#Hex Bolts Fasteners

Text

Call & WhatsApp:- +91 83690 74984

Mail:- [email protected]

Website:- https://anankafasteners.com/

#bolt#studbolt#hex#nut#hexnut#stud#ss316#ss304#monel#nickel#inconel#hastelloy#manufacturer#supplier#fasteners#ananka#anankafasteners#uk#usa#uae#mumbai#gujarat#chennai#delhi#russia#italy#france

2 notes

·

View notes

Text

Duplex Steel S32205 Bolts Suppliers

Duplex Steel S32205 bolts are increasingly popular in various industries for their exceptional properties, combining the benefits of both austenitic and ferritic stainless steels. These bolts offer outstanding mechanical strength, excellent corrosion resistance, and enhanced durability, making them ideal for numerous applications in challenging environments.

In this blog post, we'll dive deep into the features, benefits, applications, and key considerations of Duplex Steel S32205 bolts.

What is Duplex Steel S32205?

Duplex Steel S32205, also known as UNS S32205 or Duplex 2205, is a nitrogen-enhanced duplex stainless steel alloy. It consists of approximately equal parts of austenite and ferrite, giving it a microstructure that provides higher strength and better stress corrosion cracking resistance than conventional stainless steels.

Benefits of Using Duplex Steel S32205 Bolts

Long-Term Performance: With superior strength and resistance to corrosion, these bolts provide long-lasting performance in demanding applications.

Reduced Maintenance Costs: The durability of Duplex S32205 bolts minimizes the need for frequent maintenance and replacement, saving time and money.

Versatility: The bolts can be used in a wide range of applications, from industrial machinery to marine equipment, providing a versatile solution for engineers.

Environmental Benefits: Due to their extended life cycle and resistance to corrosion, these bolts reduce waste and environmental impact over time.

Considerations When Using Duplex Steel S32205 Bolts

Temperature Limitations: While Duplex S32205 offers good performance at moderate temperatures, it may not be suitable for applications requiring sustained exposure to temperatures above 300°C (572°F).

Proper Welding Techniques: Although it offers good weldability, care must be taken to avoid heat-affected zone (HAZ) cracking during welding.

Cost vs. Benefit Analysis: Duplex Steel S32205 may have a higher initial cost than other materials, but its long-term benefits often outweigh these costs, especially in corrosive environments

In addition, to never be independent and inner looking. ASTM A479 Duplex Steel UNS S32205 Round Head Bolts has higher quality which is around twice that of Type 304 austenitic treated steel. This prompts reduced plate thicknesses being used as a piece of manifestations diminishing the weight which is of explicit enormity in things, for instance, weight vessels, amassing tanks, and fundamental applications, for instance, ranges. ASME SA 479 Duplex Steel UNS S31803 Square Bolts is hot worked in the temperature extent of 954-1149 Degree C (1750-2100 Degree F). The structure of ASTM A479 Duplex Steel UNS S32205 Allen Cap Screws includes austenite pools enveloped by a tenacious ferrite arrange. Buy Duplex Stainless Steel Bolts in driving business division cost from us.

DUPLEX STEEL UNS S31803 & UNS S32205 SCREW PHYSICAL PROPERTIES

Density

lbm/in3

Electrical

Resistivity

mW•in

Electrical

Resistivity

(in x 10-6)

Heat

Capacity

BTU/lbm•°F

Thermal

Conductivity

(BTU/hr•ft•°F)

at 68°F

0.278

0.112

8.7

27.6

33.5

at 212°F

0.119

9.2

26.1

35.4

at 392°F

0.127

9.8

25.4

37.4

at 572°F

0.134

10.4

24.9

39.4

Conclusion

Duplex Steel S32205 bolts are an excellent choice for industries that require a combination of high strength, excellent corrosion resistance, and durability. Whether you are in the oil and gas sector, marine industry, or chemical processing, these bolts offer reliable performance in challenging conditions.

By choosing Duplex Steel S32205 bolts, you invest in quality, longevity, and safety, ensuring the optimal performance of your projects and operations.

For More Information:

Visit Our Website -https://www.chhajedfastners.com/

Call Us – +91-932-111-3630

Email Us- [email protected]

#STM A193 Duplex 2205 Fasteners#Hex Head Bolt#Duplex Steel UNS S31803 & UNS S32205 Bolts Manufacturers in Mumbai#Duplex Steel UNS S31803 & UNS S32205 Bolts Suppliers in Mumbai#Duplex Steel UNS S31803 & UNS S32205 Bolts Exporters in Mumbai#Duplex Steel UNS S31803 & UNS S32205 Bolts Importers in Mumbai.

0 notes

Text

#types of fasteners#socket screws#machine screws#tapping screws#hex bolts#blind rivets#Semi-Tubular Rivets

0 notes

Text

1 note

·

View note

Text

Choosing the Right Stainless Steel Fastener for Extreme Temperature Conditions

Ananka Group is one of the Top SS Fasteners Manufacturers in India, In industrial areas where high temperatures are common, choosing the right fastener materials becomes crucial. Stainless steel, which is recognized for its corrosion resistance and durability, is often the preferred material. However, not all stainless steel alloys are created equally, particularly in high-temperature applications. In this post, we'll go over the most significant factors and techniques for selecting the finest stainless steel fastener for high-temperature applications.

Understand the Operating Conditions:

Before selecting stainless steel fasteners High-temperature applications require a thorough grasp of the operating conditions. The maximum and variable temperatures, exposure to corrosive chemicals, and probable thermal cycling should all be carefully considered. This data will serve as the basis for selecting a stainless steel alloy that can handle the unique difficulties of the climate. Additionally, we are the Bolt Supplier in India

Select the Right Stainless Steel Alloy:

Different stainless steel alloys have varied degrees of resistance to high temperatures and corrosion. Some of the most often utilised alloys for high-temperature applications are:

Austenitic Stainless Steels (e.g., 304, 316):

These alloys are noted for their strong corrosion resistance and are appropriate for moderately high-temperature situations.

Ferritic Stainless Steels (e.g., 430, 446):

Ferritic alloys have strong oxidation resistance and are ideal for applications that need lower temperatures.

Martensitic Stainless Steels:

These alloys are heat-treatable and have good strength at high temperatures, making them ideal for specialised applications.

Nickel-Based Alloys (e.g., Inconel, Hastelloy):

These alloys are highly resistant to high-temperature corrosion and are often chosen for extreme conditions.

Consider Mechanical Properties:

Aside from corrosion resistance, the mechanical qualities of the selected stainless steel alloy are critical. Tensile strength, yield strength, and elongation at high temperatures are all important factors to consider. A comprehensive grasp of the mechanical qualities assures that the chosen Fastener will perform consistently under stress at high temperatures.

Evaluate Oxidation Resistance:

High temperatures frequently cause oxidation, which can affect the integrity of stainless steel fasteners. Choosing an alloy with high oxidation resistance is critical to avoiding the production of harmful oxide layers. Alloys combining chromium, aluminium, and silicon have superior oxidation resistance and can endure extended exposure to high temperatures. Also, We manufacture eye bolts, U-bolts, and Hex nuts

Thermal Expansion and Contraction:

Consider the coefficient of thermal expansion of the selected stainless steel alloy. In applications with frequent temperature changes, thermal expansion and contraction can impact the fastener's performance. Matching the thermal expansion characteristics of the fastener material to the surrounding components helps prevent issues such as loosening or stress fractures over time.

Selecting the right SS Fasteners for high-temperature applications involves a comprehensive analysis of operating conditions, material properties, and environmental factors. Engineers and industry experts may make educated judgments to enhance the lifetime and dependability of fasteners in harsh temperature settings by first knowing the application's particular needs. Always speak with a materials expert or supplier to select the best stainless steel alloy for your specific high-temperature application.

For more details:

Also Visit: Fasteners Supplier in India

#SS Fasteners#Hex nuts#U-bolts#eye bolts#Bolt Supplier in India#Stainless Steel Fasteners#SS Fasteners Manufacturers in India

0 notes

Video

youtube

👉FIXDEX M8 concrete screw 💗large quantity with best price

#youtube#FIXDEX concrete screw#concrete anchors#concrete screws#Best Concrete Screws#Concrete fasteners#Concrete Screws and Screw Bolts#Best Concrete Screw#Concrete Anchor for Screw#High Strength Concrete Screw Anchors#Concrete Anchors & Fasteners#Hex Head Concrete Screw#Fasteners for Concrete#Galvanized Concrete Screw#Concrete Screw Bolts#Concrete wedge anchor bolts#3 16 stainless steel concrete screws#rawl bolts for concrete#heavy duty concrete screws#screws for concrete floor#m8 concrete screws#m10 concrete screws#concrete screws ace hardware#blue concrete anchors#ss concrete screws#concrete wedge bolts#concrete anchor bolt#wood to concrete fasteners#screwbolts

0 notes

Text

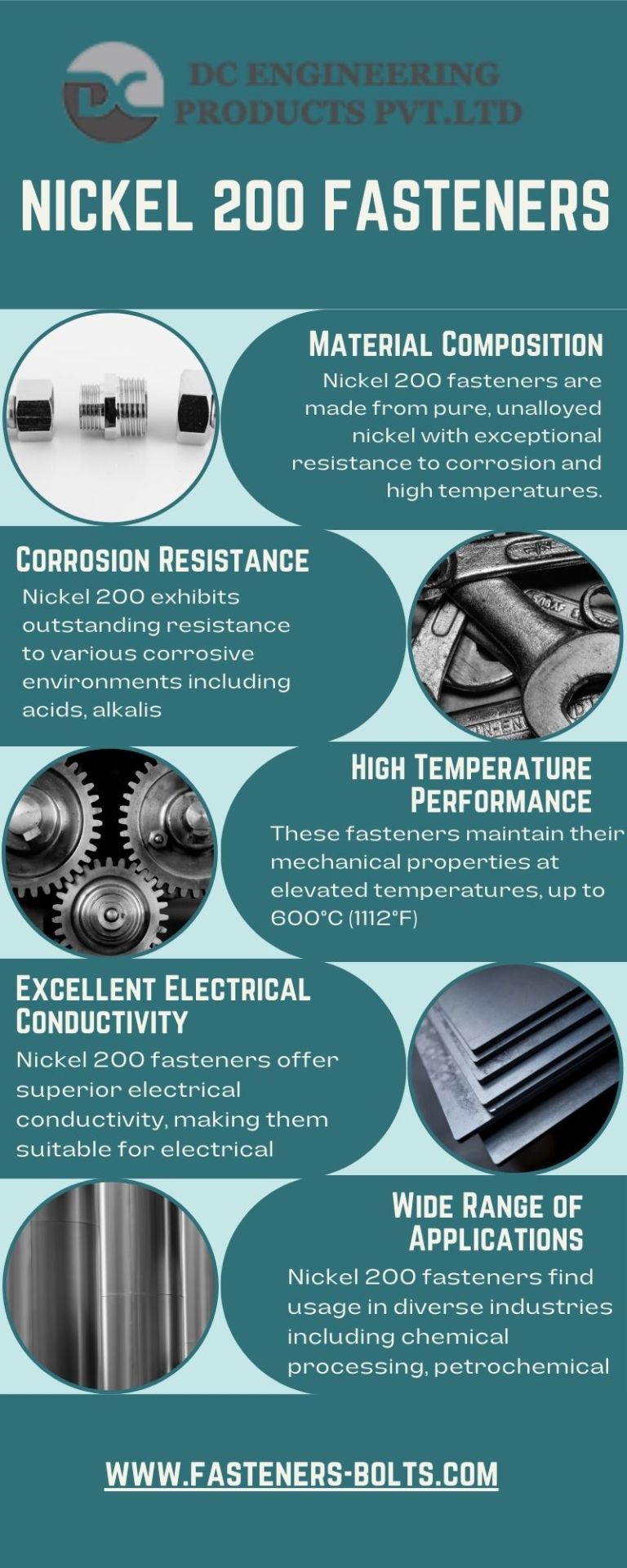

DC Engineering is leading Manufacture and Exporter of High quality of Nickel 200 Fasteners, UNS N02200 Fasteners, Alloy 200 Fasteners

#Nickel 200 Fasteners#High Nickel Alloy 200 Fastener Manufacturer#Nickel Alloy 200 Heavy Hex Nuts#Nickel 200 Hex Head Bolt#UNS N02200 Fastener#DIN 2.4066 Fasteners Supplier#Nickel 200 Spring Washer#Alloy 200 Socket Cap Screws#Nickel Alloy 200 U-bolts#Nickel Alloy 200 Hex Cap Screws#200 Nickel Alloy Hex Bolts

0 notes

Text

Bolts and Nuts for Ship Building and petrochemical industry | BigBoltNut

We manufacture world class quality bolts used in ship building industry, from zinc plated bolts & nuts to manufacturing world class stainless steel bolts and nuts for ship building, our company has the expertise to supply to this industry worldwide. Stainless steel and special marine grade bolts & nuts are used in the ship building industry which are being manufactured by us at our factory. These bolts & nuts used in the ship yards and ships are of world class quality in stainless steel and electroplated steel grades. We manufactures petrochemical stud bolts are used extensively in petrochemical project. We are exporting petrochemical grade stud bolts to over 60 countries all over the world

#washer manufacturer#high tensile fasteners#structural bolts manufacturer#stainless steel bolts#hex nuts#stud bolts#standard hex nuts

0 notes

Text

JF Engineering Products LLP is Prominent Manufacturer, Supplier and Stockist of A2-70 Stainless Steel Fasteners. We Provide High quality of A2-70 SS Fasteners at best price. Click here and Get more Info. JFE is the best manufacturer of buttweld and forged pipe fittings, flanges, fasteners, bars, pipes and tubes of high quality of various grades and materials in Mumbai, India.

#A2-70 Stainless Steel bolt#A2-70 Stainless Steel Stud Bolt#A2-70 Stainless Steel Hex Bolt#Grade A2-70 SS Fasteners#Stainless Steel Fasteners#ASTM A193 SS A2-70 Hex Bolt

0 notes

Text

Buy SS Hex Bolts in Ahmedabad at Wholesale Price

Are you looking to buy SS hex bolts in Ahmedabad? C P Fasteners is a leading SS hex bolts manufacturer in Ahmedabad, India with great experience in the automotive industry. We offer a wide range of SS hex bolts for your fastening needs. Our hex bolts are made of high-quality stainless steel, ensuring durability and corrosion resistance. Buy Now!!!

#SS hex bolts#SS hex bolts in Ahmedabad#buy SS hex bolts#SS hex bolts wholesale#buy SS hex bolts in Ahmedabad#C P Fasteners

1 note

·

View note

Text

Ananka

1: Introduction to Manufacturing Hanger Bolt Fasteners

Introduction

Hanger bolts are unique fasteners designed for applications where a stud with both machine and wood threads is required. These fasteners are used extensively in furniture assembly, wood construction, and other applications where a threaded connection is needed in both wood and metal. In this series, we will explore the process of manufacturing hanger bolts, from material selection to final quality control, providing insights into the precision and care involved in creating these versatile fasteners.

Overview of the Manufacturing Process

The production of hanger bolt fasteners follows several stages:

1. Material Selection

2. Cold Forging

3. Thread Rolling

4. Heat Treatment

5. Surface Finishing

6. Quality Control and Packaging

These stages ensure that the hanger bolts are not only strong but also precise and reliable in various applications.

Conclusion

Hanger bolts play a vital role in numerous industries, and their manufacturing involves detailed processes to ensure durability and effectiveness. The following s will explore each step in more depth, starting with material selection.

Hanger Bolt Fasteners

2: Material Selection for Hanger Bolt Fasteners

Introduction

The material chosen for hanger bolt manufacturing significantly influences their performance. As hanger bolts need to endure both mechanical stress and environmental exposure, the right material is critical. In this , we'll discuss the different materials typically used in hanger bolt production and the reasons behind these choices.

Common Materials Used

Hanger bolts are typically made from:

- Carbon Steel: This material is commonly used for its high tensile strength and cost-effectiveness, making it suitable for general-purpose applications.

- Stainless Steel: Known for its excellent corrosion resistance, stainless steel hanger bolts are ideal for outdoor or moisture-prone environments.

- Brass: Brass hanger bolts are favored for applications where non-magnetic properties and corrosion resistance are required.

- Alloy Steel: For heavy-duty applications, alloy steel hanger bolts provide superior strength and durability.

Importance of Material Selection

Selecting the correct material ensures the hanger bolts will be able to handle the mechanical loads they are exposed to while providing the required longevity. The material also impacts the bolt's corrosion resistance, which is critical in certain environments.

Conclusion

Choosing the appropriate material for hanger bolts is the first step in ensuring their reliability in service. With the right materials selected, the next step is cold forging, which we’ll cover in the following .

Hanger Bolt Fasteners manufacturer in India

3: Cold Forging in the Manufacturing of Hanger Bolt Fasteners

Introduction

Cold forging is a crucial step in manufacturing hanger bolts, forming the raw material into the desired shape without the need for heating. This method ensures high strength and precision, which are essential for the performance of hanger bolts. In this , we’ll delve into the cold forging process and its significance in producing hanger bolts.

Cold Forging Process

The cold forging process for hanger bolts involves:

- Cutting: The raw material is cut into blanks of the appropriate size.

- Heading: The blanks are placed into forging dies, and pressure is applied to form the initial bolt shape, including the head and partial threading for the wood side.

- Forming Threads: The wood threading portion of the hanger bolt is shaped during this phase.

Advantages of Cold Forging

- Increased Strength: Cold forging improves the mechanical properties of the material, increasing the bolt's strength and resistance to wear.

- Precision: The process allows for tight dimensional control, ensuring uniformity in the bolts.

- Cost-Effective: Cold forging minimizes material waste and energy consumption, making it an efficient production method.

Conclusion

Cold forging is an essential step that contributes to the durability and precision of hanger bolts. With the basic shape of the bolt formed, the next stage is thread rolling, which finalizes the threads and readies the bolt for heat treatment.

Hanger Bolt Fasteners manufacturing

4: Thread Rolling for Hanger Bolt Fasteners

Introduction

Thread rolling is one of the most critical steps in hanger bolt manufacturing. It forms the machine threads on one end of the bolt while refining the wood threads on the other. In this , we’ll explore the thread rolling process and the importance of precision in thread formation for hanger bolts.

Thread Rolling Process

Thread rolling involves the following steps:

- Machine Threads: The blank is placed between hardened dies that press and roll the metal to form precise threads on the machine end.

- Wood Threads: The threads on the wood end are either rolled or, in some cases, cut, ensuring that the hanger bolt will secure firmly in wood.

Advantages of Thread Rolling

- Improved Strength: Thread rolling produces stronger threads by compressing the material rather than cutting it, leading to enhanced fatigue resistance.

- Efficiency: Rolling threads is faster and more cost-effective than cutting, and it results in a smoother finish.

- Precision: The process ensures uniform thread dimensions, which are vital for the proper fit and function of the hanger bolts.

Conclusion

Thread rolling enhances the performance of hanger bolts by creating strong, precise threads that meet exact specifications. The next step in the manufacturing process is heat treatment, which strengthens the fastener and improves its durability.

Hanger Bolt Fasteners exporter

5: Heat Treatment for Hanger Bolt Fasteners

Introduction

Heat treatment is an essential part of hanger bolt manufacturing that alters the internal structure of the metal to enhance its mechanical properties. The process involves heating and cooling the bolts in a controlled environment to improve hardness, strength, and resistance to wear. This will discuss the heat treatment process and its benefits for hanger bolts.

Heat Treatment Process

The typical heat treatment process for hanger bolts includes:

- Quenching and Tempering: The bolts are heated to a specific temperature and then rapidly cooled (quenched) to increase hardness. After quenching, tempering follows, where the bolts are reheated to a lower temperature to reduce brittleness while maintaining strength.

- Annealing (Optional): In some cases, annealing may be used to soften the metal for further machining or to relieve internal stresses.

Benefits of Heat Treatment

- Improved Strength: Heat treatment increases the tensile and yield strength of hanger bolts, making them more resistant to mechanical stress.

- Durability: The process enhances the bolts' wear and fatigue resistance, ensuring a longer service life.

- Customization: Different heat treatment processes can be applied to achieve specific mechanical properties, depending on the application.

Conclusion

Heat treatment is a crucial process that significantly improves the performance of hanger bolts, ensuring they are strong and durable. With the bolts properly treated, the next stage is surface finishing, which provides corrosion protection and improves the appearance of the bolts.

Hanger Bolt Fasteners stockist

6: Surface Finishing and Quality Control for Hanger Bolt Fasteners

Introduction

Surface finishing and quality control are the final steps in manufacturing hanger bolts. These processes ensure the bolts are protected from corrosion, have an appealing appearance, and meet all specifications. In this , we’ll discuss the various surface finishing techniques and the rigorous quality control measures used in hanger bolt production.

Surface Finishing Techniques

Common surface finishing methods for hanger bolts include:

- Galvanizing: A zinc coating is applied to protect the hanger bolts from corrosion, making them suitable for outdoor use or damp environments.

- Electroplating: A layer of metal, such as nickel or chrome, is deposited on the surface for improved corrosion resistance and a polished appearance.

- Black Oxide Coating: Provides moderate corrosion resistance and an attractive black finish, often used for indoor applications.

Quality Control Measures

To ensure the hanger bolts meet industry standards, rigorous quality control processes are employed, including:

- Dimensional Inspection: Each bolt is measured to ensure it meets precise size and threading specifications.

- Mechanical Testing: The bolts undergo tensile strength and hardness testing to confirm they can withstand the required loads.

- Visual Inspection: Surface defects are checked, and the finish is inspected for uniformity and adherence to specifications.

Conclusion

Surface finishing and quality control ensure that hanger bolts are ready for use in a variety of applications, providing both protection and reliability. By adhering to strict quality standards, manufacturers can produce hanger bolts that perform consistently and meet the needs of their customers.

This series of s highlights the detailed manufacturing process behind hanger bolt fasteners, from material selection to surface finishing and quality control. Each stage is essential in creating strong, reliable, and high-quality hanger bolts for various industrial and commercial applications.

Hanger Bolt Fasteners manufacturer in Mumbai

0 notes

Text

SS Studs in Ahmedabad

SS Studs in Ahmedabad can be used as hanger bolts.We are leading manufacturers and suppliers of SS Studs in Ahmedabad, Gujarat, India - C P Fastener. We are another supplier of stainless steel fasteners, including studs, based in Ahmedabad.

#SS Studs in Ahmedabad#SS HEX BOLTS#High Tensile Fasteners#SS Threaded Bars Ahmedabad#SS Spring Washers#High Tensile Fasteners Ahmedabad#SS Threaded Bars

0 notes

Text

Bagadia is Well Known NUTS Manufacturers, Exporters & Suppliers based in Mumbai, India.

#hex nuts#fasteners manufacturers#foundation bolt#eyebolts manufacturer#industrial fasteners#fasteners#bolt

0 notes

Video

youtube

11B6S M3 M5 Hex Blind Self Clinching Standoff Rivet Nut Forming Cold Forging machine.

Whatsapp: +86 13431255254

#youtube#standoff rivet nut#rivet nut machine#11b6s rivet nut machine#self clinching rivet nut#cold forging machine#nut bolt former machine#hex blind rivet nut#blind rivet nut machine#fasteners#nut bolt#self clinching rivet nut machine#taishin nut former machine#taishin machine#cold header machine#11B6Snutformermachine

0 notes

Link

SS Hex Bolt in Ahmedabad: A long-lasting option for fastening!

Hex Bolt is a form of bolt with a six-sided head used for various fastening purposes. It is used to safeguard two or more objects together and is usually used in conjunction with a hex nut. The reason for its popularity is its firm grip on the product, which prevents loosening and keeps them in place for longer. The design, length, style, and material options vary by application; therefore, you should give it a shot. As we all know, it has numerous applications and thus has a high demand in various fastening applications.

Hex bolts in Ahmedabad are weaved bolts distinguished by their six-sided hexagonal-shaped head. Hex bolts can be fully threaded or partially threaded (with a clear shank along part of the body) and are useful in a variety of applications, most notably machinery and construction.

They are available in a variety of types, sizes, materials, and finishes, giving you the freedom and flexibility to choose the bolt that is best suited to your specific task or application. Because of their distinctive head shape, hex bolts are also known as hex head bolts or hexagon bolts.

Hex head bolts are flexible fasteners that can be used in a wide range of industries and applications. Hex head screws for wood, metal, and a variety of other environments and scenarios are examples of hex bolt applications.

Hex Bolt Manufacturers in Ahmedabad will provide you with all of its varieties in various materials and coatings. It is a long-lasting fastening option because it can be used on outdoor, indoor, and other construction projects. This fastener's strong grip makes it long-lasting and secure in its hold. It is also very simple to install and uninstall. You can use them in any application because they come in an infinite thread or other options that meet your needs while also giving you the best value for money.

0 notes

Video

youtube

FIXDEX & GOODFIX Attended Expo Nacional Ferretera 2023

#youtube#Fastener Fair Mexico 2023#expo nacional ferretera 2023#Fastener Fair México#Expo Seguridad México#Expo Eléctrica SOLAR#Expo Eléctrica#Expo Ferretera#Expo Nacional Ferretera#wedge anchor exhibition#Threaded rods exhibition#Hex bolts exhibition#Hex nuts exhibition#Photovoltaic bracket exhibition

0 notes