Don't wanna be here? Send us removal request.

Text

Maximizing Quality in Ophthalmic Lines with Eye Dropper Bottle Inspection Systems

Pharmaceutical packaging lines today are being redefined by smart automation. Among the most critical upgrades is the use of Eye Dropper Bottle Inspection Systems. These systems ensure real-time, non-contact, high-speed inspection of eye drop bottles—where even the smallest visual defect can compromise product integrity and regulatory compliance.

The Role of Vision Inspection in Ophthalmic Production

Eye drop bottles present unique inspection challenges. Being small, transparent or semi-transparent, and filled with sterile content, they require detailed inspection of critical areas like: - Bottle fill level - Cap alignment and closure - Dropper nozzle presence - Body scratches, smudges or discoloration A dedicated Eye Dropper Bottle Inspection System uses AI-powered vision to monitor all these aspects at once, in real time, on high-speed lines.

How the Eye Dropper Bottle Inspection System Works

1. Bottles enter via a synchronised conveyor system. 2. They pass through lighting and camera modules. 3. Multi-angle industrial cameras scan each bottle for structural and cosmetic defects. 4. Vision software compares images with quality standards using AI and predefined rules. 5. Rejected bottles are instantly removed using a pneumatic arm or air-jet mechanism. 6. Accepted bottles proceed to final packaging without interruption.

Components That Power the System

- Stainless steel conveyor with starwheel feed - High-speed machine vision cameras (top, side, fill level view) - LED lighting modules with optical diffusers - AI-enabled inspection software with parameter tuning - Auto-reject mechanism - HMI for live monitoring, access control, and reports - SCADA/Network integration options

Why Leading Manufacturers Choose Optomech

Optomech’s Eye Dropper Bottle Inspection System is trusted by India's top injectable manufacturers, especially those producing ophthalmic and nasal dropper lines. Key reasons our clients prefer Optomech: - Simple integration into existing packaging lines - Customizable inspection criteria for different bottle sizes and cap designs - Real-time report generation with rejection reasons - Minimal maintenance and fast remote service support With decades of experience and reliable field support, Optomech ensures zero compromise on inspection accuracy or machine uptime.

Key Benefits at a Glance

- Zero sampling: every bottle is inspected - High throughput: up to 400 bottles per minute - Lower QC manpower cost - Real-time decision making and traceability - Reduced product recall risk

Conclusion: Drive Efficiency with Eye Dropper Bottle Inspection Systems

Eye Dropper Bottle Inspection Systems are the new standard for quality in ophthalmic packaging. As compliance standards get stricter and competition grows, vision inspection is becoming essential—not optional. Optomech’s solution offers speed, precision, and long-term support—helping you deliver safer, cleaner, and defect-free packaging. 📩 Book a demo: [email protected] | 🌐 https://www.optomech.in/eye-dropper-bottle-inspection/

0 notes

Text

The Hidden Risks of Ignoring Flip-Off Cap Inspection in Pharma Packaging

In pharmaceutical manufacturing, every detail counts — from sterile filling to labeling. But one component often overlooked is the flip-off cap that seals injectable vials. It’s small, yes — but the consequences of not inspecting it are anything but.

Let’s talk about why ignoring flip-off seal inspection is a risk no modern pharma brand should take, and how Optomech’s FOSIS system brings precision, automation, and peace of mind to the process.

🧨 The Problem: Small Defects, Big Consequences

You may think a cap is just a cap. But even minor defects in flip-off seals can cause:

Regulatory failures during batch audits

Sterility breaches in transit or storage

Patient safety risks due to contaminated vials

Brand reputation damage from recalls or customer complaints

Typical issues include:

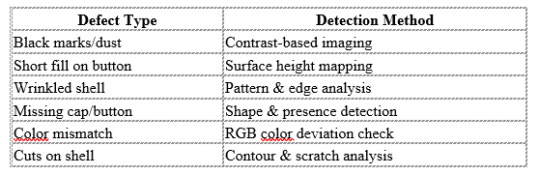

Black spots

Short filling of the PP button

Cut or dented aluminum shells

Color mismatches

Improper or missing plastic caps

Now imagine these defects slipping through manual or random inspections. That’s a compliance risk pharma companies can no longer afford.

✅ The Solution: Meet FOSIS – Flip-Off Seal Inspection System

FOSIS is Optomech’s high-speed, camera-based vision inspection system — purpose-built to scan, detect, and reject defective flip-off caps with unmatched accuracy.

🎯 Key Features at a Glance:

Speed: Inspects up to 600 caps/min

Vision Accuracy: Detects 20+ types of defects

Automation: No manual checking, no guesswork

Rejection System: Faulty caps are auto-ejected instantly

Compliance: Fully 21 CFR Part 11 compliant

🧠 How It Works:

Caps are fed into the system via a vibratory bowl.

High-speed cameras capture images from multiple angles.

Advanced algorithms compare each cap to a defect-free reference.

Defective caps are rejected, and logs are generated.

Reports can be exported via Excel/network sharing.

📊 Defects Detected by FOSIS:

🏭 Who Needs FOSIS?

FOSIS is ideal for:

Pharmaceutical manufacturers of injectable drugs

CMOs (Contract Manufacturing Organizations)

Flip-off cap producers

Companies targeting zero-defect packaging

Whether you're building a new packaging line or upgrading your existing setup, FOSIS integrates seamlessly and boosts inspection reliability from day one.

🔒 Why Flip-Off Cap Inspection Can’t Be Optional Anymore

In today’s regulated pharma landscape:

Quality audits are stricter

Sterility concerns are growing

Brand protection is non-negotiable

FOSIS isn't just a machine — it's your frontline quality gate. It helps you catch defects before regulators or customers do.

🏁 Final Takeaway: Inspection Is No Longer Optional — It's Strategic

Flip-off seal inspection may be a “last step” in the process, but with FOSIS, it becomes a first-class safeguard for your production integrity. Speed, accuracy, compliance — all in one automated system.

📞 Want to see FOSIS in action or schedule a demo? 📧 [email protected] 🌐 www.optomech.in/flipoff-inspection-system-2

#flipoffsealinspection#pharmapackaging#capdefectdetection#machinevisionqc#21cfrcompliant#injectablepackaging#optomechinspection#capinspectionmachine#visualinspectionpharma#zeroDefectPackaging

0 notes

Text

Why Flip-Off Cap Inspection Is the Missing Link in Your Pharma Packaging Line

When it comes to injectable packaging, flip-off seals are more than just aluminum caps — they’re your brand’s first line of defense in ensuring sterility, safety, and quality. Unfortunately, they’re also one of the most overlooked areas in quality control.

Enter Optomech’s FOSIS — a next-gen flip-off seal inspection system that combines machine vision, high-speed automation, and regulatory-ready software to eliminate defects before your products leave the line.

🔍 What Can Possibly Go Wrong with a Flip-Off Seal?

You’d be surprised.

During mass production, flip-off caps often suffer from:

Black spots

Short fills on the PP button

Wrinkles or dents on the aluminum shell

Color mismatches

Dust, dirt, or improper crimps

Missing caps or incomplete assemblies

Individually, these might seem minor. But together, they can:

Lead to product recalls

Fail regulatory inspections

Damage brand reputation

Cause delays in batch release

⚙️ How FOSIS Detects These Defects in Real-Time

The Flip-Off Seal Inspection System (FOSIS) uses a combination of:

High-speed vision cameras

Precision lighting and optics

Custom-developed algorithms

21 CFR Part 11 compliant software

Here's how it works:

Seals are fed through a vibratory bowl to a conveyor.

As they pass under the vision station, each cap is captured frame-by-frame.

The system checks for all defined defects in under a second.

Defective caps are immediately rejected without stopping the line.

Data is logged and reports are generated for compliance and traceability.

💼 Where Can FOSIS Be Used?

If you manufacture or package:

Injectables

Sterile vials

Flip-off caps or seals

Pharma glass bottles

…then you’re the perfect use case for FOSIS.

Whether you're a large pharmaceutical company, a contract manufacturing organization (CMO), or a packaging component supplier, FOSIS adds speed, consistency, and reliability to your inspection process.

📊 Built for Pharma Compliance & Performance

Key Features:

Inspects up to 600 caps/min

Handles cap sizes from Dia 15 mm to 36 mm

Detects over 20 defect types including:

Shell deformations

PP button cuts or flashes

Color and shade variations

User-friendly 21” touchscreen with quick product changeovers

Three-level access control: User, Supervisor, Admin

Auto reporting to Excel, with network export and historical data access

📞 Take Control of Your Cap Quality – Don’t Leave It to Chance

With market demands rising and regulatory scrutiny at an all-time high, it’s time to move beyond manual checks and partial sampling.

Optomech’s FOSIS Flip-Off Seal Inspection System gives you:

Faster output

Reduced batch rejections

Higher customer trust

Better compliance audit readiness

🧪 Ready to See It in Action?

Whether you need a demo, pricing, or integration advice, we’ve got you covered.

📧 [email protected] 📞 +91 40 23078371 🌐 www.optomech.in

0 notes

Text

Automated Silica Canister Inspection: Revolutionizing Pharmaceutical Quality Control

In the world of pharmaceutical packaging, accuracy and speed are essential. For this reason, automated silica canister inspection is becoming more popular on manufacturing floors throughout the world. When every component matters, a fault in the silica desiccant canister could endanger the entire batch of drugs. The CANIS system from Optomech was developed specifically for the purpose of inspecting silica canisters flawlessly and quickly. Automated silica canister inspection guarantees that every canister in the batch is tracked, measured, and validated, regardless of blocked mesh, short molding, or even minute diameter differences. At 14,000 canisters per hour, the CANIS machine provides your operation with continuous, real-time quality checking.

Why Desiccant Canisters Must Be Inspected Automatically

Desiccant canisters preserve the efficacy of drugs by absorbing moisture. Canisters with flaws, however, may fail to work or introduce physical pollutants. Manual inspections impede production and overlook flaws. These dangers are eliminated as output is scaled up with automated silica canister inspection.

CANIS: A Smart Investment for Pharmaceutical Compliance

CANIS offers a 100% online solution for desiccant canister inspection that combines machine vision, high-resolution cameras, and intelligent defect detection" The equipment guarantees efficiency, accuracy, and repeatability without the need for human involvement. Its purpose is to capture:- Broken mesh - Flash molding - Surface dirt - Dimensional inconsistencies - Shape defects In addition to being found, every flaw is also classified and documented. This traceability supports audits and improves confidence in your quality control protocols.

Designed for Production-Line Speed and Operator Ease

At 14,000 canisters per hour, CANIS doesn’t just keep up—it leads. The system’s ergonomic touchscreen interface lets operators adjust tolerance levels, view defect galleries, and take immediate corrective action. Its visual dashboard plots the last 100 defects for quick diagnostics. Operators get more than data—they get insights.

How Automation Reduces Cost and Error

With CANIS, plants no longer need to dedicate staff to manually inspect and sort. It reduces labor requirements while improving inspection consistency. The result: a dramatic decrease in human error, higher throughput, and a faster return on investment.

Built for Audits, Powered by Data

CANIS logs inspection data and delivers customizable reports aligned with your QA standards. With role-based access (User, Supervisor, Admin), data is protected, while managers can track performance, trends, and rejection rates.

Remote Support and Upgradability

CANIS is ready for Industry 4.0. With remote login support, your technical team or Optomech’s experts can access the machine anytime for diagnostics. Frequent firmware updates keep the system current and scalable.

One System, Many Benefits

Installing CANIS ensures: - Reduced inspection costs - Higher regulatory compliance - Real-time rejection tracking - Enhanced production visibility All the while keeping the integration cost low and the footprint small.

Watch CANIS in Action

Curious about performance? Watch our machine inspect 14,000 units per hour with precision: https://youtu.be/mqRbubOLo98

Conclusion: Adopt the Future of Inline Canister Quality

Automated silica canister inspection is not the future—it’s now. The CANIS system from Optomech represents a huge step forward for pharmaceutical packaging quality control. By detecting every anomaly in real-time and offering seamless reporting, CANIS helps you meet global standards without breaking a sweat.

Contact Optomech

Based in Hyderabad, Optomech Engineers Pvt. Ltd. leads the market with high-speed vision-based inspection systems and optical metrology tools. Website: www.optomech.in Phone: +91 40 23078371 Email: [email protected]

#o#Bottle Inspection Systems (BIS-XL#BIS-EDB)#Cap Inspection Systems (CIS-Online#CIS-XL)#Induction Sealing Integrity Verifiers (ISIVS)#Label & IML Label Inspectors (LIS-2S#IML Inspector)#Flip-Off Seal Inspection (FOSIS)#Optomech

0 notes

Text

Revolutionizing Packaging with the LIS-2S Automatic Label Inspection System

In the world of high-speed packaging, precision isn’t optional—it’s critical. Just one poorly applied or misaligned label can cost manufacturers customer trust, regulatory compliance, or even an entire product batch. Enter the LIS-2S automatic label inspection system—a cutting-edge solution designed for the pharma, FMCG, and cosmetics industries that demand nothing less than perfection. Operating seamlessly on high-speed bottling lines, this system brings unmatched accuracy and inspection reliability, ensuring every bottle leaving your facility is 100% label-verified.

Why an Automatic Label Inspection System is a Must-Have Today

Manual label inspection is quickly becoming obsolete. Human eyes can't consistently catch defects at production speeds of 14,000 bottles per hour. Plus, the margin for error grows with fatigue and environmental distractions. That’s why more companies are investing in automated, vision-based solutions. The LIS-2S automatic label inspection system detects: • Label misplacement or skew • Wrinkles or air bubbles • Incorrect label orientation • Missing labels • Overlapping or double-labeled bottles By integrating a robust vision camera setup with intelligent software, LIS-2S offers real-time decision-making—rejecting faulty products before they reach the packaging zone.

High-Speed Performance with Precision Engineering Speed without precision is a recipe for disaster. Fortunately, LIS-2S is engineered to handle both. • Throughput: Up to 14,000 bottles/hour • Inspection Modes: Front label, back label, wrap-around label • Orientation Correction: Capable of verifying label orientation in relation to bottle shape or cap • User Interface: Simple, touchscreen-based GUI for setup and monitoring • Footprint: Compact, easily integrates into existing lines without the need for reconfiguration Whether you’re packaging antibiotics in glass bottles or shampoos in PET containers, the LIS-2S adapts effortlessly, thanks to its custom configurability.

How the Automatic Label Inspection System Ensures Compliance Global compliance standards are tightening. For industries like pharma or cosmetics, even a 0.01% labeling error can result in batch rejection, penalties, or blacklisting by retailers. The automatic label inspection system gives manufacturers a proactive way to stay ahead of audits. Key compliance advantages: • 21 CFR Part 11 ready (for pharma) • Customizable reports & batch logs • Traceability of rejected units • Audit trail with user access control Plus, it helps ensure packaging meets branding standards—logos are correctly placed, labels are level, and branding integrity is never compromised.

Designed for Indian Manufacturing. Built for Global Standards. Optomech’s LIS-2S isn’t just fast and smart—it’s designed with real production environments in mind. Unlike imported systems that are complex to maintain, the LIS-2S offers: • Local tech support & quick servicing • Easy-to-source spares • Customization for Indian bottle formats (HDPE, PET, Glass, etc.) • Affordable total cost of ownership compared to foreign systems This makes LIS-2S a future-ready solution not just for large-scale manufacturers but also for mid-sized companies scaling up their packaging operations.

Key Benefits of Using an Automatic Label Inspection System When you switch to an automated system like LIS-2S, you unlock real, measurable improvements: • Reject rate reduced by up to 95% • Downtime minimized through predictive maintenance • Brand image protected by flawless labeling • Line efficiency improved via real-time rejection alerts • Zero human intervention means zero fatigue-based errors The ROI? Many users recover their investment within 6 to 12 months purely through reduction in wastage and customer complaints.

Where LIS-2S Fits Best This automatic label inspection system is ideal for: • Pharmaceutical packaging lines • FMCG bottling plants • Cosmetic and personal care product lines • Nutraceutical liquid packaging • Agrochemical bottle labeling Whether you're handling 100 ml syrup bottles or 1-liter shampoo containers, LIS-2S adapts to your workflow.

Smart Label Inspection, Smarter Business Investing in the LIS-2S automatic label inspection system is more than just buying a machine—it’s a strategic move. It signals to your customers, partners, and regulatory agencies that your company is committed to zero-defect manufacturing and continuous improvement. It’s not just about catching errors. It’s about preventing brand damage before it happens.

Final Thoughts: Make Every Label Count With the stakes so high in modern packaging, the question isn’t if you need label inspection automation—it’s when. And if you're serious about quality, the LIS-2S automatic label inspection system should be your answer. From regulatory peace of mind to zero-defect shipments, this is one investment your packaging line—and your brand—can’t afford to skip.

#High-speed label inspection machine#Label inspection system#Label defect detection#Automatic label inspection#Inline bottle inspection

0 notes

Text

OPTO 1200 Quick Measuring Machine — Precision Screw Inspection in Just Seconds

Opto1200- Optomech engineers pvt ltd

Revolutionize Your Quality Control with Instant, Accurate, and Hands-Free Measurement

Intoday’s era of micro-precision and mass production, quality inspection is no longer just about checking dimensions — it’s about doing it faster, smarter, and without compromise. Whether you’re manufacturing automotive components, aerospace fasteners, or industrial-grade tools, ensuring that every screw meets exact specifications is non-negotiable.

Enter the OPTO 1200 Quick Measuring Machine — a powerful, camera-based dimensional inspection system that allows users to measure 2D parts like screws instantly with incredible accuracy, without operator intervention. No complex setup. No manual handling. Just place the part, press a button, and let the system do the rest.

Why Choose OPTO 1200 for Screw Inspection?

Screws, though seemingly simple, are geometrically complex. They include multiple critical parameters like:

Thread pitch

Head diameter

Shaft length

Chamfer angle

Root diameter

Any deviation can result in poor fit, torque failure, or total product rejection.

Traditional methods like calipers, micrometers, or profile projectors are time-consuming and subject to human error. With OPTO 1200, you can measure every screw in seconds, store the results, and even generate reports — all with minimal training.

Real-World Application: Measuring a Precision Screw

Let’s walk through how a screw is measured using the OPTO 1200 system:

Step 1: Template Creation

Using Opto Precision V1 software, a template is created by simply drawing around the screw’s edge.

The software auto-detects contours and generates geometric elements like lines, circles, and arcs.

Nominal dimensions and tolerances are input by the quality team.

Step 2: Place and Measure

The operator places the screw on the OPTO 1200 stage.

On clicking the “Measure” button, the system:

Captures the image

Matches it with the template

Automatically measures:

Head diameter

Thread pitch

Shank length

Chamfer angles

Concentricity

Provides instant PASS/FAIL validation

Step 3: Reporting

The results are stored in a secure database.

A statistical report including Min, Max, Mean, Std Dev, CPK is generated.

Reports can be exported or printed as per requirement.

This is true plug-and-play metrology, making it a must-have tool for modern precision workshops.

What Makes OPTO 1200 Unique for Screw and Small Part Inspection?

1. Speed

Inspects each screw in under 5 seconds

Measures multiple screws at once on a single stage

2. Accuracy

Accuracy: ±10 μm

Repeatability: ±5 μm

Resolution: 1 μm

3. Simplicity

Just place the screw and press a button

No specialized operator skills needed

4. Reporting & Traceability

Every measurement logged

Reports generated automatically

Compliant with industrial audit requirements

Key Features at a Glance

Feature

Specification

Field of View

120 mm x 95 mm

Camera

20 MP Monochrome CMOS

Lens

Double Telecentric Optics

Software

Opto Precision V1

Display

21.5” Full HD Touchscreen

Illumination

Collimated Green LED

Accuracy

±10 μm

Repeatability

±5 μm

Report Generation

Real-time with summary stats

Industries That Benefit from OPTO 1200

If your industry relies on tight tolerance parts like screws, bolts, pins, and fasteners, the OPTO 1200 is for you:

Aerospace & Aviation

Automotive

Medical Device Manufacturing

Electronics & PCB Assemblers

Tool & Die Making

Defense & Heavy Engineering

From prototype analysis to full production QA, this machine fits right into your digital workflow.

FAQs — Quick Insights for Buyers and Operators

Q1: Can OPTO 1200 measure different types of screws?

A: Yes. You can create and save multiple templates for each screw type and recall them instantly.

Q2: How does it ensure accuracy for threads?

A: The double telecentric lens and edge-detection software ensure consistent and distortion-free thread measurements.

Q3: Can I use it for batch inspection?

A: Absolutely. You can place multiple screws and measure them all in one click.

Q4: Is it difficult to operate?

A: Not at all. It’s user-friendly with an intuitive interface — no metrology experience required.

Q5: Does it store past reports and results?

A: Yes. Every measurement and inspection report is saved and can be retrieved anytime.

Conclusion: Make Screw Inspection Smarter, Faster, and Reliable with OPTO 1200

In a manufacturing world driven by precision and productivity, the OPTO 1200 is your edge. It empowers your team to inspect complex parts like screws with unparalleled accuracy, zero human error, and faster cycle times.

Whether you’re inspecting 10 parts a day or 1,000, the OPTO 1200 guarantees performance, repeatability, and ease — all packed into one powerful machine.

Measure better. Deliver faster. Trust OPTO 1200.

0 notes

Text

Top 1 botlle inspection System in 2025 -Optomech

Imagine inspecting 11,000 bottles per hour with microscopic accuracy—all without human intervention. That’s the power of Machine Vision Inspection!

🔬 AI-driven defect analysis for unmatched precision ⚡ Ultra-fast processing keeps up with high-speed lines 📊 Automated data logging for compliance and tracking

The BIS-XL system ensures zero-defect manufacturing, helping companies meet the highest quality standards effortlessly.

Are you still relying on manual inspections in 2025? Let’s talk about automation!

Contact us:

Visit: https://www.optomech.in/bottle-inspection-system/

cantact us : 91+ 8106733649

Contact us for Demo Feel free To Ask

#BottleInspection#MachineVision#InspectionSystem#Automation#ManufacturingExcellence#QualityAssurance#FoodSafety#PharmaInspection#BeverageIndustry#IndustrialAutomation#NonDestructiveTesting#VisionSystems#Optomech

0 notes

Text

Best Tool for Effortless Measurements Quick Measuring Machine (QMM)-Optomech

Introduction

In today’s production and quality assurance, the need for sharp and precise measurements is greater than ever. Classical methods of measurement may be subject to time consultation and human error, leading to disability in production. This is where the quick measuring machines (QMM) come in.

A quick measuring machine is a sophisticated, high-speed, contactless inspection device that is programmed to measure components with precise, recurrence and less operator intervention. Through the application of automatic measurement, high-definition imaging and clever software algorithms, these machines assist manufacturers in the enhancement of product quality and the rate of manufacturing by minimizing wastage.

What is a quick measuring machine (QMM)?

A quick measuring machine is an automatically operated optical measuring system that records high-speed images of an ingredient and instantly measures its dimensions, geometry and surface profiles. As opposed to standard measuring equipment that needs manual inputs and multiple phases, a QMM gives precise, real-time measurements within seconds.

How a quick measurement machine operates?

Hold the component-part in position at the measurement stage of the machine.

The auto capture of the image is the profile of the Capture-e-Regalution Camera Object.

Software Processing — Software edges are detected by intelligent measurement, controlled and dimensions.

Rapid results — The machine gives a precise measurement report in seconds.

Key attributes of fast measuring machines

✔ Ultra-Fast measurement-high speed image minimizes the time of inspection with capture and processing.

✔ Non-contact measurement-avoids damage to dancing or intricate components.

✔ High-resolution ensures digital imaging-illiterate and precise analysis of measurement.

✔ Automatic edge detection and pattern recognition — detects edges and compare results with CAD model.

✔ User-friendly interface-a spontaneous touch-screen or easy operation with a computer-based control system.

✔ Measure multiple components at one time, enhancing multi-part inspection-defense.

✔ Data Reporting and Storage — Exports and saves measurement reports for traceability and quality control.

Types of quick measuring machines

1. Manual quick measuring machines Operator help is needed to concentrate on the situation and concentration.

Ideal for low volume and special measurement.

Low scale economical for industries.

2. Semi-automatic quick measuring machines Part automation, less manual adjustment.

Ideal for mid-range production setup.

The manual is more accurate and efficient than the model.

3. AU Fully automatic, without the need for operator intervention.

Ensures uniform, recurrence and high-collective measurement.

Ideal for mass production and high-thorpoot manufacturing.

Use of quick measuring machines

Automotive and aerospace — guarantees speedy quality inspection of engine components, gear and structural parts.

Medical Equipment ensures accurate, sterile and contactless measurements for-registory equipment and transplantation.

Electronics and PCB industry measures micro-clashes and intricate PCB layouts with industry-high magnification.

Tools and dye manufacturing molds and tooling provide high-colored inspection of tooling.

General Manufacturing and Prosecuting Engineering — Applied in metals, plastic components and industrial parts for quick quality inspections.

Advantages of rapid measuring machines

High speed and efficiency — gives results in seconds, inspection saves time and boosts productivity.

Unrivaled accuracy — avoids human errors with digital, automatic measurements.

Cost-affect- waste saves money by minimizing work and production downtime.

universal application — can be used for a variety of materials and component sizes.

Live data and reporting-grade control, compliance and procedure assistance enables to adapt.

How to select the right quick measuring machine?

When choosing a quick measuring machine, take into account the following:

Component size — Select a machine that is capable of varying the size of your part.

accuracy needs — high resolution cameras and sophisticated software provide higher accuracy.

Production quantity- CNC QMMs suit mass production, whereas manual QMMs work best for small scale or special inspection.

Software integration — Make sure that the system supports CAD model and quality control database.

Conclusion

Adapt your inspection process with quick measurement machines

A quick measuring machine is a game-chain for industries that require rapidly,

📞 Get in Touch!

For more details about Quick Measuring Machines or to schedule a product demo, contact us today!

🔗 Visit our website: https://www.optomechengineers.com/quick-measuring-machine/

📧 Email: [email protected]

📞 Call: +91 8106733649

#Optomech#QuickMeasuringMachine#PrecisionMeasurement#Metrology#QualityControl#Manufacturing#Automation#MachineVision

1 note

·

View note