#High Pressure Washer in India

Text

https://vootclean.com/product-category/cold-water-high-pressure - Cold Water High-Pressure Jet Cleaner and Washer are perfect for everyday cleaning of equipment, Cars, and buildings to get rid of tough dirt

#High Pressure Washer in India#High Pressure Washer Machine in India#Industrial High pressure washer in India

0 notes

Text

The STIHL RE 80 electric high-pressure cleaner is particularly handy thanks to its low weight and compact design. The robust high-pressure pump with aluminum pump head generates a maximum pressure of 120 bar. So you can effectively and thoroughly carry out cleaning tasks around the house. Two standard nozzles allow you to complete various cleaning tasks. The adjustable flat jet nozzle is suitable for quick cleaning of more sensitive surfaces, while the rotor nozzle with powerful point jet also Efficiently removes stubborn dirt. You can also use the supplied cleaning agent spray set to achieve even better cleaning results. You can quickly connect the 5 m long high-pressure hose to the device and the gun using the quick-release couplings.

0 notes

Text

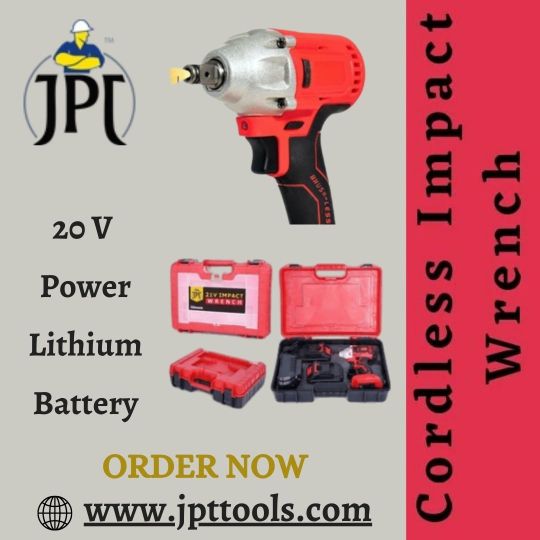

Empower Your Projects with JPT's Power Tools India

It's time to take charge of your projects with JPT's Power Tools India. Our high-performance tools empower you to achieve your goals with efficiency, making your project tasks seamless and successful. Elevate your workmanship with JPT's Power Tools today.

Follow us at:

Facebook- https://www.facebook.com/JPTTools/

Instagram- https://www.instagram.com/jpttools/

Twitter- https://twitter.com/JptTools

LinkedIn- https://www.linkedin.com/in/jpt-tools-04674822b/

YouTube- https://www.youtube.com/channel/UCM8k-ECK3AHUIzrEz7fFkAQ

#Power Tools India#Cordless Impact Wrench with Batteries#High Pressure Washer for Car#Best Cordless Impact Wrench#Cordless Reciprocating Saw#Best Impact Driver Bits Set

0 notes

Text

"The Role of Ultrasonic Cleaning in Protecting Product Quality Across Industries"

Seppa Solutions Glass Bottle Washer is a top-tier industrial glass bottle cleaning system designed for seamless integration into any production line. To ensure product safety and quality, it employs cutting-edge cleaning technology, including high-pressure jets, ultrasonic technology, and sterilization cycles. The machine is ideal for beverage manufacturing, pharmaceuticals, and cosmetics, where glass bottles are used for packaging alcoholic and non-alcoholic drinks. Its energy-saving features reduce water and energy consumption while maintaining high cleaning standards. Seppa Solutions' automated features reduce the risk of human error, ensuring uniform and high-quality cleaning. By choosing Seppa Solutions, you're investing in superior technology that guarantees clean, sterile, and reusable bottles every time.

#automatic glass bottle washer#automatic glass bottle cleaning machine#glass bottle cleaner#glass bottle washers#glass bottle cleaning machine#glass bottle washing#glass bottle washers machine#bottle washer#glass bottle washer#bottle washing machine#bottle cleaner

0 notes

Text

The Role of Bolts & Nuts in Industrial Applications – Akbarali Enterprises

Akbarali Enterprises, a renowned Bolt Manufacturer in India and one of the top Nuts manufacturers in India has established itself as a leader in producing high-quality industrial-grade fasteners. With a strong commitment to manufacturing excellence, the company offers a comprehensive range of bolts and nuts that meet the demands of various industries. Regarding industrial applications, the quality and reliability of bolts and nuts play a critical role in ensuring safety, durability, and efficiency.

High-Quality Bolts from Akbarali Enterprises

Bolts are a fundamental component in countless applications, from construction and machinery to automotive and infrastructure projects. Akbarali Enterprises stands out as a trusted Bolt Manufacturer known for its wide variety of bolts designed to meet the highest industry standards. As one of the leading Bolts Suppliers in India, Akbarali Enterprises provides solutions that ensure the strength and durability required in demanding environments.

Types of Bolts Offered

Akbarali Enterprises offers an extensive range of bolts, each tailored to specific applications. Some of the key types of bolts available include:

Carriage Bolts: These bolts are widely used in wood and metal construction due to their smooth, domed head and square neck that prevents turning during installation.

Hex Bolts: Hex bolts are commonly used in heavy-duty industrial applications where strong, secure fastening is essential.

Anchor Bolts: These bolts are designed for securing structural elements to concrete or masonry surfaces, making them ideal for construction projects.

Eye Bolts: Eye bolts are perfect for lifting applications, providing a secure connection point for rigging equipment.

As a leading Bolt Manufacturer in India, Akbarali Enterprises ensures that every bolt is manufactured precisely, providing high tensile strength, corrosion resistance, and reliability even in the most challenging environments.

Comprehensive Range of Nuts by Akbarali Enterprises

Just as bolts are essential for holding components together, nuts are the complementary fasteners that complete the job. Akbarali Enterprises is recognized as a top Nuts manufacturer in India, offering a wide selection of nuts for various industrial applications. The company's expertise in fastener manufacturing has positioned it as a trusted Nut Supplier in India, providing high-quality nuts that meet international standards.

Types of Nuts Offered

The extensive range of nuts offered by Akbarali Enterprises includes:

Hex Nuts: These are among the most commonly used nuts in a variety of applications, providing a strong and secure hold when paired with corresponding bolts.

Square Nuts: Designed for use in tight spaces, square nuts offer more surface area in contact with the material, ensuring greater strength and durability.

Flange Nuts: Flange nuts have a built-in washer that distributes pressure more evenly, making them ideal for high-vibration environments.

Lock Nuts: Lock nuts are designed to prevent loosening due to vibrations or torque, ensuring a secure hold in machinery and automotive applications.

As a reliable Nut Supplier, Akbarali Enterprises provides a wide range of nuts made from high-quality materials, ensuring long-lasting performance in even the harshest environments.

Precision and Durability with Akbarali Enterprises

At Akbarali Enterprises, precision and durability are at the forefront of every product they manufacture. The company utilizes advanced manufacturing techniques and high-quality materials to produce bolts and nuts that adhere to stringent quality control standards. As a leading Bolt Manufacturer and Nuts manufacturer in India, Akbarali Enterprises ensures that all fasteners offer superior strength, resistance to wear and tear, and protection against corrosion.

Nut Weight Chart in Kg and mm

For industries that require precise specifications, knowing the exact dimensions and weight of nuts is critical for selecting the right fasteners. Akbarali Enterprises provides a comprehensive Nut Weight Chart in Kg and mm, which serves as a valuable reference for engineers, architects, and project managers.

This chart helps users determine the weight of various nuts based on their size (in mm) and material composition. Whether it's for construction, machinery, or automotive use, having access to a detailed Nut Weight Chart in Kg and mm ensures that the correct fastener is chosen for each application, reducing the risk of failure and improving overall performance.

Commitment to Quality and Customer Satisfaction

As a prominent Bolt Manufacturer in India and Nut Supplier in India, Akbarali Enterprises is committed to providing customers with the highest level of quality and service. The company’s extensive portfolio of fasteners is backed by decades of experience, industry expertise, and a focus on innovation.

Akbarali Enterprises understands the unique needs of different industries and works closely with clients to provide customized solutions. Their robust distribution network ensures timely delivery of fasteners, making them one of the most reliable bolt suppliers in India and Nut manufacturers in India.

Conclusion

In the fastener industry, reliability, precision, and quality are non-negotiable. Akbarali Enterprises has consistently proven itself as a leader in the manufacturing of industrial-grade bolts and nuts, offering a diverse range of products tailored to meet the specific needs of various sectors. Whether you're in construction, automotive, or heavy machinery, you can trust Akbarali Enterprises to deliver fasteners that exceed expectations. With their comprehensive Nut Weight Chart in Kg and mm and commitment to customer satisfaction, Akbarali Enterprises is your go-to source for high-quality bolts and nuts in India.

We are also the leading fasteners manufacturer in India. and Stainless Steel Fasteners Manufacturer in India.

Website: akbarfasteners.com

0 notes

Text

Inline Flow Indicators, Sequence Valve, PP Pipe Clamp, Manufacturer

Manufacturer and Supplier of Inline Flow Indicators, Inline Flow Indicator, Sequence Valve, PP Pipe Clamp, Pressure Gauges, Industrial Valves, Mumbai, India.

Quick Release Coupling, Quick Release Couplings, Ball Valve, Ball Valves, Gemel Ball Valves, Industrial Ball Valves, Quick Coupling, Quick Couplings, Camlock Coupling, Camlock Couplings, Camlock Quick Coupling, Camlock Quick Couplings, Micro Hose, Micro Hose For High Pressure, Micro Hose For Pressure Fittings, Test Coupling, Test Couplings, Minipress Test Coupling, Minipress Test Couplings, Test Point Coupling, Test Point Couplings , Threaded Test Coupling, Threaded Test Couplings, Bulkhead Test Coupling, Bulkhead Test Couplings, Female Swivel Test Coupling, Female Swivel Test Couplings, Plug in Test Coupling, Plug in Test Couplings, Pressure Gauge Adaptors, Cartridge Valve, Cartridge Valves, Hydraulic Hoses, Hydraulics Hose, Hoses Crimped Hydraulic, Hydraulic Systems, Pneumatic Systems, Hydraulic Accessories, Hydraulic Couplings, Hydraulic Fitting, Hydraulic Fittings, SS304 Hydraulic Fittings, SS316 Hydraulic Fittings, CS Hydraulic Fittings, DIN 2353 Fittings, Pressure Gauge, Pressure Gauges, Industrial Valves, Coupling Valves, Hydraulic Components, Inline Valve, Inline Valves, Inline Flow Indicator, Inline Flow Indicators, Portable Hydraulic Crimping Machine, Portable Hydraulic Crimping Machines, Portable Hydraulic Instrument, Portable Hydraulic Instruments, Pressure Gauge Anti Shock Valve, Pressure Gauge Anti Shock Valves, Stainless Steel Hydraulic Components, High Pressure Check Valve, High Pressure Ball Valve, High Pressure Flow Control Valve, High Pressure Needle Valve, Non Return Valve, Gemels Italy Ball Valves, Holmbury Uk Couplings, Minipress Italy Couplings, Oleoweb Italy Valves, SS304 Csermeto Fittings, SS316 Csermeto Fittings, Flat Face Coupling, Quick Connect Disconnect Coupling, Screw Coupling 1000 Bar, Dust Cap, Test Point, Test Hose, Test Point Coupling, Test Point Hose, SAE Flange Ball Valve, Rotating Union, Hose Burst Check Valve, Compensated Load Control Valve, Compensated Flow Control Valve, Load Shuttle Ball Valve, End Stroke Valve, Single Acting Pilot Check Valve, Double Acting Pilot Check Valve, Double Cross Line Direct Acting Relief Valve, Single Cross Line Direct Acting Relief Valve, Sequence Valve, Single Counter Balance Valve, Dual Counter Balance Valve, Hand Pumps, Tube Clamp, Instrumentation Fittings, Lubrication Fittings, PP Pipe Clamp, Dowty Seal Copper Washer, Bonded Seal, Nut, Ferrule, asia, asian, india, indian, mumbai, maharashtra, industrial, industries, thane, navi mumbai, pune, nashik, aurangabad, ratnagiri, nagpur, ahmednagar, akola, amravati, chandrapur, dhule, jalgaon, raigad, sangli, satara, belgaum, kolhapur, belgaon.

0 notes

Text

How Long Do Bimetallic Washers Last? | Durability & Longevity Insights

The article provides an in-depth look at the factors affecting the lifespan of bimetallic washers .

It outlines key considerations such as:

Material Composition: The choice of metals used in bimetallic washers affects their durability. Common combinations include stainless steel shims and copper or aluminum. Each metal has unique properties that influence the washer’s lifespan.

Environmental Conditions: Exposure to harsh environments can impact the longevity of bimetallic washers. Factors like temperature fluctuations, humidity, and exposure to chemicals or corrosive substances can cause wear and tear. For example, bimetallic washers used in outdoor settings might need to resist UV rays and moisture.

Load and Stress: The amount of stress and load applied to the washers affects their longevity. Excessive pressure or repetitive motion can lead to deformation or failure over time. Choosing the right bimetallic washers for your specific load requirements is essential.

Installation Quality: Proper installation ensures that bimetallic washers perform as intended. Incorrect installation, such as improper torque or alignment, can lead to premature wear or damage. Following manufacturer guidelines and using appropriate tools can prevent these issues.

Maintenance Practices: Regular maintenance and inspections can help extend the lifespan of bimetallic washers. Checking for signs of wear, corrosion, or damage allows you to address potential issues before they become severe.

The typical lifespan of bimetallic washers ranges from 5 to 10 years under standard conditions, but may be shorter in harsh environments or specialized applications. To extend their life, the article suggests regular inspections, maintaining a clean environment, proper lubrication, correct installation, and prompt issue resolution.

The article also compares bimetallic washers to other types of washers, highlighting their unique benefits and performance in various conditions. This article also helps in selecting the appropriate bimetallic washer involves considering several factors:

Application Requirements: Match the washer to your specific application, considering factors like load, temperature, and exposure to chemicals.

Quality and Manufacturer: Choose high-quality washers from reputable suppliers. Explore options from bimetallic washer manufacturers or shim manufacturers who offer reliable products.

Custom Solutions: In some cases, custom bimetallic washers might be necessary to meet precise requirements. Consult with shim washer manufacturers India or stainless steel shim manufacturers for tailored solutions.

The lifespan of bimetallic washers depends on various factors including material composition, environmental conditions, and proper maintenance. By understanding these factors and following best practices, you can maximize the durability and performance of your bimetallic washers. Whether you’re using them in industrial, automotive, or specialized applications, proper care and selection will ensure you get the most out of these versatile components.

0 notes

Text

Why Choose Hastelloy Fasteners? Benefits, Applications, and Best Practices

Brief Overview of Hastelloy Fasteners

Hastelloy fasteners are specialized components made from Hastelloy alloys, a series of high-performance nickel-based superalloys. These alloys are known for their exceptional resistance to corrosion, oxidation, and high temperatures. Hastelloy fasteners are produced to endure harsh environments and extreme conditions, making them suitable for applications where regular fasteners would fail. The alloy's composition typically includes nickel, molybdenum, and chromium, which contribute to its outstanding strength and durability. Hastelloy fasteners are designed to provide reliable performance in challenging situations, such as high-pressure or chemically aggressive environments.

Importance in Various Industries

Hastelloy fasteners are critical in several key industries due to their superior properties. For example:

Aerospace Industry: In aerospace applications, Hastelloy fasteners are used in components exposed to high temperatures and corrosive substances, such as jet engines and rocket systems. Their ability to withstand extreme conditions without degrading ensures safety and reliability in flight operations.

Chemical Processing: In the chemical industry, Hastelloy fasteners are crucial for equipment that handles corrosive chemicals and acids, ensuring durability and safety in highly aggressive environments. Their resistance to chemical attacks helps maintain the integrity of processing equipment and prevents failures that could lead to hazardous situations or production downtime.

Marine Industry: For marine applications, Hastelloy fasteners are used in environments where exposure to seawater and marine atmospheres can cause rapid deterioration of standard materials. Their resistance to saltwater corrosion ensures the longevity and reliability of marine structures and equipment.

1. What Are Hastelloy Fasteners?

Definition and Composition

Hastelloy fasteners are specialized components crafted from Hastelloy alloys, which are nickel-based superalloys designed to perform in extreme conditions. The term "Hastelloy" refers to a range of alloys developed by Haynes International, known for their exceptional performance in harsh environments.

Key Properties and Benefits

Hastelloy fasteners are renowned for several key properties:

Corrosion Resistance: One of the most notable features of Hastelloy fasteners is their excellent resistance to a wide range of corrosive environments, including acids, chlorides, and seawater.

High-Temperature Stability: Hastelloy fasteners maintain their strength and integrity even at elevated temperatures. They are designed to withstand extreme heat without losing their mechanical properties, making them suitable for aerospace, power generation, and high-temperature industrial applications.

Strength and Durability: These fasteners exhibit high tensile strength and durability, ensuring they can handle significant mechanical loads and stresses. Their robustness makes them ideal for use in critical applications where failure is not an option.

2. Hastelloy Fasteners Manufacturers in India

Leading Manufacturers

India hosts several reputable manufacturers specializing in Hastelloy fasteners. Here are a few notable ones:

1. Ananka Group

Reputation: Known for their extensive experience in the fasteners industry and commitment to quality, Ananka Group is a leading manufacturer in India.

Product Range: Offers a comprehensive range of Hastelloy fasteners, including bolts, nuts, washers, and screws, designed for various industrial applications.

Overview of Manufacturing Processes

The manufacturing of Hastelloy fasteners involves several advanced processes to ensure high performance and durability. Key steps include:

1. Material Preparation: The manufacturing process begins with the preparation of Hastelloy alloy, which is melted and cast into billets or ingots. These billets are then forged or rolled to the desired shape.

2. Machining: The forged or rolled Hastelloy is machined into the required fastener shapes, such as bolts, nuts, and washers. This involves precision cutting, threading, and shaping to meet specific dimensional requirements.

3. Heat Treatment: To enhance the mechanical properties of Hastelloy fasteners, they undergo heat treatment processes such as annealing or aging.

4. Surface Treatment: Depending on the application, surface treatments like passivation or coating may be applied to enhance corrosion resistance and finish quality.

5. Inspection and Testing: Rigorous quality checks are conducted, including nondestructive testing (NDT), dimensional inspection, and performance testing, to ensure the fasteners meet required standards and specifications.

Quality Standards and Certifications

Trusted manufacturers of Hastelloy fasteners comply with several quality standards and certifications to ensure the reliability and performance of their products. Important standards include:

1. ISO 9001: This certification indicates that the manufacturer adheres to international quality management standards, ensuring consistent product quality and customer satisfaction.

2. ASTM Standards: Compliance with ASTM (American Society for Testing and Materials) standards ensures that Hastelloy fasteners meet specific material properties and performance criteria.

3. NACE MR0175: For applications in corrosive environments, adherence to NACE MR0175 standards confirms the fasteners' suitability for use in sour service conditions.

4. API Specifications: Manufacturers supplying fasteners for the oil and gas industry often comply with API (American Petroleum Institute) specifications, ensuring that products meet industry-specific requirements.

5. CE Marking: In some cases, manufacturers may also hold CE marking certification, indicating that their products conform to European Union standards for safety, health, and environmental protection.

3. Hastelloy Fasteners Stockists in India

Role of Stockists

Stockists play a crucial role in the fasteners' supply chain by acting as intermediaries between manufacturers and end-users. Their primary functions include:

Maintaining Inventory: Stockists hold substantial inventories of Hastelloy fasteners to ensure that they can meet the immediate needs of their customers. By keeping a well-stocked inventory, they help prevent delays in the supply chain and ensure that fasteners are readily available when needed.

Providing Timely Delivery: They facilitate quick and efficient delivery of fasteners to various industrial customers. Their ability to promptly supply products helps prevent production downtime and ensures that projects can proceed without interruption.

Offering Custom Orders: Many stockists provide custom solutions to meet specific requirements that may not be available in standard inventory. This includes special sizes, grades, or configurations of Hastelloy fasteners tailored to unique applications.

Logistics Support: Stockists manage the logistics of transporting fasteners from the manufacturer to the end-user.

Key Stockists and Their Services

Several leading stockists in India are known for their expertise in handling Hastelloy fasteners. Here are a few notable ones:

1. Metals & Alloys

Services: Metals & Alloys is a leading stockist that provides a comprehensive selection of Hastelloy fasteners. They provide comprehensive inventory management, custom orders, and fast delivery services. Their logistics support includes packaging and shipping to various locations across India.

2. Global Fasteners

Services: Global Fasteners is well-regarded for its extensive stock of Hastelloy fasteners and its ability to fulfill both standard and custom orders. They offer value-added services such as technical support, fast turnaround times, and robust customer service.

3. Apex Metal Industries

Services: Apex Metal Industries specializes in Hastelloy fasteners with a focus on high-quality inventory and efficient supply chain management. They offer tailored solutions, including custom sizes and grades of fasteners, as well as logistics and distribution support to meet specific customer needs.

4. Alloy Components Pvt. Ltd.

Services: Alloy Components Pvt. Ltd. is known for its comprehensive stock of Hastelloy fasteners and its expertise in handling complex orders. They offer inventory management, prompt delivery, and personalized customer service to meet various industrial needs.

How to Choose a Reliable Stockist

Selecting a dependable Hastelloy fasteners stockist is crucial for ensuring that you receive high-quality products and reliable service.

Reputation: Research the stockist's reputation within the industry. Look for reviews, testimonials, and references from other customers to gauge their reliability and service quality.

Service Quality: Evaluate the stockist’s service quality, including their responsiveness, customer support, and ability to handle special requests. A reliable stockist should provide clear communication and efficient service.

Stock Availability: Ensure that the stockist maintains a comprehensive inventory of Hastelloy fasteners. They should have the capability to provide a wide range of sizes, grades, and types to meet your specific needs.

Experience and Expertise: Choose a stockist with experience and expertise in handling Hastelloy fasteners. Their knowledge of the product and industry can be valuable in providing accurate information and solutions.

Logistics and Delivery: Consider the stockist's logistics capabilities, including their ability to deliver fasteners on time and handle packaging and shipping efficiently. Timely delivery is essential to prevent disruptions in your operations.

Customization Options: If you require custom fasteners, ensure that the stockist can accommodate special orders and provide tailored solutions to meet your specific requirements.

By carefully evaluating these factors, you can select a reliable Hastelloy fasteners stockist that will provide the quality, service, and support necessary for your industrial applications.

4. Hastelloy Fasteners Exporters from India

Export Trends and Markets

The export of Hastelloy fasteners from India has been growing due to several factors:

Rising Demand for High-Performance Materials: Global industries, including aerospace, chemical processing, and marine, have increasing demands for high-performance materials like Hastelloy fasteners. This demand drives exports as Indian manufacturers and exporters cater to these needs.

Technological Advancements: Indian manufacturers have invested in advanced technologies and processes, improving the quality and performance of Hastelloy fasteners. This has helped them compete effectively in the international market.

Diversification of Markets: Indian exporters are expanding their reach to new and emerging markets, including countries in North America, Europe, the Middle East, and Asia-Pacific. This diversification helps mitigate risks and tap into various growth opportunities.

Focus on Compliance and Standards: Exporters are increasingly focusing on meeting international quality standards and certifications, such as ASTM and ISO, to enhance their competitiveness in global markets.

Specific Use Cases and Examples

1. Aerospace Engines

Example: In jet engines, Hastelloy fasteners are used to secure critical components like turbine blades and combustion chambers. Their ability to withstand high temperatures and oxidative environments is essential for maintaining engine performance and safety.

2. Chemical Reactors

Example: Hastelloy fasteners are employed in chemical reactors where they secure reactor vessels and other equipment exposed to corrosive chemicals. Their resistance to acids and chlorides ensures that the reactors operate efficiently without risk of fastener failure.

3. Marine Equipment

Example: On offshore oil rigs, Hastelloy fasteners are used to assemble and secure structural components and equipment exposed to seawater. Their resistance to saltwater corrosion prevents rust and degradation, ensuring the longevity of marine structures.

4. Gas Turbines

Example: In power plants, Hastelloy fasteners are used in gas turbines where they withstand high temperatures and pressures. Their ability to maintain strength and resist oxidation ensures the reliability and efficiency of the turbines.

5. Oil Drilling Rigs

Example: Hastelloy fasteners are used in oil drilling rigs to secure high-pressure valves and other critical components. Their resistance to the harsh conditions of drilling environments helps prevent leaks and equipment failures.

Benefits of Choosing Hastelloy Fasteners

Durability and Corrosion Resistance

Longevity: Hastelloy fasteners are renowned for their exceptional durability, making them suitable for use in environments where other materials might degrade quickly. The high-strength alloy is resistant to wear and tear, ensuring that the fasteners maintain their integrity over long periods of use.

Superior Corrosion Resistance: One of the standout features of Hastelloy fasteners is their outstanding corrosion resistance. Hastelloy alloys are designed to withstand aggressive environments, including exposure to acids, chlorides, and high-temperature steam. This resistance is particularly valuable in industries like chemical processing and marine engineering, where components are subjected to harsh conditions.

Examples: In chemical reactors, Hastelloy fasteners can prevent issues like rust and corrosion that might compromise the safety and efficiency of the equipment. In marine environments, their resistance to saltwater corrosion helps avoid premature failure and maintenance issues.

High-Temperature Stability

Performance Under Extreme Conditions: Hastelloy fasteners excel in high-temperature applications, maintaining their mechanical properties and structural integrity even when exposed to temperatures that can cause other materials to weaken or fail. This high-temperature stability is crucial for applications in aerospace engines, gas turbines, and power generation.

Thermal Expansion and Oxidation Resistance: The alloy's resistance to thermal expansion and oxidation ensures that it performs reliably in environments where temperature fluctuations are common. This property prevents issues such as thermal cycling that could lead to premature failure.

Examples: In jet engines, Hastelloy fasteners endure extreme temperatures and maintain their strength and functionality, ensuring the engine operates efficiently. In power plants, their stability helps avoid issues related to thermal stress and deformation.

LongTerm Cost Efficiency

Reduced Maintenance and Replacement Costs: The durability and corrosion resistance of Hastelloy fasteners contribute to their long-term cost efficiency. By resisting corrosion and wear, Hastelloy fasteners minimize the need for frequent replacements and maintenance, saving both time and money.

Enhanced Equipment Reliability: The high performance of Hastelloy fasteners ensures that equipment and machinery operate reliably and safely. This reliability minimizes downtime and the associated costs of repairs or replacements, leading to overall cost savings for businesses.

Examples: In industrial applications where Hastelloy fasteners are used, such as in chemical processing or aerospace, the reduced frequency of replacements and maintenance translates to lower operational costs and fewer disruptions to production.

Overall, Hastelloy fasteners offer significant benefits through their durability, corrosion resistance, and high-temperature stability. These advantages contribute to long-term cost efficiency by reducing maintenance needs, extending service life, and ensuring reliable performance in demanding applications.

How to Select the Right Hastelloy Fastener

Factors to Consider

1. Environmental Conditions

Corrosive Environments: Assess the chemical exposure of the application. Hastelloy alloys vary in their resistance to different chemicals and environments. For instance, Hastelloy C276 is highly resistant to a wide range of chemicals and is suitable for applications in harsh environments.

Temperature Extremes: Consider the operating temperatures. Some Hastelloy alloys are better suited for high-temperature applications than others.

2. Load Requirements

Mechanical Strength: Determine the load and stress the fastener will endure. Hastelloy fasteners come in various grades, each with specific mechanical properties. Ensure the chosen fastener can handle the required loads without deforming or failing.

Stress Factors: Evaluate the dynamic and static stresses involved. High-stress environments may require fasteners with enhanced tensile strength and fatigue resistance.

3. Compatibility

Material Compatibility: Make sure the Hastelloy fastener is compatible with other materials used in the assembly to prevent issues like galvanic corrosion or material degradation. Incompatible materials can lead to galvanic corrosion or other issues.

Design Specifications: Match the fastener’s specifications with the design requirements of the application, including dimensions, threading, and any special features needed.

Common Grades and Specifications

1. Hastelloy C276

Properties: Known for its excellent resistance to corrosion and oxidation, this grade is suitable for applications involving aggressive chemicals and high temperatures.

Specifications: Typically used in chemical processing, pollution control, and high-temperature applications.

2. Hastelloy B3

Properties: Offers outstanding resistance to hydrochloric acid and other reducing environments.

Specifications: Ideal for use in chemical processing environments with strong acids.

3. Hastelloy X

Properties: Provides exceptional high-temperature strength and oxidation resistance. It is well-suited for applications in gas turbines and other high-temperature environments.

Specifications: Commonly used in aerospace and power generation industries.

4. Hastelloy C22

Properties: Offers superior resistance to both oxidizing and reducing environments, including strong acids, seawater, and other corrosive agents.

Specifications: Used in chemical processing and marine applications due to its versatile corrosion resistance.

5. Hastelloy B2

Properties: Known for its resistance to hydrochloric acid and other corrosive chemicals, with improved stress-corrosion resistance compared to other grades.

Specifications: Suitable for highly corrosive environments, including chemical and pharmaceutical industries.

Tips for Ensuring Compatibility

1. Review Application Requirements

Environment Analysis: Carefully analyze the operating environment to choose a Hastelloy grade that meets the specific corrosion resistance and temperature requirements.

Load Assessment: Determine the mechanical load and stress the fastener will experience. Choose a grade with adequate tensile and yield strength.

2. Consult Technical Specifications

Manufacturer’s Data: Refer to the technical data provided by the fastener manufacturer to understand the properties and limitations of each Hastelloy grade.

Standards Compliance: Ensure that the fasteners comply with relevant industry standards and specifications for your application.

3. Check Compatibility with Other Materials

Avoid Corrosion Issues: Confirm that the Hastelloy fasteners will not react negatively with other materials in the assembly, which could lead to corrosion or other problems.

Fit and Finish: Verify that the fasteners match the design requirements in terms of size, threading, and other dimensions.

4. Seek Expert Advice

Consult Specialists: If in doubt, consult with engineers or fastener specialists who can guide on selecting the right Hastelloy fasteners for your specific needs.

Technical Support: Reach out to the fastener supplier or manufacturer for recommendations based on your application’s requirements.

By considering these factors and guidelines, you can select the most appropriate Hastelloy fasteners for your project, ensuring optimal performance and reliability in demanding environments.

Conclusion

Hastelloy fasteners stand out as a valuable choice for various demanding applications due to their exceptional material properties. Their superior corrosion resistance, high-temperature stability, and mechanical strength make them indispensable in industries where performance and reliability are crucial. Whether in aerospace, chemical processing, marine engineering, or high-temperature power generation, Hastelloy fasteners ensure longevity and efficiency, even in the harshest environments.

The advanced properties of Hastelloy alloys such as resistance to aggressive chemicals, extreme temperatures, and mechanical stress translate to enhanced equipment reliability and reduced maintenance costs. By choosing Hastelloy fasteners, you not only invest in high-quality components but also gain peace of mind knowing that your applications are supported by some of the most robust and durable materials available.

For more information on Hastelloy fasteners or to request a quote, please contact Ananka Group. Our team of experts is ready to assist you with your fastener needs and provide solutions tailored to your specific requirements.

FAQs about Hastelloy Fasteners

Q1. What Is Hastelloy Made Of?

Composition: Hastelloy is a trademarked name for a series of nickel-based superalloys primarily composed of nickel (Ni) with varying amounts of chromium (Cr), molybdenum (Mo), and other elements. The exact composition can vary depending on the specific grade of Hastelloy, but typical elements include:

Nickel (Ni): The primary element, providing the base for the alloy and contributing to its overall strength and resistance to corrosion.

Chromium (Cr): Enhances oxidation resistance and improves high-temperature stability.

Molybdenum (Mo): Provides resistance to corrosion in reducing environments and improves the alloy's strength.

Tungsten (W), Iron (Fe), and Cobalt (Co): May be included in certain grades to further enhance specific properties.

Example Grades:

Hastelloy C276: Contains nickel, chromium, and molybdenum with small amounts of tungsten and iron.

Hastelloy B3 is primarily composed of nickel and molybdenum, with a minimal amount of chromium.

Q2. How Do Hastelloy Fasteners Compare to Other Materials?

Performance Comparison:

Corrosion Resistance: Hastelloy fasteners excel in environments where other materials, such as stainless steel or carbon steel, may fail due to corrosion. Hastelloy’s superior resistance to acids, chlorides, and other corrosive substances makes it ideal for harsh chemical environments.

High-Temperature Stability: Compared to common materials like standard steel or aluminum, Hastelloy maintains its strength and stability at high temperatures. This makes it suitable for applications in aerospace and power generation where extreme heat is a factor.

Strength and Durability: Hastelloy fasteners offer higher tensile strength and durability compared to materials like regular stainless steel, which might be prone to degradation under extreme conditions.

Suitability:

Stainless Steel: While stainless steel is generally resistant to corrosion, Hastelloy provides superior performance in more aggressive environments and higher temperatures.

Titanium: Hastelloy offers better resistance to certain types of chemical corrosion and can handle higher temperatures, whereas titanium is lighter and has an excellent strength-to-weight ratio.

Carbon Steel: Hastelloy significantly outperforms carbon steel in terms of corrosion resistance and high-temperature stability, making it a better choice for extreme conditions.

Q3. What Are the Typical Sizes and Grades Available?

Sizes: Hastelloy fasteners come in various sizes to accommodate different applications. Common sizes include:

Bolts: Ranging from small diameters like M2 to larger sizes like M30, with varying lengths.

Nuts: Standard sizes that match the corresponding bolts, including hex nuts, locknuts, and specialty types.

Screws: Available in different thread types and lengths to suit specific needs.

Grades:

Hastelloy C276: Widely used for its broad resistance to corrosion and high-temperature stability.

Hastelloy B3: Suited for environments with high concentrations of hydrochloric acid and other corrosive chemicals.

Hastelloy X is ideal for high-temperature applications, such as those in the aerospace and gas turbine industries.

Hastelloy C22: Known for its exceptional resistance to both oxidizing and reducing environments.

Q4. What Are the Maintenance Requirements for Hastelloy Fasteners?

Routine Inspection: Regularly inspect Hastelloy fasteners for signs of wear, corrosion, or damage. Even though Hastelloy is highly resistant to corrosion, periodic checks help ensure that the fasteners are still in optimal condition.

Cleaning: Clean Hastelloy fasteners using appropriate methods to avoid damage. Typically, a mild detergent and water solution or a specialized cleaner for metal alloys can be used. Avoid abrasive cleaners or harsh chemicals that might affect the alloy’s surface.

Avoiding Contaminants: Ensure that Hastelloy fasteners are not exposed to incompatible materials or contaminants that could affect their performance. For instance, avoid contact with substances that might cause galvanic corrosion.

Proper Storage: Store Hastelloy fasteners in a clean, dry environment to prevent contamination or damage. Proper storage conditions help maintain their quality until they are needed for use.

Handling: Handle Hastelloy fasteners carefully to prevent mechanical damage or deformation. Use proper tools and techniques to install and remove them.

0 notes

Text

Fastener Quality: Why does it Matter?

The foundation of any construction project or mechanical system relies highly on its components, their longevity, and integrity. While engineers ensure the foundation and other system factors are intact, fasteners are some of the overlooked elements of the system. Fastener quality is one of the most overlooked factors. The following article explains why it is prominent to opt for quality fasteners like stainless steel bolts and nuts, screws, and washers.

What are fasteners?

Fasteners are mechanical components essential for connecting two parts of a system temporarily or permanently. Each fastener has a specific purpose. For instance, permanent fasteners like nails or rivets have a one-time use and design that joins two parts permanently. Removal of these fasteners damages them and makes them useless.

Another category of fasteners available at any fastener manufacturer in India is non-permanent fasteners. These fasteners have a design that facilitates seamless removal. Non-permanent or temporary fasteners can be reused. They can be assembled and disassembled per requirements. Permanent fasteners like stainless metal screws and bolts find application in multiple industries. These fasteners are further classified as threaded fasteners, like stainless steel screws and bolts, and non-threaded fasteners like rings, pins, etc.

Why is fastener quality vital?

Fasteners impart stability and strength to a structure or a system. The quality of fasteners is critical as it ensures you are not compromising on the structural integrity. Using low-quality fasteners causes safety issues, system failures, and high repair costs. Here is why choosing high-quality fasteners is vital for your system:

Fastener quality defines its strength and durability

One must choose durable and strong fasteners as they can withstand the system pressure and weight. High-quality fasteners define the load capacity of the system.

High-quality fasteners ensure optimal corrosion resistance.

When you source fasteners from a reputed fastener manufacturer and suppliers like Fasteners and Fixtures LLP, it guarantees the use of high-quality raw materials. It ensures the fastener material is corrosion-resistant, making it perfect for critical environments. Corrosion-resistant metal fasteners allow them to operate in surroundings with chemicals, marine applications, and other hazardous mediums prone to corrosion. Using a corrosion-resistant fastener guarantees the safety and longevity of your system.

Quality fasteners ensure optimal compatibility.

Stainless fastenings sourced from a reputed stainless steel fastener manufacturer are compatible with the system material. For instance, stainless steel fasteners are perfect for a system dealing with stainless steel.

Cost should not be a deciding factor for quality fasteners.

Although the fastener cost is a prominent consideration in fastener selection, it must not be the only

deciding factor. Quality fasteners can cost more initially, but they save replacementand repair costs in the future.

Why Fasteners and Fixtures LLP?

Fasteners are metal fastenings that can hold together different parts. Nuts, bolts, screws, and washers are some of the metal fastener types. Although fastener quality is vital, knowledge about fasteners is also critical. When you opt for a reputed fastener manufacturer and supplier, ensure appropriate knowledge and guidance about fasteners per your application. Experts at Fasteners and Fixtures LLP. have proper training and aid you in fastener selection, saving time and costs. The experts at the company offer advice on the fastener specification, finish, size, design, and more. They also help you choose the right thread type of the stainless metal screws, types of nuts and bolts, etc.

Final thoughts

At Fasteners and Fixtures LLP., our experts understand the importance of quality fasteners. As a leading company offering metal fasteners in India, we ensure our customers receive top- notch product quality and competitive pricing. Don’t know how to find the right fastener for your project? Want to know more about fasteners or the difference between a Stainless Steel 304 fastener and an Inconel Alloy 600 fastener? Consult Fasteners and Fixtures LLP.

0 notes

Text

Rajlaxmi Machine Tools offers Ramato | Roent Make Car Washer, Sprayer Pump, Pressure Pump, Industrial Pump, Plunger Pump, Single Piston Pump, Two Piston Pump, Three Piston Pump, Pressure Washer, Car Washing Pump, Service Pump, Mud Pump, Self Priming Pump, Nozzle, Sprayer, Agricultural Pump, Portable Washer, HTP Pump, High Pressure Washer, Service Pump, Piston Pump and All Type of Pump Manufacturer From Rajkot Gujarat Bharat (INDIA).

#RajlaxmiMachineTools#RamatoPumps#RoentPumps#CarWasher#SprayerPump#PressurePump#IndustrialPump#PlungerPump#SinglePistonPump#TwoPistonPump#ThreePistonPump#PressureWasher#CarWashingPump#ServicePump#MudPump#SelfPrimingPump#Nozzle#Sprayer#AgriculturalPump#PortableWasher#HTPPump#HighPressureWasher#PistonPump#AllTypeOfPumps#PumpManufacturer#RajkotPumps#GujaratPumps#IndiaPumps#PumpSolutions#HighPressurePumps

0 notes

Text

https://vootclean.com/high-pressure-machines/ - High-pressure machines are essential tools for various industrial cleaning and maintenance tasks, providing the power and precision needed to tackle tough jobs effectively.

0 notes

Text

Article Scrap Plastic Washing Plant Manufacturer

R Mech Machines LLP is an Article Scrap Plastic Washing Plant Manufacturer in Ahmedabad,

Gujarat, India.

We are located in Ahmedabad, Gujarat, India.

We are a Manufacturer, Exporter, and Supplier of Plastic Scrap Turbo Washing Machines, Plastic Scrap Grinder Machines, Plastic Scrap Shredder Machines, Blade Sharpening Machines, Screw Press Squeezer Machines, and Friction Washer Machines.

Our washing plants use cutting-edge technology to efficiently clean plastic waste. This includes high-pressure washing systems, friction washing, and flotation techniques to ensure that all contaminants are effectively removed.

Designed to handle large volumes of plastic scrap, our plants are capable of processing various types of plastic waste, including PET, HDPE, LDPE, and more. This versatility makes them suitable for diverse recycling operations.

Our plants incorporate energy-efficient technologies that reduce operational costs and environmental impact. This includes optimized motor systems and heat recovery mechanisms that enhance overall efficiency.

Our equipment meets stringent environmental regulations and standards, ensuring that your recycling operations are both eco-friendly and compliant with local and international guidelines.

Industries We Serve

Recycling Facilities

Manufacturing

Waste Management

R Mech Machines LLP is Article Scrap Plastic Washing Plant Manufacturer in Ahmedabad,

and Exporter in Jordan and including locations like Zarqa, Irbid, Russeifa, Sahab, Ae Ramtha, Aqaba,

Mafraq, Madaba, As-Salt, Al-Jizah, Aydoun, Jerash, Beit Ras, Al Husn, Naour, Karak, Kufranjah.

For more information about our Article Scrap Plastic Washing Plants or to discuss your specific requirements, please reach out to us.

View Product: Click here

Read the full article

0 notes

Text

How to Use Bosch Pressure Washer - JPT TOOLS

Bosch Pressure Washer

JPT Tools is pleased to carry a wide selection of machine shop tools and equipment. Our machine tools for sale are comprised of a variety of different products that are used to shape, cut, grind, shear, form, and basically shape metal into the desired part. I had used a few Bosch Pressure Washer over the years, so when I made the decision to buy my father a new one, I assumed I understood everything there was to learn about pressure washers (after his old washer stopped working). I went online and began my investigation. The elderly man is a stickler for cleanliness, so I really only wanted to buy a cheap pressure washer to assist him keep his patio and walls clean, but I wound up browsing the internet. In the end, I chose the Bosch Pressure Washer Extra pressure washer, and even though it wasn't exactly inexpensive, I was happy with its performance and I still am (I even "steal" it occasionally without the man's permission!). Here are several causes.

Highly Efficient Cleaning Action - Bosch Pressure Washer

For a few reasons, the Bosch Pressure Washer performs well with nozzles. Let's start by discussing the motor. It has a strong Bosch series motor (1700 watts), which provides the energy for incredibly effective assembly. The machine's engine makes it perfect for cleaning anything like bicycles, vehicles, walls, patios, and boats. Second, the aquatak's nozzle, which uses a variety of lances, offers the best water pressure release and regulation for even the most challenging tasks.

Design Pressure Washer to work any environment

When designing the aquatic, Bosch unquestionably kept the demands of the client in mind. The upright light's user-friendliness and design make this very plain. Even though it only weighs 7.2 kg, the aquatak has two sturdy wheels. Due to its portability and ease of use, the aquatak doesn't require you to exert much effort when utilizing it. My dad is an elderly man, so I was careful to choose a pressure washer that wouldn't put him under additional stress. So far, he hasn't voiced any complaints. The aquatak also contains a few hooks for hanging the hose and other supplies, making it more convenient to use.

0 notes

Text

"From Lotions to Liquor: How Seppa Solutions is Leading the Way in Glass Bottle Hygiene"

Glass bottle cleaners are critical in industries such as beverage manufacturing, medicines, and cosmetics for product safety and quality. They are used to package alcoholic and non-alcoholic beverages and have ultrasonic cleaning and sterilization capabilities. For delicate chemicals like perfumes, serums, and lotions, the cosmetics sector uses glass bottles. Utilizing high-pressure jets, ultrasonic, sterilization cycles, and cutting-edge cleaning technologies, the Seppa Solutions Glass Bottle Washer offers a comprehensive solution. To save water and energy usage while upholding strict cleaning standards, it has energy-saving features and adjustable settings. For dependable commercial glass bottle cleaning systems, Seppa Solutions is a pioneer.

#automatic glass bottle washer#glass bottle washers#glass bottle cleaning machine#automatic glass bottle cleaning machine#glass bottle cleaner#glass bottle washer#industrial glass bottle washer#industrial bottle washing#industrial bottle washer#water bottle washer machine#bottle washers machines#bottle washing machine#bottle washer#water bottle cleaner machine#bottle washer machine

0 notes

Text

Need a Car Washer Machine?

Are you looking for the perfect car washer machine to keep your vehicle sparkling clean? We have got you covered with a range of options, from high pressure car washers to portable ones that fit your needs perfectly.

Enjoy the convenience of our battery powered car washers designed to make your cleaning routine a breeze. Our mission is to offer you top notch solutions with the latest technology.

As a renowned brand in India for agricultural equipment, we also bring a perfect solution to boost performance and efficiency.

Contact Chandakagro Equipments today for all your car washer and agricultural equipment needs.

0 notes

Text

A HD Stucchi Italy Couplings, Flat Face Quick Release Couplings, Mumbai, India

Manufacturer and Supplier of A HD Stucchi Italy Couplings, Flat Face Quick Release Couplings, Inline Valves, Inline Flow Indicator, Mumbai, India.

Quick Release Coupling, Quick Release Couplings, Ball Valve, Ball Valves, Gemel Ball Valves, Industrial Ball Valves, Quick Coupling, Quick Couplings, Camlock Coupling, Camlock Couplings, Camlock Quick Coupling, Camlock Quick Couplings, Micro Hose, Micro Hose For High Pressure, Micro Hose For Pressure Fittings, Test Coupling, Test Couplings, Minipress Test Coupling, Minipress Test Couplings, Test Point Coupling, Test Point Couplings , Threaded Test Coupling, Threaded Test Couplings, Bulkhead Test Coupling, Bulkhead Test Couplings, Female Swivel Test Coupling, Female Swivel Test Couplings, Plug in Test Coupling, Plug in Test Couplings, Pressure Gauge Adaptors, Cartridge Valve, Cartridge Valves, Hydraulic Hoses, Hydraulics Hose, Hoses Crimped Hydraulic, Hydraulic Systems, Pneumatic Systems, Hydraulic Accessories, Hydraulic Couplings, Hydraulic Fitting, Hydraulic Fittings, SS304 Hydraulic Fittings, SS316 Hydraulic Fittings, CS Hydraulic Fittings, DIN 2353 Fittings, Pressure Gauge, Pressure Gauges, Industrial Valves, Coupling Valves, Hydraulic Components, Inline Valve, Inline Valves, Inline Flow Indicator, Inline Flow Indicators, Portable Hydraulic Crimping Machine, Portable Hydraulic Crimping Machines, Portable Hydraulic Instrument, Portable Hydraulic Instruments, Pressure Gauge Anti Shock Valve, Pressure Gauge Anti Shock Valves, Stainless Steel Hydraulic Components, High Pressure Check Valve, High Pressure Ball Valve, High Pressure Flow Control Valve, High Pressure Needle Valve, Non Return Valve, Gemels Italy Ball Valves, Holmbury Uk Couplings, Minipress Italy Couplings, Oleoweb Italy Valves, SS304 Csermeto Fittings, SS316 Csermeto Fittings, Flat Face Coupling, Quick Connect Disconnect Coupling, Screw Coupling 1000 Bar, Dust Cap, Test Point, Test Hose, Test Point Coupling, Test Point Hose, SAE Flange Ball Valve, Rotating Union, Hose Burst Check Valve, Compensated Load Control Valve, Compensated Flow Control Valve, Load Shuttle Ball Valve, End Stroke Valve, Single Acting Pilot Check Valve, Double Acting Pilot Check Valve, Double Cross Line Direct Acting Relief Valve, Single Cross Line Direct Acting Relief Valve, Sequence Valve, Single Counter Balance Valve, Dual Counter Balance Valve, Hand Pumps, Tube Clamp, Instrumentation Fittings, Lubrication Fittings, PP Pipe Clamp, Dowty Seal Copper Washer, Bonded Seal, Nut, Ferrule, asia, asian, india, indian, mumbai, maharashtra, industrial, industries, thane, navi mumbai, pune, nashik, aurangabad, ratnagiri, nagpur, ahmednagar, akola, amravati, chandrapur, dhule, jalgaon, raigad, sangli, satara, belgaum, kolhapur, belgaon.

#Quick Release Coupling#Quick Release Couplings#Ball Valve#Ball Valves#Gemel Ball Valves#Industrial Ball Valves#Quick Coupling#Quick Couplings#Camlock Coupling#Camlock Couplings

0 notes