#centrifugal pumps

Text

An end suction pump has axial suction and a 90-degree angle separating the suction and discharge. The End Suction Pump is one term for this kind of centrifugal pump. A centerline discharge is used in numerous designs to comply with local, national, or worldwide regulations. The two primary types of end-suction centrifugal pumps are long coupled and tightly coupled. The second kind is referred to be a Mon bloc style by some. The primary casing characteristic of larger end-suction pumps is frequently a twin volute, which lessens the stresses operating on the impeller, motor, shaft, and bearings.

It is the kind of pump that is most frequently utilized globally. Its construction and operation are really simple. Flows can be very low or very high, and pressures can range from moderate to high. Most of the time, the pump is one stage, although some manufacturers provide multi-stage models as well. Here, cast iron, bronze, and stainless steel are the most often utilized materials.

The centrifugal pump is a versatile pumping technology that is widely used in a wide range of daily tasks and businesses. End suction pumps are available from Flowmore in a range of materials to suit a range of applications.

Alternatives

Pumps that are mounted on frames or close-coupled are available. A close-coupled pump does not require field alignment because the impeller is attached directly onto the motor shaft.

Lined end-suction pumps are a robust choice for applications involving very abrasive liquids due to their structure. Such pumps are equipped with a long-lasting, replaceable liner that can withstand a lot of abuse.

0 notes

Text

Precision in Every Pump! 🎯 TITECHO multi-stage pumps deliver precise and powerful performance for any industrial application. Invest in quality with TITECHO. #TITECHO #Pumps #PrecisionEngineering #IndustrialPumps

Visit: www.cntecho.com

#efficiency#ac motor#single phase motor#acmotor#pump#engineeringexcellence#motor#titecho#cntecho#innovation#electric pump#dc pump#Centrifugal Pumps#Submersible pumps#Multistage pump

1 note

·

View note

Text

Explore the world of industrial pumps in manufacturing. Know the types employed and the rationale behind their selection.

0 notes

Text

Centrifugal Pump Types Essential for Pharmaceutical Manufacturing

In the pharmaceutical industry, precision and dependability are key. In this industry, the centrifugal pump stands as one of the most critical components that ensure these standards are maintained. These pumps play an essential role in different processes, including liquid transfer to sustain sterile conditions. Differentiating between various types of industrial centrifugal pumps and their applications is helpful for experts when choosing suitable equipment.

In this blog, we discuss about types of centrifugal pumps used in the pharmaceutical industry, their examples, practical uses and the role of centrifugal pump manufacturers in India.

Overview of Centrifugal Pumps

Centrifugal Pumps are mechanical devices designed to move fluids by converting the kinetic energy from rotation into hydrodynamic energy. They are widely used in the pharmaceutical industry due to their high efficiency, reliability, and capability to handle various fluids like corrosive and viscous liquids.

Types Of Centrifugal Pumps In Pharmaceutical Industry

1. Single-Stage Centrifugal Pumps

Single-stage centrifugal pumps usually have one impeller and are typically employed in applications requiring minimum to medium pressure levels. They are simple, economical and best suited for moving liquids from one point to another.

Example: A single-stage centrifugal pump used by a pharmaceutical company for transferring purified water from a storage tank to the production line.

2. Multistage Centrifugal Pumps

These include several impellers which increase the fluid pressure at each stage. Such pumps are used where there is a need for high pressure as they could be applied in boiler feed systems or even high-pressure cleaning.

Example: In manufacturing sterile injectables, a multistage centrifugal pump ensures that there is a supply of highly pressurized water required during the cleaning and sterilization process.

3. Sanitary Centrifugal Pumps

Sanitary centrifugal pumps are designed with materials and finishes that prevent contamination, making them perfect for handling sensitive pharmaceutical products. They are easy to clean and meet stringent sanitary standards.

Example: A pharmaceutical company employs sanitary centrifugal pumps to transfer active pharmaceutical ingredients (APIs) in a sterile environment, ensuring product purity and compliance with regulatory standards.

4. Magnetic Drive Centrifugal Pumps

These centrifugal pumps eliminate the need for mechanical seals by using magnetic couplings to transfer torque. This makes them perfect for handling hazardous liquids or sensitive fluids because it reduces the chances of leaking and contamination.

Example: Magnetic drive centrifugal pumps are used by a pharmaceutical plant to handle volatile solvents required in pharmaceutical formulations to make them operate without any danger of leakage.

5. Self-Priming Centrifugal Pumps

Self-priming centrifugal pumps can re-prime themselves even if air enters the system. They are used in applications where the pump may need to start with an empty suction line.

Example: Self-priming centrifugal pumps are used by a pharmaceutical company during wastewater treatment operations where there may be different fluid levels that the pump must deal with.

Practical Applications of Centrifugal Pumps in the Pharmaceutical Industry

Fluid transfer: Movement of raw materials, intermediates, and finished products within the facility.

Cleaning systems: These provide necessary pressures for cleaning and sterilization systems.

Filtration processes: This involves circulating fluids through filtration systems to remove impurities.

Cooling systems: These ensure effective cooling of equipment as well as processes being undertaken.

Choosing The Right Centrifugal Pump

Among other factors, the selection of the proper type of centrifuge pump depends on certain fluid properties along with flow rate and pressure requirements coupled with environmental conditions unique to each application. Partnering with reputable centrifugal pump manufacturers in India, like Fristam Pumps, ensures access to high-quality, reliable equipment tailored to the pharmaceutical industry's needs.

Conclusion

Pharmaceutical processes must be optimized by understanding various types of centrifugal pumps and their applications. Depending on the requirements, each form may have several options including multi-stage, single-stage, magnetic drive or even sanitary pumps. By picking out the right category of industrial centrifugal pumps, pharmaceutical companies can ensure efficient, safe and reliable operations.

For top-quality centrifugal pumps manufacturer in India and expert guidance partner with Fristam Pumps, the leading name in industrial centrifugal pumps.

FAQs:

1) What are centrifugal pumps, and why are they used in the pharmaceutical industry?

Centrifugal pumps are mechanical devices that move fluids using rotational kinetic energy. They are used in the pharmaceutical industry for their efficiency, reliability, and ability to handle various fluids, ensuring precise and sterile processes.

2) What types of centrifugal pumps are commonly used in the pharmaceutical industry?

Common types of centrifugal pumps in the pharmaceutical industry include single-stage, multistage, sanitary, magnetic drive, and self-priming pumps.

3) What are the applications of centrifugal pumps in the pharmaceutical industry?

Centrifugal pumps in the pharmaceutical industry are used for fluid transfer, cleaning systems, filtration processes, and cooling systems.

4) What are the benefits of using centrifugal pumps in the pharmaceutical industry?

The benefits of using centrifugal pumps in the pharmaceutical industry include efficiency, reliability, precise fluid handling, and maintaining sterile conditions.

#centrifugal pumps#Pharmaceutical Industry#Pump Types#IndustrialPumps#PumpMaintenance#PharmaceuticalEquipment#PumpSelection

0 notes

Text

How to Use a Centrifugal Pump for Maximum Efficiency

Centrifugal pumps play a role across industries by facilitating the efficient movement of fluids. Whether it's in water treatment or chemical processing, ensuring these pumps operate at their best is essential for cost-effective operations. This article explores strategies to enhance the efficiency of your pump, ultimately leading to energy savings and improved performance over time.

0 notes

Text

Centrifugal Pumps: A Cornerstone in Fluid Handling

Centrifugal pumps are a staple in fluid handling applications, renowned for their efficiency, reliability, and versatility. These pumps are essential across various industries, providing the necessary force to move fluids through systems with ease. This blog delves into the features, benefits, and applications of centrifugal pumps, highlighting the high-quality solutions offered by Raah International.

What is a Centrifugal Pump?

A centrifugal pump is a type of rotodynamic pump that uses a rotating impeller to increase the velocity of a fluid. The fluid enters the pump near the rotating axis, is accelerated by the impeller, and exits through the discharge outlet. This process converts kinetic energy into hydrodynamic energy, resulting in a steady flow of liquid.

Key Features of Centrifugal Pumps

High Efficiency:

Centrifugal pumps are designed to handle large volumes of fluids efficiently, making them ideal for applications requiring high flow rates.

Simple Design:

The straightforward design with fewer moving parts reduces maintenance requirements and enhances reliability.

Versatility:

Suitable for a wide range of fluids, including water, chemicals, and slurries, allowing for broad application across various industries.

Durable Construction:

Constructed from robust materials that can withstand harsh operating conditions and corrosive environments.

Quiet Operation:

Typically operate with minimal noise, making them suitable for environments where noise reduction is crucial.

Types of Centrifugal Pumps

Single-Stage Centrifugal Pumps:

Features: Consist of a single impeller, ideal for applications requiring low to moderate pressure.

Applications: Commonly used in water supply systems, irrigation, and HVAC systems.

Multi-Stage Centrifugal Pumps:

Features: Multiple impellers arranged in series to increase pressure.

Applications: Suitable for high-pressure applications such as boiler feed, reverse osmosis, and high-rise building water supply.

Submersible Centrifugal Pumps:

Features: Designed to operate while fully submerged in the fluid being pumped.

Applications: Used in sewage treatment, flood control, and water wells.

End-Suction Centrifugal Pumps:

Features: Fluid enters the pump horizontally through the suction nozzle.

Applications: Widely used in industrial, commercial, and residential water systems.

Benefits of Using Centrifugal Pumps

Cost-Effective:

Typically have lower initial costs and are more economical to operate and maintain compared to other types of pumps.

Easy Installation:

Simple design and construction make them easy to install and integrate into existing systems.

Wide Range of Applications:

Capable of handling various types of fluids, including clean water, chemicals, and slurries, making them versatile for multiple industries.

Reliable Performance:

Known for their reliability and ability to provide continuous, consistent flow, crucial for critical applications.

Energy Efficiency:

Designed to operate efficiently, reducing energy consumption and operational costs.

Applications of Centrifugal Pumps

Water Supply and Distribution:

Essential for municipal water supply systems, irrigation, and residential water distribution.

Chemical Processing:

Used for transferring and circulating chemicals in processing plants, ensuring safe and efficient operation.

Oil and Gas Industry:

Employed in refining processes, transporting petroleum products, and managing wastewater.

HVAC Systems:

Integral to heating, ventilation, and air conditioning systems, providing efficient circulation of fluids.

Wastewater Treatment:

Used in sewage treatment plants for transporting and processing wastewater and sludge.

Raah International’s Centrifugal Pump Solutions

Raah International offers a comprehensive range of centrifugal pumps designed to meet the diverse needs of various industries. Their products are characterized by:

Advanced Technology: Incorporating the latest innovations to ensure superior performance, precision, and durability.

Robust Construction: Engineered for long-lasting reliability in demanding environments.

Custom Solutions: Providing tailored centrifugal pump solutions to meet specific operational requirements and industry standards.

For more detailed information on Raah International’s centrifugal pump offerings and to explore a range of products tailored to your specific needs, visit there Centrifugal Pump page.

0 notes

Text

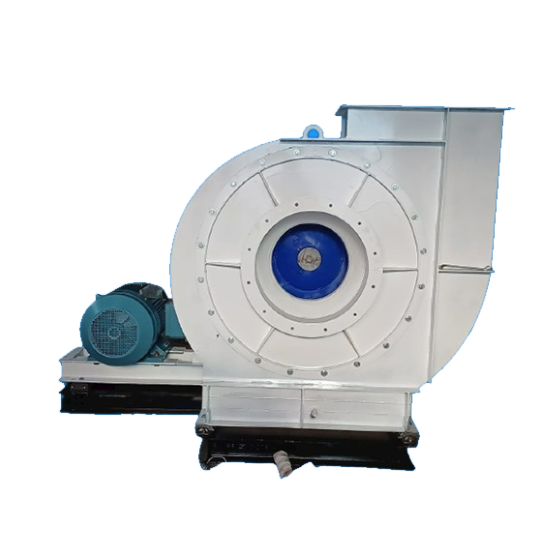

No. 1 Centrifugal Blower Manufacturers

Centrifugal Blower Manufacturers

AMCS Cooling Systems has carved a niche for Centrifugal Blower Manufacturers. These workhorse fans are the backbone of countless industrial applications, and AMCS stands out for its commitment to quality, innovation, and customer focus. AMCS centrifugal blowers are meticulously designed and crafted to withstand the demanding environments of factories and plants. They leverage technology and high-grade materials to deliver exceptional performance.

Centrifugal Blower

Centrifugal Blower Manufacturers, AMCS blowers are optimized for airflow, minimizing energy consumption. This translates to cost savings on your electricity bill and a reduced environmental footprint. Built to last, AMCS blowers can endure continuous operation for extended periods. Their robust construction ensures minimal maintenance requirements, keeping your operations running smoothly. Noise reduction is a key focus for AMCS. Their blowers are engineered to operate at minimal noise levels, creating a more pleasant and productive work environment.

Airmake Cooling

AMCS understands that a one-size-fits-all approach doesn't work in the industrial world. That's why they take pride in their collaborative process. Their team of highly skilled engineers works closely with clients to understand their specific needs. This allows them to design and manufacture custom centrifugal blowers that perfectly match the application, ensuring optimal airflow and performance. The commitment extends beyond the sale. Centrifugal Blower Manufacturers, AMCS prioritizes exceptional after-sales support, providing comprehensive service to ensure their blowers continue to deliver peak performance for years to come.

Centrifugal Blower

AMCS Cooling Systems stands out from the crowd. Their focus on innovation, quality, and customer satisfaction makes them the trusted partner for businesses seeking high-performance and reliable centrifugal blowers. Whether you need a blower for an HVAC system, a chemical processing plant, or any other industrial application, AMCS has the expertise and the commitment to deliver the perfect solution.

If you want to know more about our product how they are useful for your work , please contact us today . Our team is always here to help and find best solutions for your specific needs.

Visit:- https://www.airmakecooling.com/centrifugal-blower.html

Address : PLOT NO. 49 UDYOG KENDRA - II, ECHOTECH-III Noida - 201306 (U.P.), (India)

Twitter :- https://twitter.com/make_air

#manufacturer#air quality#high quality#centrifugal blower suppliers#amcs#curators#manufacturing#centrifugal blower manufacturers#centrifugal pumps#centrifugal blower

0 notes

Text

Industrial Centrifugal Pumps Supplier & Exporter

MS Radix, a renowned Centrifugal Pump supplier and exporter, offers a comprehensive range of high-performance pumps for diverse industrial and agricultural applications. These versatile pumps utilize centrifugal force to efficiently transfer liquids, making them a popular choice for various fluid handling needs. The straightforward design with rotating impellers ensures smooth operation, efficient flow, and minimal maintenance requirements. These pumps can handle a wide range of liquids, including water, solvents, chemicals, and even oils with varying viscosities. Centrifugal pumps are capable of delivering high flow rates, ideal for applications requiring large volumes of liquid transfer. The efficient design and minimal moving parts contribute to lower operating costs compared to some alternative pump technologies.

For more details clicks here - https://www.msradix.com/centrifugal-pump.html

0 notes

Text

Are You Looking For Fire Fighting Pumps Manufacturer in India?

If you are Looking for Fire Fighting Pumps for you industries. Creative Engineers are the leading manufacturer from Ahmedabad, India. Our Fire Fighting Pump are available in Ahmedabad, Vadodara, Vapi, Gandhinagar, Surat, Rajkot, Halol, Nagpur, Mumbai, Bangalore, Hyderabad, Pune, Pimpri Chinchwad. South Africa, Dubai, Nepal, Sri Lanka.

Fire fighting pump are essential equipment designed to combat fires efficiently. Typically powered by electricity, diesel, or gasoline, fire fighting pumps come in various sizes and configurations. A fire pump is a part of a fire sprinkler system’s water supply and can be powered by electricity, diesel or steam. The pump intake is either connected to the public underground water supply piping, or a static water source.

For ore Details

Click here : https://www.sspumpsindia.com

0 notes

Text

VND Plastico Pumps is a renowned manufacturer located in Vadodara, Gujarat. We specialize in producing centrifugal pumps that cater to various industries. Our pumps are designed to transfer water, chemicals, and light fuels with high efficiency and reliability. In addition, we have a wide range of pumps that are specifically designed for different industrial applications. We are committed to providing our customers with durable and high-quality products that meet their specific needs. Visit at https://www.vndplasticopumps.com

#Centrifugal Pumps#centrifugal pump manufacturers#air pump manufacturers#gujarat#Industrial Pumps#Leak-Proof Pumps#Chemical-resistant Pumps#Positive Displacement Pumps#Vacuum Pumps

0 notes

Text

The efficiency of a centrifugal pump plays a crucial role in the production processes of virtually every industry. No matter what industry you operate in – whether it’s food, pharmaceutical, cosmetic or chemical – the performance of your centrifugal pump can have a significant impact on the overall efficiency of your production.

A centrifugal pump functioning at its maximum competence level not only ensures smooth and regular production, but also can be a distinction in terms of efficiency and operating charges. These machines, when operating at peak performance, can increase the power of production units, optimize energy use and reduce downtime due to maintenance issues or breakdowns.

At Flowmore, the experts understand the importance of efficient centrifugal pumps in modern industry. With decades of experience in the design and manufacturing of these devices, Flowmore is committed to providing pumping solutions that not only meet, but exceed performance expectations.

The function of centrifugal pump in the production process

First of all, centrifugal pumps are responsible for transferring liquid inside industrial machinery for the generation of hydraulic energy. In this way, they are very important in any production process, so that the manufacture of goods does not depend exclusively on other more expensive forms of energy.

0 notes

Text

Efficient, Reliable, TITECHO! 🌐 Our multi-stage pumps are the perfect solution for industries seeking reliable and efficient water pumping solutions. Discover the TITECHO advantage today! #TITECHO #WaterPumps #Efficiency #IndustrialSolutions

Visit: www.cntecho.com

#Multistage pump#Submersible pumps#Centrifugal Pumps#dc pump#electric pump#motor#pump#efficiency#single phase motor#engineeringexcellence#acmotor#ac motor#cntecho#titecho#innovation

1 note

·

View note

Text

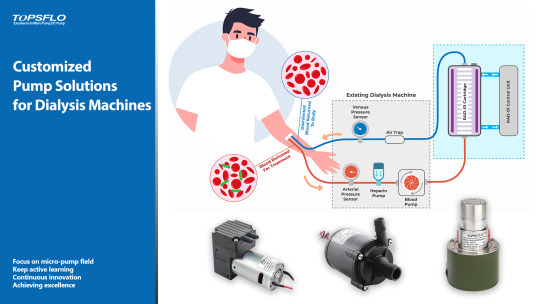

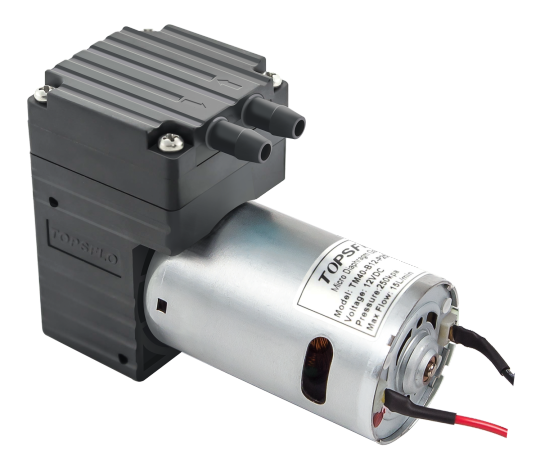

𝗠𝗶𝗰𝗿𝗼 𝗣𝘂𝗺𝗽 𝗮𝗻𝗱 𝗙𝗹𝘂𝗶𝗱𝗶𝗰 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻𝘀 𝗳𝗼𝗿 𝗠𝗲𝗱𝗶𝗰𝗮𝗹 𝗜𝗻𝗱𝘂𝘀𝘁𝗿𝘆 - 𝗛𝗲𝗺𝗼𝗱𝗶𝗮𝗹𝘆𝘀𝗶𝘀 𝗣𝘂𝗺𝗽

Overview

Hemodialysis serves as a vital renal replacement therapy for individuals battling chronic renal failure. Over the years, the prevalence of chronic renal failure has risen steadily, particularly due to factors like diabetic nephropathy, hypertensive nephropathy, and renal artery stenosis. This surge in patients necessitates hemodialysis treatment to sustain life.

Dialysis is a life-sustaining treatment for patients with end-stage kidney failure whose kidneys can no longer function. The dialysis machines removing water, solutes, and toxins from the blood. Dialysis works on the principles of diffusion across a semipermeable membrane. Blood flows by one side of a semipermeable membrane and a dialysate on the opposite side. The two main types of dialysis are hemodialysis and peritoneal dialysis.

In peritoneal dialysis, wastes and water are removed from the blood inside the body using the peritoneum as a natural semipermeable membrane.

However, in hemodialysis, the patient’s blood is pumped through a dialyzer. Blood flows through fibers, while dialysis solution flows around the outside of the fibers. The patient’s blood is cleaned in a dialyzer machine from waste products such as urea, creatinine, potassium, and extra fluid pass through the membrane, while the blood cells, protein, etc. remain in the blood.

Choosing the Right Dialysis Pumps

In hemodialysis machines, two circuits are crucial: the blood circuit for extracorporeal circulation lines and the hydraulic circuit for managing dialysis fluid. The hydraulic circuit involves various pumps, TOPSFLO offers a range of pumps engineered to meet OEM specifications for dialysis devices (Model recommendations are as follows):

1. Centrifugal Pumps

2. Diaphragm Gas Pump

3. Magnetic Drive Gear Pumps

External gear pumps are widely acclaimed for their pivotal role in powering dialysis machines, particularly in the medical sector. These pumps operate through the synchronization of two identical gears, commonly referred to as the "motor" and "driven" gears. The motor gear, propelled by a motor, in turn, drives the other gear, facilitating fluid transport by trapping small volumes between the gear teeth and the outer housing wall. This mechanism efficiently moves fluid from the inlet side to the outlet side, making external gear pumps a preferred choice for applications requiring precise fluid pressurization and minimal pressure fluctuations.

The distinctive advantages of external gear pumps contribute to their suitability for health technology applications, notably in hemodialysis machines. These advantages include exceptional priming capacity, ensuring swift initiation of fluid movement. Moreover, these pumps exhibit compatibility with wide temperature variations, a critical feature considering the temperature fluctuations experienced during post-treatment washing. Additionally, the compact size of external gear pumps further enhances their appeal for medical applications, offering an efficient and space-saving solution for fluid management in hemodialysis machines.

Pumps can operate at a temperature of 38°C throughout the dialysis cycle to prevent thermal shock to the patient. Their quiet operation is crucial for patient comfort. Stable performance, vacuum maintenance, and differential pressure are critical factors for the machine's operation, especially biocompatibility. The disinfectants in dialysis equipment pack strength, yet their corrosiveness poses challenges. Enter TOPSFLO pumps, crafted from materials demonstrated to endure numerous chemical heat clean cycles, ensuring unwavering performance. The outcome? A durable pump boasting biocompatibility, minimal noise, and significant reductions in long-term maintenance costs. Choose us for a pump solution where materials make the difference, offering reliability and longevity.

TOPSFLO pumps precisely and safely manage fluids within dialysis systems. As one of leaders in micro pump and fluidic solutions for the medical industry, TOPSFLO collaborates with customers to provide technical solutions, ensuring critical parameters for safety and performance are met.

Conclusion

TOPSFLO's commitment to innovation and collaboration makes it a reliable partner in the development of medical devices. For more information or to discuss a new project, welcome to have a consultation.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

#hemodialysis#dialysis machine#hemodialysis machine#centrifugal pumps#gear pumps#diaphragmairpump#medical pump#Youtube

0 notes

Text

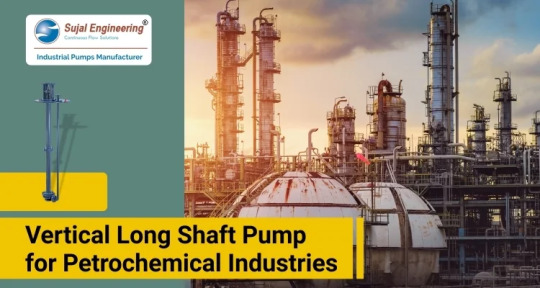

Vertical Long Shaft Pump for Petrochemical Industries

Introduction

Vertical Long Shaft Pump is one of the most popular and frequently used pumps in recent years. Robust design, long life, and high capacity make this pump an excellent choice for numerous industrial applications.

But is it the right choice for the Petrochemical Industry?

The petrochemical industry is one of the evolving industries which produces a remarkable range of valuable products that are important in almost all areas of modern society.

The petrochemical industry includes the transfer process of various abrasive and hazardous chemicals. To help transfer these chemicals from one point to another, a vertical shaft pump is required.

In this blog, we will take a comprehensive look at vertical long-shaft pumps and provide you with all the details you need to make an informed purchase.

Additionally, we will also discuss how vertical shaft pumps are used in petrochemical industries and highlight some of their key features and benefits.

Continue reading to get a clear understanding of vertical pumps and decide if it’s the right choice for you.

What Is A Vertical Long Shaft Pump?

The vertical long shaft sump pump is a single-stage industrial pump used for a diverse range of applications ranging from chemically aggressive fluids to automatic drainage of wastewater.

A vertical sump pump consists of a motor, discharge head, pipe columns, line and pump shaft, radial or channel impellers, and a suction bell.

Sujal Engineering is one of the leading vertical long-shaft pump manufacturers in India. Our vertical pump is designed for various high-pressure and high-head applications where vertical lift is required.

The vertical long-shaft sump pump also covers a wide range of hydraulic conditions to meet every pumping requirement in the industry with optimum efficiency.

To Read Full Blog : Vertical Long Shaft Pump

#centrifugal pumps#industrial pumps#centrifugal pump manufacturers#centrifugal pump manufacturer#centrifugal pump#centrifugalpump#industrial pump manufacturers#pump manufacturer

0 notes

Text

2024 - Top Quality Centrifugal Fans and Blowers Manufacturers in India

Centrifugal Fans and Blowers Manufacturers in India

Teral-Aerotech is a Top Centrifugal Fans and Blowers Manufacturers in India, offering a wide range of high-quality ventilation products. Their centrifugal blowers are engineered for high efficiency and low noise, making them suitable for various industrial and commercial applications. The company prides itself on its mission to develop, manufacture, and market top-notch ventilation products, with a focus on reliability, quality, and customer satisfaction.

Centrifugal Fans and Blowers

Centrifugal Fans and Blowers Manufacturers in India, Teral-Aerotech's centrifugal blower fans are precision designed to deliver efficient air movement and increase air or gas pressure. They offer a variety of fan types, including Double Inlet Double Width (DIDW) and Single Inlet fans, with features such as forward curved or backward curved impellers.

Teral

These fans are suitable for a wide range of applications, including general ventilation, pressurization, and various industrial processes, thanks to their high volume air displacement capabilities. The company's commitment to excellence is evident in its emphasis on trust, customer satisfaction, and continuous product development. They also prioritize timely delivery and aim to be the most reliable company for quality, availability, and delivery reliability.

Centrifugal Fans and Blowers

With a strong focus on customer relationships and community engagement, Teral-Aerotech is dedicated to providing the right products with the right performance characteristics, delivered at the right time. Their wide range of centrifugal blowers and fans, coupled with a commitment to quality and customer satisfaction, positions them as a leading manufacturer in the industry.

If you want to know more about our product how they are useful for your work , please contact us today . Our team is always here to help and find best solutions for your specific needs.

Visit:- https://www.blowers-fans.com/centrifugal-fan-blowers.html

Address : PLOT NO.188-89,ECOTECH EXTENSIONS-1, KASANA GREATER NOIDA-201301,(NEAR ASIAN PAINT) UTTAR PRADESH,INDIA

1 note

·

View note

Text

Centrifugal Pump Manufacturers, Suppliers, Dealers, Exporters in Chakan, Maharashtra

A centrifugal pump is a dynamic mechanical device that transports fluids by converting rotating kinetic energy to hydrodynamic energy. This type of pump is widely utilized in a variety of industries, including water delivery, wastewater treatment, and chemical processing.

To know more - https://www.flowtechpumps.co.in/centrifugal-pump.php

0 notes