#Hydraulic Pumps

Text

Why a Servo Motor is the Ultimate Choice for Consistency

When it comes to precision and reliability, servo motor are in a league of their own. But what makes them the ultimate choice for consistency in various applications? Let’s break it down.

Precision Engineering: Servo motors are designed with advanced control systems that allow them to achieve exceptionally accurate positioning and speed control. This precision is crucial in applications ranging from robotics to manufacturing processes, where even the smallest deviation can lead to significant issues.

Feedback Mechanisms: A key feature of servo motors is their built-in feedback systems. These systems continually monitor the motor’s performance and adjust its operation in real-time. This ensures that the motor maintains the desired performance, even in the face of changing loads or environmental conditions.

Reduced Mechanical Wear: Because servo motors provide smooth and consistent operation, they experience less wear and tear compared to other motor types. This not only extends their lifespan but also reduces maintenance needs, ensuring that your machinery runs efficiently over time.

Energy Efficiency: Servo motors are designed to use energy more efficiently by adjusting their output to match the load. This efficiency not only helps in reducing operational costs but also minimizes the environmental impact of your operations.

Versatility: Whether you’re dealing with precise movements in a CNC machine or maintaining consistent speed in a conveyor system, servo motors can be tailored to meet the specific requirements of various applications. Their adaptability makes them a reliable choice for industries seeking consistency.

In summary, the precision, feedback mechanisms, reduced wear, energy efficiency, and versatility of servo motors make them the ultimate choice for achieving and maintaining consistency. When reliability and accuracy are non-negotiable, servo motors stand out as the top solution.

0 notes

Text

Hydraulic pump

https://miraclemotorvehicle.com/wp-admin/post.php?post=296&action=edit#

1 note

·

View note

Text

Find Local Hydraulic Pumps Manufacturer, Supplier at Indian Trade Bird?

Best Hydraulic Pumps manufacturer, Supplier and Exporter from Ahmedabad, Belgaum, Bengaluru, Chennai, Ghaziabad, Hyderabad, Kolkata, Mumbai, Nagpur, New Delhi, Pune, Rajkot, Sarkhej, Vapi, Visakhapatnam.

Finding Local Vacuum Pump Suppliers

When searching for local Hydraulic Pumps suppliers, proximity becomes a significant advantage, offering various benefits such as shorter lead times, reduced shipping costs, and easier access to technical support and spare parts. Additionally, We have local suppliers facilitate closer collaboration and relationship building, which can be invaluable in ensuring seamless operations. Business directories, trade associations, and online platforms serve as valuable resources for identifying nearby Hydraulic Pumps manufacturers. Furthermore, attending networking events, and industry trade shows, seeking referrals from colleagues and peers can aid in the search for local suppliers. Collaborating with local vacuum pump suppliers fosters a sense of partnership and mutual support. This partnership allows for greater flexibility in customization, faster response times to urgent requirements, and a deeper understanding of local market dynamics and regulations, ultimately enhancing efficiency and reliability.

Hydraulic Pumps manufacturers play a crucial role in providing essential equipment for a wide range of applications across various industries. By understanding the different types of Hydraulic Pumps, their applications, and key considerations when selecting manufacturers, businesses can make informed decisions to ensure optimal performance, reliability, and efficiency.

For More Details

Click here: https://www.indiantradebird.com

0 notes

Text

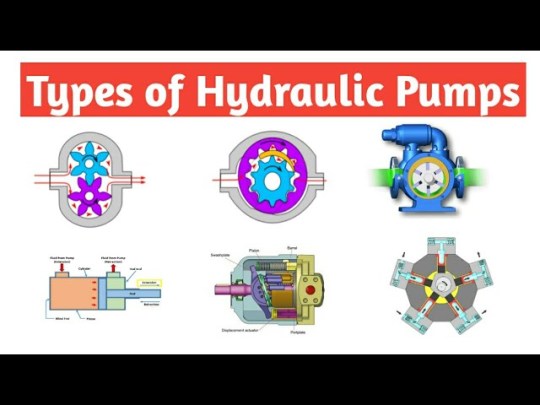

Top Types of Hydraulic Pumps and Their Various Applications

Hydraulic systems are essential components of various industries, providing the power needed to perform a wide range of tasks. At the heart of these systems are hydraulic pumps, which play a crucial role in generating the necessary fluid power.

In this blog, we'll explore the top types of hydraulic pumps and their diverse applications, shedding light on their functionality and significance in different settings.

Understanding Hydraulic Pumps

Before delving into the specific types of hydraulic pumps, it's important to understand their fundamental purpose. Hydraulic pumps are mechanical devices designed to generate flow and provide power to hydraulic systems.

They convert mechanical energy into hydraulic energy by pressurising hydraulic fluid. This pressurised fluid is then utilised to perform various tasks, making hydraulic pumps integral components of a wide array of applications.

Types of Hydraulic Pumps

1. Gear Pumps

Gear pumps are one of the most common types of hydraulic pumps. They operate using the intermeshing of gears to pump fluid.

With their simple design and ability to handle a wide range of viscosities, gear pumps are widely used in applications such as automotive power steering systems, forklifts, and construction equipment.

2. Vane Pumps

Vane pumps utilise vanes to push fluid through the pump. These pumps are known for their quiet operation and ability to handle low-to-medium pressure applications.

They find extensive use in industrial and mobile hydraulic systems, as well as in aerospace and automotive applications.

3. Piston Pumps

Piston pumps use reciprocating pistons to pressurise fluid. They are capable of handling high-pressure applications and are often used in heavy machinery, hydraulic presses, and other industrial equipment where high power density is required.

4. Radial Piston Pumps

Radial piston pumps consist of a set of pistons arranged radially around a drive shaft. These pumps are known for their high efficiency and are commonly employed in high-pressure hydraulic systems, including those used in plastic injection moulding machines, hydraulic presses, and marine equipment.

5. Axial Piston Pumps

Axial piston pumps feature pistons arranged in a circular array within a cylinder block. They are widely utilised in various hydraulic systems, including industrial machinery, agricultural equipment, and construction machinery, thanks to their ability to handle high pressure and provide efficient performance.

Applications of Hydraulic Pumps

Industrial Machinery

In the industrial sector, hydraulic pumps play a critical role in powering heavy machinery such as presses, extruders, and injection moulding machines.

The high pressure and power density provided by piston pumps and radial piston pumps make them well-suited for these demanding applications.

Construction Equipment

Construction and earthmoving equipment rely heavily on hydraulic pumps to provide the power needed for tasks such as lifting, lowering, and manoeuvring heavy loads. Gear pumps and vane pumps are commonly used in hydraulic systems within excavators, dump trucks, and cranes.

Aerospace and Automotive Systems

Vane pumps are often employed in aerospace and automotive applications where quiet operation and efficient fluid handling are essential. These pumps are utilised in aircraft hydraulic systems, as well as in power steering and automatic transmission systems in automobiles.

Agriculture

In the agricultural sector, hydraulic pumps are integral to the operation of various equipment, including tractors, harvesters, and irrigation systems. Axial piston pumps are well-suited for these applications due to their ability to handle high pressure and provide reliable performance in demanding agricultural environments.

Marine Equipment

Radial piston pumps are commonly used in marine hydraulic systems to power steering, winches, and other equipment on ships and offshore platforms. Their high efficiency and ability to handle high-pressure applications make them ideal for these marine applications.

Conclusion

Hydraulic pumps are indispensable components of hydraulic systems across diverse industries. Understanding the various types of hydraulic pumps and their applications is crucial for selecting the right pump for specific tasks and ensuring efficient and reliable operation.

By exploring the functionality and significance of hydraulic pumps, we gain a deeper appreciation for the pivotal role they play in powering a wide range of machinery and equipment.

As we've seen, the versatility and performance of hydraulic pumps make them essential for achieving powerful and precise hydraulic operations across numerous applications. Whether in industrial settings, construction sites, aerospace and automotive systems, agriculture, or marine environments, hydraulic pumps continue to drive innovation and efficiency in hydraulic power systems.

Source URL: https://hydraulicpumpsau.blogspot.com/2024/04/top-types-of-hydraulic-pumps-and-their.html

0 notes

Text

Hydraulic Pumps | Tafe Power Engines

Whether you're an engineer, a farmer, or just someone curious about how things work, this blog is sure to pique your interest. We’re talking about hydraulic pumps.

Let's kick things off by acknowledging the unsung heroes behind the scenes—the hydraulic pump manufacturers. These companies are the true backbone of the hydraulic industry, producing the heart and soul of hydraulic systems. Companies like TAFETafe have been leading the way in manufacturing high-quality hydraulic pumps that power a multitude of applications.

Now, let's zoom in on one specific aspect: Hydraulic Tractor Pumps.

If you've ever wondered how tractors do their heavy lifting, the answer lies in the hydraulic tractor pump. These pumps are the muscles that give tractors the strength to plough fields, lift heavy loads, and perform a myriad of other tasks. TAFE, for example, offers a range of hydraulic tractor pumps designed to provide reliable and efficient power for agriculture.

Key Features of Hydraulic Tractor Pumps:

Precision and Power: Hydraulic tractor pumps are engineered for precision control. They allow operators to smoothly adjust the hydraulic flow, ensuring delicate tasks like planting and harvesting are executed with finesse.

Durability: The agricultural environment is tough, but so are these pumps. They are built to withstand dust, dirt, and harsh weather conditions, ensuring longevity.

Ease of Maintenance: Nobody wants downtime during the planting or harvesting season. These pumps are designed for easy maintenance, allowing farmers to get back to work quickly.

Efficiency: TAFE’s hydraulic pumps are known for their efficiency, which means less fuel consumption and reduced environmental impact.

So, whether you're managing a large farm or just curious about the machinery that keeps agriculture moving, hydraulic tractor pumps are an essential part of the equation.

If you're interested in exploring the world of hydraulic pumps further, be sure to check out TAFE’s lineup. Their commitment to quality and innovation is a testament to the importance of hydraulic pumps in today's world. The next time you see a tractor at work on a farm, remember the incredible power behind the scenes—the hydraulic tractor pump!

0 notes

Text

Top 10 Must-Have Construction Machine Parts for Efficiency and Safety

Introduction

In the world of construction, efficiency and safety are paramount. Construction machine parts play a pivotal role in ensuring both. Whether you are a construction professional or an equipment enthusiast, understanding the must-have construction machine parts is crucial for optimizing performance and safeguarding your workforce. In this article, we will delve into the top 10 must-have construction machine parts for efficiency and safety, while also highlighting leading construction machine parts suppliers known for their high-quality components.

The Foundation of Construction: High-Quality Machine Parts

When it comes to construction machinery, the quality of its components determines its longevity and performance. Before we dive into the top 10 must-have parts, let's explore why high-quality construction machine parts are essential.

The Significance of High-Quality Construction Machine Parts

High-quality construction machine parts offer several advantages, including increased durability, reduced downtime, improved safety, and enhanced productivity. The following sections will elucidate these benefits further.

Top 10 Must-Have Construction Machine Parts

Now, let's examine the essential construction machine parts that are indispensable for ensuring both efficiency and safety on construction sites.

Hydraulic Pumps and Motors

Hydraulic systems are the lifeblood of construction machinery. High-quality hydraulic pumps and motors are crucial for smooth and precise equipment operation.

Heavy-Duty Tracks and Tires

Durable tracks and tires are essential for stability and maneuverability, especially for heavy equipment like excavators and bulldozers.

Engine Components

The engine is the heart of any construction machine. Components such as filters, belts, and hoses are vital for engine health and performance.

Transmission and Gearbox

Efficient transmission and gearbox components ensure the seamless transfer of power, enabling precise control over the equipment.

Safety Systems

Safety should never be compromised. Must-have safety systems include backup cameras, collision detection, and roll-over protection structures (ROPS).

Boom and Bucket Attachments

Attachments like booms and buckets are essential for various tasks. High-quality attachments enhance versatility and efficiency.

Electrical Components

Electrical components, including wiring harnesses and control panels, are vital for modern construction machinery's advanced features.

Filters and Filtration Systems

Filters and filtration systems help maintain clean hydraulic and engine fluids, preventing damage and extending the lifespan of parts.

Bearings and Bushings

Bearings and bushings reduce friction and wear in moving parts, contributing to smoother operation and longer component life.

Seals and Gaskets

Leakage can lead to downtime and safety hazards. High-quality seals and gaskets ensure fluid containment and prevent contamination.

Leading Construction Machine Parts Suppliers

To acquire these must-have construction machine parts, it's crucial to partner with reliable suppliers known for their commitment to quality and performance. Here are a few Leading construction machine parts suppliers:

Unispares India

Unispares India has a reputation for supplying top-tier construction machine parts that meet industry standards. Their commitment to quality makes them a preferred choice among construction professionals.

Conclusion

In the dynamic world of construction, efficiency and safety are non-negotiable. The top 10 must-have construction machine parts outlined in this article serve as the backbone of any successful construction project. Investing in high-quality components from reputable suppliers is an investment in the long-term success of your construction endeavors. By prioritizing the quality of these essential parts, you ensure that your construction machinery operates efficiently, safely, and reliably, ultimately leading to project success and worker well-being.

0 notes

Text

0 notes

Text

Best Quality of Hydraulic Cylinder Repair

Our professional and experienced team can also handle a variety of hydraulic repair services. We will carefully inspect, fix, and rigorously test your newly restored cylinder to ensure maximum performance. Visit our website or call us at 337-882-7955.

#marine services#hydraulic cylinder#air compressor#hydraulic pumps#pneumatic pump repair#centrifugal pumps

0 notes

Text

The Ultimate Checklist for Confused Buyers: How to Purchase a Hydraulic Pump in India

Buying a hydraulic pump can be a daunting task, especially in a diverse and vast market like India. With countless brands and models to choose from, making an informed decision is crucial. Here's a comprehensive checklist to guide you through the process of purchasing a hydraulic pump in India.

Identify Your Requirements: Understand the specific needs of your application. Consider factors such as pressure range, flow rate, and the type of fluid to be used. This will help narrow down your options and ensure you choose a pump that meets your operational demands.

Research Reputable Brands: In India, several brands offer high-quality hydraulic pumps. Look for manufacturers with a good reputation and extensive experience in the industry. Check for certifications and standards compliance to ensure reliability and performance.

Evaluate Specifications: Compare the technical specifications of various pumps. Pay attention to aspects like power source, size, weight, and efficiency. Make sure the pump you select aligns with your system's requirements and space constraints.

Consider After-Sales Service: Reliable after-sales service is crucial for the maintenance and longevity of your hydraulic pump. Choose a supplier that offers robust customer support, easy availability of spare parts, and a comprehensive warranty.

Budget and Cost Analysis: While it's tempting to opt for the cheapest option, quality should not be compromised. Evaluate the total cost of ownership, including maintenance, energy consumption, and potential downtime costs. Sometimes, investing in a higher-priced, quality pump can save you money in the long run.

Seek Expert Advice: If you're still uncertain, consult with industry experts or engineers. They can provide valuable insights and recommendations based on your specific requirements.

Check Reviews and Testimonials: Reading reviews and customer testimonials can provide an unbiased perspective on the performance and reliability of different hydraulic pumps. This can help you avoid common pitfalls and make a more informed decision.

By following this checklist, you can navigate the complexities of purchasing a hydraulic pump in India with confidence. Ensure you take your time to research, compare, and evaluate all options before making your final decision.

0 notes

Text

Are you looking for Hydraulic Pumps Manufacturer, Supplier And Exporters In India?

If you are looking for Hydraulic Pumps at best price, Indian Trade Bird is a B2B portal where you can find Best Hydraulic Pumps manufacturer, Supplier and Exporter from Ahmedabad, Belgaum, Bengaluru, Chennai, Ghaziabad, Hyderabad, Kolkata, Mumbai, Nagpur, New Delhi, Pune, Rajkot, Sarkhej, Vapi, Visakhapatnam.

Manufacturer, supplier, and exporter of Hydraulic Pumps like Electro Hydraulic Pumps, Hydraulic Pumps, Parker Hydraulic Pumps, Sep hydraulic pump, Hydraulic Pump with Jack. Hydraulic Pumps operate based on the principle of positive displacement. A hydraulic pump is a mechanical source of power that converts mechanical power into hydraulic energy.

For More Details

Click here : https://www.indiantradebird.com/

0 notes

Text

Hydraulic Pump Leaks Causes, Detection, and Repairs

Welcome to our comprehensive guide on hydraulic pump leaks! In this blog post, we will delve into the intricate world of hydraulic pumps, exploring their significance in various industries, the potential causes of leaks, methods for detection, repair techniques, and preventive measures.

So, buckle up and get ready to enhance your understanding of hydraulic pump maintenance and ensure the optimal performance of your equipment.

Hydraulic pumps are pivotal in numerous industries, powering machinery and equipment essential for various operations. From construction and manufacturing to automotive and aerospace sectors, the efficient functioning of hydraulic pumps is instrumental in driving productivity and performance. However, the occurrence of hydraulic pump leaks can significantly impact the overall efficiency and safety of equipment, making it imperative to address this issue promptly and effectively.

II. Understanding Hydraulic Pumps

Before delving into the complexities of hydraulic pump leaks, let's establish a foundational understanding of these critical components. Hydraulic pumps are mechanical devices designed to generate fluid flow within a hydraulic system, facilitating power transmission to different machinery parts. These pumps come in various types, including gear, piston, and vane pumps, each serving specific purposes in different applications. Maintaining the efficiency of hydraulic pumps is essential to ensure the seamless operation of equipment and machinery across diverse industries.

III. Causes of Hydraulic Pump Leaks

1. Wear and Tear on Seals and Gaskets:

The primary reason behind hydraulic pump leaks often boils down to the natural wear and tear of seals and gaskets. These vital components, subjected to continuous exposure to high-pressure hydraulic fluids, gradually degrade over time. The resulting deterioration compromises their integrity, leading to fluid seepage and the potential for leaks. As these seals and gaskets lose their resilience, the hydraulic system becomes susceptible to leakage, necessitating regular inspection and replacement to maintain optimal functionality.

2. Contamination from External Factors:

The infiltration of external contaminants poses a significant threat to hydraulic systems, potentially resulting in pump leaks. Dirt, debris, and various particulate matter can infiltrate the hydraulic system through seals or other access points. Once inside, these contaminants compromise the pump's integrity, hindering its smooth operation and potentially causing leaks. Preventative measures, such as regular system checks, proper sealing, and maintaining a clean working environment, are crucial to minimizing the risk of contamination-related leaks.

3. High Pressure Leading to Component Failure:

Excessive pressure within the hydraulic system exerts undue stress on pump components, increasing the likelihood of failure and subsequent leaks. The sustained high pressure strains the pump, causing components to weaken or malfunction over time. This stress-induced failure can manifest as cracks, fractures, or ruptures in the pump assembly, resulting in leaks. Proper maintenance practices and adhering to recommended pressure limits are essential in preventing component failure due to excessive pressure, thereby reducing the risk of hydraulic pump leaks.

IV. Detecting Hydraulic Pump Leaks

Accurately identifying hydraulic pump leaks is crucial for initiating timely repairs and preventing further damage to equipment. Here are some effective methods for detecting leaks:

Visual Inspection for Oil Stains or Puddles:

Regular visual inspections of the equipment and its surrounding areas can reveal telltale signs of hydraulic fluid leaks, such as oil stains or puddles, indicating the presence of a leak.

Monitoring Fluid Levels and Pressure Readings:

Tracking fluid levels and pressure readings in the hydraulic system can help in identifying fluctuations that may signify leaks or pressure-related issues.

Using Leak Detection Dyes:

Application of specialised leak detection dyes can aid in pinpointing the exact location of hydraulic pump leaks, facilitating targeted repair efforts.

V. Impact of Hydraulic Pump Leaks

The ramifications of hydraulic pump leaks extend beyond mere operational disruptions, encompassing broader implications for equipment performance and maintenance costs:

Decreased System Efficiency:

Leakage of hydraulic fluid compromises the system's overall efficiency, potentially leading to reduced performance and productivity.

Increased Maintenance Costs:

Addressing hydraulic pump leaks and their associated effects often means heightened maintenance expenditures, impacting the overall operational budget.

Potential Safety Risks for Equipment Operators:

Leakage of hydraulic fluid can create hazardous working conditions, posing safety risks for equipment operators and personnel in the vicinity.

VI. Repairing Hydraulic Pump Leaks

Effective repair of hydraulic pump leaks is essential for restoring the optimal functionality of equipment. Key repair techniques include:

Replacing Worn-Out Seals and Gaskets:

Identifying and replacing worn-out or damaged seals and gaskets is crucial for preventing further fluid leakage from the hydraulic pump.

Flushing the System to Remove Contaminants:

Thoroughly flushing the hydraulic system to eliminate contaminants and impurities can mitigate the risk of leaks and enhance overall system integrity.

Addressing Pressure-Related Issues:

Systematically addressing pressure-related issues, such as regulating pressure settings and ensuring the integrity of pressure control mechanisms, can prevent future leaks.

VII. Preventing Hydraulic Pump Leaks

Proactive measures to prevent hydraulic pump leaks are integral to maintaining equipment reliability and longevity. Consider the following preventive strategies:

Regular Maintenance Schedules:

Establishing routine maintenance schedules for hydraulic systems, including inspections, fluid checks, and component assessments, can pre-emptively address potential issues and mitigate the risk of leaks.

Using High-Quality Replacement Parts:

Utilising high-quality, OEM-recommended replacement parts for hydraulic pumps and associated components can bolster system resilience and minimise the likelihood of leaks.

Taking Proactive Measures to Reduce Contamination Risks:

Implementing measures to minimise the ingress of external contaminants into the hydraulic system, such as effective filtration and sealing practices, can safeguard against potential leaks.

Conclusion

In conclusion, the effective management of hydraulic pump leaks is essential for ensuring equipment's sustained performance and safety in diverse industrial settings. By understanding the causes, detection methods, repair techniques, and preventive measures associated with hydraulic pump leaks, individuals and businesses can proactively address these challenges and uphold the efficiency of their hydraulic systems.

As we conclude this informative discussion, it is paramount to emphasise the significance of prompt action in addressing hydraulic pump leaks. By prioritising maintenance, leveraging effective detection methods, and implementing preventive measures, businesses can fortify their hydraulic systems against potential leaks and sustain operational excellence.

We hope this comprehensive guide has equipped you with valuable insights into the world of hydraulic pumps and the critical considerations surrounding leaks and maintenance. Remember, vigilance and proactive maintenance are the keys to ensuring uninterrupted equipment performance and operational reliability when it comes to hydraulic pump leaks.

So, until next time, stay informed, stay proactive, and keep those hydraulic pumps leak-free!

Source: Hydraulic Pump Leaks Causes, Detection, and Repairs

0 notes

Text

0 notes

Text

A hydraulic pump is a mechanical device that converts mechanical energy into hydraulic energy. Hydraulic energy is the energy of a fluid in motion. Hydraulic pumps are used in a wide variety of applications, including construction equipment, industrial machinery, and automotive vehicles.

0 notes

Text

One of the sad facts about “no such thing as heaven” is that while I really want to make Fire Nation military apparatus explode in interesting ways, different from canon, I don’t have a good explanation for how any of the kids would know engineering. Zuko left the Fire Nation before he could be exposed to the regular hell that’s maintaining a coal powered ship. He has no idea that they could stop the drill by turning the boiler rooms into makeshift pressure bombs or a dozen other ways to mess with the engine pumps.

#no such thing as heaven#Katara honey you could just. drain the water. from the pump system.#just drain the water from the hydraulics#sweetheart…….#it didn’t have to be that difficult.#happily I AM chucking far more boulders at far more tanks#one day I’ll finish that fic about coaling#I know way more than I want to about ww1 era British navy ships to not finish that fic

3 notes

·

View notes

Text

We will be showcasing our cutting-edge #hydraulictool sets designed for emergency rescue projects. If you're in search of a reliable portable hydraulic tools manufacturer, this is your chance to meet us in person!

Let’s connect, know your needs, and explore how our tools can power your projects.

Contact:

Website: http://e.zondargroup.com/

Email:[email protected]

Whats:0086-15973148822

0 notes