#Graphite Electrode

Text

Affected by supply and demand, the price of graphite electrodes continues to rise

At present, the price of graphite electrodes continues to rise, mainly due to high costs and low profits. Graphite electrode companies are highly motivated to increase prices. In addition, the supply side of the current graphite electrode market is shrinking, and some companies are still reducing production and controlling production. Therefore, driven by supply and cost, graphite electrode companies have increased their prices.

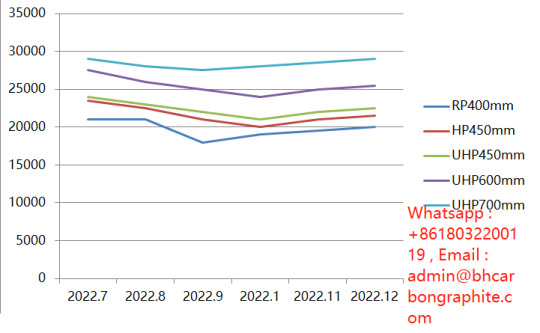

Graphite Electrode price trend

Recently, the price of graphite electrodes in China has increased by 1000/ton. As of December 2022, the mainstream price of graphite electrodes in China (diameter 300mm-600mm): RP 21500-23500 yuan/ton; HP 22000-24500 yuan/ton; UHP 23500-28000 yuan/ton; UHP 700mm is 30500-31500 yuan/ton. However, due to poor demand from steel mills, no transactions have been made after the price adjustment. The specific analysis is as follows:

1. With the price of graphite electrodes currently low and profits insufficient, businesses hope prices will rise.

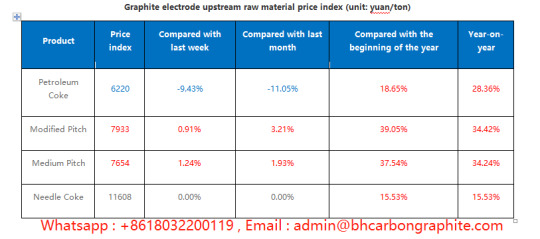

At present, the raw material price of graphite electrodes is 6230 yuan/ton, down 9.42% from last week. However, The graphite electrode industry has a long production cycle and price declines tend not to have an immediate impact. The production cost for a graphite electrode is about 20,000-21,000 yuan/ton. Graphite electrode prices are not high enough currently, the market is on a rebound and graphite electrode companies haven't been able to reverse their losses.

2. Graphite electrodes have low productivity. The industry has priced them higher than normal due to the lack of supply.

It is understood that the overall operating rate of the graphite electrode market is still insufficient. At the end of December, the overall operating rate was less than 40%. On the one hand, due to the impact of the epidemic in some areas, there is a shortage of labor force, increasing labor costs; on the other hand, as the end of the year approaches, the production of some enterprises is also restricted. Affected by environmental protection supervision, the production of graphite electrodes in Handan, Hebei is limited.

Recommend a high-quality manufacturer of graphite electrodes:https://www.bhcarbongraphite.com/

3. Demand is reduced, and graphite electrode companies are under greater pressure.

Export: According to foreign trade salesmen, compared with last year, the export orders of graphite electrodes have decreased significantly this year, and there is pessimism about the market.

In terms of steelmaking plants: Electric furnace steelmaking plants are losing money, operating less, and the demand for graphite electrodes is relatively small. Long-process steel mills mainly purchase on demand. The rise in the price of graphite electrodes may stimulate steel mills to replenish their stocks, thereby easing the pressure on graphite electrode companies.

2023 Market Forecast

At present, the operating rate of graphite electrode enterprises is insufficient, the cost is high, and the demand in the downstream market is weak. Therefore, graphite electrode enterprises want to push up prices and reverse losses. However, due to the impact of downstream demand, there is still no significant improvement. After the price rises, there is no order volume.

Therefore, I predict that after the Lunar New Year, all walks of life will resume work and production one after another, the demand and supply will increase significantly, and the price of graphite electrodes will develop steadily and positively.

That's all, welcome to communicate with us.

2 notes

·

View notes

Text

High-Performance Graphite Electrodes for Industrial Efficiency

Optimize your industrial processes with high-performance graphite electrodes from Orient Carbon & Graphite Co., Ltd. These electrodes are designed to provide exceptional conductivity and durability, making them ideal for use in steel making, electric arc furnaces, and other high-temperature applications. With a commitment to quality and innovation, Orient Carbon & Graphite ensures their products meet the stringent requirements of modern industries. Visit the link to explore their range of graphite electrodes and enhance your operational efficiency.

0 notes

Text

A Professional Manufacturer of Graphite Petroleum Coke (GPC). Super quality with competitive price.

0 notes

Text

Transforming Steel Making with Graphite Electrodes

Hey there! Have you ever wondered about the steel-making process and the technology behind it? Well, I have some exciting news to share with you - the steel production industry has undergone a significant transformation with the advent of graphite electrodes.

Gone are the days of using traditional carbon electrodes in electric arc furnaces. Graphite electrodes, made from high-purity graphite, have now taken the stage. With their uniform density and porosity, and their key properties such as high thermal stability, low electrical resistance, and chemical resistance, it's no wonder they've become the preferred choice for high-temperature industrial processes.

The use of graphite electrodes has brought numerous benefits to the steel production process. For starters, they allow for higher current densities, leading to increased productivity and reduced energy consumption. And, with a longer lifespan compared to traditional carbon electrodes, they reduce maintenance costs and increase production uptime.

But wait, there's more! The use of graphite electrodes also has a positive impact on our environment. They emit fewer harmful gases and particulates, making the steel production process more eco-friendly.

In conclusion, the switch to graphite electrodes in the steel production industry has revolutionized the process, making it more efficient, reliable, and environmentally responsible. And as technology continues to advance, it's safe to say that graphite electrodes will continue to play a pivotal role in shaping the future of the steel-making industry.

0 notes

Text

0 notes

Text

Graphite Electrodes Market 2024-2031: Powering Industrial Innovation

The graphite electrodes market is set to experience significant growth and transformation from 2024 to 2031, driven by the increasing demand for high-quality electrodes across various industries. Graphite electrodes, essential components in electric arc furnaces, play a critical role in the production of steel, aluminum, and other metals, making them indispensable in modern industrial processes.

Graphite electrodes are conductive materials used in electric arc furnaces for melting and refining steel and other metals. These electrodes exhibit high thermal and electrical conductivity, making them ideal for extreme temperature environments encountered in metal smelting and refining processes.

Get Your Sample Now - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=23711

The graphite electrodes market is projected to witness robust growth during the forecast period, fueled by factors such as growing industrialization, infrastructure development, and advancements in manufacturing technologies. The market’s expansion is also driven by the increasing demand for steel and aluminum in the construction, automotive, and aerospace industries.

Market Segmentation:

By Service Type: Ultra-High Power (UHP), High Power (HP), Regular Power (RP).

By Sourcing Type: Petroleum Coke, Needle Coke.

By Application: Steel Manufacturing, Non-Ferrous Metals, Silicon Metal Production, Others.

By Industry Vertical: Steel, Aluminum, Automotive, Aerospace, Construction, Others.

By Region: North America, Europe, Asia Pacific, Latin America, Middle East & Africa.

Regional Analysis:

North America: Dominated by the steel industry, driving demand for graphite electrodes in electric arc furnace operations.

Europe: Strong presence of automotive and aerospace industries, fostering demand for graphite electrodes in metal production and fabrication processes.

Asia Pacific: Witnessing rapid industrialization and infrastructure development, fueling demand for steel and aluminum production, driving market growth.

Market Drivers and Challenges:

Drivers:

Growing Demand for Steel and Aluminum in Construction and Manufacturing Sectors

Technological Advancements in Graphite Electrode Manufacturing Processes

Increasing Use of Electric Arc Furnaces in Metal Recycling and Secondary Steel Production

Challenges:

Volatility in Raw Material Prices, Particularly Needle Coke

Environmental and Regulatory Concerns Regarding Emission Controls in Metal Production

Competition from Alternative Metal Smelting Technologies

Market Trends:

Development of Ultra-High Power Graphite Electrodes for Enhanced Performance and Efficiency

Integration of Digitalization and Automation in Electric Arc Furnace Operations for Improved Productivity

Adoption of Sustainable Sourcing Practices and Recycling Initiatives for Needle Coke

Future Outlook:

The future of the graphite electrodes market looks promising, driven by the increasing demand for steel and aluminum in various end-use industries and the continuous evolution of manufacturing processes. As industries strive for efficiency, sustainability, and cost-effectiveness, graphite electrodes will remain vital components in metal production and fabrication processes.

Key Market Study Points:

Analysis of Technological Innovations and Their Impact on Electrode Performance and Durability

Assessment of Regulatory Landscape and Its Influence on Market Dynamics

Identification of Emerging Applications and Growth Opportunities in Key End-Use Industries

Evaluation of Supply Chain Dynamics and Raw Material Sourcing Strategies

Gain valuable insights into the Graphite Electrodes Market with our comprehensive research report - https://www.transparencymarketresearch.com/checkout.php?rep_id=23711<ype=S

Competitive Landscape:

The graphite electrodes market is characterized by intense competition, with key players focusing on product innovation, research and development, and strategic partnerships to gain a competitive edge. Major companies in the market include Showa Denko K.K., Graphite India Limited, Tokai Carbon Co., Ltd., HEG Limited, and GrafTech International Ltd.

Recent Developments:

Introduction of Advanced Graphite Electrode Grades for Specific Applications and Operating Conditions

Investment in Research and Development to Develop Sustainable and Environmentally Friendly Electrode Manufacturing Processes

Strategic Collaborations and Partnerships to Expand Market Presence and Product Portfolio

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

A new fullertube molecule is found - Technology Org

New Post has been published on https://thedigitalinsider.com/a-new-fullertube-molecule-is-found-technology-org/

A new fullertube molecule is found - Technology Org

For years, C130 fullertubes—molecules made up of 130 carbon atoms—have existed only in theory. Now, leading an international team of scientists, an UdeM doctoral student in physics has successfully shown them in real life – and even managed to capture some in a photograph.

Illustration of the discovery of the C130-D5h molecule, published on the cover page of the prestigious “Journal of the American Chemical Society” last December. Image credit: JACS

This feat in the realm of basic research has led Emmanuel Bourret to have a cover-page illustration of his discovery in a prestigious scientific journal, the Journal of the American Chemical Society.

First published online last October, Bourret made the discovery as the lead scientist of an inter-university team that also included researchers from Purdue University, Virginia Tech, and the Oak Ridge National Laboratory in Tennessee.

A fullertube is basically an assembly of carbon atoms arranged to form a closed tubular cage. It is related to fullerenes, molecules that are represented as cages of interconnected hexagons and pentagons, and come in a wide variety of sizes and shapes.

For example, a C60 fullerene is made up of 60 carbon atoms and is shaped like a soccer ball. It is relatively small, spherical and very abundant. C120 fullerenes are less common. They are longer and shaped like a tube capped at either ends with the two halves of a C60 fullerene.

Found in soot

The C130 fullertube (or C130-D5h, its full scientific name) is more elongated than the C120 and even rarer. To isolate it, Bourret and his team generated an electric arc between two graphite electrodes to produce soot containing fullerene and fullertube molecules. The electronic structure of these molecules was then calculated using density functional theory (DFT).

“Drawing on principles of quantum mechanics, DFT enables us to calculate electronic structures and predict the properties of a molecule using the fundamental rules of physics,” explained Bourret’s thesis supervisor, UdeM physics professor Michel Côté, a researcher at the university’s Institut Courtois.

Using special software, Bourret was able to describe the structure of the C130 molecule: it is a tube with two hemispheres at the ends, making it look like a microscopic capsule. It measures just under 2 nanometres long by 1 nm wide (a nanometre is one billionth of a metre).

“The structure of the tube is basically made up of atoms arranged in hexagons,” said Bourret. “At the two ends, these hexagons are linked by pentagons, giving them their rounded shape.”

Bourret began doing theoretical work on fullertubes in 2014 under his then-supervisor Jiri Patera, an UdeM mathematics professor. After Patera passed away in January 2022, Bourret then approached Côté, who became his new supervisor.

Existence shown in 2020

Two years before that, Bourret had read an article by Purdue University at Fort Wayne professor Steven Stevenson, who described the experimental isolation of certain fullertubes, demonstrating their existence but not identifying all of them.

One of the C130 fullertubes brought to light by Emmanuel Bourret. Image credit: JACS

Under Côté’s guidance, Bourret set to work advancing knowledge on the topic.

“Emmanuel had a strong background in abstract mathematics,” Bourret recalled, “and he added an interesting dimension to my research group, which focuses on more computational approaches.”

Are any possible future applications in the offing?

“It’s hard to say at this stage, but one possibility might be hydrogen production,” said Côté. Currently, a catalyst made of platinum and rubidium, both of which are rare and expensive, is used. Replacing them with carbon structures such as C130 would make it possible to produce hydrogen in a ‘greener’ way.”

Last year, Bourret’s groundbreaking work earned him an invitation to deliver a paper at the annual meeting of the U.S. Electrochemical Society (ECS), in Boston. This May, he’ll chair a panel on fullerenes and fullertubes at the ECS annual meeting in San Francisco.

Source: University of Montreal

You can offer your link to a page which is relevant to the topic of this post.

#2022#applications#arc#Article#atoms#background#Capture#carbon#carbon atoms#catalyst#chemical#december#electrochemical#electrodes#electronic#experimental#Explained#form#Full#fullerene#Fundamental#Fundamental physics news#Future#Giving#graphite#hydrogen#hydrogen production#illustration#international team#it

0 notes

Text

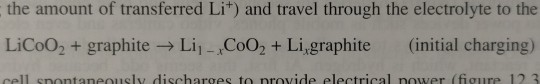

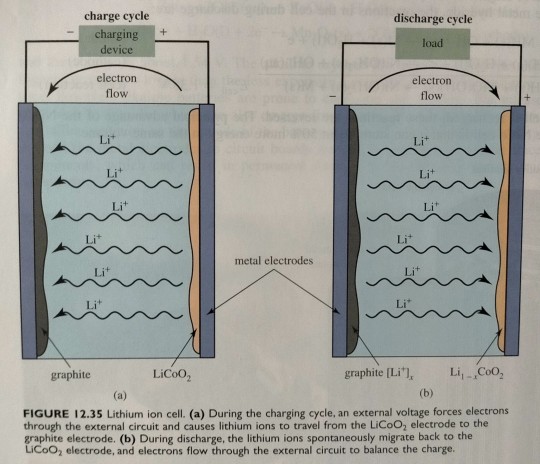

When the cell is being charged (figure 12.35a), Li+ ions leave LiCoO2 (with x being the amount of transferred Li+) and travel through the electrolyte to the graphite:

When the cell spontaneously discharges to provide electrical power (figure 12.35b), Li+ ions move back through the electrolyte to the cobalt oxide, while the electrons move through the external circuit from the graphite electrode (anode) to the cobalt oxide electrode (cathode).

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#lithium ion batteries#lithium#graphite#cobalt oxide#cobalt#electrode#electrolyte

1 note

·

View note

Link

#adroit market research#vanadium redox flow batteries#vanadium redox battery market#vanadium redox batteries#graphite felt electrode

0 notes

Text

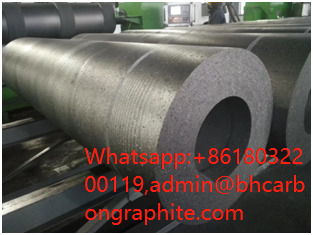

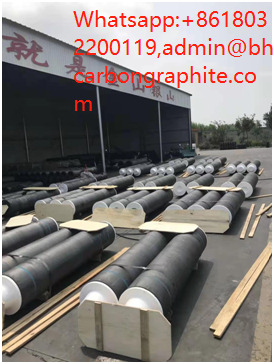

Definition and characteristics of graphite electrode

Definition: Graphite electrodes are mainly made of petroleum coke and needle coke, coal tar pitch is used as a binder, and are made by calcination, batching, kneading, pressing, roasting, graphitization, and machining. The conductor that releases electric energy to heat and melts the charge can be divided into ordinary power graphite electrode, high power graphite electrode, and ultra-high power graphite electrode according to its quality index.

In general, carbon is created by carbonizing mixed coke substances with a binding pitch at 1,000°C in a baking furnace. When this carbon is graphitized in an electric furnace at 3,000°C, the formless carbon body takes on the structure of crystalline graphite. This is called graphite. Carbon materials are generally pitch saturate and re-baked to enhance electrical and mechanical properties before graphitization.

Graphite electrode characteristics:

• High-temperature resistance.

• Good thermal and electrical conductivity.

• Low thermal expansion.

• Good machinability.

• Good chemical resistance.

• Corrosion resistant, longer life than most metal electrodes.

•Compared with the traditional 50hz ground electrode, the resistivity is small and very suitable for high-frequency current.

These days Graphite Electrodes can be used in many ways in our daily life. Graphite Electrode is a very significant object that is employed in the electric curve heater for steel making, for its luminous electrical conductivity and extraordinary anti-thermal shock capability. As a conductor, graphite electrodes are mainly used in electric arc furnaces to release electric energy in the form of arcs to heat and melt the charge. These features make Graphite Electrodes the most appropriate material to melt scraps, DRI, etc. by arc energy.

That's all, welcome to communicate with us.

Our company produces Recarburizer , Graphite Electrode , Premelting-Refining Slag ,Please contact us if necessary ,Whatsapp:+8618032200119, e-mail : [email protected]

0 notes

Text

Premium Graphite Electrodes for Exceptional Performance

Experience exceptional performance with graphite electrodes from Orient Carbon & Graphite. Our graphite electrodes are manufactured using advanced techniques and high-quality materials to deliver superior conductivity, durability, and consistency. Whether for electric arc furnaces or other industrial applications, our electrodes are meticulously crafted to meet the highest standards of quality and reliability. Choose Orient Carbon & Graphite for premium graphite electrodes that ensure optimal performance and longevity in your operations.

0 notes

Text

Graphite electrode

Tuonai is a professional manufacturer of graphite products in Hebei Province. Our company mainly engaged in the production, R&D and sales of graphite products, with advanced production lines, testing rooms (product content detection), which form an advanced equipment, perfect procedures of complete graphite product R&D and testing system. The annual production capacity of carbon powder and various graphite products is about 30,000 tons.

power graphite electrodes are essential components used in electric arc furnace (EAF) steelmaking and other metallurgical processes. These electrodes are designed to withstand high temperatures and electrical currents, making them suitable for applications requiring high power input. High power graphite electrodes play a crucial role in the steelmaking process by facilitating the generation of electric arcs and enabling the transfer of electrical energy to the raw materials, thus contributing to the efficient melting and refining of steel. Their superior thermal and electrical conductivity properties, coupled with excellent mechanical strength, make them indispensable for modern steel production. As a result, they are widely utilized in the steel industry and are critical for achieving high productivity and cost efficiency in steelmaking operations.

1 note

·

View note

Text

Reform Industries with Carbon Electrodes - Meet Orient Carbon, Your Trusted Graphite Electrode Supplier

In today's rapidly advancing world, the demand for efficient and sustainable energy solutions has never been greater. Carbon electrodes play a pivotal role in powering various industries, from steel and aluminum production to electric arc furnaces and more. Orient Carbon, a leading graphite electrode supplier, is at the forefront of this revolution, providing top-notch carbon products to meet diverse industrial needs.

Unleashing the Power of Carbon Electrodes

Carbon electrodes are a critical component in electrical systems, known for their exceptional conductivity and durability. These electrodes are widely used in electric arc furnaces, where they facilitate the melting of metals through high-temperature reactions. Orient Carbon's graphite electrodes are manufactured using cutting-edge technology, ensuring optimal performance, and helping industries achieve higher energy efficiency.

Sustainable Solutions for a Greener Future

As industries worldwide shift towards sustainable practices, Orient Carbon takes pride in delivering eco-friendly graphite electrodes. These electrodes have a longer lifespan, reducing the frequency of replacements and minimizing waste. Additionally, Orient Carbon's commitment to environmentally conscious production processes lowers their carbon footprint significantly.

Empowering the Steel and Aluminum Industries

The steel and aluminum sectors heavily rely on carbon electrodes to transform raw materials into essential end products. Orient Carbon's graphite electrodes ensure stable and efficient operations, resulting in cost savings and enhanced productivity for steel and aluminum manufacturers. The consistent quality of Orient Carbon's electrodes guarantees optimal performance in demanding environments, leading to smooth production processes.

Choose Orient Carbon for Reliable Graphite Electrodes

When it comes to superior carbon electrodes, Orient Carbon stands out as a trusted supplier. Their commitment to innovation, sustainability, and customer-centricity has made them a preferred choice in the industry. So, whether you're powering steel production or driving advancements in aluminum manufacturing, Orient Carbon has the perfect carbon electrode solution for you. Embrace the power of Orient Carbon's graphite electrodes and be a part of a greener and more efficient future.

0 notes

Text

Best machining graphite company in India

Who We Are

EXPO is a global leader in manufacturing Graphite products and machining. We create our products using globally acclaimed manufacturing techniques and provide excellent service while trading with our industry. We have completed more than two decades in the market in machining Graphite and specialize in producing EDM electrodes and Customized Graphite products.

We Do -

Fabricate Insulation Boards as per your Furnace needs

Let us take your job of creating insulation board as per your furnace requirement and resulting in increase in efficiency and further cost reduction.

Machining Graphite

Carbon is an element that can form into several different allotropes including graphite, diamond, and fullerite. Graphite is the most steady type of carbon and is the most well-known, as carbon naturally occurs as graphite under standard conditions. Graphite is generally known for its better conductivity and resistance for high heat and corrosion. This makes it a typical material in high heat, high-pressure circumstances in the aerospace, electrode, nuclear, energy, and military industries. Despite the fact that graphite can deal with extreme high-pressure circumstances effortlessly, it is really an exceptionally delicate, rough, and fragile material.

Graphite is ordinarily utilized in the Electrical Discharge Machining (EDM) industry. It can prove tricky to machine, particularly for EDM electrodes that require outstanding accuracy and structural consistency.

Graphite Machining has the remarkable capacity to meet the carbon and graphite needs from unrefined substances through filtration and accurately machined parts. EDM Electrodes can have small ribs and elements which require small dai cutters and tools , and graphite is commonly machined without coolant and at high velocities. This makes the ideal machining focus one with high spindle speeds and ideal residue extraction system.

Graphite Machining Techniques -

As far as machine arrangement, the one significant tip to recollect is to consistently try not to utilize coolant. Graphite is a genuinely permeable material, thus it can ingest coolant and go about as a "coolant wipe," which will cause issues with finished parts. Inside the machine and on the tooling, the coolant can really respond with the graphite dust and make a grating slurry, which will cause issues while machining. A vacuum framework or dust collector is suggested for clearing material while machining graphite. Any other way, covered apparatuses ought to have the option to run dry.

Something else to note while machining graphite is that since graphite doesn't deliver chips, but instead a haze of extremely grating dust, it tends to be destructive to operators and machines without legitimate consideration. Operators ought to be wearing a protective mask to try not to breathe in the graphite dust. Appropriate ventilation and keeping up with air quality in the shop is likewise key for the security of engineers when working in graphite.

Since the graphite dust is likewise incredibly conductive, it can undoubtedly harm non-defensive circuits inside your CNC machine, which can cause major electrical issues. While coolant isn't suggested, a vacuum framework can assist in removing the dust, holding it back from aggregating a lot inside the machine and preventing major issues

#EDM Graphite Electrodes Manufacturer and Supplier#*EDM Graphite Electrode Suppliers#Top Graphite Product Manufacturers & Dealers#Best EDM Graphite supplier near me

0 notes