#India Industrial Gases Industry

Text

Industrial Gases Market In India Is Significantly Growing Due To The Continuous Industrialization And Development Happening In The End User Market- Ken Research

1. Indian industrial market is picking up pace with its global counterparts and is exploring the dynamics that this market is offering.

To Know More about this report, download a Free Sample Report

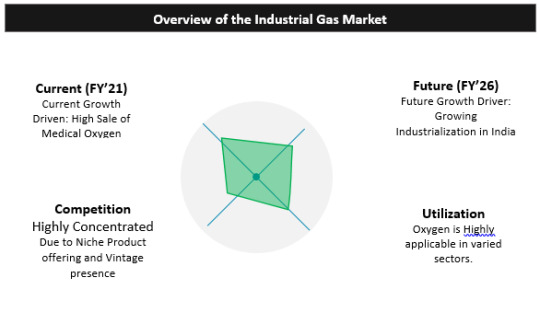

There exists a long tail of small manufacturers for Industrial Gas in Indian market. The role of industrial gases is constantly being revised to make various manufacturing processes sustainable and economical. Moreover, Indian industrial market is also picking up pace with its global counterparts and is exploring the dynamics that this market is offering. When it comes to the impact of the global pandemic, healthcare market increased its use of Oxygen gas drastically which in turn has resulted in an increased demand for gases. Market is also witnessing a growing competition between domestic and international players in India such as Inox Air Products, Praxair-Linde and more. This has also led to a significant price reduction of industrial gases in India. Apart from the healthy competition brewing between local and global player, the vigorous competition amongst small manufacturers along with the issue of overcapacity, lack of funding for smaller players and minimal technology up-gradation are some issue that the industry deals with.

2. Overall industrial gas market is highly concentrated among the top players but it has a fragmented tail with many small scale producers

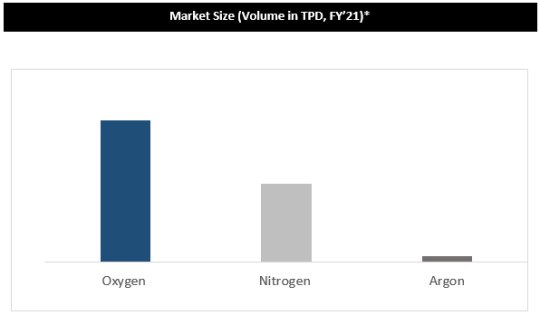

When it comes to the overall industrial gases market in India, it is expected that the market size will increase manifold in upcoming years owing to an increased utilization Rate for Oxygen, Argon and Nitrogen, as India is becoming a pivot for manufacturing. Moreover, initiatives such as “Make in India” have also driven industrialization to some extent. Talking about the oxygen market, it is expected to grow at a CAGR of 6.7% in terms of volume in TPD. Its popularity can be attributed to it being the key component for most industrial process and its diversified uses in different sectors. The Nitrogen & Argon gas market is expected to grow at a CAGR of 8% & 6% respectively. While nitrogen has the same use as oxygen in most cases, argon has been popular because of an increasing interest towards blended gases.

3. Industrial Gases market is highly concentrated as well as organized among the Top Players, however it is very fragmented among the small scale Industries

Visit This link Request for Custom Report

Industrial Gas Market is highly concentrated among the top player. It is distributed in both organized and fragmented sector. Many small scale producers exist in the market which results in a large fragmented section. When it comes to the key product segment, oxygen is the key product segment & argon is the least.

For more insights on the market intelligence, refer to the link below

India Industrial Gases Market Research Report

#Air Liquide Industrial Gases Market Sales#Air Water Industrial Gases Market Revenue#Covid-19 Impact India Industrial Gases Industry#Covid-19 Impact India Industrial Gases Market#Evaluation Summary Report India Industrial Gases Market share#HS Kanthi Industrial Gasses Ltd. Industrial Gases Market Size#India Industrial Gases Exports#India Industrial Gases Growth Strategy Market Report#India Industrial Gases Imports#India Industrial Gases Industry#India Industrial Gases Industry Research Report#India Industrial Gases Makers#India Industrial Gases Manufacturers#India Industrial Gases Market#India Industrial Gases Market Analysis#India Industrial Gases Market Competition#India Industrial Gases Market Competition Benchmarking#India Industrial Gases Market Evaluation Report#India Industrial Gases Market Forecast#India Industrial Gases Market Future Outlook#India Industrial Gases Market Growth#India Industrial Gases Market Major Players#India Industrial Gases Market Research Report#India Industrial Gases Market Revenue#India Industrial Gases Market Revenue Forecasting#India Industrial Gases Market Sales#India Industrial Gases Market Shares#India Industrial Gases Market Size#India Industrial Gases Market Trends#India Industrial Gases Tanker Manufacturers

0 notes

Text

BEST PRESSURE VESSELS MANUFACTURERS, SUPPLIERS IN PUNE INDIAA pressure vessel is a storage vessel or tank designed to hold fluids (gases/ liquids/ both) at high pressures. These include industrial compressed air receivers, flash

#BEST PRESSURE VESSELS MANUFACTURERS#SUPPLIERS IN PUNE INDIA#A pressure vessel is a storage vessel or tank designed to hold fluids (gases/ liquids/ both) at high pressures. These include industrial co#flash#heat exchanger

0 notes

Text

India Industrial Gases Market Outlook to 2026

Explore the expansive Indian industrial gases industry, its growth trajectory, and key players shaping the industry landscape. Delve into the competitive arena, discovering India industrial gases market major players, their strategies, and how they strive to lead and innovate in this dynamic and evolving market. Stay informed about the latest developments and gain insights into the future outlook of the Indian industrial gases market, including anticipated trends, growth prospects, and the factors that will drive this market forward in the coming years.

0 notes

Text

The World's Forests Are Doing Much Better Than We Think

You might be surprised to discover... that many of the world’s woodlands are in a surprisingly good condition. The destruction of tropical forests gets so much (justified) attention that we’re at risk of missing how much progress we’re making in cooler climates.

That’s a mistake. The slow recovery of temperate and polar forests won’t be enough to offset global warming, without radical reductions in carbon emissions. Even so, it’s evidence that we’re capable of reversing the damage from the oldest form of human-induced climate change — and can do the same again.

Take England. Forest coverage now is greater than at any time since the Black Death nearly 700 years ago, with some 1.33 million hectares of the country covered in woodlands. The UK as a whole has nearly three times as much forest as it did at the start of the 20th century.

That’s not by a long way the most impressive performance. China’s forests have increased by about 607,000 square kilometers since 1992, a region the size of Ukraine. The European Union has added an area equivalent to Cambodia to its woodlands, while the US and India have together planted forests that would cover Bangladesh in an unbroken canopy of leaves.

Logging in the tropics means that the world as a whole is still losing trees. Brazil alone removed enough woodland since 1992 to counteract all the growth in China, the EU and US put together. Even so, the planet’s forests as a whole may no longer be contributing to the warming of the planet. On net, they probably sucked about 200 million metric tons of carbon dioxide from the atmosphere each year between 2011 and 2020, according to a 2021 study. The CO2 taken up by trees narrowly exceeded the amount released by deforestation. That’s a drop in the ocean next to the 53.8 billion tons of greenhouse gases emitted in 2022 — but it’s a sign that not every climate indicator is pointing toward doom...

More than a quarter of Japan is covered with planted forests that in many cases are so old they’re barely recognized as such. Forest cover reached its lowest extent during World War II, when trees were felled by the million to provide fuel for a resource-poor nation’s war machine. Akita prefecture in the north of Honshu island was so denuded in the early 19th century that it needed to import firewood. These days, its lush woodlands are a major draw for tourists.

It’s a similar picture in Scandinavia and Central Europe, where the spread of forests onto unproductive agricultural land, combined with the decline of wood-based industries and better management of remaining stands, has resulted in extensive regrowth since the mid-20th century. Forests cover about 15% of Denmark, compared to 2% to 3% at the start of the 19th century.

Even tropical deforestation has slowed drastically since the 1990s, possibly because the rise of plantation timber is cutting the need to clear primary forests. Still, political incentives to turn a blind eye to logging, combined with historically high prices for products grown and mined on cleared tropical woodlands such as soybeans, palm oil and nickel, mean that recent gains are fragile.

There’s no cause for complacency in any of this. The carbon benefits from forests aren’t sufficient to offset more than a sliver of our greenhouse pollution. The idea that they’ll be sufficient to cancel out gross emissions and get the world to net zero by the middle of this century depends on extraordinarily optimistic assumptions on both sides of the equation.

Still, we should celebrate our success in slowing a pattern of human deforestation that’s been going on for nearly 100,000 years. Nothing about the damage we do to our planet is inevitable. With effort, it may even be reversible.

-via Bloomburg, January 28, 2024

#deforestation#forest#woodland#tropical rainforest#trees#trees and forests#united states#china#india#denmark#eu#european union#uk#england#climate change#sustainability#logging#environment#ecology#conservation#ecosystem#greenhouse gasses#carbon emissions#climate crisis#climate action#good news#hope

3K notes

·

View notes

Text

The vast majority (99%) of the 281,000 metric tonnes of carbon dioxide (CO2 equivalent) estimated to have been generated in the first 60 days following the 7 October Hamas attack can be attributed to Israel’s aerial bombardment and ground invasion of Gaza, according to a first-of-its-kind analysis by researchers in the UK and US.

According to the study, which is based on only a handful of carbon-intensive activities and is therefore probably a significant underestimate, the climate cost of the first 60 days of Israel’s military response was equivalent to burning at least 150,000 tonnes of coal.

The analysis, which is yet to be peer reviewed, includes CO2 from aircraft missions, tanks and fuel from other vehicles, as well as emissions generated by making and exploding the bombs, artillery and rockets. It does not include other planet-warming gases such as methane. Almost half the total CO2 emissions were down to US cargo planes flying military supplies to Israel.

Hamas rockets fired into Israel during the same period generated about 713 tonnes of CO2, which is equivalent to approximately 300 tonnes of coal – underscoring the asymmetry of each side’s war machinery.

[...]

David Boyd, the UN special rapporteur for human rights and the environment, said: “This research helps us understand the immense magnitude of military emissions – from preparing for war, carrying out war and rebuilding after war. Armed conflict pushes humanity even closer to the precipice of climate catastrophe, and is an idiotic way to spend our shrinking carbon budget.”

[...]

Even without comprehensive data, one recent study found that militaries account for almost 5.5% of global greenhouse gas emissions annually – more than the aviation and shipping industries combined. This makes the global military carbon footprint – even without factoring in conflict-related emission spikes – the fourth largest after only the US, China and India.

1K notes

·

View notes

Photo

On this day, 2 December 1984, the world's worst industrial disaster took place in Bhopal, India, when the Union Carbide chemical plant leaked poisonous gases to five million people, killing, blinding and disabling tens of thousands. The crumbling plant had no health and safety measures. The chief executive responsible, Warren Anderson, went unpunished, and of the $470 million compensation paid to the Indian government, only a small fraction made its way to the victims and their families: an average of $500 each. Those exposed continue to die prematurely today, and children continue to be born with disproportionately high incidences of birth defects, cancers and chronic illnesses. https://www.facebook.com/workingclasshistory/photos/a.296224173896073/2150061398512332/?type=3

442 notes

·

View notes

Text

The Heart of Boiler Systems: Exploring the Role of IBR Fitting and Flanges

Boiler systems serve as the backbone of numerous industrial processes, powering everything from heating and hot water supply to steam generation in various manufacturing operations. Within these systems, ensuring safety, efficiency, and reliability is paramount, and this is where IBR (Indian Boiler Regulations) fitting and flanges play a pivotal role. As a trusted distributor in Vadodara and a leading dealer in Gujarat, Tubetrading is dedicated to providing top-quality IBR fitting and flanges to industries across the region. In this blog post, we'll delve into the significance of IBR fitting and flanges in boiler systems, explore their crucial functions, and highlight the expertise of Tubetrading in supplying these essential components.

Understanding IBR Fitting and Flanges

IBR fitting and flanges are integral components of boiler systems that ensure seamless operation and compliance with safety standards mandated by the Indian Boiler Regulations. These regulations are designed to safeguard the integrity of boiler components, prevent accidents, and promote efficient energy utilization. IBR fitting and flanges are manufactured according to stringent specifications outlined by the IBR to guarantee durability, reliability, and performance in demanding industrial environments.

The Role of IBR Fitting and Flanges in Boiler Systems

1. Pressure Regulation: IBR fitting and flanges are designed to withstand high-pressure environments commonly found in boiler systems. They play a crucial role in regulating and controlling the flow of fluids, gases, and steam within the system, ensuring optimal pressure levels for efficient operation.

2. Sealing and Joint Integrity: Proper sealing and joint integrity are essential to prevent leaks and maintain the integrity of boiler systems. IBR fitting and flanges are equipped with robust sealing mechanisms, such as gaskets and O-rings, to create a tight seal between interconnected components, minimizing the risk of leaks and ensuring system integrity.

3. Connection and Interoperability: IBR fitting and flanges serve as connection points between various components of boiler systems, including pipes, valves, and vessels. Their standardized dimensions and configurations enable seamless interoperability, facilitating efficient assembly, maintenance, and repair of boiler systems.

4. Compliance and Certification: Compliance with IBR regulations is mandatory for all boiler components used in India. IBR fitting and flanges undergo rigorous testing and certification processes to ensure compliance with safety standards and regulatory requirements, providing peace of mind to industries reliant on boiler systems.

Tubetrading: Your Trusted Supplier of IBR Fitting and Flanges in Gujarat

As a reputable distributor and dealer of IBR fitting and flanges in Vadodara and Gujarat, Tubetrading prides itself on delivering superior-quality products and exceptional service to its customers. Here's why industries trust Tubetrading for their IBR fitting and flanges needs:

1. Extensive Product Range: Tubetrading offers an extensive range of IBR fitting and flanges, including elbows, tees, reducers, bends, and flanges in various sizes, materials, and specifications. Whether you need standard or customized components, we have the expertise and resources to meet your requirements.

2. Quality Assurance: At Tubetrading, quality is our top priority. We partner with reputable manufacturers who adhere to strict quality control measures and comply with IBR regulations. Our products undergo thorough inspection and testing to ensure they meet the highest standards of performance, reliability, and safety.

3. Expert Guidance: With years of experience in the industry, the team at Tubetrading possesses in-depth knowledge of IBR fitting and flanges and their applications in boiler systems. We provide expert guidance and technical support to help our customers select the right components for their specific needs, ensuring optimal performance and efficiency.

4. Timely Delivery: We understand the importance of timely delivery to our customers' operations. With our efficient logistics network and inventory management systems, we strive to fulfill orders promptly and ensure on-time delivery of IBR fitting and flanges to our customers across Gujarat.

Conclusion

In conclusion, IBR fitting and flanges are the heart of boiler systems, playing a critical role in ensuring safety, efficiency, and compliance with regulatory standards. As a trusted distributor and dealer in Vadodara and Gujarat, Tubetrading is committed to supplying top-quality IBR fitting and flanges to industries across the region. With our extensive product range, quality assurance, expert guidance, and timely delivery, we are your reliable partner for all your IBR fitting and flanges needs. Contact Tubetrading today to learn more about our products and services and discover how we can support your boiler system requirements.

#IBR Fitting and Flanges distributor in Gujarat#IBR fitting and flanges distributor in Vadodara#IBR fitting and flanges dealer in Gujarat#IBR fitting and flanges#Gujarat#Maharashtra#Rajasthan#Madhya Pradesh#Daman#Uttar Pradesh

7 notes

·

View notes

Text

Preserving Assets: The Role of Corrosion Inhibitors in Industrial Maintenance

Corrosion is a persistent threat to industrial assets, causing billions of dollars in damages annually across various sectors. From oil and gas facilities to manufacturing plants, the impact of corrosion can be devastating, leading to equipment failures, production downtime, and costly repairs. However, with the right preventive measures in place, such as corrosion inhibitors, industrial facilities can effectively mitigate the risk of corrosion and prolong the lifespan of their assets. As a leading chemical company in Vadodara, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) understands the critical role of corrosion inhibitors in industrial maintenance. In this blog post, we'll explore the importance of corrosion inhibitors, their applications, and the expertise of ICPL as a corrosion inhibitor manufacturer and exporter in India.

Understanding Corrosion Inhibitors

Corrosion inhibitors are chemical compounds designed to protect metal surfaces from the damaging effects of corrosion. By forming a protective barrier on the metal surface or altering the corrosion process, inhibitors prevent or slow down the oxidation and deterioration of metals in corrosive environments. Corrosion inhibitors are widely used in various industries, including oil and gas, petrochemicals, power generation, water treatment, and manufacturing, to safeguard critical assets and infrastructure from corrosion-related failures.

The Importance of Corrosion Inhibitors in Industrial Maintenance

1. Asset Protection: Industrial facilities rely heavily on equipment and infrastructure made of metal, such as pipelines, tanks, vessels, and machinery. Corrosion inhibitors play a crucial role in protecting these assets from corrosion, extending their service life and reducing the need for frequent repairs or replacements.

2. Cost Savings: Corrosion-related failures can result in significant financial losses due to equipment downtime, production disruptions, and repair expenses. By incorporating corrosion inhibitors into maintenance programs, industries can minimize the risk of corrosion-related failures and realize substantial cost savings in the long run.

3. Safety and Reliability: Corrosion compromises the structural integrity of industrial assets, posing safety hazards to personnel and the surrounding environment. Corrosion inhibitors help maintain the reliability and safety of critical infrastructure, reducing the likelihood of accidents, spills, and environmental contamination.

4. Environmental Protection: Corrosion-related leaks and spills can have detrimental environmental consequences, polluting soil, water bodies, and ecosystems. By preventing corrosion and minimizing the risk of leaks and spills, corrosion inhibitors contribute to environmental protection and sustainability efforts.

Applications of Corrosion Inhibitors

Corrosion inhibitors find applications across various industrial sectors, where metal components are exposed to corrosive environments. Some common applications of corrosion inhibitors include:

Oil and Gas Production: In the oil and gas industry, corrosion inhibitors are used to protect pipelines, well casings, and production equipment from corrosion caused by corrosive fluids, gases, and environmental conditions.

Water Treatment: Corrosion inhibitors are added to cooling water systems, boilers, and wastewater treatment facilities to prevent metal corrosion caused by dissolved oxygen, scale formation, and aggressive ions.

Manufacturing: In manufacturing processes involving metal components, such as automotive, aerospace, and electronics manufacturing, corrosion inhibitors are used to protect parts, components, and machinery from corrosion during production, storage, and transportation.

Marine and Offshore Structures: Corrosion inhibitors are applied to marine vessels, offshore platforms, and coastal structures to protect against corrosion in seawater environments.

ICPL: Your Trusted Corrosion Inhibitor Manufacturer and Exporter in India

As the best chemical company in Vadodara, ICPL is dedicated to delivering high-quality corrosion inhibitors tailored to the specific needs of industrial clients. Here's why ICPL is the preferred choice for corrosion inhibitors in India:

Expertise and Experience: With decades of experience in the chemical industry, ICPL possesses the expertise and technical know-how to develop and manufacture corrosion inhibitors that meet the highest quality standards and regulatory requirements.

State-of-the-Art Facilities: ICPL operates state-of-the-art manufacturing facilities equipped with advanced technologies and production processes to ensure the consistent quality and performance of its corrosion inhibitors.

Customized Solutions: ICPL offers customized corrosion inhibitor formulations tailored to the unique requirements and operating conditions of industrial applications. Our team of experts works closely with clients to develop solutions that address specific corrosion challenges and performance objectives.

Global Reach: As a corrosion inhibitor exporter in India, ICPL serves clients worldwide, exporting its products to diverse markets across Asia, Africa, the Middle East, and beyond. With a strong global presence and distribution network, ICPL delivers reliable corrosion protection solutions to industries around the globe.

Conclusion

In conclusion, corrosion inhibitors play a crucial role in industrial maintenance by protecting metal assets from the damaging effects of corrosion. As a leading corrosion inhibitor manufacturer and exporter in India, ICPL is committed to providing high-quality corrosion inhibitors that safeguard critical infrastructure, ensure operational reliability, and promote cost-effective maintenance practices. With ICPL's expertise, customized solutions, and global reach, industries can effectively mitigate the risk of corrosion and preserve the integrity of their assets for years to come. Contact ICPL today to learn more about our corrosion inhibitor products and solutions.

#Corrosion inhibitor Vadodara#Best chemical company in Vadodara#Corrosion Inhibitor exporter in India#Corrosion inhibitors manufacturer in India#Oxygen scavenger Chemical in Vadodara#Oxygen scavenger Chemical supplier in Gujarat#Oxygen scavenger Chemical Manufacture India#Oxygen scavenger Chemical exporter in Gujarat#Oil and gas industry#Oil and gas companies#Oil and gas pipelines#leading Oilfield Chemicals manufacturer and exporter in India

7 notes

·

View notes

Text

When Earth Speaks

Climate change has emerged as a pressing and intricate concern in global dialogues, reshaping the dynamics of our planet's ecosystems and posing a significant menace to both the environment and humanity. With temperatures ascending, polar ice diminishing, and the frequency of extreme weather incidents surging, it is paramount not only to acknowledge this complex issue but also to urgently undertake measures to avert its far-reaching and severe ramifications.

The science underpinning climate change is rooted in the accumulation of greenhouse gases, predominantly carbon dioxide, within the atmosphere. These gases trap solar heat, causing a gradual warming of the planet—a phenomenon commonly referred to as the greenhouse effect. Human activities such as burning fossil fuels and deforestation have significantly amplified the concentration of these gases, hastening the pace of global warming.

According to the Intergovernmental Panel on Climate Change (IPCC), human actions have already induced an approximately 1.0°C increase in global temperatures from pre-industrial levels. If left unchecked, the perilous 1.5°C threshold could be breached as early as 2030, leading to dire and potentially irreversible consequences for Earth ("Global Warming of 1.5°C," IPCC, 2018). This statistical revelation underscores the gravity of the situation, implying that a 1.5-degree rise will have profoundly adverse effects on ecosystems and food production.

Evidence of climate change's impact is present worldwide. Coastal regions, exemplified by India, are grappling with rising sea levels and subsequent flooding. Escalating instances of extreme weather events—ranging from hurricanes to droughts and wildfires—have disrupted both natural systems and human lives, disturbing the delicate equilibrium that sustains our planet.

A study in the "Nature Communications" journal highlights that a 2°C temperature increase could lead to around 14% of the global population experiencing recurrent severe heatwaves, adversely affecting both health and productivity (Perkins, S. E. et al., "Increasing Risk of Concurrent Summer Drought and Heatwaves in Western Europe," Nature Communications, 2012). Agriculture, a crucial pillar of human sustenance, bears the brunt of climate change. The mounting temperatures create stress for plants, impeding growth and ultimately reducing crop yields—especially concerning staple foods like rice and wheat, vital for global food security. Created by water scarcity from intensified droughts, crop productivity falters, aggravating the food production crisis and damaging economies and societies.

Predictions by the World Bank paint a grim picture, forecasting that if inaction persists, over 143 million individuals in regions including Africa, Asia, and Latin America could be forced from their homes by 2050 due to climate-induced factors, exacerbating poverty and instability ("Groundswell: Preparing for Internal Climate Migration," World Bank, 2018).

In the past, global leaders convened in vital efforts to combat the climate crisis.

A notable example is the 1988 gathering in Wisconsin, USA, where experts and leaders, brainstormed for four days to shape the 21st century's agenda. The leaders emphasized the need for an ecologically conscious lifestyle. However, subsequent years have witnessed a escalation of global warming, deforestation and pollution. Cyclones and floods underline the severity of the challenge. Regrettably, world leaders often offer pretty much nothing. What they do is, they setup these meetings and discuss how they could get money off this cause. First off, by setting up these meetings, we as the general public, often tend to prefer their government, then they make up contracts with their other social elite friends and make money off it, well at least it seems that way. I mean its been close to two decades global warming is still at large. COVID is the only real reason why global warming somewhat even stopped.

The urgency of the situation demands a collaborative response. Governments, corporations, and individuals must join forces to curb the emissions responsible for the crisis. Transitioning to clean energy sources such as solar and wind, adopting sustainable agricultural practices, and constructing resilient infrastructure to withstand extreme weather events are pivotal steps.

Individual actions are equally influential. Embracing energy efficiency, reducing waste, and advocating for informed environmental policies can catalyze change. Furthermore, fostering awareness and understanding of climate change through education campaigns will empower individuals to contribute substantively.

In my own capacity, I am actively contributing to the urgent matter of addressing the climate crisis. Through diligent research and the creation of this paper, my goal is to create heightened awareness regarding the need for immediate action. Moreover, in the course of my everyday routine, I am making eco-conscious decisions, incorporating reusable products and practicing energy conservation. I firmly believe that these seemingly small changes, when amplified, hold the potential to become an influence in the mission of combatting climate change.

3 notes

·

View notes

Text

Understand the Benefits of Carbon Steel Pipes

What are carbon steel pipes?

Carbon steel pipe is one of the most trustworthy and durable pipe types used in many industrial applications. Since it is both light and strong, it can move solids, gases, and liquids. Bright Steel Centre is a recognised corporation that manufactures, offers, exports, and trades an impressive and top-quality approved range of industrial pipes, plates, and pipe fittings.

We provide stainless steel pipe fittings, plates made of stainless steel and high nickel.Bright Steel Centre has a buffer stock of essential items,pipes, and pipe fittings sizes 1/2 to 24, to satisfy the off-hand needs of our clients. Customers' requests for particular items are quickly fulfilled while maintaining the highest quality requirements.

Benefits of carbon steel pipes

A specific kind of pipe that is made of carbon steel pipe consists mostly of iron with a little amount of carbon. It is among the most often used types of pipes because of its benefits over other materials like PVC or stainless steel. Carbon steel pipes are strong, durable, and corrosion-resistant. They are also very cost-effective since they are far less expensive than other kinds of pipes.

Carbon Steel Seamless Pipes:

For a range of purposes, we develop and distribute carbon steel pipe goods. Iron and carbon make up the majority of carbon steel's composition. Depending on the grades, varied quantities of silicon, manganese, and copper are permitted as traces. The result is, carbon steel seamless pipe is more durable and extremely stress resistant.

Carbon Steel ASTM A335 Pipes:

For flanging (vanstoning), bending, fusion welding, and other comparable forming procedures, ASTM A335 Seamless Steel Pipe ordered in compliance with this requirement must be appropriate. When chrome and molly elements are added, ASTM A335 offers superb tensile strength, fine resistance to high temperatures, and corrosion.

Aluminium Pipes:

Aluminium is a perfect specimen for temperature control applications like solar power, freezers, and air conditioners since it very effectively absorbs heat and forms tubes. Due to their durability and lightweight, aluminium tubes are crucial in hydraulic systems, bracing, fuel lines, and frames.

Mild Steel Pipes:

Pipes made of mild steel (MS) are made of low carbon steel, which has less than 0.25% carbon. Due to the low carbon content, the pipes are easy to use and do not harden. Mild Steel Pipes. Since they are made of mild steel, they can easily be welded and shaped into a range of shapes and sizes for use in pipelining and tubing.

Alloy Steel Pipes:

Applications that call for moderate corrosion resistance, strong durability, and a reasonable price use alloy steel pipes. The two types of alloy steels are high alloy and low alloy steels.

High Nickel Alloy Pipes:

Nickel pipes are made by coating the metal surface with zinc. The nickel alloy pipe is made up of the elements nickel, manganese, carbon, silicon, sulphur, ferrous, and copper. The ability of these pipes to withstand corrosion and oxidation is outstanding. The has excellent mechanical properties, are found in High Nickel Alloy Tube.

Product Source - Carbon Steel Pipes in India

3 notes

·

View notes

Text

PTFE Lined Sight Flow Indicators: Understanding their Functionality and Applications

In many industrial processes, it is important to monitor the flow of liquids or gases through a pipeline or system. This is where sight flow indicators come in, providing a visual way to monitor the flow of fluids. Sight flow indicators can come in a range of materials and designs, but in this blog, we will focus on PTFE lined sight flow indicators manufacturers in India and their functionality and applications.

PTFE (Polytetrafluoroethylene) is a highly non-reactive and versatile material that is resistant to many corrosive chemicals and has a high temperature tolerance. When PTFE is lined on the inside of a sight flow indicator, it provides excellent corrosion resistance and makes it suitable for use in highly corrosive environments.

Functionality of PTFE Lined Sight Flow Indicators:

PTFE Lined Sight Flow Indicators are used to visually monitor the flow of liquids or gases through a pipeline. They consist of a transparent window, usually made of glass or acrylic, and a PTFE lined body that allows the fluid to flow through. The window is typically circular in shape and allows operators to see the flow of the fluid.

The PTFE lining helps protect the sight flow indicator from corrosive substances and ensures the fluid does not come into contact with any metal parts. This lining also helps to reduce friction between the fluid and the sight flow indicator, making it easier for the fluid to flow through.

Applications of PTFE Lined Sight Flow Indicators:

PTFE Lined Sight Flow Indicators have a wide range of applications across various industries due to their excellent resistance to corrosive substances. Some common applications Include:

Chemical Processing: PTFE Lined Sight Flow Indicators in Vadodara are used in the chemical industry to monitor the flow of corrosive chemicals such as acids, alkalis, and Solvents.

Pharmaceutical Industry: In the pharmaceutical industry, PTFE Lined Sight Flow Indicators are used to monitor the flow of high-purity liquids such as purified water, pharmaceutical solutions, and sterile liquids.

Food and Beverage Industry: PTFE Lined Sight Flow Indicators are used in the food and beverage industry to monitor the flow of liquids such as fruit juices, milk, and beer.

Petrochemical Industry: In the petrochemical industry, PTFE Lined Sight Flow Indicators are used to monitor the flow of corrosive liquids such as hydrochloric acid, sulfuric acid, and other hazardous substances.

Manufacturers of PTFE Lined Sight Flow Indicators:

There are many manufacturers of PTFE Lined Sight Flow Indicators manufacturers in India around the world. These manufacturers offer a range of designs and materials to suit various applications. Some of the top manufacturers of PTFE Lined Sight Flow Indicators include:

- L.J. Star Incorporated

- Kenco Engineering Company

- Techniquip Corporation

- Mettler-Toledo International Inc.

- Gems Sensors & Controls

Conclusion:

PTFE Lined Sight Flow Indicators are an essential component in many industrial processes, providing a visual way to monitor the flow of fluids through a pipeline or system. Their excellent resistance to corrosive substances and high temperature tolerance make them ideal for use in a range of applications across various industries. With the increasing demand for PTFE Lined Sight Flow Indicators, manufacturers are constantly improving their designs and materials to meet the needs of their customers.

#PTFE lined sight flow indicators manufacturers in India#PTFE Lined Sight Flow Indicators in Vadodara#manufacturers#india#vadodara

2 notes

·

View notes

Text

Strange hexagonal diamonds found in meteorite from another planet

https://sciencespies.com/space/strange-hexagonal-diamonds-found-in-meteorite-from-another-planet/

Strange hexagonal diamonds found in meteorite from another planet

Diamonds found in four meteorites in north-west Africa probably came from an ancient dwarf planet, and they are expected to be harder than Earth diamonds

Space

12 September 2022

By Alice Klein

Electron microscopy has revealed hexagonal diamonds (the dark area near the middle of the picture) in meteorites found in Africa

Alan Salek/RMIT

Mysterious hexagonal diamonds that don’t occur naturally on Earth have been discovered in four meteorites in north-west Africa.

“It’s really exciting because there were some people in the field who doubted whether this material even existed,” says Alan Salek at RMIT University in Melbourne, Australia, who was part of the team that found them.

Hexagonal diamonds, like regular diamonds, are made of carbon, but their atoms are arranged in a hexagonal structure rather than a cubic one.

Advertisement

Also known as lonsdaleite, hexagonal diamonds were first reported in meteorites in the US and India in the 1960s. However, the previously discovered crystals were so small – only nanometres in size – that it was hard to confirm whether they were truly hexagonal diamonds.

To hunt for larger crystals, Salek and his colleagues used a powerful electron microscope to peer into 18 meteorite samples. One was from Australia and the rest were from north-west Africa.

They found hexagonal diamonds in four of the African meteorites, with some crystals measuring up to a micrometre in size – about 1000 times bigger than previous discoveries. This allowed the team to confirm the unusual hexagonal structure.

“It’s an important discovery because now we have larger crystals, we can get a better idea of how they formed and maybe replicate that process in the lab,” says Salek.

Based on the chemical composition of the meteorites that brought them to Earth, the hexagonal diamonds appear to have formed inside dwarf planets, says Andy Tomkins at Monash University in Melbourne, who led the research.

The team’s analysis suggests the crystals were created by a reaction between graphite – which is made of carbon atoms layered in sheets – and a supercritical fluid of hydrogen, methane, oxygen and sulphur chemicals that probably formed when an asteroid crashed into the dwarf planet and broke it into fragments that eventually fell onto Earth.

“When the planet broke apart, it was like taking a lid off a Coke bottle – it released the pressure and that drop in pressure combined with high temperatures led to the release of this supercritical fluid,” says Tomkins.

This is similar to the process by which regular diamonds are made in labs, by heating graphite with gases like hydrogen and methane, suggesting that a few tweaks could produce lonsdaleite instead, says Salek.

Hexagonal diamonds are predicted to be about 60 per cent harder than regular diamonds based on their structure, and this extra hardness could have important industrial applications if they could be made synthetically. For example, they could potentially be used to make ultra-hard saw blades or other machine parts, says Salek.

Journal reference: Proceedings of the National Academy of Sciences, DOI: 10.1073/pnas.2208814119

Sign up to Lost in Space-Time, a free monthly newsletter on the weirdness of reality

More on these topics:

#Space

#2022 Science News#9-2022 Science News#acts of science#Earth Environment#earth science#Environment and Nature#everyday items#Nature Science#New#News Science Spies#Our Nature#planetary science#production line#sci_evergreen1#Science#Science Channel#science documentary#Science News#Science Spies#Science Spies News#September 2022 Science News#Space Physics & Nature#Space Science#Space

4 notes

·

View notes

Text

2023 Wrapped: Here Are Top 10 Logistics Trends That Defined The Year

2023 has been a year of new beginnings for the Indian logistics industry. It is the year logistics companies bounced back from the post-pandemic slump and set out to recover from their losses. The year also witnessed a steady growth in eCommerce, with the spotlight on quick commerce and last mile logistics. The later part of 2023 saw the government extending generous support to digital commerce and logistics, through initiatives like Open Network for Digital Commerce (ONDC) and National Logistics Policy (NLP).

Looking back, we can confidently assert that 2023 has been a good year for India’s logistics sector. From the increased focus on supply chain sustainability to extensive experimentation with drone deliveries, here are the top trends that defined logistics this year.

1. Greener transportation and supply chain

The amount of greenhouse gases generated by India’s transportation sector has nearly tripled since the 1990s, accounting for over 14% of our total energy emissions. The problem is quite severe if we take into account the massive carbon footprint left by India’s booming supply chain.

In 2022, there was a rise in awareness around cleaner and greener logistics practices, with a nudge on electrifying India’s cargo transportation. Logistics and transportation startups unveiled their fleet of electric (EV) and clean energy vehicles. At Blowhorn, we converted 30% of our fleet to clean fuels and took the pledge of running 100% of our fleet on clean energy by 2025.

In addition, other green practices like solar-powered warehousing, eco-friendly packaging and paperless invoicing were also adopted widely.

2. Third party logistics

The concept of third-party logistics (3PL) took off in India only a few years back. In 2022, India’s 3PL market reached a staggering $58.4 Bn in valuation, with a projected annual growth of 7.42%.By 2027, the market is estimated to reach more than $83.53 Bn.

The 3PL market is primarily driven by manufacturing, FMCG, retail and eCommerce sectors — all of which experienced commendable growth this year. Keeping in mind the needs of the modern Indian entrepreneur, 3PL service providers are also improving their operational speed with the incorporation of technology.

In the coming days, development of infrastructures like logistics parks, dedicated freight corridors, free trade warehousing zones, and container freight stations are expected to improve the efficiency of the Indian 3PL market.

3. Higher investment in technology

With higher investment technology seeping into eCommerce, retail, education, hospitality, finance, and all other sectors, why should logistics be left behind? With increasing market demand for superfast delivery, Indian logistics startups invested more on modern technology to boost their operations.

Experts believe that India is headed towards a technological revolution in logistics. Tech like Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT) are optimally benefitting the supply chain in terms of seamless management, improved route planning, warehouse automation, digital payments and much more.

At Blowhorn, we are already speeding up our deliveries with AI-powered route optimization software. Our automated warehouse management system helps in seamless handling of stored inventory and order dispatch, while we offer a real-time tracking system for all our orders. We have also adopted novel technologies like geo-fencing to reduce the menace of fake delivery attempts.

4. LaaS (Logistics as a Service)

We are well-acquainted with Software as a Service (SaaS) companies. This year saw the emergence of companies following a similar model in fulfillment, offering Logistics as a Service (LaaS). Ideally, this presents a plug and play model for your business’s logistics needs, which you can avail via a simple integration with your 3PL partner.

Blowhorn has set the ball rolling for LaaS in India, offering end-to-end logistics solutions with warehousing, transportation and hyperlocal delivery.

5. Greater supply chain transparency

With rising consumer concerns, logistics stakeholders worked towards improving supply chain visibility and transparency in 2023. Companies are striving to become more transparent with regards to the sustainability of their supply chains. Globally, 2023 saw more companies offering insights on their labor practices, job creation, sourcing methods and compliance with regulatory requirements — in a bid to enhance their brand image among the conscious modern consumer.

6. Blockchain in last mile logistics

While AI is helping to improve speed and efficiency, blockchain has been deemed as a viable solution for more transparency and visibility in last mile logistics. In India and abroad, companies have started incorporating blockchain to optimize the last mile deliveries. The technology has found best use in high value inventory tracking, secure invoicing and payments, fraud detection, improved supply chain transparency, dispute resolution and creating a fair freight marketplace.

With the launch of Open Network for Digital Commerce (ONDC) by the Indian government, there is hope that we will witness further adoption of blockchain in the digital commerce and logistics space. In fact, ONDC itself is a blockchain-based protocol which aims to create a fair and transparent marketplace for small and medium-sized businesses across India. With Blowhorn being one of the early participants of ONDC, we too are waiting and watching the best use case for blockchain in our fulfillment services in the near future to help our customers.

7. Micro-fulfillment > Traditional Warehousing

2022 saw a rise in demand for same day delivery, which is quite difficult to fulfill if your inventory is stocked in a warehouse far away from the customer's location. The longer the delivery distance, the more the delivery time — a simple thumb rule to keep in mind.

This is why top in 2023 opted for micro ecommerce-fulfillment centers or micro-warehouses. The concept of micro-warehousing follows a just-in-time inventory management approach, with goods never staying here for more than a day. The limited inventory is stocked in a network of collocated storehouses at high-demand pincodes. Not only does the process help in reducing a brand’s capital spend on inventory, but it also improves efficiency and decreases resource wastage.

Much before the pandemic, we launched India’s first micro-warehouses or micro-fulfillment centers as an experiment in 2018. Now we maintain an expansive network of micro-warehouses across 28 cities of India. Read this article to find out why more eCommerce startups are choosing micro-fulfillment in 2023-24.

8. Automation in shipping

When it comes to automation in shipping, the process works on a predefined pathway involving packaging, warehousing, material handling and security. In India, the adoption of automation in logistics and shipping has been steadily increasing since the pandemic.

In 2023, 3PL fulfillment companies like Blowhorn incorporated automated solutions to boost efficiency by** reducing overhead costs** and time, streamlining the supply chain and minimizing the chances of manual errors.

9. Extensive focus on hyperlocal logistics

2023 saw a high growth in the hyperlocal space with the emergence of newer players in the quick commerce sector. Meanwhile, eCommerce giants and existing logistics players focused more on faster deliveries to not miss out on their customer needs.

Improved internet penetration led to the growth of fast fulfillment in suburbs and rural belts, thus creating a need for hyperlocal elements like dark stores, micro-ecommerce fulfillment centers along with local delivery jobs.

At Blowhorn, we have developed a platform-agnostic technology to be able to integrate with a wide range of businesses ranging from D2C, marketplaces and omni channel players. Our hyperlocal strategy is defined by AI-based dynamic route planning, real-time order clubbing, automated warehousing, blockchain and even drone deliveries. We are aiming to build a sustainable hyperlocal delivery system to tackle small profit margins, high overhead costs and ever-evolving consumer expectations.

10. Experimentation with Drone Deliveries

Delivery by drones is not new. The idea has been widely explored by logistics providers across India but is yet to be adopted at scale. The idea of mapping a three-dimensional delivery route via drones holds immense potential and has excited the Indian government authorities as well. Jyotiraditya Scindia, the Union Minister for Civil Aviation, has stated the administration’s objective to turn India into a major drone hub by 2030.

Leading logistics players like Blowhorn and others are already chalking out the blueprint to make drone delivery an everyday reality. Gartner predicts that by 2026, more than one million drones will be carrying out retail deliveries, up from 20,000 today. Last year, the Indian government also released the draft of The Drone Rules, 2021, aiming to liberalize drone delivery while fulfilling the safety regulations. Autonomous last-mile delivery via these mini flying machines will significantly determine the growth trajectory of Indian logistics in the upcoming future.

2 notes

·

View notes

Text

It's called Fleather, and it's a new material being developed as a sustainable alternative to animal leather. It is delicate and smooth to touch, like soft lamb skin leather, and its journey begins in an unexpected place – flowers.

Fleather, made by a Kanpur-based startup called Phool, is part of an emerging trend of companies producing plant- and fungi-based leather alternatives which aim to disrupt the traditional leather industry and capitalise on growing interest in "vegan" fashion.

Producing leather from animals poses several environmental hazards. It is energy- and water-intensive and the process of tanning and treating animal skin with chemicals to make leather releases toxic heavy metals that can poison water bodies. Cattle rearing to source animal skin, meanwhile, produces greenhouse gases and contributes to deforestation. Animal rights activists also condemn leather, citing inhumane conditions in slaughter houses.

Fleather, on the other hand, is made by repurposing floral waste generated in temples across India, and it is Phool's moonshot.

The startup's journey began on a cold winter morning in 2015, when Ankit Agarwal and his friend made their way to the bustling bank of the Ganges in Agarwal's hometown Kanpur for some sightseeing.

The Ganges is believed by Hindus to be the most sacred of all rivers. But the sight that greeted the duo belied this faith. Rubbish was floating on the grey, visibly-polluted water. Among the muck were tonnes of flowers – marigolds, roses and chrysanthemums – discarded by temples and worshippers. These flowers are used in Hindu rituals and are considered sacred, meaning they can't be disposed of along with other waste.

But depositing them in a river is sometimes part of the ritual and as a result flowers are dumped in water bodies daily where they leach out harmful chemicals from pesticides, and eventually decay into mulch that contaminates the water. Undeterred by the obvious pollution, devotees take ceremonial dips in the Ganges and cup their palms to take holy sips.

The sight disturbed Agarwal, and set him on a quest to find a solution to the uniquely Indian problem of temple flower waste, which he calls "the lowest hanging fruit" among pollutants. In 2017, he zeroed in on an idea to upcycle the flowers into incense sticks, and founded Phool ("flower" in Hindi).

The company is backed by the prestigious Indian Institute of Technology in Kanpur and counts Bollywood star Alia Bhatt among its investors. Every morning Phool trucks travelled around Kanpur's temples collecting the flower waste before it was dumped into the river. At the Phool factory, workers plucked the petals and set them to dry. The dried petals were then powdered and made into a dough with essential oils which female workers then rolled into incense sticks.

But it turned out that there was a far more impactful and surprising use for the flowers, as the company was soon to discover.

6 notes

·

View notes

Text

Induction Motor Market - Forecast(2022 - 2027)

Induction Motor Market Size is forecast to reach $54.2 billion by 2026, at a CAGR of 6.5% during 2021-2026. An induction motor is an AC electric motor in which torque is produced by the reaction between a varying magnetic field generated in the stator and the current induced in the coils of the rotor. It is used in a majority of machinery, as it is more powerful and eco-friendly compared to the conventional motors in the market. North America has significant share in global induction motor market due to a developed usage of an induction motor in the significant industrial manufacturing, aerospace & defense, and automotive companies. In addition to the growing preference for electric vehicles in the U.S. is also stimulating the growth in North America.

Report Coverage

The report: “Induction Motor Market Report– Forecast (2021-2026)”, by IndustryARC covers an in-depth analysis of the following segments of the Induction Motor market

By Rotor Type: Inner Rotor, Outer Rotor

By Type: Single Phase, Three Phase

By Efficiency Class: IE1, IE2, IE3, IE4

By Voltage: Upto 1KV, 1-6.6 KV, Above 6.6KV

By Vertical: Industrial, Commercial, Residential, Agriculture, Automotive and Others

By Geography: North America (U.S, Canada, Mexico), South America(Brazil, Argentina and others), Europe(Germany, UK, France, Italy, Spain, Russia and Others), APAC(China, Japan India, SK, Aus and Others), and RoW (Middle East and Africa)

Request Sample

Key Takeaways

The rising demand for efficient energy usage over concerns of environmental impact of energy generation from conventional sources such as coal and natural gas, is expected to help grow the Induction Motor market in APAC.

The inner rotor segment is growing at a significant CAGR rate of 7.1% in the forecast period. In inner rotor type motors, rotors are positioned at the centre and surrounded by stator winding.

Automotive sector is expected to witness a highest CAGR of 8.9% the forecast period, owing to various factors such as increase in sales of electric vehicles due to rising concerns over greenhouse gases emissions, and favourable government policies in countries such as India, China and so on.

Induction Motor companies are strengthening their position through mergers & acquisitions and continuously investing in research and development (R&D) activities to come up with solutions to cater to the changing requirements of customers.

Induction Motor Market Segment Analysis - By Rotor Type

Three Phase segment is growing at a significant CAGR of 11.1%

in the forecast period. A three phase induction motor is a type of AC induction motors which operates on three phase supply. These three phase induction motors are widely used AC motor to produce mechanical power in industrial applications. Almost 70% of the machinery in industrial applications uses three-phase induction motors, as they are cost-effective, robust, maintenance-free, and can operate in any environmental condition. Moreover, induction motors are the most used in industry since they are rugged, inexpensive, and are maintenance free. In addition they are widely used in the mining metals and cement, automotive, oil and gas, healthcare, manufacturing industries and so on. Increase awareness of environmental protection across industries also contributes to the growth of three phase induction motors, as they have a low emission rate. Moreover, the shift towards industrial automation, coupled with the rising consumer confidence & promising investment plans triggers demand for the three phase induction motor in industrial application. Furthermore, the advent of Industry 4.0 and technological advancements enables a wide adoption base for the three phase induction motors. In 2019, Oriental Motor USA introduced their latest high efficiency three-phase AC induction motors equipped with a terminal box and a high strength right-angle hypoid gearhead, these new three-phase motors have the capacity of two new wattages of 30W and 40W and expands the KIIS Series Standard AC motors product line-up.

Inquiry Before Buying

Induction Motor Market Segment Analysis - By Vertical

Automotive sector is expected to witness a highest CAGR of 8.9% in the forecast period, owing to various factors such as increase in sales of electric vehicles due to rising concerns over greenhouse gases emissions, and favorable government policies in countries such as India, China and so on. In addition, the shift towards industrial automation, coupled with the rising consumer confidence & promising investment plans triggers demand for the induction motor in industrial application. Furthermore, the advent of Industry 4.0 enables a wide adoption base for the induction motors. Moreover, growing number of product launches by major manufacturers will drive the market growth in the forecast period. In September 2019, Motor and drive manufacturer WEG released the M Mining series of slip-ring induction motors which are designed especially for use in the dusty environments of iron ore operations and the cement sector. In July 2019, Ward Leonard launched 2000 HP induction motor WL29BC200 which is designed tote into a package of 15000 HP for the oil and gas industry. In September 2019, Tata Motors launched Tigor EV for private buyers as well as cab aggregators and EESL staff. he Tata Tigor electric uses a 72 V, 3-Phase Induction motor

Induction Motor Market Segment Analysis - By Geography

Induction Motor market in Asia-Pacific region held significant market share of 38.5% in 2020. Increasing compliance for energy efficient motors and rising adoption of motor-driven electric vehicles are the key factors driving market growth. The rising demand for efficient energy usage over concerns of environmental impact of energy generation from conventional sources such as coal and natural gas, is expected to help grow the Induction Motor market. In addition advancements in the agriculture sector and enormous investments in industrialization in countries such as China, India, South Korea, and Australia is driving the market growth. Further, the increasing production and sales of electric vehicles in countries including China and Japan is also analyzed to drive the market growth.

Schedule a Call

Induction Motor Market Drivers

Robust Structure of Motor

The rough physical structure of the motor is predicted to be a major driving factor for the growth of the induction motor market. Induction motor are robust in nature and can be operated in any climatic conditions. Moreover, the absence of slip rings and brushes in the motor induction eliminates the chances of sparks, which makes the operation safe even in the most explosive working conditions. In addition, induction motor is cost effective, highly reliable and the maintenance is very less, which is expected to propel the growth of the induction motor market in the forecast period 2021-2026.

Rise in Production of Electric Vehicles

The electric car market has witnessed rapid evolution with the ongoing developments in automotive sector and favourable government policies and support in terms of subsidies and grants, tax rebates. As induction motors especially three phase are widely used in electric vehicles because of high efficiency, good speed regulation and absence of commutators is analysed to drive the market growth. In addition these motor also serves as an alternative of a permanent magnet in the electric vehicles. Hence rise in production of electric vehicles is analysed to drive the market. In 2019, Ford has invested $1.45 billion in Detroit plants in U.S., to make electric, autonomous and sports utility vehicles, which is mainly aimed to increase the production of the vehicles thereby impacting on the high procurement of the induction motors. In 2019, Toyota announced plans to invest $749M in expanding the U.S. manufacturing facilities to increase the production of the electric and hybrid vehicles. In 2020, General Motors had committed boost its electric vehicle production by investing more than $7 billion. Moreover governments of several countries have been investing heavily for the development of electric vehicles. In 2019 German government has committed to invest more than $3 billion to expand electric car market growth in the region. Hence these investments and developments are analysed to be the key drivers for the growth of the electric vehicle market and thereby the growth of induction motor market during the forecast period 2021-2026.

Buy Now

Induction Motor Market Challenges

Easy availability of low-quality Induction Motors

The market for Induction Motors is highly fragmented, with a significant number of domestic and international manufacturers. Product quality is a primary parameter for differentiation in this market. The organized sector in the market mainly targets industrial buyers and maintains excellent product quality, while the unorganized sector offers low-cost alternatives to tap local markets. Local manufacturers of Induction Motors in most countries target the unorganized sector and compete strongly with the global suppliers in the respective markets. Leading market players are currently exposed to intense competition from such unorganized players supplying inexpensive and low-quality Induction Motors. This acts as a key challenge for the growth of the market.

Induction Motor Market Landscape

Product launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the Induction Motor market. Induction Motor top 10 companies include ABB Ltd. AMETEK, Inc., Johnson Electric Holdings Limited, Siemens AG, Rockwell Automation, Toshiba Corp., Hitachi Ltd., Nidec Corporation, ARC Systems Inc., among others.

Acquisitions/Product Launches

In 2021 BorgWarner launched HVH 320 Induction Motors in four variants. They are offered to light-duty passenger cars and heavy-duty commercial vehicles.

In 2020, ABB has launched new range of low voltage IEC induction motors, which are compactly designed and reduces the overall size of the equipment by minimizing space and total cost of ownership.

For more Electronics related reports, please click here

#induction motor Market#induction motor Market Size#electric motor#induction motor Market Share#induction motor Market Analysis#electromagnetic induction#induction motor Market Revenue#asynchronous motor#induction motor Market Trends#induction motor Market Growth#induction motor Market Research#induction motor Market Outlook#induction motor Market Forecast#induction motor Market Price

3 notes

·

View notes

Text

Choosing the Right Gas Line Corrosion Inhibitor for Your Needs

Corrosion is a significant challenge faced by industries that rely on gas pipelines for transportation and distribution. Gas pipelines, especially those exposed to harsh environmental conditions, are highly susceptible to corrosion, which can compromise the integrity of the entire system. This is where gas line corrosion inhibitors play a crucial role. These specialized chemicals help protect gas lines from corrosion, extending the life of the infrastructure and ensuring safe and efficient operations.

In this blog, we will explore the factors involved in choosing the right gas line corrosion inhibitor for your needs. Additionally, we will look at how gas line corrosion inhibitor manufacturers in India, gas line corrosion inhibitor exporters, and chemical manufacturers contribute to this vital sector, ensuring the global supply of high-quality solutions.

Understanding Gas Line Corrosion and Its Impact

Gas pipelines are prone to different types of corrosion, including internal and external corrosion. Internal corrosion is caused by contaminants like carbon dioxide (CO2), hydrogen sulfide (H2S), oxygen, and water present in the gas. When these contaminants interact with the pipe's surface, they form corrosive compounds that degrade the metal over time. External corrosion, on the other hand, occurs due to environmental factors such as soil composition, moisture, and atmospheric conditions.

Corrosion in gas pipelines can result in:

Leaks: Even minor corrosion can weaken the pipeline walls, causing gas leaks that pose safety risks and result in product loss.

Operational inefficiency: Corrosion can restrict the flow of gas through the pipeline, reducing the efficiency of the entire transportation system.

Costly repairs: Pipeline corrosion can lead to frequent maintenance and expensive repairs, increasing operational costs.

Environmental damage: Corrosion-related pipeline failures can cause gas to leak into the environment, potentially harming ecosystems and contributing to air pollution.

To combat these issues, gas line corrosion inhibitors are commonly used.

What Are Gas Line Corrosion Inhibitors?

Gas line corrosion inhibitors are chemical compounds designed to prevent or minimize the corrosion of metal surfaces in pipelines. These inhibitors form a protective barrier on the internal and external surfaces of the gas line, preventing corrosive agents from coming into direct contact with the metal.

There are several types of gas line corrosion inhibitors available, each formulated to target specific types of corrosion and environmental conditions. Understanding the different types and how they work is key to selecting the right inhibitor for your needs.

Types of Gas Line Corrosion Inhibitors

Gas line corrosion inhibitors can be classified into several categories based on their chemical composition and mode of action:

Film-Forming Inhibitors: These inhibitors create a protective layer on the metal surface, preventing corrosive agents from attacking the metal. Film-forming inhibitors are particularly effective for internal corrosion caused by acidic gases like CO2 and H2S. They are widely used in both gas and oil pipelines.

Passivating Inhibitors: Passivating inhibitors react with the metal surface to form a passive oxide layer, which inhibits further corrosion. These inhibitors are commonly used in pipelines carrying gases that contain high levels of oxygen.

Cathodic Inhibitors: These inhibitors work by reducing the rate of the cathodic reaction in the corrosion process. They are effective in controlling external corrosion in gas pipelines buried underground or exposed to humid environments.

Oxygen Scavengers: Oxygen scavengers are chemical agents that remove dissolved oxygen from the gas, preventing it from reacting with the metal surface. Oxygen is a primary cause of internal corrosion in gas pipelines, so using oxygen scavengers is an effective way to mitigate this risk.

Volatile Corrosion Inhibitors (VCIs): VCIs release vapors that condense on the metal surface, forming a protective film that prevents corrosion. These inhibitors are often used in gas pipelines exposed to atmospheric corrosion.

Factors to Consider When Choosing a Gas Line Corrosion Inhibitor

Selecting the right gas line corrosion inhibitor for your pipeline depends on various factors, including the type of gas being transported, environmental conditions, and the specific corrosion challenges you face. Here are some key factors to consider:

Type of Gas: The composition of the gas being transported plays a significant role in determining the type of corrosion inhibitor required. For instance, pipelines transporting sour gas (gas containing H2S) will require a different inhibitor than those carrying sweet gas (gas without H2S).

Corrosion Type: It is important to identify whether the pipeline is at risk of internal or external corrosion. Internal corrosion requires inhibitors that work inside the pipeline, while external corrosion may require cathodic inhibitors or coatings that protect the outside of the pipeline.

Environmental Conditions: The location of the gas pipeline is another crucial consideration. Pipelines in coastal or humid environments are more prone to external corrosion due to the presence of moisture and salt. In these cases, external corrosion inhibitors or coatings may be necessary.

Temperature and Pressure: High temperatures and pressures can accelerate the rate of corrosion in gas pipelines. When choosing a corrosion inhibitor, ensure that it is designed to withstand the specific temperature and pressure conditions of your pipeline.

Inhibitor Compatibility: It is essential to choose an inhibitor that is compatible with the materials used in the pipeline, as well as with other chemicals that may be present in the gas stream. Incompatible inhibitors can react with the gas or pipeline materials, leading to unintended consequences.

Regulatory Compliance: Different regions may have regulations governing the use of certain chemicals in gas pipelines. When selecting a gas line corrosion inhibitor, ensure that it meets all local and international regulatory requirements.

The Role of Gas Line Corrosion Inhibitor Manufacturers in India

India has emerged as a leading player in the global market for gas line corrosion inhibitors. Gas line corrosion inhibitor manufacturers in India offer high-quality, cost-effective solutions that cater to the specific needs of the oil and gas industry. These manufacturers utilize advanced technologies and rigorous quality control measures to produce inhibitors that meet international standards.

One of the key advantages of sourcing from Indian manufacturers is their ability to provide customized solutions. Indian manufacturers work closely with clients to develop inhibitors tailored to their unique requirements, ensuring maximum protection against corrosion. Additionally, these manufacturers often offer comprehensive technical support, helping clients choose the right inhibitor and implement it effectively.

Exporting Gas Line Corrosion Inhibitors: The Indian Advantage

India’s chemical manufacturing industry has a strong presence in global markets, with many companies acting as gas line corrosion inhibitor exporters. The country’s strategic location, skilled workforce, and competitive pricing make it an attractive source of corrosion inhibitors for international clients.

Gas line corrosion inhibitor exporters from India supply high-performance products to a wide range of industries across the world. These exporters comply with international standards, ensuring that their products meet the stringent requirements of global clients. Furthermore, Indian exporters offer logistical expertise, ensuring timely delivery and reliable supply chains for businesses in need of corrosion protection.

Why Choose a Gas Line Corrosion Inhibitor Supplier from India?

Choosing an Indian gas line corrosion inhibitor supplier can provide several benefits for businesses, including:

Cost-Effectiveness: Indian suppliers offer competitive pricing without compromising on quality, making them a cost-effective choice for businesses looking to protect their pipelines.

Customization: Indian suppliers have the expertise to customize corrosion inhibitors based on the specific needs of their clients, ensuring that the product is optimized for the environment and pipeline conditions.

Regulatory Compliance: Indian suppliers ensure that their products meet both local and international regulatory standards, giving businesses peace of mind when using their products.

Conclusion: Protecting Your Gas Lines with the Right Corrosion Inhibitor

Choosing the right gas line corrosion inhibitor is critical to the longevity and safety of your gas pipeline infrastructure. By considering factors such as the type of gas being transported, the environmental conditions, and the specific corrosion challenges, you can select an inhibitor that provides effective protection.

India’s chemical manufacturers and gas line corrosion inhibitor manufacturers offer a range of high-quality products that cater to both domestic and international markets. With their ability to provide cost-effective, customized solutions, Indian manufacturers and exporters are well-positioned to meet the global demand for gas line corrosion inhibitors.

Whether you’re looking for a gas line corrosion inhibitor supplier and exporter to support your operations, India’s industry leaders can help you find the right solution to protect your pipelines and ensure smooth, safe operations.

I have attached a report, city wise. I have given you all countries’ cities’ report. It is not possible to give in-depth report of cities from USA. Kindly check the attached file of city wise where you will find traffic from all cities, all countries.

#Gas line corrosion inhibitor supplier#Gas line corrosion inhibitor exporter#Gas line corrosion inhibitors#chemical manufacturers#Gas line corrosion inhibitor manufacturer in India#Russia#Tajikistan#Kyrgyzstan#Uzbekistan#Belarus#Azerbaijan#Armenia#Kazakhstan#Moldova#Turkmenistan#Vietnam#Malaysia#Canada

4 notes

·

View notes