#India Industrial Gases Market Competition

Text

Industrial Gases Market In India Is Significantly Growing Due To The Continuous Industrialization And Development Happening In The End User Market- Ken Research

1. Indian industrial market is picking up pace with its global counterparts and is exploring the dynamics that this market is offering.

To Know More about this report, download a Free Sample Report

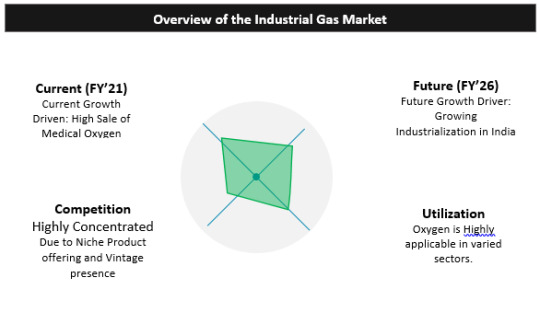

There exists a long tail of small manufacturers for Industrial Gas in Indian market. The role of industrial gases is constantly being revised to make various manufacturing processes sustainable and economical. Moreover, Indian industrial market is also picking up pace with its global counterparts and is exploring the dynamics that this market is offering. When it comes to the impact of the global pandemic, healthcare market increased its use of Oxygen gas drastically which in turn has resulted in an increased demand for gases. Market is also witnessing a growing competition between domestic and international players in India such as Inox Air Products, Praxair-Linde and more. This has also led to a significant price reduction of industrial gases in India. Apart from the healthy competition brewing between local and global player, the vigorous competition amongst small manufacturers along with the issue of overcapacity, lack of funding for smaller players and minimal technology up-gradation are some issue that the industry deals with.

2. Overall industrial gas market is highly concentrated among the top players but it has a fragmented tail with many small scale producers

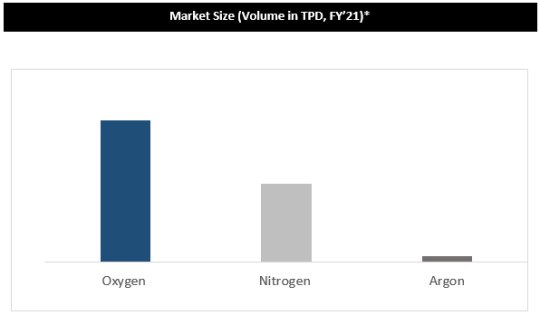

When it comes to the overall industrial gases market in India, it is expected that the market size will increase manifold in upcoming years owing to an increased utilization Rate for Oxygen, Argon and Nitrogen, as India is becoming a pivot for manufacturing. Moreover, initiatives such as “Make in India” have also driven industrialization to some extent. Talking about the oxygen market, it is expected to grow at a CAGR of 6.7% in terms of volume in TPD. Its popularity can be attributed to it being the key component for most industrial process and its diversified uses in different sectors. The Nitrogen & Argon gas market is expected to grow at a CAGR of 8% & 6% respectively. While nitrogen has the same use as oxygen in most cases, argon has been popular because of an increasing interest towards blended gases.

3. Industrial Gases market is highly concentrated as well as organized among the Top Players, however it is very fragmented among the small scale Industries

Visit This link Request for Custom Report

Industrial Gas Market is highly concentrated among the top player. It is distributed in both organized and fragmented sector. Many small scale producers exist in the market which results in a large fragmented section. When it comes to the key product segment, oxygen is the key product segment & argon is the least.

For more insights on the market intelligence, refer to the link below

India Industrial Gases Market Research Report

#Air Liquide Industrial Gases Market Sales#Air Water Industrial Gases Market Revenue#Covid-19 Impact India Industrial Gases Industry#Covid-19 Impact India Industrial Gases Market#Evaluation Summary Report India Industrial Gases Market share#HS Kanthi Industrial Gasses Ltd. Industrial Gases Market Size#India Industrial Gases Exports#India Industrial Gases Growth Strategy Market Report#India Industrial Gases Imports#India Industrial Gases Industry#India Industrial Gases Industry Research Report#India Industrial Gases Makers#India Industrial Gases Manufacturers#India Industrial Gases Market#India Industrial Gases Market Analysis#India Industrial Gases Market Competition#India Industrial Gases Market Competition Benchmarking#India Industrial Gases Market Evaluation Report#India Industrial Gases Market Forecast#India Industrial Gases Market Future Outlook#India Industrial Gases Market Growth#India Industrial Gases Market Major Players#India Industrial Gases Market Research Report#India Industrial Gases Market Revenue#India Industrial Gases Market Revenue Forecasting#India Industrial Gases Market Sales#India Industrial Gases Market Shares#India Industrial Gases Market Size#India Industrial Gases Market Trends#India Industrial Gases Tanker Manufacturers

0 notes

Text

Top Pump Parts Manufacturers & Suppliers in India | Deccanew.

Discover high-quality pump parts India from leading manufacturers and suppliers. Explore a wide range of durable, reliable components for all pump types. Learn more!

Pump parts encompass the essential components and accessories used in pumps to ensure their efficient operation and maintenance. Pumps are mechanical devices designed to transfer fluids, including liquids and gases, from one location to another. The quality and reliability of pump parts are crucial for the smooth functioning and longevity of pumping systems. Choosing reputable manufacturers and suppliers becomes paramount in ensuring the performance and durability of these components.

Understanding the Pump Parts Market in India

1. Overview of Pump Parts: Pump parts are the components that make up the structure of a pump. These include impellers, shafts, seals, bearings, valves, and casings. Each part plays a crucial role in the pump's operation, affecting its efficiency, durability, and performance. The quality of these parts is essential for ensuring the smooth functioning of the entire pump system.

2. Why India is a Hub for Pump Parts Manufacturing: India is rapidly becoming a key player in the global pump parts market. Factors such as cost-effective production, availability of raw materials, and a skilled workforce contribute to this growth. The country's strategic location also makes it a favorable hub for both domestic and international clients.

Key Factors to Consider When Choosing Pump Parts

1. Material Quality: The material of the pump parts significantly impacts their durability and performance. Look for parts made from high-grade metals like stainless steel or specialized alloys that can withstand wear, corrosion, and high pressure.

2. Compatibility: Ensure the parts are compatible with your specific pump model. Mismatched components can lead to operational inefficiencies, increased maintenance costs, and premature wear.

3. Manufacturer’s Reputation: Opt for parts from reputable manufacturers who comply with international standards. Established brands like Deccanew, Kirloskar Brothers, and Crompton Greaves offer certified products, ensuring reliability and safety.

4. Cost-Effectiveness: While cost is an important factor, it should not compromise quality. Investing in premium parts from trusted manufacturers will ultimately save money in the long run by reducing downtime and maintenance costs.

The Role of Suppliers in Ensuring Quality and Availability

1. Access to a Wide Range of Products: Suppliers play a crucial role in bridging the gap between manufacturers and end-users. By partnering with multiple manufacturers, suppliers offer a wide range of products, making it easier for customers to find the right parts for their specific needs.

2. Competitive Pricing: Suppliers often provide competitive pricing due to bulk purchasing and long-standing relationships with manufacturers. This ensures cost savings for businesses looking to procure pump parts in large quantities.

3. Support and After-Sales Service: Reliable suppliers offer excellent customer support and after-sales service, ensuring that any issues with the parts are promptly addressed. This adds a layer of security and confidence in the purchase.

Future Trends in the Pump Parts Industry in India

1. Emphasis on Sustainability: With increasing awareness about environmental impact, manufacturers are focusing on sustainable practices, including the use of eco-friendly materials and energy-efficient production methods. This trend is likely to dominate the market in the coming years.

2. Technological Advancements: The integration of advanced technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) in pump parts manufacturing is

enhancing the efficiency, monitoring, and maintenance of pumps, reducing operational costs and downtime.

3. Expansion of Export Markets: India's pump parts industry is expanding its footprint in the global market, with increasing exports to the Middle East, Europe, and Southeast Asia. This growth presents opportunities for both manufacturers and Pump Parts Suppliers to tap into new markets and enhance profitability.

The pump parts industry in India is flourishing, driven by quality manufacturing, innovation, and a growing demand for reliable components. Whether you are a manufacturer, supplier, or end-user, understanding the dynamics of this market can help you make informed decisions, ensuring optimal performance and longevity of your pump systems.

Visit: https://www.deccanew.com/pump-parts-manufacturers-suppliers-india.phpContact: 9657039991

0 notes

Text

Evolution of the Industrial Gases Market: Innovation and Demand Forecast

The global industrial gases market size is expected to reach USD 173.43 billion by 2030, registering a CAGR of 7.42% during the forecast period, according to a new report by Grand View Research, Inc. Industrial gas is a significant segment of the economic progress of any region. The region-wise market for these gases is expected to grow at a rate that is double the GDP rate. With the erudition of the world economy, the utilization of nitrogen has increased faster than that of oxygen. Argon, however, has picked up the market pace and can be expected to supersede oxygen in terms of utilities. Despite this, some countries, such as India, are still operating in the oxygen era.

With sophistication in the industrial sector, growth during the forecast period is expected to emerge from argon and nitrogen. With the diminution of fossil fuel resources, hydrogen might gain importance as a source of energy. The implementation of oxygen for environmental protection and energy conservation and the use of nitrogen gas in the food and packaging industry remains an instantaneous opportunity in the market. Using hydrogen for the desulphurization process of sour crude is anticipated to fuel demand for industrial gases. Simultaneously, LNG, shale gas CNG and LCNG could hold prospects for growth in the industry. Thus, the industry is expected to grow substantially through the use of conventional and unconventional applications.

Another major factor fostering industry growth is the rising healthcare industry. Utilization of improved medical technologies and increasing government expenditure on the healthcare industry is accelerating the applicability rate of industrial gases in various medical devices, such as Magnetic Resonance Imaging (MRI), Nuclear Magnetic Resource Imaging (NMRI), and ophthalmology. There are reputable local and international players in the global market. Some of these players have a lengthy history on the market. Due to the intense competition, the majority of players are concentrating on how to set themselves apart from the competition. For product manufacturers, creating extremely effective sales channels is yet another crucial element.

For More Details or Sample Copy please visit link @: Industrial Gases Market Report

Industrial Gases Market Report Highlights

Asia Pacific led the industry in 2022 owing to the growing electronics and healthcare industries in the region

The nitrogen product segment is estimated to register the highest growth rate from 2023 to 2030

This is owing to the increasing demand for nitrogen in the manufacturing of electronic products and devices

Over the next few years, the industry growth is anticipated to be driven by the high dependency of the healthcare and electronics sectors on industrial gases for technology advancements

Gain deeper insights on the market and receive your free copy with TOC now @: Industrial Gases Market Report

We have segmented the global industrial gases market based on product, application, distribution, and region.

#IndustrialGases#MarketAnalysis#IndustrialGasIndustry#GasSupplyChain#IndustrialGasesMarketTrends#MarketForecast#AirSeparationTechnology#GasManufacturers#IndustrialApplications#SustainabilityInGases#GasDemand#GlobalMarketInsights#EnergyAndGases#GasDistribution#FutureOfIndustrialGases

0 notes

Text

Top Benefits of Investing in Wholesale Scrubber Trucks

Top Benefits of Investing in Wholesale Scrubber Trucks

In the modern era, environmental regulations and sustainability initiatives are driving significant changes across various industries. One such change is the increasing adoption of scrubber trucks, particularly in wholesale markets. Scrubber trucks, also known as exhaust gas cleaning systems (EGCS), are designed to reduce harmful emissions from vehicles and industrial equipment. Investing in wholesale scrubber trucks offers numerous benefits, both economically and environmentally. This article explores the top benefits of investing in these innovative vehicles.

1. Cost Savings on Fuel

One of the primary benefits of investing in scrubber trucks is the potential for significant cost savings on fuel. Scrubber trucks allow for the continued use of high-sulfur fuel, which is generally cheaper than low-sulfur alternatives. By removing sulfur and other pollutants from the exhaust gases, scrubber trucks enable operators to comply with environmental regulations without the need to purchase more expensive low-sulfur fuel. This can result in substantial long-term savings, especially for businesses that operate large fleets of vehicles.

ForkLift internal combustion| China Manufacturer Trade price on Materials Handling internal combustion Fork-lifts Truck Sale Buy Online Importer of Industrial Equipment BUY in USA/UK/India/Australia

2. Compliance with Environmental Regulations

Environmental regulations are becoming increasingly stringent, particularly concerning emissions from vehicles and industrial equipment. Scrubber trucks help businesses comply with these regulations by effectively reducing the amount of sulfur and other harmful pollutants released into the atmosphere. This compliance is crucial for avoiding fines and penalties, as well as for maintaining a positive reputation in the market. Additionally, businesses that invest in scrubber trucks demonstrate their commitment to sustainability and environmental responsibility, which can enhance their brand image.

3. Improved Air Quality

By reducing the emissions of sulfur oxides (SOx) and other pollutants, scrubber trucks contribute to improved air quality. This is particularly important in urban areas and regions with high levels of industrial activity, where air pollution can have severe health impacts on the local population. Cleaner air leads to better public health outcomes, reducing the incidence of respiratory diseases and other pollution-related health issues. Investing in scrubber trucks, therefore, has a positive impact on the community and contributes to a healthier environment.

4. Enhanced Operational Efficiency

Scrubber trucks are designed to be highly efficient in their operation. They utilize advanced technology to remove pollutants from exhaust gases, ensuring that vehicles and equipment can operate at optimal performance levels. This enhanced efficiency can lead to reduced maintenance costs and longer lifespans for vehicles and equipment. Additionally, the use of scrubber trucks can minimize downtime, as they allow for continuous operation without the need for frequent fuel changes or other adjustments.

5. Market Competitiveness

Investing in scrubber trucks can provide a competitive edge in the market. As environmental regulations become more stringent, businesses that proactively adopt cleaner technologies will be better positioned to meet these requirements and avoid potential disruptions. Furthermore, customers and clients are increasingly prioritizing sustainability when making purchasing decisions. By investing in scrubber trucks, businesses can attract environmentally conscious customers and differentiate themselves from competitors who may not be as committed to sustainability.

6. Long-Term Investment

While the initial cost of purchasing scrubber trucks may be higher than traditional vehicles, the long-term benefits far outweigh the initial investment. The cost savings on fuel, reduced maintenance expenses, and compliance with environmental regulations all contribute to a favorable return on investment. Additionally, as technology continues to advance, the efficiency and effectiveness of scrubber trucks are likely to improve, further enhancing their value over time.

0 notes

Text

Aluminum Casting Market Size, Share, Growth Analysis And Forecast, 2030

The global aluminum casting market size was valued at USD 90.97 billion in 2022 and is estimated to exhibit a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030.

The increasing use of aluminum in automobiles owing to its high strength and lightweight is likely to drive the market over the coming years. Nearly 30-40% of aluminum is being used per lightweight vehicle every year and is likely to reach 70% over the coming years owing to stringent regulations on reducing fuel emissions across the globe. According to the Federal Reserve Bank of St. Louis, the global sales of lightweight vehicles reached 17.385 million units in May 2019. Thus, increasing demand for lightweight vehicles on account of soaring environmental pollution, rising disposable incomes, and changing lifestyles of consumers is anticipated to boost the demand for aluminum casting.

Gather more insights about the market drivers, restrains and growth of the Aluminum Casting Market

Increasing demand for general utility and sports utility vehicles is anticipated to drive product demand in the U.S. For instance, according to the automotive consultancy firm, LMC Automotive, the U.S. is likely to have more than 90 mainstream SUV models by 2023. Moreover, automobile manufacturers in the country are under increasing pressure to meet the regulatory requirements pertaining to the environmental impact of vehicles. As per Corporate Average Fuel Economy (CAFE), passenger cars are required to reach a fuel economy target of 54.5 miles per gallon by 2026 owing to the increasing emission of greenhouse gases, which, in turn, is anticipated to augment market growth.

The application scope of aluminum casting is widening to agricultural equipment, construction equipment, mining equipment, and other heavy-duty machinery. The growth in these types of machinery is largely attributed to developing economies such as India and Brazil, where there is a high need for modernizing equipment to attain greater levels of productivity and efficiency. India is among the largest manufacturers of farm equipment like tractors, tillers, and harvesters. Tractor sales in the country are expected to grow by nearly 8.0% from 2018 to 2022, thereby driving the market.

On the flip side, factors such as high prices of aluminum casting machinery, along with high investments in technological advancements in aluminum casting, are likely to hamper the market growth. Moreover, strict rules and guidelines laid down by the U.S. Environmental Protection Agency (EPA) and the European Environment Agency regarding harmful emissions into the environment during the casting process are likely to hinder market growth in the coming years.

Aluminum Casting Market Segmentation

Grand View Research has segmented the global aluminum casting market report based on process, end-use, and region:

Process Outlook (Volume, Kilotons; Revenue, USD Million; 2018 - 2030)

• Die casting

o Pressure die casting

o Others

• Permanent mold casting

• Others

End-Use Outlook (Volume, Kilotons; Revenue, USD Million; 2018 - 2030)

• Transportation

• Industrial

• Building & Construction

• Others

Regional Outlook (Volume, Kilotons; Revenue, USD Million; 2018 - 2030)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o Italy

o France

o Russia

• Asia Pacific

o China

o India

o Japan

o South Korea

• Central & South America

o Brazil

• Middle East & Africa

o South Africa

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

• The global sheet metal market size was valued at USD 188.31 billion in 2023 and is projected to grow at a CAGR of 7.0% from 2024 to 2030.

• The global mercury analyzer market size was estimated at USD 298.8 million in 2023 and is projected to to grow at a CAGR of 6.3% from 2024 to 2030.

Key Companies & Market Share Insights

The market is competitive and is likely to expand on account of the growing penetration of aluminum castings in EVs. For instance, in September 2020, Tesla announced the installation of aluminum casting machines for the production of chassis at a German plant, for increasing its EV production. This enables the company to leverage the market growth. Some prominent players in the global aluminum casting market include:

• Walbro

• Alcoa Corporation

• Consolidated Metco, Inc.

• BUVO Castings

• RDW Wolf, GmbH

• Georg Fischer Ltd.

• Dynacast

• GIBBS

• Ryobi Limited

• Martinrea Honsel Germany GmbH

• Bodine Aluminum

• Alcast Technologies

• Endurance Technologies Limited

• Aluminum Corporation of China Limited

Order a free sample PDF of the Aluminum Casting Market Intelligence Study, published by Grand View Research.

#Aluminum Casting Market#Aluminum Casting Industry#Aluminum Casting Market size#Aluminum Casting Market share#Aluminum Casting Market analysis

0 notes

Text

Discovering Atlantech a Leading Flow Meter Manufacturer in India

Discovering Atlantech a Leading Flow Meter Manufacturer in India

In the fast-paced world of industrial instrumentation, precision and reliability are paramount. When it comes to measuring fluid flow rates accurately, businesses across various sectors rely on advanced flow meter technologies. In India, a country known for its burgeoning industrial landscape, several manufacturers have risen to prominence, offering cutting-edge solutions that meet global standards. Among them, Atlantech stands out as a leader in flow meter manufacturing, combining innovation, quality, and robust customer support to cater to diverse industrial needs.

This comprehensive blog aims to explore Atlantech's journey to becoming a leading flow meter manufacturer in India. From their inception and technological prowess to their product offerings and market influence, we'll delve into what sets Atlantech apart in the competitive realm of flow measurement solutions.

Understanding Flow Meters: A Vital Component of Industrial Operations

Flow meters are indispensable devices used to measure the flow rate of liquids or gases through pipelines or conduits. They play a crucial role across industries such as oil and gas, water management, pharmaceuticals, chemicals, food and beverage, and more. Accurate flow measurement is not just about efficiency but also compliance with regulatory standards and optimal resource management.

In India, the demand for reliable flow meter solutions has grown significantly with the expansion of industrial sectors and the increasing emphasis on operational efficiency. Atlantech has been at the forefront of meeting these demands through their innovative product lineup and commitment to quality.

Atlantech: Pioneering Excellence in Flow Meter Technology

Founded 30 years ago, Atlantech has evolved into a powerhouse in the field of flow meter manufacturing in India. From their state-of-the-art production facilities to their dedicated research and development initiatives, Atlantech has consistently pushed the boundaries of innovation to deliver cutting-edge solutions that exceed industry standards.

Technological Advancements and Product Offerings

Atlantech offers a diverse range of flow meters tailored to meet the specific needs of different industries:

1. Electromagnetic Flow Meters: Known for their accuracy and reliability in measuring conductive liquids, Atlantech's electromagnetic flow meters are suitable for various applications, including wastewater management, chemical processing, and food and beverage industries.

2. Ultrasonic Flow Meters: These non-intrusive meters are ideal for measuring flow rates of liquids in pipes without disrupting the flow. Atlantech's ultrasonic flow meters are prized for their precision and versatility, making them a preferred choice across industries.

3. Mass Flow Meters: These meters are used for measuring the mass flow rate of gases. Atlantech's mass flow meters are engineered to deliver precise measurements, crucial for applications in pharmaceuticals, semiconductor manufacturing, and more.

Quality Assurance and Industry Standards

Atlantech places a strong emphasis on quality assurance, ensuring that all their products adhere to international standards and regulatory requirements. Their manufacturing processes are ISO-certified, underscoring their commitment to delivering products of the highest quality and reliability.

Innovation and Research & Development

At the heart of Atlantech's success lies their dedication to continuous innovation and R&D. They invest heavily in developing new technologies and enhancing existing products to stay ahead of industry trends. By collaborating with industry experts and leveraging feedback from customers, Atlantech continuously refines their product offerings to address evolving market needs.

Market Influence and Customer Satisfaction

Atlantech's reputation as a leading flow meter manufacturer in India is reinforced by their strong market presence and satisfied customer base. They have successfully penetrated diverse industrial sectors, including:

- Oil and Gas: Providing flow meter solutions for precise measurement in upstream, midstream, and downstream operations.

- Water Management: Offering solutions for efficient water flow measurement and management in municipal and industrial applications.

- Chemicals and Pharmaceuticals: Meeting the stringent requirements for accurate flow measurement in chemical processing and pharmaceutical manufacturing.

Customer-Centric Approach and Support Services

What sets Atlantech apart is their customer-centric approach. They prioritize understanding the unique requirements of each client and offer tailored solutions that ensure optimal performance and reliability. Their comprehensive after-sales support includes installation guidance, calibration services, and ongoing technical assistance, fostering long-term partnerships with their customers.

Sustainability Initiatives and Corporate Responsibility

Beyond technological prowess, Atlantech is committed to sustainability and corporate responsibility. They integrate eco-friendly practices into their operations, including energy-efficient manufacturing processes and recyclable materials in product design. By prioritizing sustainability, Atlantech not only reduces environmental impact but also aligns with the global shift towards green technologies.

Looking Towards the Future

As Atlantech continues to expand its footprint in the global market, they remain focused on driving innovation and exceeding customer expectations. Their strategic initiatives in IoT integration, data analytics, and predictive maintenance aim to further enhance operational efficiency and reliability for their clients.

Conclusion

In conclusion, Atlantech stands as a beacon of excellence in the realm of flow meter manufacturing in India. Through their unwavering commitment to innovation, quality, and customer satisfaction, they have earned the trust of industries nationwide. As they continue to innovate and adapt to technological advancements, Atlantech is poised to shape the future of flow measurement solutions, both in India and beyond.

For businesses seeking reliable flow meter solutions that combine cutting-edge technology with superior customer support, Atlantech remains the partner of choice. With a proven track record of delivering precision and reliability, Atlantech is committed to supporting industries in achieving their operational goals and driving growth in an increasingly competitive global landscape.

References

- Include references to industry reports, Atlantech's official website, customer testimonials, and other credible sources used to gather information for this blog.

Disclaimer

This blog aims to provide an overview of Atlantech as a leading flow meter manufacturer in India based on available information up to [current year]. The company's offerings and market position may evolve over time in response to industry trends and technological advancements. Readers are encouraged to conduct further research or contact Atlantech directly for the most current and specific information.

Connect with Atlantech

To learn more about Atlantech's innovative flow meter solutions or to discuss your specific requirements, visit [https://atlantech.in/] or contact their customer support team today. Discover how Atlantech can empower your business with precision, reliability, and technological excellence in flow measurement.

#electromagnetic flow meter manufacturers india#advantages of electromagnetic flow meters#flow meter supplier in india#electromagnetic flow meter application

0 notes

Text

The Role of Heat Treatment Systems in Enhancing Metal Durability & Performance

In the world of metallurgy, heat treatment systems play a crucial role in enhancing the durability and performance of metals. These systems involve a series of controlled heating and cooling processes that alter the physical and sometimes chemical properties of a material. By refining the internal structure of metals, heat treatment can significantly improve their strength, hardness, and overall performance, making them suitable for a wide range of industrial applications.

One of the most advanced and efficient methods in heat treatment is the use of Vacuum Heat Treatment Furnaces. These furnaces operate under low-pressure conditions, minimizing oxidation and contamination during the heating process. This environment is particularly beneficial for high-precision industries such as aerospace, automotive, and medical devices, where even the smallest imperfections can lead to significant failures.

HHV Thermal Technologies, a leader in this field, offers state-of-the-art vacuum heat treatment furnaces that are designed to meet the stringent requirements of modern manufacturing. Their furnaces provide precise temperature control, uniform heat distribution, and the ability to process complex shapes and alloys with high consistency. This ensures that the treated metals exhibit superior mechanical properties, such as enhanced fatigue strength and resistance to wear and corrosion.

The benefits of using vacuum heat treatment furnaces extend beyond just improving metal properties. These systems also offer environmental advantages. By operating in a vacuum, they reduce the need for harmful chemicals and gases, making the process cleaner and more sustainable. Furthermore, the energy efficiency of modern vacuum furnaces helps in reducing operational costs, making them an economically viable choice for manufacturers.

The process of heat treatment typically involves several stages, including annealing, quenching, and tempering. Each stage serves a specific purpose in modifying the metal's characteristics. For instance, annealing softens the metal, making it more workable, while quenching rapidly cools the metal to increase its hardness. Tempering, on the other hand, is used to achieve a balance between hardness and ductility, ensuring that the metal is both strong and flexible.

HHV Thermal Technologies has been at the forefront of developing innovative solutions in the field of heat treatment. Their expertise and cutting-edge technology have enabled them to create furnaces that deliver consistent and reliable results. By investing in such advanced heat treatment systems, manufacturers can ensure the longevity and performance of their products, thereby gaining a competitive edge in the market.

In conclusion, Heat Treatment Systems are indispensable in modern metallurgy, providing significant enhancements in metal durability and performance. The use of vacuum heat treatment furnaces represents the pinnacle of this technology, offering unparalleled benefits in terms of quality, efficiency, and environmental impact. With industry leaders like HHV Thermal Technologies driving innovation, the future of metal processing looks brighter and more promising than ever.

For more information, visit website: https://hhvthermaltech.com/

Contact Us

Site No. 17, Phase 1, Peenya Industrial Area, Bengaluru – 560058, India

Phone: +91-80-41931000

Fax: +91-80-41931100

Email: [email protected]

0 notes

Text

Anesthesia Gases Market is Estimated to Witness High Growth Owing to Increasing Applications in Medical Procedures

Anesthesia gases are used extensively during surgeries to induce and maintain anesthesia in patients undergoing surgical procedures. Some common anesthesia gases used are nitrous oxide, sevoflurane, desflurane and isoflurane. They help relax patients and block the transmission of pain signals from the surgical site to the brain. The increasing prevalence of chronic diseases and number of surgeries being performed globally is fueling the demand for anesthesia gases.

The Global Anesthesia Gases Market is estimated to be valued at US$ 2182.32 Bn in 2024 and is expected to exhibit a CAGR of 11% over the forecast period 2024 To 2031.

Key Takeaways

Key players operating in the Anesthesia Gases are Dirt Road Data, Inc., AgJunction LLC, Iteris, Inc., Site-Specific Technology Development Group, Inc., CropMetrics LLC, Trimble Navigation Ltd., Agribotix LLC, AgEagle Aerial Systems Inc., Granular, Inc., AgriSight, Inc., and SemiosBio Technologies Inc.

The Anesthesia Gases Market Size is expected to witness lucrative opportunities due to the rising geriatric population and increasing number of surgeries. Furthermore, innovations focused on developing less expensive anesthesia gases with improved efficacy are likely to open new avenues for market players.

Technological advancements have enabled the development of advanced anesthesia gas delivery systems with features such as optimized gas flow control, real-time respiratory monitoring and leak compensation. This has further enhanced patient safety and experience during surgical procedures.

Market drivers

Growing geriatric population - The risk of various chronic diseases and need for surgery rises with age. With an increasing elderly demographic globally, the demand for anesthesia gases is projected to surge considerably over the coming years.

Increasing healthcare expenditure - Rising disposable incomes and growing awareness about the importance of medical care have led to higher spending on healthcare services. This has provided a fillip to the number of surgeries being conducted worldwide.

Current challenges in Anesthesia Gases Market:

The anesthesia gases market faces challenges in terms of ensuring adequate and continuous supply of medical gases amidst the rising demand from healthcare facilities. Strict government regulations regarding the production, transportation and storage of medical gases also add to the compliance challenges for manufacturers. Moreover, growing shift towards green alternatives and eco-friendly technologies for reducing carbon footprint could impact the sales of certain anesthesia gases in the coming years.

SWOT Analysis

Strength: Used extensively for induction and maintenance of general anesthesia during surgical procedures. Wide application areas include cardiology, neurology, orthopedics among others.

Weakness: High infrastructure and logistics costs associated with production and supply of medical-grade gases. Stringent regulatory norms increase compliance burden.

Opportunity: Growing number of surgeries globally due to rising non-communicable diseases. Increasing healthcare expenditures in developing nations to boost demand.

Threats: Ongoing R&D into novel anesthesia techniques may pose competition in future. Potential supply chain disruptions and trade barriers can impact procurement.

Geographical regions of concentration:

North America captures over 35% share of total anesthesia gases market revenue due to well-established healthcare infrastructure and high surgical procedure rate. Asia Pacific is emerging as the fastest growing regional market with strong GDP growth in countries like India, China and Indonesia supporting healthcare investments.

Fastest growing region:

Asia Pacific anesthesia gases market is projected to witness over 13% CAGR during the forecast period on back of rapidly expanding medical tourism industry, growing disease incidence and increasing focus on bolstering healthcare access through government initiatives in several countries. Rising affluence of middle class populations will further propel the regional market expansion through 2031.

Get more insights on Anesthesia Gases Market

About Author:

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

#CoherentMarketinsights#AnesthesiaGases#AnesthesiaGasesMarket#AnesthesiaGasesMarketGrowth#AnesthesiaGasesMarketForecasts#Desflurane#Sevoflurane#Isoflurane#NitrousOxide

0 notes

Text

Specialty Gases for FPD Market Analysis, Demand, Trends and Forecast 2030

On 2024-8-8 Global Info Research released【Global Specialty Gases for FPD Market 2024 by Manufacturers, Regions, Type and Application, Forecast to 2030】. This report includes an overview of the development of the Specialty Gases for FPD industry chain, the market status of Consumer Electronics (Nickel-Zinc Ferrite Core, Mn-Zn Ferrite Core), Household Appliances (Nickel-Zinc Ferrite Core, Mn-Zn Ferrite Core), and key enterprises in developed and developing market, and analysed the cutting-edge technology, patent, hot applications and market trends of Specialty Gases for FPD.

According to our (Global Info Research) latest study, the global Specialty Gases for FPD market size was valued at US$ 984 million in 2023 and is forecast to a readjusted size of USD 1527 million by 2030 with a CAGR of 7.1% during review period.

This report is a detailed and comprehensive analysis for global Specialty Gases for FPD market. Both quantitative and qualitative analyses are presented by company, by region & country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2024, are provided.

Market segment by Type: CVD Gas、Deposition Gas、Ion Implantation Gas、Etching Gas、Laser Gas

Market segment by Application:LCD、OLED、LED

Major players covered: SK specialty、Merck (Versum Materials)、Taiyo Nippon Sanso、Linde plc、Kanto Denka Kogyo、Hyosung、PERIC、Resonac、Solvay、Nippon Sanso、Air Liquide、Air Products、Foosung Co Ltd、Jiangsu Yoke Technology、Jinhong Gas、Linggas、Mitsui Chemical、ChemChina、Shandong FeiYuan、Guangdong Huate Gas、Central Glass、Jiangsu Nata Opto-electronic Material、Hunan Kaimeite Gases

Market segment by region, regional analysis covers: North America (United States, Canada and Mexico), Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe), Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia),South America (Brazil, Argentina, Colombia, and Rest of South America),Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa).

The content of the study subjects, includes a total of 15 chapters:

Chapter 1, to describe Specialty Gases for FPD product scope, market overview, market estimation caveats and base year.

Chapter 2, to profile the top manufacturers of Specialty Gases for FPD, with price, sales, revenue and global market share of Specialty Gases for FPD from 2019 to 2024.

Chapter 3, the Specialty Gases for FPD competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast.

Chapter 4, the Specialty Gases for FPD breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2019 to 2030.

Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2019 to 2030.

Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2017 to 2023.and Specialty Gases for FPD market forecast, by regions, type and application, with sales and revenue, from 2025 to 2030.

Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis.

Chapter 13, the key raw materials and key suppliers, and industry chain of Specialty Gases for FPD.

Chapter 14 and 15, to describe Specialty Gases for FPD sales channel, distributors, customers, research findings and conclusion.

Data Sources:

Via authorized organizations:customs statistics, industrial associations, relevant international societies, and academic publications etc.

Via trusted Internet sources.Such as industry news, publications on this industry, annual reports of public companies, Bloomberg Business, Wind Info, Hoovers, Factiva (Dow Jones & Company), Trading Economics, News Network, Statista, Federal Reserve Economic Data, BIS Statistics, ICIS, Companies House Documentsm, investor presentations, SEC filings of companies, etc.

Via interviews. Our interviewees includes manufacturers, related companies, industry experts, distributors, business (sales) staff, directors, CEO, marketing executives, executives from related industries/organizations, customers and raw material suppliers to obtain the latest information on the primary market;

Via data exchange. We have been consulting in this industry for 16 years and have collaborations with the players in this field. Thus, we get access to (part of) their unpublished data, by exchanging with them the data we have.

From our partners.We have information agencies as partners and they are located worldwide, thus we get (or purchase) the latest data from them.

Via our long-term tracking and gathering of data from this industry.We have a database that contains history data regarding the market.

Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

Excellence in PTFE Production and Global Reach - Goa Polymer

In the dynamic world of industrial materials, Polytetrafluoroethylene (PTFE) stands out as a versatile and high-performance polymer. Known for its exceptional chemical resistance, low friction, and high thermal stability, PTFE is a go-to material in various applications, from electrical insulation to chemical processing. In India, Goa Polymer has emerged as a leading name in the manufacturing of PTFE products, setting benchmarks for quality, innovation, and reliability. This comprehensive guide explores Goa Polymer's journey, its role as a premier PTFE product manufacturer in India, and how it stands out in the competitive landscape.

Goa Polymer: A Legacy of Excellence

Goa Polymer was founded with a vision to revolutionize the polymer industry in India. With years of expertise and a commitment to quality, the company has established itself as a leading player in the PTFE market. From its humble beginnings to becoming a trusted name among industrial giants, Goa Polymer's journey is marked by relentless pursuit of excellence and innovation.

The Significance of PTFE Products

PTFE, commonly known by its brand name Teflon, is celebrated for its remarkable properties. The material's resistance to high temperatures, chemicals, and electrical conductivity makes it indispensable across a range of industries:

Chemical Processing: PTFE's non-reactive nature allows it to withstand harsh chemicals, making it ideal for linings, seals, and gaskets in chemical reactors.

Electrical Insulation: With its excellent dielectric properties, PTFE is widely used for insulating wires and cables in high-frequency applications.

Food Processing: The non-stick nature of PTFE is used in cooking equipment and food processing machinery to prevent sticking and ensure easy cleaning.

Aerospace and Defense: PTFE's resistance to extreme temperatures and chemicals makes it suitable for various aerospace and defense applications.

Given its importance, the demand for high-quality PTFE products is ever-growing, and Goa Polymer has risen to meet this need with unparalleled expertise.

Goa Polymer’s Product Portfolio

Goa Polymer offers an extensive range of PTFE products designed to meet diverse industrial requirements. Each product is crafted with precision to ensure it adheres to the highest standards of quality and performance. The company’s product portfolio includes:

PTFE Sheets: Ideal for use as liners, seals, and gaskets, these sheets are available in various thicknesses and sizes.

PTFE Rods: Used in manufacturing custom components, these rods offer excellent machinability and durability.

PTFE Films: Thin and flexible, PTFE films are used in applications requiring high clarity and electrical insulation.

PTFE Tubes and Pipes: Essential for conveying fluids and gases in corrosive environments, these tubes and pipes maintain their integrity under extreme conditions.

PTFE Gaskets and Seals: Customized to fit specific applications, these gaskets and seals provide reliable performance in sealing applications.

Quality Assurance at Goa Polymer

Quality is the cornerstone of Goa Polymer's operations. The company employs stringent quality control measures at every stage of production to ensure that each product meets the highest standards. Key aspects of their quality assurance process include:

Raw Material Inspection: Only the highest quality PTFE resins are used in manufacturing, sourced from reputable suppliers.

Advanced Manufacturing Techniques: Goa Polymer utilizes state-of-the-art machinery and processes to produce PTFE products with precise dimensions and superior performance.

Rigorous Testing: Each product undergoes thorough testing for chemical resistance, temperature tolerance, and mechanical strength to ensure it performs reliably in real-world applications.

Certifications: Goa Polymer holds various industry certifications that affirm its commitment to quality, including ISO 9001 for quality management systems.

Innovation and Technology

At Goa Polymer, innovation is a driving force. The company invests in research and development to enhance its product offerings and stay ahead of industry trends. Some of the technological advancements include:

Custom Solutions: Goa Polymer offers tailored PTFE solutions to meet specific customer needs, including bespoke dimensions and specialized formulations.

Advanced Manufacturing Techniques: The use of cutting-edge technologies in extrusion, molding, and machining ensures the production of high-quality PTFE products.

Sustainability Initiatives: Goa Polymer is committed to sustainability, implementing eco-friendly practices in its manufacturing processes and striving to reduce its environmental footprint.

Industry Applications and Success Stories

Goa Polymer’s PTFE products are employed across various industries, each benefiting from the material’s unique properties. Some notable applications and success stories include:

Chemical Industry: Goa Polymer has supplied PTFE liners and seals for major chemical processing plants, enhancing their operational efficiency and safety.

Electrical Industry: The company’s PTFE insulating materials are used in high-frequency cable assemblies, ensuring reliable performance in critical applications.

Food Processing: PTFE-coated equipment provided by Goa Polymer has been instrumental in improving the efficiency and hygiene of food processing operations.

Aerospace: Goa Polymer’s PTFE components have been used in aerospace applications, contributing to the performance and reliability of advanced systems.

Customer-Centric Approach

Goa Polymer’s commitment to customer satisfaction is evident in its customer-centric approach. The company values long-term relationships and strives to understand and meet the unique needs of its clients. Key aspects of their approach include:

Consultative Sales Process: Goa Polymer’s sales team works closely with clients to provide expert advice and recommendations tailored to their specific requirements.

Timely Delivery: The company ensures prompt delivery of products, adhering to agreed timelines and minimizing downtime for clients.

After-Sales Support: Goa Polymer offers comprehensive after-sales support, addressing any issues or concerns that may arise post-purchase.

Global Presence and Market Reach

While Goa Polymer is a prominent name in India, its reputation extends globally. The company has established a strong market presence through strategic partnerships and export operations. By adhering to international quality standards, Goa Polymer has successfully catered to clients across various countries, further solidifying its position as a leading PTFE product manufacturer.

Future Outlook and Expansion Plans

Looking ahead, Goa Polymer is poised for continued growth and innovation. The company plans to expand its product range, enhance its manufacturing capabilities, and explore new markets. With a focus on sustainability and technological advancements, Goa Polymer aims to maintain its leadership position in the PTFE industry and continue delivering exceptional value to its customers.

Conclusion

Goa Polymer’s standing as one of the leading PTFE product manufacturers in India is a testament to its unwavering commitment to quality, innovation, and customer satisfaction. Through its extensive product portfolio, state-of-the-art manufacturing processes, and customer-centric approach, Goa Polymer has set new standards in the industry. As the demand for PTFE products continues to grow, Goa Polymer remains at the forefront, driving excellence and shaping the future of polymer technology.

For more information about Goa Polymer and its range of PTFE products, visit their website or contact their sales team to explore how they can meet your industrial needs with precision and reliability.

0 notes

Text

Liquid-cooled charging technology leads the charge revolution for electric vehicles

The rapid advancement of electric vehicle (EV) charging infrastructure has ushered in the era of liquid-cooled charging systems, effectively mitigating temperature concerns during the charging process. This technological leap has been instrumental in the global shift away from traditional fuel vehicles, propelling the exponential growth of the electric vehicle market.

The surge in electric vehicle (EV) adoption symbolizes a significant transition towards modern transportation solutions. Within this transformative landscape, liquid-cooled charging piles have emerged as a pivotal innovation, successfully addressing the prevalent challenges associated with charging processes and garnering acclaim within the competitive industry sphere.

Global Expansion of Charging Infrastructure

The swift progress of the new energy vehicle sector on a worldwide scale is driving the expansion of the EV market. In response to this momentum, several countries have set ambitious deadlines to phase out the sale of conventional fuel-powered vehicles. Leading the charge, countries like Norway and the Netherlands aim for a ban by 2025, with others such as Germany, Belgium, Switzerland, Sweden, and India following suit by 2030. The United Kingdom and France have set a later phase-out target in 2040.

The global movement towards phasing out fuel vehicle sales is fueling the rapid growth of the EV industry. Prominent automotive manufacturers, both domestic and international, are unveiling bold plans for EV development. As EV sales continue to soar, the demand for charging infrastructure becomes increasingly crucial. Presently, Japan boasts a ratio of 7 EVs to 1 public charging station, the United States stands at 18:1, and Europe maintains a ratio of 10.8:1. While these figures are not yet optimal, ongoing enhancements are anticipated annually.

Introduction of Liquid-Cooled Charging Piles

Liquid-cooled charging piles represent a cutting-edge charging solution poised for widespread adoption. This technology effectively manages temperature fluctuations during the charging process, enhancing both the efficiency and safety of charging operations.

The architecture of liquid-cooled charging piles encompasses several key components:

1. Charging Unit: Upon connection to an EV, the charging unit activates, converting electrical energy into direct current for the vehicle's battery. This conversion process generates significant heat, necessitating efficient heat dissipation to protect both the charging pile and the EV.

2. Liquid Cooling System: Comprising a radiator, water pump, water tank, and a network of pipes, this system transfers heat from the charger to the water tank. The water pump circulates the heated liquid to the radiator for effective cooling.

3. Control System: Designed to monitor the status of the charging pile and the connected EVs, the control system makes necessary adjustments to ensure optimal performance.

Advantages of Liquid-Cooled Charging Piles

1. Enhanced Charging Speed and Current Capacity: Liquid-cooled charging piles, equipped with an integrated cooling system, enhance the current-carrying capacity, resulting in faster charging processes by mitigating heat-related constraints.

2. High Protection Level (IP65): In contrast to conventional air-cooled charging stations with an IP54 rating, fully liquid-cooled charging piles offer an IP65 protection level, enhancing resilience against dust and flammable gases and broadening their suitability across diverse environments.

3. Noise Reduction: Liquid-cooled charging piles operate at significantly lower noise levels (35dB) compared to traditional air-cooled stations, which can be noisy due to multiple cooling fans, often exceeding 70 dB.

4. Extended Lifespan and Reduced Maintenance: Liquid-cooled charging piles offer a longer service life of over a decade, streamlining maintenance routines and reducing overall costs compared to standard charging stations with a typical lifespan of approximately 5 years.

5. Integration of Vehicle-to-Grid (V2G) Technology: Liquid-cooled charging piles support V2G technology, facilitating charging during off-peak hours and electricity feed-back into the grid during peak times, optimizing grid performance and energy efficiency.

AEAUTO's Liquid-Cooled Charging Pile Solution

AEAUTO's liquid-cooled charging piles have achieved significant progress in overcoming thermal challenges associated with high-power supercharging, particularly for demanding supercharging needs ranging from 400-600A. Equipped with advanced cooling mechanisms, AEAUTO's charging piles surpass traditional air-cooled counterparts by effectively managing heat at high currents, supporting increased charging capacities.

These versatile charging stations from AEAUTO are well-suited for various settings, including public parking areas, fuel stations, logistics hubs, and EV rental facilities. They cater to concentrated charging requirements for public transport vehicles such as buses, taxis, and heavy-duty trucks, and are ideal for public service areas like highway rest stops.

In the realm of electric vehicle charging, AEAUTO's liquid-cooled charging infrastructure shines as a symbol of progress and efficiency. Tailored to meet the demands of high-power supercharging, these advanced systems not only offer adaptable solutions for diverse environments but also establish a new standard in electric vehicle charging technology, paving the way for a sustainable and dynamic future in the realm of electric mobility.

#charging stations for electric car#ev charger#ev charging#electric charging station#ev fast charger

0 notes

Text

Sachiya Steel International: Leading the Way in Large Diameter Pipe Manufacturer in India

Large Diameter Pipes play a crucial role in industrial infrastructure and construction projects, efficiently transporting fluids and gases across great distances. India, as a rapidly advancing nation with expanding infrastructure needs, is witnessing a growing demand for quality large diameter pipes. Sachiya Steel International Private Limited has emerged as India's premier producer of spiral welded large diameter pipes, setting benchmarks for quality, innovation, and customer satisfaction.

Introduction to Large Diameter Pipes

Large diameter pipes, typically defined as those exceeding 24 inches in diameter, are indispensable in many sectors, including oil and gas transmission, water supply networks, sewer systems, bridge construction, and tunnel projects. Engineered to withstand high-pressure environments while offering long-term durability, these essential pipes play a significant part in critical infrastructure projects worldwide.

Sachiya Steel International: A Pioneer in Large Diameter Pipes

Sachiya Steel International Private Limited has rapidly emerged as a leader in India’s large diameter pipe manufacturing sector. Driven by principles of excellence and innovation, Sachiya Steel has made an impressive presence by consistently delivering top-of-the-line products tailored to suit a diverse set of client needs. Their cutting-edge facilities feature state-of-the-art technology and stringent quality control protocols to guarantee that every pipe produced meets international performance and reliability standards.

Product Range and Expertise

Sachiya Steel offers an impressive variety of large diameter pipes, including:

Spiral Welded Pipes

Sachiya Steel’s spiral welded pipes are widely respected for their strength and versatility, serving as the cornerstone of its product portfolio. Crafted using high-grade steel coils, they are helically formed and welded to create seamless pipes that can withstand diverse pressures and environmental conditions.

ERW Pipes

Sachiya Steel excels at producing Electric Resistance Welded (ERW) pipes. Produced by cold-forming flat steel strips into tubular shapes before welding the edges together, these ERW pipes are known for their uniform thickness and accurate dimensions, making them suitable for structural applications.

Seamless Pipes

Sachiya Steel offers seamless pipes, made without seams or welds, which are known for their exceptional strength and reliability. These pipes are ideal for applications requiring high pressure resistance and corrosion protection, establishing Sachiya Steel as a producer of some of the highest-grade seamless steel products on the market today.

Quality Assurance and Certifications

Sachiya Steel places great emphasis on quality assurance throughout its production processes. A team of expert professionals oversees each step to guarantee that every pipe meets the highest standards of performance and quality. Sachiya Steel proudly holds ISO 9001:2015 certification, demonstrating its dedication to excellence and customer satisfaction.

Application Areas

Sachiya Steel’s large diameter pipes find widespread application across a diverse spectrum of industries and projects, including:

Oil and Gas: Transporting crude oil, natural gas, and petroleum products.

Water Supply: Distributing potable water to urban and rural areas.

Construction: Facilitating the construction of bridges, tunnels, and other infrastructure projects.

Mining: Ventilating mines and transporting minerals.

Customization and Customer Satisfaction

Sachiya Steel recognizes the unique requirements of each project and offers customized large diameter pipes. Clients can tailor specifications such as wall thickness, coatings, and finishes to their project needs. With punctual delivery and competitive pricing, Sachiya Steel has earned a reputation for reliability and client satisfaction.

Examples of Custom Coatings

Bitumen Coating (IS: 3589): Ideal for road crossings and aggressive soil conditions.

Zinc Coating (Galvanizing) (ASTM A123, IS: 1239): Suitable for structural support and outdoor applications.

Environmental Responsibility

Sachiya Steel prides itself on adhering to environmental regulations and prioritizing sustainable manufacturing practices as part of its corporate social responsibility commitments. Additionally, Sachiya Steel actively seeks to minimize its carbon footprint through efficient energy usage and comprehensive waste management strategies, demonstrating its commitment to environmental stewardship.

Conclusion

Sachiya Steel International Private Limited stands as an innovator and pioneer in India’s large diameter pipe manufacturing sector. With an expansive product range, unwavering commitment to excellence, and dedication to sustainability, Sachiya Steel continues to set industry standards while exceeding customer expectations. For industries looking for reliable large diameter pipes that drive progress and shape infrastructure development both domestically and globally, Sachiya Steel remains a trusted partner, delivering solutions that propel infrastructure development forward.

Read More: Large Diameter Pipe Manufacturer in India

0 notes

Text

Vacuum Sucker Market Size, Share 2024 to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Vacuum Sucker Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2031.” The study provides a detailed analysis of the industry, including the global Vacuum Sucker Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Vacuum Sucker?

The global vacuum sucker market revenue was USD 860.61 Million in 2021. The expected revenue CAGR over the forecast period is 6.4% and the market value is expected to reach USD 1127.26 Million in 2031.

What are Vacuum Sucker Market?

A vacuum sucker is a device crafted to generate suction by eliminating air or other gases from a confined space, inducing a partial vacuum. It usually involves a pump or mechanism that evacuates air from an enclosed area, generating negative pressure, consequently attracting fluids, particles, or objects towards the vacuum source. Vacuum suckers are utilized in a wide range of applications, ranging from household vacuum cleaners employing suction to eliminate dirt and debris to industrial settings where they play a crucial role in material handling, packaging, and diverse manufacturing processes requiring the extraction of air or gases.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1901

What are the growth prospects and trends in the Vacuum Sucker Market industry?

The vacuum sucker market growth is driven by various factors. The vacuum sucker market is witnessing robust growth, driven by a rising demand across various industries. These devices, designed to generate suction and create a partial vacuum, are finding increased applications in manufacturing, packaging, and material handling sectors. The market is experiencing continuous expansion with technological advancements, leading to product innovations and improved capabilities. Globally, the vacuum sucker market is characterized by competitiveness, as key players emphasize research and development to introduce efficient and adaptable suction solutions that meet the evolving requirements of diverse industries. Recognizing the advantages of vacuum suckers in enhancing processes and efficiency, industries are contributing to the ongoing expansion of the market. Hence, all these factors contribute to vacuum sucker market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type:

Electric Vacuum Suckers

Pneumatic Vacuum Suckers

Hybrid Vacuum Suckers

By End-Use Industry:

Automotive

Electronics

Food & Beverage

Packaging

Pharmaceutical

Logistics & Warehousing

Others

By Application:

Material Handling

Assembly & Robotics

Pick & Place

Packaging & Palletizing

Inspection & Testing

Others

By Sales Channel:

Direct Sales

Distributors/Wholesalers

E-commerce

Global Market Segmentation by Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europ

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Piab AB

Schmalz Inc.

Festo AG & Co. KG

SMC Corporation

Aventics GmbH

VACUUBRAND GMBH + CO KG

Vaccon Company, Inc.

SMC Corporation of America

Pneumadyne, Inc.

Schmalz GmbH

Vuototecnica S.p.A.

DESTACO, a Dover Company

ANVER Corporation

AERO-LIFT Vakuumtechnik GmbH

VMECA Co., Ltd.

Discover more: https://www.reportsandinsights.com/report/Vacuum Sucker-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Vacuum Sucker Market Size#Vacuum Sucker Market Share#Vacuum Sucker Market Demand#Vacuum Sucker Market Analysis

0 notes

Text

Growth Opportunities in the HDPE Pipes Market: Trends and Forecasts for 2024

High-Density Polyethylene (HDPE) pipes are renowned for their high strength-to-density ratio, making them ideal for a range of applications, including water supply, irrigation, gas distribution, and industrial usage. HDPE pipes offer advantages such as corrosion resistance, flexibility, and durability, positioning them as a preferred choice in various sectors. The HDPE pipes market has witnessed substantial growth over the past decade, driven by increasing infrastructure development, urbanization, and the need for sustainable water management solutions.

Market Size and Growth

The global HDPE pipes market is projected to grow significantly from 2021 to 2031. In 2021, the market size was valued at approximately USD 17.2 billion and is expected to reach USD 26.5 billion by 2031, growing at a compound annual growth rate (CAGR) of 4.5%. This growth is attributed to rising investments in infrastructure projects, expanding irrigation networks, and increasing adoption of HDPE pipes in various industrial applications.

Download Sample of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=77481

Market Segmentation

By Service Type

Installation Services: Includes the laying and fitting of HDPE pipes.

Repair & Maintenance Services: Involves regular upkeep and repair of existing HDPE pipe systems.

By Sourcing Type

Primary Sourcing: Directly from manufacturers.

Secondary Sourcing: Through distributors and suppliers.

By Application

Water Supply: Municipal and residential water distribution.

Irrigation: Agricultural water management systems.

Gas Distribution: Piping for natural gas and other gases.

Sewage Systems: Wastewater management infrastructure.

Industrial Applications: Usage in chemical, pharmaceutical, and other industries.

By Industry Vertical

Agriculture: Extensive use in irrigation systems.

Building & Construction: Usage in plumbing and drainage systems.

Oil & Gas: Pipelines for gas distribution.

Chemical: Transporting chemicals due to high corrosion resistance.

Others: Various other sectors including mining and textile.

By Region

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Regional Analysis

North America

North America is a mature market for HDPE pipes, with significant demand driven by replacement and upgrading of old infrastructure. The U.S. is the leading contributor in this region due to its substantial investments in water infrastructure and gas distribution networks.

Europe

Europe exhibits moderate growth, primarily due to stringent environmental regulations and the focus on sustainable development. Countries like Germany, France, and the UK are key markets in this region.

Asia-Pacific

Asia-Pacific is the fastest-growing region in the HDPE pipes market, propelled by rapid urbanization, industrialization, and agricultural developments. China and India are major contributors, with significant investments in infrastructure and irrigation projects.

Latin America

Growth in Latin America is driven by infrastructure development and the agricultural sector's expansion. Brazil and Mexico are leading markets in this region.

Middle East & Africa

The Middle East & Africa region shows considerable growth potential due to increasing construction activities, urbanization, and the need for efficient water management solutions.

Market Drivers and Challenges

Drivers

Infrastructure Development: Rising investments in water supply and sewage systems drive market growth.

Urbanization: Increasing urban population necessitates efficient water and gas distribution systems.

Agricultural Advancements: Growing need for efficient irrigation systems to boost agricultural productivity.

Industrial Growth: Expanding industrial sector demands durable and flexible piping solutions.

Challenges

High Initial Costs: The initial investment for HDPE pipes can be high compared to other materials.

Competition from Alternatives: Availability of alternative materials like PVC and metal pipes.

Environmental Concerns: Disposal and recycling of HDPE pipes pose environmental challenges.

Market Trends

Adoption of Smart Irrigation Systems: Integration of HDPE pipes with advanced irrigation technologies.

Technological Innovations: Development of new HDPE pipe grades with enhanced properties.

Sustainability Focus: Increasing use of recycled HDPE materials in pipe manufacturing.

Expansion in Emerging Markets: Growth opportunities in developing countries with expanding infrastructure needs.

Future Outlook

The HDPE pipes market is expected to continue its robust growth trajectory over the next decade. Advancements in material technology, increasing environmental awareness, and the ongoing infrastructure boom in emerging economies will fuel market expansion. Additionally, innovations aimed at improving the sustainability and performance of HDPE pipes will create new growth avenues.

Key Market Study Points

Market size and growth projections from 2021 to 2031.

Segmentation analysis by service type, sourcing type, application, industry vertical, and region.

Regional market performance and growth prospects.

Key drivers, challenges, and trends shaping the market.

Competitive landscape and recent developments in the industry.

Competitive Landscape

The HDPE pipes market is highly competitive, with key players focusing on product innovation, strategic partnerships, and regional expansion. Major companies operating in this market include:

JM Eagle Inc.

WL Plastics

ADS Inc.

Chevron Phillips Chemical Company

Aliaxis Group S.A.

Sekisui Chemical Co., Ltd.

Uponor Corporation

Pipelife International GmbH

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=77481<ype=S

Recent Developments

Product Launches: Introduction of new HDPE pipe grades with improved properties.

Mergers & Acquisitions: Strategic acquisitions to expand market presence and capabilities.

Partnerships: Collaborations with construction and agricultural companies for joint projects.

Sustainability Initiatives: Efforts to increase the use of recycled HDPE materials in production.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

The Biodegradable Films Market: Trends, Growth, and Future Prospects

The global biodegradable films market has been experiencing substantial growth, driven by increasing environmental awareness, stringent regulatory policies, and the rising demand for sustainable packaging solutions. Biodegradable films, made from natural polymers such as starch, cellulose, and polylactic acid (PLA), decompose under natural conditions, thereby reducing environmental pollution and landfill waste. This article delves into the current state of the biodegradable films market, key trends, growth drivers, and future prospects.

Market Overview

As of 2023, the biodegradable films market is valued at approximately $1.4 billion and is expected to grow at a compound annual growth rate (CAGR) of around 10% from 2024 to 2030. The market’s expansion is propelled by the increasing adoption of eco-friendly materials in various industries, including food packaging, agriculture, and consumer goods.

Key Trends Driving the Market

1. Environmental Concerns and Regulations: