Text

From roots to rugged circuits: Tree-inspired printing tech for flexible electronics

A printing technology, inspired by the resilience of tree root systems, is set to redefine the future of conformal electronics. This innovation addresses long-standing challenges related to the mechanical stability and resolution of circuits on irregular surfaces, particularly in smart robotics and advanced sensing systems. By improving both the durability and precision of electronic circuits, this new method promises to withstand extreme conditions—such as high temperatures and mechanical stress—thereby vastly expanding the potential applications and reliability of conformal electronics. Conformal electronics, which are crucial for applications like smart skins and robotics, have long struggled with significant mechanical and thermal vulnerabilities. Traditional printing methods often produce circuits that are prone to tearing, cracking, and other forms of damage, limiting their performance and dependability.

Read more.

#Materials Science#Science#Electronics#Flexible electronics#Circuits#Strength of materials#Biomimicry#Additive manufacturing

22 notes

·

View notes

Text

Il progetto europeo MIMOSA sviluppa giunzioni 3D tra metalli AM e carbon-fiber per velivoli più leggeri e riciclabili. Protagonisti TÜV Italia e Bytest, eccellenze nei test e nella certificazione. Scopri i risultati su Alessandria today.

#additive manufacturing#aeronautica sostenibile#aerostrutture#Alessandria today#atomizzazione#Bytest#certificazione aeronautica#certificazione processi#compositi carbonio#distretto aerospaziale Piemonte#eco-design#Economia circolare#Fenice#fibre di carbonio#Giorgio De Pasquale#giunzioni ibride#Google News#green aviation#Horizon Europe#innovazione materiali#italianewsmedia.com#laboratorio Volpiano#Lava#Leonardo#life-cycle assessment#lightweight structures#NDT#Pier Carlo#POLITECNICO DI TORINO#progetto MIMOSA

0 notes

Text

Bring Your Packaging Concepts to Life – One Print at a Time with Stratasys J55 Prime!

Why imagine when you can prototype ultra-realistic packaging — faster, affordable and more creatively than ever before? With Stratasys PolyJet 3D Printing, you can: ✅ Create stunning, full-color prototypes ✅ Showcase realistic textures & finishes ✅ Speed up design approvals ✅ Reduce prototyping costs significantly 💡 From cosmetic bottles to complex packaging designs, the J55 Prime makes it easy!

#altem#3d printing#additive manufacturing#stratasys#3dprinter#3d printing bangalore#packaging design#polyjet packaging

0 notes

Text

Engine Component Manufacturing and New Machining Services: Precision for Modern Performance

A high-performance vehicle, aircraft, or industrial machine starts with its engine components. The evolution of engine component manufacturing has been driven by the need for tighter tolerances, improved materials, and higher durability. Today, the industry is embracing new machining services to meet growing demands for speed, precision, and efficiency. CNC machining and additive manufacturing are among the new technologies changing how we produce engine parts. This blog explores SYRONTECH's key aspects of engine component manufacturing and the latest machining services that are shaping the future.

The Importance of Engine Component Manufacturing

Pistons, crankshafts, cylinder heads and valves all face harsh pressures and temperatures when they are in use. Building modern engines relies on very strong valves, do not wear easily and are perfectly matched. They are made using set tools, require top-quality resources and are overseen by strong quality control measures. Machining mistakes as small as a few microns may result in failure or a loss of efficiency for engines. For this reason, precision must be included, not just chosen at will. The individual quality of each component helps to determine the engine’s overall performance.

Materials Used in Engine Components

Modern engineers use different advanced materials to build engine parts. Aluminum alloys are often used because they are lightweight and are found in car engines. Both steel and cast iron are popular for their good strength and ability to resist wear in tough engines. Heat resistance and low weight have made it possible for titanium and ceramic composites to find use in aerospace engine construction. Every material needs unique work methods, its tools, and special cooling during machining. It is important to use the right material for the engine’s better performance.

Traditional vs. Modern Machining Techniques

For decades, turning, milling, grinding and drilling have been common ways to make parts for engines. They get the job done, yet they take longer and are not suited for complex shapes. New Machining Services now use CNC (Computer Numerical Control) machines for higher precision and repeatability. CNC systems automate the cutting process based on digital models, reducing errors and production time. Multi-axis CNC machines can create intricate shapes that were once impossible to achieve. These new methods are faster, more efficient, and ideal for complex engine designs.

CNC Machining in Engine Component Production

CNC machining is revolutionizing the manufacturing of engine components. It allows manufacturers to produce complex parts with high accuracy and tight tolerances. With 3-axis, 4-axis, and 5-axis capabilities, CNC machines can perform multiple operations in a single setup. This improves consistency and reduces material waste. For example, CNC milling can produce cylinder heads with intricate cooling channels, while CNC turning can precisely shape crankshafts and camshafts. The use of CAD/CAM software enhances the design and simulation process before production begins.

Additive Manufacturing for Prototyping and Small Batches

Additive manufacturing, or 3D printing, is gaining popularity in engine component development. It’s ideal for prototyping and producing small batches quickly without the need for custom tooling. Engineers can test different designs before mass production, reducing time and cost. For example, metal 3D printing is used to create turbocharger components and heat exchangers with complex internal structures. Although not yet common for mass production, additive manufacturing is valuable for innovation and design flexibility in engine development.

Surface Finishing and Coating Technologies

Surface finishing is crucial to engine component performance. After machining, parts often require polishing, honing, or coating to improve durability and efficiency. Surface treatments like nitriding, chrome plating, or ceramic coatings enhance hardness, reduce friction, and resist corrosion. These processes are especially important for moving parts like pistons and valve stems. Automated finishing systems ensure uniformity and reduce the risk of human error. The right finishing technique extends the lifespan of engine components and supports reliable engine operation.

Conclusion

The future of engine component manufacturing lies in precision, speed, and innovation. New machining services like CNC, additive manufacturing, and automation are enabling the production of smarter, stronger, and more efficient engine parts. Material science and surface finishing techniques are also evolving to meet modern performance demands. Whether in automotive, aerospace, or industrial sectors, these advancements are helping engineers push the boundaries of engine design. For companies like SYRONTECH, investing in next-generation machining services, the road ahead is full of opportunity and growth.

#Engine component manufacturing#CNC machining#additive manufacturing#3D printing#surface finishing#SYRONTECH#engine parts#precision machining#aerospace engine components#automotive engine parts.

1 note

·

View note

Text

1 note

·

View note

Text

Some photos from the printing process

9 notes

·

View notes