#Dry Screw Vacuum Pump

Text

The Evolution and Impact of Modern Vacuum Technology: A Deep Dive into Single Stage Rotary Vane Pumps and Dry Vacuum Pumps

In the realm of industrial machinery, vacuum pumps hold a significant position due to their diverse applications and essential functions. From maintaining contaminant-free environments in semiconductor manufacturing to facilitating efficient operations in the pharmaceutical industry, vacuum pumps are indispensable. Among the various types, single stage rotary vane pumps and dry vacuum pumps stand out for their unique features and broad range of uses. This blog explores these two categories, delving into their mechanisms, applications, and the leading manufacturers that drive innovation in vacuum technology.

Understanding Single Stage Rotary Vane Pumps

Single stage rotary vane pumps are a type of positive displacement pump that utilizes rotating vanes to create a vacuum. These pumps are known for their simplicity, reliability, and efficiency, making them a popular choice in various industries.

Mechanism and Functionality

A single stage rotary vane pump consists of a rotor housed within a cavity. The rotor is offset within the cavity, creating a crescent-shaped gap. As the rotor turns, the vanes extend and retract, trapping air and compressing it against the pump casing to create a vacuum. The single stage design means that the compression process occurs in one step, which simplifies the construction and maintenance of the pump.

Key Features

Compact Design: Single stage rotary vane pumps are typically compact and lightweight, making them easy to integrate into existing systems.

High Efficiency: These pumps are designed to provide high efficiency, ensuring that they can achieve and maintain the desired vacuum levels with minimal energy consumption.

Durability: Built with robust materials, single stage rotary vane pumps are designed to withstand harsh operating conditions, ensuring longevity and reliability.

Applications of Single Stage Rotary Vane Pumps

1. Laboratory and Research

In laboratories, single stage rotary vane pumps are commonly used for applications such as vacuum filtration, degassing, and distillation. Their ability to provide consistent and reliable vacuum levels is crucial for maintaining the accuracy and precision required in scientific research.

2. Medical Industry

The medical industry utilizes these pumps in a variety of equipment, including vacuum-assisted wound closure systems and diagnostic devices. The compact and reliable nature of single stage rotary vane pumps makes them ideal for critical medical applications.

3. Industrial Processes

In industrial settings, single stage rotary vane pumps are used in processes such as packaging, drying, and material handling. Their efficiency and durability ensure that they can handle the demands of continuous operation in a manufacturing environment.

Single Stage Oil Sealed Vane Pumps: Enhancing Performance

Single stage oil sealed vane pumps operate on the same principle as the standard rotary vane pump but with an added layer of oil sealing. This design enhances the performance and longevity of the pump by providing better sealing and lubrication.

Advantages of Oil Sealing

Improved Vacuum Levels: The oil seal reduces leaks, allowing the pump to achieve higher vacuum levels.

Enhanced Lubrication: Oil serves as a lubricant for the moving parts, reducing wear and extending the life of the pump.

Reduced Maintenance: The oil sealing system minimizes the need for frequent maintenance, making these pumps more cost-effective in the long run.

The Role of Dry Vacuum Pumps in Modern Industry

Dry vacuum pumps represent a significant advancement in vacuum technology, offering a cleaner and more efficient alternative to traditional oil-sealed pumps. As their name suggests, dry vacuum pumps operate without the use of oil or other sealing fluids, which presents several advantages.

Types of Dry Vacuum Pumps

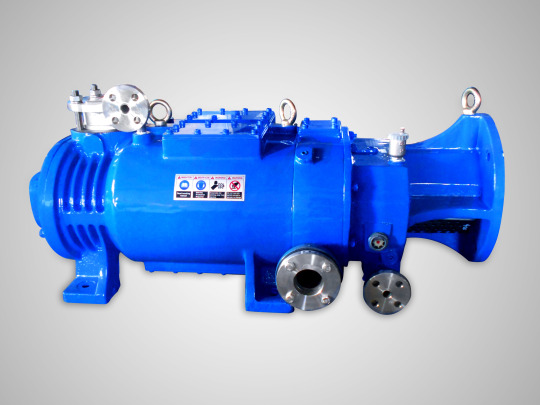

1. Dry Screw Vacuum Pump

Dry screw vacuum pumps use two intermeshing screws to trap and compress air, creating a vacuum. The absence of oil in the compression chamber means that the pumped gases remain uncontaminated, making these pumps ideal for sensitive applications.

2. Dry Rotary Vane Pump

Similar to the oil-sealed rotary vane pump, the dry rotary vane pump uses rotating vanes to create a vacuum. However, these pumps are designed to operate without oil, which reduces contamination and maintenance requirements.

Advantages of Dry Vacuum Pumps

Contamination-Free Operation: The absence of oil eliminates the risk of contamination, which is critical in industries such as pharmaceuticals and food processing.

Lower Maintenance: Without the need for oil changes and other fluid maintenance, dry vacuum pumps require less upkeep, reducing downtime and operating costs.

Environmental Benefits: Dry vacuum pumps are more environmentally friendly, as they eliminate the need for oil disposal and reduce the risk of oil leaks.

Applications of Dry Vacuum Pumps

1. Semiconductor Manufacturing

In the semiconductor industry, maintaining a contaminant-free environment is crucial for producing high-quality products. Dry vacuum pumps are used in processes such as wafer fabrication and coating, where even the slightest contamination can affect product performance.

2. Pharmaceutical Production

The pharmaceutical industry relies on dry vacuum pumps for processes such as freeze-drying and vacuum distillation. The contamination-free operation ensures that the purity and quality of pharmaceutical products are maintained.

3. Food Processing

In food processing, dry vacuum pumps are used for applications such as packaging and dehydration. Their ability to operate without oil ensures that food products remain uncontaminated and safe for consumption.

Leading Manufacturers of Vacuum Pumps

Several manufacturers are at the forefront of developing innovative vacuum pump technologies, providing high-quality solutions for various industries.

1. Edwards Vacuum

Edwards Vacuum is renowned for its range of vacuum solutions, including both single stage rotary vane pumps and dry vacuum pumps. Their commitment to innovation and quality has made them a trusted partner for businesses worldwide.

2. Leybold GmbH

Leybold GmbH offers a comprehensive portfolio of vacuum pumps, including single stage oil sealed vane pumps and dry screw vacuum pumps. Their focus on advanced technology and customer satisfaction ensures that they provide reliable and efficient solutions.

3. Pfeiffer Vacuum

Pfeiffer Vacuum is known for its high-performance vacuum pumps, catering to a diverse range of industries. Their dry vacuum pumps are designed to deliver exceptional performance while minimizing environmental impact.

Conclusion

The evolution of vacuum technology, from single stage rotary vane pumps to advanced dry vacuum pumps, has significantly impacted various industries. These pumps are essential for maintaining efficiency, reliability, and cleanliness in critical processes, ensuring that industries can meet their production and quality standards.

Single stage rotary vane pumps, with their compact design and high efficiency, remain a staple in laboratories, medical devices, and industrial processes. The addition of oil sealing further enhances their performance, making them suitable for more demanding applications.

On the other hand, dry vacuum pumps represent a leap forward in vacuum technology. Their contamination-free operation, lower maintenance requirements, and environmental benefits make them an attractive choice for industries such as semiconductor manufacturing, pharmaceuticals, and food processing.

As technology continues to advance, the future of vacuum pumps looks promising. Innovations in energy efficiency, automation, and sustainability will further enhance the performance and versatility of these essential devices. Leading manufacturers like Edwards Vacuum, Leybold GmbH, and Pfeiffer Vacuum will continue to play a pivotal role in driving this progress, ensuring that businesses worldwide can rely on cutting-edge vacuum solutions to meet their evolving needs.

In conclusion, understanding the different types of vacuum pumps and their applications is crucial for selecting the right solution for specific industrial needs. Whether opting for a single stage rotary vane pump for its simplicity and reliability or a dry vacuum pump for its contamination-free operation and environmental benefits, businesses can leverage these technologies to enhance their operations and achieve their goals.

0 notes

Text

Cutting-Edge Vacuum Solutions: Tekman Dry Screw Vacuum Pump

Discover unparalleled vacuum performance with Tekman's Dry Screw Vacuum Pump. Engineered with precision and innovation, Tekman's pumps deliver exceptional reliability and efficiency in diverse industrial applications. Benefit from advanced technology and superior design, ensuring optimal vacuum levels for your processes. Trust Tekman for high-quality vacuum solutions that exceed expectations. Experience the difference with Tekman Dry Screw Vacuum Pump.

0 notes

Text

0 notes

Text

Vacuum System And Package at Best Price in Noida

Swam dry screw vacuum pumps are designed under SWAM’s unique screw profile engineering to fulfill wide range of chemical and industrial processes. It is operating by rotating a paired screws that efficiently admit gases from inlet into the pump inside and compress through the screw’s swept volume toward the discharge.

For more information Visit Now :https://swamatics.com/ProductDetails.aspx?prod=Vacuum%20Systems%20and%20Packages

#air blower exporter#best process gas blowers#bio gas compressors#Twin lobe blowers#bio gas blowers#Turbo Blower#Mechanical vacuum re compressor#Aeration blowers#Combustion air blowers#Oxidation blowers#Dry screw vacuum pumps#Vane pumps#tri lobe rotary piston#Vacuum system and packages#Tri lobe blowers#Mechanical vacuum boosters

0 notes

Text

Dry screw pumps are increasingly used in the food industry, replacing wet pumps. An experienced technician has provided a helpful resource outlining the benefits of dry vacuum pumps in food packaging. This source explains the various advantages of dry pumps compared to other types of pumps used in the industry.

1 note

·

View note

Text

Atlas Copco UAE Vacuum Pump Solutions & services.

#vacuumpumpsuae#vacuum pump#industrial vacuum pump#vacuum pumps and systems#dry vacuum pump#oil sealed vacuum pump#vane type vacuum pump#oil sealed rotary vacuum pump#Oil Screw Vacuum Pump#screw type vacuum pump#rotary screw vacuum pump#liquid ring vacuum pump#water ring vacuum pump

1 note

·

View note

Text

Screw vacuum pumps come in different types, each suited for specific applications. Courtney & Nye provides a range of screw vacuum pumps, including dry and oil-sealed models, designed to handle diverse needs from high-volume to precision tasks. Explore our selection to find the right screw vacuum pump for your industry, ensuring optimal performance and efficiency.

0 notes

Text

How Dry Screw Vacuum Pumps Work

Writer

Eddy Chen

Printed

October 13, 2023

Phrase depend

2,104

How Screw Vacuum Pumps Work

Screw vacuum pumps are a significant a part of many industrial processes, but they continue to be a thriller to most individuals. On this weblog, we’ll present an in-depth rationalization on how screw vacuum pumps work and their quite a few advantages. We’ll first cowl the fundamentals, together with the…

0 notes

Text

Sevierville AC Repair: How to Troubleshoot Common Problems

Keeping your air conditioning system running smoothly is crucial, especially during the hot summer months. Understanding common AC issues and how to troubleshoot them can save you time and money. This article provides insights into Sevierville AC repair and offers practical tips for troubleshooting common problems.

Common AC Problems and Troubleshooting Tips

1. AC Not Turning On

One of the most common issues homeowners face is an AC unit that won't turn on. Start by checking the thermostat settings to ensure it is set to 'cool' and the temperature is set below the current room temperature. Next, check the circuit breaker to ensure it hasn't tripped. If these steps don't resolve the issue, it might be time to call a Sevierville AC repair specialist for further diagnosis.

2. Inadequate Cooling

If your AC is running but not cooling your home adequately, several factors could be at play. First, check the air filter. A clogged filter can restrict airflow and reduce cooling efficiency. Replace the filter if it appears dirty. Additionally, ensure that all vents are open and unblocked. If the problem persists, low refrigerant levels or a malfunctioning compressor might be the cause, necessitating professional Sevierville AC repair services.

3. Strange Noises

Unusual noises coming from your AC unit can indicate various issues. A buzzing sound might suggest electrical problems, while a grinding noise could signal a problem with the motor bearings. Rattling noises might indicate loose parts. While some noise issues can be resolved by tightening screws or replacing small parts, it's often best to have a Sevierville heating and cooling expert inspect the unit to prevent further damage.

4. Water Leaks

Water pooling around your AC unit is a sign of a problem. This could be due to a clogged condensate drain line or a broken condensate pump. To troubleshoot, try clearing the drain line with a wet/dry vacuum. If this doesn’t resolve the issue, there might be a more significant problem that requires professional attention. Sevierville AC repair technicians can accurately diagnose and fix leaks to prevent water damage.

5. AC Constantly Running

If your AC is running continuously without reaching the desired temperature, it might be too small for your space, or there could be an issue with the thermostat. Check if the thermostat is functioning correctly and placed away from heat sources. Additionally, inspect the outdoor unit to ensure it is clean and free from debris. If the problem persists, consulting a Sevierville heating and cooling professional can help determine if a more significant issue is at play.

Troubleshooting common AC problems can often be done with a few simple checks and maintenance tasks. However, for more complex issues, it’s best to rely on professional Sevierville AC repair services. Regular maintenance and timely repairs by a trusted Sevierville heating and cooling expert can extend the life of your system and ensure it operates efficiently. By addressing issues promptly and performing routine maintenance, you can enjoy a comfortable and cool home throughout the year.

0 notes

Video

undefined

tumblr

A Video on How Dry Screw Vacuum Pumps work? To know more visit: https://tekman.co.in/dry-vacuum-pump-manufacturer-in-vadodara.html

0 notes

Text

0 notes

Link

A dry screw vacuum pump is a type of positive displacement pump that is used to create a vacuum in a closed system. It consists of two interlocking screws that rotate in opposite directions to trap and move gas molecules from the inlet to the outlet of the pump. As the screws rotate, the volume between them decreases, which compresses the gas and increases its velocity.

0 notes

Text

Dry Screw Vacuum Pump Manufacturer, Supplier, Exporter

Swam dry screw vacuum pumps are designed under SWAM’s unique screw profile engineering to fulfill wide range of chemical and industrial processes. It is operating by rotating a paired screws that efficiently admit gases from inlet into the pump inside and compress through the screw’s swept volume toward the discharge.

For more information visit: https://swamatics.com/ProductDetails.aspx?prod=Dry%20Screw%20Vacuum%20Pump

#condencer exhausters#air blower exporter#bio gas blowers#bio gas compressors#positive displacement blowers#turbo blower#roots blower#roots blower manufacturer#truck blowers#vacuum pump manufacturer#Dry screw vacuum pumps

0 notes

Text

Risansi Screw Pumps- The Most Versatile and Effective Pumps for All Industries

Screw pumps from industrial pump manufacturers fall under the category of dry-packing gas transfer pumps. Positive displacement pumps use two screw-shaped intermeshing rotors to transfer gas along the screw's axis. They are utilized in modern vacuum applications, often in conjunction with root blowers, and as oil-free roughing pumps in high and ultrahigh vacuum frameworks.

read more: https://unbusinessnews.com/risansi-screw-pumps-the-most-versatile-and-effective-pumps-for-all-industries/

1 note

·

View note

Text

Dry Vacuum Pumps Market Growth by 2024-2033 | Global Insight Services

“Global Insight Services company has recently revised its global market reports, now incorporating the most current data for 2024 along with projections extending up to 2033.

Dry vacuum pumps are those that do not require any lubrication and can operate without any oil or water. These pumps are used in many industries where cleanliness and purity are required such as in the food, pharmaceutical and semiconductor industries.

To Know More@ https://www.globalinsightservices.com/reports/dry-vacuum-pumps-market/

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Key Trends

The key trends in dry vacuum pumps technology are:

1. Miniaturization: Dry vacuum pumps are becoming increasingly miniaturized. This is due to the increasing demand for compact and portable vacuum pumps.

2. Increased Efficiency: Dry vacuum pumps are becoming more efficient. This is due to the need to reduce energy consumption and improve productivity.

3. Improved Durability: Dry vacuum pumps are becoming more durable. This is due to the need to reduce maintenance costs and improve reliability.

Unlock Growth Potential in Your Industry – Get Your Sample Report Now@ https://www.globalinsightservices.com/request-sample/GIS22650

Key Drivers

The key drivers of the dry vacuum pumps market are the growing demand for semiconductor manufacturing, the increasing adoption of cleanroom technology, and the miniaturization of semiconductor devices.

The semiconductor industry is the major end-use industry of dry vacuum pumps. The increasing demand for semiconductor manufacturing is driven by the growing demand for miniaturized semiconductor devices, such as microprocessors, memories, and sensors.

The adoption of cleanroom technology helps to reduce the risk of contamination and improve the quality of products.

The miniaturization of semiconductor devices is another driver of the dry vacuum pumps market. The miniaturization of semiconductor devices requires the use of smaller and more precise equipment.

Unlock Insights: Request Your Customizable Report Today@https://www.globalinsightservices.com/request-customization/GIS22650

Restraints & Challenges

The key restraints and challenges in the Dry Vacuum Pumps market are the high cost of the pumps, the need for maintenance and upkeep, and the limited number of manufacturers.

Market Segmentation

By Type

Dry Screw

Dry Scroll

Others

By End-Use

Electronics

Pharmaceuticals

Chemicals

Others

Key Players

Ebara Corporation

Pfeiffer Vacuum GmbH

Atlas Copco AB

Gardner Denver Inc.

Ulvac

Agilent Technologies

Becker

Busch Group

Vacuubrand GmbH

Shanghai EVP Vacuum Technology Co. Ltd.

Drive Your Growth Strategy: Purchase the Report for Key Insights@ https://www.globalinsightservices.com/checkout/single_user/GIS22650

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis.

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com/

About Global Insight Services:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

0 notes