#HighPerformanceFasteners

Explore tagged Tumblr posts

Text

Hastelloy C22 Fasteners: Comprehensive Guide

Introduction

Hastelloy C22 is a highly versatile and corrosion resistant nickel chromium molybdenum tungsten alloy. Its exceptional resistance to a wide range of chemical environments makes it an ideal choice for manufacturing high-performance fasteners used in critical applications. This blog provides an in-depth overview of Hastelloy C22 fasteners, their characteristics, applications, and benefits.

What are Hastelloy C22 Fasteners?

Hastelloy C22 fasteners are components such as bolts, nuts, washers, and screws manufactured using the Hastelloy C22 alloy. These fasteners are renowned for their superior corrosion resistance, durability, and strength, even in extreme environments. They are widely used in industries such as chemical processing, marine engineering, and aerospace.

Chemical Composition of Hastelloy C22

The chemical composition of Hastelloy C22 contributes to its excellent properties. Below is the approximate composition of the alloy:

Nickel (Ni): 56%

Chromium (Cr): 20-22%

Molybdenum (Mo): 12.5-14.5%

Iron (Fe): 2-6%

Tungsten (W): 2.5-3.5%

Cobalt (Co): ≤2.5%

Manganese (Mn): ≤0.5%

Silicon (Si): ≤0.08%

Carbon (C): ≤0.015%

Phosphorus (P): ≤0.02%

Sulfur (S): ≤0.02%

Mechanical Properties of Hastelloy C22

Hastelloy C22 exhibits outstanding mechanical properties, making it suitable for demanding applications. Key mechanical properties include:

Tensile Strength: 690 MPa (minimum)

Yield Strength: 310 MPa (minimum)

Elongation: 45% (minimum)

Hardness: Approximately 95 HRB

Characteristics of Hastelloy C22 Fasteners

Hastelloy C22 fasteners are favored due to the following characteristics:

Corrosion Resistance: They resist pitting, crevice corrosion, and stress corrosion cracking in both oxidizing and reducing environments.

Thermal Stability: Excellent performance at high temperatures.

Versatility: Effective in a wide range of chemical environments, including acidic, alkaline, and saline conditions.

Durability: Exceptional mechanical strength ensures long-lasting performance.

Fabrication: Easy to weld and fabricate without compromising its corrosion-resistant properties.

Types of Hastelloy C22 Fasteners

Hastelloy C22 fasteners come in various forms to meet diverse industrial requirements. Common types include:

Bolts: Hex bolts, U-bolts, eye bolts, and stud bolts.

Nuts: Hex nuts, lock nuts, and heavy hex nuts.

Washers: Flat washers, spring washers, and lock washers.

Screws: Machine screws, self-tapping screws, and socket head cap screws.

Threaded Rods: Fully threaded rods and partially threaded studs.

Applications of Hastelloy C22 Fasteners

Thanks to their outstanding properties, Hastelloy C22 fasteners are used in various critical applications:

Chemical Processing: Ideal for reactors, heat exchangers, and other equipment exposed to aggressive chemicals.

Marine Engineering: Resists corrosion in seawater and marine atmospheres.

Pharmaceutical Industry: Suitable for hygienic and sterile environments.

Aerospace: Used in high-temperature and high-pressure systems.

Pollution Control: Applicable in scrubbers, filters, and stack liners.

Power Generation: Used in turbines and flue gas desulfurization systems.

Benefits of Hastelloy C22 Fasteners

Exceptional Corrosion Resistance: Ensures longevity and reliability in harsh environments.

High Strength: Can withstand significant mechanical stress without deforming.

Wide Temperature Range: Performs efficiently in both cryogenic and high-temperature conditions.

Ease of Fabrication: Can be machined and welded easily.

Versatile Applications: Suitable for a broad spectrum of industries.

Why Choose Ananka Group for Hastelloy C22 Fasteners?

Ananka Group is a leading manufacturer, supplier, and exporter of high-quality Hastelloy C22 fasteners. Here’s why you should choose us:

Expertise: Decades of experience in manufacturing and supplying corrosion-resistant fasteners.

Quality Assurance: Our fasteners comply with international standards such as ASTM, ASME, and DIN.

Customization: We offer tailor-made solutions to meet specific requirements.

Global Presence: We supply to industries worldwide, ensuring timely delivery.

Competitive Pricing: High-quality products at affordable prices.

Conclusion

Hastelloy C22 fasteners are indispensable components for industries requiring superior corrosion resistance and mechanical performance. Their versatility, durability, and exceptional properties make them a preferred choice for critical applications. If you’re looking for reliable and high-quality Hastelloy C22 fasteners, Ananka Group is your trusted partner.

Frequently Asked Questions (FAQ)

1. What makes Hastelloy C22 fasteners unique?

Hastelloy C22 fasteners are unique due to their exceptional corrosion resistance, high strength, and ability to perform in a wide range of aggressive chemical environments.

2. Can Hastelloy C22 fasteners be used in high-temperature environments?

Yes, Hastelloy C22 fasteners perform exceptionally well in high-temperature conditions, maintaining their strength and corrosion resistance.

3. Are Hastelloy C22 fasteners suitable for marine applications?

Absolutely. Hastelloy C22 fasteners offer excellent resistance to seawater and marine atmospheres, making them ideal for marine engineering.

4. Do Hastelloy C22 fasteners comply with international standards?

Yes, Hastelloy C22 fasteners manufactured by Ananka Group comply with international standards such as ASTM, ASME, and DIN.

5. Can I get customized Hastelloy C22 fasteners?

Yes, Ananka Group offers customization options to meet specific design and application requirements.

#HastelloyC22Fasteners#HastelloyFastener#NickelAlloyFasteners#IndustrialFasteners#ChemicalProcessingFasteners#HighPerformanceFasteners#HastelloyC22Bolts#HastelloyC22Nuts#HastelloyC22Washers#FastenersManufacturer#AnankaGroup#Article#Linkedin#Blog#Ananka#Fasteners#anankafasteners#manufacturer#supplier#mumbai#hex#bolt

0 notes

Text

Titanium Grade 2 Bolts, Nuts, and Fasteners

Introduction

Titanium Grade 2 is a commercially pure titanium alloy widely used for its excellent strength, corrosion resistance, and lightweight properties. Titanium Grade 2 bolts, nuts, and fasteners are popular in industries like aerospace, marine, chemical processing, and medical applications due to their superior characteristics. This blog delves into the details of Titanium Grade 2 fasteners, including their properties, applications, and advantages.

What is Titanium Grade 2?

Titanium Grade 2 is classified as a commercially pure titanium alloy (CP Titanium). It has a high strength-to-weight ratio, excellent corrosion resistance in various environments, and good weldability. The alloy contains about 99.2% pure titanium, making it ideal for applications requiring resistance to oxidation and seawater.

Chemical Composition of Titanium Grade 2

The following table outlines the chemical composition of Titanium Grade 2:

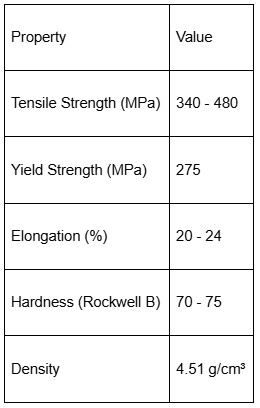

Mechanical Properties of Titanium Grade 2

Here are the mechanical properties of Titanium Grade 2 fasteners:

Features of Titanium Grade 2 Fasteners

Titanium Grade 2 fasteners are renowned for their outstanding properties, such as:

Corrosion Resistance:

Outstanding resistance to seawater, chlorides, and oxidizing agents.

Ideal for marine and chemical processing applications.

High Strength-to-Weight Ratio:

Lightweight yet strong, making them suitable for weight-sensitive applications like aerospace.

Non-Magnetic and Non-Toxic:

Suitable for medical and sensitive equipment applications.

Heat and Low-Temperature Resistance:

Performs well in temperatures ranging from cryogenic to moderately high levels.

Excellent Weldability and Ductility:

Can be fabricated and welded easily without compromising its mechanical properties.

Types of Titanium Grade 2 Fasteners

Titanium Grade 2 fasteners come in various types to cater to diverse industrial needs:

Titanium Grade 2 Bolts: Hex bolts, socket head bolts, and U-bolts.

Titanium Grade 2 Nuts include hex nuts, lock nuts, wing nuts, and dome nuts.

Titanium Grade 2 Washers are offered in various types, including flat washers, spring washers, and lock washers

Titanium Grade 2 Screws: Machine screws, wood screws, self-tapping screws.

Titanium Grade 2 Studs: Fully threaded studs, double-ended studs.

Custom Fasteners: Manufactured to specific designs and requirements for specialized applications.

Applications of Titanium Grade 2 Fasteners

Titanium Grade 2 fasteners are widely used across several industries, such as:

Aerospace Industry:

Aircraft frames, engine components, and structural fasteners due to their lightweight strength.

Marine Industry:

Shipbuilding, offshore platforms, and underwater equipment where seawater resistance is critical.

Chemical Processing:

Used in tanks, pipelines, and heat exchangers due to their resistance to harsh chemicals and oxidizing agents.

Medical Industry:

Implants, surgical instruments, and medical devices because of their biocompatibility and non-toxic properties.

Automotive Industry:

Lightweight fasteners for high-performance vehicles and exhaust systems.

Power Generation:

Used in energy production plants, including nuclear and geothermal facilities.

Advantages of Titanium Grade 2 Fasteners

Corrosion Resistance: Exceptional durability in seawater, chemical environments, and oxidizing conditions.

Lightweight: About 45% lighter than steel, reducing overall weight in critical applications.

High Strength: Provides robust fastening solutions without adding significant bulk.

Non-Reactive: Ensures compatibility with medical, aerospace, and food-grade applications.

Long Service Life: Offers long-term performance with minimal maintenance.

Why Choose Ananka Group for Titanium Grade 2 Fasteners?

Ananka Group is your trusted partner for Titanium Grade 2 fasteners, offering:

Premium Quality: Manufactured to meet stringent international standards, ensuring durability and precision.

Custom Solutions: Tailored fasteners to match specific industrial requirements.

Global Delivery: A reliable supply chain to ensure timely delivery worldwide.

Expertise You Can Rely On: Decades of experience in fastener manufacturing and industry-specific solutions.

Cost-Effective Products: High-quality fasteners at competitive prices to suit your budget.

Conclusion

Titanium Grade 2 bolts, nuts, and fasteners are a reliable choice for industries requiring lightweight, high-strength, and corrosion-resistant fastening solutions. Their wide range of applications, from aerospace to medical, makes them a reliable choice for challenging environments. At Ananka Group, we offer top-quality Titanium Grade 2 fasteners that meet international standards, ensuring durability, precision, and performance.

Frequently Asked Questions (FAQs)

Q1: What is the strength of Titanium Grade 2 fasteners?

A: Titanium Grade 2 fasteners have a tensile strength ranging from 340 to 480 MPa and a yield strength of 275 MPa.

Q2: Are Titanium Grade 2 fasteners corrosion-resistant?

A: Yes, Titanium Grade 2 fasteners offer outstanding corrosion resistance, particularly in seawater and harsh chemical environments.

Q3: Where are Titanium Grade 2 fasteners used?

A: They are used in aerospace, marine, chemical processing, medical, and automotive industries due to their strength and corrosion resistance.

Q4: Can Titanium Grade 2 fasteners be customized?

A: Yes, Ananka Group offers customization to meet specific designs and requirements.

Q5: Why choose Titanium Grade 2 over other materials?

A: Titanium Grade 2 offers a unique combination of lightweight strength, corrosion resistance, and biocompatibility, making it ideal for demanding applications.

#TitaniumGrade2Fasteners#TitaniumBolts#TitaniumNuts#TitaniumWashers#CorrosionResistantFasteners#LightweightFasteners#MarineFasteners#AerospaceFasteners#ChemicalProcessingFasteners#MedicalFasteners#HighPerformanceFasteners#AnankaGroup#FastenersManufacturer#IndustrialFasteners#anankafasteners#ananka#manufacturer#supplier#fasteners#mumbai#hex#bolt

0 notes

Text

Everything You Need to Know about Phosphor Bronze Fasteners

Phosphor Bronze, a high-performance copper-based alloy, is renowned for its exceptional toughness, strength, and durability. This alloy, composed of copper, tin, and phosphorus, stands out as one of the most resilient materials ever manufactured. Tin adds corrosion resistance, while phosphorus improves mechanical properties, making Phosphor Bronze Fasteners a go-to choice in industries that demand reliable performance under abrasive conditions.

In this blog, we’ll cover all aspects of Phosphor Bronze Fasteners, including their characteristics, types, applications, chemical composition, and more.

What Are Phosphor Bronze Fasteners?

Phosphor bronze fasteners are specialty fastening components crafted from phosphor bronze alloy, making them ideal for applications that require resistance to wear, fatigue, and corrosion. With features like low friction, high tensile strength, and excellent conductivity, these fasteners are widely used in electrical, marine, and industrial sectors.

Key Characteristics of Phosphor Bronze Fasteners

Corrosion Resistance: High resistance to seawater and various chemicals, making them suitable for marine and chemical environments.

Strength and Durability: The addition of phosphorus enhances bronze's strength, allowing it to handle heavy loads and stress.

Low Friction: With a low coefficient of friction, these fasteners experience minimal wear and tear over time.

Electrical Conductivity: Phosphor bronze’s excellent conductivity makes it an excellent choice for electrical applications.

Fatigue Resistance: Designed to withstand repeated stress, these fasteners offer an extended service life.

Types of Phosphor Bronze Fasteners

Phosphor bronze fasteners come in various types, tailored for different industrial needs:

Hex Bolts: Known for their strength, hex bolts are ideal for heavy-duty applications.

Nuts: Pair with bolts or threaded rods for secure fastening.

Washers: Distribute load evenly and protect surfaces from damage.

Screws: Corrosion-resistant and perfect for marine and electrical applications.

Studs: Provide high tensile strength, suited for demanding conditions.

Rivets: Offer permanent fastening, ideal for constant stress applications.

Applications of Phosphor Bronze Fasteners

Phosphor bronze fasteners are preferred in industries that require strength, durability, and corrosion resistance. Here’s how they are applied across sectors:

Marine Industry: Resistant to seawater, making them suitable for shipbuilding, offshore platforms, and more.

Electrical Industry: Excellent conductivity makes them ideal for connectors, terminals, and electrical components.

Chemical Industry: Resistant to various chemicals, these fasteners are valuable in chemical processing.

Automotive Industry: With high wear resistance, they are ideal for engine components.

Aerospace: Used in aircraft and spacecraft for their critical strength and durability.

Chemical Composition of Phosphor Bronze Hex Bolts

Phosphor bronze typically consists of:

Copper (Cu): 88-94%

Tin (Sn): 4-10%

Phosphorus (P): 0.03-0.35%

This high copper content provides excellent electrical and thermal conductivity, while tin and phosphorus enhance the alloy's strength and resistance.

Advantages of Phosphor Bronze Fasteners

Corrosion & Wear Resistance: Withstand harsh environments, including exposure to seawater and chemicals.

Long Service Life: Minimal wear ensures these fasteners outlast alternatives made from other materials.

Versatility: Used across various industries due to their unique properties.

Conclusion

Phosphor bronze fasteners are ideal for high-performance applications. Their strength, durability, and corrosion resistance make them indispensable in demanding industries like marine, electrical, chemical, and aerospace. By understanding their properties, types, and advantages, industries can make informed decisions on using these fasteners for specific needs.

FAQs

Why are phosphor bronze fasteners preferred over others? Phosphor bronze fasteners offer superior corrosion resistance, especially in marine environments, and excellent fatigue resistance, making them ideal for heavy-duty applications.

Are phosphor bronze fasteners suitable for electrical applications? Yes, their excellent conductivity makes them ideal for electrical connectors and terminals.

Are phosphor bronze fasteners expensive? While they may cost more than standard steel or brass fasteners, their durability and performance in high-stress, corrosive environments justify the investment.

How do phosphor bronze fasteners compare to stainless steel fasteners? Phosphor bronze fasteners offer better wear resistance and fatigue strength than stainless steel, especially in marine and electrical applications.

Which industries commonly use phosphor bronze fasteners? Phosphor bronze fasteners are widely used in the marine, electrical, chemical, automotive, and aerospace industries due to their reliable performance characteristics.

#AnankaFasteners#Ananka#PhosphorBronzeFasteners#IndustrialFasteners#MarineFasteners#ElectricalFasteners#HighPerformanceFasteners#FastenerTypes#Bronze

0 notes