#How to Implement SEDEX

Explore tagged Tumblr posts

Text

Key Documents Required for Sedex Certification

In an era where transparency, sustainability, and ethical business practices define global trade, Sedex certification has emerged as a powerful tool for organizations to build credibility with buyers and stakeholders. But for businesses—especially manufacturers—planning to undergo a Sedex Member Ethical Trade Audit (SMETA), understanding the documentation requirements is crucial for a smooth audit process.

Before diving into the list of documents, if you're new to Sedex and want to learn about its benefits, audit pillars, and process, we recommend reading this in-depth guide: 👉 Sedex Certification – All You Need to Know

If you’re unsure how to prepare or need personalized support for audit readiness, 📞 Contact us here — our compliance experts are here to help.

Now, let’s explore the key documents required for Sedex certification, supported with real Sedex certification examples.

🧾 Why Documentation is Critical for Sedex Certification

Unlike traditional product-based certifications, Sedex (via SMETA audits) evaluates your business on ethical practices, covering labor rights, health and safety, environment, and business ethics. These are not just surface-level checks; auditors dive deep into records to verify your policies, procedures, and implementation.

Having the right documents not only ensures you pass the audit—it reflects your commitment to responsible business.

📑 Category-Wise List of Key Documents for Sedex (SMETA) Audits

The SMETA audit typically covers either 2 or 4 pillars. The documentation required varies slightly based on the audit type, but here’s a comprehensive list categorized for easier understanding:

🔹 1. Labor Standards Documentation

This section verifies compliance with local labor laws and international standards on working conditions.

Employee master list with DOB, DOJ, and wages

Contracts or appointment letters

Payroll records for at least 3–12 months

Wage slips and bank transfer proofs

Time records (manual/biometric attendance)

Leave records and policy

Working hours and overtime registers

Proof of minimum wage compliance

Child labor policy and age verification process

Grievance redressal mechanism and complaint register

✍️ Sedex Certification Example:

A textile factory in Tirupur provided digitally maintained wage and working hour data integrated with a biometric system. This helped them demonstrate compliance with wage laws and reduce audit time by 30%.

🔹 2. Health & Safety Documents

These records help auditors assess whether your workplace meets occupational health and safety standards.

Health & safety policy

Fire safety certificates and inspection logs

Risk assessment and hazard analysis reports

First-aid training and emergency preparedness plans

Accident/incident register

Safety committee meeting records

Safety signboards and PPE issue registers

Building structure safety certificate

Sanitation and drinking water inspection records

Annual medical check-up reports

🔹 3. Environmental Management Documents (for 4-Pillar SMETA)

If you're opting for a 4-pillar audit, environmental compliance is evaluated.

Environmental policy

Waste management records (hazardous/non-hazardous)

Effluent treatment plant (ETP) documentation

Air and water testing reports

Energy and water usage tracking logs

Disposal vendor licenses and agreements

Carbon footprint or emission data (if available)

✍️ Sedex Certification Example:

A chemical packaging manufacturer in Maharashtra presented structured energy consumption reports and rainwater harvesting data during their audit. This proactive documentation helped them gain buyer recognition and long-term vendor approval.

🔹 4. Business Ethics & Anti-Corruption Records

Applicable for 4-pillar audits or clients with stringent ethical compliance policies.

Anti-bribery and corruption policy

Whistleblower protection policy

Employee code of conduct

Internal audits on ethics

Conflict of interest declarations

🔹 5. Training Records and HR Documentation

Auditors look for ongoing efforts to educate employees and management on compliance topics.

Employee induction & onboarding records

Health and safety training logs

Fire drill participation records

Anti-harassment workshop documentation

Training material and attendance sheets

Communication boards and notices for awareness

🔹 6. Management Systems & Miscellaneous Documents

These documents showcase the structural and managerial maturity of your organization.

Organizational chart and roles/responsibilities

Factory licenses and statutory approvals

Insurance coverage documents

CSR activity records (if any)

Audit history (previous SMETA, buyer audits, etc.)

Internal audit reports and CAPA (Corrective & Preventive Action) plans

🛠️ Why Good Documentation Boosts Audit Success

Many companies assume that having ethical practices is enough. But without written policies and records, proving your commitment becomes difficult.

Proper documentation allows you to:

Present facts transparently to auditors

Reduce non-conformities

Minimize repeat audits from different clients

Save time during follow-ups or corrective actions

Build a long-term reputation for compliance and reliability

💬 What If You’re Just Getting Started?

Don't worry—many first-time Sedex members are unsure of what’s needed. A structured gap assessment and document checklist can streamline your preparation. With expert help, you can develop or update missing documents, train your team, and complete internal audits before the official SMETA audit.

🧵 Sedex Certification in Action: A Manufacturing Industry Snapshot

Let’s look at another example.

✍️ Sedex Certification Example:

A readymade garment exporter in Delhi NCR was struggling with inconsistent HR documentation. Their buyer mandated SMETA compliance. With professional support, they standardized policies, digitized payroll and attendance systems, and created training records. Within 3 months, they passed their 4-pillar audit and secured long-term orders from a UK-based retail brand.

This highlights how right documentation can open business opportunities and solidify supplier trust.

🔁 How 4C Consulting Supports Your Documentation Journey

At 4C Consulting, we’ve helped hundreds of manufacturers across industries—including textiles, engineering, food processing, and packaging—prepare documentation for Sedex certification.

We provide:

Customized documentation kits

Gap assessments

Policy drafting support

Compliance training

Pre-audit checks and post-audit support

If you're unsure where to begin or want to prepare your documentation effectively, 📞 Get in touch with us today.

🔚 Final Thoughts

Obtaining Sedex certification is not just about ticking audit boxes—it's about creating a structured, ethical, and transparent way of working. Having the right documents in place reflects a company’s integrity and operational maturity.

When supported by genuine implementation and proactive leadership, good documentation can turn compliance into a competitive advantage.

To explore Sedex audit pillars, benefits, and best practices in more detail, don’t forget to read: 👉 Sedex Certification – All You Need to Know

0 notes

Text

How SMETA Audits Contribute to Environmental Sustainability in Supply Chains

In today’s business landscape, sustainability is no longer optional—it’s a necessity. Companies are increasingly expected to reduce their environmental impact, adopt sustainable sourcing practices, and ensure ethical supply chain management. One of the most effective ways businesses can achieve this is through SMETA Certification, which integrates environmental sustainability into supply chain audits.

The Role of SMETA Audits in Environmental Sustainability

SMETA (Sedex Members Ethical Trade Audit) is widely recognized as a leading ethical audit methodology. While its primary focus is on labour rights, health and safety, and business ethics, SMETA Certification also plays a crucial role in environmental responsibility—especially within the 4-Pillar Audit framework.

1. Environmental Risk Assessment in Supply Chains

SMETA audits evaluate how businesses and their suppliers manage environmental risks, such as: ✅ Waste management – Proper disposal and recycling of industrial and manufacturing waste. ✅ Pollution control – Reducing air, water, and soil contamination from production activities. ✅ Energy and resource consumption – Assessing the efficient use of water, energy, and raw materials.

By identifying these risks, businesses can develop action plans to minimize their environmental footprint and ensure compliance with global sustainability regulations.

2. Strengthening Compliance with Environmental Laws

Many countries and industries have strict environmental regulations in place. SMETA Certification ensures businesses align with international environmental laws and corporate sustainability goals. This includes compliance with standards such as:

ISO 14001 (Environmental Management Systems)

EU Environmental Directives

Corporate ESG (Environmental, Social, and Governance) frameworks

This alignment helps businesses avoid legal risks, fines, and reputational damage, ensuring smooth operations in international markets.

3. Reducing Carbon Footprint and Promoting Sustainable Practices

SMETA audits encourage companies to: 🚀 Optimize transportation and logistics to reduce greenhouse gas emissions. 🚀 Implement sustainable sourcing strategies that minimize deforestation and resource depletion. 🚀 Adopt clean energy solutions such as solar and wind power in manufacturing processes.

By integrating these sustainability initiatives, businesses not only reduce their environmental impact but also enhance efficiency and cost savings across their supply chains.

4. Encouraging Transparency and Stakeholder Trust

With growing consumer demand for eco-friendly products, businesses must demonstrate genuine sustainability efforts. SMETA Certification provides verified environmental performance data, enabling companies to: ✅ Improve sustainability reporting for investors and regulatory bodies. ✅ Build trust with customers and partners by showcasing ethical and sustainable practices. ✅ Gain a competitive edge in markets where green business credentials are valued.

Final Thoughts: A Pathway to a Greener Future

Incorporating environmental sustainability into SMETA audits allows businesses to move beyond compliance and actively contribute to global environmental goals. By achieving SMETA Certification, organizations can ensure their supply chains operate in a way that is ethically responsible, environmentally sustainable, and aligned with global best practices.

0 notes

Text

SEDEX Consultant: Improving Supply Chain Transparency with SEDEX

Understanding the SEDEX Consultant:

A SEDEX Consultant is a seasoned professional with in-depth knowledge and experience in SEDEX compliance and ethical sourcing practices. They serve as strategic partners, assisting organizations in understanding the SEDEX framework, conducting supplier audits, and implementing sustainable supply chain practices. SEDEX Consultants possess a deep understanding of social compliance standards, labor laws, and ethical sourcing principles, making them indispensable assets for companies committed to ethical business practices.

Why the Consultant is Needed:

In today's interconnected world, companies face increasing pressure to demonstrate ethical sourcing practices and uphold social responsibility standards. However, navigating the complexities of SEDEX compliance can be daunting, especially for organizations with extensive and diverse supply chains. A SEDEX Consultant provides the expertise and guidance necessary to navigate the SEDEX framework effectively, ensuring compliance with ethical sourcing standards and fostering transparency throughout the supply chain.

Consultant Benefits:

Expert Guidance: SEDEX Consultants offer expert guidance tailored to the unique needs and challenges of your organization. They leverage their extensive experience to develop customized compliance strategies that align with your ethical sourcing objectives.

Supplier Audits: SEDEX Consultants conduct comprehensive supplier audits to assess social and ethical performance, identify areas for improvement, and mitigate risks associated with non-compliance.

Supply Chain Transparency: By implementing SEDEX compliance measures, organizations enhance supply chain transparency, build trust with stakeholders, and mitigate reputational risks associated with unethical practices.

Enhanced Reputation: Achieving SEDEX compliance demonstrates your commitment to ethical sourcing and social responsibility, enhancing your reputation as a responsible corporate citizen and attracting socially-conscious consumers.

Risk Mitigation: SEDEX Consultants help organizations mitigate risks associated with non-compliance, including legal penalties, supply chain disruptions, and damage to brand reputation.

How 4C Consulting Helps You in Consultant:

At 4C Consulting, we understand the challenges that organizations face in achieving SEDEX compliance and upholding ethical sourcing standards. With a proven track record of implementing ISO standards at over 2000 clients and delivering more than 10,000 hours of ISO training, we are your trusted partner in the compliance journey. Our team of seasoned consultants possesses deep expertise in SEDEX compliance and ethical sourcing practices, enabling us to provide tailored solutions that drive tangible results.

When you choose 4C Consulting as your SEDEX Consultant, you gain access to:

Comprehensive Assessments: We conduct thorough assessments of your supply chain, identifying risks and opportunities for improvement in ethical sourcing practices.

Supplier Engagement: Our consultants work closely with your suppliers to ensure understanding and compliance with SEDEX requirements, fostering a culture of ethical responsibility throughout the supply chain.

Training and Capacity Building: We provide training and capacity building initiatives to enhance your team's understanding of SEDEX requirements and best practices, empowering them to drive sustainable change within your organization.

Continuous Improvement: Our commitment doesn't end with SEDEX certification. We provide ongoing support and guidance to help you continuously improve your ethical sourcing practices and maintain compliance with evolving standards.

Value-Driven Approach: We prioritize delivering value to our clients, focusing on tangible outcomes such as enhanced supply chain transparency, reduced risks, and improved brand reputation.

Partnering with a SEDEX Consultant is essential for organizations committed to ethical sourcing and social responsibility. With 4C Consulting as your trusted ally, you can navigate the complexities of SEDEX compliance with confidence, ensuring transparency, accountability, and sustainability throughout your supply chain. Contact us today to learn more about our SEDEX consulting services and embark on your journey towards ethical excellence. Contact us now.

0 notes

Text

Sandro

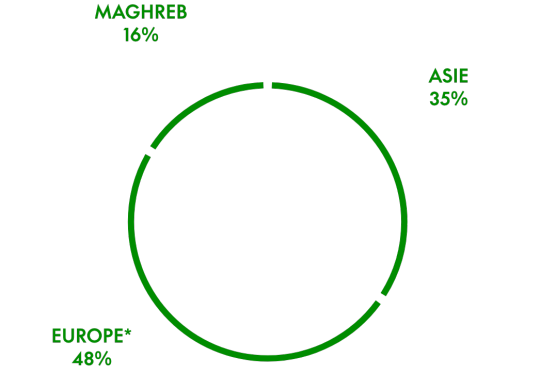

The ready-to-wear-brand Sandro, known for their casual but elegant streetwear has acknowledge its responsibility towards the environment. Despite not being sustainable yet, the brand has come up with a specific plan. Sandro aims to make by 2025 over 60% of their products eco-responsible. By the end of this year, 80% of their suppliers will be certified. Besides, since 2019 they reduced 20% of their clothing pieces. Furthermore, they permanently removed the usage of animal fur and exotic leathers from their collections.

Sandro Autumn Winter 2022-2023 Ready-to-Wear

Autumn Winter 2022-2023 Ready-to-Wear

Sandro- Spring Summer 2022 Ready-to-Wear

Spring Summer 2022 Ready-to-Wear

PRODUCTION PROCESS

Production takes place at 110 partner sites in 30 countries, including Portugal, France, Italy, Turkey, China, Serbia, Bulgaria and Tunisia. When selecting partners, we use a process based primarily on the search for technical—sometimes rare—expertise, as well as social and environmental audits.

In addition to the suppliers with whom we've fostered long-standing partnerships, we are constantly looking to strengthen the traceability of our collections to reveal every step of our production chain, right back to the raw material.

Our daily concern is also to produce in a better way, i.e. produce as close as possible to what we need. This is why we've implemented a new set of demand-planning tools in order to better adjust the volumes produced, increase distribution agility and therefore limit the amount of leftover stock at the end of a season.

SUPPLIER AUDITING

The social and environmental compliance policy for our suppliers is based on the following measures:

• All suppliers must sign a code of conduct outlining our requirements in detail.

• When referencing a new supplier, social audits or the social certifications of their manufacturing sites must be collected and reviewed.

• Social and environmental audits must be carried out, whether conducted by Sandro or requested by other companies according to the standards recognised by the SMCP Group (BSCI, Sedex, WRAP, WCA, and the SA8000 for social; ISO 14001, bluesign, STeP by OEKO-TEX for environmental).

THEIR MATERIALS AND HOW TO CARE FOR THEM

The starting point for creating our clothing and accessories is the selection and production of the raw materials used to make them. Upstream of our value chains is also where the most significant part of our sector's environmental impact lies.

We take the greatest care in selecting the materials we use. Our aim is to offer our customers high quality materials—like cotton, linen, viscose, silk, wool and cashmere—which are produced and processed using methods with a reduced environmental impact.

Keen to improve the environmental footprint of the materials making up our creations, we are now focusing our efforts on sourcing the materials we use most in our collections sustainably: organic cotton, Responsible Wool Standard (RWS) certified wool, Leather Working Group (LWG) certified leather and recycled polyester. What's more, 100% of our jeans are treated using a process that uses 95% less water than traditional treatments.

These materials represent a real challenge from an economic and supply perspective. Only available in limited quantities, we do everything we can to ensure their availability by strengthening the partnerships we have with our suppliers.

in 2022: 52% of our men's and women's collections are made using materials and/or manufacturing processes with a lower environmental impact.

2025: 80% of our men's and women's collections will be made using materials and/or manufacturing processes with a lower environmental impact.

THEIR DEFINITION OF A MORE SUSTAINABLE PIECE

At Sandro, a product is considered more sustainable if it respects one or more of these criteria:

- at least 50% of its main material is organic, recycled or meets criteria for preserving ecosystems (forests, pastureland, etc.).

- its denim is treated using eim (environmental impact measuring) technology, saving 95% of water compared to traditional treatment techniques

- the tannery, for leather items, conforms to the best industry practices in terms of water consumption, energy consumption and the use of chemicals.

0 notes

Text

SEDEX Certification - SEDEX Benefits - How to Implement SEDEX?

The supply chain is one of the most important links when a business depends on outsourcing. It becomes quite necessary to ensure that the supplier with whom we are partnering is functioning in an ethical manner. A standardized framework hence becomes one of the most effective ways to monitor functioning at the supplier’s site and also helps build a transparent supply chain. Let us get a deeper understanding of what SEDEX is.

SEDEX: An Overview

SEDEX (Supplier Ethical Data Exchange) is a global non-profit organisation that enables businesses to work together to better manage their social and environmental performance, and improve working conditions throughout the supply chain globally.

Founded in 2001 by a group of retailers, it aims to simplify the path burdening the suppliers by providing a web-based database, which enables suppliers to share ethical data, such as ethical audit reports, with their customers. Likewise, customers can keep track of their suppliers and view the ethical reports shared with them.

For a standardized framework of audits, SEDEX uses its own social auditing methodology named SMETA (SEDEX Members Ethical Trade Audit). SMETA enables businesses to assess their sites and suppliers to understand working conditions in their supply chain. During an audit the site is assessed based on the organization’s standards of labor, health and safety, environment and business ethics. These 4 factors are considered the foundational elements of SEDEX.

SEDEX Benefits

There are many benefits of having a SEDEX certification. Some of the many are as follows:

Recognition as a socially compliant organization Receiving the status of SEDEX-approved supplier and being updated in the SEDEX directory An opportunity to expand through export Compliance with legal, contractual and regulatory compliance Management of multi-tier data done simply and effectively Improved structure and focus with respect to business ethics Reduced workload and greater employee involvement

How to Implement SEDEX?

Define the scope of implementation, where we need to identify for which SMETA audit to opt for

Perform Gap Analysis

Awareness Training

Documentation & Implementation with respect to defined scope

Perform internal audit

Submit a self-evaluation form in SEDEX

Audit conducted based on SMETA criteria

Generate a Report & submit the same in SEDEX

How 4C Can Help Your Organization Get SEDEX Certification

Our skilled consultant team at 4C can help you with all the necessary steps to grow your business and guide you through the implementation process. Having served 40+ clients to get their organization SEDEX-Certified, with 800+ hours of training, 4C has a rich experience and the much-needed competence to help your organization get SEDEX Certification seamlessly. To know more about how you can strengthen your organization with SEDEX, reach out to our consultants now.

1 note

·

View note

Text

What is Sedex Certificate? What are the Advantages of Sedex Certificate?

What is Sedex Certificate?

The Supplier Ethical Data Exchange (SEDEX Certification) programme is an online system designed to give organisations the tools they need to improve the moral performance of their supply chain. This stage preserves information on reliable essential approaches and permits sharing of ethical execution knowledge with other Brands and Customers.

A general forum for the exchange of data on ethically sound creation in the stock market is the Supplier Ethical Data Exchange Database. By exchanging information on moral execution, the SEDEX Certification Audit-Database lets its users to regulate their suppliers and reduce their threats. Thus, changes are implemented across the generating chain regarding ethically sound vital techniques.

Who are providing the best Sedex ceretification in Dubai? Here, Chiltern TMC is a leading ISO Consultants in Dubai, offering various training and Certification courses with highly skilled staffs.

Associations can demonstrate to their consumers that they follow the benchmarks of an ethically and socially responsible age by undergoing a SEDEX Certification Audit in accordance with the SMETA-Guidelines and providing this information in the SEDEX-Database. On the other hand, customers may realistically control their providers in accordance with these standards, thereby reducing their risk.

Why is Sedex?

There is duplication and wasted work when companies and merchants use various systems to support and monitor ethical compliance. Impactt recognised the need for a unified platform that would promote convergence and make it easier for many stakeholders to share information.

How to connect with expertise? visit blog for getting more information

How Sedex Born?

In order to build SEDEX, a web-based data sharing system that enables participants to share and access information regarding labour standards in their supply chains, Impactt brought together a group of merchants and suppliers in 2002. Suppliers can communicate with various customers via the same platform on the progress being made in addressing non-compliances and the outcomes of audits by using SEDEX.

This increases productivity, lowers costs, and frees up suppliers to focus more on raising labour standards rather than just reporting on them.

The governance structure for Sedex as an autonomous not-for-profit limited company, owned and run by its members, was developed over the course of the following couple of years with the help of the founder members and Impactt, who served as the secretariat.

Advantages OF SEDEX Certification AUDITS:

SEDEX Audits reports decrease stock organization survey duplication by giving an extensively decent single relationship for Social Compliance Audits.

· Social Compliance Audits according to SMETA Standard connect with relationship to acceptably share and regulate store network moral information.

· SMETA Audits further develops moral trading programs supply arranges.

· Lessens gambles in friendly commitment and reasonableness through Social Compliance Audits according to SMETA Standard.

· Brands and purchasers can see, share information of providers' social consistence reviews on SEDEX data set.

The SEDEX Associate Auditor Group considering the test from SEDEX individuals to give a report plan to moral exchange reviews that could much more effectively be shared and to give continuously basic straightforwardness into the evaluator limits and practices that help reports made SMETA bearing and report positions.

Visit for more information Sedex Training in Dubai

#sedex#ISO Consulting Services#iso#iso training in UAE#ISO Training in Dubai#iso traininng and consulting

0 notes

Text

How ISO 22301:2012 Documents for Business Continuity Management System will Help in Quick Certification

Certificationconsultancy.com, one of leading readymade documentation toolkit provider is delighted to announce launch of the new ISO22301 BCMS Implementation Toolkit, which simplifies the process and reduces the costs of implementing a Business Continuity Management System (BCMS) in line with the international ISO22301 best practice standard.

Certificationconsultancy.com has launched ISO 22301 Documentation kit to provide business continuity professionals with all the tools to implement a Business Continuity Management System (BCMS). It provides a complete set of mandatory and supporting pre-written documentation templates to reduce the time spent developing documentation.

This ISO 22301 certification document contains well designed set of ISO 22301 documents, which are required for making certification process easy and effective. The entire documentation written in plain English and it is designed by team of highly experienced consultants. It includes ISO 22301 manual, mandatory procedures, sample blank forms, BCMS Standard Operating Procedures, department and requirements wise audit checklist and job description toolkit in editable formats.

Using ISO22301 documentation kit not only organization can accelerate their implementation project, but can also significantly reduce costs by deploying best practice and avoiding wasteful trial-and-error methods. The toolkit helps organization apply continual improvements and ensure organisation stays ahead of the curve.

About Certificationconsultancy .com

Certificationconsultancy.com is a pioneer for providing management system certification solution online via its popular website www.certificationconsultancy.com, which is offering readymade products like system documents, awareness training and auditor training in editable formats. The ISO documentation consultancy company had more than 1800 satisfied online customers, who purchased readymade documents and training material for system certification or/and management topics, globally in more than 65 countries. The website offers a wide range of certification solutions for QMS, EMS, ISO 17020, ISO 17021, ISO 17024, ISO 17025, ISO 20000, ISO 22301, OHSAS 18001, SA 8000, SEDEX, FSMS, FSSC 22000, ISMS, Lab Accreditation, BRC Food, BRC/IOP Packaging, CMMI and more. For more detail visit website: www.certificationconsultancy.com

For more information visit here: https://www.certificationconsultancy.com/bcms-22301-certification-documents-manual.htm

#ISO 22301 manual#ISO22301 BCMS Implementation Toolkit#ISO 22301:2019#BCMS Manual BCMS documents#procedures#audit checklist#ISO 22301 Documentation kit#Business Continuity Management System

0 notes

Photo

When making the decision of producing garments via a manufacturing plant be it internationally or domestically, it’s imperative that you physically step foot into the facility and understand whom you’re about to begin your endeavor with. Similar to how we discussed a TNA plan for your production, you must also have a criterion for how you select your factory. Here is a general guideline of what to look for: Compliance (The basics should be BSCI, SEDEX, WRAP, OKEO-TEX) General Liability Insurance (Make sure the factory is insured as this pertains to your consignment should anything go wrong) Management (Read the room - try and have an understanding of if the management team is integral – this is where your people skills come in) Industry Standard Equipment (Analyze the machinery and brands that are used in each production line, preferred if the brands are industry standard – Best equipment is Italian, Turkish, German, Japanese and Taiwanese) Look at the current production of the facility, request client list and check to see if they have worked with notable brands as that will reveal their competence. Every factory will mention they have quality control agents, but you must request their plan of quality control agency AND how its implemented. They must have a system in place of how they perform their quality control methods. Just having quality control agents is not enough. And finally, the devil’s always in the details, thoroughly review and read any purchase order, agreement, or contract that you are about to sign. https://www.instagram.com/p/CC37w8gHz8f/?igshid=bp2pvaagp8ij

#rmg#apparel#appareliii#garment#factory#space#space art#Space Study#Architecture#architettura#design#studio#minimal#Minimalistic#offwhite#qc

0 notes

Link

Readymade garment (RMG) factories, for the first of its kind, have been brought under a digital mapping system mainly to ensure transparency through credible data. Under the move, a total of 961 export-oriented garment factories, located in Dhaka district, have been mapped. Factory names, GPS location, postal address, number of workers, products, export countries, brands and buyers, memberships, affiliations, and certifications could be seen in clicking the website www.mappedinbangladesh.org. Of them, 855 units are the members of the Bangladesh Garment Manufacturers and Exporters Association (BGMEA) and 144 are the members of Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA), according to the map webpage. There are some units that have registered with both the trade bodies. About 774,422 workers have been employed in the listed factories where 60.8 percent are female and 39.2 percent are male workers. However, out of the 961 factories, 13 are not members of any of the trade bodies-BGMEA and BKMEA. Commerce Minister Tipu Munshi launched the digital map containing information on export-oriented RMG factories on Saturday (9 February) at the BGMEA headquarters in the city. Federation of Bangladesh Chambers of Commerce and Industry (FBCCI) President Shafiul Islam Mohiuddin, BGMEA President Md Siddiqur Rahman, BKMEA Vice President Mansoor Ahmed, Department of Inspections for Factories and Establishments (DIFE) Inspector General Shamsuzzaman Bhuiyan, among others, were present at the launching ceremony. One can see which inspection authority has assessed fire, electrical and structural integrity in which units. Out of the 961 factories, some 448 factories have been assessed by Accord and 169 by Alliance, according to the map information. A total of 579 units are affiliated with Business Social Compliance Initiative, 356 with SEDEX, 175 with OEKO-TEX, 126 with WRAP and 109 with ISO inspection organizations, it shows. The digital mapping project was initiated in 2017 led by Brac University with lead funding from the C&A Foundation and support from Brac USA, the BGMEA, BKMEA, and DIFE also are the strategic partners of the project. The map incorporating factories from across the country is expected to be completed in 2021. Speaking at the launching event, the minister termed the mapping time-befitting and important both for buyers and apparel makers. Tipu Munshi, however, pressed for the need for including information on buyers who so far increased prices of apparels and how much after the latest wage hike and those who expressed interests in doing so. He also stressed the need for fair prices from buyers. Pressing for fair prices of locally made apparel, FBCCI President Mohiuddin called for ensuring transparency in the whole supply chain. BGMEA President Md Siddiqur Rahman criticized media reports on workers terminations saying any smallest incident of local RMG factories got huge attention from all corners. There are many good practices that are not published, he alleged. Though apparel makers invested a huge amount of money for workplace safety, prices of apparels were not increasing in line with the cost of production, he noted. He expressed fear that many workers might be jobless due to the failure to implement the latest wage structure by the garment factories. Information of only export-oriented garment factories in the map should be incorporated, he said adding they couldn't take the responsibility of those not affiliated with the trade bodies.

0 notes

Text

New Post has been published on Quality, Manufacturing & Product Development

New Post has been published on http://quality-manufacturing.org/often-audit-supplier/

How often should you audit your supplier and why ?

Factory audit is a common process used to verify a supplier capability and compliance with some working standard, quality management system, ethical labor practice or even health and safety standard.

The topic of this article is when should you audit your suppliers ? Should you audit them once at the beginning then bye bye or should you audit them on a periodic base ?

I will answer to those question point by point.

# Auditing during sourcing phase

Most of importers use supplier audit services to verify their manufacturers capability and to make sure the vendor is genuine (not spam) before placing their first order. Quite often, an importer after having performed some online search on a global trade platform such as Alibaba, Global Sources or Made in China will enter in contact with the vendor and start communicating about a potential order.

Then, when the times come from discussion with vendor about payment terms and conditions, and especially which amount should be deposited to the vendor account to start the order, the question of the reliability, technical capability, social responsibility, financial health and genuineness of the company start to run into the buyer brain. Indeed, with a deposit amount required usually to be between 30 to 50% of the purchase order, considering mass production big number effect, the deposit amount may not be so small. How to protect this deposit and how to minimize risk related to payment is considered at the time when the payment has to be made.

The supplier audit service is then the best tool to minimize risk by verifying the background of your vendor: production process, assets such as equipment and machine, employees, organization, management, quality assurance implementation, warehouse storage management, sample management, documentation, versioning, training of new comers, hr management, etc… All of those elements can be verified during a supplier audit before placing an order to a vendor and it helps you to assess the risk of failure to get your order delayed, your products non compliant. In some circumstances, even some financial credit check can be verified to evaluate the financial health of your vendor.

Several audit types can be implemented depending on the need and the area the international buyer want to focus on. Those area can be quality management such as an ISO 9001 audit type, corporate social responsibility with standard such as SA 8000, Sedex / Smeta, WRAP or BSCI, Environmental such as with ISO 14000, health and safety with OHS 18000, or even ISO 27001 to make sure your supplier is capable to manage confidential informations properly.

For specific industries some specific quality management audit standard may fit better than ISO 9001. For medical, ISO 13485 standard and guidelines will mostly be used, for automotive it will be ISO TS 16949, while for aerospace it would rather be AS 9100.

Out of those ISO standard, if an importer is willing to sell products to international retailers, then some specific standard to each retailer might be used. So Disney audit, Walmart audit, Costco audit, Nike audit, Target audit are mostly used when you want to sell your products imported from Asia and sold to those big retailers.

# Audit periodically to check the profile of your vendor didn’t change

If you are an experienced buyer frequently purchasing in Asia you will probably know the business manufacturing landscape can change quickly here. Hence, auditing frequently your vendor can be strategically smart in order to be kept updated about your supply chain.

An example I had in the past was the case of one manufacturer of consumer electronic I worked with for manufacturing a special type of consumer electronic product:

During the sourcing phase, I audited the manufacturer and noticed they had a SMT line with pick and place machines and reflow oven. At the audit time the machines were in use to solder SMD components on PCB. The manufacturer was capable to internalize the manufacturing process of the PCBA (assembly of components on blank PCB), hence controlling which component was soldered on the PCB and how soldering was done, hence having a decent supply chain control on the electronic part of the process. So, this manufacturer was short listed as a potential candidate and it indeed became one of our supplier.

A year and half later after placing several orders, I decided to audit again this supplier to see how the company was doing now. I was surprised when I audited because I discovered that the SMT line was not in used anymore (while machine were still present at the facility). Machines were off and the level of dust on the machines indicated that the manufacturer didn’t use the SMT line for a while whereas the manufacturer was still assembling parts to become products. In short, they had decided to sub-contract the SMT process to someone one else which they didn’t inspect regularly during product, hence partly loosing control on the supply chain. When I asked why they sub-contracted whereas they had the equipment to process SMT, they told me it was cheaper to process component soldering outside their company.

A few weeks later I actually discovered the manufacturer sub-contracted because they had decided to wipe off their engineering team to sub-contract the electronic engineering to a design company and that the design company didn’t sell the IP to the manufacturer but just the PCBA where they put their margin on the top of the BOM.

Auditing a bit every year some suppliers which are strategic in your supply chain can be a good idea to verify the evolution of their capability.

# Monitor your Ip with periodic audit

When you are already working with a supplier and placing order to them you may think that everything goes smooth. Yet sometimes it doesn’t and you don’t know it. I got an example of one client who had designed and patented a design for a very special kind of bike. The client appointed a big manufacturer of bike product to mass produce his special bike. Everything was going fine until two years later after placing order when he asked me to go visiting and auditing the supplier, process which he didn’t do before placing order.

Arriving on site, I conducted my audit like always I due. When I visited the production line, the client products where currently in production on one line. A few hundred meter away of this line, a bit isolated, was another line. I was curious so I went to have a look at what the manufacturer was doing there. I was surprised when I discovered the exact same product was manufactured but under another brand name which was the factory brand name. I quickly reported to the client to know if it was normal his product was manufactured under another name. He was also amazed and told me the manufacturer didn’t let him know about it…

In short, the manufacturer was producing for the client, but was also producing for the manufacturer brand without paying royalties and infringing patent and licensing from its own client.

If the client would not have asked me to lead an audit at the supplier facility, he would have never known his manufacturing « partner » was becoming his competitor….

# Conclusion

Supplier audit can be very useful to verify your supplier capability, social responsibility, health & safety, environmental responsibility implementation, quality management system and even financial health. On the top of it, it can help you to verify your supplier capability evolution over the time to make sure it doesn’t deteriorate. Finally, auditing your supplier on a regular basis can help you to keep an eye on your supplier to make sure your product is not copied by them.

If your supplier is strategic in your supply chain or in your procurement turn over, then I would recommend you to audit your supplier once a year ideally.

0 notes

Text

Bacardi Limited Continues to Deliver Upon Corporate Social Responsibility Commitments

Bacardi Limited, the largest privately held spirits company in the world, continued to improve in its social responsibility, people, environmental, operational efficiency and sourcing programs. These accomplishments are featured in the ninth annual Bacardi Limited Corporate Responsibility (CR) Report which reinforces the Company’s strategic business initiatives and core values during the 2016 fiscal year encompassing April 1, 2015, to March 31, 2016.

“Bacardi’s commitment to being corporately responsible extends into every aspect of our business,” said Rick Wilson, senior vice president of Corporate Responsibility for family-owned Bacardi. “From the critical importance of quality ingredients and how we source our materials to the impact we leave on the world around us and the need to reduce alcohol-related harm, we actively strive to fulfill our broader responsibilities to society at large.”

The 2016 CR Report showcases the Bacardi accomplishments in five strategic pillars focusing on where our business impacts society most: 1) Marketplace; 2) Environment; 3) Responsible Sourcing; 4) People; and 5) Philanthropy & Community Investment. Achievements in the Bacardi Limited 2016 CR Report include:

Continued to work with industry members on the Beer, Wine and Spirits Producers’ Commitments to Reduce Harmful Drinking, in line with the World Health Organization’s goal to reduce harmful consumption of alcohol. As part of these Producers’ Commitments, Bacardi achieved 100% compliance with marketing agency contracts in responsible marketing.

Through our work with the International Alliance on Responsible Drinking (IARD) and local Social Aspect Organizations, piloted drunk driving prevention and underage drinking educational campaigns in key markets reaching more than 1.6 million underage individuals through more than 100 programs.

The ambitious “Good Spirited” global environmental sustainability initiative has led the way in our sourcing, packaging and operational efficiency strategies and exceeded many of our 2017 targets, including improvement in water use efficiency by 1.8% over FY15 to 46.4% and a reduction in greenhouse gas emission intensity by 20% to an overall 49% of FY06 baseline (achieved 50% in November 2016).

Achieved 0.59% waste to landfill ratio; on track to achieve Zero Waste to Landfill by 2022 as seven of 29 facilities have already achieved such status.

Reached target of 40% of sugarcane-derived products from sustainably certified sources -- a full twelve months early than our original goal of end of FY17. Of note, we are on track to achieve our 2020 goal of 100% of sugarcane-derived products from sustainably certified sources by the end of 2017.

Achieved 79% of global direct suppliers and 96% of global point of sale suppliers linked to Bacardi through Sedex, a non-profit membership organization dedicated to driving improvements in responsible and ethical business practices in global supply chains.

In FY16, 33% of our senior management roles were held by women, a testament to our Women in Leadership program.

In Safety, we continued the implementation of our Safety First program and reported our lowest ever rate of Total Recordable Incidents with the number of accident-free sites increasing from 14 to 19 out of 30, as we move closer to our vision for an accident-free Bacardi.

Bacardi is committed to the communities in which we live and work. We encourage employees to volunteer their time in programs and activities to support local charitable organizations, and we support the many worthwhile charities in our towns working to better our communities. This past year our employees volunteered more than 9,000 hours in 30 countries.

As part of the “Roar for Life” drunk driving prevention social campaign, our iconic Italian MARTINI® brand donated US$120,000 to support activities to promote local nonprofit organizations in Russia, Poland, Ukraine, and Kazakhstan.

“By living our values every day, we also commit ourselves to contributing to a more sustainable future for all. By caring deeply and passionately about our business and the world around us, we excel in creating brands consumers can trust,” adds Wilson. “Our actions are making an impact as once again Bacardi was named among the most reputable companies in the world by Forbes. An honor we proudly accept.”

To read more about Corporate Responsibility within Bacardi, including how Bacardi is the only major spirits company certified to be operating in accordance with the world’s most recognized management standards for quality (ISO 9001), environment (ISO 14001) and health and safety (OHSAS 18001), visit the Corporate Responsibility section of www.BacardiLimited.com.

About Bacardi Limited Bacardi Limited, the largest privately held spirits company in the world, produces and markets internationally recognized spirits and wines. The Bacardi brand portfolio comprises more than 200 brands and labels, including BACARDÍ® rum, GREY GOOSE® vodka, DEWAR’S® Blended Scotch whisky, BOMBAY SAPPHIRE® gin, MARTINI® vermouth and sparkling wines, CAZADORES® 100% blue agave tequila, and other leading and emerging brands.

Founded 155 years ago in Santiago de Cuba on February 4, 1862, family-owned Bacardi manufactures its brands at 29 facilities and sells in more than 160 countries. Bacardi Limited refers to the Bacardi group of companies, including Bacardi International Limited.

Media Contacts: Amy Federman +1.441.294.1110 [email protected]

K.C. Kavanagh +1.441.298.1053 [email protected]

source: http://www.csrwire.com/press_releases/39691-Bacardi-Limited-Continues-to-Deliver-Upon-Corporate-Social-Responsibility-Commitments?tracking_source=rss

0 notes

Text

Sedex Certification vs SA 8000: Key Differences You Should Know

In a world where ethical business practices and social compliance are not just appreciated but expected, global manufacturers are turning to internationally recognized standards to prove their commitment. Two of the most prominent frameworks in this space are Sedex Certification and SA 8000 Certification. While they might seem similar at a glance, they serve different purposes and apply to different business needs.

Before diving into the comparison, if you’re unfamiliar with how Sedex Certification works, we highly recommend exploring this detailed guide: 🔗 Sedex Certification: All You Need to Know – It covers everything from audit types to real industry examples that bring clarity.

And if you're seeking expert consulting or wish to implement either of these standards in your organization, feel free to get in touch here: 📩 Contact 4C Consulting – Your trusted partner in management system implementation.

Understanding Sedex Certification

Sedex (Supplier Ethical Data Exchange) is not a formal certification but a data-sharing platform that enables businesses to monitor, manage, and improve ethical performance across their supply chain. Sedex Certification usually refers to SMETA audits (Sedex Members Ethical Trade Audit), which assess a company’s compliance with key pillars like:

Labour Standards

Health & Safety

Environment

Business Ethics

These audits can be 2-Pillar (Labour and Health & Safety) or 4-Pillar (including Environment and Business Ethics).

Example: A food processing unit in Gujarat exports packaged meals to UK retailers. The buyers require the supplier to be Sedex-compliant. A Sedex 4-Pillar audit ensures the business meets their ethical and sustainability criteria.

What is SA 8000 Certification?

SA 8000 is a social certification standard developed by Social Accountability International (SAI). It focuses exclusively on workplace conditions and is rooted in international human rights, ILO conventions, and national labor laws. Unlike Sedex, SA 8000 is a formal certification issued by accredited bodies.

It emphasizes:

No child or forced labor

Safe and healthy workplaces

Freedom of association

No discrimination

Fair wages and working hours

Management systems to uphold these standards

Example: A leather goods manufacturer in Kanpur looking to sell to European clients may pursue SA 8000 Certification to demonstrate ethical labor practices, thereby gaining a competitive edge in socially conscious markets.

Key Differences: Sedex vs SA 8000

AspectSedex (SMETA Audit)SA 8000 CertificationTypeAudit methodologyCertification standardFocusBroader – ethics, safety, environmentFocused – labor standardsRecognitionPopular in UK, EU retail supply chainsGlobal ethical certificationValidityBuyer-driven (often annual)3 years with surveillance auditsNatureVoluntary platform for transparencyFormal third-party certification

Which One is Right for You?

If your goal is to meet supply chain transparency requirements and quickly become compliant with buyer expectations, Sedex is a great starting point.

If you're aiming for deeper integration of ethical labor standards into your company culture, and want a globally recognized seal of approval, SA 8000 is a better fit.

Many businesses opt for both—Sedex for audit visibility and SA 8000 for social credibility.

Final Thoughts

The modern consumer and stakeholder want more than just a quality product—they expect ethical sourcing, fair labor, and social responsibility. Whether through Sedex certification with examples like SMETA audits or a structured program like SA 8000, your commitment speaks volumes.

To learn more about Sedex audits and how they apply to industries like food, pharma, apparel, and beyond, visit this in-depth article: 🔗 Sedex Certification: All You Need to Know

Have questions or need help deciding between Sedex and SA 8000? 📞 Contact 4C Consulting – Our experts are ready to guide you toward ethical excellence.

0 notes

Text

Unlocking Ethical Trade with SEDEX Internal Auditor Training

In today’s interconnected global marketplace, ethical trade and responsible sourcing are more critical than ever. Organizations across industries are striving to uphold high standards in labor rights, health and safety, the environment, and business ethics. One powerful tool that facilitates these efforts is SEDEX (Supplier Ethical Data Exchange). To ensure compliance and continuous improvement, SEDEX Internal Auditor Training is essential. Here’s how 4C Consulting can help your organization achieve excellence in ethical trade practices.

What is SEDEX?

SEDEX is a global non-profit membership organization that drives improvements in ethical and responsible business practices in global supply chains. It provides a platform for sharing and managing supply chain data, helping businesses identify and manage risks related to labor rights, health and safety, environmental impact, and business ethics.

Importance of SEDEX Internal Auditor Training

Enhance Understanding: Gain in-depth knowledge of SEDEX principles and requirements.

Ensure Compliance: Ensure your organization meets SEDEX standards and regulatory requirements.

Improve Supplier Relationships: Build stronger, more transparent relationships with suppliers.

Mitigate Risks: Identify and manage risks in your supply chain proactively.

Drive Continuous Improvement: Foster a culture of continuous improvement in ethical practices.

Key Components of SEDEX Internal Auditor Training

Introduction to SEDEX: Understand the fundamentals of SEDEX and its role in promoting ethical trade.

Audit Process: Learn the end-to-end audit process, from planning to execution and reporting.

Risk Assessment: Gain skills in identifying and assessing risks in your supply chain.

Corrective Actions: Develop effective strategies for addressing non-compliance and implementing corrective actions.

Best Practices: Learn best practices in auditing to ensure thorough and effective assessments.

How 4C Consulting Can Help

At 4C Consulting, we specialize in providing comprehensive SEDEX Internal Auditor Training that empowers organizations to uphold high standards of ethical trade. Our expert trainers bring extensive experience and practical insights to the training process, ensuring you gain the skills and knowledge needed to excel.

Tailored Training Programs: We offer customized training solutions that cater to the unique needs of your organization.

Expert Guidance: Benefit from the expertise of our seasoned trainers who have a deep understanding of SEDEX requirements and best practices.

Practical Insights: Gain practical, hands-on experience through interactive training sessions and real-world case studies.

Continuous Support: Receive ongoing support and resources to help you implement and maintain high standards in ethical trade practices.

Partnering with 4C Consulting for SEDEX Internal Auditor Training ensures your organization is equipped to meet the highest standards of ethical and responsible business practices. Our training programs not only help you achieve compliance but also drive continuous improvement and strengthen your reputation as a leader in ethical trade.

0 notes

Text

Mastering Ethical Sourcing: SEDEX Training with 4C Consulting

Looking to enhance your supply chain transparency and ethical sourcing practices? Our SEDEX Training program is the perfect solution. At 4C Consulting Private Limited, a leading ISO Certification Consulting company with a proven track record of implementing ISO Standards for over 2000 clients, we understand the importance of SEDEX in promoting responsible business practices.

SEDEX, or Supplier Ethical Data Exchange, provides a platform for companies to manage and share ethical supply chain data. Our SEDEX Training equips organizations with the knowledge and skills needed to effectively use the SEDEX platform, conduct ethical audits, and improve supply chain transparency.

Through interactive workshops and practical sessions, participants learn how to navigate the SEDEX platform, interpret audit reports, and address ethical issues in the supply chain. By investing in SEDEX Training, organizations can demonstrate their commitment to ethical sourcing, gain a competitive edge, and build trust with stakeholders.

Partner with us to elevate your supply chain practices and unlock the benefits of SEDEX certification. Contact us today to learn more about our SEDEX Training program and take the first step towards responsible sourcing. Contact us for more information.

0 notes

Text

SEDEX Certification – Key steps for implementation SEDEX

The supply chain is one of the most important links when a business depends on outsourcing. It becomes quite necessary to ensure that the supplier with whom we are partnering is functioning in an ethical manner. A standardized framework hence becomes one of the most effective ways to monitor functioning at the supplier’s site and also helps build a transparent supply chain. Let us get a deeper understanding of what SEDEX is.

SEDEX: An Overview

SEDEX (Supplier Ethical Data Exchange) is a global non-profit organization that enables businesses to work together to better manage their social and environmental performance, and improve working conditions throughout the supply chain globally.

Founded in 2001 by a group of retailers, it aims to simplify the path burdening the suppliers by providing a web-based database, which enables suppliers to share ethical data, such as ethical audit reports, with their customers. Likewise, customers can keep track of their suppliers and view the ethical reports shared with them.

For a standardized framework of audits, SEDEX uses its own social auditing methodology named SMETA (SEDEX Members Ethical Trade Audit). SMETA enables businesses to assess their sites and suppliers to understand working conditions in their supply chain. During an audit the site is assessed based on the organization’s standards of labor, health and safety, environment and business ethics. These 4 factors are considered the foundational elements of SEDEX.

There are 2 types of audits one can opt for under SMETA: 2 Pillar Audit & 4 Pillar Audit

A SMETA-2 Pillar Audit comprises of

Labour Standards

Health and Safety

A SMETA-4 Pillar audit comprises of

Labour Standards

Health and Safety

Environment Ethics (detailed)

Business Ethics

All four pillars count on legal requirements, international standards and good practice. The added 2 pillars may not be required by all, hence it is very crucial for the auditors to know when these additional modules are required.

There are 3 categories of SEDEX memberships which one can opt for, based on their functioning:

SEDEX is Applicable to

SEDEX is applicable to all the industries irrespective of their processes, but it is most useful in industries where a lot of man power is employed & there are possibilities of social injustice. Some of such industries are as follows:

Garments and Textile Industries

Pharmaceutical Industries

Oil and Natural Gas Industries

Heavy Machine Manufacturing Industries

Automobile Manufacturing Companies

Construction Industries

Key steps for implementation

Implementation of SEDEX will mean that you comply with the following criteria which includes:

Legal Compliance and Management

Forced Labour

Wages & Benefits

Hours of Work

Freedom of Association

Child Labour

Discrimination

Abuse of Labour

Health & Safety

Environment

Bribery & Corruption / Business Practices

CSR activities & Community Involvement

SEDEX Benefits

There are many benefits of SEDEX certification. Some of the many are as follows:

Recognition as a socially compliant organization

Receiving the status of SEDEX-approved supplier and being updated in the SEDEX directory

An opportunity to expand through export

Compliance with legal, contractual and regulatory compliance

Management of multi-tier data done simply and effectively

Improved structure and focus with respect to business ethics

Reduced workload and greater employee involvement

How to Implement SEDEX?

Define the scope of implementation, where we need to identify for which SMETA audit to opt for

Perform Gap Analysis

Awareness Training

Documentation & Implementation with respect to defined scope

Perform internal audit

Submit a self-evaluation form in SEDEX

Audit conducted based on SMETA criteria

Generate a Report & submit the same in SEDEX

0 notes