#Gravure Printing Machine

Explore tagged Tumblr posts

Text

Elevate Your Production Standards with UV Graphic’s Expertise

Machines that cure are crucial for fast, effective hardening or drying of different materials such as inks, coatings, adhesives in various industries. Such machines cure by applying heat, UV, or other forms of energy so that they assure durability with high finish quality. These machines find extensive applications in industries printing, packaging, automobiles, and electronics.

UV Graphics-the supreme manufacturer of curing machines, produces the avant-garde products matching the expectations of the modern-day industries. The curing machines-a perfect example of precision and speed; even energy efficiency is guaranteed, every time-one can expect flawless output under flexible variable conditions. Some of the features include adjustable intensity of curing, automated controls, and adaptability to various substrates that truly define invaluable wealth to any production line.

Choosing UV Graphic means an acquisition of sophistication in technology, which is further strengthened by unmatchable support for any kind of business. It is because of innovation and quality that UV Graphic endeavors toward simplifying processes within an organization while excelling at achieving high achievements. From equipment to machines based on UV curing or rather on thermal curing systems, realize your modern machines of performance, reliability, and trusted partnership in the manufacturing sector.

#uv curing systems#curing machine manufacturer#rotary hot foil stamping#flexo printing machines manufacturer#gravure printing machines manufacturer#label punching machines manufacturer

0 notes

Text

SO.

Here we go again.

This fucking wallpaper saga must come to an end sometime, soon, surely???

I had all but decided on my wallpaper. I had one I was about ready to pull the trigger on and then the Wallet Incident happened. I am denied and THEN when I go to the website to purchase...

A nice pattern is released which I liked a lot.

I see this new wallpaper and say "I really like this. But I will still be cautious and buy the sample.~"

I wait patiently for it to arrive, unwrap it and.

They changed the printing process. I go to the website, and they say "hiiiiiii we are becoming more EcoFRIENDLY!!! [maybe so...I remain SUS] and doing away with the block printing process and now everything is inkjet printed uwu"

And it sucks. At least compared to the others, in my insufferably snobbish opinion.

The nice dimensional quality that you get with actual layers of paint on the paper is gone. When you are close you can see the hazy look caused by the machine printing.

AND even the patterns I got before are now going to be machine printed! I have now no choice but to return to square fucking one.

fortunately buddy found a good starting point for me, I looked at some alternatives and decided that this company looked like it would be good. They offer some screen prints and some gravure printed. Since this involves the application of ink/paint in layers I have hopes this will look how I want.

Samples arrives yesterday and it DOES.

I'm really into this black one.

One of the issues I was having deciding before was that I have colored bedding and a green dresser that I didn't want to blend into the wall with a near match, or to almost match but to be tonally too different to Look Good Together.

So....I might go for the black willow leafs pattern, which, the stems are gold? v nice imho.

#rantin and raven#the misery i feel that i will not get to do my hallway in that bramble pattern......#this black willow leaf pattern tho....feels Good. feels ME.

5 notes

·

View notes

Text

high speed BOPP film gravure printing machine automatic food bag Printing Machine

2 notes

·

View notes

Text

TAZJ401350(CSZ)(JSZ) 4feets medium-high speed MLS type decorative paper gravure printer

This model is a major repair model of early models.

Suitable for small quantity printing, sampling, and new product testing.

Adopting variable frequency motor and mechanical shaft synchronization.

Keep the original roller universal.

The purpose of establishment is to address the issue of updates and replacements for existing users.

Design speed:160m/min Print speed:140m/min Cylinder dia :Ф250—Ф450mm Print range:1250-1330mm Power capacitance of the entire machine:115kw Drying energy capacity: Verall: 300kw Gas: 800000 kcal Overall dimensions (L×W×H):17200mm×5540mm×3380mm Gross weight:Around 35T

Contact Us

Phone: +86-13757197838 (Manager Chen)

Tel: +86-0571-61071715

Fax: +86-0571-61071706

Mail: [email protected]

Add: No.32 Wujiatou, Qingke Village, Jincheng Street, Lin'an District, Hangzhou City, Zhejiang Province

0 notes

Text

Precision Printing Solutions with Singla Engravures LLP

In the dynamic world of printing and packaging, precision and consistency are non-negotiable. Singla Engravures LLP stands as a pioneer among printing cylinder manufacturers in India, known for delivering high-performance cylinders that meet international standards. Whether it’s for gravure or flexo printing, their advanced technology and skilled craftsmanship ensure a perfect print—every time.

Meeting Industry Demands with Reliable Cylinder Technology

Modern printing demands speed, detail, and repeat accuracy. Many businesses face production challenges due to poor-quality cylinders that wear quickly or deliver inconsistent results. Singla Engravures addresses these challenges with cylinders engineered to last, customized to fit any press, and built to support long production runs without compromising quality.

How Singla Engravures Manufactures Precision Printing Cylinders

Every order begins with a careful understanding of your printing needs. The cylinders are crafted using modern electroplating and laser engraving technology to produce sharp images and clean transitions. Singla’s deep experience in the industry has earned them a trusted name among printing cylinder manufacturers in India, with a commitment to innovation and quality at every stage of production.

Why Businesses Trust Singla Engravures

When you partner with Singla, you’re not just buying cylinders—you’re investing in reliability. Their products support faster production cycles, reduce machine downtime, and deliver unmatched image consistency. With a legacy of excellence and a focus on quality, Singla provides:

Precision-fit cylinders for rotogravure and flexo machines

Advanced surface treatments for durability

High-definition engraving for fine detail printing

On-time delivery across India

Tailored solutions for unique production environments

Start Scaling Your Print Performance with Singla

Whether you're in the packaging, labeling, or textile industry, Singla Engravures has the tools to take your production to the next level. As one of the most reliable printing cylinder manufacturers in India, their custom solutions help businesses improve efficiency, maintain consistency, and deliver superior print quality to clients around the world.

Frequently Asked Questions

What printing services does Singla specialize in? Singla Engravures specializes in manufacturing rotogravure and flexo printing cylinders with high precision.

Are your printing cylinders compatible with modern machines? Yes, our cylinders are designed to fit seamlessly with modern flexographic and gravure printing presses.

Do you offer customization? Absolutely. Each cylinder is customized based on your machinery specs and the type of material being printed.

What makes your cylinders stand out? Our cylinders are long-lasting, precision-engineered, and made using state-of-the-art engraving technology.

Can I place a bulk order? Yes. We cater to both small and large-scale orders with consistent quality across each unit.

Highlights of Singla Engravures LLP

Two decades of experience in cylinder engineering

In-house laser engraving and electroplating

Fast turnaround times and pan-India delivery

Dedicated support for commercial and industrial printing

Precision-focused production with global quality standards

Contact Singla Engravures LLP

Website: www.singlaengravuresllp.com Email: [email protected] Phone: +91 93131 83167

0 notes

Text

youtube

Wallpaper - Paste It Up

Wallpaper is a material that we use to cover and decorate the interior walls of homes, offices and other buildings. Wallpaper is sold in rolls and is put click here onto walls with wallpaper paste. Wallpaper began as an inexpensive substitute for paneling and tapestries.

Paper was invented in ancient China. They use to glue rice paper to their walls. A court official of the Chinese invented paper from rags. By the 10th century Arabs used wood and bamboo to create thin sheets of paper. During the 12th century Europeans commissioned artists to paint paper for their walls. In 1675 a French engraver made block designs on the wallpaper and this was very much like the wallpaper of today.

Wallpaper finally came to America in 1739. Right after the revolutionary war it was all the fashion. Everyone wanted it in their homes. In 1839 a 4 color wallpaper printing machine was invented and by 1874 there was a 12 color wallpaper printing machine in use. In 1888 the first ready to use wallpaper paste was invented. Pasting machines were not developed until the 20th century.

If you lived in the ‘20s you were sure to have one room of your house that had wallpaper. Over 400 million rolls were sold during that time. Soon after, people started to frown on embellishments. Wallpaper fell to disfavor for a time for its lavish effects and cost.

Wallpaper has had its ups and downs but after World War Two it picked up in popularity. This happened because of wall coverings that were available were easy to maintain and affordable. This new wallpaper had structural integrity as opposed to the older flimsy kind.

There is a large variety to choose from. There is wallpaper that comes plain, that you can paint your own design or others that have patterned graphics. Some printing techniques include surface, gravure, screen and rotary. You can also purchase pre-pasted paper that is easy to hang. Begin choosing your wallpaper by considering the space you are decorating and the type of surface you will be covering. Make certain you measure to ensure you will complete your project. When in doubt always order more then you will need.

I had my own experience with wallpaper. In the 1980’s I purchased wallpaper that had a twist. It was wallpaper that you could write on. I hung this in my bathroom and it had a special pen that was attached. Who ever visited me got to write a special message or saying. Don’t worry because it was also washable and believe me I had to wash it away quite a lot!

Here is a list of some of the different styles that are offered and a brief review of its character. The most popular is vinyl for its durability and easy upkeep. Another choice is fabric backed vinyl. This is usually unpasted but washable and moisture resistant. The next option is paper backed vinyl. It is prepasted and light weight. It creates a three dimensional effect and it works best on rough surfaces. Next there are textiles.

1 note

·

View note

Text

The Application of Ink Doctor Blade in Gravure Printing

The selection, installation, and adjustment of the ink doctor blade in gravure printing have a significant impact on the quality of printed products. Below are some insights on the application of the doctor blade in gravure printing and related issues.

1. Selection and Installation of the Doctor Blade

For high-speed gravure printing machines, imported, highly elastic steel doctor blades with a thickness of 0.15–0.2mm are commonly used. When installing the doctor blade, it is important that the blade is longer than the printing plate by 10–20mm to prevent ink from splashing onto the rubber roller. The steps and key points for installation are as follows: 1. The distance between the backing and the blade should be approximately 10mm. The distance between the backing and the blade should be 5–7mm. However, depending on specific circumstances, the distance can be appropriately increased (i.e., using a soft blade) or decreased (using a hard blade). 2. Place the new blade behind the backing and insert it into the blade slot. Tighten the backing screws, starting from the middle of the blade and gradually working outward. Alternate tightening from both ends. Here is a tip to avoid blade warping: when tightening the screws, it should be done in two or three rounds, not all at once. While tightening the screws, use a piece of cloth to clamp the blade and backing and pull it toward one side with force. This ensures that the blade is installed more evenly. A flat blade ensures a uniform ink layer on the printing plate. 3. Select appropriate tools and methods for blade sharpening. When sharpening a blade with a sharpening stone, if the stone is too coarse, it is not suitable for new blades. Based on practical experience, using 1-grit diamond sandpaper is suitable for sharpening both new and old blades with significant damage. If 1-grit sandpaper feels too coarse for sharpening a new blade, you can finish sharpening with finer 0-grit sandpaper. There are two main sharpening methods: one is folding the sandpaper into a "V" shape, ensuring several layers to prevent the blade from cutting through the paper and hurting the user. This method is efficient and easier to control the blade's edge angle, but it is not very safe. The other method is to use both hands to pull the sandpaper at both ends while sharpening, which is safer but less precise for controlling the angle of the blade. Both too blunt and too sharp blades can negatively affect printing quality.

2. Proper Adjustment of the Doctor Blade

The pressure, sharpness, and the contact position of the blade with the printing plate all influence printing quality. By properly adjusting these factors according to the actual needs, many printing problems can be resolved. 1. Pressure Factors that affect the pressure of the doctor blade include the cylinder pressure, the choice of soft or hard blades, and the angle at which the doctor blade crosses the printing plate. The greater the angle, the higher the pressure. Excessive pressure can reduce ink transfer efficiency and cause greater wear on both the printing plate and blade. Insufficient pressure can lead to dirty plates or visible blade lines. 2. Blade Sharpness The sharpness of the blade depends on whether it is new, the sharpening angle, and the type of abrasives (such as sharpening stones) used. The optimal sharpness should effectively clean the ink without creating blade marks. Overly sharp blades tend to produce blade marks, and they also wear out the printing plate more quickly. 3. Contact Distance between the Blade and the Printing Plate Reducing the contact distance between the doctor blade and the printing plate can improve ink transfer efficiency, but it can also cause dirty plates. Conversely, increasing the distance can reduce the occurrence of dirty plates and avoid fine line defects, but it may lower ink transfer efficiency.

Explore our book printing services on the Printing in China page. 4. Blade Flatness The flatness of the blade and whether it warps primarily depends on the installation method, though it may also be influenced by foreign matter on the blade or backing. If the blade is not flat, it can cause issues such as water drop-like marks on the print edges or intermittent lines. Some may think that rough ink or poor ink flow is the cause of such issues, but in reality, an uneven blade can also lead to these problems. 5. Movement of the Doctor Blade The lateral movement of the doctor blade is important for reducing blade lines, increasing blade utilization, and minimizing wear on the printing plate. If the blade movement is irregular, it should be adjusted to improve performance.

0 notes

Text

Rathna Packaging orders W&H blown film lines and CI flexo presses

Rathna Packaging India, a significant flexible packaging and film manufacturing company based in Bengaluru has placed orders for two Windmöller & Hölscher (W&H) Optimex II blown film lines and a pair of Alphaflex CI flexo presses to be commissioned in mid-2025. This is one of the most notable flexible packaging orders placed this year among several others for W&H. Both the Optimex lines are 2.5 meter-wide 3-layer lines.

The pair of Alphaflex CI flexo presses are both 8-color machines with rated speeds of 400 meters a minute and contain W&H Easy-Col automation for color makeready and standardization with exceptional accuracy. While making ready 80% the first cut of print checks will bring the color accuracy within 1.5 DeltaE. The second color check will bring the remaining 20% into the variance of 1.5 DeltaE. The Alphaflex CI is the same new press shown running at the W&H stand at drupa24 and containing the company’s automation technologies delivered in a standardized configuration.

Rathna Packaging is known for its high-quality sustainable solutions. With over 25 years of experience, the company has manufacturing facilities at three locations located in Hosur, and one in Krishnagiri, Tamilnadu with subsidiaries in Gujarat and Andhra Pradesh. The company makes shrink sleeves, twist wraps, oil and milk films, chub films, laminates, void-fill cushion packs, protective packaging, consumer products, and industrial packaging. Its customers include the food, beverages, pharmaceuticals, and consumer goods sectors.

Rathna Packaging has more than a dozen blown film lines from various manufacturers and it has several gravure presses. Thus this expansion project is a substantial move toward advanced and automated high-efficiency technologies. “We are proud of the fact that we have invested in the most advanced technologies from W&H. With these new technologies, we are prepared to deliver superior packaging solutions and continue our journey of growth. With the right planning and practices, we wish to plan another big expansion soon,” says Sudhakar Reddy, managing director of Rathna Packaging.

The Optimex II blown film lines support a range of applications using high-performance films tailored to various industries. The machine also comes equipped with advanced features like the EASY2 change system, an assistance system for blown film lines that supports the operator during every step of a product changeover and leads to repeatable performance.

Compared to an experienced operator, the number of necessary clicks for a product change is reduced by more than 70%, and the time needed is cut by more than half, thanks to an intuitive HMI. The operator maintains full transparency and control throughout a changeover, as the technology detects the bubble shape and frontline, ensuring reproducible high film quality.

The Alphaflex CI flexo presses bring unmatched precision and quality production to the forefront. The new presses from W&H offer better print stability and bounce-free printing even for difficult print work at speeds of 400 mpm. Designed for printers of all scales, the Alphaflex is engineered to meet industry challenges — cost pressures, productivity demands, and sustainability goals. Both the 8-color presses for Rathna Packaging include W&H’s fully integrated Easy-Col color-matching solution for precise color-match in considerably reduced time for new work and re-runs.

The Alphaflex is the newest addition to W&H's CI flexo portfolio, launched at drupa 2024. These two presses will be among the very first installations in India, marking a significant milestone for both W&H and Rathna Packaging. The flexo presses are also integrated with W&H’s IoT Ruby platform to monitor data, and automate and improve packaging production. This investment is a key enabler of Rathna’s ambitious plans of scaling its operations while maintaining its reputation for quality and sustainability.

On industry growth, Reddy adds, “Today enterprises need to compete at scale and speed faster than ever before. So that we keep pace with the time and consistently work in the direction of upgrading development, quality, manufacturing, and marketing processes.”

“This is one of the large investments that W&H has witnessed in the recent past in India. I must acknowledge Rathna Packaging’s passion to deliver the best, which also reflects in their investment which was extremely well planned, and we look forward to implementing the project,” says Anuj Sahni, sales director, W&H.

0 notes

Text

Maximize Your Label Production Efficiency with UV Graphic

Punching machines are used to create high-quality labels and shapes needed in industries such as packaging, retail, and logistics. They cut a variety of materials into perfect labels, ensuring that applications, including branding and product identification, will always have a consistent finish.

UV Graphic is one of the well-known companies in the printing and converting industry. It manufactures state-of-the-art label punching machines. These are designed with advanced technology in them which throws unique precision and speed, making them very well-suited for high-volume production lines. The machines support many materials including paper, film, and metallic foils as per the need of diversified industries.

The Label punching machines from UV Graphic are loaded with automated operation, easy setting, and low maintenance features which ensure the least possible downtime and maximized productivity for businesses. The solutions range from short runs to bigger projects as they cater for all sizes.

With UV Graphic, you are assured of state-of-the-art technology and service. The best quality and innovation are put in to see that the production process runs well in the current competitive market.

#curing machine manufacturer#gravure printing machines manufacturer#uv curing systems#rotary hot foil stamping#Label Punching Machines Manufacturer

0 notes

Text

The Manufacturing Process of HDPE Polythene Bags

High-Density Polyethylene (HDPE) polythene bags have become indispensable in numerous industries due to their strength, flexibility, and affordability. From retail to agriculture, these bags serve a wide array of functions. Singhal Industries Pvt Ltd, renowned as India’s premier packaging company, is a pioneer in the production of HDPE polythene bags. This article offers a comprehensive look at the manufacturing process of these vital packaging products, shedding light on each step involved.

Raw Material Selection and Preparation

The journey to creating quality HDPE polythene bags starts with the careful selection of raw materials. HDPE, a thermoplastic polymer, is prized for its impressive strength-to-density ratio. The primary raw materials, polyethylene granules, are sourced and rigorously tested to ensure they meet stringent quality standards. These tests ensure the final product's reliability and robustness.

Upon approval, the granules are delivered to the production facility where they undergo a drying process to remove any moisture. This step is crucial as any residual moisture can interfere with the melting and molding stages, leading to defects in the finished product.

Extrusion Process

Next in the manufacturing sequence is the extrusion process. The dried polyethylene granules are fed into an extruder, where they are heated to a specific temperature until they melt. Inside the extruder, a rotating screw propels the molten polyethylene through a die, forming a continuous thin film of polythene.

The die's configuration is crucial as it dictates the film's thickness and width. Adjustments to the die allow for the production of films with varying dimensions, catering to diverse packaging needs such as Large grow bags for trees and standard HDPE bags.

Film Cooling and Solidification

After extrusion, the molten polyethylene film needs to cool and solidify. This is usually achieved through air or water cooling methods. The film then passes through a series of rollers that stretch and flatten it, ensuring uniform thickness and a smooth surface. This stretching process not only enhances the film’s tensile strength but also improves its flexibility—essential qualities for a 50 kg HDPE bag manufacturer in india.

Printing and Customization

With the film formed and cooled, it moves to the printing and customization stage. Many HDPE polythene bags are printed with logos, product details, and other essential information. Singhal Industries Pvt Ltd utilizes advanced printing technologies, including flexographic and gravure printing, to deliver high-quality prints that are both durable and visually appealing.

Customization doesn’t end with printing. Additional features such as handles, gussets, and resealable closures can be added to the bags based on their intended use. For example, hdpe polythene bags manufacturers in india often tailor their products to meet specific industry requirements, whether for heavy-duty industrial use or food-grade applications.

Bag Formation

The continuous HDPE film is then converted into individual bags. This involves cutting and sealing the film. The film is fed into a bag-making machine that cuts it to the desired length and width. Heat sealing creates the seams and edges, ensuring the bags are airtight and durable.

For specialized applications like large grow bags for trees, additional steps might be necessary, such as reinforcing the bottoms or adding ventilation holes to support root growth and water drainage.

Quality Control and Inspection

Quality control is integral throughout the entire manufacturing process. Singhal Industries Pvt Ltd implements stringent quality control measures to ensure each bag meets the highest standards of durability and performance. Each batch of HDPE polythene bags is subjected to thorough inspections and tests, including tensile strength, puncture resistance, and load-bearing capacity tests.

Defective products are promptly identified and removed to ensure only top-quality bags reach the market. This rigorous quality assurance solidifies Singhal Industries Pvt Ltd's reputation as a leading HDPE polythene bags manufacturer in India.

Packaging and Distribution

After passing all quality checks, the HDPE polythene bags are packaged for distribution. The bags are typically bundled or rolled, based on customer specifications. Proper packaging is crucial to maintain the bags’ condition during transport and storage.

Singhal Industries Pvt Ltd boasts an extensive distribution network that ensures timely delivery of products across India and beyond. Efficient logistics and supply chain management are key to maintaining the company's standing as a reliable 50 kg HDPE bag manufacturer in India.

Environmental Considerations

In an era of heightened environmental awareness, sustainability is a key aspect of the manufacturing process. Singhal Industries Pvt Ltd is committed to reducing its environmental footprint by employing eco-friendly practices such as recycling production waste and utilizing energy-efficient machinery. Additionally, HDPE polythene bags are recyclable, promoting a circular economy and reducing plastic waste.

Conclusion

The manufacturing of HDPE polythene bags is a complex and meticulously controlled process. From the careful selection of raw materials to the final stages of packaging and distribution, every step is designed to produce durable, reliable, and versatile packaging solutions. Singhal Industries Pvt Ltd exemplifies excellence in this field by adhering to stringent quality standards and embracing sustainable practices.

Understanding the detailed process behind HDPE polythene bag manufacturing allows consumers and industries to appreciate the expertise and effort involved in producing these essential products. Whether for everyday use or specialized purposes like large grow bags for trees, HDPE polythene bags remain a critical component of modern packaging solutions.

Frequently Asked Questions (FAQs)

1. What are HDPE polythene bags?

HDPE polythene bags are made from high-density polyethylene, a strong and durable thermoplastic polymer. These bags are known for their high strength-to-density ratio, making them ideal for various packaging applications.

2. What industries use HDPE polythene bags?

HDPE polythene bags are used in a wide range of industries, including retail, agriculture, food and beverage, pharmaceuticals, and industrial sectors. They are valued for their durability, versatility, and cost-effectiveness.

3. How are HDPE polythene bags customized?

HDPE polythene bags can be customized through printing, adding features like handles, gussets, and resealable closures. Customization ensures that the bags meet specific industry requirements and branding needs.

4. Are HDPE polythene bags environmentally friendly?

HDPE polythene bags are recyclable, contributing to reduced plastic waste. Manufacturers like Singhal Industries Pvt Ltd employ eco-friendly practices and use energy-efficient machinery to minimize environmental impact.

Singhal Industries Pvt Ltd continues to lead the way in HDPE polythene bag manufacturing, setting benchmarks for quality and sustainability in the packaging industry.

0 notes

Text

0 notes

Video

youtube

Wallpaper - Paste It Up

Wallpaper is a material that we use to cover and decorate the interior walls of homes, offices and other buildings. Wallpaper is sold in rolls and is put onto walls learn more with wallpaper paste. Wallpaper began as an inexpensive substitute for paneling and tapestries.

Paper was invented in ancient China. They use to glue rice paper to their walls. A court official of the Chinese invented paper from rags. By the 10th century Arabs used wood and bamboo to create thin sheets of paper. During the 12th century Europeans commissioned artists to paint paper for their walls. In 1675 a French engraver made block designs on the wallpaper and this was very much like the wallpaper of today.

Wallpaper finally came to America in 1739. Right after the revolutionary war it was all the fashion. Everyone wanted it in their homes. In 1839 a 4 color wallpaper printing machine was invented and by 1874 there was a 12 color wallpaper printing machine in use. In 1888 the first ready to use wallpaper paste was invented. Pasting machines were not developed until the 20th century.

If you lived in the ‘20s you were sure to have one room of your house that had wallpaper. Over 400 million rolls were sold during that time. Soon after, people started to frown on embellishments. Wallpaper fell to disfavor for a time for its lavish effects and cost.

Wallpaper has had its ups and downs but after World War Two it picked up in popularity. This happened because of wall coverings that were available were easy to maintain and affordable. This new wallpaper had structural integrity as opposed to the older flimsy kind.

There is a large variety to choose from. There is wallpaper that comes plain, that you can paint your own design or others that have patterned graphics. Some printing techniques include surface, gravure, screen and rotary. You can also purchase pre-pasted paper that is easy to hang. Begin choosing your wallpaper by considering the space you are decorating and the type of surface you will be covering. Make certain you measure to ensure you will complete your project. When in doubt always order more then you will need.

I had my own experience with wallpaper. In the 1980’s I purchased wallpaper that had a twist. It was wallpaper that you could write on. I hung this in my bathroom and it had a special pen that was attached. Who ever visited me got to write a special message or saying. Don’t worry because it was also washable and believe me I had to wash it away quite a lot!

1 note

·

View note

Text

TAZJ601700 (KLLW) 5feets gravure printing (PU) coating machine

This machine is a paint free PU paper printing and coating machine.

A production model with dual functions of printing and coating.

Combination of 3 tape players, automatic cutting and material changing.

High precision full servo motor synchronous control, using hot oil and steam heating for drying.

Computer overprinting, observing printing quality in still images.

Design speed:180m/min

Print speed:160m/min

Cylinder dia:Ф250—Ф450mm

Print range:1250-1310mm

Power capacitance of the entire machine:240kw

Drying energy capacity:Gas: 3.2 million kcal (Hot oil)

Overall dimensions (L×W×H):30000mm×8000mm×8530mm

Gross weight:Around 100T

Contact Us

Phone: +86-13757197838 (Manager Chen)

Tel: +86-0571-61071715

Fax: +86-0571-61071706

Mail: [email protected]

Add: No.32 Wujiatou, Qingke Village, Jincheng Street, Lin'an District, Hangzhou City, Zhejiang Province

0 notes

Text

Solvent Recovery Machine

We offer cow urine solvent recovery equipment, solvent recovery equipment, waste solvent recycling machines, solvent recovery distillation equipment, and recycling machines. There are different solvent recovery methods that work through liquid-liquid extraction, absorption techniques, movie evaporation, crystallization, and membrane separation. Some processes are better suited to certain solvents, but the overwhelming majority of solvents utilized in printing, paints, and coatings are wonderful candidates for distillation. As the hashish business continues to grow and consolidate in favor of essentially the most cost-effective operators, the demand for labor saving extraction equipment is on the rise - gravure cylinders.

This is designed for recovery of flexographic photopolymer plate solvent washout chemical and any environmental green chemical with specialties of distilling and cooling, can be connected with in-line processor and any plate washout machine directly. With cold air circulation and drain out of residue for high speed recovery. Super recovering rate in the shortest time, is an ideal and high efficient recovery unit for flexographer - rotogravure printing cylinder.

To meet the diversified requirements of our prestigious clients, we are engaged in offering solvent recovery equipment. The specialty of the equipment is that the machine can remove the solvent from the chemicals. In addition, the machine can produce a volume quantity of. It takes just a few minutes for the unit to recover the solvent from the bulk. Moreover, the equipment is loaded with computerized controlling and micro-processing sensors aid in measuring the accurate pressure and distillation of the solvent in the substance.

The solvent recovery unit has a clever design. Only one electrical connection is required for the integrated steam heating. A high performance liquid ring vacuum pump conveys the dirt into the solvent recovery unit and guarantees continuous 24 hour operation. During automatic distillation in the solvent recovery unit, the evaporated amount of solvent is automatically replenished by the addition of dirt. This automatic mode can be set by timer. For more information, please visit our site https://packadvance.com/

1 note

·

View note

Text

Rotogravure Printing Machine

At Indian Trade Bird, we offer the best deals on Rotogravure Printing Machines. As the leading manufacturer, supplier, and exporter, we provide a variety of machines, including Pharmaceutical Printing Machines, 3 Drive Rotogravure Printing Machines, High-Speed Rotogravure Printing Machines, Film Aluminum Foil Rotogravure Printing Machines, and Automatic Rotogravure PVC Printing Machines, among others. Rotogravure, also known as gravure, is an intaglio printing process that involves engraving the image onto an image carrier. This process uses a rotary printing press, with the image being engraved onto a cylinder, similar to offset printing and flexography. Our machines are constructed using top-quality components and advanced technology, ensuring complete automation, excellent performance, high production rates, and superior quality output.

For more detail,

Visit:- https://www.indiantradebird.com/Ahmedabad/Rotogravure-Printing-machine/ITB-C1709E14

0 notes

Text

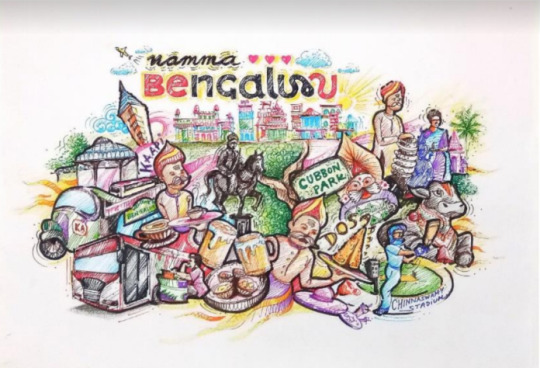

Bengaluru to host the premiere edition of Bharat Print Expo!

The Total Print and Package Converting exhibition will be held from 24-26 April 2025 at Bangalore International Exhibition Centre, Bengaluru.

"This is not just another printing exhibition," declares Anil Arora, President of ReEnvision Events Private Limited. "India is poised to become the world's third-largest economy within the next five years, and we acknowledge that specific sectors as well as regions of the country have played a crucial role in driving this growth. It is essential that we feature them prominently on our event calendar."

Bharat Print Expo is inspired by the county’s adoption of new Print and Converting technologies, coupled with the surge in e-commerce, evolving lifestyles, urbanization, and heightened awareness about personal health, that has significantly fuelled the expansion of the Print and Packaging sectors. Bengaluru is a city that mirrors its diversity, combining a rich cultural tapestry with advanced technologies. According to the Bengaluru Innovation Report, among the 780 major cities globally, 17 of the 20 fastest growing cities will be in India. Among them, Bengaluru is projected to have the world's fastest GDP growth at 8.5%, maintaining this pace until 2035. The vibrant city will hold the first edition of Bharat Print Expo, driving participation from all across the country along with a global brand presence. The venue selection was made based on a survey conducted among the exhibitors of our current show.

Exhibitor Profile

Bharat Print Expo 2025 will delve into the growing demand and prospects within South India and its surrounding areas. Exhibitors hailing from various parts of the nation will showcase cutting-edge products and solutions spanning the print and related industries, including- Printing Equipment: Offset/ Screen/ Digital/ Flexo/ Gravure; Prepress Equipment; Post-press & Packaging Converting Equipment; Label Converting & Printing Press; Paper Converting Machines; Adhesives & Consumables; Binding & Lamination; Paper, Films, Foils; Ink & Chemicals; Dies, Cutters, Rollers; Corrugated Box Making Machinery; Carton Folding Equipment; Testing Equipment, Inspection Systems & Accessories; Textile Printing Machines; 3D Printers; Wide Format Signage Printers; Plant Automation; Infrastructure, Trade Associations & Financial Organisations and Services & Software.

Visitor Profile

The exhibition will attract visitors from the entire Southern region, with extensive promotional activities planned to reach a wide audience. Targeted visitors from all over Bharat and Sri Lanka will also attend the Show. The profile will broadly include: Commercial Printers, Package Printers & Label Printers; Brand Owners & Print Buyers; Package Converters & Corrugated Box Manufacturers; Textile Printers & Professionals; Signage & Graphic Arts Specialists; Retailers, Manufacturers & Industry Suppliers; Packaging Professionals, Design Houses, Art Directors & Consultants; Trade publications, Advertising, Marketing, Media & PR Agencies; Government Bodies and Trade Associations.

Venue

The Bangalore International Exhibition Centre (BIEC) enhances its 77,000 square meters of covered space with aesthetically and functionally designed exhibition halls, along with vast open areas ideal for showcasing large and heavy machinery. The venue is conveniently linked via the Green Metro Line and is just a 45-minute drive from the airport and a 30-minute drive from the city centre.

Organizer

ReEnvision carries forward the legacy of its group companies that have launched or co-organized India’s most successful events in the printing and packaging sector including India Label Show, Pack Plus and PAMEX. ReEnvision Events Private Limited is a sister organization of Print-Packaging.com Private Limited.

"We are preparing to open bookings for the Show and anticipate a tremendous response from the industry,” concludes Anil Arora.

0 notes