#Hospital air dryer manufacturers

Text

Hospital Air Dryer

Trident is a directing Medical Air Dryer manufacturer of innovative products in Air treatment and provides optimum services to Hospital Air Dryer Manufacturers which support antiseptic, breathable air for patients.

0 notes

Text

Medical Air Dryer manufacturers

Trident is a directing Medical Air Dryer Manufacturers of innovatory products in Air treatment provides optimum services in Hospital Air Dryer Manufacturers which supports antiseptic, breathable air for the patients.

0 notes

Text

Comprehensive Solutions in Thermodynamic Services: A Leading Partner in Uttar Pradesh

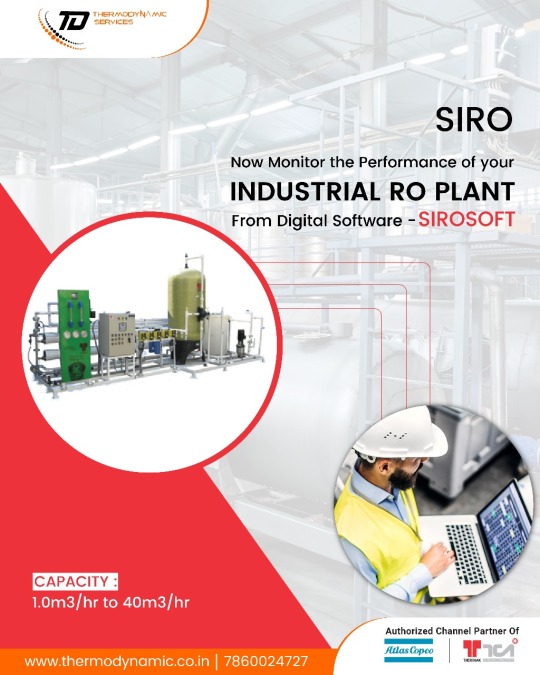

Introduction: In the bustling industrial landscape of Uttar Pradesh, Thermodynamic Services emerges as a beacon of excellence, catering to a diverse range of thermodynamic needs. With a rich history of collaboration with industry giants like Thermax Limited, Atlas Copco (India) Limited, and Buhler India Pvt. Limited, Thermodynamic Services stands as a trusted partner offering comprehensive solutions. Specializing in industrial air compressors, compressed air dryers, thermic fluid heaters, industrial water treatment plants, STP plants for hospitals, and ETP plants for industrial use in Kanpur and beyond, Thermodynamic Services is committed to addressing the most challenging issues in heat, energy, air, water, solar, and grain processing.

Industrial Air Compressor Manufacturer & Supplier in Kanpur: As a premier industrial air compressor manufacturer and supplier in Kanpur, Thermodynamic Services delivers top-of-the-line equipment tailored to meet the rigorous demands of modern industries. Drawing from years of expertise and partnerships with leading manufacturers, we provide cutting-edge solutions that ensure optimal performance and efficiency for our clients' operations.

Compressed Air Dryer / Refrigerated Air Dryer Supplier in Kanpur: Recognizing the critical importance of quality compressed air in industrial processes, Thermodynamic Services offers premium compressed air dryers and refrigerated air dryers. Our products guarantee the delivery of clean, dry air, free from moisture and contaminants, thereby safeguarding the integrity of our clients' operations and prolonging the lifespan of their equipment.

Thermic Fluid Heater Supplier/Manufacturer in Uttar Pradesh: In the realm of thermic fluid heating systems, Thermodynamic Services stands as a distinguished supplier and manufacturer in Uttar Pradesh. Our thermic fluid heaters are engineered to deliver efficient heat transfer, ensuring consistent performance and reliability across various industrial applications. With a focus on innovation and quality, we empower our clients to optimize their processes while minimizing energy consumption.

Industrial Water Treatment Plants Supplier/Manufacturer in Uttar Pradesh: Water is a precious resource, and Thermodynamic Services is committed to its responsible management through advanced water treatment solutions. As a leading supplier and manufacturer of industrial water treatment plants in Uttar Pradesh, we offer customized systems designed to meet the unique needs of each client. From filtration to purification, our solutions ensure the availability of clean water for industrial processes, enhancing productivity and sustainability.

STP Plant for Hospitals: Ensuring safe and sustainable wastewater management is imperative for healthcare facilities, and Thermodynamic Services provides tailored solutions with our STP (Sewage Treatment Plant) plants for hospitals. Compliant with regulatory standards and designed for efficiency, our STP plants effectively treat wastewater, mitigating environmental risks and promoting a healthier community.

ETP Plant for Industrial Use in Kanpur: Industries in Kanpur rely on efficient wastewater treatment, and Thermodynamic Services meets this demand with our ETP (Effluent Treatment Plant) plants for industrial use. Through advanced technologies and expert engineering, our ETP plants efficiently remove pollutants from industrial effluents, ensuring compliance with environmental regulations and fostering sustainable industrial practices.

Conclusion: Thermodynamic Services stands as a testament to excellence in thermodynamic solutions, driven by a commitment to innovation, quality, and customer satisfaction. With a proven track record of serving esteemed clients and addressing complex challenges, we continue to be the preferred partner for industries across Uttar Pradesh. Whether it's industrial air compressors, compressed air dryers, thermic fluid heaters, water treatment plants, or wastewater management solutions, Thermodynamic Services remains at the forefront, empowering industries to thrive in an ever-evolving landscape.

#Industrial air compressor manufacturer & supplier in kanpur#Air compressor dealers in Kanpur/ Uttar Pradesh#compressed air dryer / refrigerated air dryer supplier in kanpur#STP plant for hospitals#ETP Plant for industrial use in kanpur

0 notes

Text

Medical Air Dryer manufacturers

Trident is a directing Medical Air Dryer Manufacturers of innovatory products in Air treatment provides optimum services in Hospital Air Dryer Manufacturers which supports antiseptic, breathable air for the patients.

0 notes

Text

Advanced Metering Infrastructure (AMI) Market provides in-depth analysis of the market state of Advanced Metering Infrastructure (AMI) manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Advanced Metering Infrastructure (AMI) in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Advanced Metering Infrastructure (AMI) Market Report:

The report offers a comprehensive and broad perspective on the global Advanced Metering Infrastructure (AMI) Market.

The market statistics represented in different Advanced Metering Infrastructure (AMI) segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Advanced Metering Infrastructure (AMI) are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Advanced Metering Infrastructure (AMI).

Major stakeholders, key companies Advanced Metering Infrastructure (AMI), investment feasibility and new market entrants study is offered.

Development scope of Advanced Metering Infrastructure (AMI) in each market segment is covered in this report. The macro and micro-economic factors affecting the Advanced Metering Infrastructure (AMI) Market

Advancement is elaborated in this report. The upstream and downstream components of Advanced Metering Infrastructure (AMI) and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/advanced-metering-infrastructure-ami-market-100555

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Vein Finder MarketMarket Growth

Automobile Tire MarketMarket Analysis

Automotive LED Lighting MarketMarket Size

Global Peripheral Nerve Stimulators MarketMarket Share

Global Quartz Stone MarketMarket Growth

Specialty Pulp and Paper Chemicals MarketMarket

5G Security MarketMarket Share

Residential Air Purifiers MarketMarket Growth Rate

Sandalwood Oil MarketMarket Forecast

Global Analog Cheese MarketMarket Size

DNS, DHCP and IPAM (DDI) MarketMarket Growth

3D Display MarketMarket Analysis

Veterinary Imaging MarketMarket Size

Global Sports Hospitality MarketMarket Share

Global Robotic Vacuum Cleaner MarketMarket Growth

Welded Wire Mesh Panel MarketMarket

E-Signature MarketMarket Share

Drug-Eluting Balloon MarketMarket Growth Rate

Flow Switches MarketMarket Forecast

Global Organic PVC Stabilizers MarketMarket Size

4K UST Projectors MarketMarket Growth

Personalized Beauty Products MarketMarket Analysis

Skid Steer Loaders MarketMarket Size

Global Active Pharmaceutical Ingredient MarketMarket Share

Global Ready to Eat Rice MarketMarket Growth

Smart Water Cooler MarketMarket

Food Safety HACCP Software MarketMarket Share

Location-Based Services (LBS) and Real-Time Location Systems (RTLS) MarketMarket Growth Rate

Bacterial Vaginosis Drug MarketMarket Forecast

Global Stolen Vehicle Recovery System MarketMarket Size

Luxury Safari Tourism MarketMarket Growth

Telemedicine MarketMarket Analysis

Air Dryer MarketMarket Size

Global Biopharmaceutical CMO and CRO MarketMarket Share

Global Blue-green Algae Fertilizer MarketMarket Growth

Bus Handrail MarketMarket

Cricket Farming MarketMarket Share

Parallel Drive Actuator Market Market Growth Rate

Reflow Oven for PCB and Semiconductor MarketMarket Forecast

0 notes

Text

Top 5 Steam Boiler Manufacturers in India

What is Steam Boiler?

A steam boiler is a closed vessel designed to convert water into steam through the application of heat. This process typically involves the combustion of fuels such as coal, natural gas, or biomass, generating thermal energy that heats water within the boiler’s chamber. As the water reaches its boiling point, steam is produced under high pressure, ready to be harnessed for various applications.

Types of Steam Boiler:

1. Fire-Tube Boilers:

Fire-tube boilers have a cylindrical shell containing water and tubes running through it. Hot gases from combustion pass through these tubes, heating the water and generating steam. They are typically used for low to medium pressure applications such as heating buildings, processing plants, and small industrial processes.

2. Water-Tube Boilers:

Water-tube boilers have water-filled tubes that are heated externally by combustion gases. These boilers can withstand higher pressures and temperatures, making them suitable for power generation, large-scale industrial processes, and applications requiring high steam output.

3. Electric Boilers:

Electric boilers use electricity to generate steam. They are clean, quiet, and efficient, making them suitable for applications where emissions must be minimized, such as hospitals, laboratories, and residential buildings. Electric boilers are also commonly used in areas where natural gas is not readily available.

4. Biomass Boilers:

Biomass boilers use organic materials such as wood chips, agricultural residues, or biogas to generate steam through combustion. They offer a sustainable alternative to fossil fuels and are commonly used in industries such as forestry, agriculture, and waste management.

5. Hybrid Boilers:

Hybrid boilers combine different technologies, such as fire-tube and water-tube designs, to optimize performance and efficiency. They are versatile and can be customized to meet specific requirements, making them suitable for a wide range of applications, including heating, power generation, and industrial processes.

6. Condensing Boilers:

Condensing boilers are designed to maximize energy efficiency by recovering heat from exhaust gases that would otherwise be lost. They achieve this by condensing water vapor in the exhaust gases, releasing latent heat and increasing overall efficiency. Condensing boilers are commonly used in residential and commercial heating systems.

7. Package Boilers:

Package boilers are factory-assembled units that come pre-wired, pre-piped, and pre-tested, making them easy to install and operate. They are often used in temporary or remote locations, as well as in industries where space is limited or where rapid deployment is required.

8. Modular Boilers:

Modular boilers consist of multiple smaller units that can be combined to meet fluctuating steam demand or provide redundancy in critical applications. They offer flexibility, scalability, and ease of maintenance, making them well-suited for industries with varying steam requirements.

Applications of Steam Boiler:

1. Power Generation:

Steam turbines powered by steam boilers are used in thermal power plants to generate electricity. The steam produced by the boiler drives the turbine, which converts thermal energy into mechanical energy, powering electrical generators.

2. Industrial Processes:

Steam boilers are integral to numerous industrial processes, including chemical manufacturing, petrochemical refining, pulp and paper production, textile manufacturing, and food processing. They provide heat for reactors, distillation columns, dryers, sterilizers, and other equipment.

3. Heating and HVAC Systems:

Steam boilers are used for space heating and domestic hot water production in residential, commercial, and institutional buildings. They provide warmth through radiators, baseboard heaters, and underfloor heating systems, and they can also be used in HVAC systems for air humidification and dehumidification.

4. Cogeneration and Combined Heat and Power (CHP):

Steam boilers are often employed in cogeneration systems, where they simultaneously produce steam for process heating or power generation and capture waste heat for other applications, such as space heating, water heating, or absorption cooling. CHP systems improve overall energy efficiency and reduce utility costs.

5. District Heating:

Steam boilers play a crucial role in district heating systems, where steam or hot water is distributed from a central energy plant to multiple buildings or residential complexes for space heating, water heating, and other thermal energy needs. District heating systems improve energy efficiency and reduce greenhouse gas emissions compared to individual heating systems.

6. Agricultural Applications:

Steam boilers are used in agricultural operations for tasks such as soil sterilization, greenhouse heating, and grain drying. They provide heat for crop drying to preserve quality and reduce moisture content, enhancing storage and transportation efficiency.

7. Marine Propulsion:

Steam boilers power steam turbines in marine propulsion systems, driving ships and maritime vessels across oceans and waterways. Marine boilers produce steam to turn the ship’s propeller, providing propulsion for cargo ships, passenger vessels, and naval ships.

8. Pharmaceutical and Healthcare Facilities:

Steam boilers are essential in pharmaceutical manufacturing for sterilizing equipment, sanitizing surfaces, and producing purified water for injection. They are also used in healthcare facilities for autoclaving medical instruments, sterilizing surgical equipment, and providing steam for laundry and sanitation purposes.

9. Environmental Remediation:

Steam boilers are utilized in environmental remediation projects for soil vapor extraction, steam stripping, and thermal desorption. They provide heat for treating contaminated soil and groundwater, removing volatile organic compounds (VOCs) and hazardous substances from the environment.

Best Steam Boiler Manufacturer in India

If you are looking for Best Steam Boiler manufacturer in India, look no further than Steamax Energy India, we are a leading manufacturer and supplier of Industrial Steam Boiler in India. For more details, please contact us!

Website :- https://www.steamaxenergyindia.com/

Contact No. :- 7053901803

Email :- [email protected]

#steam boiler manufacturer#steam boiler manufacturer in India#Top steam boiler manufacturer in India#Best steam boiler manufacturer in India#steam boiler supplier#steam boiler supplier in India#Top supplier of steam boiler in India#steamax energy india

1 note

·

View note

Text

Beyond Borders: The Global Freeze Drying Market Offers Hope for Millions

The global Freeze Drying market a projected 8.6% compound annual growth rate (CAGR) from 2024 to 2034. A worth of USD 1,262.78 million is projected for 2024. By 2034, the market value is anticipated to reach USD 2,881.55 million.

The food processing and pharmaceutical industries are growing, which has led to a considerable increase in the usage of freeze drying as a method of preserving perishable items. Demand for freeze-dried goods is being driven by this industry, which offers numerous advantages such as improved desiccant drying and air-drying efficiency.

Enhance Research With a Sample Report:

https://www.futuremarketinsights.com/reports/sample/rep-gb-15758

Key Takeaways:

The global freeze drying market is estimated at US$1.26 billion in 2024 and is projected to reach US$2.88 billion by 2034, growing at a robust CAGR of 8.6%.

The expanding food processing and pharmaceutical industries are key drivers of market growth.

Rising awareness of freeze drying’s advantages, such as superior drying efficiency and product preservation, is fueling demand.

Competitive Analysis

The market for food freeze-drying machines has a competitive landscape with multiple freeze-drying manufacturers driving innovation and technological advancement. Leading providers of freeze drying exhibit creativity and innovation in a variety of technologies. Azbil Corporation, Zirbus Technology GmbH, and HOF Sonderanlagenbau GmbH all exhibit dependability and creative problem-solving.

The unique advantages of Cryotec.Fr, MechaTech Systems Ltd., and Millrock Technology, Inc. improve the competitive environment and drive the development of freeze-drying technology. Cuddon Freeze Dry, Martin Christ Gefriertrocknungsanlagen GmbH, and SP Industries, Inc. have a significant impact on the freeze drying market dynamics with their state-of-the-art lyophilized goods.

Pivotal Freeze Drying Providers:

Azbil Corporation

Zirbus Technology GmbH

HOF Sonderanlagenbau GmbH

Millrock Technology, Inc.

Cryotec.Fr

MechaTech Systems Ltd.

SP Industries, Inc.

Martin Christ Gefriertrocknungsanlagen GmbH

Cuddon Freeze Dry

Neologic Engineers Private Limited

Labconco Corporation

BÜCHI Labortechnik AG

Yamato Scientific America Inc.

Freeze Drying Systems Ltd.

Freeze Drying Systems Pvt. Ltd.

IMA – Industria Macchine Automatiche S.p.A.

GEA Group

Key Segments

By Product:

Dryer

Tray-style dryers

Rotary Freeze Dryers

Manifold Freeze Dryers

Accessories

Drying Chamber

Vacuum System

CIP (Clean-in-place) Systems

Other Accessories

By Scale of Operations:

Pilot-scale

Laboratory-scale

Industrial-scale

By Distribution Channel:

Biopharmaceutical Companies

Food and Beverage Companies

Academic and Research Institutes

CRO and CMO

Hospitals

Research Laboratories

By Region:

North America

Latin America

Europe

South Asia

East Asia

Oceania

Middle East and Africa (MEA)

0 notes

Text

Enhance Air Quality and Efficiency with Commercial Dryer Duct Cleaning Equipment

The core of every cooling system, whether in a home or commercial building, is the air duct system. Commercial dryer duct cleaning equipments used by professionals for duct cleaning and ensures that the cooling system runs more effectively and efficiently while also assisting in the reduction of various health issues. The lint and dust that build up in the ductwork pose a health risk because they can provide the perfect environment for bacteria to flourish.

During the summer, homes using evaporative coolers need to make sure they are cleaned and evaporative cooling replacement vents are installed for better cooling. In MAelbourne, evaporative cooling is quite common, and these units frequently release polluted air if not cleaned. In commercial settings such as restaurants, hotels, hospitals, and other facilities, as well as in company buildings and offices, the quality of the air has great significance. Duct cleaning is also essential for a business to function well in restaurants, offices, and hospitals.

A Selection of Services Provided by the Top Duct Cleaning Firms

Residential Duct Cleaning: This greatly reduces allergens in the home, especially for small children and the elderly who are protected from issues like headaches and blocked noses. The ducts are cleaned and then given a natural oil combination to disinfect and deodorise them.

Commercial Duct Cleaning: Duct cleaning services are required to keep the air that people breathe in office buildings, schools, cold storage facilities, general manufacturing facilities, and many other structures healthy.

Evaporative Cooler Cleaning: As is well known, coolers accumulate a lot of dust, dirt, and other debris, which can lead to malfunctions. The filter pads and circulation pump occasionally become clogged, which might potentially damage the cooler, therefore cleaning is required.

Split System Cleaning: The main cause of germs growing within air conditioners is moisture, and these bacteria and mould can cause asthma, nausea, and other health problems.

The air becomes significantly more fragrant and odourless after duct cleaning. Provide your information to the best duct cleaning providers to receive a free quote.

Source

0 notes

Text

Air Dryer Suppliers in India

Buying an Air Dryer: What You Need to Know

Picking the best air dryer from Colt Equipment's (p) Ltd, one of the best Air Dryer Suppliers in India, for your company's requirements is crucial. It can make or break a business, from manufacturing to hospitality.

With so many models, choosing an air dryer from Colt Equipment's (p) Ltd requires careful consideration of several factors. Energy efficiency, capacity, and other factors must be considered before buying. This article will compare the features and benefits of current air dryers from Air Dryer Suppliers in India to help you choose one for your business.

Find out what you need for drying air.

The first step in selecting the best air dryer from Colt Equipment's (p) Ltd for your company is figuring out what kinds of air drying you'll need. The first step is to determine the required material drying frequency, volume, and type. Having this knowledge will allow you to pick the perfect size and model. Think about where you plan on using the dryer and whether you need it whisper-quiet.

Take Your Capacity Needs into Account

Businesses must consider how much air they need to dry when calculating their capacity needs. How many liters of dry air per hour are required? Is the air-drying process continuous, or will it require periodic restarts throughout the day? Businesses must consider how often they must replace desiccant media or filters.

The air dryer's lifespan may change based on the moisture content and volume of the air it is drying. Paying close attention to these nuances will help businesses choose the best system from Colt Equipment's (p) Ltd, the Air Dryer Suppliers in India.

Examine the Price of Repairs and Setup

Budget for repairs and setup before buying an air dryer, as these costs add up quickly. Find a model that fits your needs and budget with a specialist. Make sure the air dryer you want fits your budget by considering installation and maintenance costs. When making a business purchase, consider each component's potential lifespan and the total cost. Businesses that maximize their resources should consider these factors before settling on an air dryer.

Check the Star Ratings for Energy Savings

There are a few important factors for air dryers from Air Dryer Suppliers to remember when determining an air dryer's energy efficiency for commercial purposes.

You can estimate the unit's daily energy consumption from this. Your room size is the most important factor in choosing a model without wasting energy.

Check your local electricity rates to see if energy-saving equipment-using businesses qualify for rebates. Last but not least, check the manufacturer's warranty or guarantee to ensure that any air dryers you buy will have any foreseeable operational issues attended to promptly and affordably.

Research Air Dryer Types

When researching air dryers for your business, many factors must be considered. When buying business equipment, price is always a factor.

Importantly, compare prices between brands and models and understand what features each model offers. Air dryers have different efficiency, noise output, energy-saving settings, and smart technology control systems.

To find the best air dryer for their needs, businesses should consider how they will use their new machine and its features. Based on daily usage and whether larger spaces need multiple units or one powerful machine, air drying machines will vary in size and capacity.

Conclusion

An essential piece of equipment is a commercial air dryer. It helps maintain a healthy and pleasant working atmosphere by reducing airborne particles and humidity. Size, noise level, energy efficiency, cost, and maintenance are some factors to consider when shopping for an air dryer from Colt Equipment's (p) Ltd, one of the best Air Dryer Suppliers.

0 notes

Text

Enhancing Efficiency and Performance: The Role of Industrial Equipment in Hospitality and Healthcare

In the dynamic realms of hospitality and healthcare, where seamless operations and top-notch services are paramount, the significance of industrial equipment cannot be overstated. From aiding in efficient hotel and hospital engineering to facilitating impeccable kitchen and laundry operations, industrial equipment plays a pivotal role in elevating the overall quality of these sectors.

Industrial Equipment Suppliers and Dealers: Navigating the Choices

Industrial equipment is the backbone of modern hospitality and healthcare industries. To ensure optimal functionality and cost-effective operations, it's crucial to partner with reputable industrial equipment suppliers and dealers. These suppliers offer a wide array of specialized machinery and tools that cater to the diverse needs of hotels and hospitals.

When seeking industrial equipment suppliers, it's important to look for those with a proven track record, quality certifications, and a diverse portfolio. Reputable suppliers often collaborate with renowned manufacturers to provide innovative and high-performance solutions. Establishing a strong rapport with reliable dealers ensures access to the latest technologies and ongoing technical support, enabling smooth operations without unnecessary downtime.

Hotel and Hospital Engineering: Precision at its Best

Behind the scenes, hotel and hospital engineering teams work tirelessly to ensure uninterrupted services. Industrial equipment forms the backbone of their efforts, enabling the efficient management of various systems. From heating, ventilation, and air conditioning (HVAC) systems to energy management solutions, industrial-grade equipment is a necessity to maintain a comfortable and safe environment for guests and patients alike.

Cutting-edge industrial equipment not only enhances the overall experience but also contributes to energy conservation and sustainability. With smart building technologies becoming increasingly prevalent, integrated equipment allows for centralized monitoring and control, optimizing resource usage and minimizing waste.

Kitchen Equipment: Where Culinary Excellence Meets Efficiency

In the hospitality sector, the kitchen is the heart of every establishment. Industrial kitchen equipment caters to the high demands of hotels and restaurants, facilitating the preparation of delectable dishes on a large scale. High-capacity ovens, commercial-grade refrigerators, and advanced cooking appliances are indispensable for meeting customer expectations and maintaining a smooth kitchen workflow.

Incorporating efficient kitchen equipment doesn't just streamline operations; it also contributes to food safety and hygiene. Temperature-controlled storage, rapid cooking technologies, and easy-to-clean surfaces are some features that prevent contamination and ensure compliance with rigorous health and safety standards.

Laundry Equipment: A Cornerstone of Cleanliness

Behind every clean and crisp hotel room or hospital bed lies a sophisticated laundry operation. Industrial laundry equipment plays a crucial role in managing the enormous volume of linens, uniforms, and other textiles in these environments. From high-capacity washing machines and dryers to industrial ironing systems, these machines are designed to handle heavy workloads while maintaining the integrity of fabrics.

Efficient laundry equipment is not only about cleanliness but also about resource efficiency. Modern machines incorporate features like water recycling, precise detergent dosing, and energy-saving modes, contributing to cost savings and environmental responsibility.

In conclusion, industrial equipment is the unsung hero that empowers the seamless functioning of hospitality and healthcare industries. From the intricate machinery powering hotel and hospital engineering to the culinary magic in commercial kitchens, and the precision of laundry operations, these sectors rely on industrial equipment to provide exceptional services.

Choosing the right industrial equipment suppliers and dealers is paramount to ensure access to top-quality machinery and reliable support. As technology continues to advance, these industries will undoubtedly witness even more innovative equipment that drives efficiency, sustainability, and excellence to new heights. So, the next time you enjoy a comfortable hotel stay or receive excellent healthcare services, remember the instrumental role that industrial equipment plays behind the scenes.

1 note

·

View note

Text

Your Trusted Source for Washroom Products in Ireland

Welcome to Anona Ltd, your premier destination for high-quality washroom products in Ireland. We understand the significance of creating a clean, comfortable, and hygienic environment, and our extensive range of products is designed to meet all your washroom needs.

Anona Ltd takes pride in offering a diverse selection of washroom products, carefully curated to enhance both functionality and aesthetics. From sanitary ware and fittings to hand dryers, soap dispensers, and waste management solutions, we have everything you require to create a well-equipped washroom.

Our commitment to excellence is reflected in the brands we partner with. We collaborate with renowned manufacturers who share our passion for quality and innovation. This allows us to offer you a wide range of options, ensuring that you find the perfect products to suit your specific requirements.

When it comes to sanitary ware, we understand the importance of durability and hygiene. Our range includes sleek and modern toilets, urinals, basins, and accessories, all crafted with meticulous attention to detail. We prioritize easy maintenance, water efficiency, and user comfort, providing you with products that are both practical and visually appealing.

In addition to sanitary ware, our range of washroom accessories is designed to enhance convenience and hygiene. Our soap dispensers offer efficient and controlled product distribution, promoting hand hygiene. We also provide a selection of paper towel dispensers, hand dryers, and air fresheners, ensuring a fresh and pleasant environment for all users.

At Anona Ltd, we recognize the need for eco-friendly solutions. We offer a variety of sustainable options, including water-saving fixtures and energy-efficient hand dryers. By incorporating these products into your washroom, you not only contribute to environmental conservation but also reduce operating costs in the long run.

Waste management is another essential aspect of a well-maintained washroom. Our range of bins and waste receptacles are designed to promote cleanliness and proper waste disposal. We offer solutions for both general waste and recycling, allowing you to create an environmentally conscious washroom environment.

At Anona Ltd, we pride ourselves on providing excellent customer service. Our knowledgeable team is available to assist you in choosing the right products for your washroom project, ensuring that you make informed decisions. We can also provide guidance on installation and maintenance, ensuring a smooth and hassle-free experience.

We understand that each washroom project is unique, and we are committed to meeting your specific requirements. Whether you are upgrading a commercial facility, renovating a hospitality establishment, or simply refreshing your home washroom, our extensive range of products caters to all budgets and design preferences.

Anona Ltd is dedicated to delivering products of the highest quality and reliability. We believe that a well-designed and properly equipped washroom contributes to a positive overall experience for users. With our comprehensive range of washroom products in Ireland, you can create a space that combines functionality, hygiene, and style.

Browse our extensive catalog and explore the possibilities for your washroom project. Contact Anona Ltd today and let us assist you in transforming your washroom into a welcoming, hygienic, and visually appealing space.

#Cleaning Suppliers Dublin#Wholesale cleaning supplies Dublin#Dublin Cleaning Supplies#Commercial cleaning supplies Dublin#Cleaning products Dublin#"Cleaning Equipments Dublin#Best cleaning products Dublin#Affordable cleaning products Dublin#Wholesale commercial cleaning supplies Dublin#Chemical cleaning products Dublin#Paper products Dublin#Catering disposables Dublin#Cleaning Suppliers Ireland#Hygiene supplies Ireland#Green cleaning products Ireland#Window cleaning products Dublin#Washroom products Ireland

0 notes

Text

Medical Air Dryer manufacturers

Trident is a directing Medical Air Dryer manufacturer of innovative products in Air treatment that provides optimum services to Hospital Air Dryer Manufacturers which support antiseptic, breathable air for patients.

0 notes

Text

Which is the best medical air dryer manufacturer in India?

When it comes to medical equipment, choosing the best products that meet the highest safety and efficiency standards is essential. One such crucial medical equipment is a medical air dryer, used to dry compressed air for medical applications. In India, there are many manufacturers of medical air dryers, but Trident Pneumatics stands out as the best in the industry.

Trident Pneumatics has been a leading Medical Air Dryer manufacturer for over three decades. The company's commitment to excellence, innovation, and customer satisfaction has made it the preferred choice for customers across various industries, including healthcare. With a strong focus on research and development, Trident Pneumatics has developed state-of-the-art medical air dryers designed to meet the stringent requirements of the healthcare industry.

Trident Pneumatics' medical air dryers are manufactured using the latest technology and the highest quality materials to ensure optimal performance, reliability, and safety. The company's products are designed to remove moisture, oil, and other impurities from compressed air, ensuring that it is clean and dry for use in medical equipment. The medical air dryers are also designed to meet the highest hygiene standards, making them ideal for healthcare settings.

One of the critical features of Trident Pneumatics' medical air dryers is their energy efficiency. The company's products are designed to consume minimal energy, reducing operating costs and minimizing the carbon footprint. The medical air dryers are also easy to install and maintain, with user-friendly interfaces that enable quick and easy monitoring of the system's performance.

Trident Pneumatics' medical air dryers are available in various configurations to suit applications and requirements. The company offers a range of products, including desiccant dryers,

Refrigerated air dryer manufacturers and membrane dryers. Each product is designed to deliver superior performance, efficiency, and durability.

Trident Pneumatics' medical air dryers are manufactured in compliance with the highest quality and safety standards. The company's products are certified by international organizations, including ISO, CE, and ASME, ensuring they meet the strictest requirements for medical equipment. In addition, the company's products are backed by a comprehensive warranty, providing customers with peace of mind and confidence in their investments.

When choosing the best Medical Air Dryer manufacturers in India, Trident Pneumatics is a clear choice. With its commitment to excellence, innovation, and customer satisfaction, the company has developed state-of-the-art medical air dryers that meet the highest quality, safety, and efficiency standards. So, whether you are a healthcare provider or a medical equipment supplier, Trident Pneumatics' medical air dryers are the ideal choice for all your compressed air needs.

0 notes

Text

KDM Global is renowned as a leading manufacturer and retailer of this excellent assortment of laboratory autoclaves, glass distillation, laminar air flow, ice lined refrigerators, tray dryers, hospital autoclaves &sterilisers, hot air ovens, biosafety cabinets, electric tray dryers, laboratory hot air ovens, drying ovens, laboratory refrigerators, stability chambers, and other related products.

Bomb Calorimeter Applications

bomb thermometer a device that is mostly used to measure combustion temperatures. The reaction occurs in a sealed area known as the calorimeter proper, in constant thermal contact with its surroundings (the jacket).

A highly active test tool known as a digital bomb calorimeter is frequently used to calculate the amount of heat produced during the combustion of test samples that are both solid and liquid. Due to its small size, superior precision, and low power usage, it is highly sought after. This device's digital display provides output in legible form. A supply capacity of 20 pieces per month is available to our customers for the offered Digital Bomb Calorimeter.

SALIENT COMPONENTS:

Manual Calculation & Measurement

Temperature Accuracy 0.1 degrees Celsius Starting Temperature Increase & Fall 3 Digital LED Display

Note: Due to ongoing development, appearance and specifications are subject to change.

For more details contact us:

Website: https://kdmglobal.business.site

Email : [email protected]

Website : https://sites.google.com/view/kdmglobal/home

Contact :8218470498

0 notes

Text

AN OVERVIEW ON MEDICAL AIR PACKAGES

Pattons Medical Manufactures>An Overview on Medical Air Packages

A patient in the hospital who needs assistance breathing, either during surgery or through a ventilator, is administered medical air. Medical Air is defined in National Fire Protection Association (NFPA) Code 99 2018 in 5.1.3.6.1 to have the following characteristics:

It shall be supplied from cylinders, bulk containers, or medical air compressor sources, or it shall be reconstituted from oxygen USP and oil-free, dry nitrogen NF.

It shall meet the requirements of medical air USP.

It shall have no detectable liquid hydrocarbons.

It shall have less than 25 parts per million (ppm) gaseous hydrocarbons.

It shall have equal to or less than one milligram per cubic meter (mg/m3) of permanent particulates sized one micron or larger in the air at normal atmospheric pressure.

The air is delivered through a distribution piping system that ends with a medical air outlet within the room. Outlet requirements per room are governed by American Institute of Architects (AIA) Guidelines for Design and Construction of Hospitals and Healthcare Facilities.

Equipment is plugged into the medical air outlet to treat the patient. Many studies have been done determining the load required for medical air compressors. The sizing can be calculated using several methods. The U.S. Typical Method is the standard calculation for medical air in the United States. To calculate by this method the following steps are taken:

Count all outlets that will be served by this system by occupancy.

Multiply by simultaneous use factor.

Add the sum of all occupancy.

Add the number of ventilators.

This sizing process attempts to size by “worst case scenario,” which means all rooms would be occupied and using some amount medical air. Ventilators being the largest consumer of medical air especially adds to the total. It is highly unlikely all outlets would be used at one time in a facility; however, the facility has to be prepared and equipped for that scenario. This leaves many facilities frustrated with what they consider grossly oversized medical air compressors.

MEDICAL AIR CENTRAL SUPPLY SYSTEMS

NFPA 99 5.1.3.6 details the requirements and the limitations of medical air central supply systems and their installation within a healthcare facility in the United States. The defining requirement 5.1.3.6.2 Uses of Medical Air states that medical air sources shall be connected to the medical air distribution system only and shall only be used for human respiration and calibration of medical devices for respiratory equipment.

Medical air cannot be used in central sterile, to run instruments, or any other use outside of patient respiration. Therefore, multiple air compressors are used within a healthcare facility, but this article will only focus on Medical Air Central Supply Systems.

Oil free air compressors are used to eliminate the potential for hydrocarbons. The most common technologies are scroll, reciprocating, and rotary screw air compressors. In addition to the air compressor, the package normally contains aftercoolers, dryers, filters, receiver and monitoring equipment, such as a dewpoint monitor and CO monitor.

REDUNDANCY REQUIREMENT: AN IMPORTANT SIZING FACTOR

No one point of failure is allowed to ensure patient safety. NFPA 5.1.3.6.3.9 (B) states that medical air compressors shall be sufficient to serve the peak calculated demand with the largest single air compressor out of service. In no case shall there be fewer than two air compressors.

This means redundancy is required and one air compressor is never allowed. The smallest would be a duplex package. The redundancy also applies to filtration and dryers as well. When sizing an air compressor, it is important to size with the load being maintained even with one unit out of service. Therefore, in a triplex skid, two air compressors can run with one as backup. A quad package can run three and so on. The air compressors will still all run in sequence to maintain even run life on all the air compressors.

An efficient way to meet the peak calculated demand and satisfy the redundancy requirement is with multiplexing smaller horsepower (hp) units. In the past, large industrial air compressors were installed, with large being 30- or 50-hp in medical air applications. This means if one Operating Room is put into use, or one ventilator is brought on-line, a 30-hp air compressor would be started up to meet the demand. This air compressor would run two to three minutes, meet demand, and shut off. This cycle is repeated throughout the life of the unit.

By multiplexing smaller hp air compressors, such as 10- or 15 -hp machines, a facility can reduce their electrical consumption. When a demand is created only one air compressor runs. If that one air compressor cannot meet the demand, then another air compressor can come on and so forth (with one staying off for redundancy). Therefore, the facility is running one 15-hp air compressor versus a 30-hp machine. In the majority of applications, only one air compressor handles the load.

Multiplexing also allows for expandability. Healthcare construction projects are often open-ended leaving flexibility in the services that the hospital is going to provide. Also, due to budget constraints, sometimes space is left shelled for future expansion. Instead of guessing at the future or sizing for future, it is possible to put expandable panels and leave space on skids for future modules. This keeps capital costs down, and the facility will have a clearer understanding of its medical air usage.

Finally, multiplexing multiple scroll air compressors takes dramatically less space, saves considerable money on installations and has lower capital costs than Variable Speed Drive (VSD) rotary screw air compressors. Pattons Medical can have a complete medical air package with multiple scroll air compressors shipped as a complete single point connection package. In new construction, this will save the contractor any additional piping and electrical wiring for components. There would be a braze for the inlet/outlet and one wiring connection. For replacement equipment, the skids can be broken apart to fit through a 30-inch door and have unions for the connections when put in place.

THE INS AND OUTS OF DESICCANT DRYER TECHNOLOGY

Dryers are an integral part of the medical air compressor package and can have an impact on the sizing and efficiency. To maintain the requirement of a maximum dewpoint of 32 °F at 50 to 55 psi at any level of demand, and allow for flexibility in skid design, desiccant dryers have become the standard for medical air packages. They perform well in low-flow conditions that are common with medical air demand.

Desiccant dryers utilize towers that contain cartridges of activated alumina. The cartridge design versus loose desiccant eliminates dusting from desiccant and is sized based on demand. Therefore, the amount of air purged will be dramatically reduced requiring less demand from the air compressor. Desiccant dryers require a purge to regenerate the desiccant to continue the ability to dry the air. It is imperative for efficiency with medical air to utilize controls for demand-based purging. The dewpoint is monitored through the dewpoint sensor. In demand-based purging, the purge does not take place until the dewpoint reaches 14 °F. This almost eliminates the air compressor running for purge outside of demand. Another benefit is the dryer can be mounted horizontally or vertically to achieve smaller footprints of the overall package.

MEETING THE NEEDS OF SMALLER HEALTHCARE FACILITIES

During the last 15 years, smaller healthcare facilities have been built to offer less acute services. These facilities are either located on the campus of larger hospitals or found as standalone buildings.

For these applications the sizing of the medical air is the same, however, the loads are much smaller. High-pressure manifolds utilizing medical air cylinders are allowed by code to deliver medical air. This requires the owner to make a financial decision of either a larger capital cost of an air compressor or the ongoing operational cost of purchasing medical gas cylinders.

If the owner decides to install a medical air compressor, the space allotted for medical air compressors is usually quite small. The location is also much closer to patients than in a large hospital setting. This led to the scroll type air compressors being used for medical air. Scroll units are much quieter and smaller than either of the reciprocating or screw type. By utilizing vertical tank configurations and appropriately sized desiccant dryers the skids can be as small as three by four feet.

INVOLVE MEDICAL GAS SPECIALISTS IN THE PROCESS

It is imperative in a replacement scenario that a facility meet with a medical gas specialist to have a medical gas survey completed. This will confirm the sizing done initially for the facility was accurate and will address any changes in acuity or services since the original air compressor was installed. The medical gas specialist will confirm the outlet counts, interview respiratory therapist, and determine if there are any code issues that will need to be addressed with a replacement. Specifically, that the inlet is code compliant and the master alarm panels have the appropriate points. Oftentimes this is missed and can affect the new air compressor being certified.

ABOUT THE AUTHOR

Shannon McAfee, Vice President of Sales and Business Development for Pattons Medical, is a chemical engineer with more than 18 years of experience in the medical gas industry.

0 notes

Text

Some words of Air dryer manufacturer in India

The Air Marshal dryers provide dry air that is more sanitary to workers, and is beneficial to both manufacturing process and products alike. This makes air dryer a critical component of your air treatment system. Air-marshal compressed air system offers you all the capabilities and helps make the production processes viable and business goals achievable. Heatless and Refrigerated air dryers are our most widely used types.

Compressed air is a critical utility in manufacturing facilities, next only to water, electricity and natural gas. At times, the compressed air needs to have less moisture content.

Key Benefits

Ensures high quality air where all contaminants are removed through multi-level processes

Low maintenance due to simple design and uncomplicated processes

High durability of components

Saves energy through optimal design

Easy to monitor and operate

Heatless Air Dryer

Our meticulously designed heatless air dryer is a simple and efficient way to provide industrial units with clean, dry and compressed air. The atmospheric air is passed over regenerative adsorbent material to fully remove moisture and provide high quality, dry and oil-free air to facilities. The resulting compressed air not only reduces chances of corrosion in the industrial unit but also does not harbor microorganisms. Air-marshal dryers give you the maximum value for money and are the best option to achieve an optimal air system in your facility.

Twin desiccant towers are used in the heatless air dryer system where a portion of the dry air flows from the online drying tower to the offline regenerating tower. Regeneration is the removal of accumulated moisture from the desiccant and is also known as purging. The dry air attracts the moisture from the desiccant and exhausts into the atmosphere.

Application

Hospital & Dental Clinics Pharmaceuticals Industry Petrochemical Engineering

Refrigerated Air Dryer

Air Marshal Refrigerated Air Dryers are energy efficient and superior performers. You can be guaranteed of reliability, efficiency and convenience when you choose an Air-marshal Refrigerated Air Dryer.

In refrigerated air dryer, the warm and moist incoming air is first cooled in air-to-air exchange. Some of the moisture is removed by condensation and the cooled air is then cooled further through air-to-refrigerant exchange. The remaining moisture is removed by condensation and drained away. The outgoing cold air is then warmed again through air-to-air exchange to ensure safety of equipment and/or products.

Application

Food Processing Industry Textile and Clothing Industry Chemical Industry

Filter

Filter provides high filtration rate to 5 micron so as to remove dust and impurity efficiently.

Application

CNC VMC & Plasma Cutting Machinery

More details to visit us a website : www.aircompressorindia.com/air-dryer

0 notes