#Honeycomb Sandwich Panel

Text

Exploring the Versatility: The Benefits of Aluminum Honeycomb Panels Across Industries

Innovation in construction materials has paved the way for revolutionary solutions in architecture, transportation, and various industrial sectors. One such advancement is the utilization of aluminum honeycomb panels. These lightweight yet sturdy structures offer a multitude of benefits across diverse applications, ranging from aerospace to interior design. In this blog, we delve into the advantages of aluminum honeycomb panels and their widespread applications in different sectors.

Lightweight Construction:

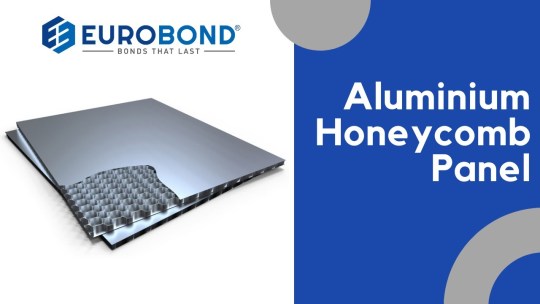

Aluminum honeycomb panels consist of a honeycomb core sandwiched between aluminum sheets. This design imparts exceptional strength while maintaining a lightweight profile. Compared to solid aluminum or steel structures, aluminum honeycomb panels offer significant weight savings, making them ideal for applications where weight reduction is critical. Industries such as aerospace, automotive, and marine benefit from this lightweight construction, enhancing fuel efficiency, maneuverability, and overall performance.

High Strength-to-Weight Ratio:

Despite their lightweight nature, aluminum honeycomb panels boast remarkable strength-to-weight ratios. The honeycomb core design distributes stress evenly across the panel, resulting in exceptional structural integrity. This characteristic makes them suitable for load-bearing applications in construction, such as building facades, cladding systems, and roofing. Additionally, their high strength-to-weight ratio allows for longer spans and greater design flexibility, reducing the need for additional support structures and simplifying installation.

Superior Thermal and Acoustic Insulation:

The honeycomb core structure of aluminum honeycomb panels acts as a barrier to heat transfer and sound transmission. This inherent thermal and acoustic insulation property makes them valuable in various sectors, including construction, transportation, and industrial applications. In buildings, aluminum honeycomb panels contribute to energy efficiency by minimizing heat loss or gain, thus reducing HVAC loads and operating costs. Similarly, in transportation vehicles, such as trains and buses, they provide a quieter and more comfortable interior environment for passengers.

Exceptional Flatness and Stability:

Aluminum honeycomb panels exhibit excellent flatness and dimensional stability, ensuring uniformity and consistency in their appearance and performance. This characteristic is particularly advantageous in architectural applications, where aesthetics play a crucial role. Whether used as exterior cladding, interior partitions, or decorative elements, these panels maintain their shape and surface quality over time, enhancing the visual appeal and longevity of structures.

Corrosion Resistance and Durability:

Aluminum is inherently resistant to corrosion, making aluminum honeycomb panels highly durable and long-lasting, even in harsh environmental conditions. This corrosion resistance makes them suitable for outdoor applications, such as building exteriors, signage, and marine vessels. Additionally, aluminum honeycomb panels are impervious to moisture, mold, and rot, further extending their lifespan and minimizing maintenance requirements.

Eco-Friendly and Recyclable:

As sustainability becomes a primary concern across industries, aluminum honeycomb panels offer an eco-friendly solution. Aluminum is fully recyclable, and the manufacturing process for honeycomb panels consumes less energy compared to other construction materials. Furthermore, the lightweight nature of these panels reduces transportation-related carbon emissions during installation and transportation, contributing to overall environmental conservation efforts.

Conclusion:

Aluminum honeycomb panels have emerged as a versatile and innovative construction material with numerous benefits across various sectors. From aerospace and automotive industries to architecture and interior design, their lightweight construction, high strength-to-weight ratio, thermal and acoustic insulation properties, and durability make them indispensable. As advancements in materials science continue, aluminum honeycomb panels are poised to play an increasingly prominent role in shaping the future of construction and industrial applications.

#eurobond acp#acp sheet#acp panels#building materials#eurobond honeycomb sheet#honeycomb sandwich panel#honeycomb panels#aluminium honeycomb sheet

1 note

·

View note

Text

Aluminium honeycomb sandwich panel are a type of composite material used in construction and manufacturing. They consist of two thin sheets of aluminum, bonded to a lightweight honeycomb core made of aluminum or other materials.

0 notes

Text

Aluminium Honeycomb Sheet: Know Its Benefits & Applications

An aluminium honeycomb sheet can be depicted as a sandwich plate that comes with a honeycomb structure at its core. It is inspired by the hexagonal shape of a natural honeycomb. This special structure makes its weight way lighter than other materials of the same volume. What is more, the overall stability and stiffness are also very good. Let us find out more about the honeycomb sheet in the following passages.

Benefits of Aluminium Honeycomb Sheet

Fire Resistance:

These panels are non-melting type and non-combustible with a fire rating of FR grade A2+. There is a hexagonal design honeycomb sheet in the core that prevents the fire from spreading rapidly.

Lightweight

Since the honeycomb sheet comes with a hollow core, it is of low density. Also, that is why the overall weight of the panel is light which makes it useful especially in aerospace engineering, metro coaches, as well as theatres.

Highly Efficient

The hexagonal honeycomb core connects with the aluminium skin on the top and bottom which makes an I-beam structure. This particular feature makes the panel highly durable and enables high-impact stress resistance.

Recyclable Material

The honeycomb panel is made with 100% recyclable and reusable aluminium alloy.

Hassle-free Installation

As these panels are lightweight and thin, they are easy to install. These can be easily installed with rivets and nuts as wall panels or in other applications.

Key Applications Of Honeycomb Sheet

These honeycomb sheets are suitable for installation in ceilings, Metro coaches, railway stations, facades, airports, etc. Suitable for both interior and exterior installation these are highly efficient and aesthetic.

Final Words

If you want to buy the best quality aluminium honeycomb sheet at the best prices, always deal with a trusted supplier. Only they offer premium quality products at competitive prices ensuring the best return on your investment.

2 notes

·

View notes

Text

PP Honeycomb Board Extrusion Line

Main application

1. Used for car trunk cover board, trunk clapboard, trunk carpet substrate, side wall decortation board, ceiling etc. interior place.

2. Used for manufacturing different kinds of high strength packing box.

PP honeycomb board through extrusion method made three layers sandwich board of one time forming, two sides is thin surface, middle is honeycomb structure; According to honeycomb structure can divide into single layer, double layer board.

PP honeycomb board also can one time forming, coat fabric at two sides, leather, with light weight and high strength, non-toxic, environment, shake absorption and cold-resistant, soundproof& heat preservation, moistureproof& heat insulation etc. advantage.

Special-shaped Surface Forming

According to the different material of products, and with full consideration to the product expansion and contraction, and gas venting nature, etc., we use high precision CNC processing equipment for the roller surface precision machining. The precision of the special surface forming roller will help ensure the quality of product to fully meet the need of users.Products may apply to drainage board, honeycomb panel, water stop plate, bubble wrap and other purposes.

Main technical specification

Model

Suitable material

Products width(mm)

Products thickness(mm)

Capacity(kg/h)

JWS75/75/75

PP

1200-2000

2-12

350-450

JWS100/100/100

PP

1200-2000

2-20

600-700

Note: The specifications are subject to change without prior notice.

Product image display

Read the full article

2 notes

·

View notes

Text

Aluminium honeycomb panel suppliers are companies that produce and distribute high-quality honeycomb panels made from aluminium. These panels consist of a core material made of hexagonal cells that are bonded between two layers of aluminium sheets, providing strength, durability, and lightness.

0 notes

Text

Aluminium Honeycomb Panels: Lightweight Giants of Modern Engineering

Aluminium honeycomb panels are a marvel of engineering, combining lightweight construction with remarkable strength and durability. These panels consist of a core made of hexagonal aluminium honeycomb cells sandwiched between two thin layers of aluminium sheets. While they might seem simple in design, their applications and benefits are vast and varied.

Unmatched Strength-to-Weight Ratio

One of the most striking features of aluminium honeycomb panels is their exceptional strength-to-weight ratio. The honeycomb structure provides incredible strength while keeping the overall weight of the panel relatively low. This makes them ideal for applications where weight reduction is crucial without sacrificing structural integrity.

Applications in Aerospace

In the aerospace industry, where every ounce matters, aluminium honeycomb panels are widely used in aircraft construction. They are utilized in aircraft interiors for wall panels, flooring, ceiling panels, and other structural components. Their lightweight nature helps reduce fuel consumption while maintaining the structural integrity necessary for flight safety.

Architectural Marvels

Beyond aerospace, aluminium honeycomb panels have found their way into architectural designs, revolutionizing the construction industry. Their versatility allows architects and designers to create innovative structures that are both visually stunning and structurally sound. From exterior cladding to interior partitions, these panels offer endless possibilities for modern architecture.

Energy Efficiency and Sustainability

Aluminium honeycomb panels also contribute to energy efficiency and sustainability in construction. Their lightweight nature reduces the load on buildings, resulting in lower energy consumption for heating, cooling, and transportation during construction. Additionally, aluminium is highly recyclable, making these panels an eco-friendly choice for green building projects.

Versatility in Transportation

In addition to aerospace applications, aluminium honeycomb panels are utilized in various transportation sectors, including automotive and marine industries. In automobiles, they are used for interior components, such as door panels, floors, and trunk liners, contributing to improved fuel efficiency. In marine applications, they offer lightweight solutions for boat hulls, decks, and bulkheads, enhancing performance and fuel economy.

Fire Resistance and Safety

Safety is paramount in any application, and aluminium honeycomb panels excel in this regard as well. Their inherent fire-resistant properties make them suitable for use in environments where fire safety is a concern, such as building interiors and transportation vehicles. Additionally, their high strength ensures structural integrity even under extreme conditions, providing peace of mind to architects, engineers, and occupants alike.

Cost-Effective Solutions

Despite their advanced engineering and superior performance, aluminium honeycomb panels offer cost-effective solutions for various industries. Their long lifespan, low maintenance requirements, and energy-efficient properties translate to significant cost savings over the lifetime of a project. Moreover, their lightweight nature reduces transportation and installation costs, further enhancing their cost-effectiveness.

Conclusion

Aluminium honeycomb panels represent the pinnacle of modern engineering, offering a perfect blend of strength, durability, versatility, and sustainability. From aerospace to architecture, transportation to construction, these panels have transformed industries and opened doors to endless possibilities. As technology advances and new innovations emerge, aluminium honeycomb panels are sure to remain at the forefront of modern design and engineering, shaping the world we live in for generations to come.

Stay informed about the latest advancements in rail technology by following our updates on Tumblr and visiting MetaCor Rail Applications.

0 notes

Text

IMAX New 65mm Film Cameras: Prototype and Features Revealed

IMAX has revealed more fascinating details on the upcoming 2nd generation of its new fleet of 65mm film cameras. The new cameras will be made from the same materials that belong to Formula One and fighter jets. That means, alloys of carbon fiber and Titanium, honeycomb sandwich panels, wireless connectivity, new optics, a five-inch full-color display, and more. The goal is to make those beasts more user-friendly. ... "And besides the body is getting new optics, a five-inch full-color display for user interaction, wireless connectivity, all the while the camera’ actually taking 15 perf IMAX analog film in 18K, that’s super exciting." -- Milos Popvic – Principal Engineer at IMAX

1 note

·

View note

Text

Aluminium Honeycomb Composite Panel is a type of sandwich panel consisting of two thin aluminium sheets bonded to an aluminium honeycomb core. This combination results in a lightweight and strong panel with excellent thermal and acoustic insulation properties. Ecocomb Aluminium honeycomb composite panels are commonly used in the construction, aerospace, and transportation industries due to their durability, stability, and resistance to corrosion. The panels can be customised in terms of size, shape, and color to meet the specific requirements of various applications. They are also easy to install and maintain, making them a popular choice for various structures, partitions, and cladding systems.

0 notes

Link

Key adapters for the first crewed Artemis missions are manufactured at NASA’s Marshall Space Flight Center in Huntsville, Alabama. The cone-shaped payload adapter, left, will debut on the Block 1B configuration of the SLS rocket beginning with Artemis IV, while the Orion stage adapters, right, will be used for Artemis II and Artemis III. NASA/Sam Lott A test version of the SLS (Space Launch System) rocket’s payload adapter is ready for evaluation, marking a critical milestone on the journey to the hardware’s debut on NASA’s Artemis IV mission. Comprised of two metal rings and eight composite panels, the cone-shaped payload adapter will be part of the SLS Block 1B configuration and housed inside the universal stage adapter atop the rocket’s more powerful in-space stage, called the exploration upper stage. The payload adapter is an evolution from the Orion stage adapter used in the Block 1 configuration of the first three Artemis missions that sits at the topmost portion of the rocket and helps connect the rocket and spacecraft. “Like the Orion stage adapter and the launch vehicle stage adapter used for the first three SLS flights, the payload adapter for the evolved SLS Block 1B configuration is fully manufactured and tested at NASA’s Marshall Space Flight Center in Huntsville, Alabama,” said Casey Wolfe, assistant branch chief for the advanced manufacturing branch at Marshall. “Marshall’s automated fiber placement and large-scale integration facilities provide our teams the ability to build composite hardware elements for multiple Artemis missions in parallel, allowing for cost and schedule savings.” Teams at Marshall manufactured, prepared, and move the payload adapter test article. The payload adapter will undergo testing in the same test stand that once housed the SLS liquid oxygen tank structural test article.NASA Teams at Marshall manufactured, prepared, and move the payload adapter test article. The payload adapter will undergo testing in the same test stand that once housed the SLS liquid oxygen tank structural test article.NASA Teams at Marshall manufactured, prepared, and move the payload adapter test article. The payload adapter will undergo testing in the same test stand that once housed the SLS liquid oxygen tank structural test article.NASA Teams at Marshall manufactured, prepared, and move the payload adapter test article. The payload adapter will undergo testing in the same test stand that once housed the SLS liquid oxygen tank structural test article. NASA At about 8.5 feet tall, the payload adapter’s eight composite sandwich panels, which measure about 12 feet each in length, contain a metallic honeycomb-style structure at their thickest point but taper to a single carbon fiber layer at each end. The panels are pieced together using a high-precision process called determinant assembly, in which each component is designed to fit securely in a specific place, like puzzle pieces. After manufacturing, the payload adapter will also be structurally tested at Marshall, which manages the SLS Program. The first structural test series begins this spring. Test teams will use the engineering development unit – an exact replica of the flight version of the hardware – to check the structure’s strength and durability by twisting, shaking, and applying extreme pressure. While every Block 1B configuration of the SLS rocket will use a payload adapter, each will be customized to fit the mission’s needs. The determinant assembly method and digital tooling ensure a more efficient and uniform manufacturing process, regardless of the mission profile, to ensure hardware remains on schedule. Data from this test series will further inform design and manufacturing processes as teams begin manufacturing the qualification and flight hardware for Artemis IV. NASA is working to land the first woman, first person of color, and its first international partner astronaut on the Moon under Artemis. SLS is part of NASA’s backbone for deep space exploration, along with the Orion spacecraft and Gateway in orbit around the Moon and commercial human landing systems, next-generational spacesuits, and rovers on the lunar surface. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single launch. News Media Contact Corinne BeckingerMarshall Space Flight Center, Huntsville, [email protected]

0 notes

Text

Exploring the Versatility: The Benefits of Aluminum Honeycomb Panels Across Industries

Innovation in construction materials has paved the way for revolutionary solutions in architecture, transportation, and various industrial sectors. One such advancement is the utilization of aluminum honeycomb panels. These lightweight yet sturdy structures offer a multitude of benefits across diverse applications, ranging from aerospace to interior design. In this blog, we delve into the…

View On WordPress

#ACP panels#ACP sheet#Aluminium composite panels#Aluminium Honeycomb Panels#Eurobond#Eurobond ACP#Eurobond ACP panels#Honeycomb Sandwich Panel

0 notes

Text

Aluminium honeycomb sandwich panels are a type of composite material used in construction and manufacturing. They consist of two thin sheets of aluminum, bonded to a lightweight honeycomb core made of aluminum or other materials.

0 notes

Text

Sandwich Sheets: Versatile Building Materials for Modern Construction

In the world of construction and architecture, innovation in building materials is a constant endeavor to meet the evolving demands of modern infrastructure. One such innovation is the use of sandwich sheets, a versatile and efficient construction material. In this article, we will explore what sandwich sheets are, their various types, applications, and the benefits they bring to construction projects.

Understanding Sandwich Sheets:

Sandwich sheet price in kerala , also known as composite panels or sandwich panels, are three-layered structures consisting of two outer layers (called facings) and a core material sandwiched between them. The core material can vary, including options like foam, polyurethane, mineral wool, or honeycomb structures. The facings are typically made of materials like metal, fiberglass, or high-density plastics.

Types of Sandwich Sheets:

1. Metal-faced Sandwich Sheets: These panels have metal facings, such as steel or aluminum, making them robust and weather-resistant. They are commonly used for roofing, wall cladding, and industrial applications.

2. Insulated Sandwich Sheets: Featuring an insulating core, these panels provide excellent thermal and acoustic insulation. They are used in constructing energy-efficient buildings and cold storage facilities.

3. Honeycomb Sandwich Sheets: These lightweight panels have a honeycomb-like core, often made of materials like aluminum or aramid fiber. They are used in aerospace, marine, and automotive industries due to their high strength-to-weight ratio.

4. Fire-resistant Sandwich Sheets: Designed to meet stringent fire safety standards, these panels have fire-resistant facings and cores. They find applications in commercial buildings and fire-rated partitions.

Applications of Sandwich Sheets:

1. Construction: Sandwich sheets are widely used in construction for roofing, wall cladding, and façade systems. Their versatility, insulation properties, and aesthetic options make them a preferred choice for modern buildings.

2. Cold Storage: Insulated sandwich sheets are ideal for constructing cold storage warehouses and refrigerated transportation vehicles, as they help maintain temperature control.

3. Industrial Facilities: These sheets are used to create partitions, enclosures, and soundproof barriers in industrial settings, improving safety and productivity.

4. Transportation: In the automotive and aerospace industries, sandwich sheets are employed to reduce weight while maintaining structural integrity.

5. Renewable Energy: Sandwich sheets are used in solar panel mounting systems and wind turbine components due to their lightweight and durable characteristics.

Advantages of Sandwich Sheets:

1. Strength and Durability: Sandwich sheets provide exceptional strength and structural stability, ensuring long-lasting performance.

2. Energy Efficiency: Insulated panels contribute to energy efficiency by reducing heat transfer and maintaining a consistent indoor climate.

3. Speed of Construction: Their prefabricated nature allows for quicker construction, saving time and labor costs.

4. Versatility: Sandwich sheets come in various sizes, colors, and finishes, offering architects and builders flexibility in design.

5. Fire and Sound Resistance: Some sandwich panels are designed to meet fire safety and sound insulation requirements.

Conclusion:

Sandwich sheets have revolutionized the construction industry with their versatility, strength, and efficiency. Whether it's creating energy-efficient buildings, robust industrial facilities, or innovative transportation solutions, these panels have become indispensable in modern construction and design. As technology advances, we can expect even more innovative uses for sandwich sheets in the evolving world of architecture and infrastructure.

For more info. visit us:

Roofing accessories

Colour coated roofing sheets supplier in bangalore

Best quality roofing sheetsMetal sheet color

0 notes

Text

PP Honeycomb Board Extrusion Line

Main application

1. Used for car trunk cover board, trunk clapboard, trunk carpet substrate, side wall decortation board, ceiling etc. interior place.

2. Used for manufacturing different kinds of high strength packing box.

PP honeycomb board through extrusion method made three layers sandwich board of one time forming, two sides is thin surface, middle is honeycomb structure; According to honeycomb structure can divide into single layer, double layer board.

PP honeycomb board also can one time forming, coat fabric at two sides, leather, with light weight and high strength, non-toxic, environment, shake absorption and cold-resistant, soundproof& heat preservation, moistureproof& heat insulation etc. advantage.

Special-shaped Surface Forming

According to the different material of products, and with full consideration to the product expansion and contraction, and gas venting nature, etc., we use high precision CNC processing equipment for the roller surface precision machining. The precision of the special surface forming roller will help ensure the quality of product to fully meet the need of users.Products may apply to drainage board, honeycomb panel, water stop plate, bubble wrap and other purposes.

Main technical specification

Model

Suitable material

Products width(mm)

Products thickness(mm)

Capacity(kg/h)

JWS75/75/75

PP

1200-2000

2-12

350-450

JWS100/100/100

PP

1200-2000

2-20

600-700

Note: The specifications are subject to change without prior notice.

Product image display

Read the full article

0 notes

Text

Ecocomb Sandwich Panels Mumbai refers to panels made in Mumbai, India using the Ecocomb technology. Ecocomb sandwich panels are composite materials made of two layers of sheets (typically metal or metal-coated) with a unique core layer of honeycomb-like structure between them. This structure provides added strength and rigidity to the panel, making it a popular choice in construction and interior design industries. Companies in Mumbai that manufacture Ecocomb sandwich panels typically offer a range of products in different sizes and finishes, catering to various customer requirements.

0 notes

Text

What is the purpose of the EN 45545 standard?

Bolstering Railway Safety: The EN 45545 Directive

Rail safety is a critical concern for passengers, operators, and authorities responsible for railway systems worldwide. As technology evolves, innovative solutions are continually sought to enhance safety measures and mitigate potential risks. One such solution making waves in the realm of rail safety is the use of Aluminium Honeycomb Panels.

Understanding Aluminium Honeycomb Panels

Aluminium Honeycomb Panels are composite materials constructed with a honeycomb core sandwiched between thin layers of aluminium. This unique design provides exceptional strength and rigidity while keeping the panels lightweight. These panels find application in various industries due to their versatility and durability, and they are particularly well-suited for use in railway systems.

The Role of Aluminium Honeycomb Panels in Rail Safety

Aluminium Honeycomb Panels play a crucial role in fortifying rail safety in several ways:

Enhanced Structural Integrity: Railway vehicles and infrastructure must withstand a range of stresses and strains during operation. Aluminium Honeycomb Panels contribute to the structural integrity of rail components, such as cabins, flooring, walls, and ceilings. Their high strength-to-weight ratio ensures that these components remain robust and resilient even under challenging conditions.

Fire Safety: Fire incidents pose a significant risk in railway environments. Aluminium Honeycomb Panels offer inherent fire resistance, thanks to the non-combustible properties of aluminum and the minimal combustible content of the honeycomb core. In the event of a fire, these panels help contain flames and limit smoke emissions, allowing passengers and crew members to evacuate safely.

Impact Resistance: Railway vehicles may encounter collisions or impacts during their lifespan. Aluminium Honeycomb Panels excel in impact resistance, absorbing and dissipating energy to minimize damage and protect passengers in the event of a collision. This feature enhances the safety of rail vehicles and reduces the risk of injury to occupants.

Durability and Longevity: Railway infrastructure is subjected to harsh environmental conditions and heavy usage. Aluminium Honeycomb Panels are known for their durability and resistance to corrosion, moisture, and temperature fluctuations. Their longevity ensures reliable performance over time, reducing maintenance requirements and enhancing the overall safety and reliability of rail systems.

Lightweight Design: The lightweight nature of Aluminium Honeycomb Panels offers additional benefits for rail safety. By reducing the weight of railway components, these panels contribute to improved fuel efficiency and reduced energy consumption. Additionally, lighter rail vehicles experience less wear and tear on tracks, minimizing maintenance costs and prolonging the lifespan of infrastructure.

Design Flexibility: Aluminium Honeycomb Panels offer designers and engineers flexibility in terms of design and customization. They can be easily fabricated into various shapes and sizes to meet specific project requirements, allowing for innovative designs that prioritize both safety and aesthetics.

Conclusion

Aluminium Honeycomb Panels are a game-changer in the realm of rail safety, offering a unique combination of strength, durability, fire resistance, and lightweight design. As railway operators and manufacturers continue to prioritize safety measures and improve the performance of rail systems, Aluminium Honeycomb Panels emerge as a reliable solution. By fortifying structural components and mitigating risks, these panels contribute to the overall safety and efficiency of rail transportation networks.

0 notes