#High Efficiency Inspection Machine Batching Machine

Explore tagged Tumblr posts

Text

Behind the Scenes: A Day in the Life of a Hot Sauce Producer

Morning: Sourcing the Best Ingredients

The day starts early at Modern Food Products with the sourcing of fresh ingredients. As a leading hot sauce supplier in KSA, the company emphasizes quality and consistency. The procurement team works closely with local farmers to ensure a steady supply of high-quality peppers, garlic, and other essential ingredients. The team conducts thorough inspections to ensure that only the best produce makes it into their sauces.

Farm Inspections and Quality Control

Farm Visits: Regular visits to farms are essential to maintain strong relationships with farmers and to ensure sustainable farming practices.

Quality Checks: Each batch of peppers is inspected for color, size, and heat level. Only the peppers that meet the strict standards are approved for processing.

Late Morning: Production Begins

Once the ingredients arrive at the production facility, the real magic begins. The production process at Modern Food Products is a well-oiled machine, designed to maximize efficiency while maintaining the highest standards of quality.

Washing and Preparing Ingredients

Cleaning: All ingredients undergo a rigorous cleaning process to remove any dirt, pesticides, or contaminants. This step is crucial for maintaining the purity and safety of the hot sauce.

Preparation: Peppers are sorted, and stems are removed. Garlic is peeled, and other ingredients are prepped according to the recipe specifications.

Mixing and Cooking

Recipe Formulation: Modern Food Products prides itself on its proprietary recipes, which are carefully guarded secrets. Each recipe is a precise blend of ingredients designed to deliver a unique flavor profile.

Cooking: The ingredients are then cooked in large vats. The cooking process is closely monitored to ensure that the flavors meld perfectly and that the sauce achieves the desired consistency. Temperature control is critical, as overheating can alter the flavor and texture of the sauce.

Afternoon: Bottling and Packaging

After cooking, the hot sauce is ready to be bottled. This stage is as crucial as the preparation and cooking stages, involving stringent hygiene and quality control measures.

Bottling Process

Sterilization: Bottles are sterilized to prevent any contamination. This is a key step in ensuring the shelf stability of the hot sauce.

Filling: The hot sauce is poured into bottles using automated machines that ensure uniformity and prevent spillage. Each bottle is filled to the exact level to maintain consistency across batches.

Labeling and Packaging

Labeling: Bottles are labeled with the brand’s distinctive design. For clients interested in hot sauce private labelling in Saudi Arabia, Modern Food Products offers customization options to create unique labels that reflect their brand identity.

Packaging: The labeled bottles are packed into boxes for distribution. Packaging is designed to protect the bottles during transit and storage, ensuring that the product reaches consumers in perfect condition.

Late Afternoon: Quality Assurance and Testing

Quality assurance is a cornerstone of Modern Food Products' operations. Throughout the day, samples from each batch are tested to ensure they meet the company’s high standards.

Sensory Evaluation

Taste Testing: A team of experienced tasters evaluates the flavor, heat level, and consistency of the hot sauce. This step ensures that every batch delivers the expected taste experience.

Visual Inspection: The color and texture of the sauce are inspected to ensure they align with the product specifications.

Laboratory Testing

Microbial Testing: Samples are tested for microbial contamination to ensure the hot sauce is safe for consumption.

Chemical Analysis: The pH levels and other chemical properties are analyzed to ensure the sauce’s stability and shelf life.

Evening: Logistics and Distribution

As the day winds down, the focus shifts to logistics and distribution. Modern Food Products, being a prominent hot sauce producer in the Kingdom of Saudi Arabia, has a well-established distribution network that ensures timely delivery to retailers and customers.

Inventory Management

Stock Monitoring: Inventory levels are monitored in real-time to ensure there is always enough stock to meet demand.

Order Fulfillment: Orders from retailers and private label clients are processed and prepared for shipping.

Shipping and Delivery

Distribution: The packed hot sauce bottles are loaded onto trucks for delivery to various locations across KSA. The logistics team ensures that the products are delivered on time and in perfect condition.

Export: For international clients, including those looking for a hot sauce supplier in KSA, the export team handles all the necessary documentation and logistics to ensure smooth international shipping.

Conclusion: The Passion Behind the Spice

The journey of hot sauce from farm to bottle is a testament to the dedication and passion of the team at Modern Food Products. As a leading hot sauce producer in the Kingdom of Saudi Arabia, the company’s commitment to quality, innovation, and customer satisfaction is evident in every bottle they produce. Whether you are enjoying their signature hot sauce or benefiting from their hot sauce private labelling in Saudi Arabia, you can be sure that each drop is crafted with care and expertise.

So, the next time you reach for that bottle of hot sauce, remember the intricate process and the hardworking individuals behind it. From the early morning farm inspections to the late evening logistics operations, every step is a crucial part of bringing that fiery flavor to your table.

#Hot sauce supplier in KSA#Hot sauce private labelling in Saudi Arabia#Hot Sauce producer in Kingdom of Saudi Arabia#Condiments manufacturer#Condiments exporter#Private Labelling services#Food processing company#Food distributors company#Food manufacturing companies#Food product company in India#India#UAE#KSA#Oman

4 notes

·

View notes

Text

Top Quality Brass Coils Manufacturers in India

Top-Quality Brass Coil Manufacturers in India – Spotlight on KWM India

India has emerged as a global leader in the production of non-ferrous metals, especially brass. Among the most widely used brass products in the industrial and manufacturing sectors are brass coils manufacturers. These coils are valued for their strength, ductility, corrosion resistance, and excellent thermal and electrical conductivity. As demand grows across sectors such as electronics, construction, automotive, and plumbing, choosing a reliable and high-quality brass coil manufacturer becomes essential. One company that has consistently delivered on quality and innovation is KWM India.

Brass Coils: A Critical Industrial Material

Brass coils are produced by rolling brass sheets into a coiled form. These coils offer great flexibility in terms of dimensions and can be cut, stamped, or molded according to specific requirements. Depending on the copper-zinc ratio, brass coils can be tailored for various properties like malleability, strength, and resistance to corrosion.

Industries use brass coils in numerous applications such as:

Electrical connectors and terminals

Radiators and heat exchangers

Architectural trims and components

Plumbing fixtures and gas fittings

Decorative hardware and consumer goods

Given their widespread use, quality becomes a top priority for any business looking to source brass coils.

KWM India – A Leader in Brass Coil Manufacturing

KWM India, based in Jamnagar, Gujarat – also known as the “Brass City of India” – is one of the country’s leading manufacturers and exporters of high-quality brass coils. With years of experience and technical expertise, KWM India has built a strong reputation for delivering precision-engineered brass products that meet both Indian and international quality standards.

What makes KWM India stand out in a competitive industry is its commitment to using only the finest raw materials, combined with advanced manufacturing techniques and stringent quality control.

State-of-the-Art Infrastructure

KWM India operates modern production facilities equipped with high-capacity rolling mills, annealing furnaces, and slitting machines. These allow the company to produce brass coils in a variety of widths, thicknesses, and tempers to meet customer-specific requirements.

Whether you need soft, half-hard, or full-hard brass coils, KWM India can customize production to deliver exactly what your application demands. The company also ensures consistency in coil thickness, smooth edges, and superior surface finish — critical factors in industries where precision matters.

Uncompromising Quality Control

One of KWM India’s strongest differentiators is its dedication to quality assurance. Every batch of brass coils mnufacturers undergoes strict quality inspections, including:

Chemical composition testing

Tensile and yield strength analysis

Dimensional accuracy checks

Surface finish inspection

KWM India is also ISO-certified, reinforcing its commitment to global quality standards. Their experienced quality control team ensures that customers receive defect-free products, every time.

Focus on Sustainability and Innovation

Apart from quality, KWM India takes pride in maintaining environmentally friendly and sustainable manufacturing practices. The company implements recycling processes and energy-efficient methods, minimizing its carbon footprint while maintaining production efficiency.

KWM India is also actively investing in research and development to enhance product performance and develop new alloys that meet the evolving needs of the market.

Customer-Focused Approach

KWM India has built long-term partnerships with clients across India, the Middle East, Europe, and Southeast Asia. Their customer-centric model includes:

Competitive pricing

On-time delivery

Customized orders

Transparent communication and support

Their technical team works closely with clients to understand their exact needs and recommend the right brass coil grade and specifications for their applications.

Conclusion

With the rapid expansion of industrial sectors worldwide, the need for high-quality brass coils is on the rise. Among the top brass coil manufacturers in India, KWM India has positioned itself as a reliable, innovative, and quality-driven partner. Their combination of technical expertise, advanced infrastructure, and customer-first philosophy makes them a top choice for businesses seeking premium brass coil solutions.

Whether you are a small-scale manufacturer or a large industrial player, sourcing brass coils from KWM India ensures that you receive not just a product, but a commitment to quality, consistency, and long-term performance.

Visit:- https://www.kmwindia.com/brass-coils.html

0 notes

Text

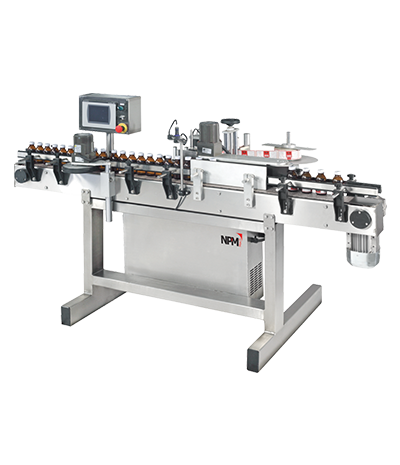

Revolutionizing Pharma Production: The Role of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Introduction

In the dynamic world of pharmaceuticals, precision, hygiene, speed, and compliance are non-negotiable. As the demand for high-quality medicines continues to rise globally, the pharmaceutical industry must meet rigorous standards in both production and packaging. This is where Pharma Packaging Machines come into play—ensuring products are safely, efficiently, and accurately packed before reaching the end-user.

At NPM Machinery Pvt. Ltd., we understand the critical importance of packaging in the pharma value chain. As a leading manufacturer of pharma packaging machines, our mission is to empower pharmaceutical companies with robust, automated, and intelligent machinery that supports regulatory compliance while improving productivity and product integrity.

In this blog, we will delve into the importance of pharma packaging machines, the types available, their benefits, and why NPM Machinery Pvt. Ltd. is your ideal partner in pharmaceutical automation.

Why Pharma Packaging Machines Matter

Pharmaceutical packaging is far more than just enclosing a product in a container. It is a protective barrier, a compliance requirement, a branding tool, and an enabler of global logistics. A well-packaged pharmaceutical product ensures:

Product integrity during transport and storage

Accurate dosage and ease of administration

Protection against contamination and tampering

Compliance with FDA and other global regulatory norms

Efficient serialization and tracking

Manual packaging simply cannot keep up with the high-volume, high-precision demands of modern pharmaceutical production. That’s where automated packaging solutions step in—offering speed, consistency, and compliance.

Core Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

At NPM Machinery Pvt. Ltd., we design and manufacture a full spectrum of advanced pharma packaging machines tailored to the needs of small-scale manufacturers as well as large pharmaceutical giants. Here are the most common types and their applications:

📦 1. Blister Packaging Machines

Ideal for packing tablets and capsules in pre-formed plastic blisters sealed with aluminum foil

Ensures tamper-proof packaging and extended shelf life

Used widely in retail and hospital pharmacy sectors

💊 2. Strip Packaging Machines

Designed to wrap tablets and capsules between aluminum or plastic strip foils

Compact, precise, and perfect for heat-sensitive medicines

Offers high output and minimal material wastage

🧪 3. Bottle Filling and Capping Machines

Automates filling of syrups, suspensions, and other liquids into bottles with accurate volume control

Integrates seamlessly with capping units for secure sealing

Customizable for different bottle sizes and materials

🏷️ 4. Labeling Machines

Applies labels accurately on bottles, ampoules, vials, or boxes

Supports serialization and barcoding for traceability

Compatible with multiple label shapes and sizes

🧼 5. Washing & Sterilizing Machines

Cleans vials, ampoules, and bottles before filling to ensure zero contamination

Uses air and water jets with complete automation

Essential for injectable and parenteral products

🧴 6. Cartoning Machines

Automates the packing of blister packs, bottles, or tubes into cartons

Integrates leaflet insertion and batch coding

Enhances product presentation and traceability

🎯 7. Inspection Machines

Detects broken tablets, missing capsules, misprinted labels, and other defects

Ensures every packaged product meets quality control standards

Reduces human error and improves customer trust

Benefits of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Choosing the right packaging solution is not just about machinery—it’s about performance, reliability, and long-term value. NPM Machinery's pharma packaging machines offer:

✅ 1. High-Speed Automation

Boost production rates with minimal human intervention

Ideal for mass manufacturing and 24/7 operations

✅ 2. Unmatched Accuracy

Delivers exact filling, sealing, and labeling

Reduces product loss and ensures dosage consistency

✅ 3. Compliance & Validation

Built with GMP, FDA, and CE compliance in mind

Supports 21 CFR Part 11 for electronic data integrity

✅ 4. Flexibility & Customization

Machines tailored to your product specifications

Modular designs allow for future scalability

✅ 5. Advanced Technology Integration

Equipped with PLC-based controls, SCADA systems, and IoT capabilities

Enables remote monitoring, real-time alerts, and preventive maintenance

✅ 6. Superior Build Quality

Made with stainless steel and corrosion-resistant materials

Long machine life, low maintenance, and robust performance

✅ 7. Global Support & Service

On-site training, remote diagnostics, and spare parts availability

Dedicated support teams for installation, validation, and upgrades

Industries We Serve

While our core strength lies in pharmaceutical packaging, our machines are versatile enough for other regulated industries such as:

Nutraceuticals

Ayurveda and Herbal

Cosmetics

Food & Beverage

Veterinary Medicine

Why Choose NPM Machinery Pvt. Ltd.?

With decades of experience, NPM Machinery Pvt. Ltd. has built a reputation for engineering excellence and customer-centric innovation. Here's what sets us apart:

✔️ 150+ skilled professionals including engineers, technologists, and validation experts

✔️ ISO-certified manufacturing with a focus on precision and safety

✔️ Custom turnkey packaging lines from design to commissioning

✔️ Strong domestic and global footprint with clients across Asia, Africa, Europe, and South America

✔️ Client-first approach—we adapt our solutions to your needs, not the other way around

Our goal is not just to sell machines—but to build long-term partnerships that add value to your production process, protect your brand, and ensure regulatory peace of mind.

Conclusion

The future of pharmaceutical manufacturing lies in smart, integrated, and efficient packaging systems. With increasing global demand, strict compliance requirements, and growing competition, investing in high-performance pharma packaging machines is no longer optional—it's essential.

At NPM Machinery Pvt. Ltd., we don’t just provide machines—we deliver confidence, quality, and peace of mind. Whether you're launching a new production line or upgrading your existing setup, we are here to guide you every step of the way with reliable, cutting-edge, and compliant solutions.

✅ Call to Action

Ready to upgrade your pharma packaging line? Partner with NPM Machinery Pvt. Ltd. and experience unmatched quality, service, and innovation. 📩 Contact us today for a free consultation or demo customized to your packaging needs! 🌐 Visit us at www.npmmachinery.com | 📞 +91-XXXXXXXXXX

0 notes

Text

5 Signs Your Auto-Component Manufacturing Business Needs an ERP Upgrade

Auto-component manufacturers operate in a high-precision, high-pressure environment. As customer expectations rise and competition intensifies, relying on outdated systems can slow you down — or worse, cost you business.

1. Inventory Discrepancies Are a Daily Headache

Are you constantly chasing raw materials, juggling spreadsheets, or facing last-minute shortages? A modern ERP offers:

Real-time inventory tracking

Batch-wise traceability

Automated stock alerts

No more guessing games. You know what’s available, what’s needed, and when to reorder.

2. Production Planning Is Still Manual

If you’re scheduling production runs on whiteboards or Excel, you’re risking:

Missed deadlines

Machine downtime

Underutilized capacity

A tailored ERP helps automate work order generation, machine allocation, and shift planning, reducing delays and boosting throughput.

3. Job-Work Tracking Feels Out of Control

Subcontracting is a vital part of auto-component manufacturing, but poor tracking leads to:

Unreturned materials

Lost accountability

Inaccurate costing

An upgraded ERP tracks every material issue, vendor process, and return, keeping your job-work cycle transparent and efficient.

4. Quality Issues Are Escalating

If you only catch defects at the end of the line — or worse, after dispatch — you’re reacting too late. A robust ERP integrates:

Inward QC

In-process checks

Pre-dispatch inspections

This means fewer rejections, less rework, and happier customers.

5. Reporting Takes Hours Instead of Seconds

Still waiting on your team to compile reports manually? If your ERP can’t generate real-time insights on production, costs, or delivery performance, it’s outdated. New-age ERPs give you:

Instant dashboards

Live KPI tracking

Mobile access on the go

Data-driven decisions shouldn’t have to wait.

✅ The Bottom Line

If even two of these signs sound familiar, your ERP is holding you back. It’s time to switch to a solution that understands the nuances of auto-component manufacturing — like PrismERP, built for SMEs that need speed, precision, and control.

0 notes

Text

Discover Premier CNC Machine Manufacturers in Canada: Excellence Today

Precision Engineering for Off-Road Innovation

When it comes to crafting high-performance components for rugged terrains, few can rival the expertise of CNC Machine Manufacturers in Canada. Leveraging state-of-the-art multi-axis machining centers, these specialists transform raw billets of aluminum, stainless steel, and titanium into parts that endure the harshest conditions. From shock-absorber mounts to skid-plate brackets, each piece is engineered with microscopic precision to guarantee perfect fitment and long-term reliability.

Advanced Materials and Cutting-Edge Techniques

The off-road arena demands materials that balance strength with weight savings. Leading providers invest heavily in additive-aided toolpath optimization and real-time thermal compensation to maximize tolerance control. By collaborating closely with OEMs, these experts push the boundaries of what’s possible—bringing you components designed for peak performance. Whether it’s flow-forming hollow shafts or micromilling intricate fin patterns, the focus remains unwavering: deliver parts that outperform and outlast.

Custom Solutions Tailored to Your Needs

No two off-road builds are the same. That’s why top-tier CNC Machine Manufacturers in Canada offer fully bespoke services, from initial design consultation through final prototype testing. Utilizing advanced CAD/CAM integration, they iterate rapidly, producing prototypes in days rather than weeks. Their ability to accommodate complex geometries and low-volume runs makes them the partner of choice for boutique fabricators and large-scale assemblers alike.

Commitment to Quality and Certification

Quality assurance is non-negotiable when lives and livelihoods depend on component integrity. Accredited shops adhere to rigorous ISO 9001 standards and routinely perform in-process inspections using CMMs, laser scanners, and dynamic balancing rigs. Traceability is maintained at every step, ensuring material certificates accompany each shipment. This meticulous approach minimizes rework and guarantees that every batch meets or exceeds stringent performance criteria.

Why Choose Arrow Manufacturing Expertise

While numerous shops claim precision, only a select few truly embody the ethos of Arrow Manufacturing Products. Their seasoned engineers bring decades of off-road experience, understanding the nuances of shock dynamics, torsional loads, and vibration damping. By marrying hands-on off-road knowledge with advanced machining capabilities, they deliver components that integrate seamlessly into your build, enhancing durability and drivability.

Sustainable Practices for a Greener Tomorrow

Environmental stewardship is at the forefront of modern manufacturing. Leading facilities implement closed-loop coolant systems, high-efficiency dust collection, and energy-optimized spindle drives to reduce waste and lower carbon footprints. They recycle or repurpose metal shavings and invest in renewable energy sources, reflecting a commitment that extends beyond the shop floor.

Your Partner in Off-Road Excellence

For builders and engineers who demand uncompromising quality, Arrow Manufacturing Products stands ready to exceed expectations. From prototype to production, their seamless workflow, stringent certifications, and focus on innovation ensure your off-road projects achieve unparalleled performance and reliability. When the trail gets tough, trust parts crafted by masters of precision to keep you moving forward.

0 notes

Text

Cutting-Edge OEM Metal Fabrication: Superior OEM Fabrication Services!

Cutting-edge industries demand precision, reliability, and efficiency at every turn, and when it comes to manufacturing complex components, nothing delivers like OEM Metal Fabrication. Utilizing state-of-the-art equipment and processes honed by years of experience, modern manufacturers can count on consistently superior results. From prototyping intricate designs to producing high volumes of components, the right partner can optimize production timelines and reduce waste, ensuring that every piece meets the tightest tolerances and most demanding specifications.

Every project starts with a deep understanding of material properties, engineering requirements, and end-use applications. By combining robust quality management systems with cutting-edge automation techniques, experts ensure that each step—from laser cutting and CNC machining to finishing and assembly—aligns perfectly with client goals. This dedication to precision is what sets leading providers of OEM Metal Fabrication apart, offering unmatched versatility across industries such as aerospace, defense, automotive, electronics, and medical devices.

Achieving true manufacturing excellence requires more than just advanced machinery; it relies on a skilled workforce committed to continuous improvement. Highly trained technicians and engineers work collaboratively with customers from concept through completion, offering design for manufacturability reviews, material selection guidance, and cost-optimization strategies. This hands-on approach transforms initial ideas into high-performance products, delivering reliable solutions on schedule and within budget through holistic OEM Fabrication partnerships.

Scalability and adaptability are vital in today’s fast-paced marketplace. Flexible production lines allow rapid changeovers between small prototype batches and large-scale runs without sacrificing quality or consistency. Automated inspection systems further guarantee that every part adheres to rigorous standards, minimizing defects and maximizing operational uptime. When manufacturers integrate these smart practices, they unlock true competitive advantage through streamlined lead times and reduced overhead in their OEM Fabrication workflows.

Beyond core manufacturing capabilities, comprehensive service offerings may include welding, metal finishing, assembly, and logistics support to ensure seamless integration into supply chains. By providing end-to-end solutions under one roof, leading metalworking specialists save clients valuable time and resources, enabling them to focus on design innovation and strategic growth. Whether launching a new product line or optimizing an existing process, partnering with a proficient provider empowers businesses to achieve new levels of performance, reliability, and cost-efficiency.

Choosing the right metal fabrication partner is a strategic decision that can shape product success and brand reputation. With proven expertise, robust quality controls, and a customer-centric ethos, top-tier OEM metalworking services deliver the precision and agility required to excel in any industry. Elevate your manufacturing potential today and experience how advanced OEM Metal Fabrication and fabrication services can drive your projects from blueprint to breakthrough.

0 notes

Text

Automated Silica Canister Inspection: Revolutionizing Pharmaceutical Quality Control

In the world of pharmaceutical packaging, accuracy and speed are essential. For this reason, automated silica canister inspection is becoming more popular on manufacturing floors throughout the world. When every component matters, a fault in the silica desiccant canister could endanger the entire batch of drugs. The CANIS system from Optomech was developed specifically for the purpose of inspecting silica canisters flawlessly and quickly. Automated silica canister inspection guarantees that every canister in the batch is tracked, measured, and validated, regardless of blocked mesh, short molding, or even minute diameter differences. At 14,000 canisters per hour, the CANIS machine provides your operation with continuous, real-time quality checking.

Why Desiccant Canisters Must Be Inspected Automatically

Desiccant canisters preserve the efficacy of drugs by absorbing moisture. Canisters with flaws, however, may fail to work or introduce physical pollutants. Manual inspections impede production and overlook flaws. These dangers are eliminated as output is scaled up with automated silica canister inspection.

CANIS: A Smart Investment for Pharmaceutical Compliance

CANIS offers a 100% online solution for desiccant canister inspection that combines machine vision, high-resolution cameras, and intelligent defect detection" The equipment guarantees efficiency, accuracy, and repeatability without the need for human involvement. Its purpose is to capture:- Broken mesh - Flash molding - Surface dirt - Dimensional inconsistencies - Shape defects In addition to being found, every flaw is also classified and documented. This traceability supports audits and improves confidence in your quality control protocols.

Designed for Production-Line Speed and Operator Ease

At 14,000 canisters per hour, CANIS doesn’t just keep up—it leads. The system’s ergonomic touchscreen interface lets operators adjust tolerance levels, view defect galleries, and take immediate corrective action. Its visual dashboard plots the last 100 defects for quick diagnostics. Operators get more than data—they get insights.

How Automation Reduces Cost and Error

With CANIS, plants no longer need to dedicate staff to manually inspect and sort. It reduces labor requirements while improving inspection consistency. The result: a dramatic decrease in human error, higher throughput, and a faster return on investment.

Built for Audits, Powered by Data

CANIS logs inspection data and delivers customizable reports aligned with your QA standards. With role-based access (User, Supervisor, Admin), data is protected, while managers can track performance, trends, and rejection rates.

Remote Support and Upgradability

CANIS is ready for Industry 4.0. With remote login support, your technical team or Optomech’s experts can access the machine anytime for diagnostics. Frequent firmware updates keep the system current and scalable.

One System, Many Benefits

Installing CANIS ensures: - Reduced inspection costs - Higher regulatory compliance - Real-time rejection tracking - Enhanced production visibility All the while keeping the integration cost low and the footprint small.

Watch CANIS in Action

Curious about performance? Watch our machine inspect 14,000 units per hour with precision: https://youtu.be/mqRbubOLo98

Conclusion: Adopt the Future of Inline Canister Quality

Automated silica canister inspection is not the future—it’s now. The CANIS system from Optomech represents a huge step forward for pharmaceutical packaging quality control. By detecting every anomaly in real-time and offering seamless reporting, CANIS helps you meet global standards without breaking a sweat.

Contact Optomech

Based in Hyderabad, Optomech Engineers Pvt. Ltd. leads the market with high-speed vision-based inspection systems and optical metrology tools. Website: www.optomech.in Phone: +91 40 23078371 Email: [email protected]

#o#Bottle Inspection Systems (BIS-XL#BIS-EDB)#Cap Inspection Systems (CIS-Online#CIS-XL)#Induction Sealing Integrity Verifiers (ISIVS)#Label & IML Label Inspectors (LIS-2S#IML Inspector)#Flip-Off Seal Inspection (FOSIS)#Optomech

0 notes

Text

Inside a Pharma Intermediate Manufacturer: How Quality & Compliance Drive Innovation

In the vast and fast-growing world of pharmaceuticals, there’s a critical step that happens before the final medicine reaches your hands—pharmaceutical intermediates. These are the building blocks of life-saving drugs. And behind every high-quality drug is a reliable pharma intermediate manufacturer committed to strict quality standards and regulatory compliance.

At Jay Fine Chem, we believe quality and innovation aren’t just goals—they’re responsibilities. As one of the trusted pharma intermediate companies in India, our mission is to create safe, effective intermediates that support global healthcare systems. Let’s take you inside the world of a pharma intermediate manufacturer, and show how quality and compliance are the real drivers of innovation.

What Are Pharma Intermediates and Why Do They Matter?

Before any medicine reaches the market, it starts with chemical compounds called pharma intermediates. These are substances formed during the steps of synthesizing active pharmaceutical ingredients (APIs). In simple terms, intermediates are the bridge between basic chemicals and the final drug.

Without high-quality intermediates, drug formulation would lack consistency and effectiveness. That’s why pharma intermediate manufacturers play such a critical role in the supply chain. At Jay Fine Chem, we make sure that every intermediate meets the highest purity and safety standards—because the quality of an intermediate directly affects the quality of the final medicine.

A Look Inside Jay Fine Chem’s Manufacturing Facilities

As a leading name among pharma intermediate companies, Jay Fine Chem takes pride in maintaining cutting-edge facilities that meet international standards. Our manufacturing plants are designed for efficiency, safety, and innovation. We follow Good Manufacturing Practices (GMP) and continuously update our processes to meet evolving global regulations.

Each batch of intermediates goes through a carefully monitored production line, supported by modern equipment and automation technology. This not only helps us maintain consistency but also reduces waste, improves timelines, and increases our ability to scale production quickly.

Our infrastructure is more than just buildings and machines—it’s the foundation of trust for our partners worldwide.

How Quality Control Sets Us Apart

At Jay Fine Chem, quality control is not a single step—it’s embedded in every part of the process. From raw material inspection to final packaging, our internal systems are designed to detect even the slightest deviation from standards.

Here's how we ensure consistent quality:

In-house QC labs for chemical and microbial testing

Batch-level documentation and audits

Certified analysts trained in international quality protocols

Real-time monitoring of parameters during synthesis

Rigorous compliance with GMP and ISO standards

We understand that in pharmaceutical manufacturing, there is no room for error. Each intermediate we produce must be safe, pure, and reliable—not just once, but every single time.

Compliance: Not Just a Requirement, But a Catalyst for Innovation

In many industries, compliance is seen as a box to check. But in pharma, it’s much more than that. For us, regulatory compliance inspires better systems, cleaner production, and smarter innovation.

Our team at Jay Fine Chem is constantly engaging with international regulatory frameworks, such as:

U.S. FDA guidelines

European Medicines Agency (EMA) regulations

International Council for Harmonisation (ICH) practices

These regulations push us to think differently—to develop new ways of producing intermediates that are safer, faster, and more sustainable.

One of our recent innovations involved redesigning a synthesis process to eliminate a hazardous solvent—reducing both risk and environmental impact. This was not just good science; it was compliance-driven innovation at its best.

Custom Synthesis and R&D: Where Innovation Comes to Life

As one of the most forward-thinking pharma intermediate companies in India, Jay Fine Chem doesn’t just manufacture intermediates—we help solve formulation challenges for our clients.

Our Research and Development (R&D) division is staffed with experienced chemists and researchers who specialize in:

Custom synthesis of new intermediates

Process development and optimization

Route scouting and impurity profiling

Scalability assessments for commercial batches

With deep experience across therapeutic segments like cardiovascular, oncology, and anti-infectives, we’re able to provide tailor-made solutions that align with global pharmaceutical trends.

Our R&D isn't about theoretical science—it's practical, real-world problem solving that supports our clients in developing next-generation medicines.

Why Global Pharma Companies Trust Jay Fine Chem

Being a pharma intermediate manufacturer comes with great responsibility. Global pharmaceutical brands count on us for reliable, high-quality intermediates that meet international standards. But trust isn’t built overnight—it’s earned over time through consistent performance.

Here’s why our clients choose Jay Fine Chem:

On-time delivery of high-purity intermediates

Responsive technical support and transparent communication

Full traceability and documentation for every batch

Flexible manufacturing capabilities for small and large volumes

Global logistics network with a presence in the U.S., Europe, and Asia

Our long-standing partnerships with both generic and innovator pharma companies are a testament to our commitment to quality, trust, and innovation.

A Responsible Manufacturer: Focus on Sustainability

In today’s world, quality manufacturing isn’t enough—it has to be responsible manufacturing. At Jay Fine Chem, we integrate sustainability into our production and business practices.

Here’s how we do it:

Green chemistry initiatives to reduce waste and energy usage

Effluent treatment plants to ensure eco-safe disposal

Recycling of solvents and safe raw material sourcing

Reducing carbon emissions through process optimization

As a leading pharma intermediate manufacturer, we understand that our environmental responsibilities go hand in hand with product integrity. We’re not just making molecules—we’re shaping a more sustainable future.

The Future of Pharma Intermediate Manufacturing

The pharmaceutical industry is evolving rapidly, and so is the role of pharma intermediate companies. With increasing demand for specialty drugs, biosimilars, and personalized medicine, the need for reliable intermediates is only going to grow.

Jay Fine Chem is prepared for this future:

Expanding our R&D pipeline for next-gen intermediates

Enhancing digital monitoring and AI in manufacturing

Investing in new facilities and compliance upgrades

Building stronger partnerships with innovators and global suppliers

Our goal is simple: to remain a trusted, agile, and forward-looking pharma intermediate manufacturer that helps bring new therapies to market—faster and more responsibly.

Conclusion: Quality and Compliance Are the Pillars of Progress

Being a pharma intermediate manufacturer is about more than chemical processes—it’s about being part of something bigger. It's about contributing to global health, standing for quality, and always aiming to do better.

At Jay Fine Chem, we’re proud to lead with both science and ethics. Our dedication to compliance fuels our creativity, and our focus on quality sets us apart among pharma intermediate companies in India.

If you're a pharma innovator, API manufacturer, or a formulator looking for a partner you can count on—Jay Fine Chem is here to deliver.

0 notes

Text

Why Is Sandblasting Held to Such High Standards in the Aerospace Industry?

In aerospace manufacturing, sandblasting is far more than a surface cleaning method—it's a mission-critical process that ensures the reliability, durability, and safety of aircraft components. Compared to general industry, the aerospace sector imposes far stricter requirements on surface preparation, abrasive materials, process controls, and equipment performance.

In this post, we’ll explore the five key dimensions that explain why precision sandblasting is non-negotiable in aerospace, and how it reflects the industry's “zero-tolerance for failure” philosophy.

✅ 1. The Technical Role of Sandblasting in Aerospace Applications

From engine components to fuselage panels, sandblasting serves a variety of functions:

Surface Preparation: Removes rust, oxides, and residues to ensure strong adhesion for coatings, bonding, or welding;

Defect Elimination: Removes burrs and weld spatter, improving precision and fit;

Fatigue Strength Enhancement: Introduces residual compressive stress to resist crack formation;

Surface Roughness Control: Precisely controls Rz values to meet adhesion and corrosion protection needs.

In short, sandblasting is not just about appearance—it’s about structural integrity in extreme operating conditions.

🧪 2. Precision Standards: Every Detail Is a Quality Gate

Sandblasting processes in aerospace follow well-defined and rigorous standards, such as:

Rust Removal Grade Sa2.5 (per GB/T 8923): Requires thorough cleaning to a near-white metal finish;

Roughness Control at Rz 60–80μm (per GB/T 13288): Ensures coating adherence and controlled thickness;

4-Hour Coating Window: Primer must be applied within 4 hours post-blasting to avoid recontamination or flash rust;

Environmental Constraints: Relative humidity must be below 85%, and surface temperature should exceed dew point by at least 3°C.

Additionally, oil-free dry air must be used for blow-off, and post-blasting contact is strictly prohibited to avoid contaminant transfer.

🧱 3. Choosing the Right Abrasives: Performance Meets Process Cleanliness

In aerospace, abrasive media must meet higher standards for purity, consistency, and recyclability:

Ceramic Beads: High hardness, minimal breakdown, ideal for engine and airframe parts;

Stainless Steel Shot: Suitable for applications demanding surface brightness and media cleanliness;

Glass Beads: Environmentally friendly, reusable, and generate low dust levels.

📌 Engineering Tip: Always align abrasive choice with substrate type, target roughness, regulatory compliance, and recycling efficiency.

⚙️ 4. Equipment Requirements: Smart, Efficient, and Clean

To meet the industry's need for repeatability and precision, sandblasting equipment must evolve beyond manual methods:

Conveyor-Type Machines: Offer high-throughput with consistent blasting quality;

Tumble Blasters: Ideal for small, irregularly shaped parts;

Automatic Media Feed Systems: Ensure stable and continuous operation;

Robotic Blasting Arms: Enable programmable paths, 3D surface tracking, and cycle time reductions up to 70%.

💡 Example: One patented auto-feeding system has significantly reduced dust emissions while improving blasting precision across multi-batch production lines.

🧾 5. Quality Inspection & Common Issues Solved

After blasting, components undergo stringent inspection before further processing:

Visual Cleanliness Check: Compared to Sa2.5 photo standards;

Roughness Verification: Using calibrated gauges or roughness test panels;

Dust Removal: Blown off with clean compressed air—no direct touch allowed.

Common FAQs in Aerospace Sandblasting:

Q: Why does rust reappear post-blasting? A: Usually due to delayed coating or high ambient humidity. Always coat within 4 hours.

Q: How to detect worn nozzles? A: Replace once the orifice diameter increases by over 25%, or blasting pattern becomes irregular.

Q: Why is roughness inconsistent? A: Check media condition, pressure stability, nozzle angle, and stand-off distance.

🔍 In Summary: Precision Is Not Optional—It’s the Standard

In aerospace, every micron of surface prep can impact component longevity and safety. That’s why sandblasting must align with high-precision standards, advanced equipment integration, and environmental best practices.

As the industry evolves, trends are clearly shifting toward:

✅ Digital monitoring

✅ Closed-loop media recovery

✅ Green, dust-free blasting systems

0 notes

Text

Requesting a Quote for the Metal Rolling Process: What Info You Need & What You'll Get

In the realm of metal fabrication, the metal rolling process stands as a cornerstone technique, pivotal for shaping and forming metal sheets into desired configurations. Whether it's for constructing cylindrical tanks, pressure vessels, or structural components, rolling processes are indispensable. When seeking to engage in such processes, obtaining a precise quote is crucial. This article delves into the essential information required to request a quote for the metal rolling process and elucidates what you can expect in return.

Understanding the Metal Rolling Process

The metal rolling process involves passing metal stock through one or more pairs of rolls to reduce thickness, ensure uniformity, and impart desired mechanical properties. This process is fundamental in manufacturing industries, facilitating the production of components with consistent cross-sections.

Key Information Required for Quotation

To obtain an accurate and comprehensive quote for the metal rolling process, it's imperative to provide detailed information. Here's a breakdown of the critical data points:

1. Material Specifications

Type of Metal: Specify whether it's carbon steel, stainless steel, aluminum, etc.

Grade: Indicate the specific grade, such as ASTM A36, SS304, etc.

Thickness: Provide the exact thickness of the metal sheets.

Width and Length: Detail the dimensions of the metal pieces to be rolled.

2. Desired Final Product

Shape and Dimensions: Outline the intended shape (cylindrical, conical, etc.) and precise measurements.

Tolerances: Specify acceptable deviations in dimensions.

Surface Finish Requirements: Indicate if there are specific surface finish standards to be met.

3. Quantity and Volume

Number of Pieces: State the total number of components required.

Batch Sizes: If applicable, mention batch sizes for phased deliveries.

4. Application and Industry Standards

End-Use Application: Describe the component's intended use to ensure compliance with relevant standards.

Industry Standards: Specify any industry-specific standards or certifications required.

5. Delivery and Timeline

Lead Time Requirements: Indicate preferred delivery timelines.

Delivery Location: Provide the destination for logistics planning.

What You'll Receive in the Quote

Upon providing the above information, the supplier will furnish a detailed quote encompassing:

1. Cost Breakdown

Material Costs: Based on the type and grade of metal.

Processing Charges: Including labor, machine usage, and overheads.

Tooling Costs: If specialized tooling is required.

Logistics and Delivery Charges: Depending on the delivery location.

2. Technical Specifications

Process Details: Outline of the rolling process to be employed.

Equipment Used: Information on the machinery, such as hydraulic plate bending machines, to be utilized.

Quality Assurance Measures: Details on inspections and testing procedures.

3. Timeline

Production Schedule: Estimated timeframes for each phase of the process.

Delivery Dates: Expected dates for dispatch and arrival.

4. Terms and Conditions

Payment Terms: Including deposit requirements and payment schedules.

Warranty and After-Sales Support: Coverage details and support services offered.

Importance of Plate Bending Capacity

The plate bending capacity of a machine is a critical factor in the metal rolling process. It determines the maximum thickness and width of metal sheets that can be effectively processed. Understanding this capacity ensures that the selected machinery aligns with project requirements, preventing potential issues related to machine limitations.

Role of Hydraulic Plate Bending Machines

Hydraulic plate bending machines are integral to modern metal fabrication due to their precision, efficiency, and versatility. These machines utilize hydraulic systems to exert controlled force, enabling the bending of metal sheets into various shapes with high accuracy. Their adaptability makes them suitable for a wide range of applications, from simple bends to complex geometries.

Selecting the Right Plate Bending Machine Manufacturers

Choosing reputable plate bending machine manufacturers is essential for ensuring quality and reliability. Factors to consider include:

Experience and Reputation: Established manufacturers with a proven track record.

Technological Advancements: Adoption of the latest technologies for enhanced performance.

Customization Options: Ability to tailor machines to specific project needs.

After-Sales Support: Availability of maintenance services and spare parts.

Conclusion

Requesting a quote for the metal rolling process is a nuanced endeavor that necessitates detailed information and careful consideration. By understanding the intricacies of the process, the significance of plate bending capacity, the advantages of hydraulic plate bending machines, and the importance of selecting reputable plate bending machine manufacturers, you can ensure a seamless and efficient fabrication experience.

0 notes

Text

Boost Industrial Washer-Extractor Efficiency for Laundry Operations

Boost Industrial Washer-Extractor Efficiency for Laundry Operations

Understand the Basics of Washer-Extractor Operations To achieve efficient operation of industrial washer-extractors, we must first deeply understand the principles behind them. The laws of mechanical operation, water temperature control, and the right chemical ratios are interrelated and affect each other. When placing clothes in the machine, operators must be extremely careful and set the load accurately according to the characteristics of different fabrics. After all, heavy linens and light fabrics have different requirements when washing, and the corresponding settings must be different. This is where water level sensors and programmable logic controllers (PLCs) are like right-hand men, who can help operators make precise adjustments so that the machine can effectively remove dirt from fabrics while minimizing resource consumption. In commercial laundry facilities, in order to ensure accuracy and consistency of operation, it is necessary to develop a standard list of wash cycle settings to effectively avoid the trouble caused by operator errors.Get more news about Washer-Extractor,you can vist our website!

Optimize the dehydration stage to save energy In the actual process of commercial laundry operation, it is not difficult to find that the high-speed dehydration stage of the washing machine dehydrator is an important part of energy consumption, and the energy consumed by it accounts for between 18% and 23% of the total energy. In order to achieve the dual goals of energy saving and machine protection, we cannot let the machine run at full speed at the beginning, but should gradually increase the speed. The advantage of doing so is that it can avoid excessive pressure on the motor and bearings in an instant, thereby extending their service life. Operators can use infrared sensors to detect the moisture content of the clothes after dehydration, so that batches with poor dehydration effects can be discovered in time. During the dehydration process, the centrifugal force should be cleverly balanced within the range that the clothes can withstand, so that the water in the clothes can be removed as much as possible without causing damage to the clothes. Once the moisture content of the clothes is reduced, the time and energy required for subsequent drying will naturally be reduced accordingly, which is of great significance for improving laundry efficiency and reducing costs.

Preventive maintenance program to extend service life Regular inspection and maintenance are essential to keep the washing machine and dehydrator in good working condition and working stably for a long time. In particular, it is important to carefully check the condition of the drum bearings and shock absorbers every week, which is particularly important when the machine often handles heavy loads. The frequency of lubricating the machine needs to be determined according to the actual use. If a place has a daily laundry volume of 10 tons or more, it is more appropriate to lubricate it once every two weeks; if the laundry volume is relatively small, it is enough to lubricate it once a month. According to the results of industry research, the use of digital maintenance logs with automatic reminders can effectively reduce equipment downtime by 37%, which undoubtedly provides a strong guarantee for the normal operation of the equipment.

Troubleshooting common performance problems Sometimes, you will encounter some performance problems when using a washing machine and dehydrator. For example, if you find that the machine shakes violently when dehydrating, generally speaking, it may be due to uneven placement of clothes or wear of some stable parts of the machine. Therefore, operators must carefully check the placement of clothes to ensure that they are correct before starting the high-speed spin. If the drainage is not smooth, it is usually because the drain pipe is blocked or the drain valve is damaged. In order to ensure smooth drainage, it is necessary to remove these parts and clean them every month, which generally restores the water flow to normal. When the machine has an error code, it requires professional technicians with their rich experience and expertise to determine whether it is a sensor failure or a mechanical problem, so as to avoid unnecessary parts replacement and save repair costs.

Implementing water recycling strategies Today, some advanced laundry facilities have realized the importance of water resources and have adopted effective water recycling strategies. By adopting a multi-stage filtration system, these facilities can recycle 65% - 80% of the wash water. After being treated with a reverse osmosis device combined with ultraviolet disinfection, the recycled water can be used again in the pre-wash stage. Taking a medium-sized laundry facility as an example, this method can save about 12,000 gallons of fresh water per week, which is a considerable number for water conservation. In addition, installing a heat exchanger can also collect heat from the drain water and use this heat to preheat the incoming cold water by 15-20°F, thereby reducing the load on the boiler. These environmentally friendly practices not only help save water and electricity bills and reduce operating costs, but also help laundry facilities obtain environmental compliance certification and improve their social image.

Improving operator safety in heavy-duty environments In heavy-duty laundry environments, operator safety always comes first. To ensure personnel safety, when performing maintenance on the machine, it is necessary to strictly follow the operating procedures and turn off the power first to prevent accidental injuries caused by accidental start-up of the machine. In places with large laundry volumes, it is very necessary to lay non-slip floors and set up ergonomic loading platforms, which can effectively prevent musculoskeletal injuries caused by long working hours for operators. The application of automatic dosing systems can reduce the opportunity for workers to come into contact with detergents and reduce potential threats to workers' health. And steam detection sensors can provide early warning of the accumulation of harmful gases, allowing operators to take timely measures to avoid danger. Regular safety inspections and timely updating of personal protective equipment (PPE) specifications can help laundry facilities strictly comply with the U.S. Occupational Safety and Health Administration (OSHA) 1910.212 machine guarding standard and create a safe and reliable working environment for operators.

0 notes

Text

How does AI visual inspection improve quality control in textile manufacturing, reducing fabric waste and returns?

In the fast-paced world of textile manufacturing, ensuring high-quality output while minimizing waste is a constant challenge. Traditional quality control methods often rely on manual inspections, which can be time-consuming, prone to human error, and inefficient at scale. Enter AI visual inspection, a game-changing technology that’s transforming how the textile industry maintains quality, reduces fabric waste, and cuts down on costly returns.

How AI Visual Inspection Works

AI visual inspection systems leverage advanced computer vision, machine learning, and deep learning algorithms to analyze fabrics at every stage of production. High-resolution cameras capture detailed images of textiles, and AI models process these images to detect defects such as:

Tears, holes, or frayed edges

Stitching irregularities

Color inconsistencies or dye imperfections

Pattern misalignments

Foreign objects or contamination

These systems are trained on vast datasets of fabric images, enabling them to identify even subtle anomalies with remarkable precision. Unlike human inspectors, AI doesn’t tire, miss details, or vary in judgment, ensuring consistent and reliable quality checks.

Benefits for Textile Manufacturing

1. Enhanced Defect Detection

AI defect detection capabilities allow systems to identify flaws in real-time, catching issues that might be overlooked by human eyes. For example, a minor weave inconsistency or a faint discoloration can be flagged instantly, preventing flawed fabrics from moving further down the production line. This early detection ensures only high-quality textiles reach the market.

2. Reduced Fabric Waste

By identifying defects early, AI helps manufacturers address issues before entire batches of fabric are produced. For instance, if a weaving machine is misaligned, AI can detect the resulting flaws and alert operators to fix the equipment promptly. This minimizes the production of defective fabric, significantly reducing material waste and the environmental footprint of manufacturing.

3. Lower Return Rates

Defective textiles that reach consumers often lead to returns, damaging brand reputation and incurring additional costs. AI quality control ensures that only flawless products are shipped, reducing the likelihood of customer complaints and returns. This not only saves money but also boosts customer satisfaction and loyalty.

Real-World Impact

In textile factories worldwide, AI visual inspection is already making a difference. For example, a major textile manufacturer in India implemented an AI-based system and reported a 30% reduction in fabric waste within the first year. Another company in Europe saw a 25% decrease in customer returns after integrating AI into their quality control process. These success stories highlight the technology’s potential to drive both economic and environmental benefits.

Conclusion

AI visual inspection is revolutionizing quality control in textile manufacturing by delivering unmatched precision, efficiency, and sustainability. By catching defects early, reducing fabric waste, and minimizing returns, this technology is helping manufacturers save costs and build stronger reputations.

#ai#aivisualinspection#aidefectdetection#aiqualitycontrol#artificialintelligence#TextileIndustry#ombrulla

0 notes

Text

Leading Manufacturer of Pharmaceutical Machinery in China: Comprehensive Solutions for Vial and Ampoules Packaging Line

As a trusted manufacturer of pharmaceutical machinery and equipment, we specialize in delivering complete solutions designed for the production of tablets, liquids, capsules, powders, granules, and especially Vial and Ampoules Packaging Line. Our robust manufacturing capabilities, advanced R&D, and unwavering commitment to quality position us at the forefront of the pharmaceutical equipment industry in China and globally.

Why Choose Our Pharmaceutical Machinery Solutions

Unmatched Expertise in Pharmaceutical Engineering

We bring decades of experience in pharmaceutical engineering, offering high-precision machinery tailored for all production stages. Our pharmaceutical equipment is designed to comply with international standards such as GMP, CE, and ISO, ensuring safe, efficient, and compliant pharmaceutical production.

End-to-End Production Capabilities

From tablet compression machines to granule processing units, our product lineup covers every essential stage of pharmaceutical manufacturing:

Tablet Press Machines

Capsule Filling Machines

Liquid Filling and Sealing Machines

Powder Mixing & Blending Systems

Granulation Lines

Vial and Ampoules Packaging Line

Our integrated solutions streamline production processes, reduce downtime, and increase yield, which directly translates into higher profitability for pharmaceutical manufacturers.

Vial and Ampoules Packaging Line – Precision and Performance

Fully-Automated Packaging Line for Sterile Injectables

Our Vial and Ampoules Packaging Line offers high-speed, fully automated systems suitable for sterile environments. These lines are designed to handle delicate ampoules and glass vials with pinpoint precision, ensuring integrity, sterility, and consistent quality across batches.

Key features of our vial and ampoule packaging lines include:

Washing, Sterilizing & Drying Units

Liquid Filling Systems (Peristaltic or Piston Pump Based)

Rubber Stoppering and Capping Machines

Ampoule Sealing & Vial Crimping

Visual Inspection Systems

Labeling & Serialization Modules

Integrated PLC and SCADA Control Systems

Each component is designed to maintain aseptic conditions, protect product integrity, and deliver consistent performance.

Core Components of Vial and Ampoules Packaging Line

1. Automatic Vial and Ampoule Washing Machines

These machines are engineered to remove particulates and contaminants from containers using multi-stage ultrasonic and pressure-based washing with WFI (Water for Injection) and clean compressed air. Features include:

In-feed and out-feed automation

Multiple needle spray systems

Customizable formats for different vial sizes

2. High-Temperature Sterilization Tunnels

Utilizing dry heat sterilization, our tunnels eliminate microbial contamination and maintain the sterility of containers post-wash. They feature:

HEPA filtration

Conveyor system with variable speed

Temperature monitoring and validation systems

3. Liquid Filling and Stoppering Machines

These are precision filling machines with servo-driven pistons or peristaltic pumps, ensuring accurate filling volumes for even the smallest doses.

Filling range flexibility (0.1 ml to 100 ml)

In-line or rotary stoppering mechanisms

Laminar airflow units integrated for Class 100 environments

4. Sealing and Capping Units

For ampoules, flame-sealing systems provide hermetic closures, while for vials, aluminum caps are crimped tightly for maximum security.

Flame annealing systems for ampoules

Rotary or linear vial crimping systems

Cap feeding and sorting automation

5. Visual Inspection Systems

High-speed cameras and AI-powered software ensure every ampoule or vial is visually inspected for foreign particles, fill volume, seal integrity, and cosmetic defects.

360-degree inspection

Rejection systems for non-conforming units

Batch reporting and traceability

6. Labeling, Serialization, and Track & Trace

Incorporating advanced serialization technology, our labeling systems help comply with global traceability regulations including 21 CFR Part 11, EU FMD, and DSCSA.

Inkjet and thermal transfer printing

Tamper-evident labels

QR code and barcode support

Made in China, Trusted Worldwide

Our pharmaceutical machinery, proudly made in China, is exported to over 70 countries, including markets in Europe, the Americas, Middle East, Southeast Asia, and Africa. We offer turnkey projects and full support, from design consultation to post-installation training and after-sales service.

Custom-engineered solutions are our specialty. Whether you need a small-scale line for clinical trials or a full commercial production system, we provide flexible configurations tailored to your needs.

Innovation and Compliance – Our Manufacturing Promise

Research-Driven Development

Our dedicated R&D center is continuously innovating to enhance performance, reduce footprint, and integrate AI, IoT, and smart automation into our systems.

Digital twin modeling

Predictive maintenance systems

Cloud-connected data analytics

Regulatory Compliance

Our equipment complies with international regulatory frameworks, including:

GMP (Good Manufacturing Practices)

FDA 21 CFR Part 11

EU Annex 1 Guidelines

WHO and PIC/S Recommendations

Each machine undergoes rigorous FAT (Factory Acceptance Testing) and SAT (Site Acceptance Testing) to ensure seamless compliance during audits.

Unparalleled Customer Support and Global Services

Our team of multilingual engineers and service professionals provides 24/7 remote and on-site support to ensure uptime, training, and continuous improvement. Our global network of distributors and service hubs ensures fast delivery of spare parts and preventive maintenance services.

Industries We Serve

Our solutions are ideal for:

Pharmaceutical manufacturers

Biotech companies

Veterinary drug producers

Clinical research facilities

Contract manufacturing organizations (CMOs)

Partner with Us for Advanced Pharmaceutical Machinery Solutions

As a manufacturer of pharmaceutical machinery, we are proud to set benchmarks in precision engineering, sterile manufacturing, and packaging automation. Our specialized Vial and Ampoules Packaging Line is one of the most trusted solutions for injectable drug manufacturers worldwide.

Contact us today to discuss your production needs and discover how our China-based manufacturing facility can support your end-to-end pharmaceutical production goals.

Contact us:

GRAND INTELLIGENT EQUIPMENT (GUANGZHOU) CO.,Ltd

301A, Building 5, No.333, Juhuashi Ave, Huadu District, Guangzhou City, Guangdong, China.

+86-15361285728 ; +86-020-86886090

Email [email protected]

Wenzhou Grand Machinery Technology Co.,Ltd

Floor 4, Building 2, No.116, Xinglong Road, Wanquan Town, Pingyang County, Wenzhou City, Zhejiang Province, China

+86-15323319612 ; +86-577-65565288

Also available on

On Whatsapp

On Facebook

On Twitter

On Pinterest

On Youtube

On Tumblr

0 notes

Text

Rubber Mould Paver Block Manufacturer in Surat – The Top Choice for Quality and Durability

When it comes to transforming outdoor spaces, nothing beats the aesthetic appeal and durability of rubber mould paver blocks. Whether it's for residential driveways, commercial complexes, or municipal walkways, these blocks provide a combination of strength and style. If you're searching for a Rubber Mould Paver Block Manufacturer in Surat, your hunt ends at Krishna Paver Block, the trusted name in the industry.

Why Choose Rubber Mould Paver Blocks?

Rubber mould paver blocks are known for their fine finish, uniformity, and resistance to wear and tear. These pavers are crafted using high-quality rubber moulds that ensure sharp edges, smooth surfaces, and attractive patterns. Unlike traditional cement blocks, rubber mould pavers maintain consistency in texture and design.

Key Benefits:

High strength and durability

Elegant finish with vibrant colors

Weather and load resistant

Easy to install and maintain

Customizable patterns and sizes

At Krishna Paver Block, we combine innovation with quality to deliver paver blocks that not only look great but also last for decades.

Krishna Paver Block – Leading Rubber Mould Paver Block Manufacturer in Surat

Based in Surat, Gujarat, Krishna Paver Block has built a solid reputation for providing top-quality paver solutions across multiple cities. We specialize in the manufacturing of rubber mould paver blocks for various industrial, commercial, and residential applications.

Our focus is on customer satisfaction, timely delivery, and superior product quality. Over the years, we have catered to large-scale infrastructure projects as well as small private installations, making us the most reliable Rubber Mould Paver Block Manufacturer in Surat.

Our Manufacturing Process – Precision with Perfection

We believe that quality starts at the source. Our manufacturing facility is equipped with modern machinery and a dedicated team that ensures each paver block meets our high standards.

Step-by-Step Process:

Mould Preparation – High-grade rubber moulds are used for uniformity.

Concrete Mixing – A perfect mix of cement, aggregates, and color pigments.

Vibrating & Curing – Advanced vibration machines help eliminate air gaps.

Demoulding – After proper setting, pavers are carefully demoulded.

Curing Process – Blocks are cured under controlled conditions for maximum strength.

Quality Inspection – Every batch undergoes rigorous checks before dispatch.

This meticulous process helps us stay at the top as a trusted Rubber Mould Paver Block Manufacturer in Surat.

Applications of Our Rubber Mould Paver Blocks

Our versatile paver blocks are suitable for various applications:

Driveways and Pathways

Garden Landscapes

Commercial Parking Areas

Residential Courtyards

Public Parks and Footpaths

Industrial Zones

With enhanced interlocking systems and anti-skid surfaces, our paver blocks are perfect for both heavy and light traffic areas.

Why Krishna Paver Block is the Best Rubber Mould Paver Block Manufacturer in Surat

There are several reasons why contractors, architects, and homeowners choose Krishna Paver Block:

✔ Unmatched Quality

Our pavers meet all industry standards and are tested for compressive strength, water absorption, and finish.

✔ Wide Design Range

From classic to contemporary, we offer multiple designs, patterns, and color options.

✔ Customization Available

Looking for a custom design? We can tailor the blocks to your exact project needs.

✔ Quick Turnaround

Our efficient production line ensures timely delivery without compromising on quality.

✔ Affordable Pricing

We offer premium-quality paver blocks at competitive prices to suit all budgets.

Expanding Beyond Surat – Serving Neighboring Cities

While we are proud to be recognized as a leading Rubber Mould Paver Block Manufacturer in Surat, our services don’t end there. We are also a trusted supplier in several neighboring cities:

✅ Rubber Mould Paver Block Manufacturer in Navsari

We’ve delivered numerous successful projects in Navsari with durable and stylish paver block solutions.

✅ Rubber Mould Paver Block Manufacturer in Bardoli

Our rubber mould paver blocks are the top choice for contractors and architects in Bardoli due to their long life and low maintenance.

✅ Rubber Mould Paver Block Manufacturer in Ankleshwer

In the industrial town of Ankleshwer, we supply heavy-duty pavers that can withstand high traffic and extreme conditions.

✅ Rubber Mould Paver Block Manufacturer in Chikhli

From garden paths to building entrances, our products enhance the beauty and safety of spaces in Chikhli.

✅ Rubber Mould Paver Block Manufacturer in Hajira

Our precision-engineered blocks are used in various infrastructure and port projects in Hajira.

✅ Rubber Mould Paver Block Manufacturer in Bharuch

Known for strength and performance, our blocks are widely used in Bharuch’s residential and commercial projects.

✅ Rubber Mould Paver Block Manufacturer in Valsad

With a growing base in Valsad, our pavers are becoming the go-to option for builders and developers.

Frequently Asked Questions

Q1: What makes rubber mould paver blocks better than traditional pavers?

Rubber moulds provide smoother finishes and better design accuracy. The blocks are more uniform, durable, and visually appealing.

Q2: Can I choose my own design and color?

Yes! At Krishna Paver Block, we offer full customization to suit your aesthetic and functional requirements.

Q3: How long do these blocks last?

With proper installation and minimal maintenance, rubber mould paver blocks can last for over 20 years.

Q4: Do you provide installation services?

While we mainly focus on manufacturing and supply, we do have a network of professional installers we can recommend.

Contact Krishna Paver Block – Your Local Rubber Mould Paver Block Manufacturer in Surat

If you’re planning your next paving project, don’t settle for less. Choose a partner who brings experience, quality, and innovation to the table.

📍 Visit Us: Krishna Paver Block, Surat, Gujarat 🌐 Website: https://krishnapaverblock.com

Final Thoughts

Choosing the right paver block manufacturer can make all the difference in your construction or landscaping project. With Krishna Paver Block, you not only get the best Rubber Mould Paver Block Manufacturer in Surat but also a long-term partner committed to your satisfaction. Whether you are in Surat, Navsari, Bardoli, Ankleshwer, Chikhli, Hajira, Bharuch, or Valsad – we’re ready to serve you with top-tier paver block solutions.

Build with confidence. Build with Krishna Paver Block.

0 notes

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support