#Hastelloy C22 Butt Weld Fittings

Text

How to Choose the Right Hastelloy C22 Buttweld Pipe Fittings

Hastelloy C22 Pipe Fittings , is a fabric inside the global corrosion-resistant alloys. Its specific combo of nickel, chromium, molybdenum, and tungsten makes it the cross-to choice for stressful packages that contain harsh chemical substances, excessive temperatures, and severe pressures. But when constructing your Hastelloy C22 piping gadget, you need the proper fittings to make sure a seamless and steady connection.

That's in which Hastelloy C22 Buttweld Pipe Fittings are available.

Here's a manual to help you choose the ideal Hastelloy C22 Butt Weld Fittings in your assignment:

1. Understanding Buttweld Fittings:

Buttweld fittings are the workhorses of pipe becoming. They have beveled ends which are designed to be joined to the usage of a welding technique. This creates an everlasting, high-energy connection appropriate for high-pressure and high-temperature applications. When it involves Hastelloy C22, butt welding is the preferred approach due to the material's super weldability.

2. Selecting the Fitting Type:

Hastelloy C22 Buttweld Pipe Fittings are available in diverse styles and sizes to accommodate different piping configurations. Common sorts include:

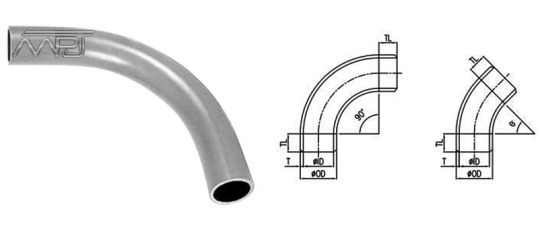

Elbows: Used for changing the path of the pipe. Available in various angles (ninety°, 45°, and so forth.) and radius lengths (long or short).

Tees: Create a department line from the main pipe. Offered in equal (all 3 stores identical size) or lowering (one outlet is a smaller diameter) configurations.

Reducers: Connect pipes of different diameters. Available in concentric (smooth transition) or eccentric (one aspect slopes greater for clearance) options.

Caps: Seal the cease of a pipe.

3. Specifying Dimensions and Standards:

Once you've selected the fitting kind, don't forget the particular dimensions needed for your assignment. This consists of the pipe diameter, wall thickness, and time table (pipe wall thickness designation). It's vital to ensure your fittings adhere to industry requirements like ASME B16.Nine or ASME B366, which assure compatibility and overall performance.

4. Material Certification:

Since hastelloy c22 pipe fittings stockist is utilized in important applications, make certain your preferred Hastelloy C22 Pipe Fittings Supplier offers right fabric certification. This documentation verifies the chemical composition and mechanical homes of the fittings, ensuring they meet the required Hastelloy C22 grade (UNS N06022).

5. Inventory and Lead Time:

Hastelloy C22 is a specialty cloth, so without difficulty to be had stock is probably constrained. When choosing a dealer, inquire approximately their stock degrees and lead instances for the precise Hastelloy C22 Buttweld Pipe Fittings you require. Partnering with a provider with a validated track document in Hastelloy C22 merchandise can help avoid mission delays.

Conclusion:

By carefully considering these elements, you could ensure you select the most suitable Hastelloy C22 Buttweld Pipe Fittings for your challenge. Remember, the proper fittings are important for a steady, lengthy-lasting piping system which can resist the toughest situations. Don't hesitate to discuss with a good Hastelloy C22 Pipe Fittings Supplier for professional advice and make certain an easy and a hit venture execution.

#Hastelloy C22 Pipe Fittings#Hastelloy C22 Butt Weld Fittings#Hastelloy C22 Pipe Fittings Supplier#HASTELLOY C22 BUTTWELD FITTINGS#hastelloy c22 pipe fittings stocksit

0 notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL

Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes

Text

All you need to know about Butt Weld Fittings

Butt weld fittings are essential components used in various industries to join and connect pipes or tubes seamlessly. These fittings play a crucial role in creating a robust and leak-free piping system. As a leading butt weld fittings manufacturer and supplier, stockist, and exporter in India. Bullion Pipes & Tubes LLP offers an extensive range to suit various project needs. Our fittings are available in different sizes, specifications, material grades, and types, ensuring you find the perfect fit for your specific application.

In this comprehensive guide, we will delve into all you need to know about butt weld fittings and how they cater to the needs of different applications.

What Are Butt Weld Fittings?

Butt weld fittings are designed to have smooth inner surfaces, ensuring minimal friction and pressure drop in the flow of fluids. This characteristic makes them ideal for applications where flow velocity and efficiency are critical factors. Additionally, the absence of crevices or threads in butt weld fittings prevents the accumulation of debris, reducing the chances of contamination and facilitating easy cleaning and maintenance.

Comprehensive Range of Butt Weld Fittings

We take pride in offering a comprehensive range of buttweld pipe fittings, including

Butt Weld Elbows: Available in 45-degree, 90-degree, and 180-degree angles, providing flexibility in directing the flow of fluids.

Butt Weld Crosses: Ideal for intersecting pipelines, ensuring smooth fluid flow in multiple directions.

Butt Weld Caps: Used to seal the end of a pipe, protecting it from contaminants and preventing leakage.

Butt Weld Tees: Available as equal and unequal tees, facilitating even or uneven flow distribution.

Butt Weld Reducers: Both concentric and eccentric reducers for smooth transitions between pipes of different diameters.

Butt Weld Stub Ends: Facilitating easy flange connections without welding.

Advantages of Butt Weld Fittings

Excellent Structural Integrity: Butt weld fittings create a continuous and strong joint that enhances the structural integrity of the entire piping system. This is especially important in applications where safety and reliability are paramount.

Smooth Inner Surface: The absence of internal disruptions such as threads or flanges ensures a smooth inner surface, minimizing turbulence and pressure loss during fluid flow.

Strong and Reliable Joints: The welding process used to join the pipes ensures a permanent and robust connection, reducing the risk of leaks or failures.

Suitable for High-Pressure and High-Temperature Applications: Butt weld fittings are capable of withstanding extreme pressures and temperatures, making them suitable for critical and demanding industries.

Disadvantages of Butt Weld Fittings

Skilled Labor for Welding: Proper welding requires skilled labor, which may increase the installation cost compared to other types of fittings that do not require welding.

Slightly More Expensive: Butt weld fittings can be slightly more expensive than other fittings due to the welding process and the need for precision manufacturing.

Materials & Grades we offer - Buttweld Fittings

Stainless Steel Buttweld Fittings

SS 904L

SS 304/304L/304H, 316/316L/316Ti, 321/321H, 310/310S, 317/317L, 347/347, 446

Titanium Buttweld Fittings

Titanium Alloy Gr 2

Titanium Alloy Gr 5

Monel Buttweld Fittings

Monel K500

Monel 400

Carbon Steel Buttweld Fittings

Inconel Buttweld Fittings

Inconel 718

Inconel 600

Inconel 601

Inconel 625

Alloy Steel Buttweld Fittings

Alloy Steel P5

Alloy Steel P9

Alloy Steel P11

Alloy Steel P12

Alloy Steel P22

Alloy Steel P91

Aluminium Buttweld Fittings

Nickel Buttweld Fittings

Nickel Alloy 200/201

SMO 254 Buttweld Fittings

Duplex Steel Buttweld Fittings

Duplex UNS S32205

Duplex UNS S31803

Hastelloy Buttweld Fittings

Hastelloy C22, Hastelloy B2

Hastelloy C276

Super Duplex Steel Buttweld Fittings

Super Duplex Steel S32750

Super Duplex Steel S32760

Incoloy Buttweld Fittings

Incoloy 800/800H/800HT

Incoloy 825

Alloy 20 Buttweld Fittings

Applications of Buttweld Fittings

Buttweld fittings are a type of pipe fittings used to connect pipes or tubes with a butt welding process. They are widely used in various industries for a range of applications due to their structural integrity and reliability. Some of the common applications of buttweld fittings include:

Plumbing and Water Supply

Oil and Gas Industry

Chemical Processing

Petrochemical Industry

Power Generation

Pharmaceutical Industry

Food and Beverage Industry

HVAC Systems

Shipbuilding

Construction

Nuclear Power Plants

Other Application

How to Select the Right Butt Weld Fitting?

Choosing the right butt weld fitting is essential to achieve an efficient and reliable piping system. Consider the following factors during selection:

Project Requirements: Understand the specific needs of your project, such as fluid type, pressure, temperature, and flow rate.

Material Compatibility: Ensure that the material of the fitting is compatible with the material of the pipes to prevent corrosion and ensure longevity.

Fitting Dimensions: Select fittings with dimensions that match the pipe size to achieve a secure and leak-free joint.

Industry Standards and Codes: Adhere to industry-specific standards and codes to maintain the quality and safety of the piping system.

Installation and Welding Process of Buttweld Fittings

Proper installation and welding are critical to ensuring the effectiveness of buttweld pipe fittings. Follow these steps for a successful installation:

Preparation: Clean the pipe ends and fittings thoroughly to remove any dirt, grease, or debris that could affect the quality of the weld.

Alignment: Ensure precise alignment of the pipes and fittings before welding to create a strong and reliable connection.

Welding: Employ the appropriate welding method, such as TIG or MIG, to create a robust and leak-proof joint.

Inspection: Thoroughly inspect the welds for defects using non-destructive testing methods to ensure the integrity of the joints.

Leak Testing: Before putting the system into service, conduct a leak test to verify the integrity of the joints and prevent potential leaks.

Final Thoughts!..

Butt weld fittings are vital components in creating strong and reliable connections within piping systems. Bullion Pipes & Tubes LLP stands at the forefront as the leading butt weld fitting supplier, manufacturer, stockist, and exporter in India. With an extensive range of fittings and a commitment to quality, we cater to diverse industrial needs across India and various countries as well including Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, and Russia. Our buttweld pipe fittings offer exceptional strength, leak resistance, and versatility, making them the ideal choice for critical applications. When selecting the right fitting, consider the specific project requirements, material compatibility, and adherence to industry standards.

Choose Bullion Pipes & Tubes LLP for all your butt weld fitting needs, and experience excellence in quality and service. Contact us today to explore our vast range of fittings and find the perfect solution for your piping requirements.

0 notes

Text

Hastelloy C276 Pipe Fittings Manufacturers, Suppliers and Exporters in Mumbai, India

1 note

·

View note

Text

Hastelloy c22 Pipe Fittings Manufacturer

Creative Piping Solutions is a Manufacturer and Exporter, Supplier of Hastelloy Alloy C22 Pipe Fittings, which is a superb choice for a range of applications that need superior performance. Welding of those Hastelloy C22 Butt Weld Fittings are often done by gas tungsten – arc, gas metal – arc and shielded metal – arc processes. For optimum corrosion performance, therefore, the reannealing of cold-worked parts of our Hastelloy C22 Elbow (following an outer fiber elongation of 7 % or more) is very important.

This property of our Hastelloy C22 Tee, combined with its commercial availability, makes it a superb choice for demanding specifications. Hastelloy C22 Reducer is used for processed Foods – like in equipment, systems, and parts for spreads, meat, poultry, fruit, nuts, baking, dressing, and sauces.

Hastelloy C22 Cross is usually used for pickling system components, plate heat exchangers, selective leaching systems, sulfur oxide cooling towers, supranational systems, and tubular heat exchangers. Hastelloy C22 Bend is additionally utilized in Paper processing, Waste disposal. Hastelloy C22 Stub End is also used for chemical processing, marine and fuel reprocessing.

know more

1 note

·

View note

Text

PIPE FITTING COLLAR

COLLAR PIPE FITTINGS TUBING, COLLAR PIPE FITTINGS EXPORTER, CARBON STEEL COLLAR PIPE FITTINGS, SS 310/310S COLLAR PIPE FITTINGS, STAINLESS STEEL 316/316S COLLAR FITTINGS, ANSI B16.9 BUTTWELD COLLAR FITTINGS, COLLAR PIPE FITTINGS WITH FERRULE FITTINGS SUPPLIER, COLLAR PIPE FITTINGS CONNECTOR, ASME B16.9 BUTT WELD COLLOR, COLLAR PIPE FITTINGS STOCKIST, ALLOY STEEL COLLAR PIPE FITTINGS EXPORTER, SS 304/304L COLLAR FITTINGS, SS 904L COLLAR FITTINGS, NICKEL ALLOY COLLAR PIPE FITTINGS, COLLAR PIPE FITTINGS INSTRUMENTATION PIPE FITTING,LEADING COLLAR PIPE FITTINGS MANUFACTURER, INCONEL 600/601/625 COLLAR FITTINGS, STAINLESS STEEL COLLAR PIPE FITTINGS STOCKIST, HASTELLOY C22/C276 COLLAR FITTINGS.

We have specialization to manufacture customized ANSI/ASME B16.9 Butt Weld Collar per customers’ specifications, we welcome small quantity order.

Mcneil Instruments Inc (India) is Manufacturer, Stockists & Supplier of premium quality range of ANSI/ASME B16.9 Butt Weld Collar, Stainless Steel Flanges & Other Stainless Steel Pipe fittings that are manufactured under the expert guidance of our diligent workforce. we are highly experienced company in ANSI/ASME B16.9 Butt Weld Collar & other pipe fittings. our ANSI/ASME B16.9 Butt Weld Collar & Other Fitting products are manufactured using quality material and go through a rigorous quality check at all stages of production to ensure quality. Designed in compliance with international quality standards, these ANSI/ASME B16.9 Butt Weld Collar are corrosion resistance, sturdy and durable. we also supply ANSI/ASME B16.9 Butt Weld Collar & other pipe fittings Flanges in customized size. Our Product Supply Division offers a broad portfolio of Steel Flanges and ANSI/ASME B16.9 Butt Weld Collar. When you place an order with Mcneil Instruments Inc (India), you will receive the products that will stand up in service from people that will stand behind their product.

Checkout Technical Specification & Material of Construction — http://www.mcneilinstruments.com/collar-pipe-fitting.html

Copyright 2021 Mcneil Instruments — http://www.mcneilinstruments.com/

#plumber#fitting#pipe#industrial#valve#valveman#valvesupplier#pipeline#elbw#tee#vessel#chemical#contractor#waterplant

0 notes

Link

ANSI B16.9 304L Custom STUB END DN40 Sch10S

FOB Price USD 1 - 1,900/Piece

Port Ningbo or Shanghai Port

MOQ 1 Piece

Supply Ability 1000 Pieces Per Day

Payment Terms L/C,T/T,Western Union,MoneyGram

Packaging Seaworthy plywood cases or pallets

Delivery 2 - 10 days

Quick Details

Material: 304L

Technics: Cold forming

Type: Custom Stub End

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Yaang

Connection: Welding

Head Code: Round

Size: 1 1/2" (DN40)

Packaging & Delivery

Packaging Details:fumigation free plywood cases or as per customers' requests

Delivery Detail:Delivery after receiving deposit

Specifications

ANSI B16.9 304L Custom STUB END

Size: 1 1/2" (DN40)

Thk: SCH10S

Material: 304L

China Custom Stub End Manufacturer Yaang offers ANSI B16.9 304L Custom Stub End, DN40, Sch10S.

Dimensions butt welded Stub Ends schedule 10S ANSI B16.9

NPSODTGFR

1½48.33.588174

Composition ranges for 304 grade stainless steel

Grade

C

Mn

Si

P

S

Cr

Mo

Ni

N

304

min.

max.

-

0.08

-

2.0

-

0.75

-

0.045

-

0.030

18.0

20.0

-

8.0

10.5

-

0.10

304L

min.

max.

-

0.030

-

2.0

-

0.75

-

0.045

-

0.030

18.0

20.0

-

8.0

12.0

-

0.10

304H

min.

max.

0.04

0.10

-

2.0

-

0.75

-0.045

-

0.030

18.0

20.0

-

8.0

10.5

-

Mechanical properties of 304 grade stainless steel

Grade

Tensile Strength (MPa) min

Yield Strength 0.2% Proof (MPa) min

Elongation (% in 50mm) min

Hardness

Rockwell B (HR B) max

Brinell (HB) max

304

515

205

40

92

201

304L

485

170

40

92

201

304H

515

205

40

92

201

304H also has a requirement for a grain size of ASTM No 7 or coarser.

Physical properties of 304 grade stainless steel in the annealed condition

Grade

Density (kg/m3)

Elastic Modulus (GPa)

Mean Coefficient of Thermal Expansion (μm/m/°C)

Thermal Conductivity (W/m.K)

Specific Heat 0-100°C (J/kg.K)

Electrical Resistivity (nΩ.m)

0-100°C

0-315°C

0-538°C

at 100°C

at 500°C

304/L/H

8000

193

17.2

17.8

18.4

16.2

21.5

500

720

Grade specifications for 304 grade stainless steel

Grade

UNS No

Old British

Euronorm

Swedish SS

Japanese JIS

BS

En

No

Name

304

S30400

304S31

58E

1.4301

X5CrNi18-10

2332

SUS 304

304L

S30403

304S11

-

1.4306

X2CrNi19-11

2352

SUS 304L

304H

S30409

304S51

-

1.4948

X6CrNi18-11

-

-

These comparisons are approximate only. The list is intended as a comparison of functionally similar materials not as a schedule of contractual equivalents. If exact equivalents are needed original specifications must be consulted.

Type

304L Stub End

Standard

ASME B16.9, MSS SP-43, HG205099, HG20621,

GB/T12459-2005, GB/T13401, SH3408-96,etc.

Size

1/2"-48"(DN15-DN600)

Wall thickness

SCH5S-SCH40S

Type

Type A, Type B,Type C

Surface treatment

Lathe finish&Abrasive blasting

Stainless steel

304, 304L,304H, 316, 316L,309S,310S, 321,321H,347H,316Ti

Duplex steel

2205, etc

Super duplex steel

2507, etc

WP304 Stub End

What are they?

WP304 Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired.

They are also called Lap Joints and Vanstone Flared Laps.

How do they work?

A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

Why?

Since Stub Ends are made from material compatible with the designed piping system, back up flanges do not have to be made from the same material. The flange can be made from less expensive material because it never comes in contact with the process fluid.

WP304 Stub Ends' Types

WP304 Stub Ends are typically manufactured by two methods. Type A & B Stub Ends are made similar to forged fittings such as Elbows and Flanges. Type C Stub Ends are made by forming pipe to the desired dimensions.

WP304 Stub Ends are available in two standard lengths, MSS and ANSI.

WP304 Stub Ends are normally provided with a standard weld bevel

WP304 Stub Ends dimensions are found on our fitting dimensions page.

Type "A" - Type "B" - Type "C" - Type "CS"

Where can we find the high quality ANSI B16.9 304L Custom STUB END DN40 Sch10S.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

Yaang offer a made to order

custom fittings

service to customers that require something non-standard. This may be something simple like a reduction in the bore of the product to meet a higher working pressure, an increase of the thread lengths, the use of exotic materials or simply you have a fitting and you don’t know where to get it from, we can reverse engineer the product and create it exactly as the sample.We have had many requests throughout the years for some of the very bespoke and unusual requests for Non-Standard Fittings and Custom Fittings. No matter how complicated we like the challenge.

If you have a Non-Standard Fittings or Custom Fittings request and we say we cannot make it then it simply cannot be done.

Standard Fittings in Other Material:

The list below shows the range of materials available for Non-Standard Fittings or Custom Fittings.

C1144 Stressproof

1018

12L14

4130

4140

4340

C464 Brass

CDA C510 Bronze

Aluminum 6061 T-6

17-4

13-8 MO

303

304

316L

Nitronic 50 and 60

Super Duplex 2507

Hastelloy 276 and C22

Monel 400 and K-500

Titanium

Inconel 625, 718 and 925

Non-Standard and Hard-to-Find Fittings:

Standard connections in unusual sizes

Standard connections in non-standard lengths

Standard connections with non-standard ID and/or OD

Metric, SAE, Socket or Butt Weld connections

Custom Fittings:

Pipe couplings

Half couplings, full couplings

flange

Manifolds with unusual connection combinations

Custom parts

Pipe unions

Olets

Pipe elbows

Pipe tees

If any inquiry, please feel free to contact by email [email protected]

Related products:

More>>

CHINA Stainless Steel 90 degree Elbow

ANSI B16.9 A815 UNS S32750 2507 Seamless Equal Tee 2 Inch Sch80

90 Degree Stainless Steel Threaded Elbow

Lap Joint Stub Ends

0 notes

Text

Piggable bends

M P Jain Tubing Solutions LLP is one of the leading Manufacturer, Stockist, and Exporter of ANSI/ASME B16.9 Piggable Bend in Mumbai, India. We are in this domain since 1972. We are ISO 9001:2015 certified company and most trusted Suppliers of Piggable Pipe Bends. We keep intensive stock of SS Piggable Bend to fulfill urgent requirements of our clients at reasonable prices.

One of the oldest Manufacturer, Stockist, Exporter of ANSI and ASME B16.9 Piggable Bend, Piggable Pipe Bends, Piggable Bend Suppliers at best price in India. We keep the largest stock of stainless steel Piggable bends, carbon steel Piggable bends, nickel alloy Piggable bends, alloy steel Piggable bends, Monel Piggable bends in all dimensions.

Benefits of Butt Weld Pipe Fittings

Butt welding fittings have the following benefits

Welded connection offers more robust connection

Continuous metal structure adds to the strength of the piping system

An option of various turn radius using Short Radius (SR), Long Radius (LR) or 3R Elbows

Cost effective compared to their expensive threaded or socket weld counterparts.

Stainless Steel Welded Fittings are also available in SCH 10, allowing a thinner wall option.

Stainless Steel Butt Weld Fittings are more common in SCH 10 and SCH 40 configuration.

allow a strong and leak-proof pipe to fitting connection

minimize the pressure drops and the turbulence along the pipeline

have a long service life

are rather cheap to purchase and deploy

Butt weld fittings with matching pipe schedules offer seamless flow inside the pipe. A full penetration weld and properly fitted LR 90 Elbow, Reducer, Concentric reducer etc. offers gradual transition via welded pipe fitting.

ANSI and ASME B16.9 Piggable Bend Specifications

Type: Butt weld (BW)

Standards: ASME / ANSI – B 16.9

ASTM A403 – ASME SA403 – ‘Standard Specification for Wrought Austenitic Stainless steel Piping Fittings’

API 590-605

ASME B16.9 – ‘Factory-Made Wrought Buttwelding Fittings’

ASME B16.25 – ‘Buttwelding Ends’

ASME B16.28 – ‘Wrought steel Buttwelding Short Radius Elbows and Returns’

MSS SP-43 – ‘Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications’

Dimension: A NSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313

Thickness: Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc.

Schedule: Sch 5 TO Sch XXS.

Size: 1/2” TO 36”, (Seamless up to 24”), (Welded 8” TO 36”)

ANSI and ASME B16.9 Piggable Bend Material and Grades

Stainless Steel Piggable Bend:

ASTM A403 WP316/316L

ASTM A403 WP304/304L

ASTM A182 F316L, 304L

DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404

Carbon Steel Piggable Bend:

ASTM A234 Gr. WPB

ASTM A420 Gr. WPL6

ASTM A105

ASTM A350 Gr. LF2

Nickel Alloy Piggable Bend:

Monel 400 & 500

Inconel 600 & 625

Incolloy 800, 825

Hastelloy C22, C276

Hastelloy

Nickel

Monel

Inconel

Alloy20

Copper Nickel

Cupro-Nickel 90/10

Cupro-Nickel 70/30

Standard:

ASTM / ASME SB 336

UNS 10276 HASTELLOY C 276 Bend

UNS 2200 NICKEL 200 Bend

UNS 2201 NICKEL 201 Bend

UNS 4400 MONEL 400 Bend

UNS 8020 ALLOY 20 Bend

UNS 8825 INCONEL 825 Bend

UNS 6600 INCONEL 600 Bend

UNS 6601 INCONEL 601 Bend

UNS 6625 INCONEL 625 Bend

Alloy Steel Piggable Bend:

ASTM a234 wp1 / wp5 / wp9 / wp11 / wp22 / wp91

As a leading manufacturer, stockist, and exporters of ANSI and ASME B16.9 Piggable bend, we are providing high-quality Piggable bends, SS piggable bend, piggable bend radius at best price in India.

For More Details

Address: 205 Kika Street, Gulalwadi Mumbai, India

Tel: 022-23465538 / 022-23460403

Fax: +91-22-23424250

Mob: +91 9619390230

Email: [email protected]

Visit our site: http://www.mpjainco.com/

0 notes

Text

Hastelloy c22 Pipe Fittings Exporters

Hastelloy C22, also known as alloy C22, is a versatile austenitic nickel-chromium-molybdenum-tungsten alloy with enhanced resistance to pitting, crevice corrosion and stress corrosion cracking. The high chromium content provides good resistance to oxidizing media while the molybdenum and tungsten content give good resistance to reducing media. Om Tubes being Hastelloy c22 Pipe Fittings Exporters provides you with best and fast delivery.

Om tubes is a huge manufacturer of Hastelloy c22 pipe fittings. We supply pipe fittings of all standards and certificates in various grades across nations. We solve all your industrial corrosion problems with pure Hastelloy C22 Pipe Fittings. Om tubes understand the importance of properties of the alloy in the applications, hence each of our products is tested and verified against heat, pressure and corrosion. At Om Tubes Hastelloy C22 Pipe Fittings undergo various test for better product quality.

All Hastelloy C22 Pipe Fittings are produced with a NACE 3.1 certificate and a mill test certification. Hastelloy c22 is bought over by our most trusted raw material suppliers and are well documented for legitimacy.

The few popularly demanded types Hastelloy c22 pipe fittings are:

· Hastelloy c22 Butt weld pipe Fitting

· Hastelloy c22 Socket weld pipe Fitting

· Hastelloy c22 threaded pipe Fitting

· Hastelloy c22 Forged Fittings

To know more about Hastelloy c22 Pipe Fittings visit: - http://omtubes.com/hastelloy/hastelloy-c22/hastelloy-c22-pipe-fittings/

Contact us via:-

����Call / Whats App: - +918169670750 / +91 9867511799

☎Tell:- +91 2267436562

📧Mail us: - [email protected]

🌐Website:- http://omtubes.com/

0 notes

Text

hastelloy tube fittings

Hastelloy Tube Fittings Manufacturers Supplier Stockist and ExporterWe are happy to announce that we domestically lead in the manufacture and supply of Hastelloy Tube Fittings. Out efficient and dedicated team is backed by superior infrastructure facilities and which has helped us become a market leader and top the list of manufacturers and suppliers of Metal Fittings

We have large stock for Hastelloy C276 Tube Fittings, Hastelloy C22 Tube Fittings and Hastelloy B2 Tube Fittings.We offer Fittings in Hastelloy (butt weld, socketweld & threaded) 90 deg elbow, 90 deg long bend, 180 deg u bend, 45 deg elbow, 45 deg long bend, concentric reducer, eccentric reducer, equal tee, unequal tee, end cap / pipe cap, union, nipple, swage nipple, full & half coupling, cross, plug, bush.

Olets: Insert Weldolet, Branzolet, Coupolet, Sweepolet, Elbolet, Weldolet, Sockolet, Nippolet, Swagged Nippolet, Threadolet.

0 notes

Link

MSS-SP43 (A) ASTM A815 UNS32750 GR2507 STUB END BW 2 Inch SCH10S

FOB PriceUSD 1 - 1,900/Piece

PortNingbo or Shanghai Port

MOQ1 Piece

Supply Ability1000 Pieces Per Day

Payment TermsL/C,T/T,Western Union,MoneyGram

PackagingSeaworthy plywood cases or pallets

Delivery2 - 10 days

Quick Details

Material: Super Duplex 2507 (UNS32750)

Technics: Cold forming

Type: Stub End

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Yaang

Connection: Welding

Head Code: Round

Size: 2 Inch (DN50)

Packaging & Delivery

Packaging Details:fumigation free plywood cases or as per customers' requests

Delivery Detail:Delivery after receiving deposit

Specifications

MSS-SP43 (A) ASTM A815 UNS32750 GR2507 STUB END

Size: 2 Inch (DN50)

Thk: SCH10S

Material: Super Duplex 2507 (UNS32750), etc

China STUB END Manufacturer Yaang offers MSS-SP43 (A) ASTM A815 UNS32750 GR2507 STUB END, 2 Inch, SCH10S.

Super duplex stainless steel 2507 (UNS32750) Chemical Composition %

GradeChemistry (Typical Values)Mechanicals

SpecificationCrNiMoCuNWSiMnP

maxS

maxC

maxFeUTS

N/mm²

(min)0.20%

Proof

(min)Elong

% (min)Hardness

HB (max)PREN

250725.07.03.80.750.250.280.801.200.0350.0200.030Bal750500-5502527041

Type

2507 Stub End

Standard

ASME B16.9, MSS SP-43, HG205099, HG20621,

GB/T12459-2005, GB/T13401, SH3408-96,etc.

Size

1/2"-48"(DN15-DN600)

Wall thickness

SCH5S-SCH40S

Type

Type A, Type B,Type C

Surface treatment

Lathe finish&Abrasive blasting

Stainless steel

304, 304L,304H, 316, 316L,309S,310S, 321,321H,347H,316Ti

Duplex steel

2205, etc

Super duplex steel

2507, etc

UNS32750 GR2507 Stub End

What are they?

UNS32750 SAF2507 Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired.

They are also called Lap Joints and Vanstone Flared Laps.

How do they work?

A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

Why?

Since Stub Ends are made from material compatible with the designed piping system, back up flanges do not have to be made from the same material. The flange can be made from less expensive material because it never comes in contact with the process fluid.

UNS32750 GR2507 Stub Ends' Types

UNS32750 GR2507 Stub Ends are typically manufactured by two methods. Type A & B Stub Ends are made similar to forged fittings such as Elbows and Flanges. Type C Stub Ends are made by forming pipe to the desired dimensions.

UNS32750 GR2507 Stub Ends are available in two standard lengths, MSS and ANSI.

UNS32750 GR2507 Stub Ends are normally provided with a standard weld bevel

UNS32750 GR2507 Stub Ends dimensions are found on our fitting dimensions page.

Type "A" - Type "B" - Type "C" - Type "CS"

Where can we find the high quality MSS-SP43 (A) ASTM A815 UNS32750 GR2507 STUB END, 2 Inch, SCH10S.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry, please feel free to contact by email [email protected]

Related products:

More>>

ASME B16.9 UNS S31803 2205 Concentric Reducer SCH10S

ASME B16.9 ASTM A815 UNS32750 GR2507 60 Degree 3D Bend SCH160S DN100

ASTM B366 UNS N06022 Hastelloy C22 Equal Tee

ASTM A312 TP310S pipe tee

ASTM B366 UNS N10665 Hastelloy B2 Pipe Cross

316L/304L 45 Degree Elbow Stainless Steel Pipe Fittings , Butt Weld Elbow

Stainless Steel Threaded and Socket welded Unions& Pipe fittings

2205 stainless pipe tee

0 notes

Link

ASME B16.9 ASTM A815 UNS S31803 Reducing Tee 1-1/2 - 1/2 Inch SCH40S

FOB PriceUSD 1 - 1,900/Piece

PortNingbo or Shanghai Port

MOQ1 Piece

Supply Ability1000 Pieces Per Day

Payment TermsL/C,T/T,Western Union,MoneyGram

PackagingSeaworthy plywood cases or pallets

Delivery2 - 10 days

Quick Details

Material:2205 (UNS S31803)

Technics:Forged

Type:Reducing Tee

Place of Origin:Zhejiang, China (Mainland)

Model Number:Reducing Tee

Brand Name:Yaang

Connection:Welding, Weld

Shape:Equal

Head Code:Round

Packaging & Delivery

Packaging Detail:Plywood case or fumigation woodern case

Delivery Detail:Usually 2-10 days depend on the quantity

Specifications

ASME B16.9 ASTM A815 UNS S31803 Reducing Tee

1) Size: 1-1/2 - 1/2 Inch

2) THK: SCH40S

3) Material: 2205 (UNS S31803)

ASME B16.9 ASTM A815 UNS S31803 Reducing Tee, like all pipe tees, is in the shape of T with two ends of equal size and the third one slightly smaller. In other words, uns s31803 smls reducing tee is a type of pipe fitting in which the branch port size is smaller than the ports of the run. This type of pipe fitting can also consider size reduction from one of the run ports to the other.

China Reducing Tee Manufacturer Yaang supplies ASME B16.9 ASTM A815 UNS S31803 Reducing Tee, 1-1/2 - 1/2 Inch, SCH40S.

Duplex stainless steel 2205 Chemical Composition %

Grade

C

Mn

Si

P

S

Cr

Mo

Ni

N

2205 (S31803)

Min

Max

-

0.030

-

2.00

-

1.00

-

0.030

-

0.020

21.0

23.0

2.5

3.5

4.5

6.5

0.08

0.20

Type

UNS S31803 Reducing Tee

Size

SMLS Elbow: 1/2"~24" (DN15 - DN600)

Welded Elbow: 1/2"~48" (DN15 - DN1200)

Wall thickness

sch10, sch20, sch30, std, sch40S, sch60,

xs, sch80, sch100, etc

Standards

ASME, ASTM, DIN, JIS, etc

Material

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc

Stainless Steel: ASTM A182 F304/304L/316/316L, etc

Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc.

Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc

Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800,

Hastelloy C276, Hastelloy C22, Hastelloy B1/B2/B3, Alloy 20, etc

Cu-Ni: 90/10,70/30, etc

Surface treatment

Transparent oil, rust-proof black oil or hot galvanized

Applications

Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc

NPS

O.D.

D

O.D.

D1

Center to End

C

Center to End

M

1¼ - 1/2

42.2

21.3

48

48

Application of ASME B16.9 ASTM A815 UNS S31803 Reducing Tee

1. They are manufactured to be used in flow lines for gases, fluids in industrial processes, medical, construction and many other specialized applications.

2. The UNS S31803 Reducing Tee is constructed of heavy materials for rigid applications like extreme high/low temperature resistance etc.

3. The UNS S31803 Reducing Tee is specifically designed for use on process and control systems, instrumentation, and equipment used in chemical, petroleum, fluid power, electronic and pulp and paper plants.

UNS S31803 is widely used in the chemical field and petrifaction field, such as the element of chloride organic and catalyze system.This material especially suit for high temperature environments, impure inorganic acid and organic acid (such as formic acid and acetic acid), sea-water corrosion environments.

ASME B16.9 ASTM A815 UNS S31803 Reducing Tee's Packing & Shipping

1) Packing Method:

Normal packing: plastic film or bubble paper wrapped on product's surface ,protect ends with caps , pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request .

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

Where can we find the high quality ASME B16.9 ASTM A815 UNS S31803 2205 Reducing Tee.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry about products, please feel free to contact us [email protected]

Related products:

More>>

ASTM A403 WP316/316L SMLS Elbow 90DEG 2Inch

Stainless steel schedule 40 Butt Weld Pipe Fittings

Super Duplex Steel UNS32750 GR2507 Seamless Concentric Reducer DN300-150 SCH40S

B16.9 A815 UNS S31803/2205 SMLS Stub End 6 Inch SCH20S

A182 MSS-SP95 F316L Concentric Reducing Threaded Swage Nipple 4inch-2inch SCH80 CL3000

ASME B16.9 A234WPB 3D 90 Degree SMLS Bend

butt welding fittings pipe reducer

ASTM A815 UNS31803 GR2205 3D BEND 90DEG SCH40S DN300

0 notes

Link

ASTM B366 Incoloy 825 Equal Tee 150NB SCH80S

FOB PriceUSD 1 - 1,900/Piece

PortNingbo or Shanghai Port

MOQ1 Piece

Supply Ability1000 Pieces Per Day

Payment TermsL/C,T/T,Western Union,MoneyGram

PackagingSeaworthy plywood cases or pallets

Delivery2 - 10 days

Quick Details

Technics: Cold Forming

Type: Incoloy 825 Equal Tee

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Yaang

Connection: Welding

Shape: Equal

Head Code: Round

Standards: ASTM B366

Surface Treatment: Sand Rolling, Sand Blasting

Material: UNS NO8825 (Incoloy 825)

Packaging & Delivery

Packaging Details:Plywood case or fumigated woodern case or as per customers' requests.Delivery Detail:2 - 10 days after receiving the deposit

Specifications

ASTM B366 Incoloy 825 Equal Tee 150NB SCH80S

Standards:

ASTM: Incoloy Alloy 825

UNS: N08825

W.Nr.: 2.4858

DIN: NiCr 21 Mo

1. Size: 6 inch (DN150)

WT

: Sch80S2.

Material

: UNS NO8825 (Incoloy 825)

3. High quality, competitive price.

Incoloy 825 is a nickel-iron-chromium alloy with additions of molybdenum, copper and titanium. This nickel steel alloy’s chemical composition is designed to provide exceptional resistance to many corrosive environments. It is similar to alloy 800 but has improved resistance to aqueous corrosion. It has excellent resistance to both reducing and oxidizing acids, to stress-corrosion cracking, and to localized attack such as pitting and crevice corrosion. Alloy 825 is especially resistant to sulfuric and phosphoric acids. This nickel steel alloy is used for chemical processing, pollution-control equipment, oil and gas well piping, nuclear fuel reprocessing, acid production, and pickling equipment.

China Equal Tee Manufacturer Yaang supplies ASTM B366 Incoloy 825 Equal Tee, 150NB, SCH80S.

Incoloy Alloy 825 (UNS N08825) Chemical Composition, %

Type

Incoloy 825 Equal Tee

Size

Seamless 1/2" To 48" Welded To 72"

Wall thickness

Sch5S-Sch160, XS,XXS

Standards

ANSI, ASTM,DIN, JIS, BS, ISO, GB, SH, AND HG etc

Material

Stainless Steel: ASTM A403 WP304, 304L, 310, 316, 316L, etc

Carbon Steel: ASTM A234 WPB, WPC ASTM A105 WPHY 42, etc

Alloy Steel: ASTM A234 WP1, etc Low Temperature: ASTM A420 WPL 1, etc

Duplex and super duplex steel: ASTM A815 UNS S31803/S32205/S32750/S32760/S32550

Surface treatment

Sand Rolling, Sand Blasting ,Acid Cleaning.

Packing

wooden case, pallet or as customers’ requirement

Applications

Petroleum,chemical,power,gas,metallurgy, shipbuilding, construction, etc

ASTM Specifications

Pipe SmlsPipe WeldedTube SmlsTube WeldedSheet/PlateBarForgingFittingB423 B424B425B564B366, B564

General Mechanical Properties

Tensile (ksi).2% Yield (ksi)8530-35

Alloy 825 has good mechanical properties from cryogenic temperatures to moderately high temperatures. However, exposure to temperatures above 1000° F can result in microstructural changes that significantly lower ductility and impact strength. Alloy 825 should not be used at temperatures where creep-rupture properties are design factors.

Corrosion Resistance

Alloy 825 has a high level of corrosion resistance. It resists general corrosion, pitting, crevice corrosion, intergranular corrosion, and stress-corrosion cracking in both reducing and oxidizing environments.

In what applications is Incoloy 825 used?

Chemical Processing

Pollution-control

Oil and gas well piping

Nuclear fuel reprocessing

Components in Pickling equipment like heating coils, tanks, baskets and chains

Acid production

APPLICATIONS:

1. Pipe and Tubes for petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce pipes with special specifications according to customers’ requirements;

Where can we find the high quality ASTM B366 Incoloy 825 Equal Tee 150NB SCH80S.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

If any inquiry, please feel free to contact by email [email protected]

Related products:

More>>

ASTM A815 SDUP UNS32750 GR2507 Seamless Concentric Reducer SCH160S DN100-DN80

Stainless Steel Butt Welded Pipe Fitting Stainless Elbow

SDUP ASTM A790 UNS32750 GR2507 90DEG 3D Bend SCH40 DN200

Stainless Steel 10d Pipe Bend Elbow

ASTM A815 UNS31803 GR2205 SMLS 30DEG ELBOW LR SCH80S 80NB

ASTM B366 UNS N06022 Hastelloy C22 Pipe Cap

ASTM A312 TP347H pipe fitting Manufacturer

ASTM A403 MSS SP-43 WP316 Stub End DN80 SCH40S

0 notes

Link

B16.9 A815 UNS S31803/2205 SMLS Stub End 8 Inch SCH20S

FOB PriceUSD 1 - 1,900/Piece

PortNingbo or Shanghai Port

MOQ1 Piece

Supply Ability1000 Pieces Per Day

Payment TermsL/C,T/T,Western Union,MoneyGram

PackagingSeaworthy plywood cases or pallets

Delivery2 - 10 days

Quick Details

Material: Duplex 2205 (UNS S31803)

Technics: Cold forming

Type: Stub End

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Yaang

Connection: Welding

Head Code: Round

Size: 8 Inch (DN200)

Packaging & Delivery

Packaging Details:fumigation free plywood cases or as per customers' requests

Delivery Detail:Delivery after receiving deposit

Specifications

B16.9 A815 UNS S31803/2205 SMLS Stub End

Size: 8 Inch (DN200)

Thk: SCH20S, R=12.7

Material: Duplex 2205 (UNS S31803)

Duplex stainless steel 2205 Chemical Composition %

Grade

C

Mn

Si

P

S

Cr

Mo

Ni

N

2205 (S31803)

Min

Max

-

0.030

-

2.00

-

1.00

-

0.030

-

0.020

21.0

23.0

2.5

3.5

4.5

6.5

0.08

0.20

Type

2205 SMLS Stub End

Standard

ASME B16.9, MSS SP-43, GB/T13401, etc.

Size

1/2"-48"(DN15-DN600)

Wall thickness

SCH5S-SCH40S

Type

Type A, Type B,Type C

Surface treatment

Lathe finish&Abrasive blasting

Stainless steel

304, 304L,304H, 316, 316L,309S,310S, 321,321H,347H,316Ti

Duplex steel

2205, etc

Super duplex steel

2507, etc

Nominal pipe size

Sch.*

Dimensions in mm

Weight

ASTM

ASTM

UNS

in.DtGFR. max.kg/pce304/304L316/316LS31803

1/210s

40s21.3

21.32.11

2.7734.9

34.950.8

50.83.18

3.180.070

0.090●

●●

●-

-

3/410s

40s26.7

26.72.11

2.8742.9

42.950.8

50.83.18

3.180.100

0.120●

●●

●●

●

110s

40s33.4

33.42.77

3.3850.8

50.850.8

50.83.18

3.180.160

0.170●/▲

●●/▲

●●

●

1 ¼10s

40s42.2

42.22.77

3.5663.5

63.550.8

50.84.76

4.760.220

0.250●

●●

●●

-

1 ½10s

40s48.3

48.32.77

3.6873.0

73.050.8

50.86.35

6.350.250

0.310●/▲

●●/▲

●●

●

210s

40s60.3

60.32.77

3.9192.1

92.163.5

63.57.94

7.940.430

0.610●/▲

●●/▲

●●

●

2 ½10s

40s73.0

73.03.05

5.16104.8

104.863.5

63.57.94

7.940.570

0.800●/▲

●●/▲

●●

-

310s

40s88.9

88.93.05

5.49127.0

127.063.5

63.59.53

9.530.730

1.130●/▲

●●/▲

●●

-

410s

40s114.3

114.33.05

6.02157.2

157.276.2

76.211.11

11.111.090

1.870●/▲

●●/▲

●●

-

510s

40s141.3

141.33.40

6.55185.7

185.776.2

76.211.11

11.111.470

2.280●/▲

●●/▲

●-

-

610s

40s168.3

168.33.40

7.11215.9

215.988.9

88.912.70

12.702.150

3.570●/▲

●●/▲

●●/▲

●

810s

40s219.1

219.13.76

8.18269.9

269.9101.6

101.612.70

12.703.220

6.070●/▲

●/▲●/▲

▲▲

-

1010s

40s273.1

273.14.19

9.27323.9

323.9127.0

127.012.70

12.704.700

9.550▲

▲

▲

▲

▲

-

1210s

40s323.9

323.94.57

9.53381.0

381.0152.4

152.412.70

12.707.110

14.290▲

▲

▲

▲

▲

-

1410s

STD355.6

355.64.78

9.53412.8

412.8152.4

152.412.70

12.707.800

15.500▲

-▲

▲-

-

1610s

STD406.4

406.44.78

9.53469.9

469.9152.4

152.412.70

12.709.000

17.380▲

-▲

▲-

-

1810s457.24.78533.4152.412.7011.000▲▲-

2010s508.05.54584.2152.412.7013.500▲▲-

2410s609.66.35692.2152.412.7019.000▲▲-

* Schedule

UNS S31803/2205 SMLS Stub End

What are they?

UNS S31803/2205 SMLS Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired.

They are also called Lap Joints and Vanstone Flared Laps.

How do they work?

A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

Why?

Since Stub Ends are made from material compatible with the designed piping system, back up flanges do not have to be made from the same material. The flange can be made from less expensive material because it never comes in contact with the process fluid.

UNS S31803/2205 SMLS Stub Ends' Types

UNS S31803/2205 SMLS Stub Ends are typically manufactured by two methods. Type A & B Stub Ends are made similar to forged fittings such as Elbows and Flanges. Type C Stub Ends are made by forming pipe to the desired dimensions.

UNS S31803/2205 SMLS Stub Ends are available in two standard lengths, MSS and ANSI.

UNS S31803/2205 SMLS Stub Ends are normally provided with a standard weld bevel

UNS S31803/2205 SMLS Stub Ends dimensions are found on our fitting dimensions page.

Type "A" - Type "B" - Type "C" - Type "CS"

Where can we find the high quality B16.9 A815 UNS S31803/2205 SMLS Stub End 8 Inch SCH20S.

You can visit this website: www.yaang.com (Yaang Pipe Industry Co., Limited).

China Stub End Manufacturer Yaang supplies B16.9 A815 UNS S31803/2205 SMLS Stub End, 8 Inch, SCH20S.

If any inquiry, please feel free to contact by email [email protected]

Related products:

More>>

SDUP ASTM A790 UNS32750 GR2507 90 Degree 3D Bend SCH40S DN200

ASTM A815 2507 Super Duplex Stainless Steel Equal Tee

Butt Welded Pipe Stainless Steel Fitting

MSS-SP43 ASTM A815 UNS31803 GR2205 Welded Stub End BW SHOT LENGTH THK9.35MM DN600

ASTM B366 UNS N10276 Hastelloy C276 90 Degree Elbow

1/2-80 Inch Stainless Steel 90 Degree Elbow

316L NPT Half Pipe Nipple 1 - 1/2 Inch 150LB

ASTM B366 UNS N06022 Hastelloy C22 Pipe Cross

0 notes

Link

316L Socket Weld Tee DN20 3000LBS

FOB PriceUSD 1 - 1,700/Piece

PortNingbo or Shanghai Port

MOQ1 Piece

Supply Ability1000 Pieces Per Day

Payment TermsL/C,T/T,Western Union,MoneyGram

PackagingSeaworthy plywood cases or pallets

Delivery2 - 10days

Quick Details

Material: 316L

Technics: Forged

Type: Socket Weld Tee

Place of Origin: Zhejiang, China (Mainland)

Model Number: 316L-Socket-Weld-Tee-20

Brand Name: Yaang

Pressure: 3000LBS

Size: DN20

Ends: Socket Weld Ends

Packaging & Delivery

Plywood case or fumigated woodern case

or as per customers' requests.

Specifications

Type: Socket Weld Tee

Material: 316L

Pressure: 3000LBS

Size: DN20

Ends: Socket Weld Ends

A Socket Weld Tee is a pipe attachment detail in which a pipe is inserted into a recessed area of a Valve, fitting or flange. In contrast to buttweld fittings, Socket Weld Tees are mainly used for small pipe diameters (Small Bore Piping); generally for piping whose nominal diameter is NPS 2 or smaller.

China Socket Weld Tee Manufacturer yaang supplies 316L Socket Weld Tee, DN20, 3000LBS.

If any inquiry, please feel free to contact by email [email protected]

Chemical Composition and Mechanical Property For 316L

Steel Grade

Chemical Composition

Mechanical Performance

C(Max)

Si(Max)

Mn(Max)

P(Max)

S(Max)

Ni

Cr

Mo

N

Tensile Strength

(Min)

Yield Strength

(Min)

psi

Mpa

psi

Mpa

316L

0.03

0.75

2.00

0.045

0.03

10.0–14.0

16.0–18.0

2.00–3.00

0.1

485

170

Related products:

More>>

stainless steel elbow 1/2 - 48 Inch 90 degree

ASME B16.11 A105 Threaded Full Coupling 2 Inch 3000PSI

ASTM B366 UNS N06022 Hastelloy C22 Concentric Reducer

A815 S32750 pipe fitting

ASTM B366 UNS N10665 Hastelloy B2 Eccentric Reducer

Butt Weld Eccentric Reducer Stainless Steel Pipe Fittings ASTM A105 WPB/A403 WP304

Stainless Steel 304 316 WELDOLET MSS SP-97

1.4462 duplex pipe stub end

0 notes

Link

ASTM A182 316L Pipe Union DN25

FOB PriceUSD 1 - 1,700/Piece

PortNingbo or Shanghai Port

MOQ1 Piece

Supply Ability1000 Pieces Per Day

Payment TermsL/C,T/T,Western Union,MoneyGram

PackagingSeaworthy plywood cases or pallets

Delivery2 - 10 days

Quick Details

Material: 316L

Technics: Forged

Type: Pipe Union

Place of Origin: Zhejiang, China (Mainland)

Model Number: 316L-Pipe-Union-25

Brand Name: Yaang

Connection: Welding

Shape: Equal

Head Code: Round

Packaging & Delivery

Plywood case or fumigated woodern case

or as per customers' requests.

Specifications

Type: Pipe Union

Material: 316L

Pressure: 3000#

Size: DN25

Pipe Union is a type of fitting equipment designed in such a way to unite two pipes which can be detached without causing any deformation to the pipes. Any kind of small diameter piping connections requiring a positive seal and easy assembly as well as disassembly are made with the help of pipe union. In other words, the pipe unions can disjoint two pipes very easily. They are widely demanded in the pipe fitting market.

China Pipe Union Manufacturer yaang supplies ASTM A182 316L Pipe Union, DN25.

If any inquiry, please feel free to contact by email [email protected]

Chemical Composition and Mechanical Property For 316L

Steel Grade

Chemical Composition

Mechanical Performance

C(Max)

Si(Max)

Mn(Max)

P(Max)

S(Max)

Ni

Cr

Mo

N

Tensile Strength

(Min)

Yield Strength

(Min)

psi

Mpa

psi

Mpa

316L

0.03

0.75

2.00

0.045

0.03

10.0–14.0

16.0–18.0

2.00–3.00

0.1

485

170

Related products:

More>>

stainless steel elbow 1/2 - 48 Inch 90 degree

ASME B16.11 A105 Threaded Full Coupling 2 Inch 3000PSI

ASTM B366 UNS N06022 Hastelloy C22 Concentric Reducer

A815 S32750 pipe fitting

ASTM B366 UNS N10665 Hastelloy B2 Eccentric Reducer

Butt Weld Eccentric Reducer Stainless Steel Pipe Fittings ASTM A105 WPB/A403 WP304

Stainless Steel 304 316 WELDOLET MSS SP-97

1.4462 duplex pipe stub end

0 notes