#High-Precision Investment Castings for Aerospace Applications

Explore tagged Tumblr posts

Text

Investment Castings for Aircraft Structural Elements A Focus on Unitritech's Excellence

Investment castings, also known as precision castings, play a crucial role in the aerospace industry, particularly in the manufacturing of structural elements for aircraft. These castings are made using a wax pattern that is coated with a refractory ceramic material. Once the ceramic material hardens, the wax is melted away, leaving a precise mold that can produce high-tolerance, intricate components ideal for aerospace applications.

One of the leading manufacturers in this field is Unitritech, renowned for their superior investment castings for structural elements of aircraft. Unitritech utilizes advanced technologies and stringent quality control processes to ensure that each casting meets the rigorous demands of the aerospace industry. Their investment castings are characterized by exceptional strength, lightweight properties, and the ability to withstand extreme temperatures and pressures, making them perfect for critical structural components of aircraft.

Unitritech's commitment to innovation and excellence has positioned them as a top choice for aerospace manufacturers seeking reliable and high-performance structural elements. Their expertise in producing complex geometries and maintaining tight tolerances ensures that every component contributes to the overall safety, efficiency, and performance of the aircraft.

In summary, investment castings are essential for the aerospace industry, and Unitritech stands out as a premier provider of these critical components, ensuring the highest standards of quality and performance in aircraft structural elements.

#High-Precision Investment Castings for Aerospace Applications#Reliable Structural Elements for Aircraft in Investment Castings#Durable and Lightweight Investment Castings for Aerospace#Quality Investment Castings for Aerospace Structural Elements#Precision Casting for Critical Aircraft Components#Ensuring Flight Safety with Precision Investment Castings

0 notes

Text

What are all the types of aluminium fabrication?

Aluminum fabrication design encompasses a myriad of techniques and processes that transform raw aluminum into various finished products. Each method offers unique advantages, catering to diverse applications across industries ranging from aerospace to construction and automotive to electronics.

Extrusion stands as one of the most common aluminum fabrication techniques, involving the shaping of aluminum alloys by forcing them through a die. This process enables the creation of complex profiles with consistent cross-sectional shapes, ideal for applications requiring lightweight yet durable components such as window frames, structural beams, and heat sinks.

Sheet metal fabrication utilizes flat sheets of aluminum, which are cut, bent, and formed into desired shapes and sizes. From precision components for electronics to automotive body panels and aircraft fuselages, sheet metal fabrication offers versatility and efficiency in producing lightweight, corrosion-resistant parts with high structural integrity.

Casting processes, including sand casting, die casting, and investment casting, are employed to create intricate aluminum components with precise geometries. Sand casting is suitable for producing large, complex parts such as engine blocks and transmission housings, while die casting offers fast production of small to medium-sized components with tight tolerances. Investment casting, also known as lost-wax casting, enables the creation of finely detailed parts for aerospace, medical, and jewelry applications.

Welding plays a crucial role in aluminum fabrication, allowing for the joining of aluminum components through various techniques such as TIG (tungsten inert gas) welding, MIG (metal inert gas) welding, and resistance welding. TIG welding ensures precise control over the welding process, making it suitable for thin materials and intricate designs, while MIG welding offers higher deposition rates for thicker sections. Resistance welding methods like spot welding and seam welding are commonly used in automotive assembly and sheet metal fabrication.

The diverse types of aluminum fabrication techniques provide manufacturers and designers with a wealth of options to meet specific performance, cost, and design requirements. Whether it's extrusion, sheet metal fabrication, casting, or welding, each method contributes to the production of high-quality aluminum components for a wide range of applications. With expertise and quality materials from Alugrow Trading, manufacturers can leverage the full potential of aluminum fabrication to bring their designs to life.

Alugrow Trading

2 notes

·

View notes

Text

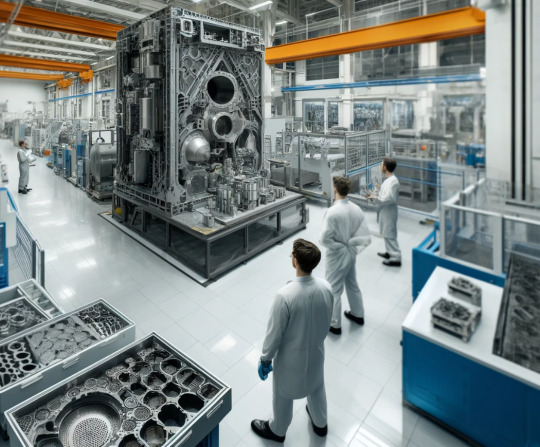

Vacuum Induction Furnace Solutions from HHV: Precision, Purity, and Performance for Advanced Manufacturing

As the demand for high-performance materials in aerospace, defense, medical, and industrial applications grows, manufacturers face increasing pressure to deliver metals and alloys of exceptional purity and consistency. A critical solution enabling this level of quality is the Vacuum Induction Furnace. This technology combines the advantages of vacuum environments with precise induction heating, making it indispensable for producing high-purity metals and speciality alloys. At the forefront of this innovation is HHV Thermal Technologies, a trusted name in advanced thermal processing equipment. Their range of Vacuum Induction Furnace systems is designed to meet the most demanding requirements in modern manufacturing, providing unmatched precision, purity, and performance.

Why Vacuum Induction Furnace Technology Matters

A Vacuum Induction Furnace is essential in metallurgical processes where contamination control and temperature uniformity are critical. By operating in a vacuum or controlled atmosphere, these furnaces eliminate exposure to oxygen, nitrogen, and other gases that could degrade the material’s quality. The result is ultra-clean melts and refined microstructures ideal for high-end applications.

HHV’s Vacuum Induction Furnaces are particularly valuable in the production of superalloys, titanium, high-grade stainless steel, and speciality materials used in sectors like aerospace, nuclear, electronics, and biomedical engineering. These materials must meet stringent mechanical and chemical specifications, and any deviation can lead to failure in high-stress environments.

Moreover, the precision of induction heating in HHV’s systems allows for fast, efficient melting with precise temperature control. This results in superior energy efficiency and reduced processing times, translating into operational cost savings and higher throughput for manufacturers.

HHV Thermal Technologies: Engineering Excellence in Vacuum Induction Furnaces

HHV Thermal Technologies brings years of design expertise, process knowledge, and engineering innovation to its Vacuum Induction Furnace solutions. Each system is engineered with advanced features such as programmable control systems, high-efficiency induction coils, and robust vacuum chambers that can withstand repeated thermal cycling and metallurgical stresses.

HHV offers a variety of furnace configurations—including lab-scale systems for research and development, as well as large industrial systems for mass production. Clients can choose from horizontal or vertical designs, customized crucible sizes, and integrated automation to suit their specific melting and casting needs.

In addition to the hardware, HHV’s support services set them apart. From initial consultation and installation to training and after-sales maintenance, HHV ensures that clients maximize the value of their investment. Their team also assists in process development, helping customers fine-tune melting protocols to meet precise metallurgical goals.

The company’s commitment to quality is evident in its adherence to international standards and continuous R&D efforts aimed at improving energy efficiency, throughput, and material integrity.

Conclusion

In a world where material performance defines product success, the Vacuum Induction Furnace has become an essential tool in advanced manufacturing. HHV Thermal Technologies is leading the charge with highly customizable, precision-engineered solutions that deliver clean, consistent, and cost-effective results across industries. Whether you're developing new materials or scaling up production, HHV’s vacuum induction technology is a powerful ally in achieving your goals.

For more information, visit the website: https://hhvthermaltech.com/

Contact Us

Site No. 17, Phase 1, Peenya Industrial Area, Bengaluru – 560058, India

Phone: +91-80-41931000

Fax: +91-80-41931100

Email: [email protected]

0 notes

Text

Mastering Precision and Quality: A Comprehensive Guide to Sand Casting for Your Manufacturing Needs

In the realm of metal fabrication, sand casting stands as one of the most versatile, cost-effective, and reliable processes for producing complex metal components. Whether you’re in automotive, aerospace, power generation, or general industrial manufacturing, partnering with a specialized sand casting company ensures you receive durable parts that meet exacting specifications. This blog explores the sand casting process, its advantages, material options, quality control measures, and why choosing an experienced partner can transform your production workflow.

1. Understanding the Sand Casting Process

Sand casting, sometimes called sand molded casting, involves creating a mold cavity in a specially formulated sand mixture, then pouring molten metal into that cavity to form the desired shape. The core steps include:

Pattern Creation: A pattern—made from wood, plastic, or metal—mimics the final part’s geometry.

Mold Preparation: The pattern is placed in a flask and packed tightly with a mixture of silica sand and a binding agent (often clay or chemical resin).

Core Placement (if needed): For internal cavities or undercuts, preformed sand cores are positioned inside the mold.

Mold Assembly: Once the sand sets, the two halves (cope and drag) are assembled around the pattern or core.

Metal Pouring: Molten metal—aluminum, steel, brass, bronze, or other alloys—is poured into the mold via sprues and runners.

Cooling and Shakeout: After solidification, the sand mold is broken away (shaken out), revealing the raw casting.

Cleaning and Finishing: Excess metal (sprues, runners) is removed, and the part undergoes cleaning, shot blasting, grinding, or machining for final dimensions and surface finish.

This time-tested method accommodates part sizes from a few ounces to several tons, making it ideal for both prototypes and high-volume production runs.

2. Key Advantages of Sand Casting

Cost Efficiency

Sand casting requires minimal capital equipment compared to die casting or investment casting. Patterns are relatively inexpensive to produce, and the sand can be reclaimed and reused, driving down per-part costs—especially for low to medium volumes.

Design Flexibility

Complex geometries, internal passages, and thin walls are achievable through core placement and careful mold design. Sand casting accommodates changes quickly; altering a wooden or plastic pattern is faster and more affordable than retooling metal dies.

Material Versatility

Virtually any metal that can be melted and poured is suitable for sand casting. Common materials include:

Aluminum Alloys: Lightweight, corrosion-resistant, excellent thermal and electrical conductivity.

Gray and Ductile Iron: High strength, wear resistance, and damping properties.

Carbon and Alloy Steels: Robust mechanical properties for heavy-duty applications.

Bronze and Brass: Good machinability, corrosion resistance, and aesthetic appeal.

Scalability

Sand casting is equally effective for one-off prototypes or large batches of identical parts. Production capacity can be quickly ramped up or down, providing agility for customers with fluctuating demand.

3. Critical Material Considerations

Selecting the right metal alloy and sand mixture has a direct impact on casting quality and mechanical performance:

Sand Mixtures: Silica sand is most common, but zircon and chromite sands can be used for specialized high-temperature applications. Binder types (clay, chemically bonded, or oil bonded) are chosen based on mold strength and permeability requirements.

Alloy Selection: Match alloy properties to end-use conditions. For high-temperature environments, heat-resistant steels or nickel alloys may be preferable. For lightweight housings, aluminum or magnesium alloys excel.

Mold Coatings: Applying a refractory coating inside the mold cavity reduces metal penetration, improves surface finish, and facilitates shakeout.

A knowledgeable sand casting partner works with you to optimize these parameters, ensuring each casting meets performance and cost targets.

4. Ensuring Quality Through Rigorous Control

High-precision components demand stringent quality management throughout the casting process:

Pattern and Mold Inspection: Regular checks for pattern wear, mold integrity, and core accuracy prevent dimensional deviations.

Metallurgical Testing: Spectrographic analysis, tensile testing, and hardness measurements confirm alloy composition and mechanical properties.

Non-Destructive Evaluation (NDE): Techniques like X-ray, ultrasonic testing, and dye penetrant inspection detect internal defects or surface cracks.

Dimensional Verification: Coordinate measuring machines (CMMs) and laser scanners compare cast parts to CAD models, ensuring tight tolerances.

Process Documentation: Detailed records of sand properties, pouring temperatures, and cycle times facilitate traceability and continuous improvement.

By embedding quality checks at every stage, a reputable sand casting company minimizes scrap, rework, and delivery delays.

5. Applications Across Industries

Sand casting’s combination of flexibility and robustness has earned its place in diverse sectors:

Automotive: Engine blocks, transmission housings, steering knuckles, brake components.

Aerospace: Structural brackets, housings, turbine components (in specialized alloys).

Oil & Gas: Valve bodies, pump housings, flange fittings.

Construction Equipment: Excavator arms, pump housings, heavy-duty gears.

Agriculture Machinery: Tractor parts, hydraulic pump blocks, gearbox housings.

Industrial Machinery: Gearboxes, pump casings, compressor components.

Each application benefits from the process’s ability to produce durable, custom-shaped metal parts at competitive costs.

6. Choosing the Right Sand Casting Partner

When selecting a sand casting supplier, consider these criteria:

Experience and Expertise: Look for a company with decades of hands-on casting experience and a proven track record in your industry.

Technical Capabilities: Ensure they offer end-to-end services—pattern making, mold preparation, casting, heat treatment, machining, and finishing—under one roof.

Certifications: ISO 9001, AS9100 (aerospace), or API certifications (oil & gas) demonstrate commitment to quality and regulatory compliance.

Capacity and Lead Times: Verify their ability to handle your required volumes and delivery schedules.

Customer Collaboration: A partner who offers design for manufacturability (DFM) guidance can help optimize your parts for casting, reducing cost and lead time.

Building a collaborative relationship with your sand caster ensures open communication, problem-solving, and shared commitment to project success.

7. Sustainable Practices in Sand Casting

Modern foundries increasingly embrace eco-friendly initiatives:

Sand Reclamation: Advanced thermal or mechanical reclamation systems recover over 90% of used molding sand.

Energy Efficiency: Upgraded furnaces and heat recovery units reduce fuel consumption and emissions.

Waste Management: Recycling metal scrap and safe disposal of spent binders minimize environmental impact.

Green Binders: Water-based or biodegradable binder systems eliminate harmful volatile organic compounds (VOCs).

These sustainable measures not only reduce operational costs but also align with corporate social responsibility goals and regulatory requirements.

8. Case Study: From Prototype to Production

Consider a manufacturer of agricultural pump housings seeking to transition from low-volume prototypes to a production run of 5,000 units per year. An experienced sand casting partner worked closely to:

Refine the CAD Model: Added uniform wall thickness and optimized gating to improve metal flow.

Develop Durable Patterns: CNC-machined aluminum patterns ensured consistent mold accuracy for thousands of pours.

Implement Quality Gates: In-process inspections at mold setup, pour, and post-shakeout maintained a defect rate below 1%.

Integrate Secondary Machining: In-house CNC machining and pressure testing delivered ready-to-install housings.

The result: a reliable supply of pump housings that met stringent dimensional and performance requirements, with a 20% cost reduction compared to alternative processes.

9. Maximizing Your ROI with Sand Casting

To get the most value from sand casting:

Early Involvement: Engage your casting partner during the design phase for DFM insights.

Batch Planning: Combine production runs for multiple part numbers to leverage economies of scale.

Inventory Management: Use just-in-time deliveries or blanket orders to balance lead times and inventory carrying costs.

Continuous Improvement: Regularly review casting yields, scrap rates, and customer feedback to identify process enhancements.

Treating your sand casting supplier as a strategic collaborator will unlock process efficiencies, cost savings, and superior part performance.

10. Conclusion

Sand casting remains an indispensable process for manufacturing robust, intricately shaped metal components across countless industries. Its adaptability to various materials, cost-effective tooling, and scalability from prototypes to high-volume runs make it a cornerstone of modern fabrication. Partnering with a seasoned sand casting company—one that offers comprehensive capabilities, rigorous quality control, and sustainable practices—ensures you receive parts that meet your specifications, budget, and timeline.

Whether you’re exploring a new product design or scaling up production, the right sand casting partner can provide the expertise and resources to turn your vision into reality. Embrace the proven strengths of sand casting and position your business for success with precision-engineered metal components that stand the test of time.

0 notes

Text

Carbide Drilling Tool Market Growth Analysis, Market Dynamics, Key Players and Innovations, Outlook

Global carbide drilling tool market size was valued at USD 997 million in 2024. The market is projected to grow from USD 1,057 million in 2025 to USD 1,472 million by 2032, exhibiting a CAGR of 5.7% during the forecast period.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/1104/carbide-drilling-tool-2025-2032-583

Carbide drilling tools are precision cutting instruments manufactured primarily from tungsten carbide, a material renowned for its exceptional hardness, wear resistance, and thermal stability. These tools enable efficient drilling operations across diverse materials including hardened steels, titanium alloys, cast iron, and aluminum composites. The product category encompasses multiple variants such as step drills for creating graduated holes, multi-diameter drills for simultaneous bore sizing, and specialized designs for aerospace and automotive applications where dimensional accuracy is critical.

List of Key Carbide Drilling Tool Manufacturers

Sandvik AB (Sweden)

Kennametal Inc. (U.S.)

OSG Corporation (Japan)

Walter AG (Germany)

Guhring KG (Germany)

Sumitomo Electric Industries (Japan)

Nachi-Fujikoshi Corp. (Japan)

Mikron Tool (Switzerland)

Tungaloy Corporation (Japan)

Plansee Group (Austria)

WIDIA (U.S.)

Allied Machine & Engineering Corp. (U.S.)

Segment Analysis:

By Product Type

The market is segmented based on application into:

Solid Carbide Drills

Indexable Carbide Drills

Specialized Drills

By Coating Type

Coated Carbide Tools Segment Dominates Due to Superior Wear Resistance and Extended Tool Life

The market is segmented based on type into:

Coated

Subtypes: TiN, TiCN, TiAlN, Diamond-coated, and others

Non-coated

By Drill Type

The market is segmented based on drill type into:

Straight shank drills

Taper shank drills

Step drills

Core drills

Multi-diameter drills

By Size

Medium-Sized Drills (6-12mm) Dominate Due to Balanced Performance in Most Applications

The market is segmented based on size into:

Micro drills (below 1mm)

Small drills (1-6mm)

Medium drills (6-12mm)

Large drills (12-25mm)

Extra large drills (above 25mm)

By Application

Automotive Segment Leads Due to High Precision Requirements in Engine Component Manufacturing

The market is segmented based on application into:

Automotive

Oil & Gas

Electronics & Semiconductors

Aerospace & Defense

Others

Key Coverage Areas:

· ✅ Market Overview

o Global and regional market size (historical & forecast)

o Growth trends and value/volume projections

· ✅ Segmentation Analysis

o By product type or category

o By application or usage area

o By end-user industry

o By distribution channel (if applicable)

· ✅ Regional Insights

o North America, Europe, Asia-Pacific, Latin America, Middle East & Africa

o Country-level data for key markets

· ✅ Competitive Landscape

o Company profiles and market share analysis

o Key strategies: M&A, partnerships, expansions

o Product portfolio and pricing strategies

· ✅ Technology & Innovation

o Emerging technologies and R&D trends

o Automation, digitalization, sustainability initiatives

o Impact of AI, IoT, or other disruptors (where applicable)

· ✅ Market Dynamics

o Key drivers supporting market growth

o Restraints and potential risk factors

o Supply chain trends and challenges

· ✅ Opportunities & Recommendations

o High-growth segments

o Investment hotspots

o Strategic suggestions for stakeholders

· ✅ Stakeholder Insights

o Target audience includes manufacturers, suppliers, distributors, investors, regulators, and policymakers

FREQUENTLY ASKED QUESTIONS:

▶ What is the current market size of Global Carbide Drilling Tool Market?

The Global Carbide Drilling Tool market was valued at USD 997 million in 2024 and is projected to reach USD 1472 million by 2032, growing at a CAGR of 5.7% during the forecast period.

▶ Which key companies operate in Global Carbide Drilling Tool Market?

Key players include Sandvik, Kennametal Inc, OSG Corporation, Guhring, Nachi-Fujikoshi, Walter, Sumitomo Electric Industries, Makita Corporation, BIG DAISHOWA, WIDIA, among others.

▶ What are the key growth drivers?

Key growth drivers include increasing demand from automotive and aerospace industries, technological advancements in tool materials, and rising industrialization in emerging economies.

▶ Which region dominates the market?

Asia-Pacific holds the largest market share, driven by China's manufacturing sector growth, while North America leads in technological innovation.

▶ What are the emerging trends?

Emerging trends include development of nano-coated carbide tools, integration of IoT for tool condition monitoring, and sustainable manufacturing practices.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/1104/carbide-drilling-tool-2025-2032-583

0 notes

Text

Minimax TEC Dry Powder Fire Extinguisher – Specialized Protection for Class D Metal Fires

When it comes to fire safety in environments involving combustible metals, standard fire extinguishers are simply not enough. Class D fires—caused by metals such as magnesium, titanium, potassium, and sodium—require a unique extinguishing agent that can neutralize the reaction without intensifying the hazard. That’s where the TEC dry powder fire extinguisher from Minimax comes into play.

Minimax, a leading fire safety equipment manufacturer in India, offers a specialized TEC powder (D-Class) gas cartridge-type fire extinguisher designed specifically to combat challenging metal fires. Engineered with precision and certified for industrial-grade use, this extinguisher is an essential tool for safety in manufacturing facilities, foundries, laboratories, and metal processing units.

What Is a TEC Dry Powder Fire Extinguisher?

A TEC dry powder fire extinguisher uses a specially formulated powder designed to extinguish Class D fires, which involve combustible metals. These fires are dangerous because they can burn at extremely high temperatures and may react violently with water or CO₂-based extinguishing agents.

TEC powder works by smothering the fire, absorbing heat, and forming a crust over the burning material to cut off the oxygen supply. This method effectively prevents re-ignition and suppresses the fire without causing chemical reactions that could worsen the situation.

Key Features of the Minimax TEC Powder Fire Extinguisher

Designed for Class D Fires: Specifically formulated to tackle metal fires involving elements such as magnesium, aluminum, sodium, and lithium.

Gas Cartridge Operation: Activates only during use, ensuring long shelf life and safety.

Available in Multiple Sizes: Suitable for small-scale labs to large industrial areas.

ISI Certified and BIS Approved: Meets IS: 11833 standards for Class D extinguishers.

Corrosion-Resistant Body: Durable outer casing ensures long-term reliability in industrial settings.

Simple Operation: User-friendly design for quick deployment in high-stress situations.

Applications of TEC Dry Powder Fire Extinguishers

Minimax TEC extinguishers are ideal for:

Foundries and metal casting units

Aerospace and defense manufacturing

Chemical laboratories handling reactive metals

Automotive part production facilities

Battery manufacturing plants

Workshops using grinding or cutting tools on flammable metals

These environments demand specialized fire safety measures, and the TEC dry powder fire extinguisher provides the exact protection required.

Why Minimax?

Established in 1903, Minimax is one of the most trusted fire safety solution providers in India. Their commitment to quality, innovation, and regulatory compliance has made them a preferred choice across industries. The TEC dry powder extinguisher is a reflection of their focus on providing customized safety equipment for high-risk industrial scenarios.

Minimax offers not only a range of fire extinguishers but also complete fire protection systems, consulting services, installation, training, and maintenance contracts to ensure your fire safety infrastructure is always ready.

Advantages of TEC Dry Powder Fire Extinguishers

Specifically targets metal-based fires that cannot be treated with conventional extinguishers

Prevents re-ignition and chemical flare-ups

Non-reactive with flammable metals

Compact, reliable, and easy to deploy

Long service life with minimal maintenance

Maintenance and Safety Considerations

It’s important to regularly inspect and maintain your TEC extinguishers to ensure functionality during emergencies. Minimax recommends scheduled servicing and offers AMC (Annual Maintenance Contracts) to industrial clients for ongoing support and peace of mind.

Call to Action

If your facility works with combustible metals or operates in high-risk manufacturing environments, investing in a TEC dry powder fire extinguisher is not optional—it’s essential.

Choose Minimax for reliable, industry-approved fire protection solutions that keep your people, assets, and operations safe.

0 notes

Text

Satellite Gear Blanks

Ever wondered what makes those massive agricultural machines and rugged off-highway vehicles tick without skipping a beat? One unsung hero behind that smooth power transfer is the satellite gear blank. Let’s explore this fascinating world, one gear at a time!

What Are Satellite Gear Blanks?

The Role of Gear Blanks in Mechanical Systems

At its core, a gear blank is the raw, unfinished form of a gear. It's like cookie dough before it's shaped and baked. Gear blanks are machined into precise gears that drive our machines. These components ensure power transmission from one mechanical part to another.

Why They're Called "Satellite" Gear Blanks

The term satellite refers to gears that rotate around a central gear, commonly found in planetary gear systems. These blanks are designed specifically for such configurations. They're not floating in space, but they do orbit another component—kind of like moons of a mechanical planet.https://ramcosteels.com/applications/agri-machinery-and-off-highway/

Key Materials Used in Manufacturing

Not all gear blanks are created equal. The choice of material plays a crucial role in performance, longevity, and cost.

Forged Steel

Forged steel offers excellent strength and resistance to wear. It's the go-to for heavy-duty applications.

Alloy Steel

With a mix of elements like chromium and molybdenum, alloy steel improves hardness and fatigue resistance. Think of it as the protein shake for metal.

Powder Metallurgy

This technique blends powdered metals and compresses them into solid gear blanks. It’s perfect for creating complex shapes with minimal waste.

The Manufacturing Process of Satellite Gear Blanks

Creating satellite gear blanks isn’t just about shaping metal—it’s a multi-step process requiring accuracy and expertise.

Stage 1: Material Selection

It all starts with picking the right metal based on the gear's final purpose—strength, wear resistance, or weight reduction.

Stage 2: Forging or Casting

The selected material is heated and shaped using high-pressure forging or mold-based casting to form a preliminary blank.

Stage 3: Heat Treatment

Next, the blanks undergo heat treatment to enhance mechanical properties like hardness and toughness.

Stage 4: Machining & Finishing

Precision machining gives the blank its final shape, ensuring it meets strict dimensional and tolerance requirements.

Applications Across Industries

Satellite gear blanks aren’t just for one type of machine—they’re used in a wide array of applications.

Agricultural Machinery

Tractors, harvesters, and seeders rely on planetary gear systems that house satellite gears for smooth operation in tough terrain.

Off-Highway Vehicles

Construction and mining equipment benefit from these gears due to their ability to handle high torque and low-speed operations.

Aerospace Components

Space is unforgiving. Satellite gears in aerospace applications must be incredibly durable and lightweight.

Why Precision Matters in Gear Blanks

A tiny error in the gear blank can lead to massive mechanical failures down the line. Here’s why getting it right matters:

Load Distribution

Properly manufactured blanks ensure that gears share the load evenly, avoiding early wear and tear.

Noise Reduction

Precision machining reduces vibration and operational noise—essential for comfort and safety.

Gear Life and Efficiency

Accuracy directly affects the lifespan and efficiency of the gear. Better fit = better function.

Satellite Gear Blanks vs Conventional Gear Blanks

Let’s get into the nitty-gritty of how these two types stack up.

Structure & Strength

Satellite gear blanks are typically stronger and more complex due to their load-sharing requirements in planetary systems.

Design Complexity

Unlike conventional blanks, satellite versions often need specialized shapes and higher tolerances.

Benefits of High-Quality Satellite Gear Blanks

Investing in top-tier gear blanks isn’t a luxury—it’s a necessity for reliable machine performance.

Durability

Top-notch materials and precision ensure long-lasting performance under extreme conditions.

Smooth Power Transmission

These blanks minimize jerks and interruptions, providing seamless energy transfer.

Cost Efficiency in the Long Run

High-quality blanks reduce maintenance needs and extend equipment lifespan—saving money over time.

Common Challenges in Production

Of course, gear blank production isn’t without its bumps in the road.

Material Defects

Impurities in the raw material can weaken the gear, making inspection critical.

Dimensional Tolerances

If measurements are off by even a millimeter, it can lead to gear failure.

Surface Finish Issues

Rough or uneven surfaces can cause friction, heat buildup, and wear.

Future Trends in Satellite Gear Blank Technology

The future is bright—and surprisingly high-tech—for gear blanks.

Lightweight Alloys

New materials like titanium-aluminum hybrids are being explored for weight reduction without sacrificing strength.

Additive Manufacturing (3D Printing)

Complex gear designs can now be 3D-printed with metal powders—opening doors to customization like never before.

AI-Powered Quality Control

AI and machine learning are being used to detect manufacturing defects with pinpoint accuracy, reducing human error.

Choosing the Right Supplier

When sourcing satellite gear blanks, your choice of supplier can make or break your project.

Certifications & Standards

Look for ISO or TS certifications to ensure quality compliance.

Experience & Customization Capabilities

A good supplier will offer design tweaks to meet your specific gear system needs.

After-Sales Support

Reliable suppliers won’t disappear after the sale—they’ll help with troubleshooting and replacements too.

Conclusion

Satellite gear blanks may be small, but they’re mighty. From agricultural beasts to aerospace marvels, these components play a key role in ensuring smooth, efficient mechanical performance. Whether you're a manufacturer, engineer, or machine enthusiast, understanding the ins and outs of satellite gear blanks can give you a huge edge in choosing the right parts, preventing downtime, and maximizing performance. It’s all about precision, durability, and picking the right partner.

0 notes

Text

How Stainless Steel Investment Castings Revolutionize Modern Manufacturing

In the world of modern manufacturing, precision and efficiency are crucial factors that determine the success of any production process. Over the years, stainless steel investment castings have emerged as one of the most versatile and efficient methods for producing high-quality, complex metal components. The technique, often referred to as "lost-wax casting," is especially popular due to its ability to produce stainless steel products with exceptional detail and durability. These benefits, along with the increasing demand for stronger, more durable parts in industries such as aerospace, automotive, medical, and industrial equipment, have led to the rise of stainless steel investment castings products as a revolutionary solution in modern manufacturing.

The Basics of Stainless Steel Investment Casting

Stainless steel investment casting is a process where a mold is created from a wax pattern, which is coated with a ceramic shell. Once the mold is hardened, the wax is melted away, and molten stainless steel is poured into the mold to create the final component. This process allows manufacturers to produce complex geometries and intricate designs that would be challenging, if not impossible, to achieve with traditional casting methods.

The versatility of stainless steel investment casting products makes them ideal for producing components used in high-performance applications, such as turbine blades, medical implants, and engine parts. These products are designed to withstand extreme conditions, including high temperatures, corrosion, and stress, making stainless steel investment casting a go-to method for industries where material performance is critical.

The Advantages of Investment Casting

Stainless steel investment casting offers several significant advantages over traditional manufacturing methods. These advantages have made it a popular choice for businesses looking to improve product quality, reduce manufacturing costs, and streamline production. Here are some of the key advantages of investment casting:

1. Precision and Detail

One of the most significant benefits of stainless steel investment casting is its ability to produce highly detailed and precise parts. The investment casting process can create components with incredibly fine details, thin walls, and complex shapes, which might be difficult or impossible to achieve using other techniques. This level of precision allows for the production of parts that fit perfectly into complex assemblies, reducing the need for additional machining or adjustments.

2. Complex Geometries and Shapes

Another major advantage is the ability to produce parts with complex geometries and shapes. The wax patterns used in investment casting can be easily customized, enabling the creation of intricate designs without the need for additional tooling or complex machining. This is particularly valuable in industries like aerospace, where components often need to be highly specialized and optimized for performance.

3. Material Strength and Durability

Stainless steel is known for its exceptional strength, corrosion resistance, and durability, which makes it an ideal material for investment casting. Components made from stainless steel investment castings products can withstand extreme temperatures, pressures, and corrosive environments, making them suitable for demanding applications like engine parts, medical devices, and industrial machinery. This durability helps extend the lifespan of the parts, reducing the frequency of replacements and maintenance costs.

4. Reduced Waste and Cost-Effective Production

Investment casting is a highly efficient process that minimizes material waste. The wax patterns used in the casting process are made with precision, ensuring that the final product is as close to the desired shape as possible. This minimizes the need for additional machining and reduces material waste, which can result in significant cost savings over time. Additionally, since investment casting requires fewer steps compared to traditional manufacturing methods, it can lead to shorter lead times and faster production rates.

5. Wide Range of Materials

While stainless steel is the most commonly used material in investment casting, the process is versatile enough to accommodate a variety of alloys, including high-performance materials like Inconel, titanium, and cobalt-chromium. This makes investment casting an ideal choice for industries that require specific material properties, such as resistance to heat, wear, or corrosion. Stainless steel investment casting products can be tailored to meet the precise needs of the application, whether it's a part for a high-pressure turbine or a biocompatible medical implant.

6. Reduced Need for Secondary Operations

Because stainless steel investment casting products are made with such high precision, they often require little to no additional processing or finishing. The smooth surface finish and tight tolerances achieved during the casting process can eliminate the need for secondary operations like grinding, machining, or polishing. This not only reduces production time but also lowers overall manufacturing costs, making it a cost-effective solution for producing high-quality components.

Applications of Stainless Steel Investment Castings

The advantages of stainless steel investment casting have led to its widespread adoption across various industries. Some of the most common applications include:

1. Aerospace

In the aerospace industry, the demand for lightweight, durable, and high-performance parts is critical. Stainless steel investment castings are used to produce turbine blades, compressor blades, exhaust nozzles, and other critical components that must perform in extreme conditions. The precision of investment casting allows manufacturers to create complex geometries that optimize airflow and reduce weight, improving the overall efficiency of aircraft engines.

2. Medical Devices

The medical industry also relies on stainless steel investment casting to produce implants, surgical instruments, and other high-precision devices. Stainless steel’s corrosion resistance and biocompatibility make it an ideal material for medical applications. Components like joint replacements, dental implants, and surgical tools can be manufactured with the high precision required to ensure optimal performance and patient safety.

3. Automotive

In automotive manufacturing, stainless steel investment castings are used to produce engine parts, exhaust systems, and transmission components. The process allows for the production of complex and lightweight parts that meet the high standards required for automotive applications. The ability to create parts with minimal material waste and high durability also contributes to reducing the overall cost of production.

4. Industrial Equipment

Stainless steel investment castings are also widely used in the production of industrial machinery, pumps, valves, and other components that require resistance to wear, corrosion, and high temperatures. These products must operate reliably in harsh environments, making the durability and precision of investment casting essential for long-term performance.

MS Machining: Your Trusted Partner in Stainless Steel Investment Castings

When it comes to high-quality stainless steel investment castings, MS Machining stands out as a leading provider of precision casting solutions. The company offers a comprehensive range of services, including custom stainless steel investment casting products, that cater to various industries and applications. With a focus on quality, innovation, and customer satisfaction, MS Machining delivers components that meet the highest industry standards.

To learn more about stainless steel investment castings and explore MS Machining's capabilities, visit https://ms-machining.com/stainless-steel-investment-castings/.

Conclusion

Stainless steel investment casting has undoubtedly revolutionized modern manufacturing by offering unmatched precision, flexibility, and material strength. The ability to create complex geometries with minimal waste and high durability has made it an invaluable technique across industries like aerospace, medical, automotive, and industrial equipment. As the demand for high-performance parts continues to grow, the advantages of investment casting will remain a driving force in shaping the future of manufacturing. Whether you’re producing turbine blades for an aircraft or medical implants for patients, stainless steel investment castings products are the key to achieving the level of quality and performance required in today’s competitive manufacturing environment.

0 notes

Text

Investment Casting Market Forecast 2034: Industry Set to Double by 2034

The global investment casting market, valued at US$ 16.9 billion in 2023, is poised for significant growth over the next decade. Analysts project the market to expand at a compound annual growth rate (CAGR) of 6.5% from 2024 to 2034, reaching an impressive valuation of US$ 33.9 billion by the end of 2034. This surge is driven largely by expanding demand from the aerospace and defense sectors, as well as the increasing integration of additive manufacturing technologies in the investment casting process.

Understanding Investment Casting

Investment casting, also known as lost-wax casting, is a precision metal-forming process that involves creating a wax replica of the desired part. This wax pattern is then encased in a ceramic mold. Once the ceramic hardens, the wax is melted away, leaving a cavity for molten metal to be poured in, forming the final component. This method is ideal for manufacturing complex shapes with high dimensional accuracy and excellent surface finish.

Materials commonly used in investment casting include carbon steel, stainless steel, alloy steel, aluminum, copper, nickel alloys, titanium, and magnesium. Each offers specific properties like ductility, strength, and corrosion resistance suited for various industrial applications.

Key Growth Drivers

Aerospace & Defense Sector Expansion

The aerospace and defense sector remains a vital growth engine for the investment casting market. Investment casting is essential in manufacturing temperature-sensitive components used in jet engines and industrial gas turbines. These components require intricate geometries and must withstand extreme operating conditions, which investment casting can provide with high precision.

For example, the development of gas turbine engines with advanced aerothermal designs relies heavily on investment cast parts. The rising demand for fuel-efficient, high-performance engines in both commercial and military aviation is significantly propelling market growth.

In 2023, Safran announced plans to establish a maintenance, repair, and overhaul (MRO) facility for LEAP commercial aircraft engines in India, reflecting increasing regional investments. Similarly, GE Aerospace has committed over US$ 650 million to enhance its global manufacturing plants, emphasizing 3D printing-enabled production of LEAP and GE9X engines, which incorporate numerous 3D printed components.

Integration of Additive Manufacturing (Rapid Investment Casting)

The advent of additive manufacturing (AM) has revolutionized the investment casting process. Rapid Investment Casting (RIC) integrates AM technologies to replace traditional pattern-making, drastically reducing lead times and costs without compromising quality.

RIC enables manufacturers to quickly prototype and produce complex castings, improving flexibility and responsiveness in various industries. The technology’s adoption is accelerating, especially in aerospace, where time-to-market and precision are critical.

Regional Insights

Asia Pacific currently holds the largest share of the investment casting market. The region’s dominance is fueled by robust automotive manufacturing, increased defense spending, and investments in marine gas turbine production. Indian companies such as Bharat Heavy Electricals Limited (BHEL) and Bharat Forge are key contributors, supplying marine turbines tailored to naval requirements.

The automotive sector’s rapid growth in India, with nearly 26 million vehicles produced between April 2022 and March 2023, is also boosting demand for precision cast components.

Market Segmentation

The market is segmented by material types—ferrous alloys such as carbon and stainless steel, and non-ferrous alloys including aluminum and titanium. Applications span turbine blades, engine components, suspension parts, medical equipment, valves, and ship propellers, among others. End-use industries include aerospace, automotive, industrial machinery, energy, oil & gas, marine, and medical sectors.

Competitive Landscape

Major players in the investment casting market include Gujarat Precision Cast Pvt. Ltd., Impro Precision Industries Limited, IPCL, Kovatch Castings, MetalTek, Milwaukee Precision Casting, Niagara Investment Castings Ltd., Precision Castparts Corp., and Redstone Manufacturing. These companies invest in digital foundries and advanced ceramic 3D printing technologies to meet stringent fuel economy and emission standards.

Notable recent developments include Texmo Precision Castings’ acquisition of a majority stake in Germany-based Feinguss Blank, and a joint venture between 3DCERAM Sinto and Avignon Ceramic to advance 3D-printed ceramic cores for aviation.

Analyst Viewpoint

The investment casting market is set for robust growth driven by innovation and increasing demand in high-performance industries. The integration of additive manufacturing, strategic investments by aerospace giants, and expanding end-use sectors position the market for sustained expansion.

Industry players that invest in technological advancements and regional production capabilities will likely capture significant market share. The Asia Pacific region, in particular, presents vast opportunities owing to its booming automotive and defense sectors.

Conclusion

The investment casting market is undergoing transformative growth fueled by cutting-edge manufacturing technologies and expanding aerospace and defense applications. With a projected market value of US$ 33.9 billion by 2034, stakeholders must focus on innovation, regional expansion, and strategic collaborations to capitalize on emerging opportunities and maintain competitive advantage.

0 notes

Text

Dormer Drill Bits Explained: Types, Uses, and Buying Tips

Dormer drill bits are known globally for their quality, performance, and durability. Designed for both professionals and DIY users, Dormer offers a wide range of drill bits suited for various materials and applications. Whether you're drilling into metal, wood, or plastic, Dormer has a solution tailored to your needs. Here's a detailed look at the types of Dormer drill bits, their uses, and tips to help you buy the right one.

Types of Dormer Drill Bits Dormer manufactures several types of drill bits to match different tasks. The most common include:

High-Speed Steel (HSS) Drill Bits: Ideal for general-purpose drilling in materials like steel, aluminum, and plastics. These are widely used in workshops and industries.

Cobalt Drill Bits: Perfect for tougher materials such as stainless steel and cast iron. They offer increased heat resistance and extended tool life.

Carbide Drill Bits: Known for extreme durability and precision, these are best for hard materials and CNC applications.

Jobber Length Drill Bits: Standard length drills for everyday drilling tasks.

Stub Drill Bits: Shorter in length, they are less prone to deflection and ideal for precision drilling.

Common Uses of Dormer Drill Bits Dormer drill bits are used in industries like automotive, aerospace, metal fabrication, woodworking, and construction. Whether it’s for making holes in sheet metal, drilling pilot holes in wood, or creating threads in machinery parts, Dormer bits ensure clean and efficient results.

Buying Tips When purchasing Dormer drill bits, consider the following:

Material Compatibility: Choose the right type based on the material you plan to drill. For example, cobalt for stainless steel, HSS for general use.

Coating: Some Dormer bits come with TiN or TiAlN coatings for added wear resistance and heat tolerance.

Drill Size: Ensure the drill bit size matches your application. Dormer offers both metric and imperial sizes.

Packaging: Invest in sets if you need multiple sizes for a variety of projects.

Supplier Credibility: Always buy from authorized distributors to ensure authenticity and quality.

Dormer drill bits combine performance and reliability, making them a preferred choice for both professionals and hobbyists. Understanding their types and applications helps you get the best results for any drilling job.

#vaultex safety shoes#esab welding machine#dormer drill bits#national paints uae#warning tape supplier in uae

0 notes

Text

High-Quality Investment Casting Solutions by Aleader Machinery

Investment Casting stands as one of the most precise and refined processes in the manufacturing world, delivering complex parts with exceptional accuracy and integrity. At Aleader Machinery, we pride ourselves on offering Investment Casting solutions that meet the highest industry standards, made possible by our excellent casting capabilities and commitment to quality. Our company is dedicated to providing customers with high-quality casting products tailored to a wide range of applications, ensuring every requirement is met to the greatest extent.

Understanding Investment Casting and Its Superior Advantages

Investment casting, also known as lost-wax casting, is an intricate manufacturing method that allows the creation of metal parts with fine detail and smooth finishes. It involves creating a wax pattern, coating it with ceramic material, and then melting the wax away to form a mold. Molten metal is poured into this mold to produce parts with unparalleled accuracy. The precision and versatility of investment casting makes it indispensable for industries demanding components with complex geometries.

One of the key reasons customers choose Aleader Machinery’s investment casting services is because of our ability to produce parts that require minimal post-processing, reducing overall manufacturing costs and speeding up delivery times. Our advanced technology and skilled team ensure that every product aligns perfectly with customer specifications.

Our Extensive Casting Capabilities

Aleader Machinery’s casting capabilities are backed by state-of-the-art equipment and a highly trained workforce dedicated to excellence in investment casting. We specialize in a broad spectrum of metals and alloys including stainless steel, carbon steel, aluminum, and special alloys, providing flexibility to our clients to choose the best materials for their applications.

Our casting process supports the production of parts of varying sizes—ranging from small precision components to larger, more robust industrial equipment parts. Thanks to our efficient production workflows, we are able to provide both prototype and mass production runs, offering cost-effective solutions without compromising quality.

Meeting Diverse Application Requirements

Investment casting products from Aleader Machinery find utility across multiple industries. From aerospace to medical devices, automotive to industrial machinery, our casting solutions cater to the unique demands of each sector. The ability to manufacture parts with intricate details, thin walls, and complex shapes make our casting services indispensable for high-performance applications.

Our customers benefit from components that are not only durable but also offer high dimensional accuracy and reproducibility. We work closely with clients to understand their application requirements and customize our processes accordingly to deliver castings that contribute to their product’s success and longevity.

Commitment to Quality and Compliance

At Aleader Machinery, quality is not just a goal but a fundamental principle. Our investment casting operations undergo rigorous quality control inspections throughout every stage of production. We employ precise measurement techniques and non-destructive testing methods to ensure that every casting meets or exceeds industry standards.

Our quality assurance team also ensures compliance with relevant certifications and regulations, providing clients with peace of mind that their casting products hold up under stringent audits and performance criteria. This dedication to quality establishes Aleader Machinery as a trusted partner for superior investment casting solutions.

Technology and Innovation Driving Excellence

In today’s competitive manufacturing market, staying ahead requires continuous innovation. Aleader Machinery invests heavily in modern casting technology and research. Our facilities are equipped with advanced molding systems, computer-controlled casting processes, and automation that improve precision and reduce human error.

We also leverage cutting-edge software for simulation and process optimization, allowing us to predict potential defects and optimize weight distributions before actual production begins. This technological edge ensures that our investment casting products consistently exceed client expectations.

Environmental Responsibility in Casting

Aleader Machinery recognizes the importance of environmental stewardship in manufacturing. Our investment casting processes are designed to minimize waste and energy consumption. We recycle materials where possible, utilize eco-friendly binders, and comply with strict environmental regulations to reduce our carbon footprint.

Choosing Aleader Machinery means partnering with a company committed not only to quality but also to sustainable manufacturing practices.

Customized Solutions for Customer Satisfaction

Every client has unique casting needs, and Aleader Machinery thrives on delivering tailored investment casting solutions. Whether it’s a small batch prototype or a large-scale production order, we adapt our workflows and materials selection to fit the exact demands of your project.

Our dedicated customer service team works alongside production engineers to ensure clear communication and timely updates throughout the casting lifecycle. This collaborative approach ensures client satisfaction and long-term partnership success.

Industry-Leading Turnaround Times and Reliability

Timely delivery is crucial in manufacturing supply chains, and Aleader Machinery excels in providing reliable lead times for all our investment casting projects. By optimizing each step, from pattern production to final finishing, we ensure fast turnaround without compromising quality.

Our flexibility to scale production according to demand means clients can depend on us for both expedited jobs and consistent volume orders.

Highly Skilled Workforce Empowering Precision

The excellence of Aleader Machinery’s investment casting solutions begins with our talented team. Our technicians and engineers are experts in metallurgy, pattern making, and casting operations, trained to bring out the best in every project.

This expertise allows us to overcome complex casting challenges and consistently produce flawless parts meeting customer requirements to the fullest.

Applications of Aleader Machinery’s Investment Castings

Our investment casting components serve critical functions in aerospace engines, medical implants, automotive drivetrain parts, and power generation equipment. The ability to produce components with optimal strength and finish makes us a preferred supplier to demanding sectors.

We also cater to industrial machinery requiring wear-resistant parts, ensuring longevity and superior performance through our casting processes.

Why Choose Aleader Machinery for Your Investment Casting Needs?

Choosing Aleader Machinery means accessing a partner committed to excellence in investment casting. Our combination of advanced technology, skilled workforce, and customer-centric approach ensures best-in-class casting products tailored to your exact needs.

We stand behind the quality and durability of every casting we deliver, backed by rigorous testing and quality control for your peace of mind.

Global Reach with Localized Service

Aleader Machinery serves clients across markets worldwide while maintaining an attentive and localized service model. Our global distribution network ensures reliable shipping and logistics, while our customer service teams provide personalized support.

This balance allows us to respond swiftly to inquiries and resolve challenges effectively, no matter where our clients are located.

Exploring the Future of Investment Casting with Aleader Machinery

The future of manufacturing lies in innovation and adaptability. Aleader Machinery continuously expands its investment casting capabilities by integrating new materials, refining processes, and exploring emerging technologies such as additive manufacturing integration and digital twins.

This forward-thinking approach ensures our customers receive the most advanced casting solutions available today and tomorrow.

Partnering for Success in Complex Manufacturing Environments

Complex manufacturing demands partners who can deliver not only products but also strategic value. Aleader Machinery collaborates closely with customers to optimize casting designs, materials, and processes, creating value beyond simple production.

Our expertise in investment casting enables us to contribute to product innovation, cost savings, and enhanced manufacturing workflows.

A Legacy of Reliability and Trust

With years of experience in investment casting, Aleader Machinery has built a reputation for reliability and integrity. Our customers trust us to handle sensitive projects and deliver superior castings consistently.

This legacy inspires continuous improvement in every aspect of our operations.

Customer Testimonials Reflecting Excellence

Clients consistently praise Aleader Machinery for attention to detail, superior casting quality, and exceptional customer service. Their success stories inspire our team to maintain high standards in investment casting and customer collaboration.

We are proud to play a pivotal role in their manufacturing achievements.

Comprehensive Support from Design to Delivery

Our investment casting services cover the entire production spectrum starting from design consultation, tooling, prototype development, to full-scale manufacturing and delivery. We provide value-added services such as secondary machining and finishing to deliver ready-to-use components.

This comprehensive approach reduces complexity for clients and streamlines supply chain management.

Ensuring Long-Term Client Success

Aleader Machinery is more than just a casting provider; we strive to be a strategic partner for our clients’ long-term growth. Our adaptive manufacturing solutions and commitment to innovation support the evolving needs of our customer base across industries.

With Aleader Machinery, customers gain a partner invested in their success throughout the product lifecycle.

Contact Aleader Machinery for Unmatched Investment Casting Solutions

If you are looking for top-tier investment casting capabilities that combine precision, quality, and customer focus, Aleader Machinery welcomes your inquiry. Our team is ready to discuss your requirements and deliver casting solutions tailored specifically to meet your needs.

Experience the difference of working with a reliable, innovative casting partner committed to excellence in investment casting.

1 note

·

View note

Text

Fused Alumina Market in Europe Set for Steady Expansion, Fueled by Abrasives and Refractories

The Europe fused alumina market stood at USD 454.6 Mn in 2022 and is poised to grow at a CAGR of 4.1%, reaching USD 649.4 Mn by 2031. Fused alumina, known for its exceptional hardness, thermal stability, and chemical resistance, continues to be in high demand across a spectrum of industries including abrasives, refractories, ceramics, and renewable energy applications.

Market Overview: Fused alumina plays an indispensable role in industrial manufacturing, particularly in sectors such as automotive, aerospace, construction, and energy. With Europe undergoing rapid energy transitions and witnessing steady infrastructure development, demand for high-performance materials such as fused alumina has surged. Analysts highlight that increased investment in high-temperature resistant materials especially in steel, cement, and glass industries is propelling the need for both brown and white fused alumina.

Market Drivers & Trends

The key drivers behind the rising market demand include:

Booming Automotive Sector: The resurgence of the automotive industry across Europe, especially in Germany and France, has fueled demand for abrasives that rely heavily on fused alumina.

Expansion in Construction & Infrastructure: Ongoing urbanization and renovation of aging infrastructure are creating high demand for abrasives and refractories.

Renewable Energy Transition: Applications in the manufacture of wind turbines and other clean energy components are opening new opportunities for high-temperature fused alumina use.

Sustainability Trends: There is a growing focus on eco-efficient, recyclable, and durable materials—white fused alumina fits well into this sustainable materials ecosystem.

Latest Market Trends

Rising Preference for White Fused Alumina (WFA): Known for its high purity (above 99% alumina), WFA is gaining prominence in ceramic and refractory applications, including kiln linings and furnace insulation.

Increased Use in Aerospace: Spain and Italy are investing in aerospace component production, creating demand for high-quality abrasive materials.

Adoption in Clean Manufacturing: High resistance to corrosion and stress at elevated temperatures makes fused alumina ideal for cleanroom and precision manufacturing environments.

Key Players and Industry Leaders

The Europe fused alumina market is moderately fragmented and highly competitive, with several key players and emerging companies actively investing in R&D and strategic acquisitions.

Key Players Include:

Alteo Alumina

Henan Ruishi Renewable Resources Group Co.,Ltd

Yichuan Shengyu Abrasives Co.,Limited,

Imerys

Saint-Gobain

Others

Access important conclusions and data points from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85848

Recent Developments

May 2023: LKAB Minerals acquired Intermag to strengthen its mineral processing capabilities and regional reach in Europe.

June 2022: RUSAL commenced the construction of an advanced alumina production facility in Russia, investing over 400 Bn Rubles.

April 2022: Saint-Gobain Ceramics acquired Monofrax to expand its portfolio in fused cast refractories.

June 2021: Imerys launched a refractory-focused plant in India to diversify geographically and enhance its product offerings.

These strategic moves by major players are aimed at improving operational efficiencies and fulfilling growing demand across key European markets.

Market Opportunities

High-Tech Refractory Applications: The increasing use of fused alumina in high-tech refractory castables and isotactic pressed refractories offers significant market opportunities.

Growth in Metal Fabrication: Rising demand for fabricated metal products in the construction, automotive, and aerospace sectors will bolster abrasive consumption.

Emerging Markets in Northern Europe: Countries like Sweden and Belgium are investing heavily in infrastructure, unlocking new demand zones for fused alumina.

Future Outlook

From 2023 to 2031, the market is expected to maintain stable growth due to:

Greater focus on cleaner, sustainable energy.

Recovery and growth in heavy industries post-pandemic.

Technological innovations in material sciences boosting the application of fused alumina in high-performance use cases.

By 2031, the Europe fused alumina market is projected to be increasingly driven by high-purity product segments and tailored applications in niche industries.

Market Segmentation

By Type:

Brown Fused Alumina (BFA)

Applications: Grinding wheels, cutting tools, blasting media, bonded abrasives, and refractories

White Fused Alumina (WFA)

Applications: High-tech refractory castables, isotactic pressed refractories, and ceramic components

Bubble Alumina

Applications: Lightweight high-temperature insulation

By Grade:

Refractory

Abrasive

Vitrified

Others

By Application:

Abrasives (grinding, cutting, blasting)

Refractories (pre-cast shapes, monolithics)

Ceramics

Others

Regional Insights

Germany: The largest consumer, driven by its dominant automotive industry and strong engineering sectors.

France: Focused on advanced manufacturing and sustainable materials.

Italy & Spain: Expansion of aerospace manufacturing and refractory production.

Sweden & Belgium: Emerging players investing in infrastructure and clean energy projects, fueling demand for high-performance abrasives and refractories.

Why Buy This Report?

Comprehensive Analysis: In-depth insights on current and future trends, growth drivers, and industry challenges.

Detailed Segmentation: Covers fused alumina by type, grade, application, and country-wise data.

Company Profiling: Extensive profiles of leading players with business strategy and financial overview.

Opportunity Mapping: Identification of high-growth application areas and emerging regional markets.

Strategic Insights: Ideal for investors, manufacturers, distributors, and policy makers for informed decision-making.

Frequently Asked Questions (FAQs)

Q1. What was the value of the Europe fused alumina market in 2022? A1. The market was valued at US$ 454.6 Mn in 2022.

Q2. What is the projected market size by 2031? A2. The market is forecast to reach US$ 649.4 Mn by 2031, growing at a CAGR of 4.1%.

Q3. What are the major drivers of this market? A3. Industrial growth in construction, automotive, renewable energy, and aerospace, along with the increased demand for high-temperature materials, are key growth drivers.

Q4. Which countries are leading in fused alumina demand? A4. Germany, France, Italy, and Spain are key markets, with Belgium and Sweden emerging as important demand hubs.

Q5. Who are the top players in the market? A5. Major companies include Saint-Gobain, Imerys, Alteo Alumina, Henan Ruishi, and Yichuan Shengyu Abrasives.

Explore Latest Research Reports by Transparency Market Research: Sustainable Construction Materials Market: https://www.transparencymarketresearch.com/sustainable-construction-materials-market.html

Conductive Carbon Black Market: https://www.transparencymarketresearch.com/conductive-carbon-black-market.html

Fire Collars Market: https://www.transparencymarketresearch.com/fire-collars-market.html

Acesulfame Potassium Market: https://www.transparencymarketresearch.com/acesulfame-potassium-market.html About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Global Special Bar Quality Steel Market: Forecast and Competitive Overview 2025–2032

Global Special Bar Quality (SBQ) Steel market was valued at $35.4 billion in 2024 and is projected to reach $44.16 billion by 2031, growing at a CAGR of 3.3% during the forecast period. SBQ steel represents a premium category of steel products manufactured to meet stringent quality standards for applications requiring superior strength, toughness, and dimensional accuracy compared to standard carbon steel bars.

SBQ steel is characterized by its exceptional mechanical properties, including high tensile strength, excellent fatigue resistance, and superior surface finish. These properties make it ideal for critical applications where component failure could lead to safety concerns or significant performance issues. The material's enhanced characteristics are achieved through controlled steelmaking processes and specialized heat treatment methods.

Key Characteristics of SBQ Steel

SBQ steel stands out in the steel market due to its unique properties:

Enhanced cleanliness with minimal non-metallic inclusions for improved fatigue resistance

Superior dimensional accuracy and surface finish for precision applications

Excellent machinability characteristics for efficient component manufacturing

Consistent mechanical properties throughout the material cross-section

Optimized microstructure for improved toughness and ductility

Production Process

The manufacturing of SBQ steel involves specialized processes to achieve its premium characteristics:

Electric arc furnace or basic oxygen furnace steelmaking with tight chemistry control

Secondary refining processes including ladle metallurgy for inclusion control

Continuous casting with electromagnetic stirring for uniform solidification

Precision rolling with controlled temperature and reduction ratios

Specialized heat treatment processes for optimal microstructure development

Advanced inspection and testing procedures for quality assurance

Market Dynamics

The SBQ steel market is influenced by several key factors:

Growing demand from automotive sector for high-performance components

Increasing infrastructure development in emerging economies

Stringent safety and performance standards in industrial applications

Technological advancements in steel production and processing

Shift toward lightweight materials in transportation applications

Applications

SBQ steel finds application across multiple industries:

Automotive: Axles, steering components, transmission parts, and suspension components

Industrial Machinery: Shafts, gears, and heavy equipment components

Energy: Components for wind turbines, oil and gas equipment

Construction: High-strength structural components

Aerospace: Landing gear components and structural elements

Market Segmentation

The SBQ steel market can be segmented by product form:

Round bars

Square bars

Hexagonal bars

Flat bars

Special profiles

Regional Market Overview

The SBQ steel market shows distinct regional characteristics:

Asia-Pacific: Dominant market share with strong industrial base and infrastructure growth

North America: Mature market with focus on high-value applications

Europe: Strong automotive and industrial base driving demand

Middle East & Africa: Emerging market with infrastructure development

Industry Challenges

The SBQ steel industry faces several challenges:

Volatility in raw material prices

Stringent environmental regulations

High capital intensity of production

Competition from alternative materials

Technical challenges in product development

Future Outlook

The SBQ steel market is expected to experience steady growth, driven by:

Increasing demand from automotive electrification

Infrastructure investments in developing economies

Technological advancements in steel production

Growing focus on sustainable manufacturing

For detailed market analysis and forecasts, please refer to our comprehensive research reports.

Download FREE Sample Report: Special Bar Quality (SBQ) Steel Market

View Detailed Research Report: Special Bar Quality (SBQ) Steel Market

0 notes

Text

Die Casting Companies in India: Driving Precision Manufacturing and Innovation

India is fast emerging as a global hub for precision manufacturing, and die casting companies in India are at the forefront of this industrial revolution. With a strong foundation in engineering, skilled labor, and competitive pricing, die casting firms in India are playing a vital role in supplying components to industries such as automotive, aerospace, electronics, medical, and consumer goods.

In this blog, we’ll explore what die casting is, why India is a prime destination for die casting services, key players in the industry, and how to choose the right partner for your manufacturing needs.

What is Die Casting?

Die casting is a metal casting process in which molten metal is forced into a mold cavity under high pressure. These molds, also known as dies, are made from hardened tool steel and can produce complex shapes with high precision and surface finish.

The most common metals used in die casting include:

Aluminum

Zinc

Magnesium

Copper

Lead and Tin alloys

There are two main types of die casting:

Hot Chamber Die Casting – Best for low-melting-point metals like zinc and magnesium.

Cold Chamber Die Casting – Suitable for metals like aluminum and copper that have higher melting points.

Why India for Die Casting?

1. Cost-Effective Manufacturing

Indian companies offer high-quality die casting services at significantly lower costs compared to their Western counterparts. This cost advantage makes India an attractive destination for outsourcing and global supply chain integration.

2. Skilled Workforce

India has a vast pool of skilled engineers, technicians, and machine operators trained in precision manufacturing. This ensures consistent quality and the ability to handle complex design requirements.

3. Growing Infrastructure